Full Text Searchable PDF User Manual

By Appointment to

Her Majesty Queen Elizabeth II

Suppliers of Commercial Refrigeration

Foster Refrigerator, King’s Lynn

Call: +44 (0)843 216 8800 Fax: +44 (0)843 216 4700 Email: support@foster-uk.com

www.fosterrefrigerator.co.uk

A Division of ITW Ltd

Foster Refrigerator

Oldmedow Road

King’s Lynn

Norfolk, PE30 4JU

United Kingdom

ISO 9001

ISO 14001

English

Original Oper

ation Instructions

EcoPro G2

Cabinet & Counter Models

00-556483 August 2016 Issue 7 GB

Controller & Display - Versions FD1-11 & FD1-14

1

Single Cabinets

EP700F

EP700G

EP700H

EP700H2

EP700H2BK

EP700HBK

EP700HH

EP700HL

EP700HSTB

EP700HU

EP700HMH

EP700P

EP700W

EP700L

EP700L2

EP700L2BK

EP700LBK

EP700LL

EP700LSTB

EP700LU

EP700LHM

EP700M

EP700M2

EP700MU

G700G

G700H

G700L

G700M

G700W

Double Cabinets

EP1440G

EP1440H

EP1440H4

EP1440HSTB

EP1440HU

EP1440W

EP1440L

EP1440L4

EP1440LSTB

EP1440LU

EP1440M

EP1440M4

EP1440MU

G1440H

G1440L

G1440M

Broadway

EP820HU

EP820LU

Workout

EP820MW

EP820LW

Counters

EP1/2G

EP1/2H

EP1/2L

EP1/2M

EP1/2P

EP1/3G

EP1/3H

EP1/3L

EP1/3M

EP1/3P

EP1/4G

EP1/4H

EP1/4L

EP1/4M

EP2/2H

EP2/3H

Models Applicable to This Manual

GB

2

General Electrical Safety

Foster Refrigerator recommends that the equipment is electrically connected via a Residual Current Device; such

as a Residual Current Circuit Breaker (RCCB) type socket, or through a Residual Current Circuit Breaker with

Overload Protection (RCBO) supplied circuit.

Disposal Requirements

If not disposed of properly all refrigerators have components that can be harmful to the environment. All old

refrigerators must be disposed of by appropriately registered and licensed waste contractors, and in accordance

with national laws and regulations.

Start-Up and Operation

After unpacking, clean and allow the cabinet or counter to stand for 2 hours before turning on (cleaning

directions supplied within this manual)

. Ensure the cabinet is situated on a firm, level surface away from both

hot and cold air sources, as this will affect its performance.

Vaporiser Tray (Dual Temperature Models Only)

On delivery, the tray is attached to the rear of the cabinet. Remove the two fixing screws and slide the vaporiser

tray underneath the cabinet, into the two fixed runners.

Bend the corner tabs of the tray upwards, then using the guide holes already in the cabinet secure the tray in

position with the two screws originally removed.

The heaters electrical connection to the cabinet will already be in place. Ensure the drain line pipe is angled in an

upright position to form an air lock.

Please make sure that when positioning a dual temperature model with an external vaporiser tray the tray does

not come into contact with any other surfaces.

Clearance (All models)

Make sure that a minimum clearance of 310mm above and 50mm around the ca

binet or counter

is available for

ventilation and effective operation.

Connect the unit to a suitable mains power outlet and turn the supply on. Please do not plug or unplug the unit

with wet hands.

The cabinet will energise briefly showing followed by the power switch slowly pulsing with a blank display.

The unit is now in standby.

Standby

Pressing the power switch for 3 seconds will turn the unit on (the switch backlight is static and the display shows

the operating temperature) or into standby (the switch backlight pulses slowly on and off).

As the operating temperature has been preset no adjustments are required. Allow the cabinet to reach its normal/

set operating temperature before loading.

I

mportant Note to the Installer:

Please ensure that this document is passed to the user as it contains

important guidelines on operation, loading, cleaning and general

maintenance and should be kept for reference.

GB

3

GB

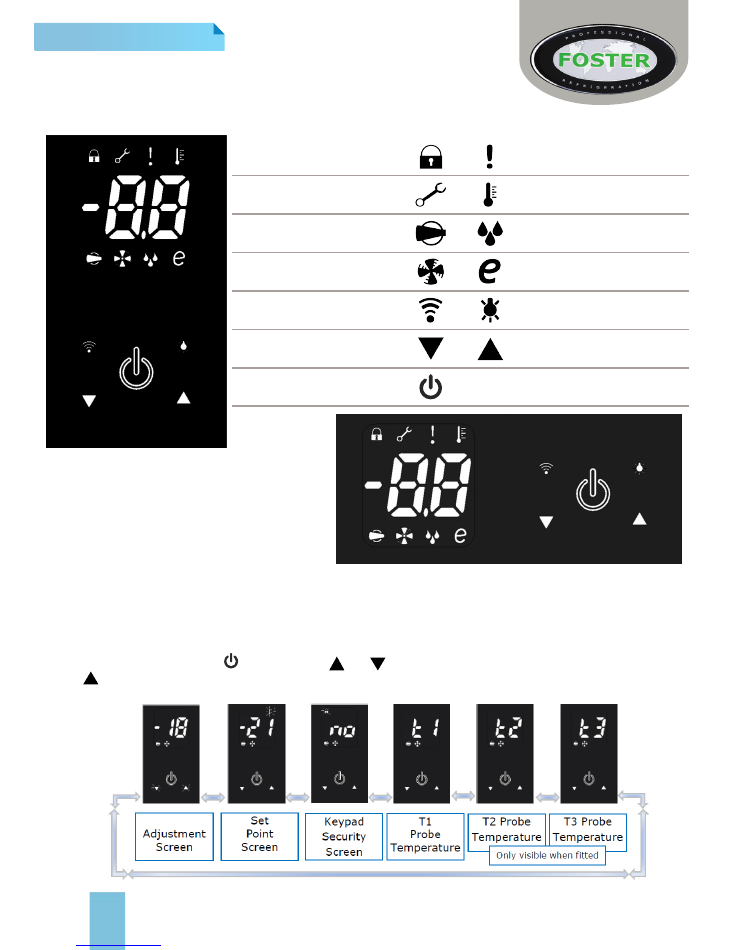

Display Icons and Switches

(Some icons or switches are only visible during adjustment, when activated by parameters or through operation/

manual selection).

User Adjustment Mode

You are required to enter this mode to make any setup changes.

These include Set Point, Keypad Security and display of T1, 2 or 3 probe temperatures.

Press and immediately release after which the and switches will flash/pulse together.

Press to scroll through the following screens:

(Cabinet Version)

Keypad Lock

Warning/ Alarm

Service Mode

Temperature Setting

Compressor Function

Defrost Function

Evaporator Fan Function

Reduced Energy Mode

Data Download Switch

Light Switch

Decrease Switch

Increase Switch

Power Switch

(Counter Version)

4

GB

To exit this mode scroll back to the adjustment screen and press or wait for 30 seconds and the display will

revert to the normal display showing the operating temperature.

Set Point and Other Mode Adjustments

Access the adjustment mode as described above. Using the or switches to scroll to the

mode that requires adjustments i.e ‘Set Point’ this is the minimum temperature the cabinet is

allowed to

cool down to (the display shows the temperature and flash/pulsing icon ).

To adjust this press and release the icon will show constantly. Adjust the setting with the

or switch. Confirm the change by pressing and releasing again, the next mode will

automatically show.

Scroll through the modes with the or switch until you return to the adjustment screen and

press and release to exit and save.

If at any point the display is left for 30 seconds it will revert to the normal display and no

changes will be saved.

Keypad Security Settings

Access the ‘Keypad Security’ screen as described above.

The screen will show the current status, initially preset to ‘ ’, with flashing. Press and

release and will show constantly. (If you modify this setting with to show ‘ ‘ the keypad

will be locked, will show constantly and the cabinet will not be able to be put into standby,

carry out a manual defrost, adjust temperature set point, download data or switch on/off the units

lights. To confirm any change you

must

press again so the next screen ‘ ’ shows).

Exit any of the ‘Adjustment Modes’ as described above.

Internal Light (where fitted)

To switch on the lights press and release so that the switch backlight is on continuously.

To switch off press and release and the switch backlight will flash/pulse.

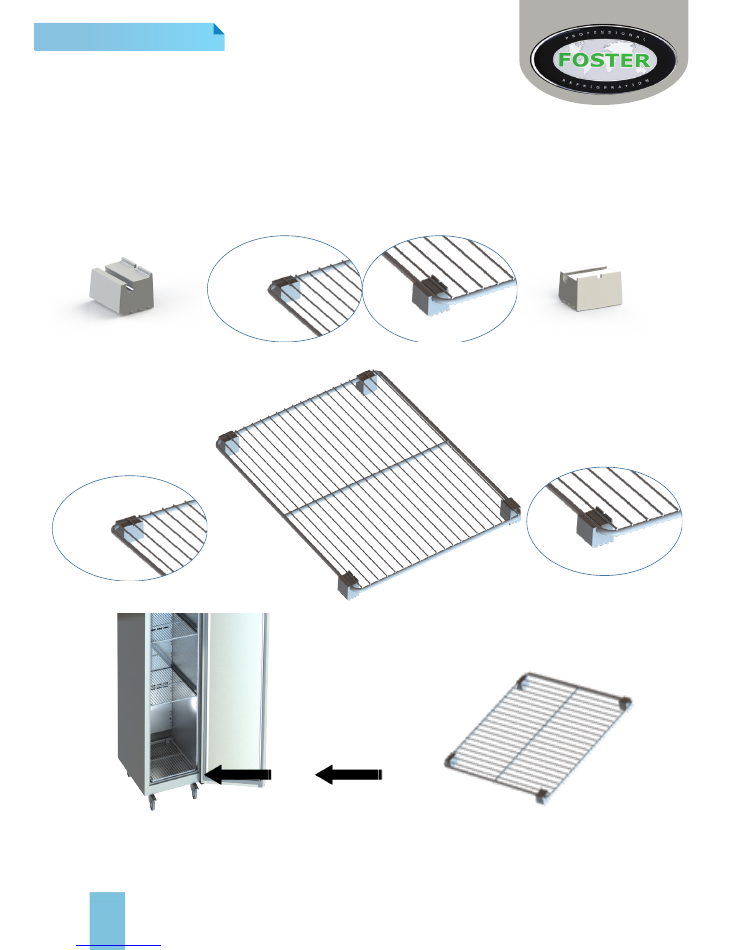

Shelves and Supports

G2 shelving for low, high or meat temperature cabinets consist of two trayslides per shelf. These slot directly into

the rear of the cabinet’s airduct and have ladderacking to support the front.

Shelves are the standard wire gastronorm style that slide onto the trayslides. Fish cabinets come with fixed

racking and fish bins, wine cabinets with the required bottle racking/holder assembly. Both of these are fitted

instead of standard shelving.

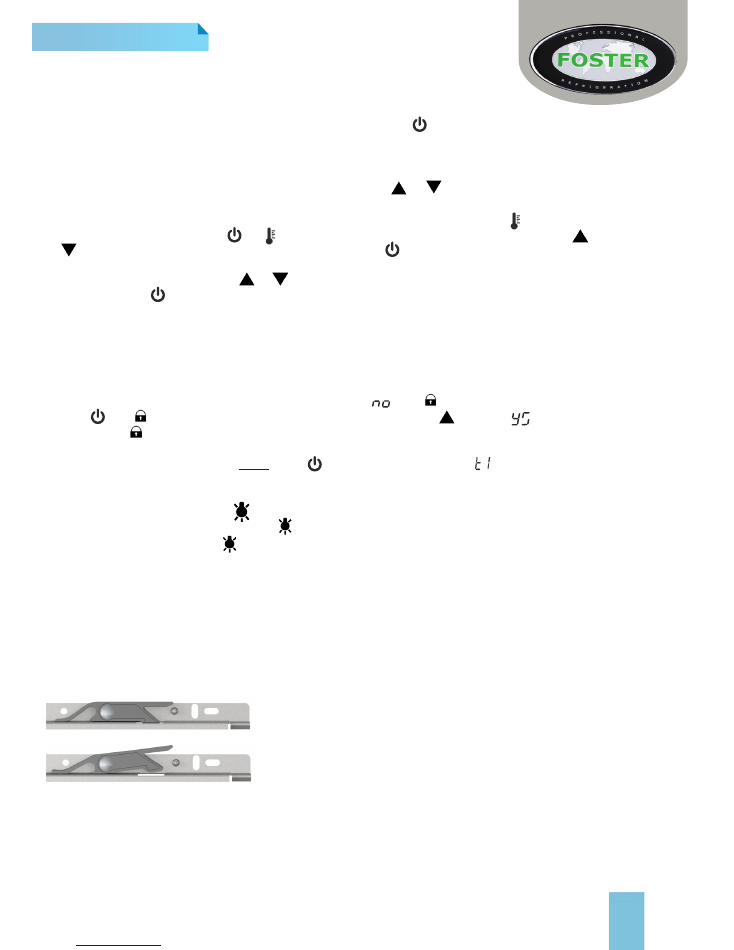

Chef and Standard Drawers

(on counter models only)

To Remove a Chef Drawer

Pull out the drawer to its full extent. Lift the side release lever upwards (as

shown in the 2nd diagram).

With the lever lifted the drawer can be removed from the sliders and the

counter.

To Remove a Standard Drawer

Pull out the drawer to its full extent. Lift the drawer body upwards and then retract the drawer body towards you

again.

Food

Cover all foods and separate raw and cooked foods to avoid cross contamination.

5

GB

Loading and Airflow

Ensure that there is no more than 40kg of evenly distribute product placed on or within each shelf or drawer.

Always ensure the air can circulate around/through the stored product.

It is important that for optimal energy performance that adequate airflow is maintained around the perimeter of the

shelves, and around all stored products.

On all models please ensure that no product is placed on the unit base.

Door & Drawer Lock

To lock the door or drawer insert the key and turn 90°, turn in the opposite direction to unlock.

Defrost

All Foster G2 cabinets are fitted with a fully automatic defrost system to ensure that the evaporator coil remains

free from ice during normal use. Melt-water is evaporated using either the heat from the refrigeration system or a

separate electric heater (dependent upon model and configuration)

To activate a manual defrost

- while the cabinet is in ‘run’ mode press and hold for 5 seconds. After 3

seconds the display will go blank then return after a further 2 seconds. At this point a defrost will be performed

(subject to underlying operating parameters), this will terminate automatically.

Cleaning and Maintenance

Important: Before cleaning, the unit should be put into standby and then the power supply should be

turned off at the mains. Please do not plug or unplug the unit with wet hands. Only when cleaning has

been completed and the unit is dry should the cabinet be turned back on at the mains.

Suitable P.P.E (Personal Protective Equipment) should be worn at all times.

Regular Maintenance:

>

As

and when required remove all product and shelving (beware of cold and or sharp components) from

the unit. Clean exterior and interior surfaces with mild liquid detergent, following the directions on the

pack at all times. Rinse surfaces with a damp cloth containing clean water. Never use wire wool, scouring

pads/powders or high alkaline cleaning agents i.e bleaches, acids and chlorines as these may cause

damage.

>

All gaskets should be inspected on a regular basis and replaced if damaged. To clean, wipe with a warm

damp soapy cloth followed by a clean damp cloth. Finally thoroughly dry.

>

Shelves and their supports can be removed for cleaning. The shelves are dishwasher safe; however the

vertical supports should be cleaned with warm soapy water then rinsed and dried.

>

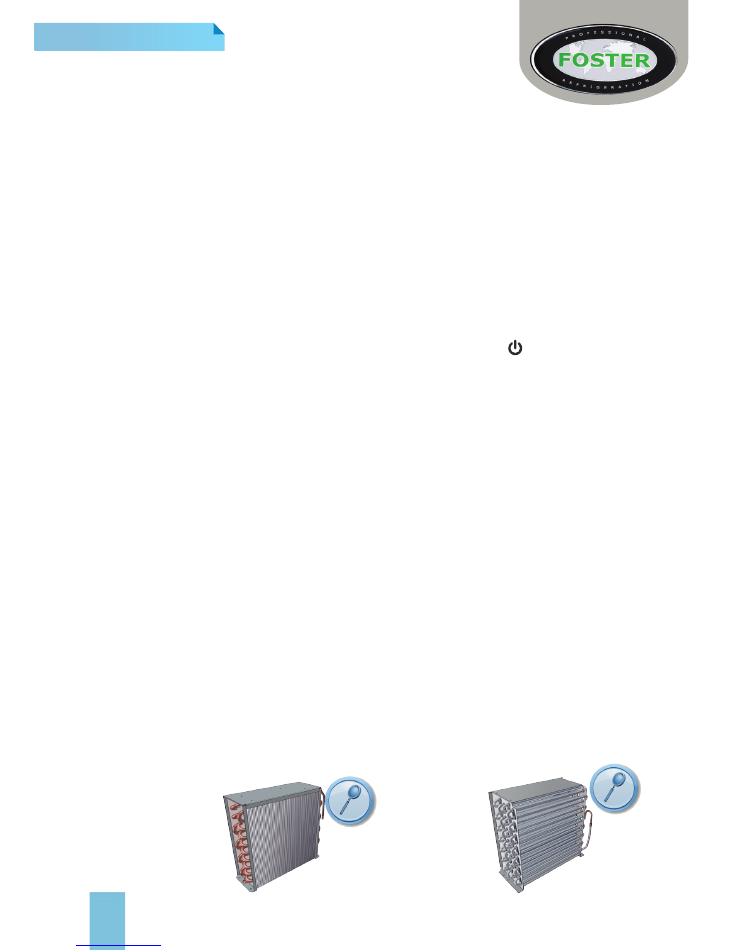

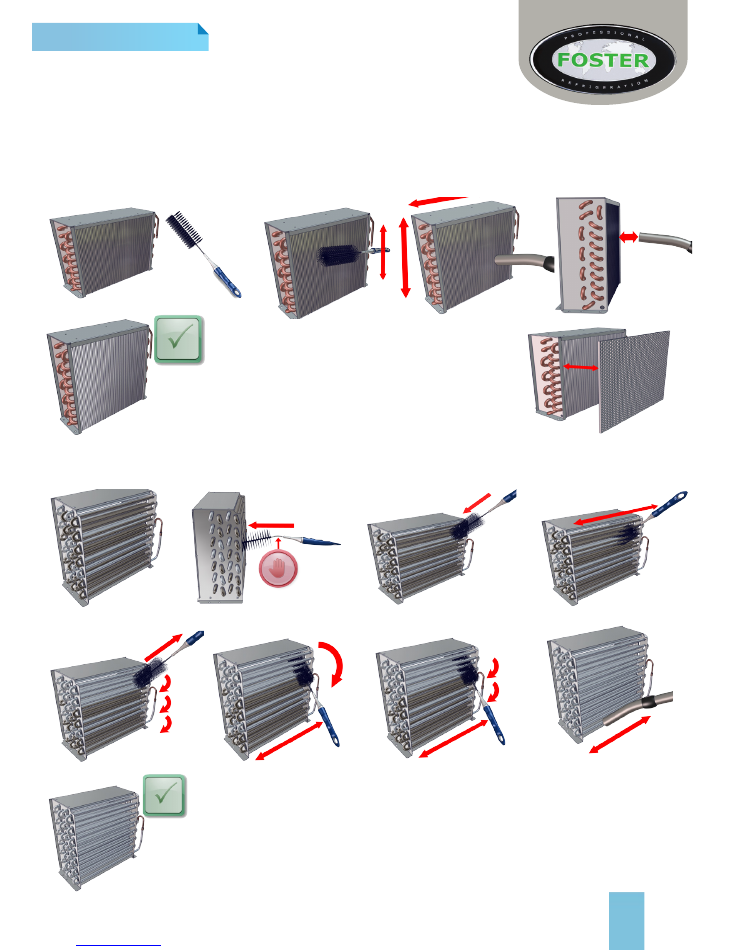

Condenser Cleaning

Maintenance should take place on a regular basis or as and when required by a competent/trained

personnel.

+Stayclear

Coil

Traditional Fin

Coil

4 to 6

6

If there are any stubborn grease deposits left on or through the condenser call your supplier to carry out

a full service (this is normally chargeable). Failure to maintain the condenser may invalidate the warranty

of the condensing unit and cause premature failure of the motor/compressor. Do not use a wire brush to

clean the condenser.

Traditonal Fin Condenser Coil

Hoover or brush the air filter(where fitted)

+Stayclear Condenser Coil

GB

2

1

2

1

3

4

5

6

7

GB

GB

Fitting instructions for Rubber Feet

The rubber feet are provided, enabling a shelf to be positioned on the floor of the cabinet.

If this is required simply clip the feet onto the shelf as demonstrated below

Rubber Foot Rear

Position

Rubber Foot Front

Position

After rubber feet are attached place shelf in the bottom of the unit

8

GB

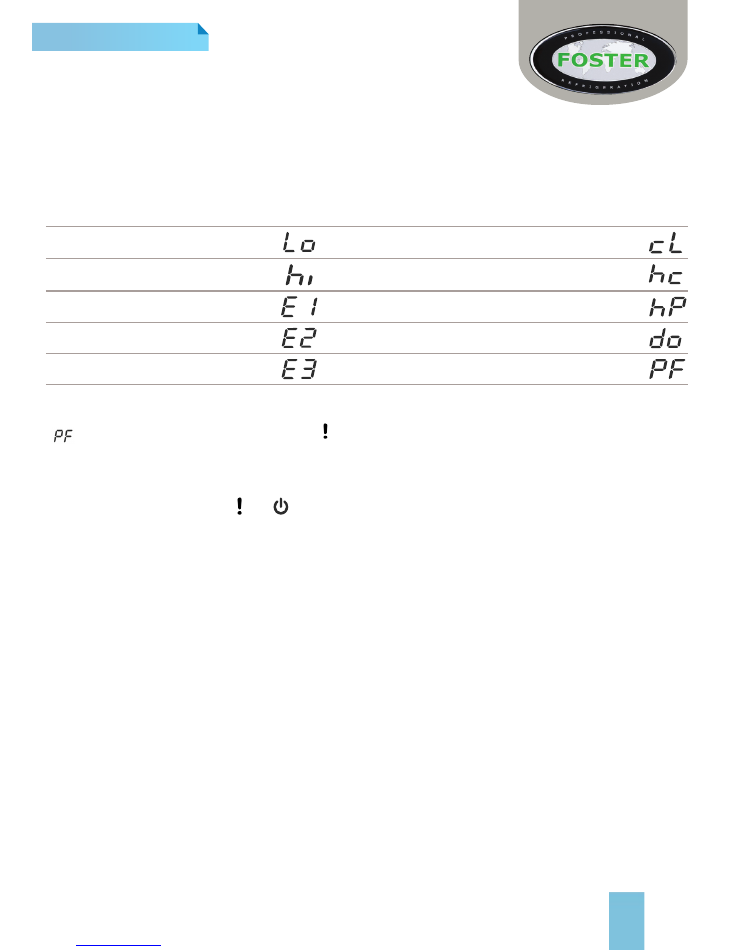

Troubleshooting

Alarms/Warnings

Low Temperature Alarm

Condenser Clean Warning

#

High Temperature Alarm

Condenser High Temperature Alarm

#

T1 Air Probe Failure

High Pressure Alarm

#

T2 Evaporator Probe Failure

#

Door Open Alarm

#

T3 Condenser Probe Failure

#

Mains Power Failure

#

#

only displayed if applicable to model and enabled through parameters.

Power Failure Warning

‘ ‘ will be displayed, the alarm will sound and will show when there has been a mains power failure that

has affected the internal air temperature of the cabinet

(not applicable to units when in standby mode).

When mains power is restored the cabinet will continue to operate, and adjust the temperature as

required.

The warning will sound and show until has been pressed and released, to cancel the alarm.

We would recommend the contents of the unit are inspected.

Before calling your supplier please make sure that:

a.

The plug has not come out of the socket and the mains power supply is on i.e. is the controller

illuminated?

b.

Check to see if the unit is in standby

c.

The fuse for the cabinet is intact

d.

The cabinet is positioned correctly – cold or warm air sources are not affecting the performance

e.

The condenser is not blocked or dirty

f.

The products are placed in the unit correctly

g.

Defrost is not in progress or required

If the reason for the malfunction cannot be identified, disconnect the electrical supply to the unit and contact your

supplier. When requesting a service call, please quote the model and serial number which can be found on the

silver label located on the inside of the unit (starts E......).

9

Require another language?

This manual is also available for download in the following languages:

Français

FR

Nederlands

NL

Deutsch

D

Español

ES

Česky

CZ

Pусский

RU

Magyar

HU

Nynorsk

NO

Íslenska IS

To download please visit

www.foster-spares.com

and select the appropriate model of

refrigerator/ freezer.

GB

Polski

PO

10

>

Page Left Blank Intentionally

<

GB

UK Head Office

Foster Refrigerator

Oldmedow Road

Kings Lynn

Norfolk

PE30 4JU

a Division of ITW (UK) Ltd

Tel: +44 (0)843 216 8833

Fax: +44 (0)843 216 4707

Email: support@foster-uk.com

Website: www.fosterrefrigerator.co.uk