Full Text Searchable PDF User Manual

DFM FUEL FLOW METERS

DFM 50/100/250/500

one-chamber and differential

OPERATION MANUAL

(includes Service S6 DFM software manuals)

Version 6.4

This document is intended for fuel flow meters

manufactured after 01.01.2016

Contents

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

2

Contents

Revision history ......................................................................................................... 4

Terms and Definitions ................................................................................................ 5

Introduction .............................................................................................................. 7

1 DFM general information and technical specifications ................................................. 10

1.1 Purpose of use and application area .................................................................. 10

1.2 Exterior view and delivery set ........................................................................... 13

1.3 DFM modifications ........................................................................................... 14

1.3.1 Autonomous fuel flow meters with display .................................................... 14

1.3.2 Fuel flow meters with display and interface cable .......................................... 15

1.3.3 Fuel flow meters with interface cable ........................................................... 16

1.3.4 Differential fuel flow meters with interface cable ........................................... 17

1.3.5 Differential autonomous fuel flow meters with display .................................... 18

1.4 Measurement range and accuracy ..................................................................... 19

1.5 Unit structure and operation principle ................................................................ 20

1.6 Technical specifications .................................................................................... 22

1.6.1 Working fluids ........................................................................................... 22

1.6.2 Main specifications .................................................................................... 23

1.6.3 Specifications of measuring chambers .......................................................... 25

1.6.4 Power supply modes .................................................................................. 26

1.6.5 Operation modes ....................................................................................... 27

1.6.6 Displayed data .......................................................................................... 28

1.6.7 DFM protection from tampering and intervention ........................................... 31

1.6.8 DFM pulse output signal specifications ......................................................... 32

1.6.9 RS-232 and RS-485 output interfaces specifications and protocol .................... 33

1.6.10 CAN output interface specifications and protocol .......................................... 34

1.7 DFM and tracking devices compatibility .............................................................. 36

1.8 DFM selection ................................................................................................. 37

1.8.1 Selection depending on engine power (boiler output capacity) ........................ 37

1.8.2 Selection depending on fuel flow rate in supply and return lines of the engine .. 38

2 DFM installation .................................................................................................... 39

2.1 Exterior inspection prior to works start .............................................................. 39

2.2 Estimation of vehicle condition .......................................................................... 40

2.3 General installation instructions ........................................................................ 41

2.4 Fuel flow meters mounting schemes .................................................................. 43

2.4.1 Typical diesel engine fuel system scheme ..................................................... 43

2.4.2 DFM installation before the pump ................................................................ 44

2.4.3 DFM installation after the pump .................................................................. 46

Contents

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

3

2.4.4 Differential DFM installation scheme ............................................................ 48

2.5 Electrical connection ........................................................................................ 51

2.6 Fuel flow meter configuration ........................................................................... 54

2.6.1 Connecting DFM to PC................................................................................ 54

2.6.2 User interface ........................................................................................... 58

2.6.3 User authorization ..................................................................................... 59

2.6.4 Working with DFM profile ........................................................................... 60

2.6.5 Configuration for connection to external terminal unit .................................... 62

2.6.6 Operation check ........................................................................................ 63

2.6.7 Configuration for specific operation conditions .............................................. 64

3 Measurement accuracy check ................................................................................. 66

3.1 Test conditions ............................................................................................... 66

3.2 Conducting the tests ....................................................................................... 67

4 Accessories .......................................................................................................... 69

4.1 Mounting kits ................................................................................................. 69

4.2 Connecting cables ........................................................................................... 74

4.3 Additional accessories ...................................................................................... 75

4.4 DFM DA 250 deaerator .................................................................................... 77

5 Registered Events control ...................................................................................... 79

6 Diagnostics and troubleshooting ............................................................................. 80

7 Verification .......................................................................................................... 81

8 Maintenance ......................................................................................................... 82

9 Packaging ............................................................................................................ 83

10 Storage ............................................................................................................. 84

11 Transportation .................................................................................................... 85

12 Utilization/re-cycling ............................................................................................ 86

Contacts ................................................................................................................. 87

Annex A Overall dimensions and weight .................................................................... 88

Annex B Vehicle inspection report ............................................................................. 98

Annex C Template of check test report ...................................................................... 99

Annex D Register map of DFM output messages under Modbus protocol ....................... 100

Annex E DFM COM data transfer protocol .................................................................. 103

Annex F Signal cables ............................................................................................ 108

Annex G DFM CAN connection options ...................................................................... 109

Annex H SPN of DFM Functional Modules .................................................................. 113

Annex I DFM firmware upgrade ............................................................................... 122

Annex J Videos ...................................................................................................... 123

Revision history

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

4

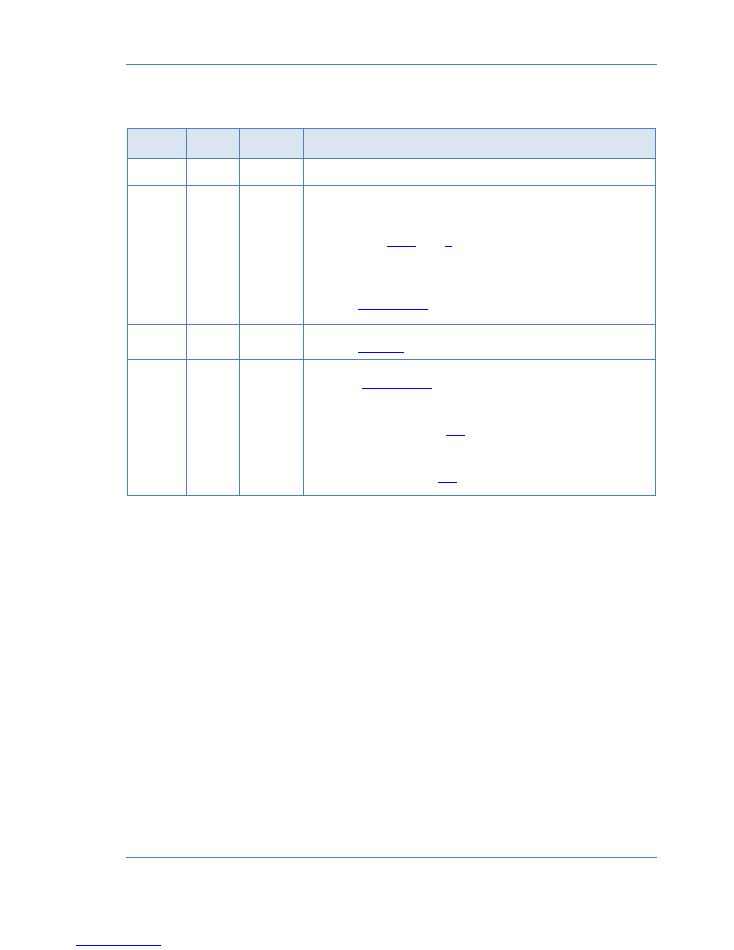

Revision history

Version

Date

Editor

Description of changes

1.0

01.2007

Basic version.

6.2

12.2016

OD

Concept of recommended re-calibration interval of DFM

is introduced. Re-calibration interval of DFM is defined

by volume of fuel went through measuring chamber of

DFM (see

1.6.3

and

8

).

Description of new version of flow meter available for

order is added - DFM 250 HP and DFM 500 HP charac-

terized

by

higher

fuel

consumption

rate

(see

Introduction

, figure 1).

6.3

01.2017

OD

DFM COM data transfer protocol updated

(see

annex E

, table E.5).

6.4

06.2017

OD

Clarifications in DFM order identification codes added

(see.

Introduction

, figure 1).

Table of measurement range and accuracy is divided in

two separate parts: for one-chamber and for differen-

tial flowmeters (see

1.4

).

General installation instructions are amended with de-

scription of symbols on DFM body for proper installation

into fuel lines (see

2.3

, figure 20).

Terms and Definitions

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

5

Terms and Definitions

ORF 4

— is the Telematics Service by Technoton developed for receiving and

processing Onboard Reports via Internet, displaying Operational Data

overlapped on area

maps, information storage in database and Analytical

Reports generation upon user’s request.

S6

— is the vehicle onboard data bus developed by

TECHNOTON

to enable

integrating the GPS/GLONASS-based vehicle monitoring system into the

vehicle electrical equipment. It comprises a set of cables, interfaces and

protocols. Physically, it is implemented on the basis of CAN 2.0B

(ISO 11898-1:2003) and K-Line (ISO 9141). S6 bus data exchange protocol

complies with SAE J1939 International Standard.

To get more details on S6 telematics bus visit

http://s6.jv-technoton.com/en/

PGN

(Parameter Group Number) — is a combined group of S6 parameters, which has com-

mon name and number. Functional Modules (FM) of the Unit can have input/output PGNs

and setup PGNs.

SPN

(Suspect Parameter Number) — informational unit of S6. Each SPN has determined

name, number, extension, data type and numerical value. The following types of SPN exist:

Parameters, Counters, Events. SPN can have a qualifier which allows qualification

of param-

eter’s value (e.g. – Onboard power supply limit/Minimum).

Analytical report

—

report generated in ORF4 on vehicle or group of vehicles operation for

chosen time period (usually a day, week or month). Can be composed of numbers, tables,

charts, mapped route of vehicle, diagrams.

Onboard equipment

(OE) — Telematics System Elements, directly installed in vehicle.

Onboard Reports

(the Reports) — iInformation about vehicle which is returned to a user of

Telematics System in accordance with inputted criteria. The Reports are generated by a

terminal unit both periodically (Periodic Reports) and on Event occurrence (Event Report).

GNSS

(Global Navigation Satellite System) — System for area positioning of an object

through satellite signal processing. GNSS is composed of space, ground and user segments.

Currently, there are several GNSSs: GPS (USA), GLONASS (Russia), Galileo (EU), Compass

(China).

Online monitoring

— remote monitoring of location and vehicle operation in real time, the

accumulation of information and preparation of Analytical Reports by requests of ORF 4

user.

Parameter

— vehicle’s characteristics varying over time or in space. E.g. hourly fuel con-

sumption, speed, fuel volume in tank, coordinates. The Parameter is usually depicted as a

chart and an average value.

Route

— data massive, consisting of coordinates, speed and direction of vehicle’s move-

ment. Corresponds to a real route of the vehicle. Depicted as lines on the Map. Direction of

vehicle’s movement is depicted by arrows.

Terms and Definitions

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

6

Server

— hardware and software combination of Telematics Service ORF 4, designed for

Operation Data processing and storage, also for generation and transfer of Analytical Re-

ports upon User’s request.

Event

—

relatively rare and sudden change in SPN. For example, the attempt to falsify val-

ues of ―Instant fuel consumption‖ counter by applying electromagnetic field to fuel flow me-

ter will be recognized as ―Interference‖ Event. An Event can have one or several character-

istics. ―Interference‖ Event has the following: date/time and duration of interference. When

the Event occurs, a terminal unit registers the time of occurrence, which is later mentioned

in a report on the event. Thus, the Event is always attached to exact time and place of oc-

currence.

Counter

—

cumulative numerical characteristics of Parameter. Counter is represented by a

number, which can only grow in time. Examples of Counters: fuel consumption, engine op-

eration time, total distance and other.

Telematics system

— complex solution for real-time and after trip vehicle monitoring and

control. Main vehicle parameters monitored: route, fuel consumption, operation time, tech-

nical condition of vehicle, safety. Consists of OE, Communication channels, Telematics Ser-

vice ORF 4.

Vehicle

— an object controlled within Telematic system. Usually Vehicle means a truck,

tractor or bus, sometimes a locomotive or river boat. From Telematic system point of view,

stationary objects are also considered to be vehicles: diesel gensets, stationary tanks,

boilers/burners.

Function Module

(FM) — unit-embedded component of hardware and software combination,

executing a group of special functions. Uses input/output PGNs and settings PGNs.

Unit

— an element of Onboard Equipment of Vehicle, which is connected to Telematics In-

terface S6. Particularly, in this document Unit means DFM fuel flow meter.

Introduction

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

7

Introduction

The Operation Manual contains guidelines and rules which refer to

DFM fuel flow meters

(hereinafter

DFM

), developed by JV

Technoton

, Minsk, Belarus.

The manual contains information on design, operation principle, specifications and

instructions on installation, use and maintenance of DFM. The manual provides guidelines

on DFM configuration with

Service S6 DFM

software (version 1.11 and higher).

— is a precise tool for fuel consumption measurement. DFM can be

as a part of

Teleamtic System

or as stand-alone solution.

DFM features:

conformity with European and national automotive standards and directives;

fuel consumption and operation time control – overall and in different engine opera-

tion modes;

protection against unauthorized interference in operation and data ―tampering‖;

maximum information richness of output data

*

;

high reliability of data transmission over digital interfaces

*

;

unique self-diagnostics feature to monitor the stability and accuracy of data

*

;

possibility of integration into on-board

Telematics Interface

of vehicles

**

;

embedded battery allows data (

Counters

,

Events

) storage in the internal non-volatile

memory of flow meter;

thermal correction function with adjustable coefficient which ensures automatic cor-

rection of values to the ambient temperature

***

;

easiness of flow meter configuration with S6 SK service kit, which is similar for all

Onboard Equipment based on S6 Interface

***

;

built-in mud filter;

minimum fluid flow resistance;

100 % of DFM are verified with a certified metrological test rig;

full set of high-quality elements for installation;

great operating experience, high-quality technical support, affordable price.

*

DFM 232/485/CAN.

**

DFM CAN.

***

For DFM with interface cable.

Introduction

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

8

See figure 1 for identification codes for

DFM

ordering:

Figure 1 — DFM order identification codes

Example of DFM order identification codes:

―Fuel flow meter DFM 50B‖

(max. flow rate 50 l/h, model - autonomous with display)

―Fuel flow meter DFM 250 AK, 0.5 %‖

(max. flow rate 250 l/h, model - without display, output interface – normalized pulse, in-

creased measurement accuracy, inaccuracy is ±0.5%)

―Fuel flow meter DFM 500DK HP‖

(max. flow rate 600 l/h, model - differential without display, output interface – normalized

pulse, higher maximum consumption rate)

―Fuel flow meter DFM 500CD‖

(max. flow rate 500 l/h, model - differential autonomous with display)

―Fuel flow meter DFM 500CCAN‖

(max. flow rate 500 l/h, model - differential with display, output interface – CAN 2.0B)

* A

symbol is not specified for differential fuel flow meters.

**

For autonomous fuel flow meters

Z

version is not used.

***

This version is delivered upon special order. Designation

U

is available only for

one-chamber flowmeters, designation

P

— only for differential DFM flowmeters.

Introduction

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

9

For DFM fuel flow meter with output interface configuration a service kit is used (S6 SK or

SK DFM), which is ordered additionally, and software

Service S6 DFM

. You can download

and/or update your Service DFM software at

http://www.jv-technoton.com/

, in

Software/Firmware

category.

ATTENTION:

It is strongly recommended to follow strictly the instructions of the

present Manual when using, mounting or maintaining DFM.

The Manufacturer guarantees DFM compliance with the requirements of technical

regulations subject to the conditions of storage, transportation and operation set out in this

Manual.

ATTENTION:

Manufacturer reserves the right to modify DFM specifications that do

not lead to a deterioration of the consumer qualities without prior customer notice.

DFM general information and technical specifications / Purpose of use and application area

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

10

1 DFM general information and technical

specifications

1.1 Purpose of use and application area

f

low meters are designed for fuel consumption measurement

directly in fuel line of vehicles and stationary engines.

Figure 2 — DFM puprose of application

Application area

— DFM fuel flow meters are used both as a part of

Telematics

System

and as a stand-alone solution (

see figure 3)

.

a) within GPS/GLONASS vehicle telematics system

DFM general information and technical specifications / Purpose of use and application area

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

11

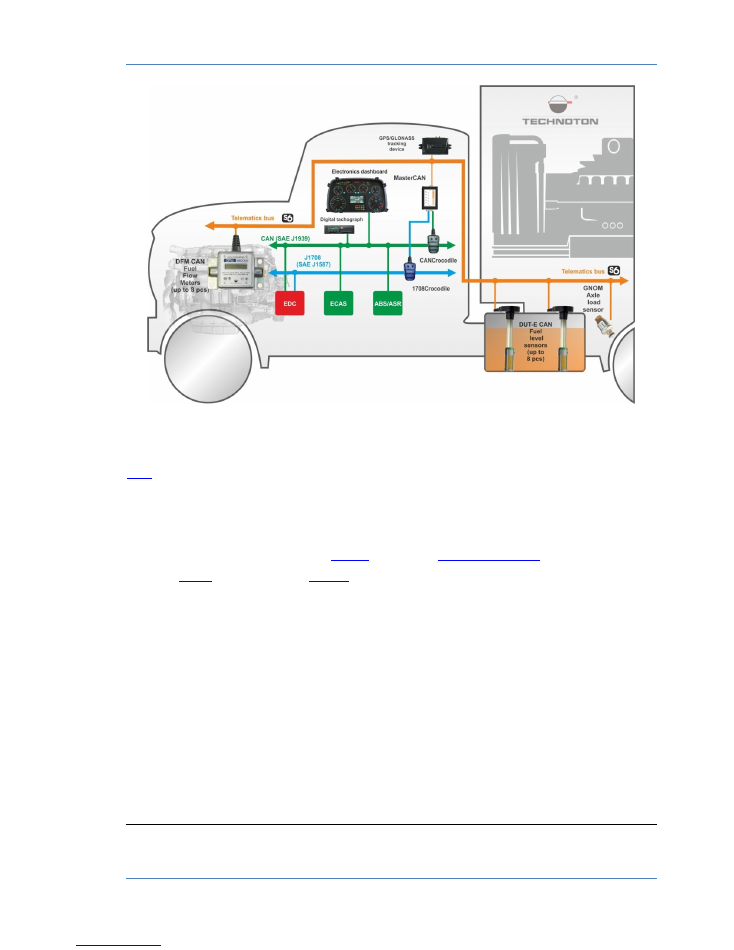

b) within S6 Telematics Interface

*

Figure 3 — DFM examples of application

DFM

are mounted into fuel supply line of the vehicle engine. DFM measure actual (instant)

fuel consumption rate and generates an output signal to forward it to a vehicle tracking

device (see figure 3 a)

.

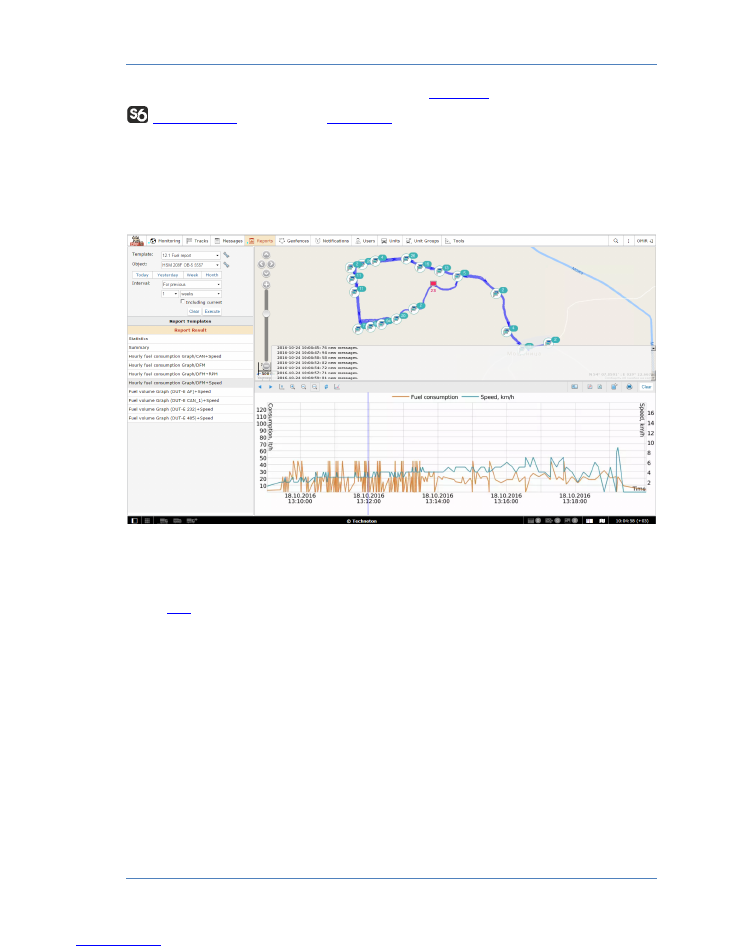

Terminal unit gathers, registers, stores received signals and transfers them to telematic

Server. Software installed on the

Server

generates

Analytical reports

, which allow time-

related

Route

control and

Vehicle

fuel consumption monitoring via web-browser

(

see Figure 4

).

DFM with pulse output

interface

provide data on actual fuel consumption of engine

(overall fuel consumption and average instant fuel consumption)

DFM with digital output interface

provide real-time control over extended set of infor-

mation:

instant fuel consumption;

engine operation time – overall and in different engine operation modes;

fuel consumption – overall and in different engine operation modes;

voltage in on-board power network;

total operation time of flow meter and duration of power-supply from embedded

battery;

flow meter’s malfunctions;

evidence of interference to flow meter’s operation.

*

Only for DFM CAN.

DFM general information and technical specifications / Purpose of use and application area

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

12

Using J1939 output protocol makes possible

DFM CAN

operation as a part of

telematics bus

together with

DUT-E CAN

fuel level sensors and other factory-built or

additional equipment (see figure 3 b). Tracking device with a single CAN interface port can

receive data from up to 8 DUT-E CAN sensors and up to 8 DFM CAN meters. This possibility

is especially useful while Vehicles with several engines (river boats, locomotives,

technological vehicles, diesel genset stations) are equipped.

Figure 4 — Example of Analytical Report generated in ORF 4 sofware,

based on the DFM CAN data

Use of

DFM

provides vehicle owners with the following:

actual fuel consumption records;

registration of machinery working time;

normalizing of fuel consumption quotas;

fuel theft detection and prevention;

real-time monitoring and fuel consumption optimization;

fuel consumption tests for engines.

DFM general information and technical specifications / Exterior view and delivery set

DFM fuel flow meters. Operation manual. Version 6.4

© Technoton, 2017

13

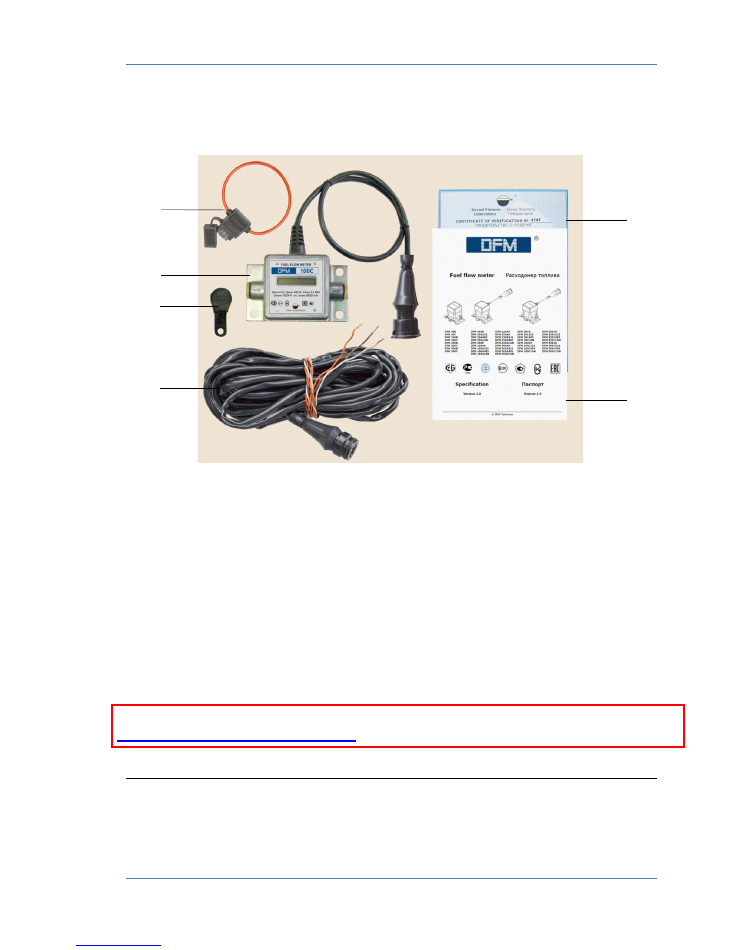

1.2 Exterior view and delivery set

1

DFM fuel flow meter

– 1 pc;

2

iButton key

*

– 1 pc;

3

fuse with holder (2 A)

**

– 1 pc;

4

7.5m connection cable CABLE DFM 98.20.003 (7.5 m)

***

– 1 pc;

5

Verification certificate

– 1 pc;

6

Specification

– 1 pc.

Figure 5 — DFM delivery set

*

For DFM meters with built-in display.

**

Not applicable for autonomous DFM fuel flow meters.

***

Only for DFM meters with pulse interface output.

5

6

3

2

1

4

Download full version from Technoton Document center

http://docs.jv-technoton.com/