Full Text Searchable PDF User Manual

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

1 /

19

SERVICE MANUAL

“ SFERA ”

BASIC TECHNICAL MANUAL

THE CONTENTS OF THIS DOCUMENT ARE INTENDED FOR NECTA’S AFTER SALES PERSONNEL.

AFTER SALES SERVICE

Snack & Food

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

2 /

19

NOTE

The above systems and functional units are specific to this machine.

All functional units installed but not listed in this document, are also used in other machines in the same range;

therefore they will be described in a separate manual for machines belonging to the same range, where all base

functional units will be described more in detail.

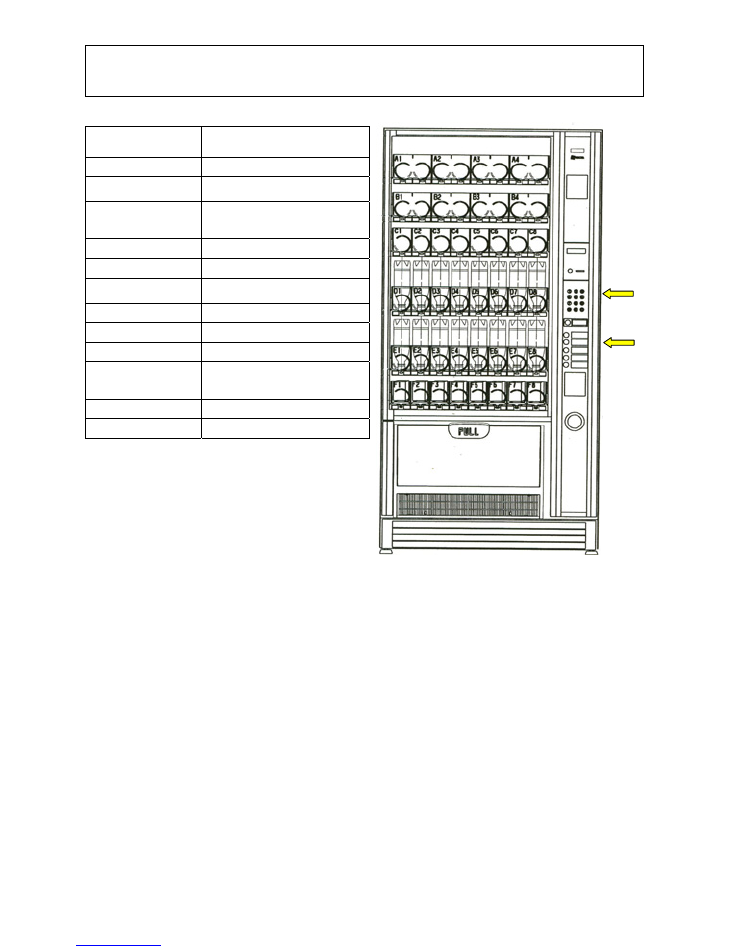

Sfera:

View of user interface

TABLE OF CONTENTS

1

2

3

4

5

6

7

8

9

Layout - Models

Electrical systems, connections and configuration

Vending systems

Power supply and Wiring

Cooling unit

Cabinet and Door

Trouble-shooting

HACCP directive (Use instructions)

Periodical cleaning and hygiene

( Daily – Weekly – Yearly )

Pages 3-4-5

Pages 6-7-8-9-10

Page 10

Page 12

Page 13

Page 14

Pages 15 -16

Page 17

Pages 18 -19

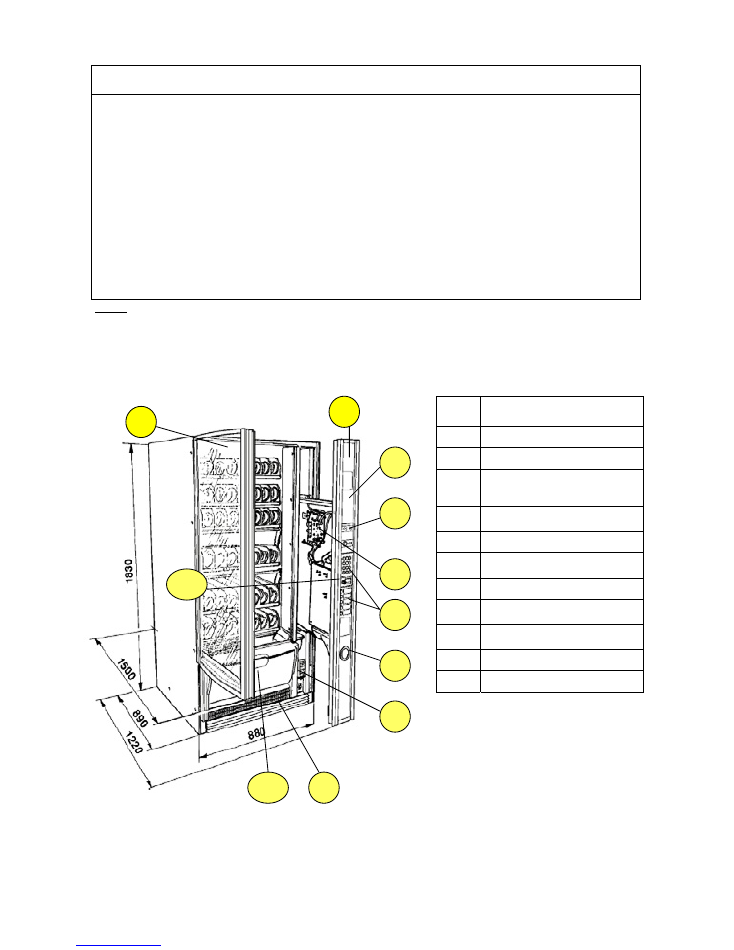

Ref.

DESCRIPTION

1

Rounded glass door

2

Advertising spaces

3

Compartment pre-set for key-type

payment systems or other

systems

4

Machine status information

display

5

CPU board

6

Double keypad with direct and

numeric selection

7

Coin return compartment

8

Power supply unit / fuses / door

safety switch

9

Removable grille for cleaning the

condenser’s filter

10

Product dispensing compartment

11

Key lock

1

2

8

4

1

2

7

6

5

3

8

4

9

10

11

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

3 /

19

1 – LAYOUT - MODELS

Example of Sfera model’s codification

Layout Italy - Version

6-40R / I LX

Meaning

:

SFERA

with

6

trays for a total of

40

selections

Refrigerated version

R

(a non refrigerated version is also available)

Country

: Italy

I

Approved by

IMQ

Q

NB 1:

(if the letter Q is not present it means that such version is not approved by IMQ, or that it is awaiting

approval

Version

LX

-

Model with double keypad (Numeric and direct for five advertised selections)

NB2: without such code, the machine is supplied with only the 12-button numeric keypad

DESCRIPTION

VARIABLES

TRAYS

Up to 6 max

HEIGHT 0F TRAYS

96 mm min and up to 219 mm

max

PARTITIONS PER

TRAY

2 triple + 1 double (or 2 singles)

4 doubles

8 singles

PRICES PER TRAY

One for each selection

TIME BANDS

Available for configuration

PAYMENT SYSTEMS

Serial – EXE- as standard feature

MDB – BDV – with additional board

VEND SYSTEMS

With single and double spiral

DIMENSIONS

H 1830 x L880 x D 890

WEIGHT

-----

OVERALL

DIMENSION

(with door open)

H 1830 x L 880 x D1 1500

LAMP

1 x 36 W (Flourescent/Neon)

ABSORBED POWER 510 W

Numeric

keypad

5-selection

direct

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

4 /

19

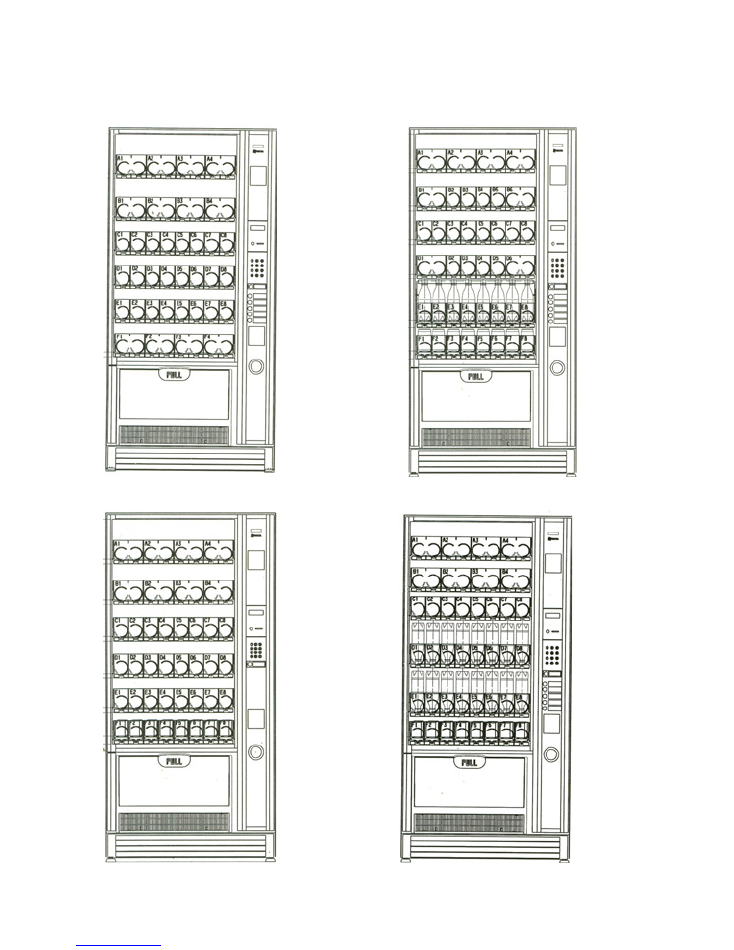

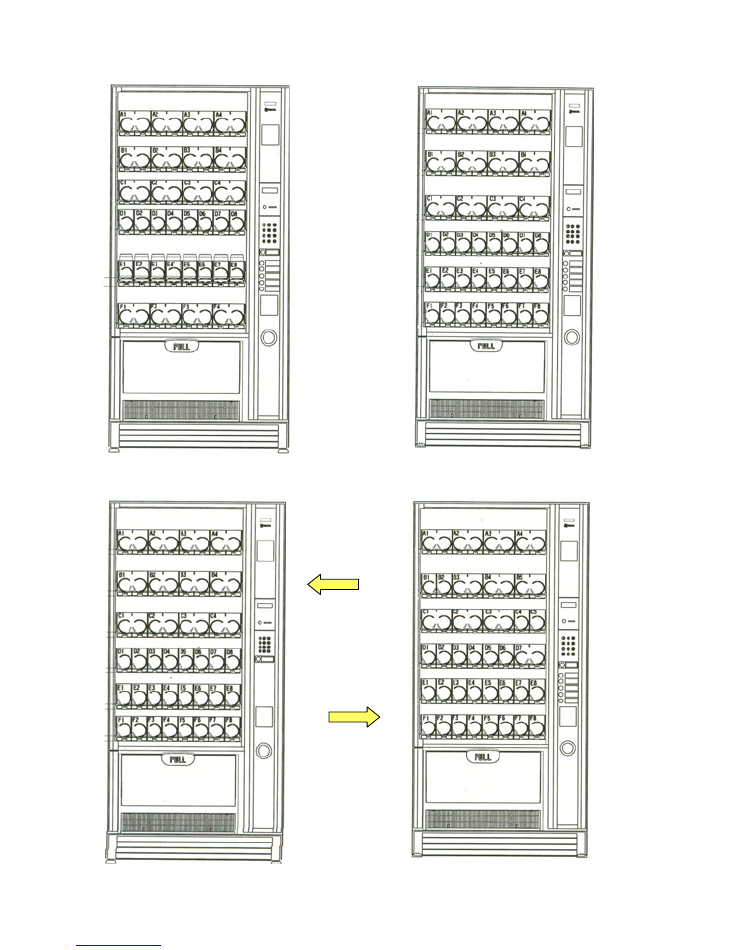

Examples of different tray configurations and positions.

The examples correspond to real layouts (the code is indicated on the side); in any case there are many

configurations options with simple and quick change operations.

Release spirals with different pitches are provided, as indicated in the user manual

Sfera 6 – 40 R/F

Sfera 6 – 36 R/F

Sfera 6 – 36 R/I

Versions provided

for the French

market

Sfera 6 – 40 R/I LX

Versions provided

for the Italian

market

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

5 /

19

Sfera 6 – 36R / B

Sfera 6 – 36R/UK

Sfera 6 – 32R / E

Sfera 6 – 36R / D

Version provided

for Spain

Version provided

for Belgium

Version provided

for Germany

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

6 /

19

2 - ELECTRICAL SYSTEMS - CONNECTIONS - CONFIGURATIONS

The machine is designed to operate under a single-phase voltage of

230 V AC (+5-10V)

It is protected with

two

T 6,3 A

fuses on both phases.

A safety transformer supplies power to very-low voltage components

(24 V DC),

while the cooling unit and

the Flourescent lamp are powered with the mains voltage.

With regard to the safety transformer:

The primary winding is protected with a

T 800 mA fuse

The secondary winding 25 V is protected with the following fuses::

T 1 A – T 4 A

The slide-out compartment door is fitted with a bipolar safety switch.

The switch is located on the front panel of the power supply unit, and when opening the compartment it

disconnects the power from all parts that can be accessed for normal maintenance and cleaning operations.

The only parts that stay energised are those protected by suitable covers carrying a plate with the warning

"

Disconnect power before removing the cover

”; to clear the voltage the power the power supply cable

must be disconnected from power outlet

or in the case of connection to a dedicated power board, it should

be set to

OFF

The power cable can be supplied as standard feature and chosen

among the following types:

HO5 RN – F copper with a 3 x 1.5 mm

2

section

1)

HO5 VV – F ,, ,, ,, ,,

2)

HO7 RN – F ,, ,, ,, ,,

In all configurations the cable is fitted with a

SCHUKO

plug

permanently fixed to the cable

NOTE :

In the event of replacement cables of exactly the same

characteristics must be used.

Since the “SFERA” vending machine is approved by an

electrical safety certification institute (IMQ), replacements

with non-original components are not permitted.

Otherwise the electrical safety certificate and the warranty will

be void.

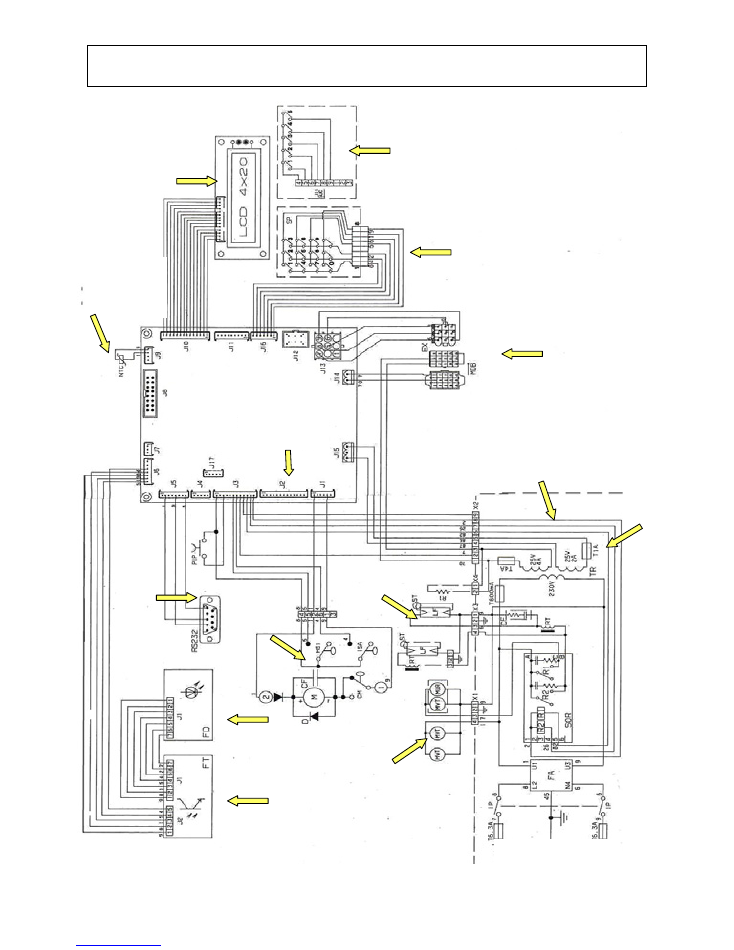

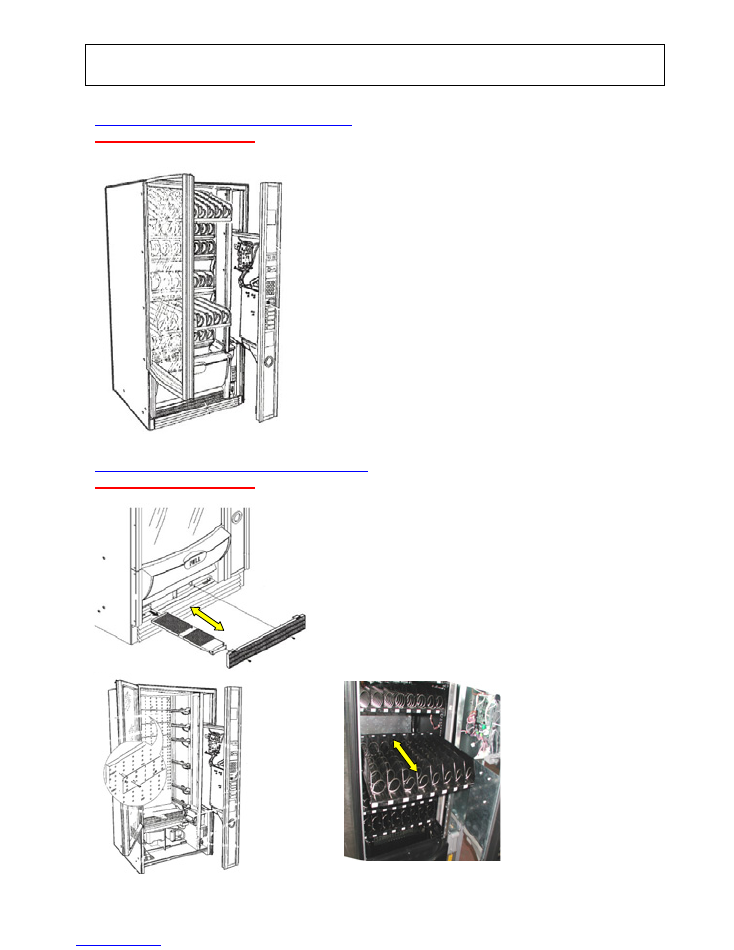

ACTUATION BOARD AND CONNECTIONS

(Electrical compartment open)

A flourescente lamp is located vertically on the right-

hand side inside the cabinet; the starter is fitted

inside the lamp holder. (see page 12)

The ballast is located inside the power supply

compartment.

The CPU board controls also the 24 V actuations by

means of TRIACs and Darlington switches, while the

lamp and the cooling unit are controlled by a relay

card located inside the power supply compartment.

(see page 12)

Some versions are provided with monitoring of the

selected product fall into the dispensing

compartment by means of a card with

receiver/transmitter diodes (infrared).

If during a selection the barrier is not interrupted it

means that a product is finished or jammed, in this

case the system will further attempt releasing the

product with small rotations; if also this fails the

selection is disabled and the customer is entitled to a

new selection.

CPU board and connections

Fluorescent lamp compartment

Protection

fuses

bipolar safety

switch

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

7 /

19

2.1 – CONNECTIONS, BOARD, WIRING DIAGRAMS

D

IRECT SELECTION PUSH

-

BUTTON CARD

N

UMERIC SELECTION

PUSH

-

BUTTON CARD

LCD display Board

Payment system

connections

NTC Probe

Cooling unit

control

J12

R

ATIOMOTOR

CONNECTIONS

P

OWER SUPPLY UNIT

CPU

(C

ENTRAL

P

ROCESSING

U

NIT

)

BOARD

RS232

PORT

-

P

RINTER

,

P

ROGRAMMER

,

PC

Phototransistor card

Receiver

Transmitter

photodiode card

P

OWER SUPPLY

:

230 V 50 H

Z

C

OOLING UNIT

CONTROL CARD

F

LUORESCENT LAMP

CONTROL

T

RANSFORMER

C

ONTROL OF

SLIDER LOCK KIT

CONNECTIONS CPU

BOARD

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

8 /

19

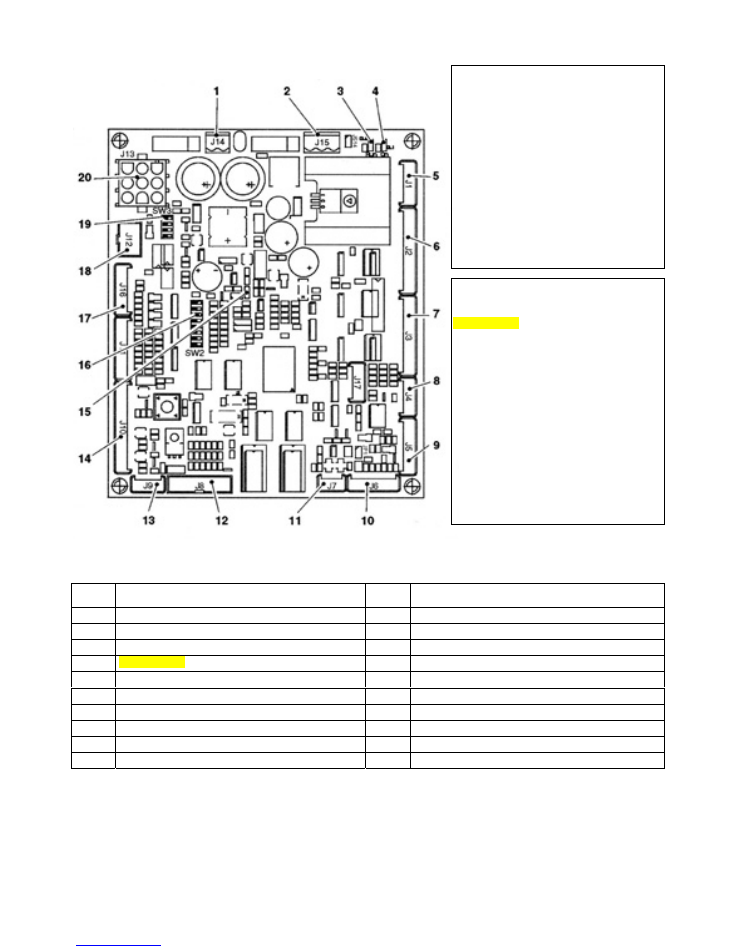

CPU BOARD( SUC)

N° rif.

COMPONENT DESCRIPTION

N° rif.

COMPONENT DESCRIPTION

1

Coin mechanism power supply connector

11

CAN BUS connector

2

Board power supply connector

12

Validator connector

3

GREEN LED

( DL2)

13

NTC sensor connector

4

YELLOW LED

5 V dc ( DL1)

14

LCD display connector

5

Connector for push-button panel LED’s

15

LED RED

6

Spiral ratiomotor control connector

16

Configuration minidip SW2 (will be eliminated)

7

RED LED

reset CPU

17

Selection push-button panel connector

8

Input/output connector

18

Expansion board connector for MDB

9

Connector not used

19

Coin mechanism setting minidips

10

Programmer device connector

20

Expansion board connector for BDV / EXE

CPU BOARD

LAYOUT

COLOURED LED FUNCTIONS

GREEN LED

blinking during the normal operation

YELLOW LED

It glows when 5 V DC is present in the board

RED LED

it glows when the software is reset

(program

malfunction)

Minidip functions 1-4

REF.(20)

Coin mechanism setting 2-3

By default set to OFF

Minidip 1-8

(16)

Default configuration setting fixed to OFF

Both minidips will be eliminated in the near

future, therefore since now the configuration

is only via software setting.

The CPU board is housed inside the payment

system compartment, on the sliding door, and

includes all low-voltage (24 V DC) actuations,

it controls the display, the push-button card,

the photodiode barrier, the payment system

and the NTC probe that monitors that cooling

unit temperature.

The software is written in a Flash EPROM that,

by means of a special program, can be

rewritten and updated without replacing.

It is powered from the power supply unit

through connection J15 (ref. 2)

The photodiode barrier is supplied as standard

feature in some versions, or as an after-sales

kit.

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

9 /

19

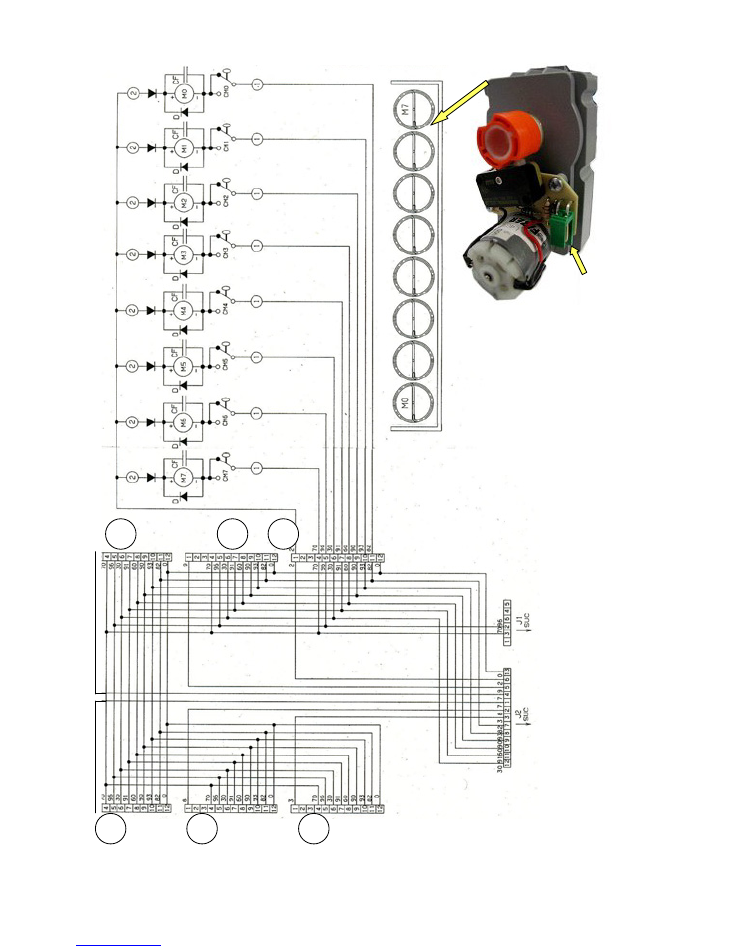

TRAY CONNECTION WIRING DIAGRAM

CONNECTOR

Detail of spiral control ratiomotor

To connector

J 12

CPU board

4

5

1

6

3

2

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

10 /

19

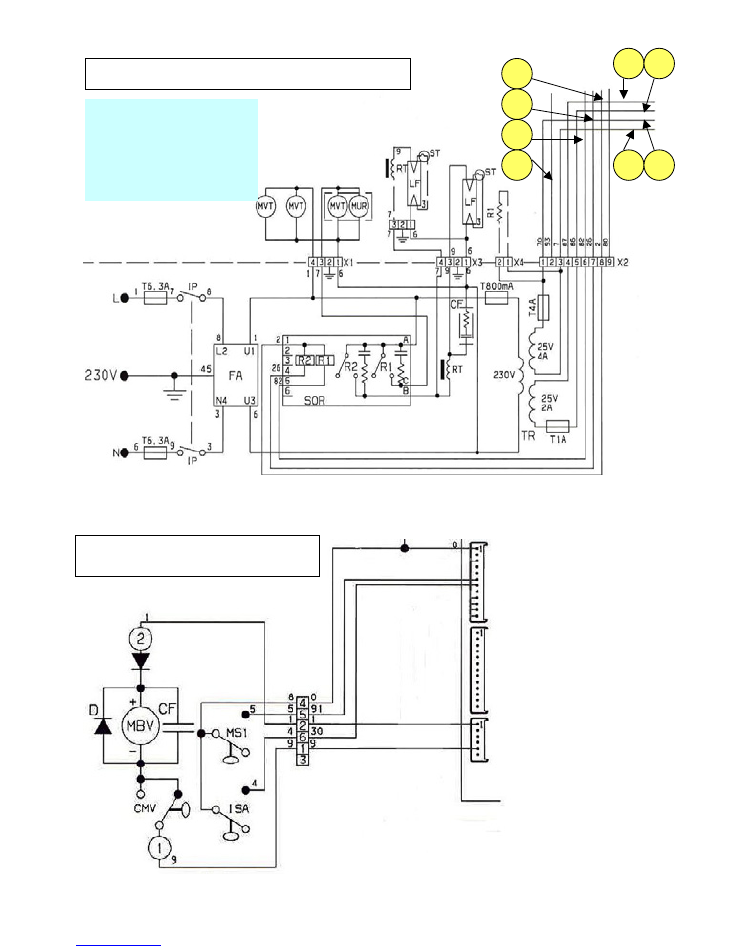

POWER SUPPLY AND LIGHTING DIAGRAM

2

1

3

4

5

6

7

Wiring diagram of dispensing

compartment slider lock device kit

1 – 2

Power supply - EXE

3 – 4

Connector

J14

- 24 V DC

CPU board power supply

5-6-7-8

Connector

J3

IN / OUT to

CPU

8

J 3

J 2

J 1

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

11 /

19

3 – VENDING SYSTEMS

“Sfera” is a vending machine belonging to the S&F range, with

product dispensing by means of the rotation of spirals.

During their rotation the steel spirals, because of their

“auger

effect”

, push forward the product loaded onto the tray,

dropping it in the dispensing compartment.

As an optional kit on request, some versions are provided with

infrared barriers with receiver/transmitter diodes and transistors

that detect the falling product and signal to the software that

the product was released correctly. In the event the barrier is

not interrupted, the option of trying the selection again is given;

if the selection fails again, the option of another choice or

refund is given. (SW option)

The tray is modular, and by simply moving the partitions it is

possible to change it from single to double or triple; there are

also some specific accessories for dispensing special products.

Different pitch spirals are provided, to be able to dispense 20 to

76 mm wide products.

In addition the spirals can be right or left hand, to be used in

double compartment configuration with double spiral. The

ratiomotor is fitted with a “minidip” switch to reverse the

rotation.

The tray is held into position automatically by a stop located on

the guides; to slide out the tray it need to be lifted slightly from

the front and then pulled fully to the second safety stop. To

extract it completely it needs to be lifted further and then

removed (after disconnecting the electrical connector located on

the right side). As standard feature, the vending machine is

provided with 6 trays, however up to 8 trays can be fitted by

reducing the space between trays

(see configuration instructions).

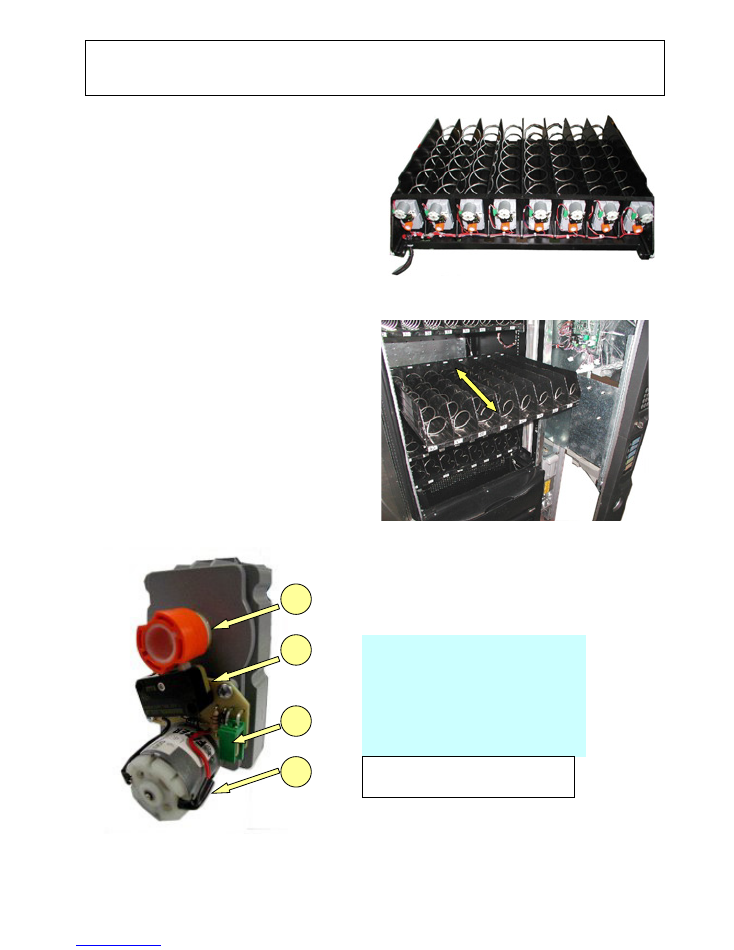

S

PIRALS ROTATION RATIOMOTOR

1

2

3

4

1 - Limit microswitch control cam

2 - Microswitch

3 - Motor control card

4 - Motor

Tray with configuration of 8 single sectors

- View from ratiomotors side

Tray with configuration of 8 single sectors

- View while being removed

Useful pitch:

20, 26, 30, 36, 42, 50, 60, 76

right and left rotation

20

Right-hand 180° rotation with central partition for dispensing

sticks

Availability of spiral pitches and

direction of rotation

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

12 /

19

4 - POWER SUPPLY AND WIRING

Like all other NECTA products, the “SFERA” vending

machine is type-approved (or awaiting approval) by IMQ,

therefore all components and electric units are certified as

conforming to European directives, and all cables are fully

sheathed and provided with double insulation. The door

cables are sectioned and fitted with special connectors to

facilitate disassembly of the door.

All connectors for the vending machine control function

branch out from the power supply unit: Keypads, payment

systems, ratiomotors, heating elements, display, cooling

units, electronic cards.

The power supply unit transforms the grid electricity to 24 V

AC and the CPU board acts as rectifier and controller of

actuations to the power users.

All actuations are under extra-low safety voltage, while the

lamps and the cooling unit are controlled by means of

special relay cards at the grid voltage.

The power supply unit is housed in a removable galvanised

steel metal box for greater accessibility.

When opening the door a safety switch is deactivated,

disconnecting the power from all accessible parts.

The unit is protected by electrical interference suppressor

systems in conformity with the European directives.

The power supply unit houses a safety transformer for the

extra-low voltage, the grid fuses, the transformer secondary

winding fuses, the fluorescent lamps ballasts, the relay card

for controlling the cooling unit, the noise interference

suppressors and the safety switch.

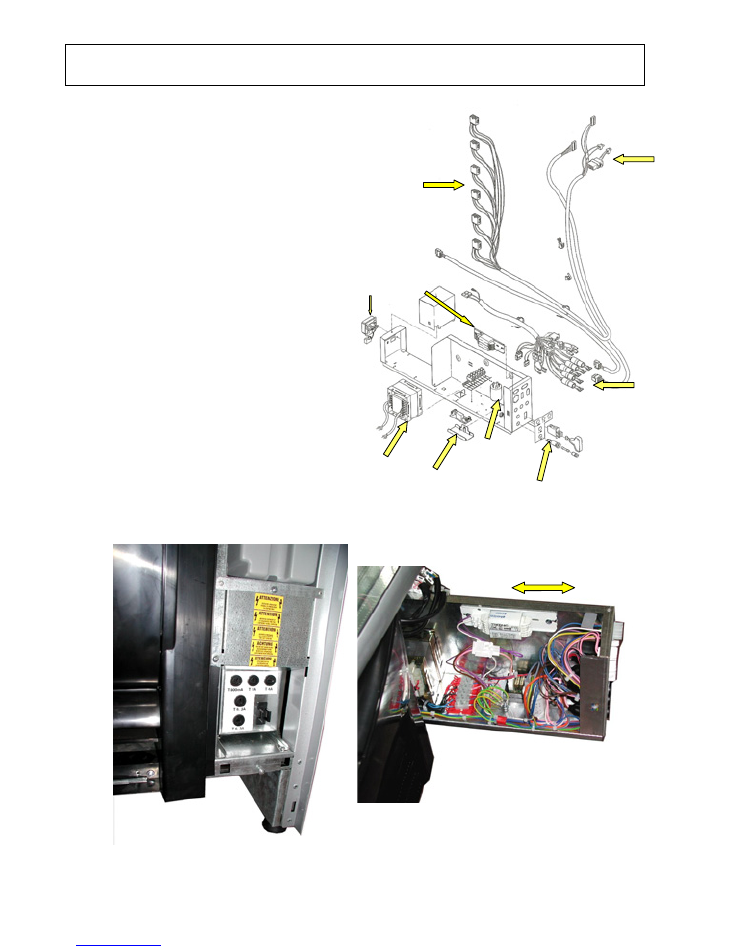

Vending trays

connectors

Connectors to

the door

Main

connectors

and fuses

Safety

transformer

Bipolar safety

switch

Lamps

ballasts

Radio

interference

suppressor

Power cable

input from

the mains

Power supply unit being removed

Power supply unit in operating

position showing fuses and safety

switch with protective casing

Cooling unit

control relay

card

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

13 /

19

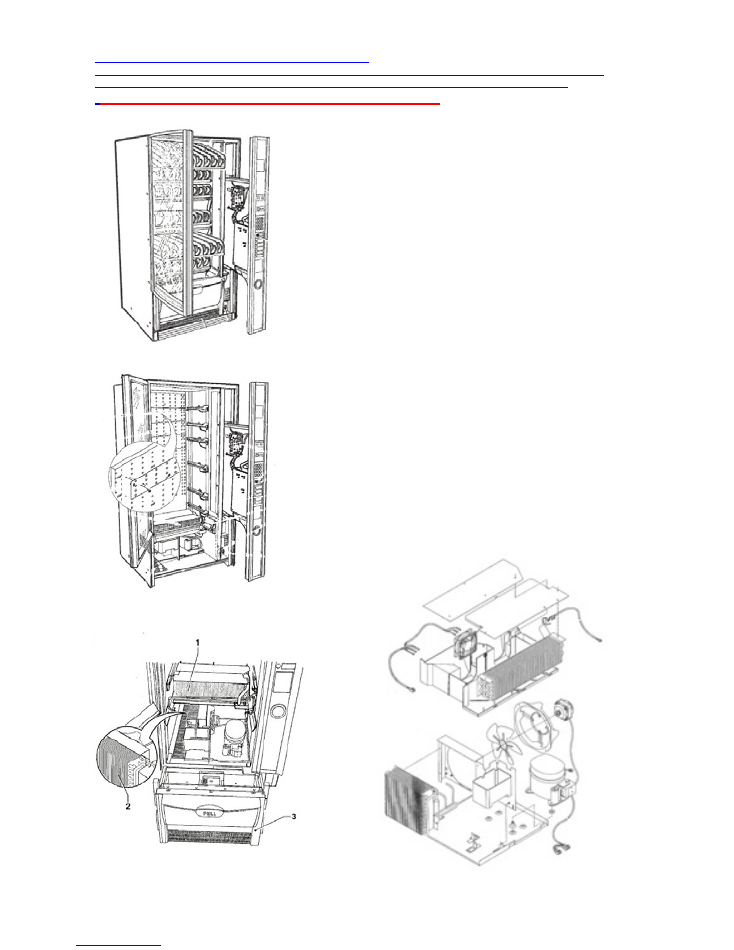

5- COOLING UNIT

The internal temperature controlled by means of an

NTC

type electronic, controlling a traditional type cooling unit,

but with design features that will bring it to the top of

what is currently available on the market.

Yje NTC probe has an internal resistance that varies

according to the ambient temperature change.

At the temperature of 0° C it is 2612 Ohm

At the temperature of 3° C it is 2267 Ohm

At the temperature of 30°C it is 733 Ohm

This way the software controls the unit switching on and

off with extreme accuracy.

The unit is controlled by means of a relay card located in

the power supply unit (SOR card).

When the machine is switched on, the software reads the

value (in Ohm) from the NTC probe and, according to that

value, sends a signal to the relay card that activates or

deactivates the cooling unit operation.

The cooling unit is very compact, with the air intake for the

condenser cooling from the lower part of the base through

a filter that removes the dust; such filter is accessible and

easy to remove for cleaning FIG. 2. The cooling air is

expelled from the front side through the lower grille,

allowing installation in a bank of machines or in a small

space without causing problems to the cooling unit.

In order to completely remove the cooling unit the

dispensing compartment assembly has to be removed

(quick and simple operation), therefore remove the

fastening screws from the unit and support the evaporator

during the extraction operation, ensuring that the power

cable and the power supply unit connector are

disconnected. FIG 3

The control software has the option of setting switching on

time periods, or the safety temperature. See specific

programming manual for further details. It is possible to

set the first two trays with a temperature suitable for

perishable food products.

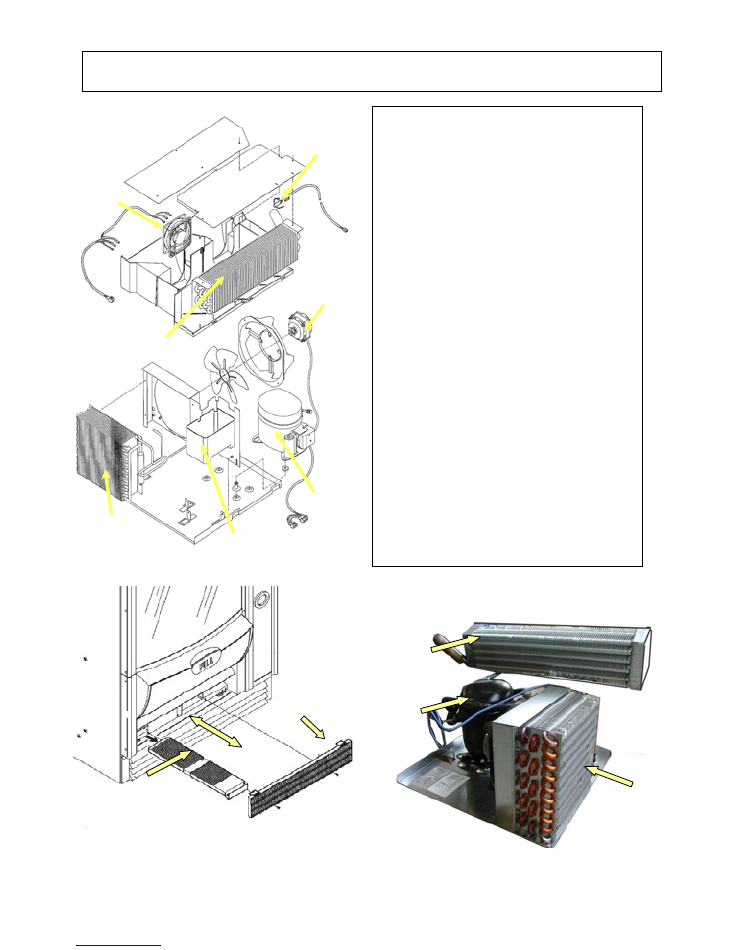

FIG. 2

Condensation dust

removing filter

Removable

external grille

FIG. 3

Perspective view of cooling unit

Evaporator

Condenser

Compressor

Evaporator

Condenser

FIG. 1

Compressor

Fan

Liquid waste container

NTC Probe

Evaporator fan

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

14 /

19

6– CABINET AND DOOR

Porta vetrata

The cabinet is made of pre-varnished sheet-metal, assembled with rivets

and various reinforcements; pre-formed polystyrene foam insulation

panels are placed between the external pre-varnished sheet-metal part

and the internal refrigerated box part.

The advantage of this solution, compared to the injected polyurethane

foam insulation, is mainly form an environmental point of view, as in

the event of future scrapping of the machine, the cabinet can be

disassembled completely without any complications . ( almost

impossible in the case of cabinet injected with foam and welded)

The base is made from sturdy sheeting, welded and varnished to obtain

greater stability. The feet are adjustable for perfect levelling. By

removing the lower grille a regular trans-pallet can be used for routine

moviment of the machine.

The SFERA is provided with two opening systems: main door and side

sliding compartment.

The main door, for loading products, is a glass front type with double

glazing.

The handle for opening is part of the perimeter profile of the frame,

and locking is by means of a single lock located inside the sliding

compartment on the right.

A sliding compartment is located on the front right side, with the user

interface integrated on its front panel; the CPU board and the payment

system compartment are fitted inside on the central wall.

The following are fitted on the front panel (user interface) : the main

display, the coin slot and the coin return button, the selection keypad

and the lock, that as well as ensuring a three-point lock it keeps the

glass door closed.

The sliding compartment is protected by a safety switch that

disconnects the 230 V AC power, leaving anyway the option of

operating in programming mode by inserting the special key in the

safety switch slot.

The dispensing compartment, with hinged hatch opened from the

upper side, is located on the lower base; such compartment is fitted

with an anti-theft device and anti-vandalism system that will keep it

closed when no selections are made, permitting opening only during a

selection.

Before opening the glass door the sliding door, provided

with a lock, must be opened. To close everything proceed

in the reverse order, i.e. close the glass door, then push

the sliding compartment into position and lock with the

key.

Detail of polystyrene foam insulation

and assembly with rivets

Detail of anti-vandalism closing

mechanism (Kit on request)

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

15 /

19

PROBLEM

(and/or indication on the

display)

POSSIBLE CAUSE

SOLUTION

The display indicates the

message:

“Compressor”

If the compressor runs for 24 hours

consecutively without the cabinet reaching

the temperature set via the SW, the machine

is locked and the selection disabled.

The following could be the cause:

Lack of gas in the refrigeration circuit due to

possible leaks.

Failure to the evaporator’s electric fan.

Failure to the condenser’s electric fan or PTC

triggered.

Clogged lower and/or side grille

Failed probe (in this case the message “probe

failure” will be displayed)

Normally two to four hours are required to

reach the operating temperature

(according to the load). A longer time

means that there is a malfunction: check

for any small leaks in the refrigerating gas

circuit; if necessary repair the leak and

charge with the correct dose of gas.

Check that the electric fans work correctly.

Check for the correct cooling airflow inside

the refrigerated box. In the case of failure

to components, replace with original parts.

The display indicates the

message

“Coin mechanism”

If the CPU for more than 30 seconds does

not receive communication impulses from an

Executive serial coin mechanism, or 75

seconds from a BDV serial coin mechanism,

or if it receives an impulse for longer than 2

seconds, the machine locks and the

selections are disabled.

Replace the coin mechanism with one that

is certain to work and check the

communication. Check connections.

Check the CPU board, and if necessary

replace with that is certain to work.

Check that the 24 V DC power supply fuse

is intact.

The display indicates the

message

“RAM data”

One or more areas of the RAM contain wrong

data, which could change the operating

default values.

The machine will continue working, but some

parameters could have been changed, with

consequences to the general functioning -

the RAM needs to be initialised as soon as

possible to recover data from the EPROM.

Initialise the CPU again.

After initialising, all data settings will go

back to the default settings; restore the

customised data using the programmer or

a PC.

If, in spite of initialising, the malfunction

persists, replace the CPU board with an

already tested one that is certain to work.

It the malfunction persists, replace the

cables or check the suitability of

connections.

The machine was designed to comply with

the EMC directive, but if located in an

environment subject to high interference

immunity problems could arise, therefore

in the event of such interference persisting

the vending machine should be moved to

a different location.

The display indicates the

message

“Probe”

The temperature control probe in the

refrigerated box is of the NTC type, with the

internal resistance that lowers as the

temperature rises.

If the probe is interrupted, the machine locks

after 5 minutes from the failure and the

selections are disabled (THE DISPLAY WILL

INDICATE THE TEMPERATURE – 5 ° C)

If there is a short-circuit in the probe, the

machine locks after 60 minutes and the

selections are disabled (THE DISPLAY WILL

INDICATE THE TEMPERATURE +32° C)

NB

: AFTER THE SENSOR FAILURE HAS BEEN

DISPLAYED FOR TWO HOURS, A

COMPRESSOR FAILURE WILL ALSO BE

INDICATED.

Check the internal resistance in the NTC

probe using a digital multimeter: A

resistance of 730 ohm corresponds to a

temperature of 30° C.

A resistance of 2612 ohm corresponds to a

temperature of 0° C (melting ice).

Replace the probe with an original one;

before installing the new one check that

the internal resistance corresponds to the

above parameters.

Reset the failures by accessing the special

software function. See programming

manual

7 – TROUBLESHOOTING

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

16 /

19

The display indicates the

message

“Motor failure n. XY

”

At machine start, an automatic test routine

checks the presence of trays and their

number, therefore a motor failure is not

indicated, as they are not activated. When a

selection is made a microswitch is activated,

which must close at the end of the cycle;

should this function not occur the motor

locks or continues running because of an

actuation card failure.

In this case a time-out is triggered to stop

the motor, placing it out of service.

Check that there are no interferences to

the motor rotation.

Check that the motor is efficiently running.

Check that the microswitch is efficiently

working.

Check that in fact there is not a time-out.

If the motor does not pick up at all, check

the electrical connection ensuring that a

24 V DC reaches the motors.

If all checks are OK replace the card, as

the actuation or the software may be

malfunctioning.

The display indicates the

message

“product finished”

This information can be displayed in the

version fitted with infrared sensors. And it

means that the barrier was not interrupted

during a selection due to two possible

causes: 1) end of product, 2) jammed

product

The software automatically tries to make

the product drop with small movements,

and if this fails the selection is blocked. In

this case the failure must be reset after

correcting the problem.

The software allows a new selection to be

made and the customer does not lose his

credit.

The display indicates a

number of

trays not

corresponding

to the real

situation

At machine start, an automatic test routine

checks the presence of trays and their

number, therefore if a tray is not indicated it

is because it is not electrically detected.

Check that the cables are correctly

connected.

Check that the cables are efficient.

The machine does not

start and the

display is

off

The vending machine is protected against

short-circuits with two line fuses (one on

each phase),

with fuses on the secondary winding and on

CPU board power supply (see wiring

diagram).

Check that the fuses are intact and if

necessary replace. First identify the cause

of the blown fuses.

Check the power supply cable.

The transformer’s functioning.

The refrigerated box

does

not cool down

and the

operating temperature is

not reached in spite of

being correctly set

The cooling unit sucks in air from the lower

section and expels it downwards through the

front grille. This route must be free.

Ensure that there are no objects in the lower

section of the vending machine.

Check that the pre-filter is not clogged.

The amount of refrigerant is not sufficient

The probe is interrupted or short-circuited, or

moved away from the correct position set at

the factory

(After some time the display indicates the

message “probe failure” or “unit failure”, or

both).

The vending machine can be positioned

against a wall,

but no objects can be positioned under the

vending machine base.

Check for small leaks using a special

instrument and detecting foam.

Restore the charge after eliminating the

leak.

Check that the NTC probe is positioned

and functioning correctly.

The internal lamps do

not

light

Switching on and off of the lamps can be

programmed; therefore check that such

option was not included in the programming.

Probable failure to the starter / ballast

Check the functioning of the flourescent

lamp, starter and ballast

Check the functioning of the relay card

(SOR) that controls the 230 V AC power

supply

Check in the special software program that

the time band setting is correct.

The display indicates the

message:

“programming”

The CPU and payment system compartment

door closure is monitored by a microswitch

that in the event of actuation with the door

open indicates

“Programming”

In this situation it is not possible to have

correct operation.

If the warning is with the door closed, check

the microswitch.

Check that microswitches are activated

correctly, check that cables are not

damaged or disconnected.

Replace the microswitches and/or the

cables

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

17 /

19

HACCP DIRECTIVE (EEC 93/43 and 96/3)

Outline and instructions for use

Notes: What is indicated by the EC Directive

Directives

EEC 93/43 and 96/3

concern the hygiene of food products and are based on the

HACCP

(

H

azard

A

nalysis

C

ritical

C

ontrol

P

oint).

The purpose of this directive is to safeguard the consumer health, suggesting a series of actions to be taken by

the vending company, aimed at checking, identifying and correcting any critical aspects in the foodstuff chain,

from the purchase of products and machines to the dispensing of the product.

The

HACCP

is a system used to analyse any potential risks in the manufacturing and distribution cycle of food

product and to identify critical points where such risks can occur; the system also highlights the actions to be

undertaken and the decisions to be made with regard to such critical points, as well as the implementation of

checking and monitoring procedures.

Therefore, each vending company must develop a Company Hygiene Self-control Manual according to the

provisions of the directive - and if necessary use the information and recommendations formulated by some

associations in the sector. The manual must contain a programming and checking schedule for the hygiene

condition of each vending machine, and when a new machine is added this must be updated immediately.

Important notes

:

For a correct use of the machine, the directives must be fully applied.

The operator is responsible for

correct operations on a vending machine

HACCP Directives (EEC 93/43 and 96/3)

Guidelines for correct application

Ensure hygiene control with a special manual for correct hygiene practices.

After cleaning, do not touch the surface of any elements that may come into contact with food.

Wash your hands thoroughly, preferably using disinfectant, before starting any hygiene operations

Use disposable sterile gloves

Always use a clean cloth to wipe dry.

Keep the work area tidy.

Check that the product packages are intact and not damaged.

Use products within the recommended time period (see expiry date on the package).

Always use products from the warehouse according to the principle of “first-in first-out”.

Consumables must be kept and transported separate from the cleaning and hygiene products.

Drums and sectors must be cleaned regularly (see operating instructions).

Do not fill internal zones of the machine with products to be loaded in a second occasion.

The products that need to be kept at a refrigerated temperature must be transported to the location of the

machine in containers that maintain the products at the ideal temperature or in containers that do not allow

excessive temperature difference.

CLEANING THE MACHINE

Carefully observe the following cleaning instructions! Considering that:

The Snakky normally dispenses products with a long shelf life, but it can be enabled to dispense short shelf

life products; in this case cleaning must be more frequent and stricter.

In the following instructions, only the cleaning and hygiene operations for the

FIRST

case are described.

Clean the machine, preferably at the end of the day or in the morning before the machine is used, and

before loading the products to be sold.

Fill in the checklist log for cleaning operations.

When the display indicates an error message immediately check the trouble-shooting sheet.

Use only recommended cleaning products approved for foodstuff, preferably liquid; do not use powder and

abrasive products that could scratch plastic surfaces.

8 – HACCP DIRECTIVE

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

18 /

19

DAILY CLEANING AND HYGIENE

( Expected time 4 min.)

WEEKLY CLEANING AND HYGIENE

( Expected time 8 min.)

9 – PERIODIC CLEANING AND HYGIENE

In addition to the daily cleaning operations:

Remove the lower grille and slide out the pre-filter of the

cooling unit condenser (FIG. 1)

Clean and if necessary remove the dust with a vacuum

cleaner

(alternatively blow with compressed air in a different place

from the installation area).

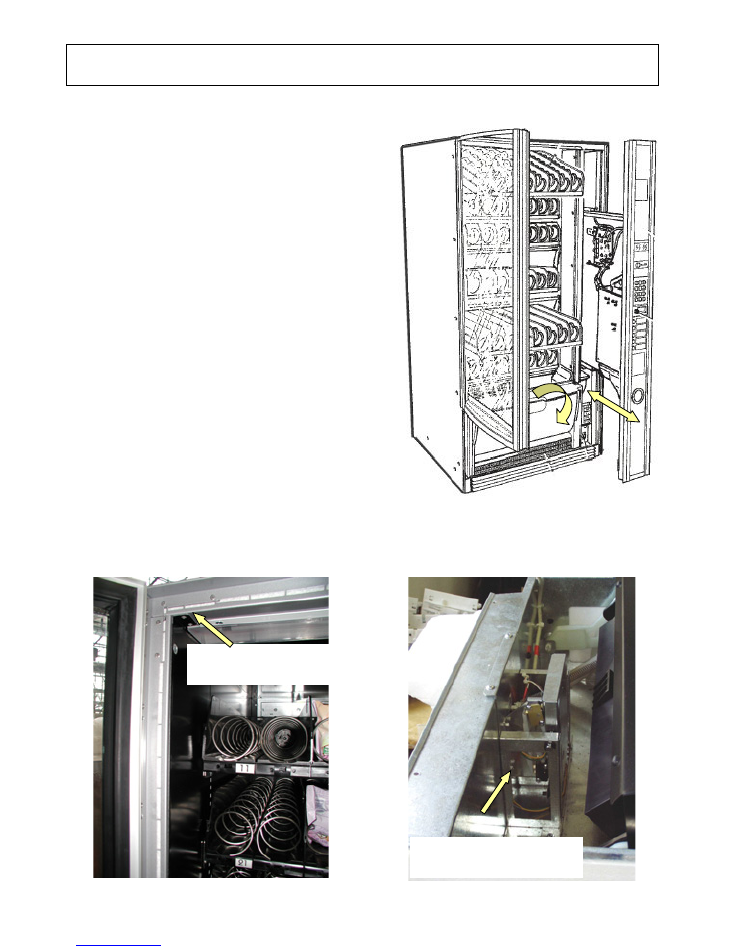

Slide out the trays without removing them (FIG. 2-3) and

clean the inside of the cabinet with a cloth dampened with a

chlorine based detergent.

Check that there are no small insects.

Open the door and disconnect the machine form the

power supply (FIG 1).

Clean the outside and inside of the glass front with

suitable detergent.

Clean the inside of the trays with a cloth dampened

with chlorine-based detergents.

Wipe the dispensing compartment and the flap door

with a clean cloth

(These operations must be carried out before loading

the machine in the morning)

Dust all of the inside of the refrigerated box, especially

the base.

Enter the operation in the HACCP log.

When loading new products, check the expiry date of

the unsold ones and load the new products according

to the FIFO. (first in - first out) logic.

FIG. 1

FIG. 2

FIG. 3

FIG. 1

NECTA SPA TECHNICAL MANUAL

“

SFERA

“

Manual

“ SFERA”

19 /

19

ANNUAL CLEANING AND HYGIENE

The “annual” period is intended as maximum term, as such maximum time must be reduced in accordance to the

specific situation and location of the vending machine to maintain its perfect state of hygiene at all times.

Expected time 20 min. (excluding the pull-down time “

* ”)

Open the door and disconnect the machine form the

power supply (FIG.1

Remove all trays, placing them in a clean area or in any

case protected by possible interference (FIG. 2)

Clean the inside of the refrigerated box with a damp

cloth soaked in chlorine-based detergents.

Completely remove the cooling unit

(FIG . 3) thoroughly clean the internal base and

make hygienic.

Remove all the dust from the fans and cooling unit

condenser (FIG. 4 ).

Clean and make hygienic the condensation tray (FIG.

4)

Reassemble the cooling unit proceeding in the reverse

order.

Reinsert into the operating position.

Clean the external parts, especially the coin-return

compartment and the push-buttons. Reassemble all

trays after cleaning the internal product loading parts.

Thoroughly clean the inside of the dispensing

compartment.

Start the machine and bring the internal temperature

to operating value.

Load all vending products.

*

Pull-Down: technical term that defines the length of time

required for bringing the temperature inside the cabinet to

the correct level

FIG. 1

FIG. 2

FIG. 3

FIG. 4