Full Text Searchable PDF User Manual

SERVICE INSTRUCTION

E F F I C I E N C Y I N D E N T I S T R Y

®

ELECTROLS UPGRADE AND REPLACEMENT

How to properly upgrade the gray box Electrols to S1

Electrols, and how to replace the S1 Electrols PC Board

BULLDOG MODELS

Procedures

Important Features

1 Phase Gray Box Electrols Upgrade

3 Phase Gray Box Electrols Upgrade

S1 Electrols PC Board Replacement

3 Phase Motor Startup

Page

6

7

8

14

15

• 550

(855.xxxx.xxx)

• QT

(809.xxxx.xxx)

• QT E

(809E.xxxx.xxx)

BISON MODELS

Procedures

Important Features

1 Phase Gray Box Electrols Upgrade

3 Phase Gray Box Electrols Upgrade

S1 Electrols PC Board Replacement

3 Phase Motor Startup

Page

10

11

12

14

15

• BISON

(818.xxxx.xxx)

(826.xxxx.xxx)

• BISON E

(818E.xxxx.xxx)

(826E.xxxx.xxx)

STANDARD MODELS

Procedures

Important Features

1 Phase Gray Box Electrols Upgrade

3 Phase Gray Box Electrols Upgrade

3 Phase Motor Startup

Page

2

3

4

15

• 550

(955.xxxx.xxx)

• 1400

(914.xxxx.xxx)

*Note: Instructions relating to Standard 1400 models also apply to Standard 1200 and 2800 models.

Page 2

STANDARD

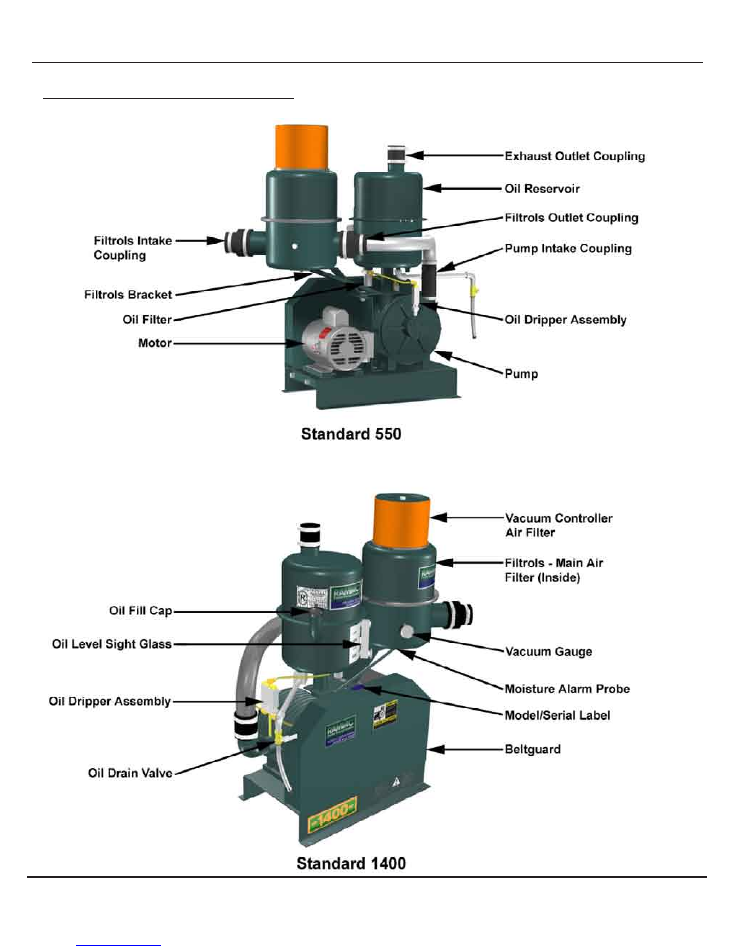

Standard Models Important Features

Page 3

STANDARD

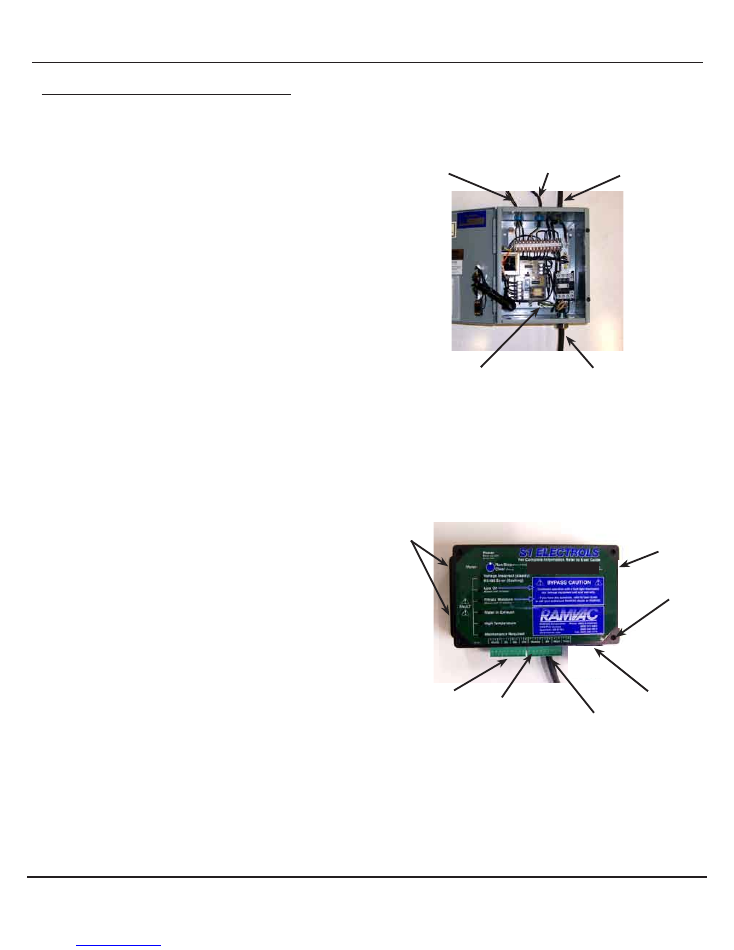

1 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on all

1 phase Standard models.

1. Secure disconnect.

2. Disconnect gray box Electrols.

a. Disconnect power source wires from L1, L2, and GND. Remove

cord grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm probe wires from P1 and P2.

Remove wires from cord grip.

d. Disconnect remote switch wires from R1, R2, and RL. Remove

wires from cord grip.

3. Discard gray box Electrols.

4. Install S1 Electrols using the 4 mounting holes.

5. Remove the cover screws and cover.

Note: There will be 2 wires under L1 screw and 2 wires under

GND screw.

6. Install cord grip and power source wires in side knockout on S1

Electrols.

a. Connect power source wires to L1, L2, and GND.

7. Install cord grip and motor wires to bottom knockout on S1 Electrols.

a. Connect motor wires to L1, M1 and GND.

8. Install cover using the screws previously removed.

9. If present, disconnect oil switch (spade terminals) from moisture

alarm cord.

a. Connect supplied extensions to wires coming from oil switch and

connect to terminals 1 and 2 on terminal plug “12DE34”.

10. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”.

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC User Guide” for further installation instructions.

11.

Connect

low voltage remote switch wires to terminal plug FGH.

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

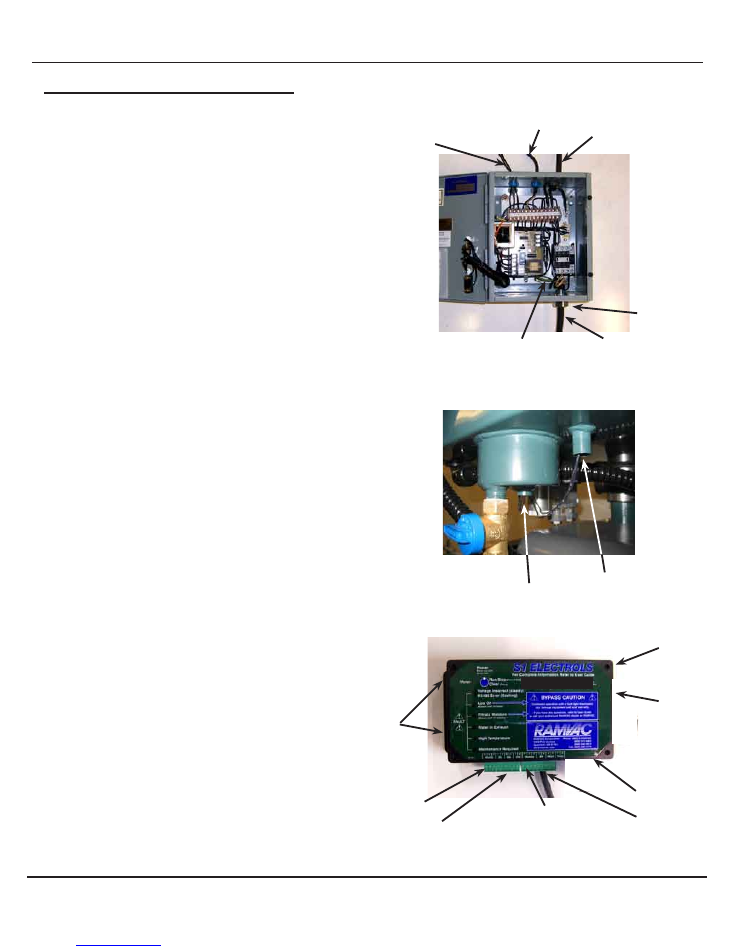

Power Source Wires

L1, L2, GND

1 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Remote Switch Wires

R1, R2, RL

Moisture Probe Wires

P1, P2

Motor Wires 2T1, 4T2

Motor Ground

S1 Electrols

Install Power

Source Wires

Install Motor Wires

Connect Remote

Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

S1 Electrols

Mounting Holes (4)

Motor Ground Lug

If Present,connect

oil switch to “1 2”

Cover Screws (4)

Page 4

STANDARD

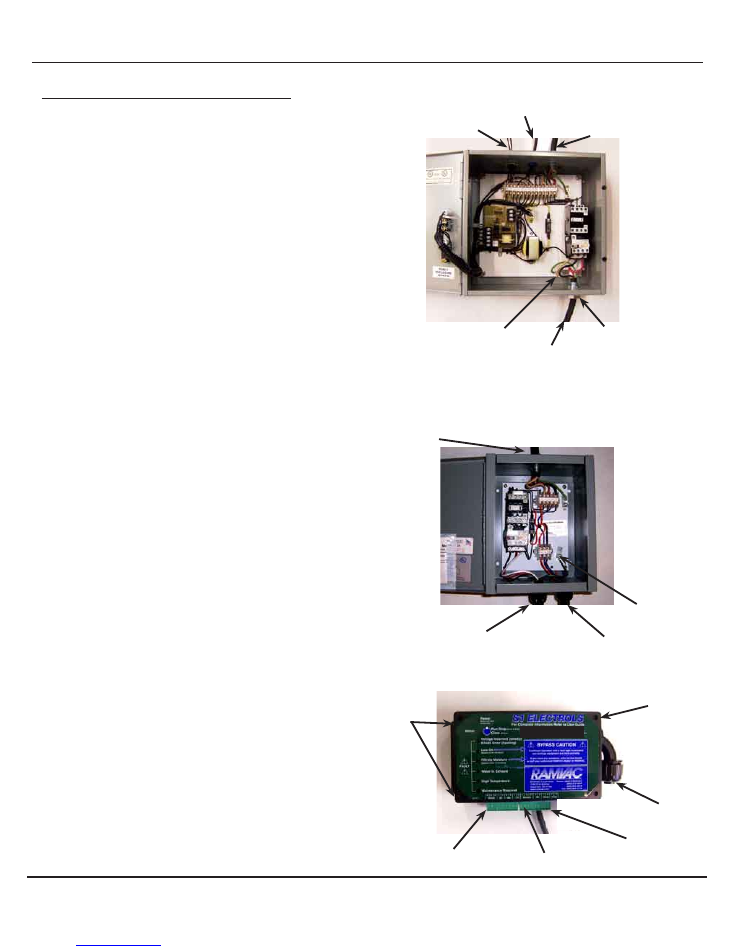

3 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on all

3 phase Standard models.

1. Secure Disconnect.

2. Remove items from gray box Electrols.

a. Disconnect power source wires from L1, L2, L3 and GND.

Remove cord grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, 6T3 and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm probe wires from P1 and P2. Remove

wires from cord grip.

d. Disconnect remote switch wires from R1, R2, and RL. Remove

wires from cord grip.

3. Discard gray box Electrols.

4. Install motor starter.

5. Install S1 Electrols using the 4 mounting holes.

6. Install cord grip and power source wires into top knockout on motor

starter.

a. Connect power source wires to L1, L2, L3 and GND.

7. Install cord grip and motor wires into bottom knockout on motor

starter.

a. Connect motor wires to 2T1, 4T2, 6T3 and motor ground.

8. Install motor control wires marked C1, C2, C3, and GND from

S1 Electrols into bottom knockout on motor starter.

a. Connect wires C1, C2, C3, and GND to appropriate terminals.

9. If present, disconnect oil switch (spade terminals) from moisture

alarm cord.

a. Connect supplied extensions to wires coming from oil switch and

connect to terminals 1 and 2 on terminal plug “12DE34”.

10. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”.

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC Manual” for further installation instructions.

11. Connect low voltage remote switch wires to terminal plug “FGH”.

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

12. Perform

“ 3 Phase Motor Startup”

procedure.

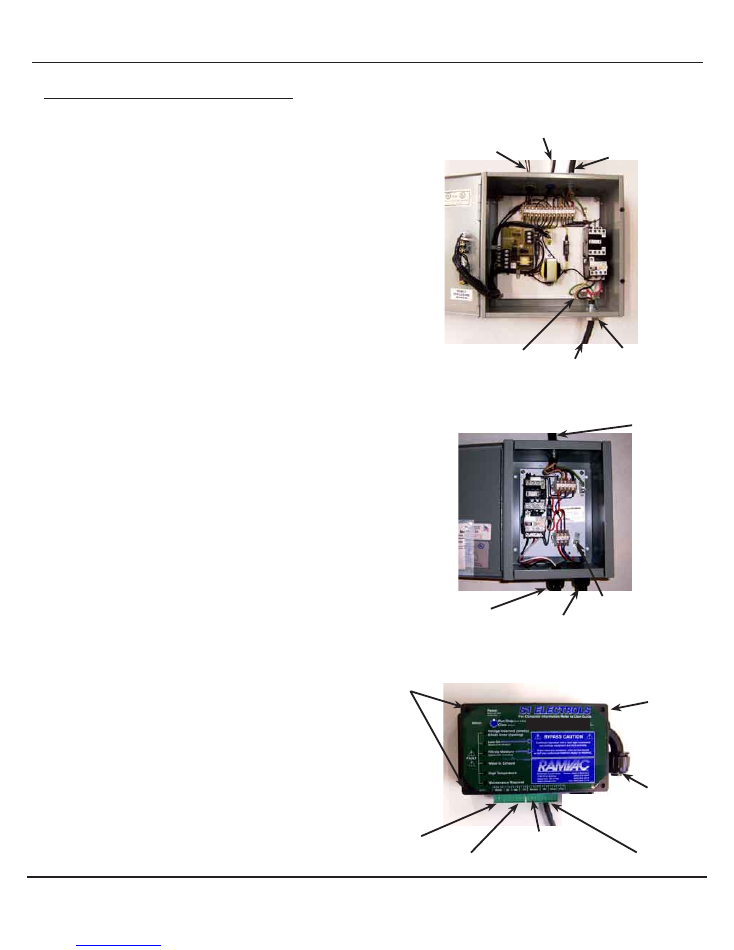

S1 Electrols

Power Source Wires

L1, L2, L3, GND

3 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Motor Wires 2T1, 4T2, 6T3

Motor Ground

Cord Grip

Remote Switch Wires

R1, R2, RL

Moisture Probe Wires

P1, P2

Motor Ground Lug

Motor Control Wires

C1, C2, C3, GND

Connect Remote

Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

S1 Electrols Mounting

Holes (4)

Motor Starter

Note: Motor Starter have several variations

Motor Wires 2T1, 4T2, 6T3

Motor Ground.

Motor Ground Lug

Power Source Wires

L1, L2, L3, GND

3 Ft Conduit with

motor control wires

If present, connect

Oil Switch to “1 2”

Cover Screws (4)

Page 5

NOTES

Page 6

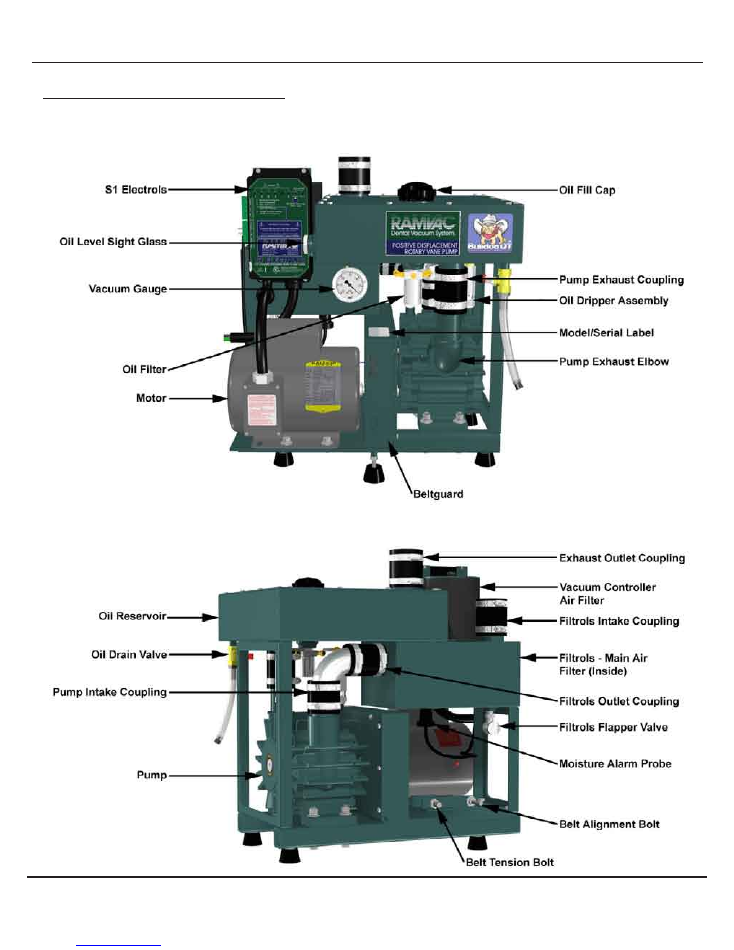

BULLDOG

Bulldog Models Important Features

Page 7

BULLDOG

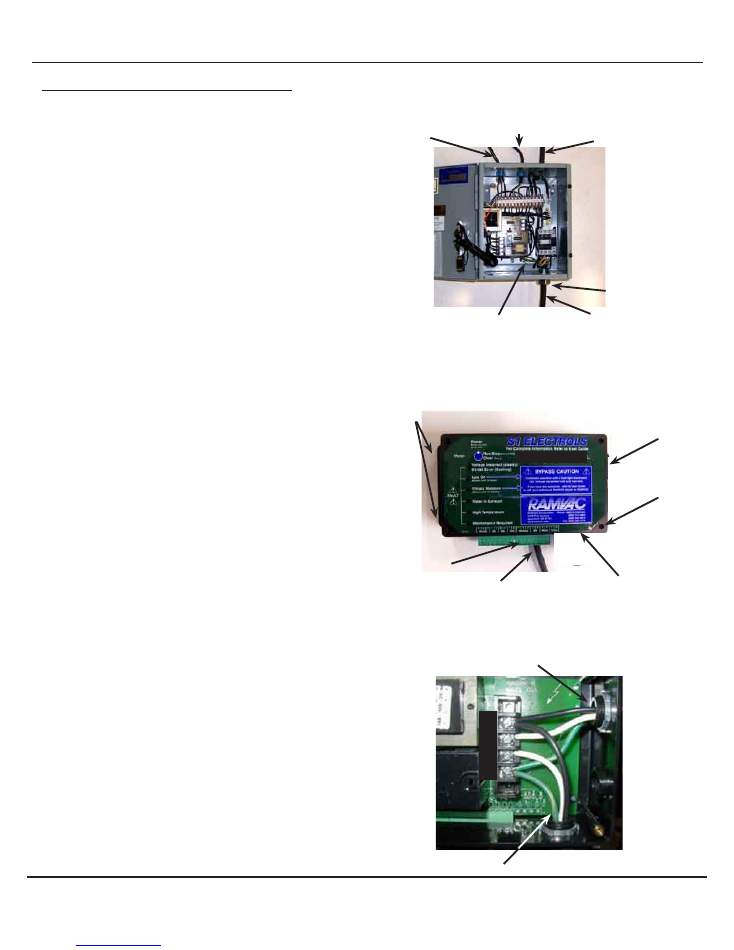

1 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on all

1 phase Bulldog models.

1. Secure Disconnect.

2. Remove items from gray box Electrols.

a. Disconnect power source wires from L1, L2, and GND. Remove

cord grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm probe wires from P1 and P2.

Remove wires from cord grip.

d. Disconnect remote switch wires from R1, R2, and RL.

Remove wires from cord grip.

3. Discard gray box Electrols.

4. Install S1 Electrols using the 4 mounting holes.

5. Remove the cover screws and cover.

Note: There will be 2 wires under L1 screw and 2 wires under

GND screw.

6. Install cord grip and power source wires in side knockout on

S1 Electrols.

a. Connect power source wires to L1, L2, and GND.

7. Install cord grip and motor wires to bottom knockout on S1 Electrols.

a. Connect motor wires to L1, M1 and GND.

8. Install cover using the screws previously removed.

9. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC Manual” for further installation instructions.

10. Connect low voltage remote switch:

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

L1

L2

M1

GND

S1 Electrols

S1 Electrols

Remote Switch Wires

R1, R2, RL

Power Source Wires

L1, L2, GND

Moisture Probe Wires

P1, P2

Motor Wires

2T1, 4T2, Motor Ground

Cord Grip

Power Source Wires

Motor Wires

Install Power

Source Wires

Install Motor Wires

Connect Remote

Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

1 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Motor Ground Lug

S1 Electrols Mounting

Holes (4)

Cover Screws (4)

Page 8

BULLDOG

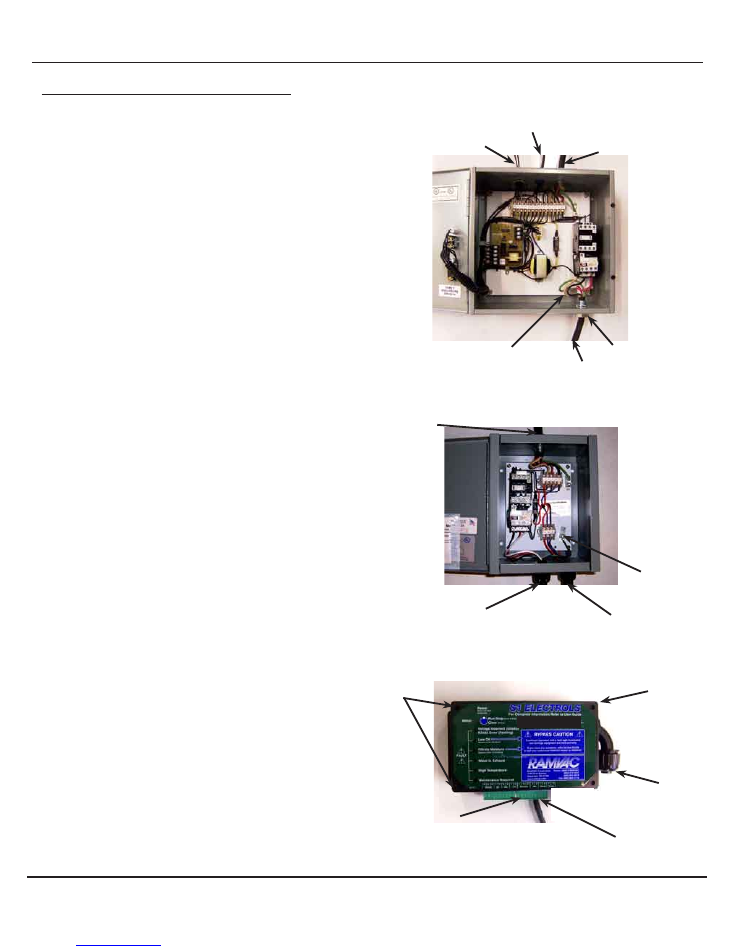

3 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on 3

phase Bulldog models.

1. Secure Disconnect.

2. Remove items from gray box electrols.

a. Disconnect power source wires from L1, L2, L3 and GND.

Remove cord grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, 6T3 and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm Probe wires from P1 and P2.

Remove wires from cord grip.

d. Disconnect remote switch wires from R1, R2, and RL.

Remove wires from cord grip.

3. Discard gray box Electrols.

4. Install motor starter.

5. Install S1 Electrols using the 4 mounting holes.

6. Install cord grip and power source wires into top knockout on

motor starter.

a. Connect power wires to L1, L2, L3 and GND.

Note: There will be 2 wires in the motor ground lug.

7. Install cord grip and motor wires into bottom knockout on motor

starter.

a. Connect motor wires to 2T1, 4T2, 6T3 and motor ground.

8. Install cord grip and control wires marked C1, C2, C3, and GND from

S1 Electrols

into bottom knockout on motor starter.

a. Connect wires C1, C2, C3, and GND to appropriate terminals.

9. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”.

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC Manual” for further installation instructions.

10. Connect remote switch wires to terminal plug “FGH”.

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

11. Perform

“ 3 Phase Motor Startup”

procedure.

Connect Low Voltage

Remote Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

S1 Electrols

Power Source Wires

L1, L2, L3, GND

3 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Motor Wires 2T1, 4T2, 6T3

Motor Ground

Cord Grip

Remote Switch Wires

R1, R2, RL

Moisture Probe Wires

P1, P2

Motor Ground Lug

Motor Starter

Note: Motor Starter have several variations

Motor Wires 2T1, 4T2, 6T3

Motor Ground

Motor Control Wires

C1, C2, C3, GND

Motor Ground Lug

Power Source Wires

L1, L2, L3, GND

3 Ft Conduit with

motor control wires

S1 Electrols Mounting

Holes (4)

Cover Screws (4)

Page 9

NOTES

Page 10

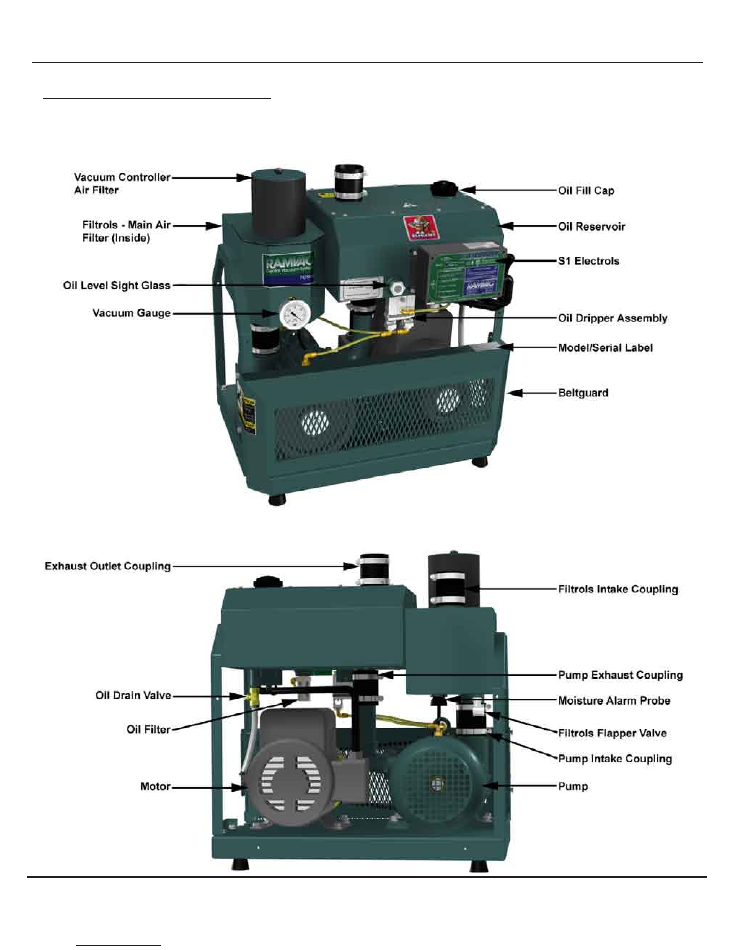

BISON

Bison Models Important Features

1 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on

1 phase Bison models.

1. Secure Disconnect.

2. Remove items from gray box Electrols.

a. Disconnect power source wires from L1, L2, and GND. Remove

cord grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm probe wires from P1 and P2. Remove

wires from cord grip.

d. Remove remote switch wires from R1, R2, and RL. Remove wires

from cord grip.

3. Discard gray box Electrols.

4. Install S1 Electrols using the 4 mounting holes.

5. Remove the cover screws and cover.

Note: There will be 2 wires under L1 screw and 2 wires under

GND screw.

6. Install cord grip and power source wires in side knockout on S1 Electrols.

a. Connect power wires to L1, L2, and Gnd.

7. Install cord grip and motor wires to bottom knockout on S1 Electrols

a. Connect motor wires to L1, M1, and Gnd.

8. Install cover using the screws previously removed.

9. Disconnect oil switch and water switch (2 spade terminals)

from moisture alarm cord.

a. Cut spade terminal ends from switch wires.

b. Install the supplied spade terminals on each of the 4 wire ends.

c. Connect supplied extensions to wires and connect to terminals.

i. Connect the oil switch wires to terminals 1 and 2 on terminal

plug “12DE34”.

ii. Connect the water in exhaust switch wires to terminals 3 and 4

on terminal plug “12DE34”.

10. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”.

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC Manual” for further installation instructions.

11. Connect remote switch wires to terminal plug “FGH”.

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

Page 11

BISON

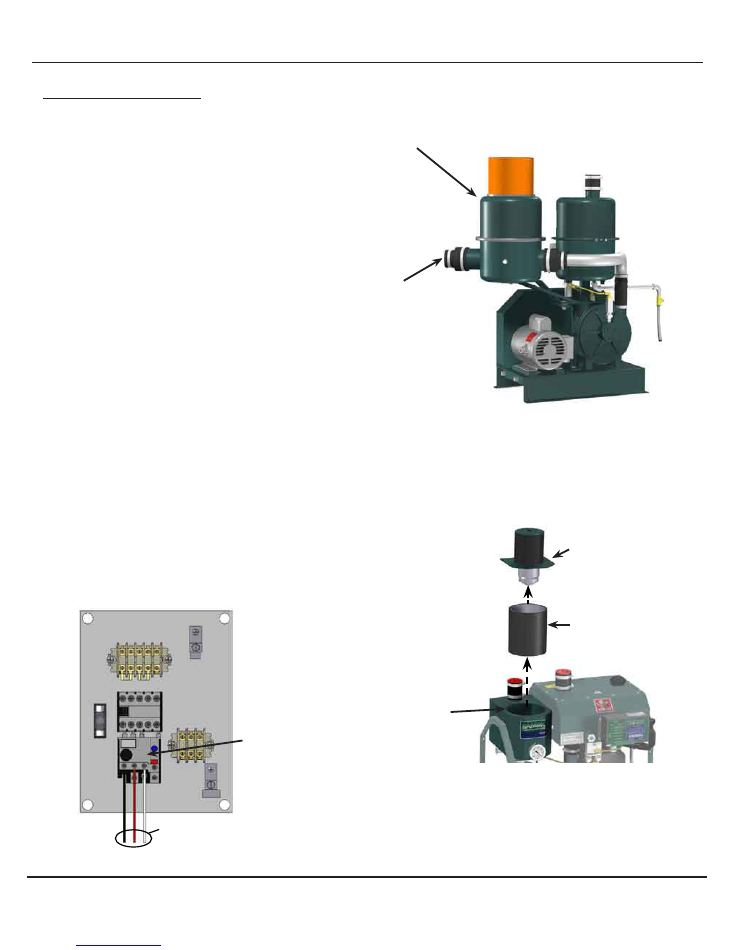

1 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Remote Switch Wires

R1, R2, RL

Power Source Wires

L1, L2, GND

Moisture Probe Wires

P1, P2

Motor Wires 2T1, 4T2

Motor Ground

Cord Grip

Install Power

Source Wires

Install Motor

Wires

Connect Remote

Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

S1 Electrols

Connect Water in

Exhaust to “3 4”

Connect Oil

Switch to “1 2”

Bison Reservoir Switches

Oil Switch

Water in Exhaust Switch

Motor Ground Lug

S1 Electrols

Mounting Holes (4)

Cover Screws (4)

Page 12

BISON

3 Phase Gray Box Electrols Upgrade

How to upgrade gray box Electrols to S1 Electrols on 3

phase Bison models.

1. Secure Disconnect.

2. Remove items from gray box Electrols.

a. Disconnect power wires from L1, L2, L3 and GND. Remove cord

grip and power source wires from gray box Electrols.

b. Disconnect motor wires from 2T1, 4T2, or 6T3 and motor ground.

Remove cord grip and motor wires from gray box Electrols.

c. Disconnect moisture alarm probe wires from P1 and P2.

Remove wires from cord grip.

d. Disconnect remote switch wires from R1, R2, and RL.

Remove wires from cord grip.

3. Discard gray box Electrols.

4. Install motor starter.

5. Install S1 Electrols using the 4 mounting holes.

6. Install cord grip and power source wires into top knockout on motor starter.

a. Connect power wires to L1, L2, L3 and GND.

Note: There will be 2 wires in the motor ground lug.

7. Install cord grip and motor wires into bottom knockout on motor starter.

a. Connect motor wires to 2T1, 4T2, 6T3 and motor ground.

8. Install cord grip and control wires marked C1, C2, C3, and GND from

S1 Electrols into bottom knockout on motor starter.

a. Connect wires C1, C2, C3, and GND to appropriate terminals.

9. Disconnect oil switch and water switch (spade terminals)

from moisture alarm cord.

a. Cut spade terminal ends from switch wires.

b. Install the supplied spade terminals on each of the 4 wire ends.

c. Connect supplied extensions to wires and connect to terminals.

Note: See Bison Reservoir Swtches illustration on previous

page for specific locations.

i. Connect the oil switch wires to terminals 1 and 2 on terminal

plug “12DE34”.

ii. Connect the water in exhaust switch wires to terminals 3

and 4 on terminal plug “12DE34”.

10. Connect moisture alarm probe wires to terminals J and K on terminal

plug “56JK78”.

Note: If Electrols is part of a VSC or MPC, refer to “VSC or

MPC Manual” for further installation instructions.

11. Connect remote witch wires to terminal plug “FGH”.

a. Connect switch wire to F.

b. Connect light wire to G.

c. Connect common wire to H.

12. Perform

“ 3 Phase Motor Startup”

procedure.

Connect Remote

Switch to “FGH”

Connect Moisture

Alarm Probe to “JK”

S1 Electrols

Power Source Wires

L1, L2, L3, GND

3 Phase Gray Box Electrols

Note: Gray Box Electrols have several variations

Motor Wires

2T1, 4T2, & 6T3

Cord Grip

Remote Switch Wires

R1, R2, and RL

Moisture Probe Wires

P1, P2

Motor Ground Lug

Motor Starter

Motor Wires 2T1, 4T2,

6T3, Motor Ground

Motor Control Wires

C1, C2, C3, GND

Motor Ground Lug

Power Source Wires

L1, L2, L3, GND

3 Ft Conduit with

motor control wires

S1 Electrols Mounting

Holes (4)

Connect Oil

Switch to “1 2”

Connect Water in

Exhaust to “3 4”

Cover Screws (4)

Page 13

NOTES

Page 14

S1 ELECTROLS PC BOARD REPLACEMENT

S1 Electrols PC Board Replacement

How to replace the S1 Electrols PC board on all models.

1. Secure Disconnect.

2. Remove original Electrical Specifications decal from top of S1

Electrols.

3. Apply new Electrical Specifications decal to top of S1 Electrols.

Note orientation and position of termnal plugs for re-installation

4.

Remove terminal plugs attached to S1 Electrols.

5. Remove cover screws and open cover.

Note orientation of power source and motor wires for proper

connection.

6. Disconect power source and motor wires from terminal strip.

7. Remove corner screws on the pc board. Remove pc board.

8. Install replacement pc board in S1 Electrols box and secure it with

corner screws.

9. With proper orientation connect power source and motor wires to

terminal strip.

10. Install cover using screws previously removed.

11. With proper orientation, insert terminal plugs into S1 Electrols.

L1

L2

M1

GND

Bison Model S1 Electrols

Terminal plugs

Electrical Specification Label

Bulldog Model S1 Electrols

Ribbon cable

Corner screws (4)

(corner of PC board)

Power Source Wires

Motor Wires

Terminal plugs

Electrical Specification Label

3 Phase Wiring

1 Phase Wiring

L1

L2

M1

GND

Motor Wires

Power Source Wires

Motor Control Wires

Motor Wires

Remove Cover Screws (4)

Page 15

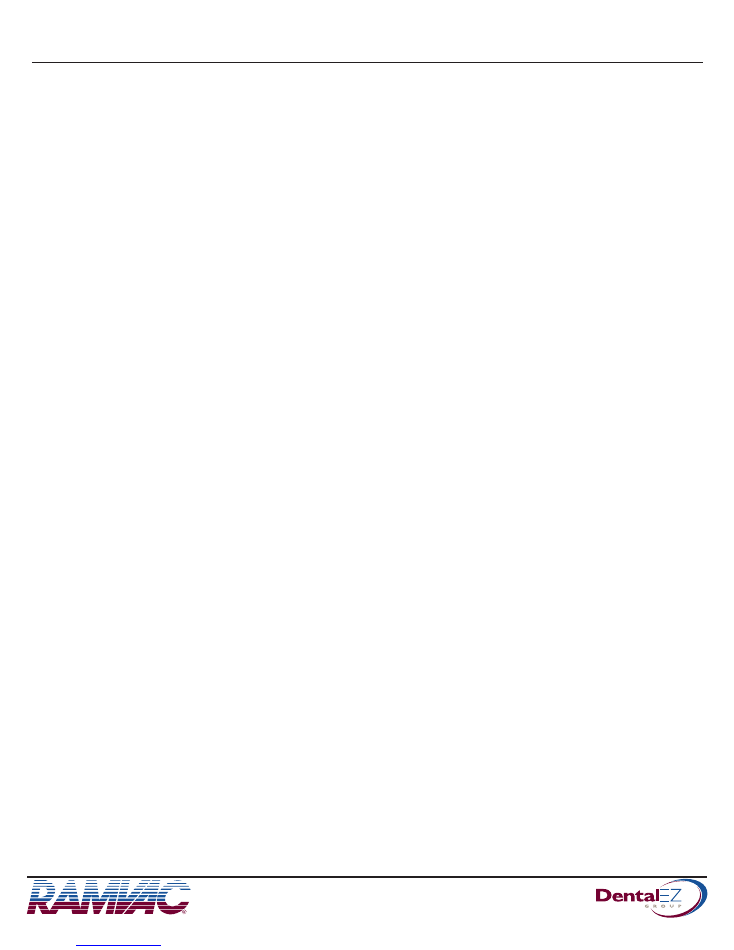

3 PHASE MOTOR START-UP

3 Phase Motor Start-up

How to properly start a 3 phase unit the first time or after

changes to motor, motor starter or Electrols.

1. Turn power on at disconnect.

Caution: Pump has 50% chance of rotating backwards.

DO NOT ALLOW debris to enter pump.

2. Check for correct pump rotation:

a.

Standard Models:

i. Loosen Filtrols intake coupling and remove line.

ii. Place hand by Filtrols intake to determine airflow.

b.

Bulldog and Bison Models:

i. Remove vacuum controller and main air filter from power unit.

ii. Place hand in Filtrols close to pump inlet to determine airflow.

3. Run vacuum unit long enough to determine airflow direction, then

turn pump off.

a. If air blows out of inlet pipe:

i. Reverse any two motor wires on motor overload.

ii. Repeat step 3.

b. If air sucks into inlet pipe:

i. Clean any oil or debris out of Filtrols.

4. Complete 3 phase motor start-up

a.

Standard Models:

Reinstall Filtrols inlet line

b.

Bulldog and Bison Models:

Reinstall main air filter and

vacuum controller.

Vacuum Controller

Main Air Filter

Filtrols - (Main Air

Filter inside)

Note: Contents inside

motor starters will vary.

For simplicity, not all motor

starter wiring is shown.

Switch any two of these wires to

reverse rotation.

Standard Models

Bison and Bulldog Models

Motor Starter

Filtrols Intake

Coupling

Motor Overload

Filtrols

3100 First Avenue

Spearfish SD 57783 USA

Web: ramvac.com

Phone:

Fax:

1-800-5-RAMVAC

1-605-642-4614

1-605-642-3776

SOF_7.2.3-01-139.doc

Effective Date: 25-Oct-05

Page 16 of 16

NOTES