Full Text Searchable PDF User Manual

1

www.phywe.com, © All rights reserved

09057-99 / 2115

Operating Instructions

XR 4.0 expert unit, X-ray unit, 35

kV

09057-99

PHYWE Systeme GmbH & Co. KG

Robert-Bosch-Breite 10

37079 Göttingen

Germany

Tel

+49

(0)

551

604-0

Fax

+49

(0)

551

604-107

E-mail info@phywe.de

Fig. 1: 09057-99, XR 4.0 expert unit, X-ray unit, 35

kV

The unit complies

with the applicable

EC regulations.

1

SAFETY INSTRUCTIONS

2

OPERATING INSTRUCTIONS

3

INSTRUCTIONS OF THE GERMAN X-RAY

ORDINANCE

4

PURPOSE AND CHARACTERISTICS

5

FUNCTIONAL AND OPERATING ELEMENTS

6

OPERATION

7

CHECKLIST

8

TECHNICAL DATA

9

SCOPE OF SUPPLY

10

ACCESSORIES

11

WARRANTY

12

DISPOSAL

13

APPENDIX

1 SAFETY

INSTRUCTIONS

Read the operating instructions thoroughly and com-

pletely prior to starting the unit. This is important for your

own protection and for avoiding damage to the unit.

Use the unit solely for its intended purpose.

The unit is intended for use in dry and dust-free rooms

where there is no risk of explosion.

Prior to connecting the unit to the mains power supply,

ensure that the protective conductor of the power supply

unit is correctly connected to the protective conductor of

the mains power supply network. The mains power plug

may only be plugged into a mains power socket that is

equipped with a protective conductor. Do not eliminate

this protective effect by using an extension lead without a

protective conductor.

Ensure that the mains voltage that is stated on the type

plate of the unit matches the mains voltage of your power

supply network.

When setting the unit up, ensure that the mains power

switch and the device plug are freely accessible. Ensure

also that the venting slots of the unit are not covered or

blocked.

Do not connect any devices to the unit other than the

ones that are intended for this purpose.

Attention: Disconnect the unit from the power supply

prior to loosening, replacing, or removing any of the ca-

ble connections!

Ensure that no liquids or objects penetrate the unit

through the venting slots.

2

www.phywe.com, © All rights reserved

09057-99 / 2115

Do not start the unit if the mains power cable or the unit

itself are damaged.

Switch the unit off after using it. Continuous operation is

not permissible. The maximum runtime per day is

10 hours. It is not a syfety risk if you the tube for longer

intervals but this could reduce the lifetime of the tube.

Start the unit at least twice per year and check its safety

functions. The tests that are included in the checklist at

the end of this document must be performed.

If damaged, the unit must be returned to the manufac-

turer for repair. Only the manufacturer or a certified com-

pany that has been appointed by the manufacturer are

authorised to repair and maintain the unit.

Since X-ray units generate dangerous radiation that is

hazardous to health, only trained and qualified persons

are authorised to start the X-ray unit in accordance with

the local, country-specific rules and regulations.

In Germany: When working with the X-ray unit, the man-

datory measures and duties that are outlined in the Ger-

man X-ray ordinance (Röntgenverordnung, RÖV) must

be strictly complied with.

The requirements of the certificate are to be followed

In particular, the operator must ensure that

o

the X-ray unit is protected against access by unau-

thorised persons;

o

the unit is not in use longer than necessary;

o

persons working with the unit do not remain in the

direct vicinity of the unit longer than absolutely

necessary.

The use of the unit is prohibited if

o

the sliding door that is made of lead-containing

acrylic glass and that is used for opening the ex-

periment chamber, or the other protective glass

windows that are used to observe the X-ray unit

and the experiment chamber, are damaged;

o

the fan at the X-ray plug-in side inside the unit is

inoperative (acoustic check);

o

the safety circuits for interrupting the X-ray opera-

tion when the sliding door is opened do not oper-

ate properly.

How to clean:

o

Do not use diluter/thinner!

o

Clean with cloth and appropriate cleaning agent.

Transport

o

Do not stress the drawer during transport. The

device should stand only on its feet.

o

During transport make sure that the sliding

door is not locked with the lock bar. If so,

unlock the door using button IV, Fig 5 (switch

on the device to use the button). The door

should not be open either - fix it with the

S-LOCK.

2 OPERATING

INSTRUCTIONS

The device fulfils the technical requirements that are

summarised in the current guidelines of the European

Community. The characteristics of the product entitle it to

bear the CE mark.

The unit must be used under the supervision of an expert

and in the electromagnetically controlled environment at

research, teaching, and training facilities (schools, uni-

versities, institutes, and laboratories).

This means that, in such an environment, radio transmis-

sion devices, e.g. mobile phones, should not be used in

the direct vicinity of the unit. The connected cables must

not be longer than 2

m.

Electrostatic charges or similar electromagnetic phe-

nomena (HF, bursts, indirect lightning discharge, etc.)

may affect the unit so that it will not work within the

specified data range.

Occuring interfering signals may result in an automatic

shutdown of the high voltage during measurement! In

this case please follow section 6.6.

The following measures reduce or eliminate potential in-

terferences: avoid carpets; provide equipotential bond-

ing; perform the experiments on a conductive, earthed

surface; use shields and shielded cables. Do not use ra-

diofrequency transmitters (radio sets, mobile phones) in

the direct vicinity of the unit. After a total exit by actuating

the mains power switch, perform a reset.

This unit corresponds to class A of the standard DIN

EN 61326 and may be used without any restriction only in

non-residential areas. If - although the use of the unit is re-

stricted to special classrooms in a school or another training

facility - electromagnetic interf erences occur in the surround-

ing residential area, the operator can be required to take the

appropriate measures (e.g. shielding, long distance with re-

gard to sensitive equipment, short periods of use, use of the

shortest possible connecting cables, etc.) and to pay for

these measures.

3 INSTRUCTIONS OF THE GERMAN X-RAY

ORDINANCE

In Germany, the operation of the X-ray unit is subject to the

regulations that are outlined in the X-ray ordinance (Rönt-

genverordnung, RöV). In accordance with this ordinance, the

unit fulfils the mandatory requirements of an X-ray unit for

schools as well as those of a full-protection device.

In Germany, the operation of the unit is not subject to ap-

proval, but to reporting. Thus, report the unit to the appropri-

ate controlling institution.

For reporting, the test certificate and a copy of the design ap-

proval must be submitted to the responsible authorities. Only

specifically trained and instructed personnel is authorised to

operate the unit. When this unit is used as an x-ray device for

schools a radiation protection officer must be authorized.

If the unit operates at the maximum operating data, the local

dose rate at a distance of 0.1

m from the parts of the housing

that can be touched is less than 1

μ

Sv/h.

Two independent safety circuits monitor the opening of the

sliding door that leads to the experiment chamber.

X-rays can only be generated when the sliding door is prop-

erly locked. The safety circuits also prevent the maximum

permissible operating values of the tube from being ex-

ceeded.

Do not use the device if the X-ray unit is manipulated in a

way that is not necessary for its set-up or for performing ex-

periments. It is absolutely forbidden to loosen the safety

screws of the sheet steel housing or to tamper with the win-

dows. Only the manufacturer is authorised to repair the unit.

For any operation of the unit outside of Germany, the appli-

cable local rules and regulations must be complied with.

3

www.phywe.com, © All rights reserved

09057-99 / 2115

4 PURPOSE

AND

CHARACTERISTICS

4.1 Purpose of the unit

The X-ray unit is a demonstration unit as well as a unit for

laboratory courses. It has been specially developed to fulfil

the requirements of education at schools and universities. In

addition to its use in the education of physics, it can also be

used for education in the medical sector and the related

technical disciplines. A particularly noteworthy distinguishing

feature of this microprocessor-controlled compact unit is the

quick-change feature of the X-ray tubes that enables the per-

formance of experiments with different X-ray tubes and,

thereby, different anode materials.

The following X-ray tubes, which are integrated in special,

ready-to-use plug-in units, are available:

Plug-in unit with a Cu X-ray tube

order no. 09057-51

Plug-in unit with a Mo X-ray tube order no. 09057-61

Plug-in unit with a Fe X-ray tube

order no. 09057-71

Plug-in unit with a W X-ray tube

order no. 09057-81

Do not use other plug-ins (predecessors 09057-50 / -60 /

-70 / -80 are still compatible).

Apart from simple fluoroscopic experiments and experiments

on dosimetry, the integrated rate meter and the additional

goniometer enable spectroscopic experiments on atomic

physics and solid-state physics.

The operating and control parameters are set either directly

on the unit or with a computer via USB.

A colour TFT display in the control panel is used for the direct

control of the unit (and for displaying all of the operating and

control parameters as well as the measurement values). The

keys around the display in the control panel enable the com-

plete operation and control of the unit in its basic functions.

4.2 Overview of the possible experiments

The following experiments can be performed with the unit

and the corresponding additional components:

Radiography of objects and observation with the aid of a

fluoroscopic screen

Preparation of X-ray images of irradiated objects

Detection of the ionising effect of X-rays (dosimetry)

Detection of Bragg reflection

Characterisation of X-ray spectra

Determination of the characteristic X-ray lines of various

anode materials (Cu, Mo, Fe, and W), thereby verifying

Moseley’s law

Detection of the characteristic lines K

α

1

and K

α

2

in higher

order diffraction

Monochromatisation of X-rays with the aid of monocrys-

tals or metal foil

Crystal analysis with the aid of X-ray spectroscopy and

Laue and Debye-Scherrer methods

Determination of Planck’s quantum of action from the

short-wave limit of the bremsspectrum (Duane-Hunt law

of displacement)

Determination of the Rydberg constant

Determination of the absorption coefficients as a function

of the thickness and atomic number of the absorber ma-

terial and of the photon energy

Detection of absorption edges

Demonstration of the effects of contrast media in medical

applications

Compton

scattering

5 FUNCTIONAL AND OPERATING ELEMENTS

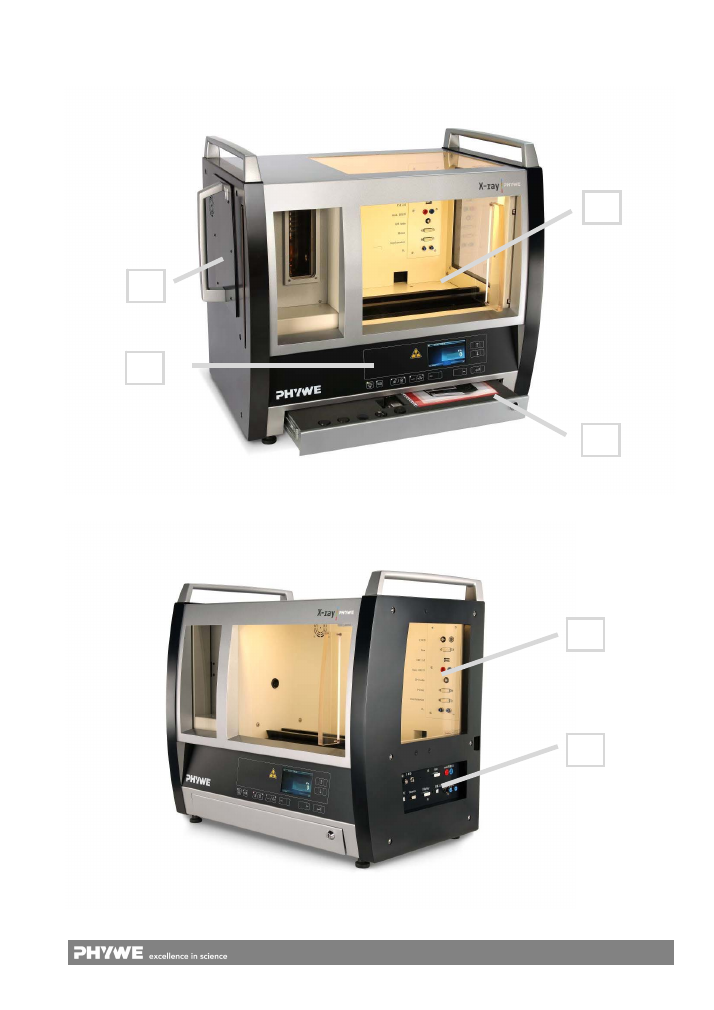

5.1 XR 4.0 X-ray expert unit

The XR 4.0 X-ray expert unit includes the following main

components (see Fig. 2 and Fig. 3).

5.1.1 Experiment chamber

For performing experiments and for holding additional

equipment, such as a goniometer or other experiment mate-

rial.

5.1.2 Control panel

For setting the operating values and control quantities as well

as for displaying all of the available measurement values.

5.1.3 Tray for accessories

For storing additional components.

5.1.4 Tube plug-in unit with a plug-in bay

Module in which the X-rays are generated.

5.1.5 Socket panel in the experiment chamber

For connecting various components, either for the connection

to the XR 4.0 X-ray expert unit or for the connection to other

peripheral equipment via the socket panel on the outside on

the right-hand side of the unit.

5.1.6 External Socket panel

The external socket panel on the right-hand side of the unit is

the counterpart of the socket panel inside the experiment

chamber.

4

www.phywe.com, © All rights reserved

09057-99 / 2115

Fig. 2: Front view of the XR 4.0 X-ray expert unit (09057-99) including X-ray tube

Fig. 3: View from the right side

XR 4.0 X-ray expert unit (09057-99)

1

4

2

3

5

6

5

www.phywe.com, © All rights reserved

09057-99 / 2115

5.2 Experiment chamber (

1

)

The experiment chamber (Fig. 4) includes the following func-

tional elements:

5.2.1 Sliding door (A)

Made of lead-containing acrylic glass. The door is perma-

nently monitored by a safety circuit and it is either locked or

released via an actuator.

For monitoring the position of the sliding door (open/closed),

two independent encoders are connected to the central

safety unit of the XR 4.0 X-ray expert unit. If the sliding door

is closed and the unit is in a safe state, the operator can lock

the sliding door via the control panel. The position of the ac-

tuator for this purpose is monitored by two additional inde-

pendent encoders that are also connected to the central

safety unit.

In order to open the sliding door,push it first against the stop

on the right-hand side.The S-Lock is now unlocked and the

door can be opened.

X-rays can only be generated when the door is locked.

5.2.2 X-ray outlet (B)

The X-ray outlet is located on the left-hand side of the ex-

periment chamber. It is used to hold metal tubes with circular

double-apertures for generating a beam of rays that is suited

to the experiment in question.

5.2.3 Socket panel in the experiment chamber (C)

Socket panel for the connection of devices that are located

inside the experiment chamber, e.g. a goniometer. The sock-

ets connect the devices either with the X-ray unit itself or they

lead to the external socket panel that is located on the right-

hand side of the unit (looping-through). This enables, for ex-

ample, the control or read-out from the outside of a digital

camera that is located inside the experiment chamber.

5.2.4 Working channel (D)

The working channel is located on the back wall of the ex-

periment chamber, at the bottom on the right-hand side. It

ends on the right-hand side outside of the unit and, thereby,

forms a connection through which, for example, a contrast

medium can be fed into the experiment chamber through

hoses during the operation of the unit. The shape and cross-

section of the working channel ensure that no X-radiation can

escape.

5.2.5 Optical bench (E)

An optical bench is fastened to the bottom of the experiment

chamber along the optical axis of the X-rays. The adapters

that are required for the experiments can be attached to, and

shifted on, this optical bench.

5.2.6 Temperature monitoring system

The temperature of the air inside the experiment chamber is

monitored and controlled via a fan system.

5.2.7 Interior lighting

The linear LED lighting for illuminating the experiment cham-

ber can be activated as required.

5.2.8 Holder for the goniometer

The goniometer 09057-10 is magnetically secured inside the

experiment chamber via magnetic foil and has an electrical

connection to the XR 4.0 X-ray expert unit (plug & measure).

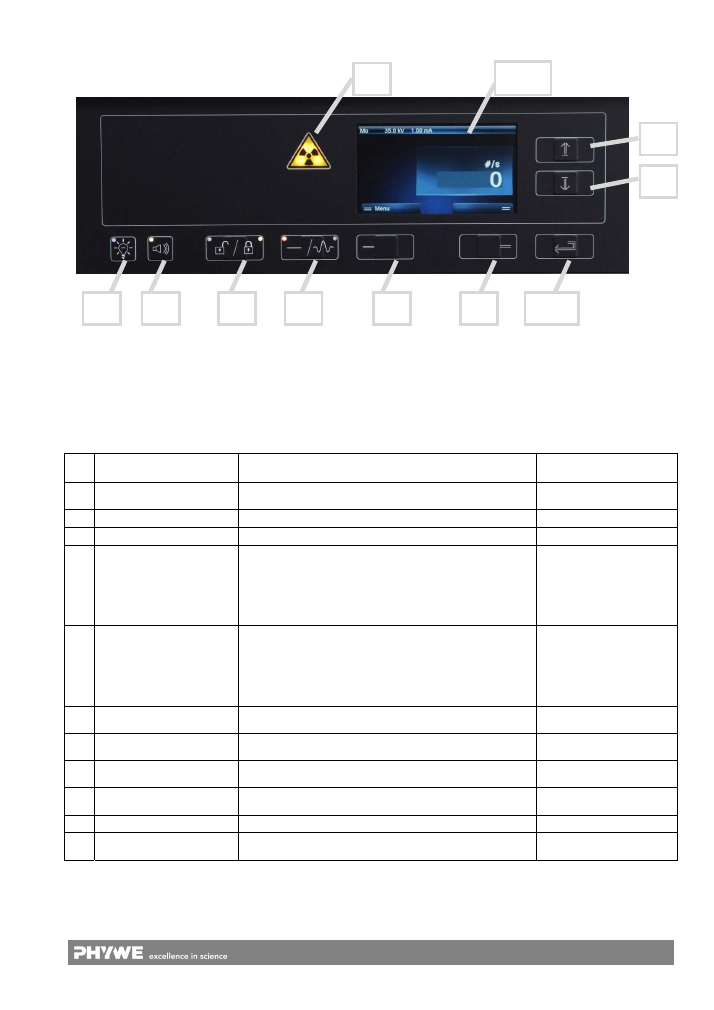

5.3 Control panel at the front of the unit (

2

)

The control panel at the front of the unit is shown in Fig. 5

and described in Table 1.

5.4 Tray for accessories (

3

)

The lower part of the XR 4.0 X-ray expert unit includes a tray

with moulds for the following components (for example):

Geiger-Müller counter tube

X-ray

energy

detector

Diaphragms

Fig. 4: experimentation chamber

C

D

B

E

A

6

www.phywe.com, © All rights reserved

09057-99 / 2115

Table 1: Overview of the functional elements of the control panel

No. Name/Type

Function

Lighting colour:

function activated

I

Triangular warning symbol

“X-rays”

X-ray status indication

Bright yellow ( 2 LEDs)

II

Lighting (button)

For switching the light in the experiment chamber on/off

Green

III

Loudspeaker (button)

Acoustic indication of the pulses

Green

IV

Door status (button)

For locking and unlocking the door

White:

not

lockable

Left LED green:

door can be locked

right LED green:

door

locked

V

X-rays (button)

For activating the X-radiation

White: it is not possible

to swith on the unit

Left LED green:

X-ray can be activated

right LED green:

X-ray is activated

VI

Button (no name)

The selection of the menu function will be displayed on the

screen above (on the bottom on the left-hand side)

White

VII

Button (no name)

The selection of the menu function will be displayed on the

screen above (on the bottom on the right-hand side)

White

VIII Arrow key “up” (button)

For setting experiment parameters and for scrolling through

the menu

White

IX

Arrow key “down” (button)

For setting experiment parameters and for scrolling through

the menu

White

X

Enter (button)

For confirming the selected value

White

XI TFT

display

For displaying the menus for the manual control of the unit

(77

mm x 50

mm)

Polychrome

Fig. 5: Control panel at the front of the unit

VIII

IX

I

XI

II

III

IV

V

VI

VII

X

7

www.phywe.com, © All rights reserved

09057-99 / 2115

5.5 X-ray plug-in unit (

4

)

Plug-in unit for holding the adjusted X-ray tube in a sheet

steel housing with a carrying handle, ready for use in the

X-ray XR 4.0 X-ray expert unit. The housing of the tube has a

catch lock and two safety contact pins that enable the tube

operation only if the plug-in unit has been installed correctly.

Fig. 6: X-ray plug-in unit on the left-hand side of the unit

The bay for receiving the X-ray plug-in unit is equipped with

coupling sockets and subsequent safety switches. These are

connected to the central safety monitoring system of the

XR 4.0 X-ray expert unit.

The following ready-prepared plug-in units are available:

Plug-in unit with a Cu X-ray tube

order no. 09057-51

Plug-in unit with a Mo X-ray tube order no. 09057-61

Plug-in unit with a Fe X-ray tube

order no. 09057-71

Plug-in unit with a W X-ray tube

order no. 09057-81

The plug-in units consist of a sheet steel housing with a fac-

tory-adjusted X-ray tube. In order to prevent them from over-

heating, the tubes are enclosed in a Duran glass cylinder.

This glass cylinder has side connecting pieces through which

forced air cooling via a fan in the XR 4.0 X-ray expert unit is

ensured.

The plug-in units also have an HV plug and a plug for the

tube cathode heating so that the operating values can be

taken over from the corresponding sockets of the XR 4.0

X-ray expert unit.

Make sure that the plug-in is inserted completely. Otherwise,

it is not going to work.

Handle the plug-ins with care!

5.6 Socket panel inside the experiment chamber (

5

)

Fig. 7: Socket panel inside the experiment chamber

The socket panel at the back wall of the experiment chamber

(Fig. 7) includes the following sockets for the connection of

components in the experiment chamber. The names that are

stated inside the unit are printed in italics.

From the top down:

X RED:

For connecting the X-ray energy detector

09058-30 to the multi-channel analyser 13727-99; BNC

signal cable, supply cable (direct connection to the ex-

ternal socket panel on the right-hand side of the unit).

Aux:

Multi-pole socket for connecting various devices in

the experiment chamber (direct connection to the exter-

nal socket panel on the right-hand side of the unit).

USB 2.0:

Socket for connecting digital cameras etc. (di-

rect connection to the external socket panel on the right-

hand side of the unit).

Max 600

V

: 2

mm x 4

mm sockets, e.g. for charging the

capacitor plates (order no. 09057-05) for dosimetry ex-

periments (direct connection to the external socket panel

on the right-hand side of the unit).

GM tube:

BNC socket for connecting the Geiger-Müller

counter tube, type B 09005-00.

Motor:

Socket for connecting the rotating stage XRstage

09057-42 of the computed tomography set XRCT 4.0

X-ray 09180-88.

Goniometer:

Connecting socket for the goniometer

09057-10.

N

2

:

For feeding in protective gas or for the connection to

a vacuum pump (direct connection to the external socket

panel on the right-hand side of the unit).

8

www.phywe.com, © All rights reserved

09057-99 / 2115

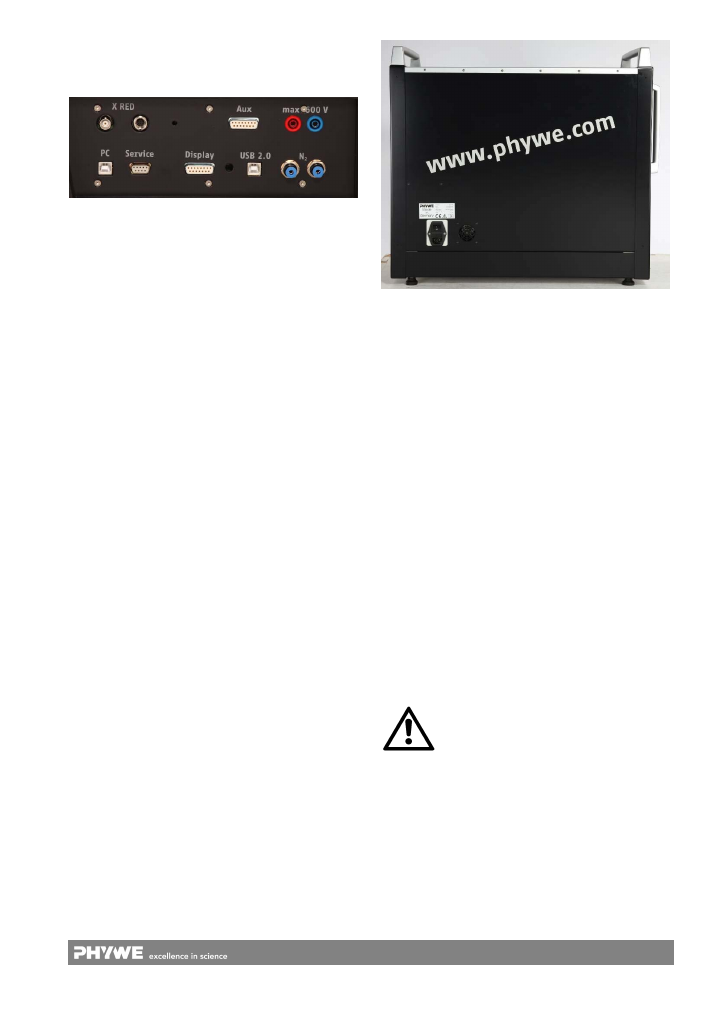

5.7 External socket panel on the right-hand side (

6

)

The external socket panel (Fig 8) on the right-hand side of

the unit is the counterpart of the socket panel inside the ex-

periment chamber.

Fig. 8: External socket panel on the right-hand side of the unit

Here, the following components can be connected. The

names that are stated on the unit are printed in italics.

Lower line of the socket panel:

PC:

For the connection to the control PC via the “meas-

ure” USB 2.0 port.

Service

: For the connection of a specially configured PC

for updating the device settings and for diagnosis pur-

poses (for authorised specialist personnel only).

Display:

For the connection of a “Display Connect” RF

adapter (09057-19). It is used to display measurement

values and device parameters on the large-scale display

unit (07157-93).

USB 2.0:

Socket for connecting digital cameras etc. (di-

rect connection to the socket panel inside the experiment

chamber).

N

2

:

For feeding in protective gas or for the connection to

a vacuum pump (direct connection to the socket panel

inside the experiment chamber).

Upper line of the socket panel:

X RED:

For connecting the X-ray energy detector 09058-

30 to the multi-channel analyser 13727-99; BNC signal

cable, supply cable (direct connection to the socket panel

inside the experiment chamber).

Aux:

Multi-pole socket for connecting various devices in

the experiment chamber (direct connection to the socket

panel inside the experiment chamber).

Max 600 V

: 2 x 4-mm-sockets, e.g. for charging the ca-

pacitor plates (order no. 09057-05) for dosimetry experi-

ments (direct connection to the socket panel inside the

experiment chamber).

6 OPERATION

This section describes the start-up of the unit and provides

an overview of its operation. Please read this section care-

fully in order to avoid problems or malfunctions.

6.1 Transport

Do not stress the drawer during transport. The device

should stand only on its feet.

During transport make sure that the sliding door is not

locked with the lock bar. If so, unlock the door using but-

ton IV, Fig 5 (switch on the device to use the button). The

door should not be open either - fix it with the S-LOCK.

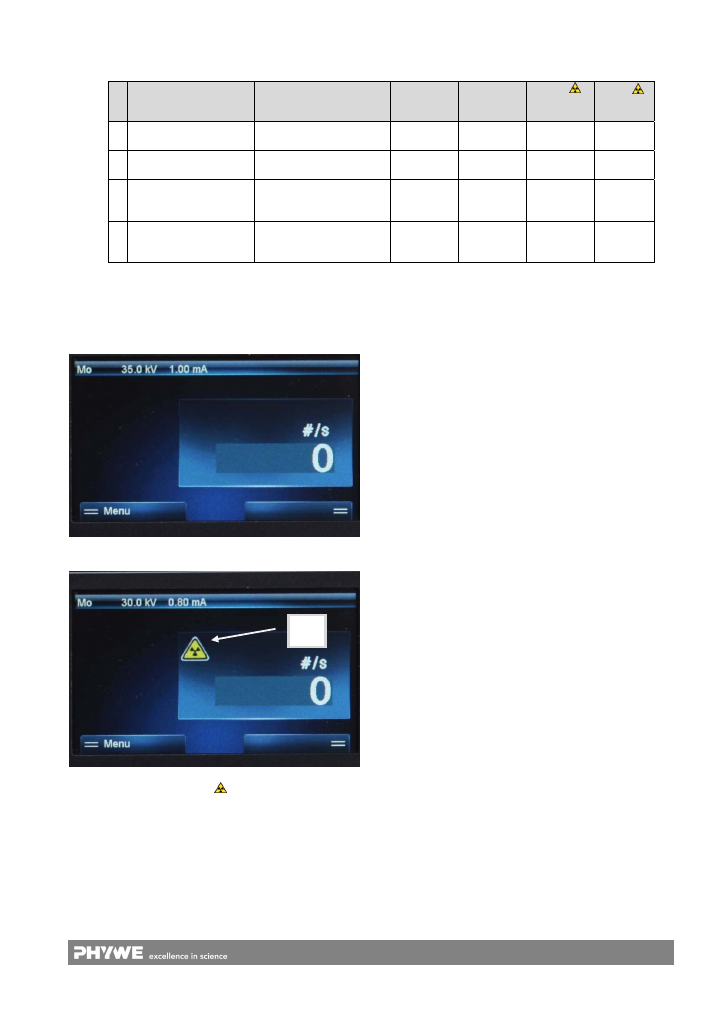

6.2 Start-up

Connect the unit to the power supply via the supplied power

cable with an IEC connector. The socket for this purpose is

located at the back of the unit (see Fig. 9).

Fig. 9: Back of the unit with the socket for the power cable

and the central ON/OFF switch

6.3 Starting the unit

The central ON/OFF switch of the unit is located at the back

of the unit (Fig. 9). Actuate this switch to switch the unit on.

After the start, the unit will perform an automatic self-test

(safety test). For this purpose, the operator must open the

sliding door completely one time and then close it again. The

device status that is thus determined will be indicated on the

display unit in the control panel via the colours of the but-

tons IV and V.

In order to open the sliding door, push it first against the stop

on the right-hand side.The S-Lock is now unlocked and the

door can be opened.

If the unit had been switched off with the door being locked,

the door will be automatically unlocked once the unit is

switched on. The operator must then open the radiation pro-

tection door once and close it again (check of the safety cir-

cuit; described in the operating instructions and on the dis-

play unit).

If the X-ray plug-in is completely inserted and the door is

closed with the use of the SLOCK the left LED of button IV is

glowing in green. All other LEDs are enlighted in white. Now,

the unit is ready for use.

If this is not the case, contact the Service of PHYWE for help.

Caution:

It is only possible to lock the sliding door, if the

plug in with the X-ray tube is completely inserted

into the device.

if you switch off the device while it is locked you

have to switch it on again to unlock the door.

When used for the first time, the X-ray tubes should not run

at full power. Instead, we recommend letting the tubes run for

approximately 10 minutes at the maximum beam current, but

with an acceleration voltage that is limited to 25

kV maximum.

This procedure must also be repeated if a tube has not been

used for several weeks.

9

www.phywe.com, © All rights reserved

09057-99 / 2115

The unit has four device statuses that are listed in Table 2.

Depending on the status, the unit can be controlled entirely

via the buttons on the control panel together with the graphi-

cal representation.

Fig. 10: Screen for controlling the unit at the front of the unit.

The x-radiation is not activated.

Fig. 11: Screen for controlling the unit at the front of the unit.

The x-radiation is active. Sign

appears on the screen.

The change of the representation and the control of the unit

via the menu are performed via the buttons VI-X (Fig. 5).

As soon as the x-radiation is activated a yellow symbol ap-

pears on the screen (See Fig. 11).

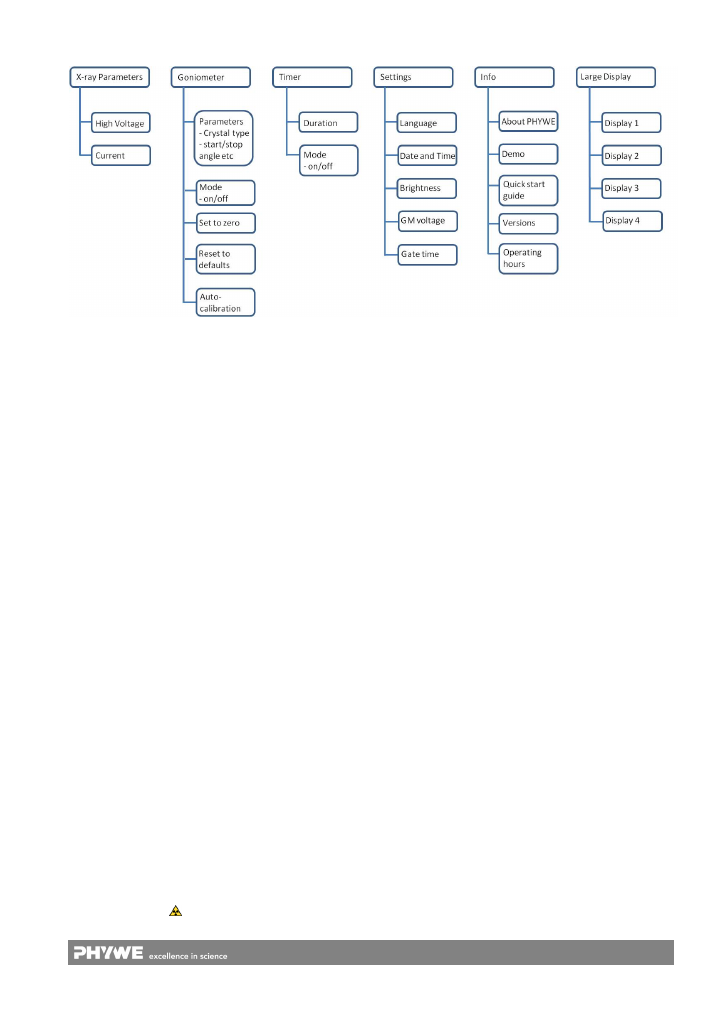

6.4 Menu

structure

On the main level, the menu structure of the unit includes the

following items:

1. X-ray

parameters

2. Goniometer

3. Timer

4. Settings

5. Info

6. Large

Display

The buttons VI-X on the control panel are used to navigate

through the menu, to change the settings, and to quit the

menu.

6.4.1 X-ray parameters

This menu is used to set the high voltage and the beam cur-

rent. By selecting the submenus for the high voltage or beam

current and by pressing the dynamic buttons on the right of

the display unit, the high voltage of the tube can be set to a

value between 0.0 kV and 35.0 kV and the emission current

to a value between 0.00 mA and 1.00 mA.

6.4.2 Goniometer

Menu and parameterisation of the goniometer (09057-10).

The operation of the goniometer in the X-ray unit is described

in the operating instructions for 09057-10.

6.4.3 Rotation stage

Menu and parameterisation of the rotation stage XRstage

(09057-42). The operation of the rotation stage inside of the

X-ray unit is described un the operating instructions for

09057-42.

6.4.4 Timer

This menu is used to define the start and stop conditions for

the experiments (X-radiation ON/OFF).

6.4.5 Settings

This menu is used to define certain fundamental settings.

6.4.6 Info

Menu for status information concerning the unit.

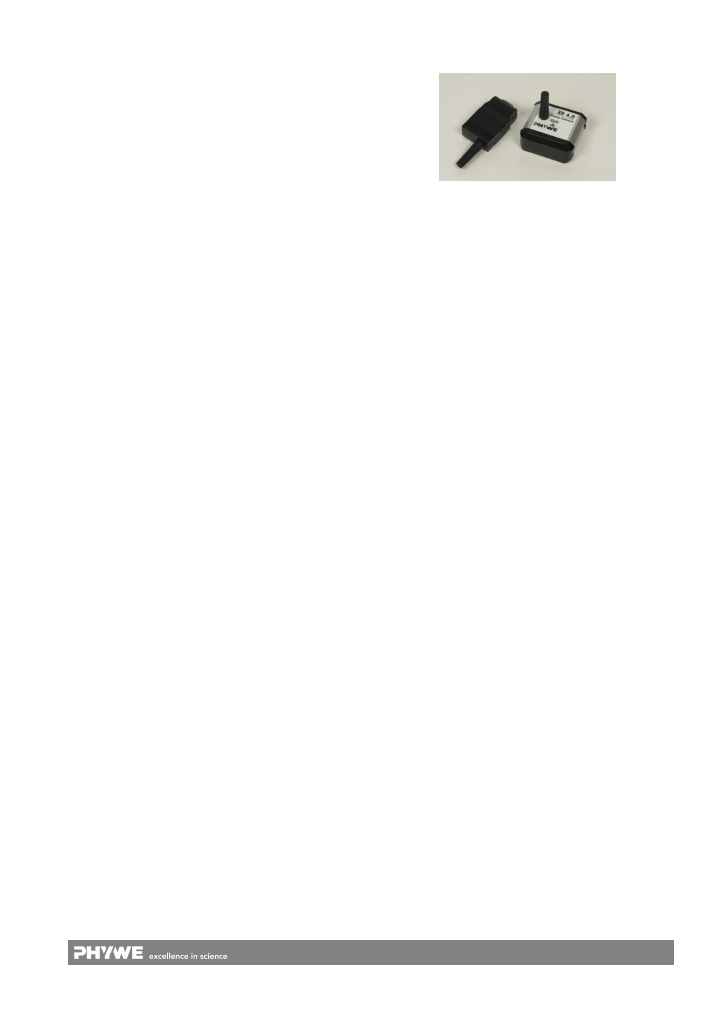

6.4.7 Large Display

If a sender (09057-09) is connected to the XR 4.0 expert unit

and transfers date to a large display in this part of the menu

the parameter for the display can be set.

Table 2: Overview concerning the three possible operating states

Status/X-radiation

Description

Button IV

Button V

Sign

panel

(Fig. 5, I)

Sign

Display

(Fig. 11)

1 Cannot be switched on

The sliding door is not

closed and not locked.

white white

off off

2 Cannot be switched on

The sliding door is closed

but not locked

Left LED

green

white off

off

3 Can be switched on

The unit is in a safe state

and the X-radiation can

be activated.

Right LED

green

Left LED

green

on off

4 On

The unit is in a safe state

and the X-radiation is ac-

tive.

Right LED

green

Right LED

green

on on

Y

10

www.phywe.com, © All rights reserved

09057-99 / 2115

Fig. 12: Menu structure of the unit - overview

6.5 Control via a PC with “measure”

As an alternative with regard to the direct control of the unit

via the control panel, the control of the unit and the represen-

tation of the measurement values can also be realised with

the aid of a PC and the “measure” software (14414-61).

6.6 Automatic shutdown of high voltage in case of fail-

ure

In case of interfering signals in the mains supply, the high

voltage will automatically be cut off in means to protect the

device from defects (introduced with firmware V

2.1). This

can be discerned by the fact that the x-ray tube stops to

gleam.

Running measurements eventually will not stop during the

shutdown, so they probably have to be restarted.

After removing the source of interference, check the door

status button IV and lock the door, if necessary (LED has to

be green). Afterwards, the device can be put into operation

again by pressing the X-ray button V. Thus, the high voltage

is switched on again and the measurement can be repeated.

If the device is controlled via a PC, the USB connection has

to be unplugged and plugged in, anew.

7 CHECKLIST

According to this list the device should be checked at least

two times per year:

1. Check if the device shows any damage.

2. All glass panes must be undamaged.

3. Start the x-ray device according to chapter 6.1, 6.2 of this

operating instruction. Perform a functional test of the

status indications, e.g.:

Do all LEDs work porperly?

Is symbol „I“ enlighted in operating state 3 (Ta-

ble 3)?

4. Check all functionalities according to table 2 of this oper-

ating instruction:

In operating state 1 and 2 it is not possible to acti-

vate the x-radiation.

In operating state 3 the x-radiation is not active, the

door is locked.

Only in operating state 4 the x-radiation is active.

Does sign

appear on the screen (Fig. 11)?

If you activate the x-radiation with the following pa-

rameters: anode current 1

mA, anode voltage

35

kV, the x-ray tube should gleam brightly.

The device is only ready for use if the tests are performed in

the right way and successfully. Even if

only one

test fails the

device must not be used. Please contact the Phywe service

in this case. (service@phywe.com).

8 TECHNICAL

DATA

Operating temperature range: 5-40

°C, typically 25

°C

Rel. humidity < 70

%

Microprocessor-controlled XR 4.0 X-ray expert unit with a

central safety monitoring system and two independent

monitoring circuits for the door position and two inde-

pendent monitoring circuits for the actuator of the door

locking system

4 X-ray tubes that are visible during the operation (Fe,

Cu, Mo, and W)

Lead enforced acrylic class windows, safe according to

DIN EN 61010

Integrated display unit for displaying measurement val-

ues and device parameters

“Display Connect” interface for the connection of a large-

scale display unit

Experiment chamber accessible during the operation via

a working channel

Integrated LED line for interior lighting (can be activated

as required)

Internal and external socket panel for easy cabling

Loudspeaker for the acoustic indication of measurements

with the Geiger-Müller counter tube

N

2

:

max 5 bar

Lockable tray for storing accessories

High voltage: 5.0-35.0

kV

Emission current: 0.0-1.0

mA

counter tube voltage: 100-600

V

Counting

time:

0.5-100

s

Exposure time: 0-100 minutes

11

www.phywe.com, © All rights reserved

09057-99 / 2115

With an additional goniometer: (not included in the

XR 4.0 X-ray expert unit)

o

Angular increment: 0.1-10°

o

Rate:

0.5-100.0

s/increment

o

Sample rotation range: 0-360°

o

Counter tube rotation range: 10

…

+170°

o

PC control via Sub-D socket

Housing (mm³ without feet and handles): 682

x

562

x

446

(W

x

H

x

D)

Experiment chamber (mm³): 440

x

345

x

354 (W

x

H

x

D)

Connection:

110/240

V-, 50/60

Hz

Power consumption: 200

VA

Mass:

63.2

kg; with tube: 68.2

kg

PC control via USB 2.0

9 SCOPE OF SUPPLY

09057-99 XR 4.0 expert unit, X-ray unit, 35

kV

Mains power cable

USB

cable

“measure X-ray” software (14414-61)

10 ACCESSORIES

An extensive range of packages and accessories for the

X-ray unit is available:

09057-51 XR 4.0 X-ray Plug-in Cu tube

(predecessor 09057-50 compatible)

09057-61 XR 4.0 X-ray Plug-in Mo tube

(predecessor 09057-60 compatible)

09057-71 XR 4.0 X-ray Plug-in Fe tube

(predecessor 09057-70 compatible)

09057-81 XR 4.0 X-ray Plug-in tungsten tube

(predecessor 09057-80 compatible)

09057-10 XR 4.0 X-ray goniometer

09057-26 XR 4.0 X-ray fluorescent screen

14414-61 XR 4.0 Software measure X-ray

09057-18 XR 4.0 X-ray optical bench

09057-49 XR 4.0 X-ray protection cover

01200-02 Handbook Physics X-Ray Experiments

09056-05 XR 4.0 X-ray Lithium fluoride crystal, mounted

09056-01 XR 4.0 potassium bromide (KBr) crystal, mounted

09056-02 XR 4.0 X-ray Absorption set for X-rays

09057-01 XR 4.0 X-ray Diaphragm tube

d

= 1

mm

09057-02 XR 4.0 X-ray Diaphragm tube

d

= 2

mm

09057-03 XR 4.0 X-ray Diaphragm tube

d

= 5

mm

09056-03 XR 4.0 X-ray Diaphragm tube w. nickel foil

09058-03 XR 4.0 X-ray Diaphragm tube w. zirconium foil

09057-04 XR 4.0 X-ray Compton attachment f.x-ray-unit

09058-01 XR 4.0 X-ray NaCl-monocrystals, set of 3

09056-04 XR 4.0 X-ray Chemical set for edge absorption

09058-11 XR 4.0 X-ray Crystal holder for Laue-pattern

09058-09 XR 4.0 X-ray holder for powder probes (diffrac-

tometry)

09057-08 XR 4.0 X-ray film holder

09058-02 XR 4.0 X-ray Univ. crystal holder f. x-ray-unit

09058-30 XR 4.0 X-ray energy detector (XRED)

13727-99 Multi channel analyser - extended version

09058-31 XR 4.0 X-ray Specimen set metals for X-ray

fluorescence

09058-32 XR 4.0 XRED cable 50

cm

07157-93 Large-scale display, digital

09057-19 XR 4.0 Display-Connect, set of transmitter and

receiver

Fig. 13: XR 4.0 Display Connect module

For display of measured values and device parameters, the

large-scale display can be connected via the Display Connect

set. For this purpose, the TX adapter of the Display Connect

module must be connected to the external socket panel

("Display” socket). The RX adapter must be connected to the

large-scale display. The values are selected via the menu on

the control panel.

Sets

XRE 4.0 X-ray expert set 09110-88

XRW 4.0 X-ray wireless demonstration upgrade set,

09115-88

XRP 4.0 X-ray solid state upgrade set, 09120-88

XRC 4.0 X-ray characteristics upgrade set, 09130-88

XRS 4.0 X-ray structural analysis upgrade set, 09140-88

XRI 4.0 X-ray imaging upgrade set, 09150-88

XRM 4.0 X-ray material analysis upgrade set, 09160-88

XRD

4.0

X-ray

dosimetry

and radiation damage upgrade

set, 09170-88

XRCT 4.0 X-ray Computer Tomography upgrade set,

09180-88

11 WARRANTY

We give a warranty of 24 months for units supplied by us in-

side the EU, and a warranty of 12 months outside the EU.

Any damage that is due to non-compliance with the operating

instructions, improper use, or natural wear is excluded from

the warranty.

The manufacturer can only be held liable for the function and

safety-relevant properties of the unit, if the maintenance, ser-

vice, and modifications of the unit are performed solely by the

manufacturer or by an institution that is expressly authorised

by the manufacturer.

12

www.phywe.com, © All rights reserved

09057-99 / 2115

12 DISPOSAL

The packaging mainly consists of environmentally-friendly

materials that should be returned to the local recycling sta-

tions.

PHYWE Systeme GmbH & Co. KG

Customer Service

Robert-Bosch-Breite 10

37079 Göttingen

Germany

Telephone +49

(0)

551

604-274

Fax +49

(0)

551

604-246

13 APPENDIX

Symbols

Warning

Warning, radioactive sub-

stance or ionising radiation.

Do not dispose of this product with normal

household waste. If this unit needs to be

disposed of, please return it to the address

that is stated below for proper disposal.

13

www.phywe.com, © All rights reserved

09057-99 / 2115

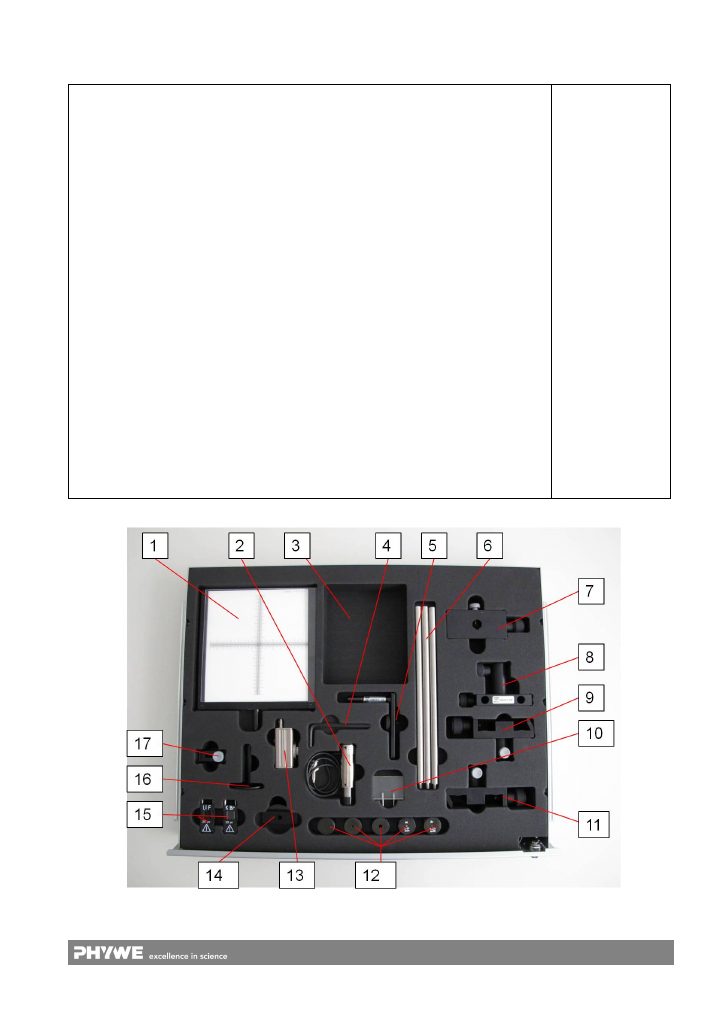

General map to fill the tray for accessories:

space

Art. no.

Name

Included in XRE

1

09057-26

XR 4.0 X-ray fluorescent screen

x

2

09005-00

Counter tube, type B

3

free for e.g. 14608-00 Data cable USB, plug type A/B

x

4 Allen

key

x

5

09057-15

XR 4.0 X-ray Adapter for digital camera

6

09057-21

XR 4.0 X-ray external optical bench

7

08286-00

Slide mount for optical profile-bench

x

8

09057-29

XR 4.0 X-ray slide for external optical bench

9

08286-01

Slide mount for optical bench,

h

= 30

mm x

10

09058-04

XR 4.0 X-ray Compton attachment for x-ray-unit

11

08286-01

Slide mount for optical bench,

h

= 30

mm x

12

09057-01

XR 4.0 X-ray Diaphragm tube

d

= 1

mm

09057-02

XR 4.0 X-ray Diaphragm tube

d

= 2

mm

09057-03

XR 4.0 X-ray Diaphragm tube

d

= 5

mm

09056-03

XR 4.0 X-ray Diaphragm tube with nickel foil

09058-03

XR 4.0 X-ray Diaphragm tube with zr foil

13

09058-30

XR 4.0 X-ray energy detector (XRED)

14

09058-11

XR 4.0 X-ray Crystal holder for Laue-pattern

15

09056-05

XR 4.0 X-ray Lithium fluorid crystal, mounted

09056-01

XR 4.0 X-ray Potassium Bromide Crystal, mounted

16 09824-00

Table

with

stem

x

17

09058-02

XR 4.0 X-ray Universal crystal holder for x-ray-unit