Full Text Searchable PDF User Manual

1

Installation and User Manual/Warranty

ONLINE Drinking Water System

Model Numbers

:

KRAUSEN 8 00 WHITE

KRAUSEN 8 00 ADVANCE

KRAUSEN 8 00 EVOLUTION

Dear customer,

Thank you for purchasing KRAUSEN water purifier!

You now have water treatment equ

ipment that is at the world’s leading position in today’s water

treatment field. It produces pure water that can be consumed directly so the water you drink is cleaner and

also beneficial to your health.

Before you install and use this water purifier, please be sure to read the user manual, this enables

qualified and standardized installation as well as reasonable use and maintenance to maximize the

effectiveness of your water purifier.

If you experience difficulties during installation or usage, please contact your local distributor to carry

out repairs or maintenance for you.

2

Contents Page

Safety Considerations…………………………………………………3

Product Introduction……………………………………………………4

Installation Method……………………………………………..………7

◆

Pre-

Installation Preparations………………………………………..……

7

◆

Instructions for Proper Installation……………………………….………

7

◆

Installation Notes……………………………………………...…..………

9

Adjustment Methods………………………………………...…………9

Usage Methods…………………………………………………………9

Maintenance and Up

keep……………………………………..………10

◆

Computer board control

………………………………………………

10

◆

Filter Replacement Time……………………………….…………………

10

◆

Filter Replacement Method……………………………….………………

11

◆

Notes ……………………………………………………………….……

…11

Failure Diagnosis and Resolution……………………….……………11

After-

Sales Service……………………………………..………………12

Packing List………………………………………………………………12

3

Safety Considerations

(Be sure to read and remember these safety considerations

)

In order to avoid property damage and harm to you and others, make note of the following safety

precautions.

★

Ignoring the following safety precautions could result in a risky situation:

Warnings

If you ignore contents in this section, it may cause permanent damage to the

water purifier or cause serious property damage.

Notes

If you ignore the contents in this section, it may lead to damage of some parts of the

water purifier or may result in some property damage.

Warnings

Do not disassemble or modify this

water purifier on your own!

Unauthorized disassembly

or modification of the machine

could

lead

to

machine

malfunctions

or

leakage

accidents. Please check with

the store where you purchased

this

product

for

product

consultation in order to arrange for repairs.

Do not put things on the top of the

machine!

Obstructing the heat dissipation

may lead to machine damage or

fires

.

Do not put heavy things on the

machine!

if you put heavy things on

the machine, it may damage

the spare parts inside, cause

the leakage, malfunction even

serious property damage..

Do not use this water purifier under high

water pressure conditions!

Operating

under

high-

pressure conditions may cause

the water purifier pipes to

rupture, resulting in leakage, the

machine working improperly, or

even serious property damage.

Recommended inlet pressure is

0.05MPa to 0.35MPa.

Do not let the machine come in contact

with corrosive materials!

These materials could

corrode the outer cover and

affect the water parts or some

toxic

and

hazardous

compounds could penetrate

the

water

purifier

pipes,

leading to contaminated water

production and machine leakage, which could even

cause bodily and property damage.

Do not put the water purifier close to the

fire!

Do not put the water purifier

near a fire source or place

where the temperature is too

high,

this

may

cause

deformation or melting of the

machine, causing damage or

leakage, which could lead to

serious bodily and property damage.

4

Notes

Do not use the water purifier when the

sewer is blocked up!

If it is used while

the sewer is blocked, it may

cause the waste water to

back up or pollution to get

inside the water purifier.

The waste water discharge pipe and

wastewater ratio device cannot be

blocked!

When the waste water

discharge pipes and waste water

ratio device are clogged, it may

lead to high TDS effluent, the RO

membrane may get blocked or

the water purifier may not work.

Water purifier inlet water temperature

should not exceed 38

℃

!

If the inlet water

temperature is over 38

℃

, it

will damage the reverse

osmosis membrane leading

to membrane failure.

Do not use in conditions under 5

℃

!

If the temperature in the room is below 5

℃

, please be

sure to take measures

to prevent freezing, such

as starting the heater or air

conditioner to prevent leakage

or cracked pipes caused from

water freezing inside the machine.

Do not use this water purifier outdoors!

If this water purifier is used

outdoors, it can lead

to

accelerated aging of the

water purifier pipes and

parts, which can cause

leaking or machine failure.

Do not use the water purifier in direct

sunlight!

When the water purifier is in

sunlight for a period of time, it

may create a breeding ground

for microorganisms so the water

purifier

water

quality

will

decrease, and they may pollute

the internal components of the water purifier.

5

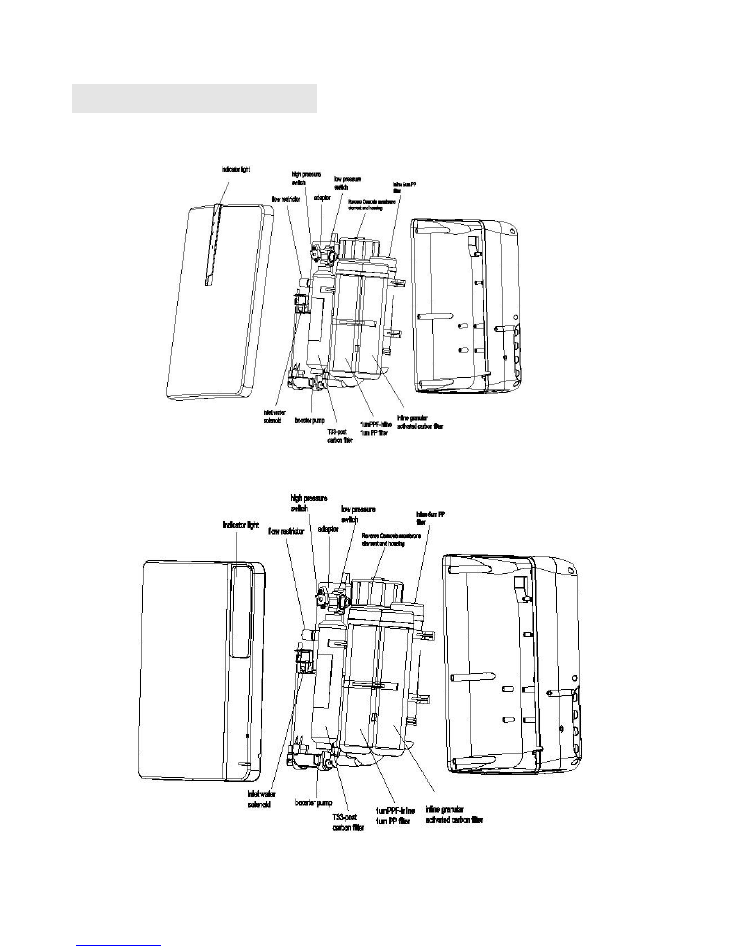

Product Introduction

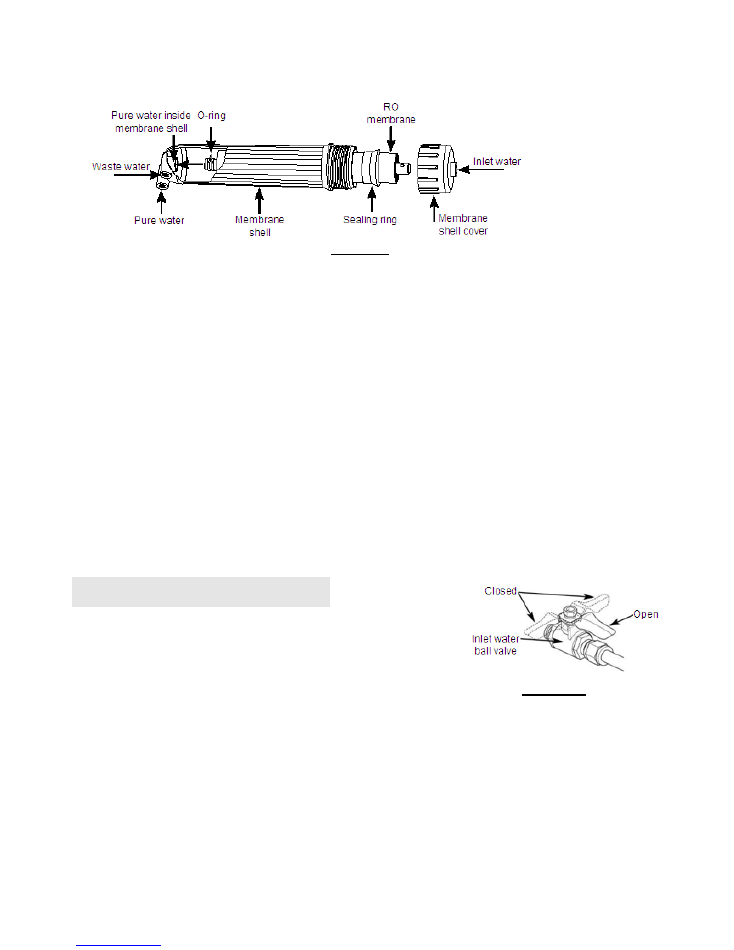

1. Blown-up profile of the water purifier

1(a)

1(b)

6

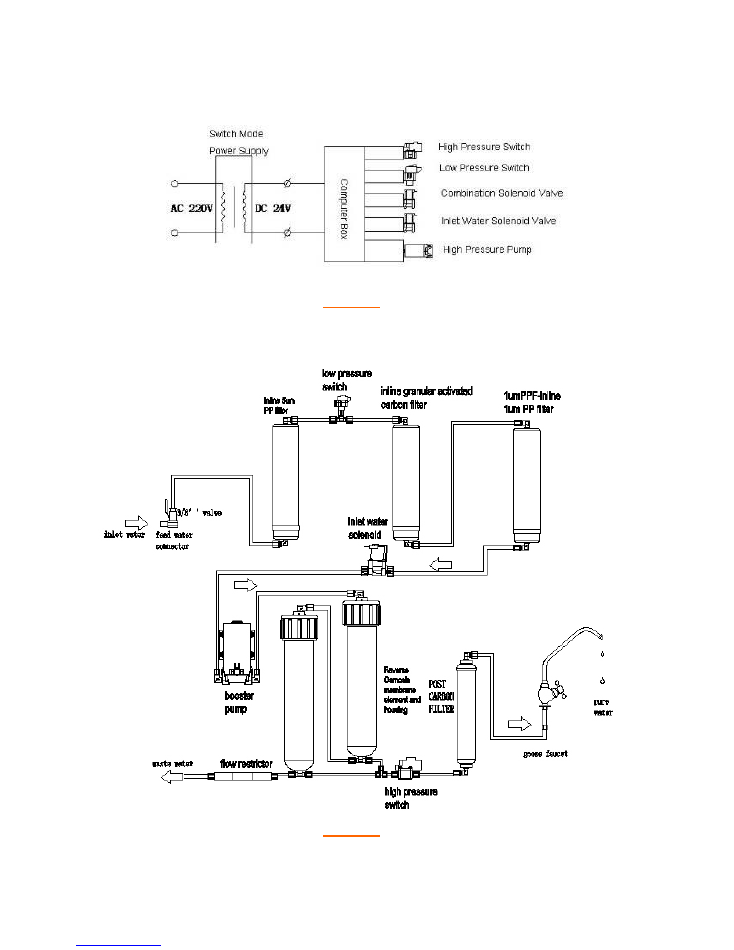

2. Electrical diagram

Diagram 2

3. Water route map

Diagram 3

7

4. Technical Parameters

Voltage

AC 220V 50HZ

Power Rating

75W

Suitable Water Pressure

0.05MPa

~

0.35MPa

Operating Pressure

≤0.85MPa

Inlet Temperature

5-38

℃

Maximum Inlet Water TDS Value

≤1000PPM

Maximum Daily Water Production Volume

800 Gallons, approximately

2880

Liters

Electric Shock Protection Type

Type II

Suitable Water Quality

Municipal tap water meeting the

GB5749-2006 standards

Note: Due to product improvements, the above parameters may change but the product name plate shall

stay the same. TDS refers to the influent total dissolved solids.

5. Water Purifier Main Parts Function Introduction

Using the current most advanced international RO technology,

standard configuration

is as follows:

①

First is a Inline 2.5`` 5-micron PP filter:

The aperture of the PP filter is 5 microns, can effectively filter rust, sand, other larger particles and solid

impurities in water.

②

Second is a Inline 2.5`` granular activated carbon filter:

Can effectively adsorb chlorine, humus, disinfection by-products, odors, colors, and other materials.

③

Third is Inline 2.5`` 1-micron PP filter:

Can further remove small particles in the water, suspended solids, colloids, etc.

④

Fourth stage

is

x

2

RO membr

s

ane :

Aperture is 0.0001 micron (0.1 nm), reduces bacterium by 4,000 fold, reduces viruses by over 200 fold,

so you can effectively remove bacteria, viruses, heavy metals, pesticide residues, and other harmful

substances from the water.

⑤

The fifth-stage is a post-activated carbon filter:

Regulates water taste, keeps water fresh.

Note:

This machine also has an optional configuration:

Pretreatment Filter: KDF two stage filter, KDF three stage filter

Post-filter: Alkaline filter, infrared mineralization activated carbon filter, alkaline sterilization filter,

sterilizing filter

8

6. Water Purifier Accessory Functions

High Pressure Pump:

Boosts pressure to create a stable environment for the RO membrane.

Low Voltage Switch:

To prevent pump idling. When the inlet water pressure is less than 0.03 MPa

or when the inlet water stops, the low-voltage switch automatically shuts off

the power source so the machine stops.

High-Voltage Switch:

Prevents pump from fully turning. When the pressure tank is full or has

reached the set pressure, power supply is automatically cut off to stop the

machine.

Inlet Water Solenoid Valve: Connects or cuts off incoming water. Operating pressure range is less than

0.6MPa.

Non Return Valve:

controls the flow direction.

Flow restrictor: control the ratio of pure and waste water

7. Direct flow purifier features:

1.

Design without storage tank:

New advanced design. The water flow is equal to the normal one with

tank. The user can get the pure water at the same time the machine is producing water. This design

solves the contamination problem (such as odors, bacteria etc) caused by long time pure water storage

in tank. It supplies the real

“pure and fresh water”.

2.

Large Production Capacity and Big Water Flow:

Use a

2

4

x

00G RO membra

s

ne . The production

capacity is

15

16

-

times of the standard 50G one, and is equal to the water flow of 50G model with

tank. It

can reach

1 5

. L/min

2

~ .0L/min

3.

Suitable for low water pressure:

It can start working if the feed water pressure is no less than

0.03Mpa.

4. Digital Computer Box Automatic Control System:

The system can automatically control the water

auto flush process for the RO water purifier to ensure more reliable and safe operation of this machine;

5. Indicator light Display:

Indicator light show the working status, it is easy for the maintenance.

6. The inlet and outlet water is on the side:

easy for the

machine

’s installation.

7. Quick connector: New advanced design, quick connectors make it easy for installation, usage

and maintenance.

8. Inline filter, easily dismantle: only dismantle the inline filter to make easily changing

9

Installation Method

This company recommends that professionals install the machine for you, because you must use drills and

other power tools in the installation process. If you are installing it yourself, please refer to the following

steps and diagrams:

1. Pre-Installation Preparations

①

Confirm the location the water purifier will be installed (when installing, it should depend on the actual

circumstances)

②

Confirm the various tools required for installation

Adjustable spanner

1

Drill

1

6.2mm drill bit

1 (waste water hole)

Hole saw,

φ14mm

1 (high-speed steel or marble hole saw)

Phillips and flathead screwdrivers

1 of each

Scissors

1 pair

18-21mm wrench

1

14-16mm wrench

1

Needle nose pliers

1

③

Confirm that you have all the connectivity accessories required for installation

④

Prior to installation turn off the water and/or electricity

2. Instructions for Proper Installation

①

Inlet water metal hose and 3-way inlet water joint installation method (if the metal hose diameter is

3/8

’’ the 3-way inlet water joint must be purchased separately)

First close the inlet water valve. Unscrew from the metal hose. Remove the 3-way inlet water

joint from the water purifier accessories box, thread one end of the inlet water 3-way joint into the

inlet water valve outlet; one end of the newly unscrewed metal hose should be screwed into the

3-way inlet water joint screw nut (See Diagram 4).

10

Diagram 3

②

3-way inlet water joint and inlet water ball valve installation method

Take out the inlet water ball valve from the water purifier accessories box, wrap one end of the ball

valve external threads with the appropriate Teflon tape (See Diagram 5), if you have silica gel,

spread a little on and then screw the ball valve into the corresponding hole of the 3-way inlet water

joint (See Diagram 6). Take out the

Ø 9mm water pipe from the accessories box, using scissors

cut a suitable length of pipe, connect one end of the pipe with the inlet water ball valve (See

Diagram 4), finally screw the nut in place.

Diagram 5 Diagram 6

③

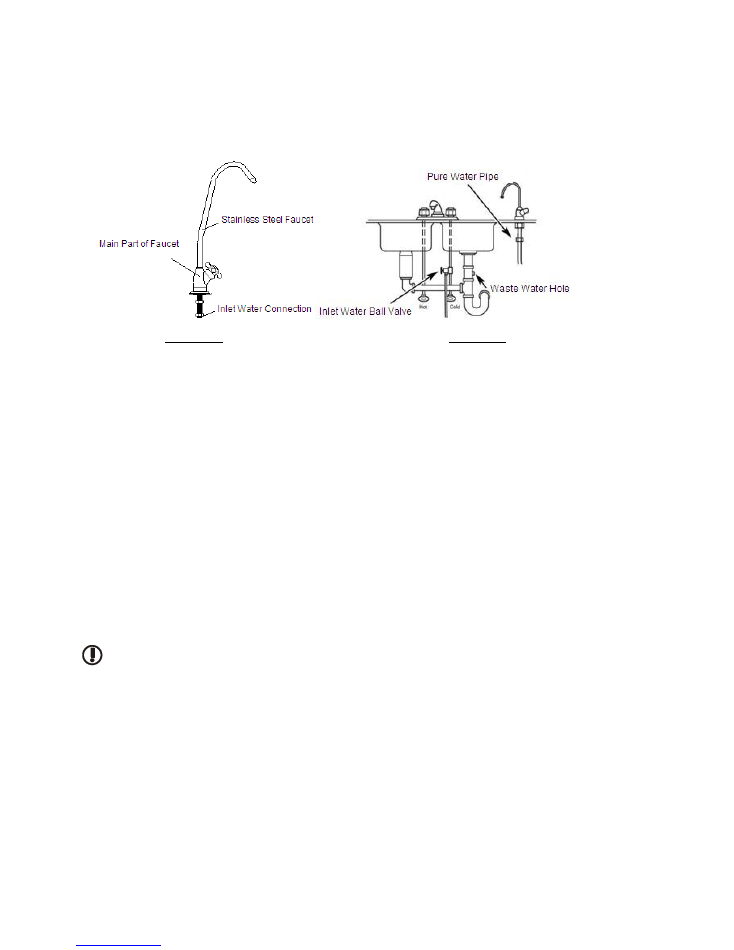

Gooseneck faucet installation

In the counter where the faucet is to be installed drill a φ14mm hole in an appropriate position, then

take out the faucet from the water purifier accessory box. Start the faucet installation: first put the

stainless steel neck on the faucet main body (See Diagram 7), then lower the main part of the

faucet into the already drilled hole, and then put the spacer on the lower part of the faucet. Screw

the fixed nut into the bottom end of the faucet to fix the faucet to the counter, finally put the

11

appropriate length of

Ø6mm pipe into the water inlet connection, put on the nut and hollow ball,

screw to the bottom of the faucet (see Diagram 7). If you want to fix the faucet to the wall, please

use the faucet hanging piece. (when installing be sure to tighten the joints to prevent leakage)

Diagram 7 Diagram 8

④

Waste water pipe installation

Using a

φ6mm drill punch a small hole into the sink drain pipe, take a suitable length of the 6mm

water pipe, lay one end just inside the hole (See Diagram 8), put some silica gel where the 6mm

pipe and the drain pipe connect to prevent leakage, use a cable tie to fix the waste water pipe to the

drain pipe. (for large flow water purifiers you need waste water clip inserted into the already drilled

drain pipe hole)

⑤

RO Membrane Installation

First take the water purifier out from the packaging, open the water purifier outer cover, unscrew the

membrane shell cover inlet water connection end, take out the inlet water pipe, then use the membrane

shell wrench to unscrew the membrane shell cover. Take the RO membrane from its packaging, put the

end of the membrane with the O-ring into the reverse osmosis membrane shell (See Diagram 9) and push it

in, finally screw the membrane shell cover back on, and use the membrane shell wrench to tighten the

membrane shell cover, put the inlet water pipe into the membrane shell inlet water connector and screw in

the nut, then put the membrane shell card into the large single clip and put the water purifier cover back on.

。

Warning:

◆

When installing the RO membrane, you should pay attention to the direction of the membrane;

◆

When installing the RO membrane, you should first make sure that one end of the membrane has

two O-ring;

◆

When installing, be sure to put the end with the O-ring into the end of the membrane shell with the

pure water connection, when installing correctly you only need a little force to put the reverse

osmosis membrane into the membrane shell, if you encounter too much resistance, please do not

force the reverse osmosis membrane into the membrane shell, doing so may cause permanent

damage to the membrane shell or membrane components (the membrane manufacturer does not

assume responsibility for returned components due to damage during installation);

◆

Damage to the membrane shell and reverse osmosis membrane element caused as a result of

the above reasons is not covered under the water purifier warranty.

12

Diagram 9

3. Installation Considerations

①

When installing the water pipes, cannot install a drain stopper, in addition, for the water pipe bottom

connector, the screw nut should have no wire teeth exposed.

②

If the inlet water pipe is 9mm, should ensure that the inlet water tube and connector have 30-40cm

of straight piping to avoid burst pipe accidents caused by bending in the pipe.

③

If the power cord wiring needs to be longer, then according to the wiring requirements use a

Φ8mm

pinched tube to wrap around the connection, then on the outside wrap around insulating electrical

tape, do not place it on the floor, it should be suspended in the air or in another place away from the

ground.

④

When installing, if you need to make a hole in the wall, you should first make sure that there are no

electricity or water lines in the location you plan to drill.

⑤

This machine must be connected to the safety socket that has the earth wire. Otherwise the

manufactory should not be responsible for any accident.

⑥

This machine is installed with the adaptor, it must not touch in much water when installing,

otherwise it would cause the electrical accident.

Adjustment Methods

After confirming that the water route connections are correct, confirm that

you have a power supply and/or water supply. Then follow these steps

to troubleshoot the machine:

Diagram 10

1. Open the tap water inlet valve as well as the water purifier inlet water ball valve, plug in the power

source (See Diagram 10), close the storage tank ball valve, then automatically start a 120 second

flushing process, water will start to drain through the discharge outlet.

2. Wait for the water purifier to operate stably (about 5-10 seconds), check each connection to make

sure it is secure, see if there is any leakage from the membrane shell, filters, etc.

3. Close the pure water gooseneck faucet and storage tank ball valve, wait approximately 30 seconds,

check whether or not the water purifier waste water has stopped.

4. Open the gooseneck faucet, observe whether pure water is flowing through the faucet, if no pure

water is flowing, check whether the tap water pressure is too low or whether the high pressure

13

switch cannot be reset.

5. Wait until the machine is operating, close the inlet water ball valve, after a short time observe

whether it has stopped operating, if it has stopped operating, check whether the low-voltage switch

can be reset.

6. Wait some time to make sure everything is correct, then the water purifier can be used safely.

Usage Methods

1. The major components of this product are plastic, when using the product always observe the integrity

of the water purifier to ensure safe use.

2. In order to prevent microbial contamination of membrane components during storage and transportation

the reverse osmosis membrane element package contains a small amount of protective solution while

the post-activated carbon filter will emit activated carbon powder the first time it is used. So for the first

hour the water purifier is operated, do not open the water storage tank. it is recommended that the

water produced is thrown out, otherwise the pure water taste may be unusual.

3. When you start operating the water purifier the pure water TDS value may be a little high, after running

for some time the TDS value for pure water will gradually decrease until it is stable.

4. When you are using the water purifier, the inlet water ball valve should be opened and the pure water

faucet needs to be turned on. When you are not using water turn off the water faucet, the high

pressure switch will automatically cut off the water supply.

5. In these

“usage methods”, “usage” refers to when the power supply is connected and/or the inlet water

ball valve is open so the water purifier is in a working condition.

Maintenance and Upkeep

1. Filter Replacement Time

①

This machine’s filter replacement cycle for the various filters is derived from statistical indicators on

average tap water use estimates. If there are big discrepancies between the user’s actual water

quality and utilization rate and the average indicators, there will be more obvious differences

between the filter’s actual use time and the estimated cycle such as premature filter clogging,

premature failure, etc. If this happens, filter replacement should be based on actual use, you

should also promptly contact your local after-sales service department.

②

This machine’s estimated filter replacement cycle is based on average household water

consumption and is suitable only for residential use, do not install this machine in places that require

large volumes of water. If the water volume requirements are large, this company has appropriate

machines for business purchase.

③

According to economic statistics on municipal tap water, a three person family on average uses 10L

of water a day, according to the water volume and inlet water quality conditions, overall filter volume

is approximately as follows (the following data is for reference only):

14

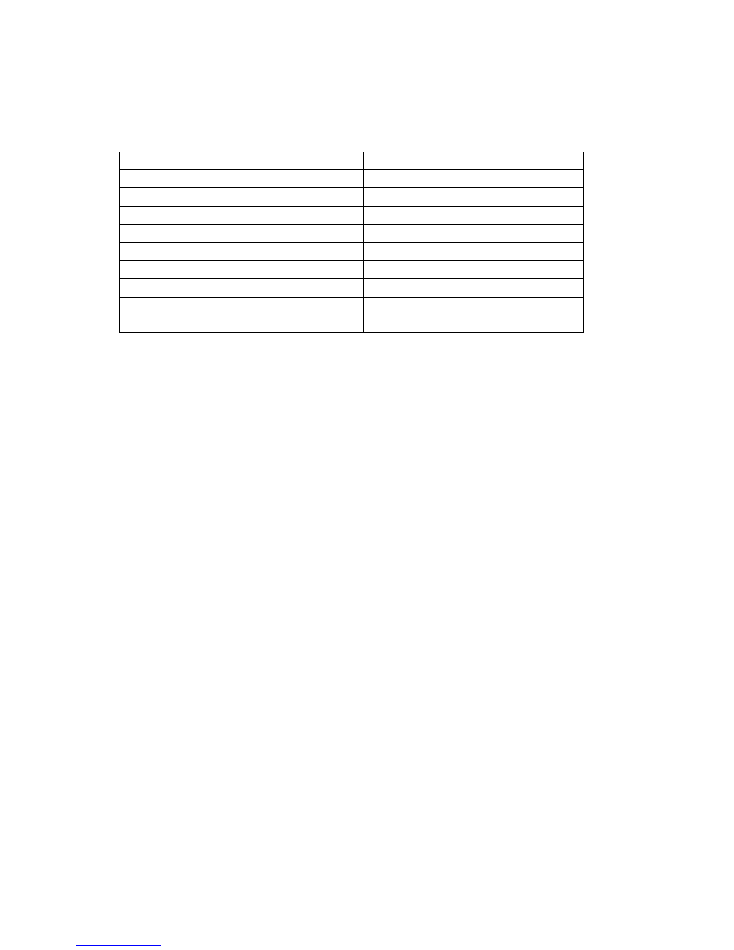

Progression

Water Volume (tons)

First: Inline 2.5`` 5-micron PP filter

7.5

Second: Inline 2.5`` 85C granular activated carbon filter

7.5

Third: Inline 2.5`` 1-micron PP filter

10

Fourth: RO membrane

According to the using

conditon

Fifth: Post-activated carbon filter

6

Note: It is recommended that filter element replacement is carried out by after-sales staff.

Water quality has a great influence on the life of the filter, the RO

membrane’s lifespan is

affected by many factors, the above table expresses lifespan under standard conditions, in

actual usage, because the water quality may be different, the lifespan may exceed the above

estimate, it may also be lower than the estimate, this data is for reference only. Under normal

circumstances if the following situations are experienced, you should consider replacing the

filter:

◆

Poor water quality, taste declines, TDS value of water rises;

◆

Water flow is significantly reduced, check to see if the filter or membrane is blocked (and

determine that it was not caused by a temperature drop);

◆

If the filter’s outer surface is covered in mud or the filter has significantly changed color;

◆

If serious filter clogging leads to no pure water from the water purifier.

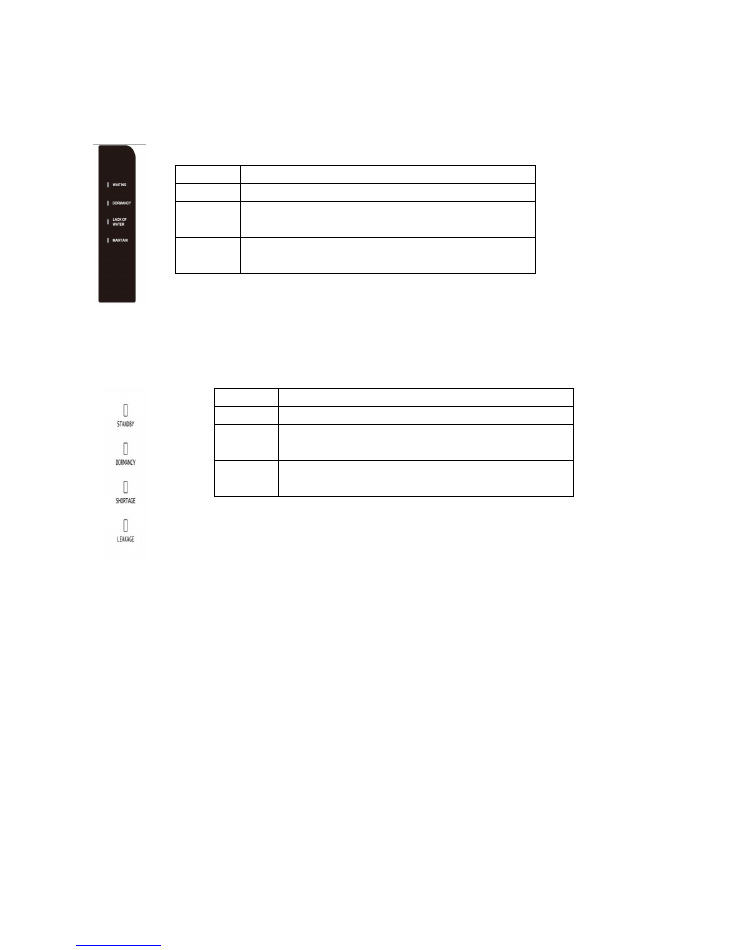

2. Filter Replacement Method

①

Replacing the filters

First close the inlet water ball valve and unplug the power supply. Open the front cover of the

machine. Unscrew the nuts on both sides of the old filter, and pull out the water pipe. Take out the

old filter and remove the connectors on both ends. Wrap each of the connector with Teflon tap (If

you have silica gel, it

’

s better to have a little on), then mount onto the both ends of the new filter.

Finally assemble the water pipe back and place the filter back onto the single clip. Pay attention to

the arrow on the filter, and connect pipes according to arrow indicating (left

—

water inlet,

right

—

water outlet).

Diagram 12

②

For replacement of membrane elements please see “RO Membrane Installation” (Page 10).

15

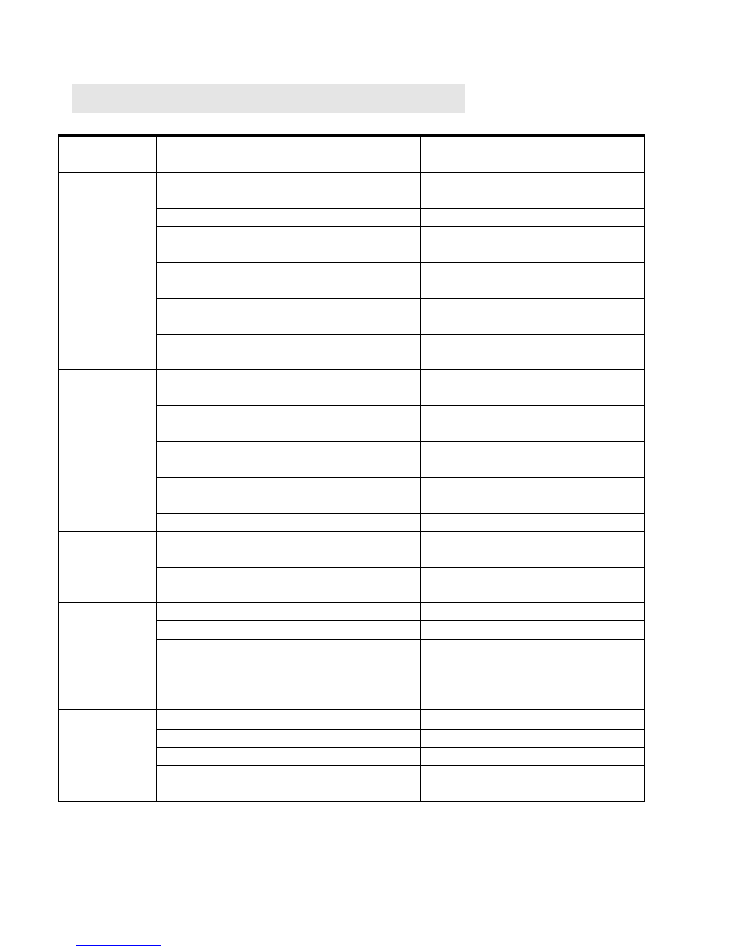

3. Computer box control

(

a

)

indicator light display

(

from top to bottom

)

:

1.full

,

2.sleep

,

3.shortage

,

4.leakage

。

A

(

b

)

indicator light display

(

from top to bottom

)

:

1.full

,

2.sleep

,

3.shortage

,

4.leakage

。

B

The computer box controls the working status, to ensure the machine work normally, and the RO membrane is in

excellent working condition.

1.

The machine will protect itself by stopping to work too long time in sleep condition. (this

machine is for domestic use, it would not happen to sleep condition when use normally. Only you

forget to close the faucet or exceed the standard volume, the computer box would automatically

stop the machine for protection.)

2.

when the light turns on from the top to bottom, it means working normally.

3.

when the light shines, it means you need to change the filter. Light 1,2,3,4 separately represent

the first, second, third and fifth stage filter

4.

If the machine continuously works more than 45 minutes, it would stop 45 minutes for

protection(sleep condition). After the sleep period, the machine can work normally.

5.

when the inlet water comes from the shortage condition to normal water pressure, the low

pressure switch will last 5 seconds to normal work, and at that time the shortage light will be on

for 5 seconds.

6.

when the leakage needle examine the water leakage, the machine will delay 5 seconds to stop, in

full

This light will be on when the tank is full

sleep

The machine is not working now

shortage

The low pressure switch is shut off, check the inlet water

and its pressure

,

leakage

The needle on the bottom show the league inside, pls check

the pipe or the connector.

full

This light will be on when the tank is full

sleep

The machine is not working now

shortage

The low pressure switch is shut off, check the inlet water

and its pressure

,

leakage

The needle on the bottom show the league inside, pls check

the pipe or the connector.

16

this condition the light will keep the same before leakage, then the leakage light will be on. If the

leakage disappears, the machine will delay 10 minutes (leakage light is still on) to the former

normal work..

7.

when it comes to the filter life span, the step to the original: press the moving button on the full

condition, when heard the reminding voice, the full light shining means the first stage filter is

ready to renew. Press the renew button and heard the reminding voice, then the full light keep

turning on, now the first stage filter finished renew. When you want to renew the second, third,

and fifth stage filter, pls press the moving button until it comes the corresponding shining, then

follow the above step.

A is for moving button, B is for renew button.

4. Notes

①

RO membrane water production volume

The RO membrane component water volume is influenced by the inlet water pressure and water

temperature, this machine’s stated volume of

8

00GPD is tested with net pressure of 0.5MPa

and

inlet water temperature of 25

℃

, if the net pressure is less than 0.5MPa or if the inlet

water temperature is less than 25

℃

, the RO membrane element water production will be

less than

8

00GPD.

②

Disposal of old filters

After replacing old filters, they cannot be cleaned and reused; it is recommended that you dispose

of them with solid waste garbage

Notes

★

When any of the following situations occur, immediately disconnect the water purifier water

source (close the inlet water ball valve) and/or the power source and carry out repairs.

· If the water purifier pipes or related components are leaking.

· If the water purifier’s related components stop working.

· If any components leak electricity.

· If there are any other anomalies or failures.

★

When you go out or do not use the machine, disconnect the water purifier water source

(close the inlet water ball valve) and/or power source.

★

If the water purifier parts are damaged, it is recommended that the water purifier be entrusted to

the manufacturer or distributor, service center, or specialized technical personnel for replacement

to prevent loss caused by improper operation, the manufacturer is not liable for losses caused by

operation or use not in accordance with the instructions and reminders

17

Failure Diagnosis and Resolution

Failure

Experienced

Reason

Resolution Method

The machine

will not start

The power source is not connected

Check the power source or the

power source plug

Low inlet water pressure or no water

Check the inlet water pressure

Low-pressure switch failure, cannot

connect the power source

After connecting the inlet water,

measure the resistance, replace

High-pressure switch cannot be restored

After letting off the pressure,

measure the resistance, replace

Switch Mode Power supply is burned out

Measure the output voltage,

replace

Fuse in the computer box burned out

Measure the output voltage,

replace

The high

pressure pump

is working

properly, but no

water is being

produced

High-pressure pump has lost pressure

Measure the water pump pressure,

replace

Inlet water solenoid valve is faulty, no water

can get in (no pure water)

Replace the solenoid valve

A pre-filter is blocked

Observe the pure water and waste

water, replace the pre-filter

Non return valve is blocked (waste water,

no pure water)

Replace the non return valve

The RO Membrane is plugged

Clean or replace the RO membrane

The machine is

turned off but

waste water has

not stopped

Inlet solenoid valve failed, cannot

effectively cut off the water supply

Observe the waste water, replace

the inlet solenoid valve

Non return valve has lost pressure (small

waste water flow rate)

Observe the waste water, replace

the non return valve

After the

machine is filled

with water

(stand by), the

machine starts

repeatedly

Non return valve has lost pressure

Replace the non return valve

High-pressure switch failure

Replace the high pressure switch

System is exhibiting a loss of pressure

After checking the non return valve,

check whether there is water

leakage in the pipelines

The pure water

flow is small or

not flowing

Pre-filter is plugged

Replace the pre-filter

RO membrane is plugged

Wash or replace the RO membrane

Inlet solenoid valve failure

Replace the inlet solenoid valve

High pressure pump pressure is not

enough

Measure the high pressure pump

water pressure, replace

18

After-Sales Service

1. The warranty is valid from the date of installation.

2. Warranty period: One-year machine warranty. The warranty does not include consumables

(consumables include filters, RO membranes, and storage tanks).

3. Please keep the warranty in a safe place, for maintenance you must have your purchase invoice,

only then is the warranty effective.

4. No invoice, altered machine number, the user replacing parts or modifying the water purifier on their

own, the user not following the requirements of the user manual, and men-made damage do not fall

under the scope of the warranty.

5. If your water purifier exhibits abnormal behavior, please immediately turn of the water source, cut

off the power, and contact your local vendor.

Notes

:

The company reserves the right to change product design, configuration, and specifications without

notice.

The company has the final explanation rights if this manual is unclear, has mistakes, or if there were

printing problems which caused problems.

Packing List

· Main machine (including

x

2

RO membran

s

e )

1 unit

· Water pipe (ø6mm and ø9mm)

Each 1 roll

· Installation and User Guide

1 copy

· Gooseneck faucet

1

· Membrane shell wrench

1

· Accessory pack

1 package

Notes

:

Unit Conversion: 0.1MPa

=

1.02Kg/cm

2

=

14.5Psi

1Psi

=

0.07 Kg/cm

2

1 Gallon

=

3.785 Liters