Full Text Searchable PDF User Manual

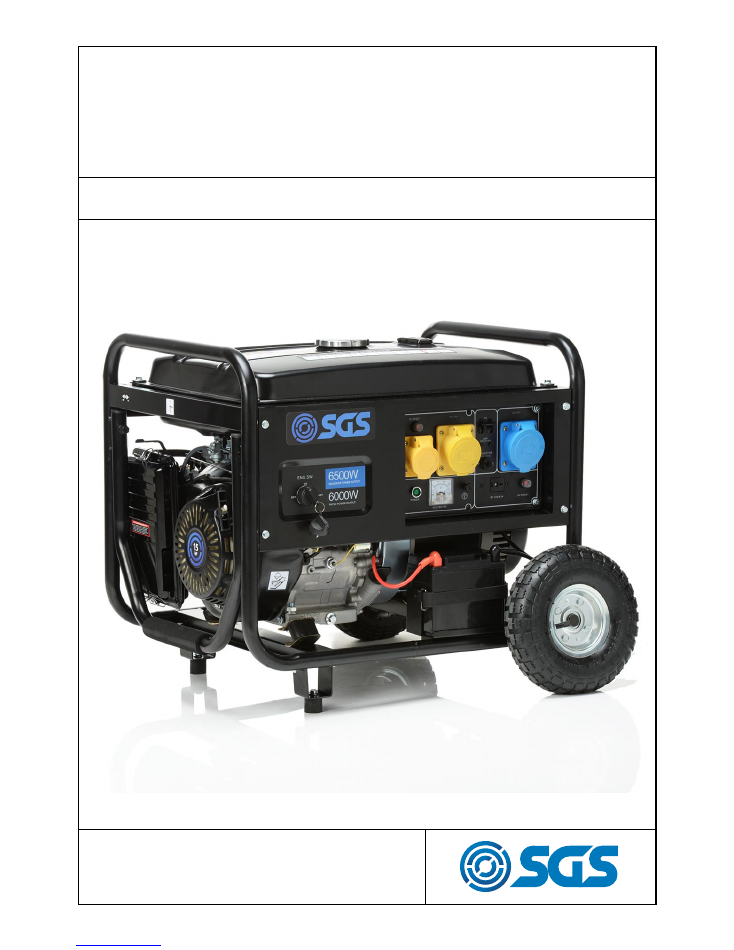

SPG2200, SPG3000, SPG6500

FOR YOUR SAFETY

PLEASE READ THESE INSTRUCTIONS CAREFULLY

AND RETAIN THEM FOR FUTURE USE.

OWNER’S MANUAL

PETROL GENERATOR

PAGE 3

PAGE 2

WARRANTY

This generator is covered by a 24 month warranty from the

initial date of purchase. This is a domestic warranty provided

directly by SGS Engineering. Please keep a recipt of your pucr-

chase as this may be required as proof of purchase.

You will invalidate your warranty if the product is found to

have been misused, tampered with, modified, overloaded or

used for a commercial application for which it was not de-

signed. The warranty will also be rendered invalid if the main-

tenance prodcedure has not been followed.

You must contact SGS Engineering prior to returning any

product. This warranty does not effect your statutory rights.

TABLE OF CONTENTS

WARRANTY

2

TABLE

OF

CONTENTS 3

UNDERSTANDING THE GENERATOR

GENERATOR

SAFETY

4

EXHAUST

GAS

PRECAUTIONS

5

EARTHING

THE

GENERATOR

5

COMPONENTS LOCATION DIAGRAM

6

PREPARING YOUR GENERATOR

FIXING

THE

WHEELS

8

FILLING THE GENERATOR WITH OIL

9

FILLING THE GENERATOR WITH PETROL

10

STARTING THE GENERATOR

Pull

start. 11

Electric

start.

12

USING THE GENERATOR

OPERATING

THE

GENERATOR

15

SHUTTING DOWN THE GENERATOR

16

TROUBLESHOOTING, MAINTENANCE & SERVICING

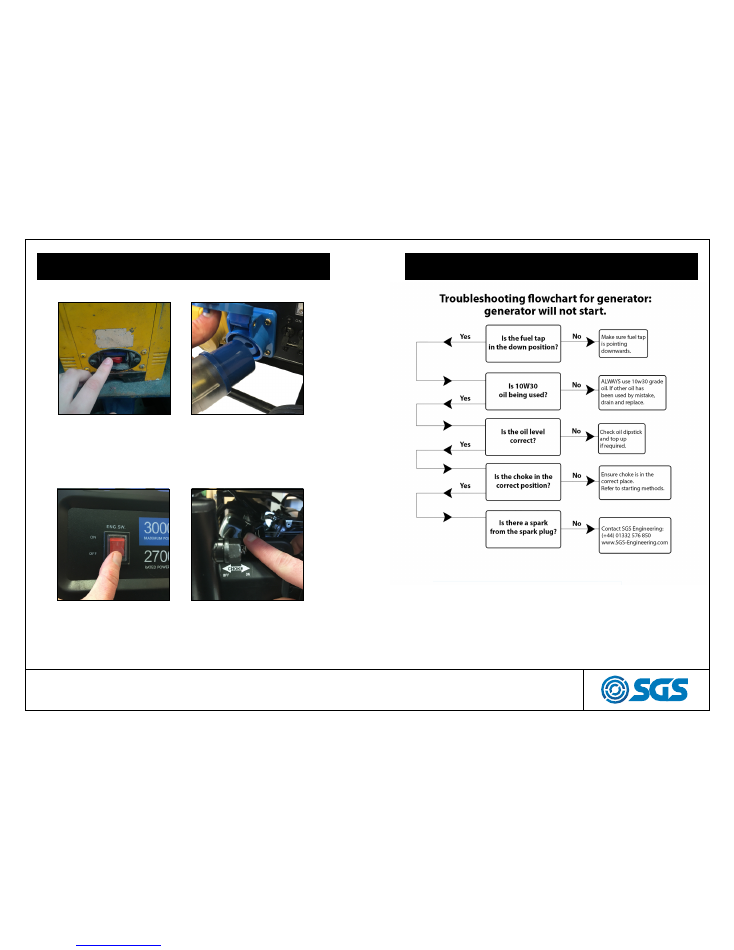

TROUBLESHOOTING STARTING A GENERATOR

17

GENERATOR TROUBLESHOOTING

Generator

will

not

start.

18

Generator is difficult to start.

18

No

electrical

output.

19

Engine making “revving” sounds

19

MAINTENANCE

SCHEDULE

20

MAINTENANCE INSTRUCTIONS

Spark

plug

maintenance. 21

Air

filter

maintenance.

21

Engine

oil

maintenance.

22

Fuel

filter

maintenance.

22

Draining

the

fuel. 23

Draining

the

oil.

23

CERTIFICATE

OF

CONFORMITY

24

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 5

PAGE 4

EXHAUST GAS PRECAUTIONS

• Always ensure that there is adequate ventilation when

using the generator.

• Always position the generator so that the exhaust is point-

ing away from people or animals.

• Never use the generator indoors or in an enclosed area. (i.e

workshop, garage, lockup etc)

EARTHING THE GENERATOR

• In most situations the frame of a portable generator need

not be grounded (connected to earth) and the frame may

serve as the earth.

• An earth connector lug is fitted to the generator, for use

if required to connect to an earth. This connection should

only be undertaken after full consultation with a competent,

qualified electrician.

• Earth spike not provided as not required for general use.

Exhaust fumes can be fatal!

GENERATOR SAFETY

Only use outdoors.

Never use during wet conditions.

Do not smoke whilst handling fuels.

In emergency, switch engine switch to ‘off’.

Always operate on level ground!

If in doubt about anything, contact us on

(+44) 01332 576 850.

Always consult this manual for effective product

knowledge.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 7

PAGE 6

GENERATOR COMPONENTS LOCATION DIAGRAM

230 V

output

12 V

charging

outputs

Handle

(certain

models only)

Fuel

tank

Air filter box

Engine

switch

Wheels

(certain

models

only)

Pull start

115 V

output

GENERATOR COMPONENTS LOCATION DIAGRAM

Choke

selector

Spark

plug

Carburettor

adjustment

screw

Oil

filler

cap

Fuel

gauge

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 9

PAGE 8

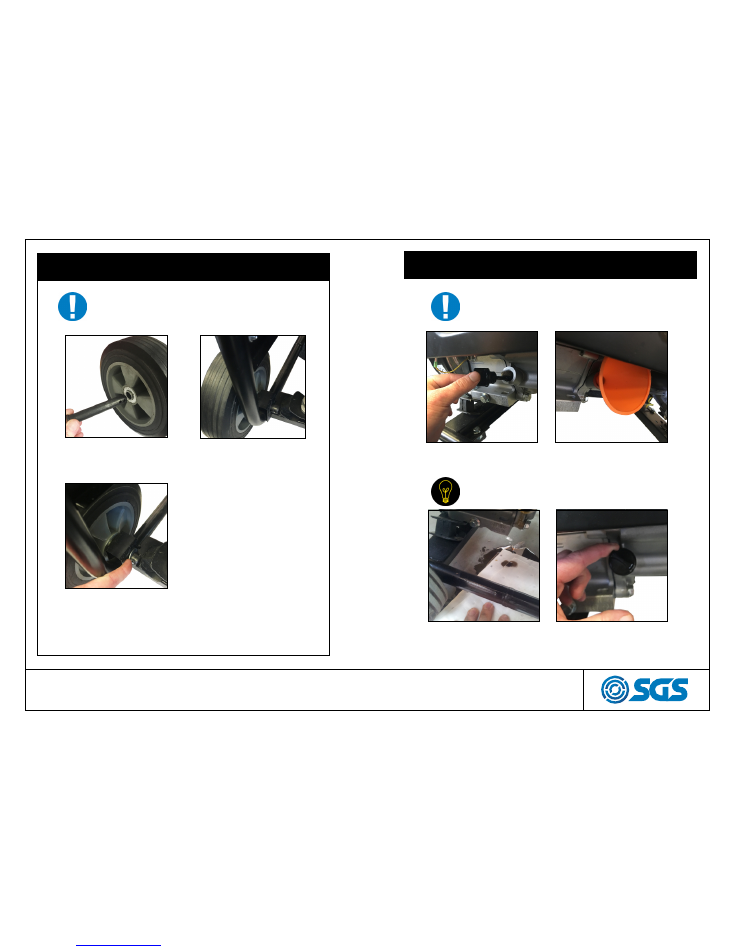

FIXING THE WHEELS (SPG3000, SPG6500)

1. Push the axle through the

wheel.

2. Slot the wheel and axle on

the frame.

3. Insert split pin through

axle hole and spread pin.

DO NOT tip the generator on its side to fit the wheels.

FILLING THE GENERATOR WITH OIL

1. Remove the oil

reservoir filter cap.

2. Fill with 10W30 oil to the

centre line of the dipstick.

3. Wipe up any oil spillages

with a rag.

4. Re-insert the oil reservoir

filler cap.

Tip: When filling with oil, use a funnel with a hose.

NEVER tip the generator onto its side to fill with oil.

ONLY USE 10w30 GRADE OIL. Other oils will pre-

vent the generator from starting.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 11

PAGE 10

FILLING THE GENERATOR WITH PETROL

1. Unscrew fuel filler cap.

2. Fill with unleaded fuel

until at least 3/4 full.

3. Screw fuel filler cap

closed.

4. Fuel level can be indicated

through the fuel tank window.

Tip: ALWAYS use clean, unleaded petrol in the

generator. NEVER use 2-stroke or other fuels.

STARTING THE GENERATOR - PULL START

1. Disconnect all

equipment cables from the

230 V and 115 V outlets.

2. Turn the circuit breaker to

the ‘off’ position.

3. Turn the fuel tap down-

wards, this means the fuel

supply is ‘on’.

4. Turn the choke to the

‘left’ position.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 13

PAGE 12

STARTING THE GENERATOR - PULL START

5. Switch the engine switch

to the ‘on’ position.

6. Pull the pull starter cord

lightly, until it tenses, then

pull briskly.

7. Once generator engine

starts, move choke lever

over to the right

.

THE GENERATOR SHOULD REQUIRE ONLY ONE

OR TWO PULLS TO START. Otherise please contact

SGS Engineering on 01332 576 850.

STARTING THE GENERATOR - ELECTRIC START

1. Disconnect all

equipment cables from the

230 V and 115 V outlets.

2. Turn the circuit breaker to

the ‘off’ position.

3. Turn the fuel tap down-

wards, this means the fuel

supply is ‘on’.

4. Turn the choke to the

‘left’ position.

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 15

PAGE 14

STARTING THE GENERATOR - ELECTRIC START

7. Turn the engine start key

to ‘start’ position untill

generator engine starts.

8. Once generator engine

starts, move choke lever

over to the right

.

1. Start the engine and allow to run for a few minutes in order

for it to warm up.

NEVER have any appliances/tools etc plugged in

when starting the generator engine.

2. After engine has warmed up, you can then plug in appli-

ances/tools into the generator outlets. As a general rule,

switch on appliances/tools etc that you think will take the most

power demand first.

3. ALWAYS ENSURE the correct voltage is selected, using the

voltage selector.

If the appliance/tool has a standard 3 pin plug it

must be used in conjunction with a flylead and

plugged into the blue socket.

If the appliance / tool has a blue socket attached then it is 230

V, and must be plugged into the BLUE outlet on the genera-

tor.

If the appliance / tool has a yellow socket attached then it is

115 V, and must be plugged into the YELLOW outlet on the

generator.

OPERATING THE GENERATOR

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 17

PAGE 16

SHUTTING DOWN THE GENERATOR

1. Switch OFF any

appliances/tools that are

plugged into any outlets on

the generator.

2. Unplug any appliances/

tools that are plugged into

any outlets on the

generator.

3. Switch the generator to

the ‘OFF’ position.

4. Turn the fuel tap so it is

pointing ‘LEFT’ into the off

position.

TROUBLESHOOTING STARTING A GENERATOR

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 19

PAGE 18

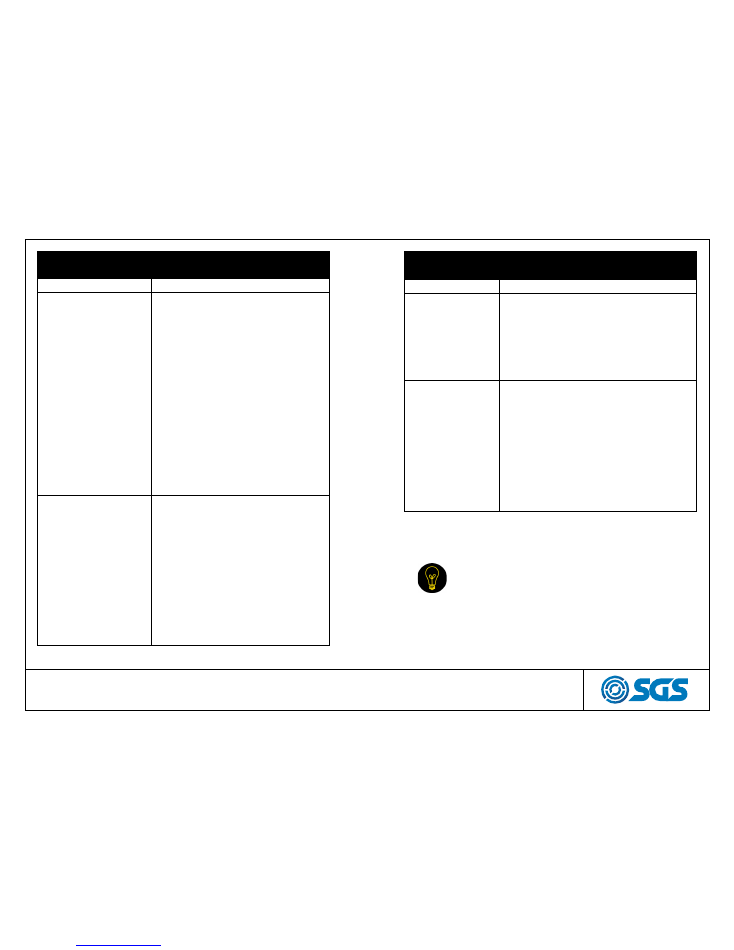

GENERATOR TROUBLESHOOTING

PROBLEM

SOLUTION

Generator will not start.

• Check fuel valve tap is in the ‘down’

position.

• Check the oil level is correct.

• Check 10W30 oil is being used.

• Check choke is in the correct position

(refer to starting methods).

• Check there is a spark - Remove your

HT (high tension) lead from the top of

your spark plug. Remove the spark plug

and reconnect the lead, then touch the

metal on the spark plug against the

generator frame. Gently pull the starter

cord mechanism, listen for an audible

‘ticking’ sound and/or small flashes

coming from the very tip of the spark

plug. If there is no audible ‘ticking’ and/

or small flashes, the spark plug may

need replacing.

Generator is difficult to

start.

• The air filter is dirty - clean the filter

• The fuel filter is dirty - clean the filter

• If the pull start mechanism is too ‘hard’

when trying to pull it, it may denote that

there is too much oil. Check the oil level

by using the dipstick and drain excess

oil from the oil sump bolt at the bottom

of the generator.

• If the pull start mechanism feels too

‘slack’ (i.e easy to pull), there may be

not enough compression in the genera-

tor engine for it to work properly. Please

contact SGS Engineering.

GENERATOR TROUBLESHOOTING

PROBLEM

SOLUTION

No electrical output.

• Check the breaker switch is up.

• The device being powered is faulty.

• Check that the voltage output switch is set

to 115 or 230V.

• Check the connecting lead from the appli-

ance/tool into the generator is physically

sound.

Engine making “rev-

ving” sounds

• If your generator is ‘hunting’ (surging), it

may need a carburettor adjustment. Turn

the brass screw on the carburettor clockwise

slowly and listen for the engine sound. If it

does not improve then try turning the screw

anticlockwise.

See our help and advice section for videos and guides on

setting up, starting and maintaining your generator.

http://www.sgs-engineering.com/help-advice

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 21

PAGE 20

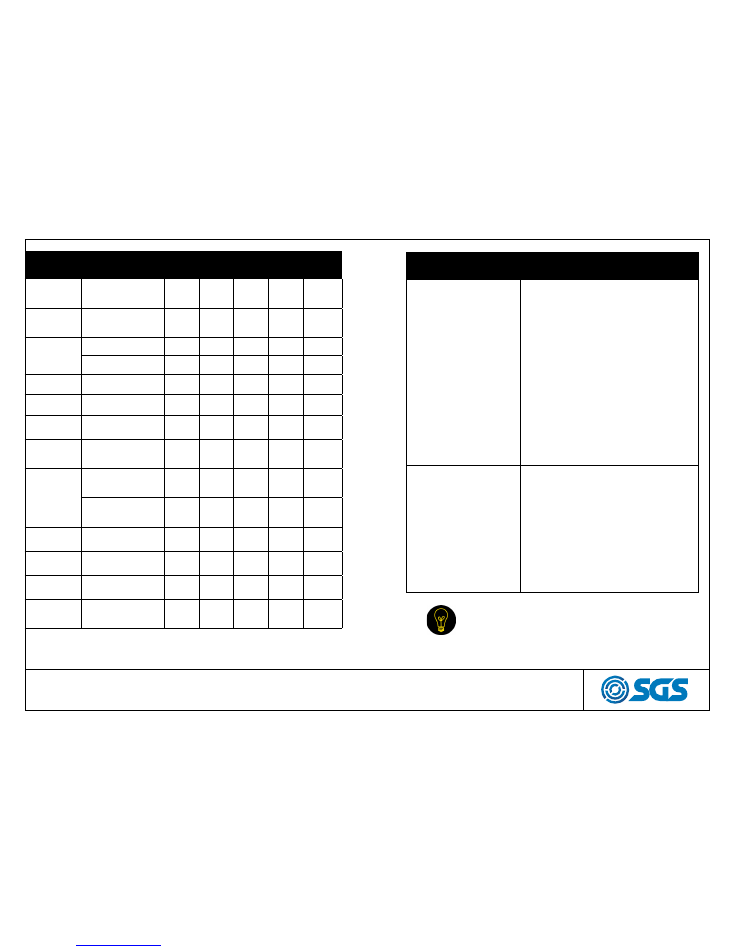

MAINTENANCE SCHEDULE

Tip: Parts replacements are only to be carried out

by competent persons. If in any doubt, please

contact SGS Engineering for help.

Spark plug maintenance.

• Remove the spark plug cap from the

spark plug.

• Use a spark plug spanner (supplied) to

remove the spark plug.

• Check for discoloration and use a wire

brush to remove any carbon build up.

• Check the spark plug gap with a feeler

gauge, it should be between 0.6 and

0.7 mm. Adjust if necessary.

• Check the overall condition of the spark

plug and replace if damaged.

• Reinstall the spark plug and replace the

spark plug cap.

• CAUTION: ALLOW THE ENGINE

TO COOL BEFORE REMOVING THE

SPARK PLUG.

Air filter maintenance.

• Remove the air filter element.

• Wash it in a solution of warm water and

mild detergent.

• Rinse thoroughly and leave it to dry.

Once it is completely dry immerse the

filter in clean engine oil and squeeze

the filter to remove excess oil.

• Replace the filter into its original posi-

tion and replace and secure the cover.

MAINTENANCE INSTRUCTIONS

ITEMS

REMARKS

PRE-OP-

ERATION

CHECK

(DAILY)

INITIAL 1

MONTH or

10HR

EVERY 3

MONTHS

or 50HR

EVERY 6

MONTHS

or 100HR

EVERY 12

MONTHS or

300HR

Spark plug

Check condition, adjust

gap and clean. Repeat if

necessary.

X

Engine oil

Check oil level.

X

X

Replace.

X

Air filter

Clean. Replace if

necessary.

X

Fuel filter

Clean fuel drain filter.

Replace if necessary.

X

Valve

clearance

Check and adjust when

engine is cold.

X

Fuel line

Check fuel hose for

crack or damage.

Replace if necessary

X

Exhaust

system

Check for leakage.

Retighten or replace

gasket if necessary.

X

Check muffler screen.

Clean / replace if

necessary.

X

Caraburet-

tor

Check choke operation.

X

Starting

system

Check key start ignition.

X

Decarboni-

sation

More frequently if`

necessary

X

Fittings/

Fasteners

Check all fittings and

fasteners. Correct if

necessary.

X

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 23

PAGE 22

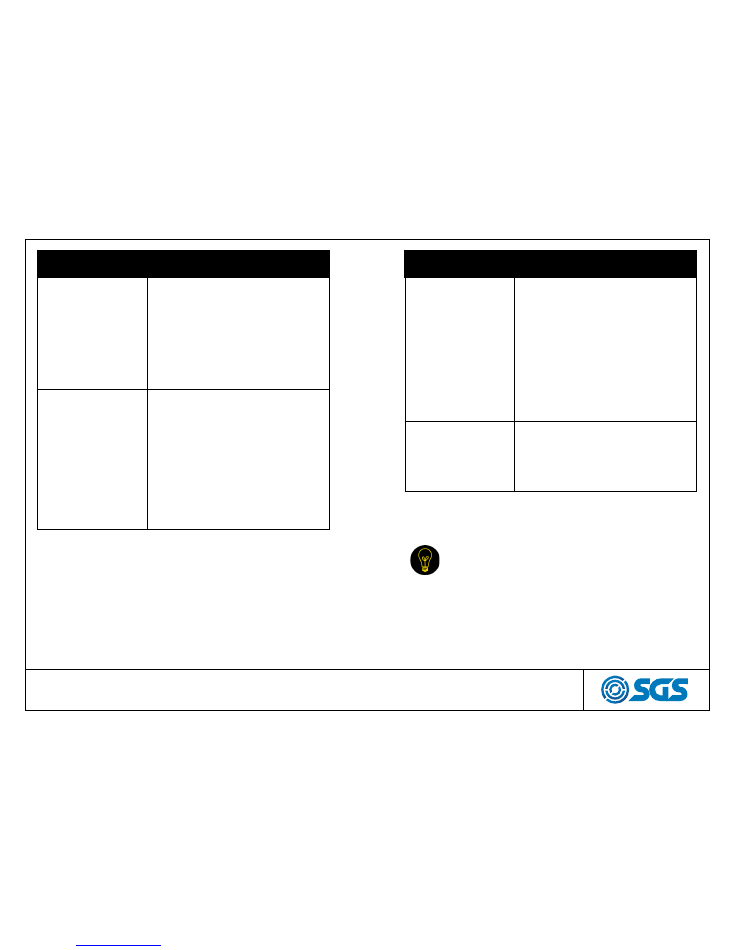

MAINTENANCE INSTRUCTIONS

Engine oil maintenance.

• Warm up the engine on level ground.

• Turn the engine off.

• Remove the oil filler sump plug. Open

the drain sump plug and let the oil drain

completely into a pan placed under the

engine.

• Refit the drain sump plug and fill the en-

gine with clean FOUR STROKE oil only.

Replace the filler cap.

Fuel filter maintenance.

• Inside of the fuel tank, there is a fuel

filter, this filter will need checking peri-

odically.

• Remove the fuel cap from the fuel tank.

• Lift out the fuel filter.

• Clean the filter with solvent. If the filter is

damaged, contact SGS Engineering.

• Replace the filter and fuel cap.

WARNING: DO NOT SMOKE AND/OR

HAVE ANY NAKED FLAMES

DURING THIS PROCESS

MAINTENANCE INSTRUCTIONS

Draining the fuel.

• You should drain your generator of fuel

before you put it into storage.

• Fuel goes stagnant if you left to stand for

too long; this may damage your genera-

tor and affect how it runs.

• Pull the fuel hose from the casing while

leaving it attached to the fuel tap.

• Set to the tap to the ON position.

• Place the fuel hoes into an appropriate

container or bottle.

• Tilt the generator towards the fuel hose

and allow all the fiel to drain.

Draining the oil.

• Place a tray underneith ther oil sump

screw.

• Remove the sump screw

• Tilt the generator towards yourself and

allow all the oil to drain.

See our help and advice section for videos and guides on

setting up, starting and maintaining your generator.

http://www.sgs-engineering.com/help-advice

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 25

PAGE 24

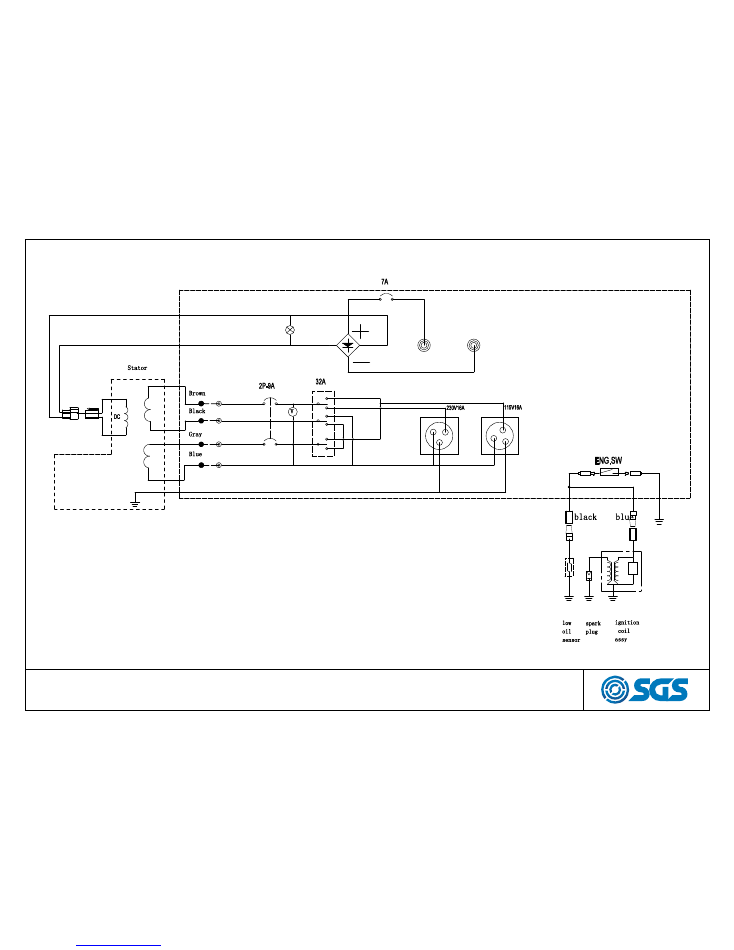

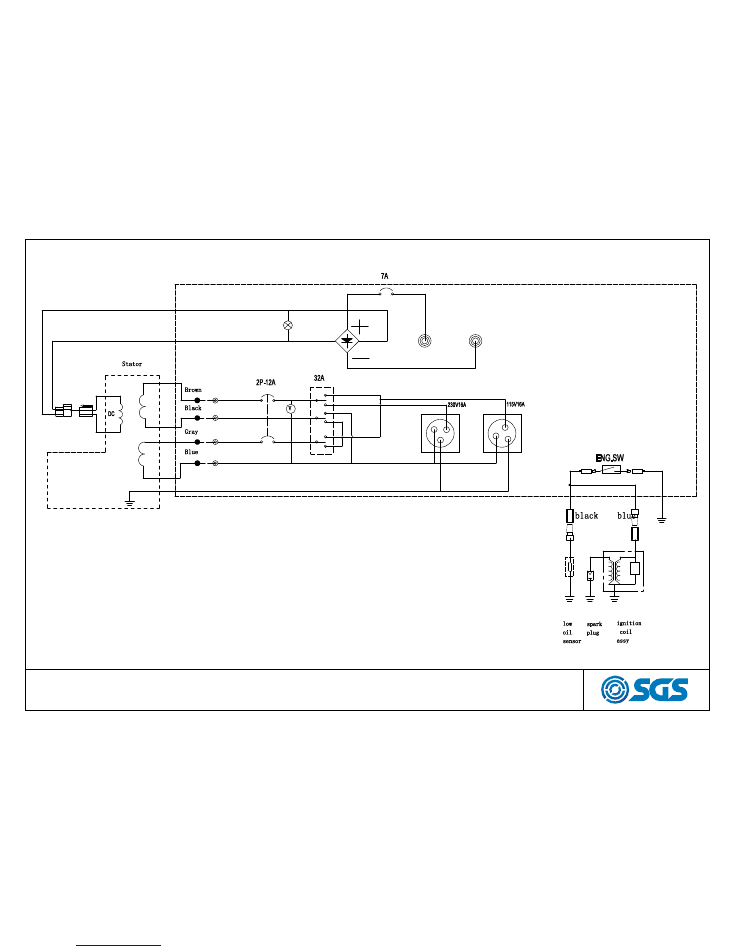

SPG2200 WIRING DIAGRAM

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 27

PAGE 26

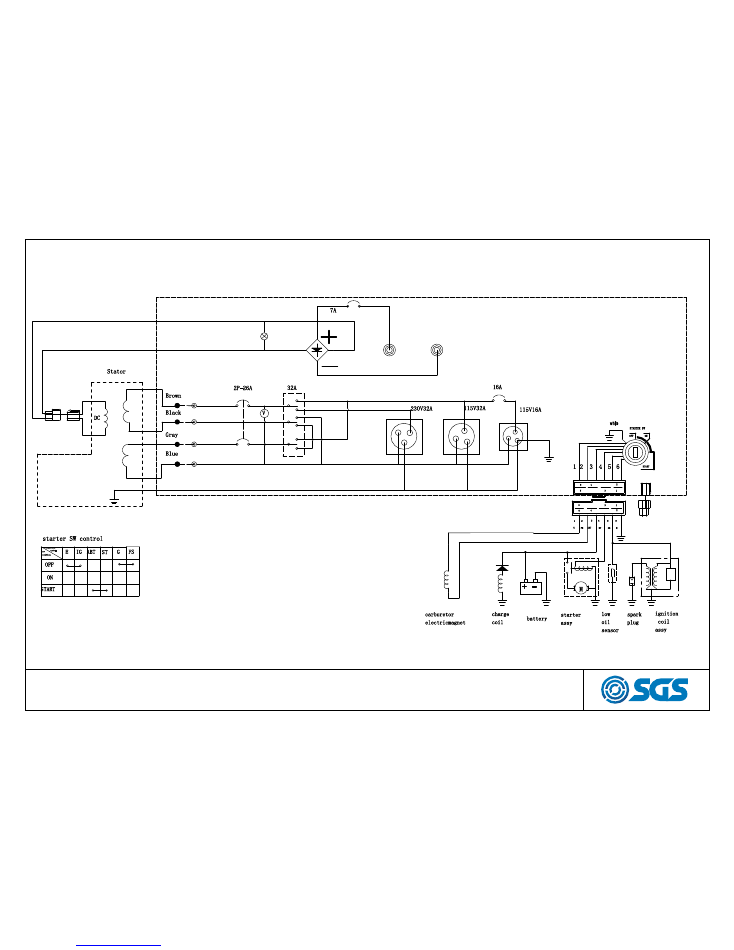

SPG3000 WIRING DIAGRAM

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

PAGE 29

PAGE 28

SPG6500 WIRING DIAGRAM

WWW.SGS-ENGINEERING.COM

CALL FOR ASSISTANCE:

01332 576 850

EC Declaration of Conformity

This is an important document and should be retained

MANUFACTURER’S NAME:

TYPE OF EQUIPMENT:

PART NUMBER:

I, the undersigned, hereby declare that the equipment specified above con

-

forms to the above European Communities Directive(s) and Standard(s).

PLACE:

DATE:

(Signature)

Robert Wyatt

Company Secretary

Derby, UK

24th JUNE 2015

SGS Engineering (UK) Ltd

SGS Engineering (UK) Ltd

2 West Side Park

Raynesway

Derby, DE21 7AZ

Petrol Generator

SPG2200/SPG3000/SPG6500

2004/108/EC

Electromagnetic Compatibility Directive

2006/42/EC

Machinery Directive

2006/95/EC

Low Voltage Equipment Directive

2000/14/EC

Noise Emissions Directive (amended 2004/26/EC)

97/68/EC

Emission of Gaseious Particulates (emended 2004/26/EC)

EN12601:2001, EN60204-1:2006, EN55012:2002+A1:2005,

EN ISO 3744:1995, ISO 8528-10:1998

APPLICATION OF EC

COUNCIL DIRECTIVES / STANDARD: