Full Text Searchable PDF User Manual

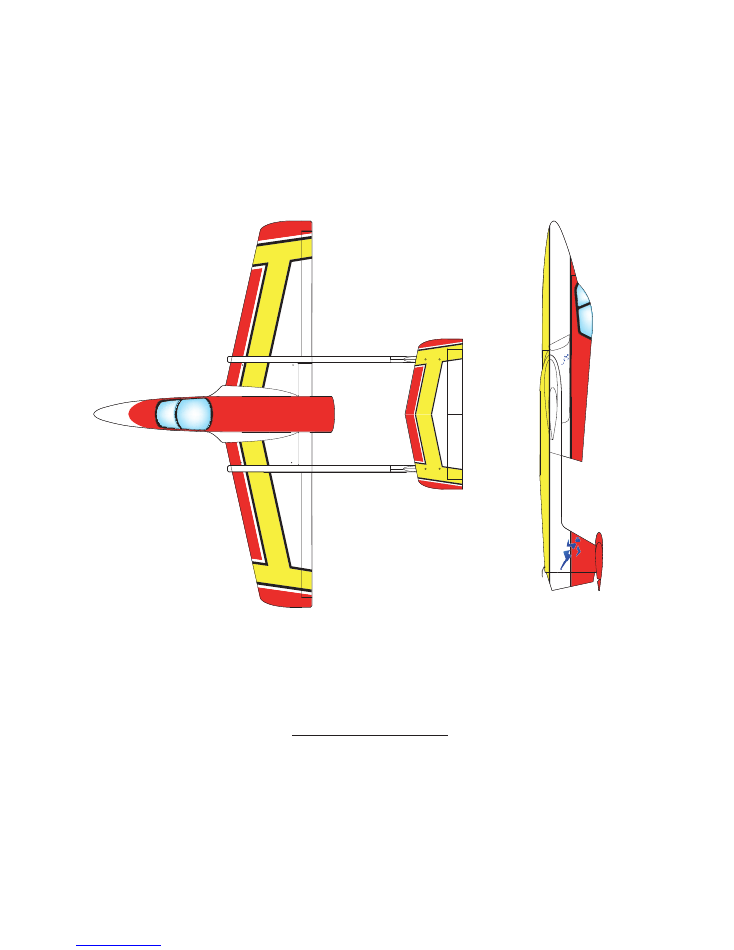

Wingspan........ 75.5" (1920mm)

Length............. 73" (1850 mm)

Weight 14lb.( 6.35kg ) Dry.

Radio....... 5 to 7 Channels.

Designer Alan Cardash

Boomerang RC Jets,

LLC

.

Website www.boomerang

-RC-

jets.com

SPRINT

Boomerang

Aerobatic Sport / Trainer Jet for 12 to 22 Lb. Thrust turbines

Almost ready to fly. Speed range from 18 to 150 MPH.

SAFETY PRECAUTIONS

The SPRINT turbine model is designed for experienced modellers. This model is not

recommended for beginners to R/C flying and should not be attempted by those with insuf-

ficient building and flying experience. This manual is for guidance only. If you are unsure of

any model building techniques, seek help from an experienced model builder or contact

Boomerang

RC

Jets

LLC

.

for assistance. Jet models are dangerous if construction

is carelessly or incorrectly carried out. As the building assembly of this kit is out of our

control after point of sale, no liability is accepted by

Boomerang RC Jets LLC

.

for any

accident or loss, however caused. Purchase of this kit implies acceptance of these condi-

tions by the purchaser. To decline these terms, return the unused kit to your supplier for full

refund.

S

P

R

I

N

T

Boomerang

S

P

R

I

N

T

3

1

2

3

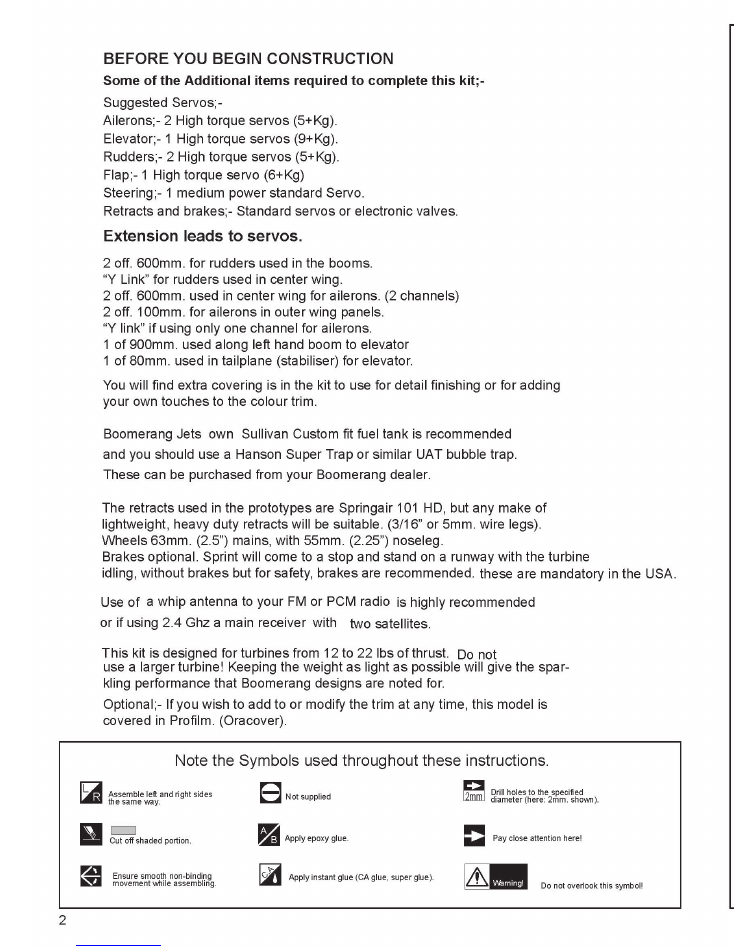

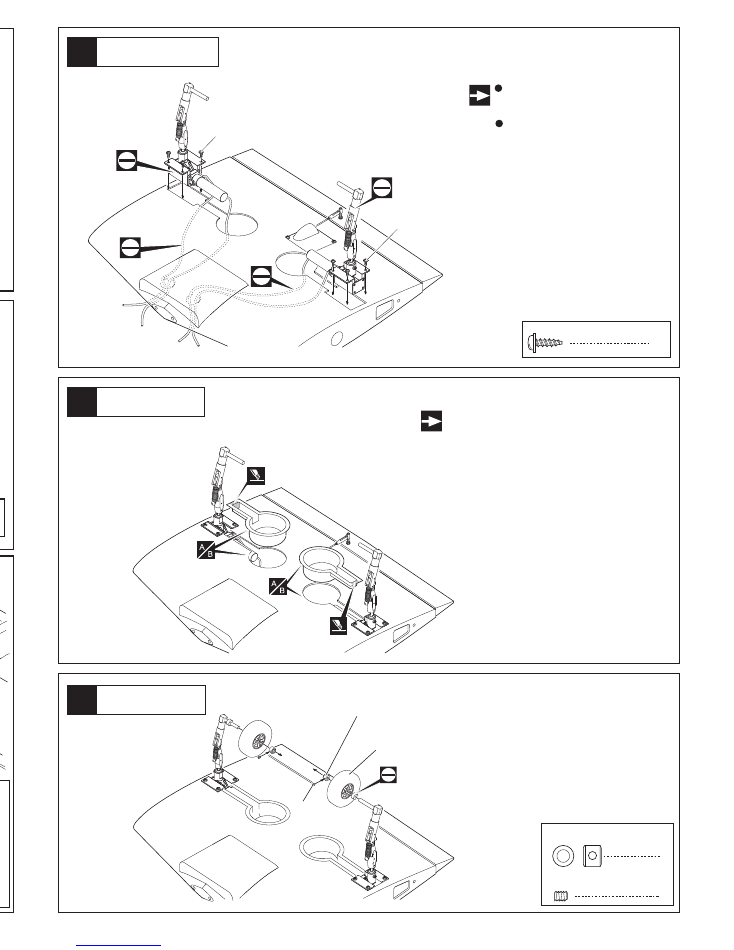

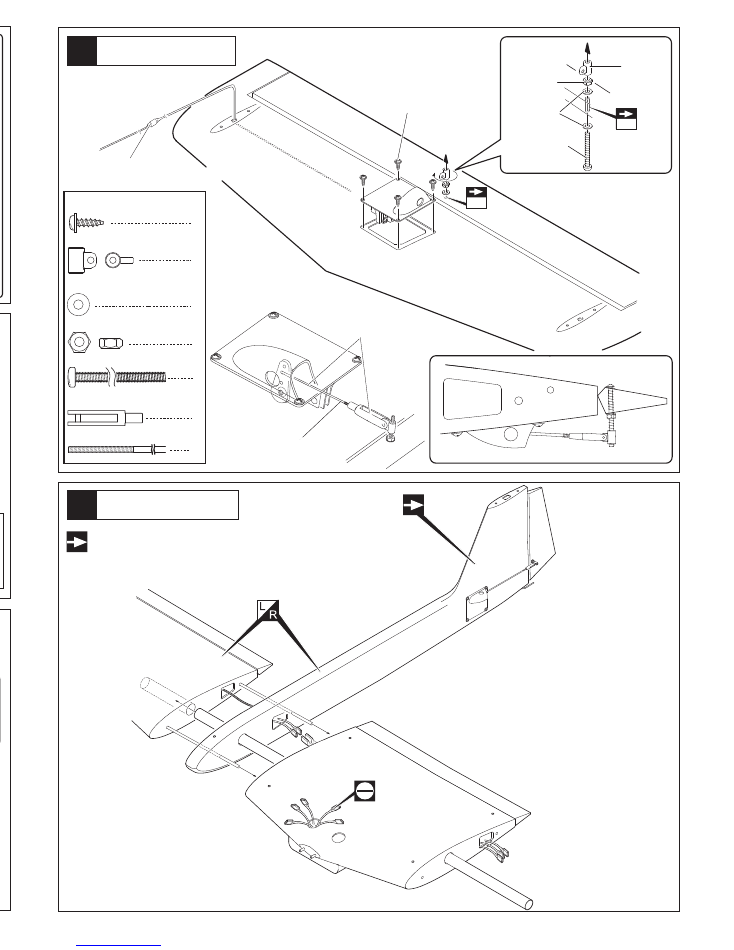

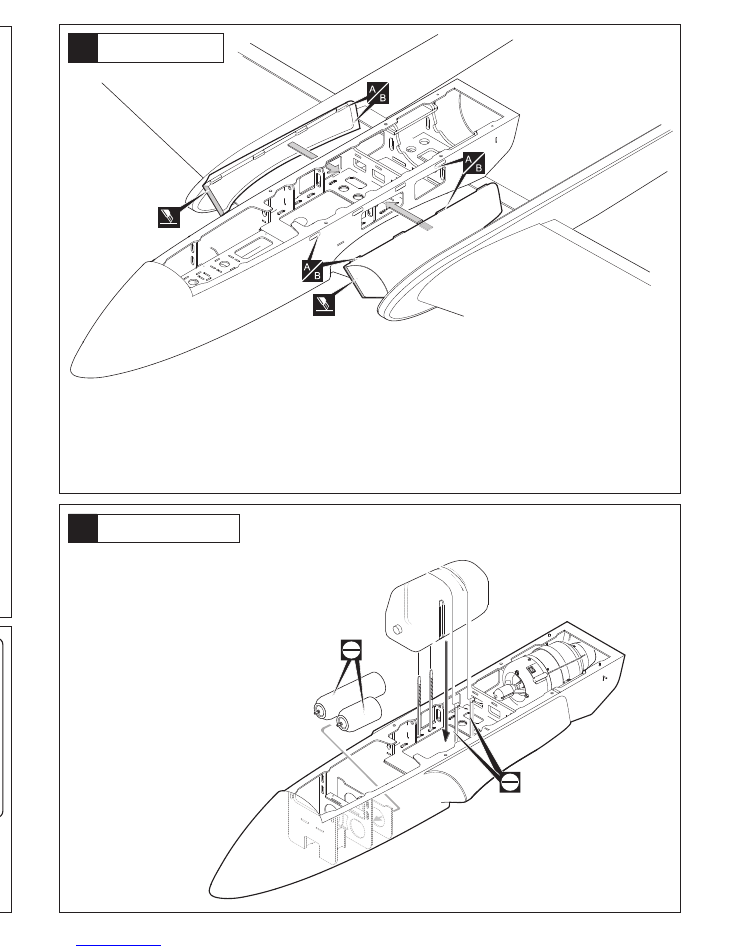

Centre Wing

2.6 x12mm Screws

1

2 x 200mm

Pushrod

1

Clevis

4

Self-adhesive

Self-adhesive

Self-adhesive

Open the holes for

access to the wing

fixing bolts then apply

the self adhesive

rings.

Warning!

Cut away covering film.

Not supplied

Be sure to glue securely.

This is Vital for safe flying!

Apply thin Cyano glue to both

sides of hinges to ensure good

penetration.

Typical Servo Mount

Flap Servo Installation

14

29

30

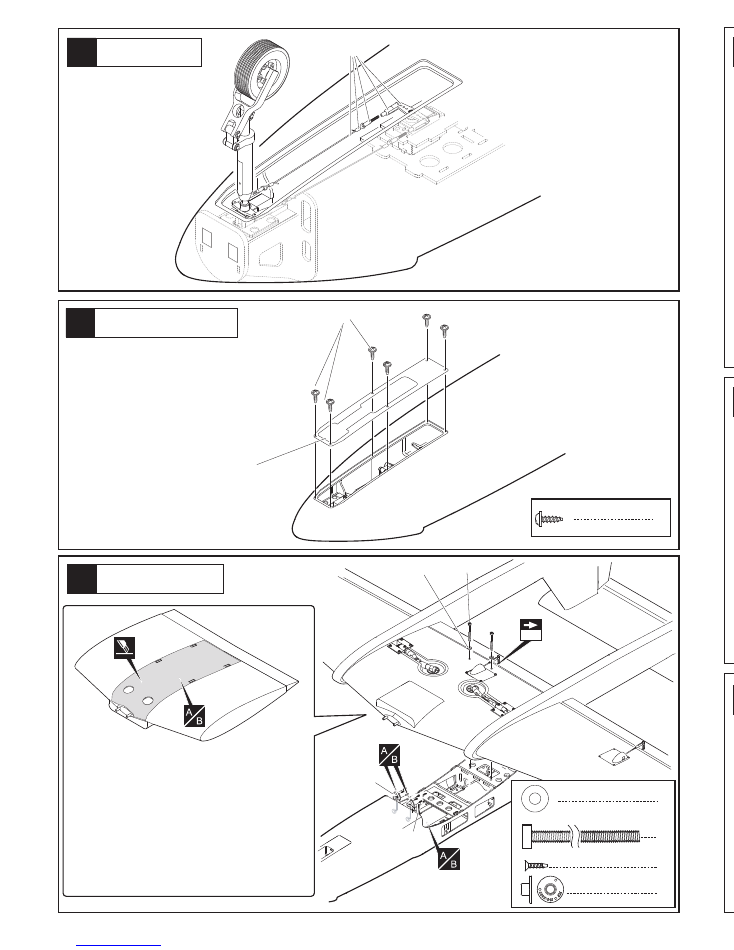

Check Hatch fit

Canopy fix

1

Aluminum tube

Aluminum tube

Drill to suit your servos.

Not supplied

Not supplied

2.6 x12mm

TP Screw

Cut away covering film.

For Main Landing Gear

3mm

3mm

3mm Nut

3mm Washer

4

2.6 x12mm TP Screw

1

1

2

1

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm Horn

3 x 50mm Bolt

31

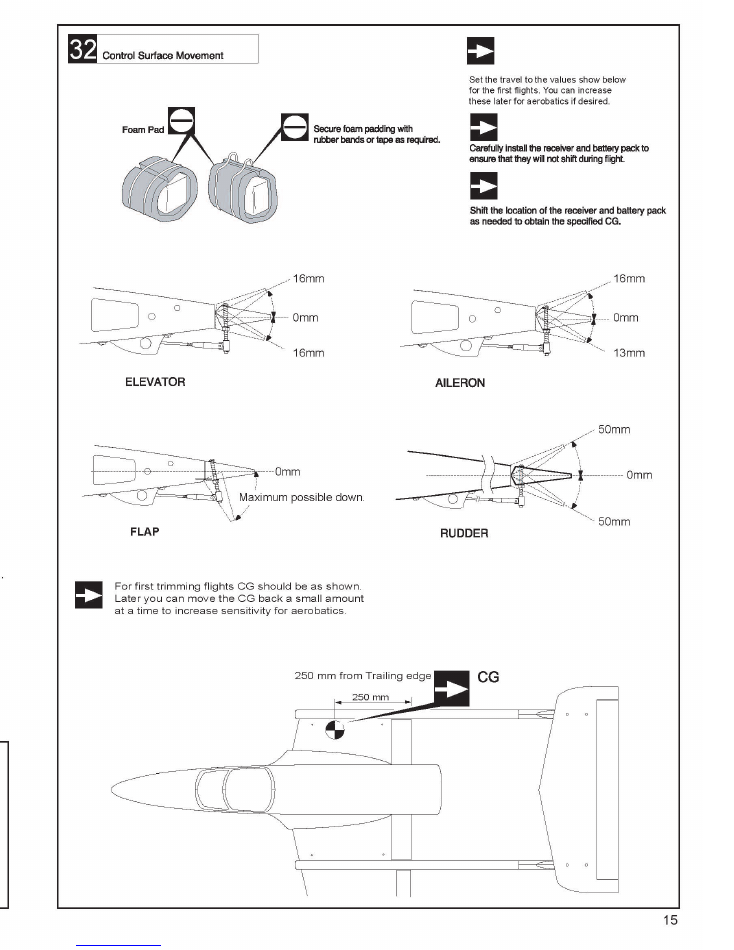

Decals

84

9

U.

S.

AI

R

FO

RC

E

SP

RI

NT

12

84

9

U.S

.A

IR

FO

RC

E

SP

RIN

T

128

49

84

9

849

USAF

USAF

USAF

S

P

R

I

N

T

Boo

m

e

r

a

ng

S

P

R

I

N

T

S

P

R

I

N

T

Boo

m

e

r

a

ng

S

P

R

I

N

T

Boomerang S

P

R

I

N

T

S

P

R

I

N

T

Trim the hatch latch and if necessary adjust

the front peg to achieve a good sliding fit.

A small smear of grease

on the slots & alloy

buttons

will help the hatch to slide easily

into place.

4

4

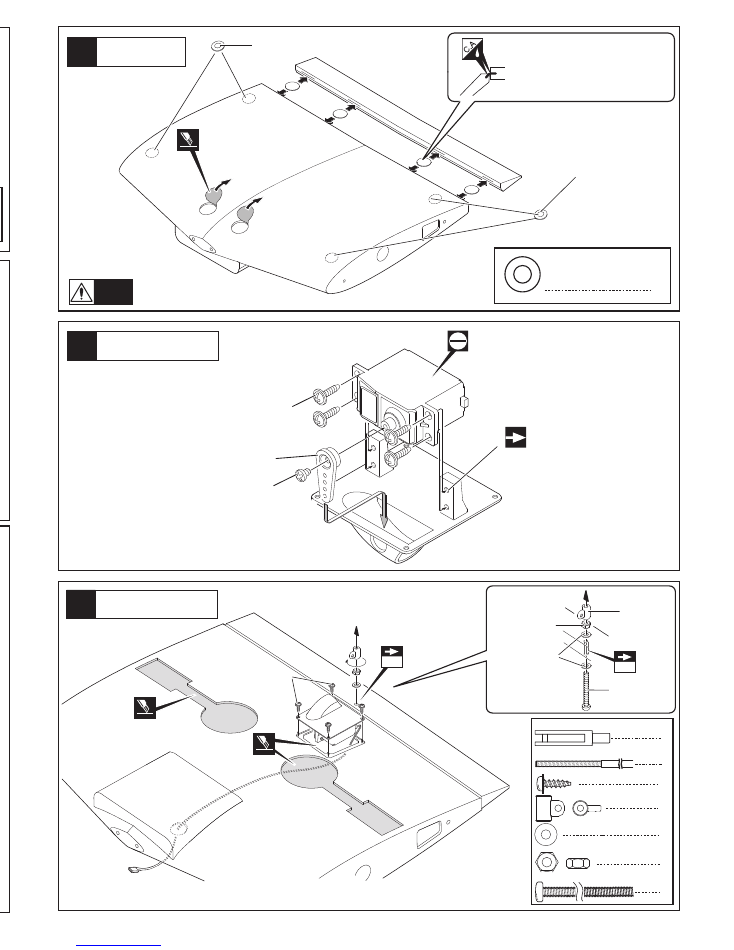

To Make the Pushrods to the length required;-

(1)

Make a 90 degree bend in the wire at the length required

to meet the output hole in the servo arm with the servo

centred.

(2) Now make a second bend off at 90 degrees to the first one,

left or right, in the wire at approx. 3mm away from the first

bend.

(3) Straighten the wire by gripping each side of the “Z” bend

with pliers and slowly turning until the ends are in line. Now

cut off the excess wire. The output hole in the servo arm

may have to be drilled out to accommodate the “Z” bend

wire passing through it. Adjustment of the pushrod length

is carried out by adjusting the clevis along the threaded

part of the pushrod.

An extra pushrod is supplied to allow for possible error.

13

28

27

Fuel Tank etc

Pushrods

Cut

90

90

90

5

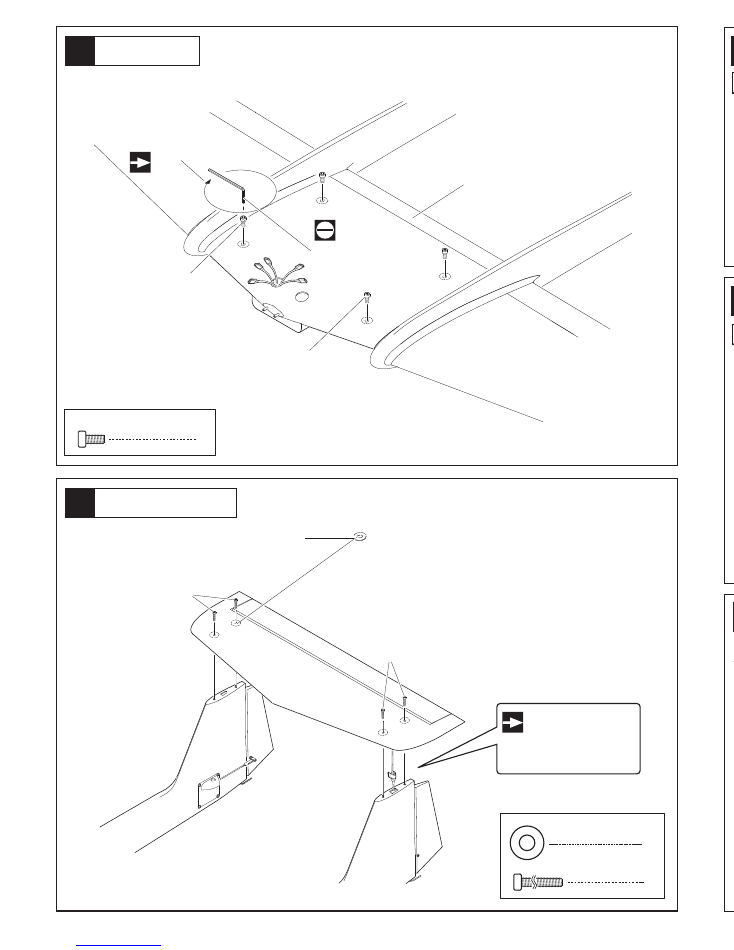

Flap control

Note hinge position and the control horn

Rearward to allow maximum 90 degree

downward movement for the flap.

Assemble left and right sides

the same way.

2mm.pushrods and clevises (Supplied)

Supplied

Fix with silicon sealant.

Air Intakes

Cut away covering film.

Cut away covering film.

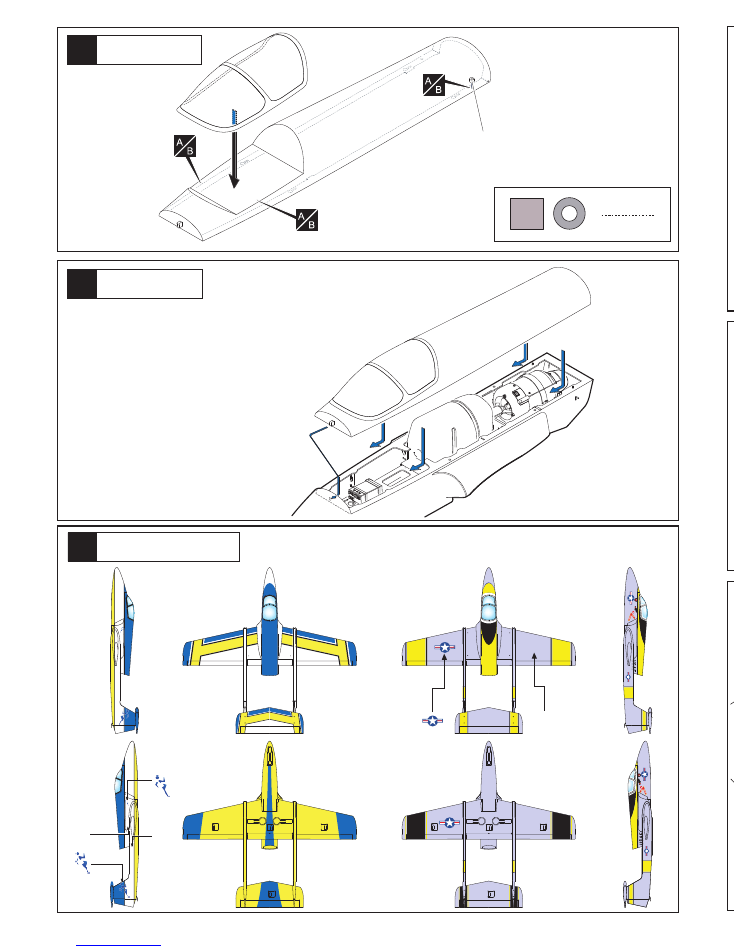

A custom Sullivan 3.7 litre fuel tank made for this kit is

available from your Boomerang Jets dealer. Otherwise it

is possible to fit any container from 2 litres up by

modifying the fuselage formers as required. Ensure that

the tank is well secured by using long cable tie wraps

through the formers. Do not simply depend on the tank

bay floor for this. A full tank of fuel weighs anything up to

8 Lbs (4 Kilos) and in a negative G manoeuvre can exert

considerable upward pull.

Clean up the front opening of the air intakes as necessary. After carefully

stripping away covering from the small cutouts in the upper fuselage use

the air intakes as a guide to how much covering to remove from each side

of the fuselage, opening up the airflow openings each side and leaving a

bare wood gluing surface just a few mm. smaller than the intakes all round

ready to fix the intakes using thick CA glue. In addition the “FOD” protective

mesh supplied can be added to the inside openings of all the intakes to

prevent debris being sucked in by the turbine while running at high RPM.

As with all turbine models, it is important to prevent this if you are flying

from dusty or gritty surfaces.

5

7

8

6

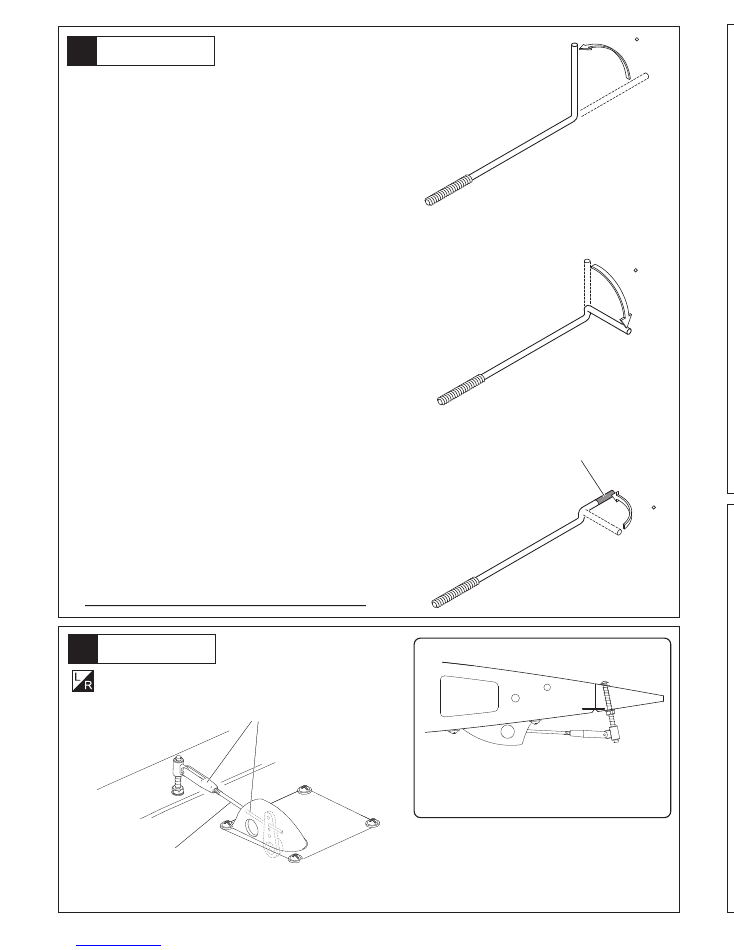

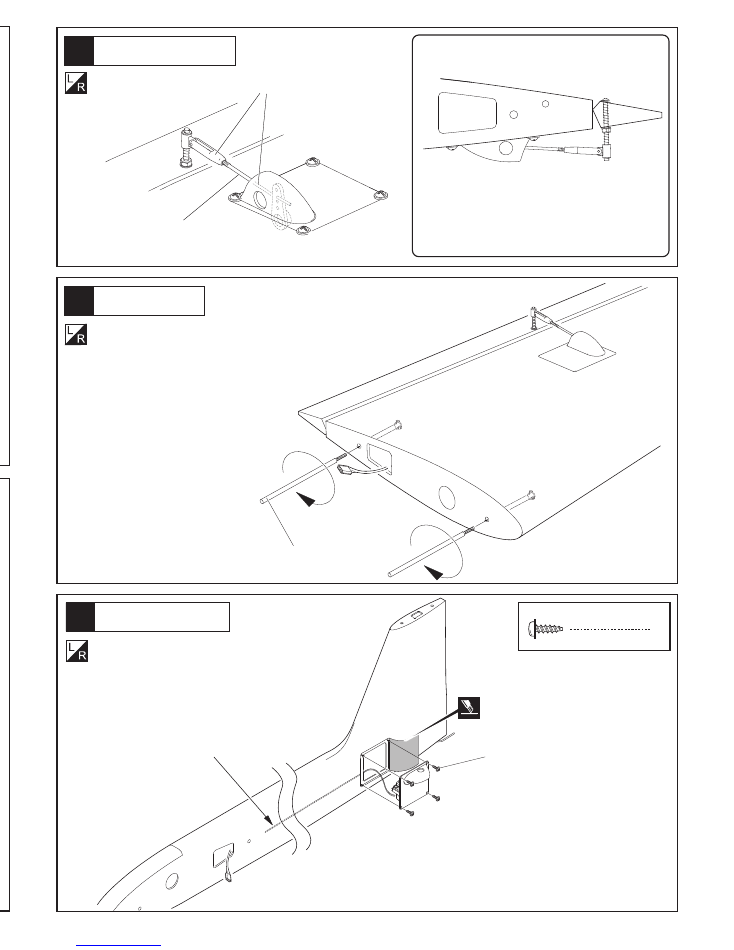

Main Landing Gear

Main Landing Gear

2

2

5.2mm Collar

3 x 4mm grub Screw

12

26

24

25

6

2 x 8mm TP Screw

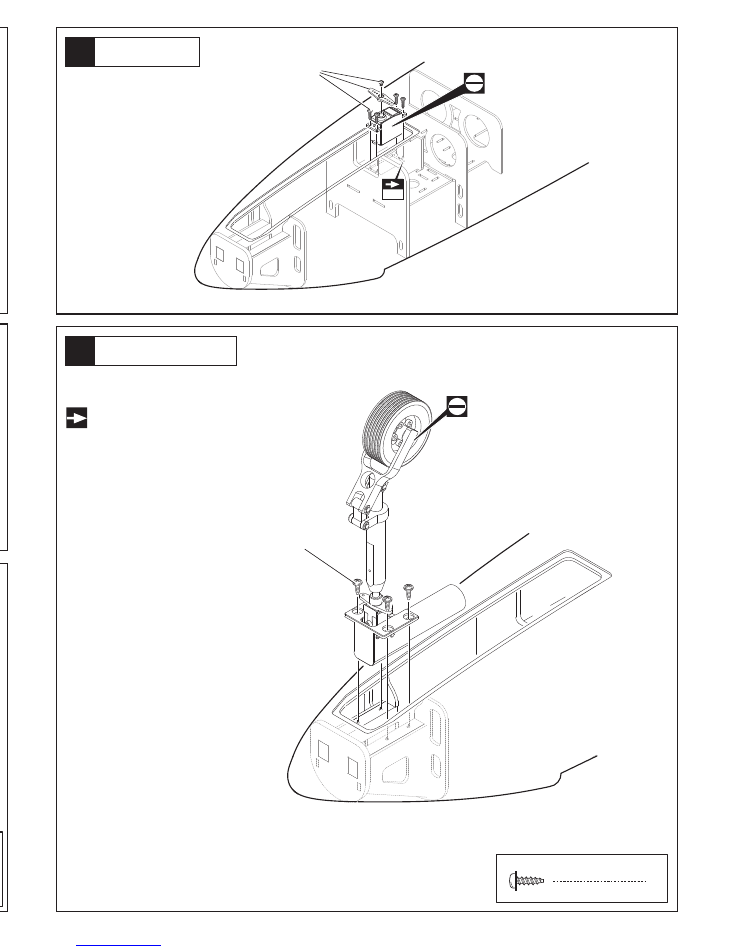

Noseleg

Noseleg Cover Plate

2.6 x12mm

TP Screw

16

2.6 x12mm TP Screw

2.6 x12mm

TP Screw

Requires some modification

on main gear cover.

For Retractable landing gear

.

Not Supplied.

Not Supplied.

Not Supplied.

Main Landing Gear

Cut off shaded portion.

The main leg retracts should

be fitted about ½” inboard of

the centre wing tip.

2 x 8mm TP Screw

Trim the cover plate as required.

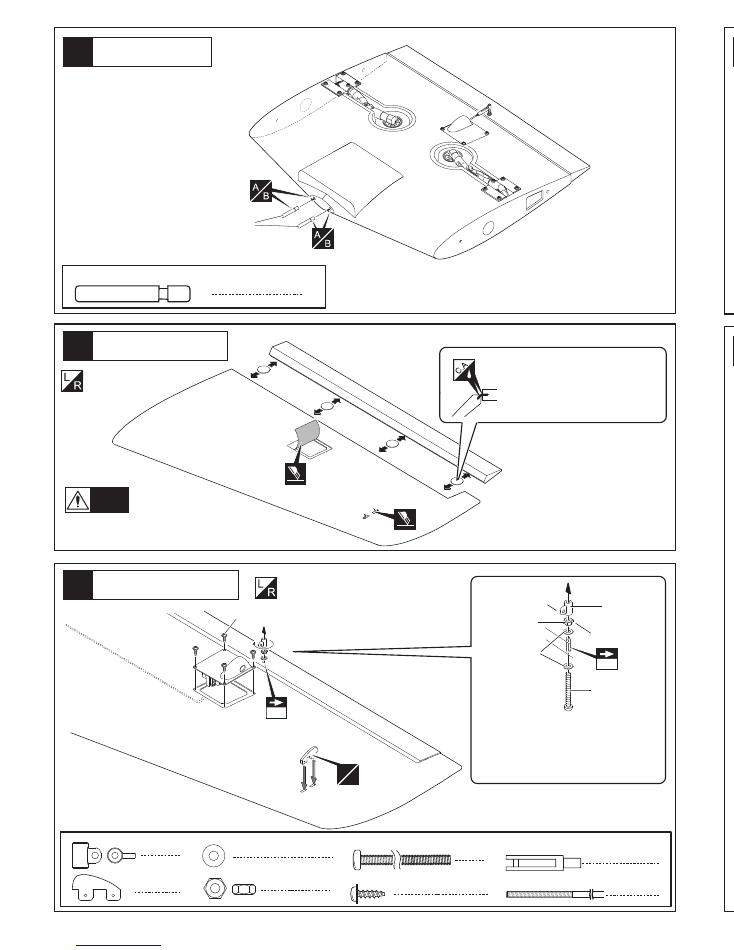

Fuselage/Wing joining

4mm

4mm Washer

4 x 50mm Bolt

NO:1007

2x8mm Screw

2

2

4 x 50mm Bolt

4mm Washer

2

NO:1007

2x8mm Screw

6

Cut away the covering from the slots on top of the centre wing. Place

the fuselage wing seat tabs into the slots. Mark the wingtop covering

along each side where the fuselage sits on the wing. Remove the

fuselage and carefully cut through the covering without damaging the

balsa abd strip off the the film between the marks you have made.

Now strip the covering carefully from the underside edge only of the

fuselage wing seat. Before finally gluing the wing to the fuselage, drill

and inset the alloy dowels to the front of the wing,. These will slip into

the parts No. 1007 supplied which should be epoxied to the former

using these dowels to adjust their position. Drill a 4mm hole through

the wing and plywood plate in the fuselage near the trailing edge and

fit the blind nuts on the topside of the ply. When satisfied with the fit,

epoxy the fuselage to the wing and tighten the bolts moderately with

washers to give a strong wing fix. The wing is not designed to be

removable.

Cut off shaded portion.

55mm

5.2mm Collar

3 x 4mm

grub Screw

For Retractable landing gear

Not Supplied.

NOTE;

Do not fix plastic wheel wells until the

servo wires and air lines are in place.

Level off the surface around the retract units.

The height of the landing gear should be

approximately as follows;

Noseleg 11cms. and mains 12cms.

from underside surfaces to the wheel axles.

Not Supplied.

6

10

11

9

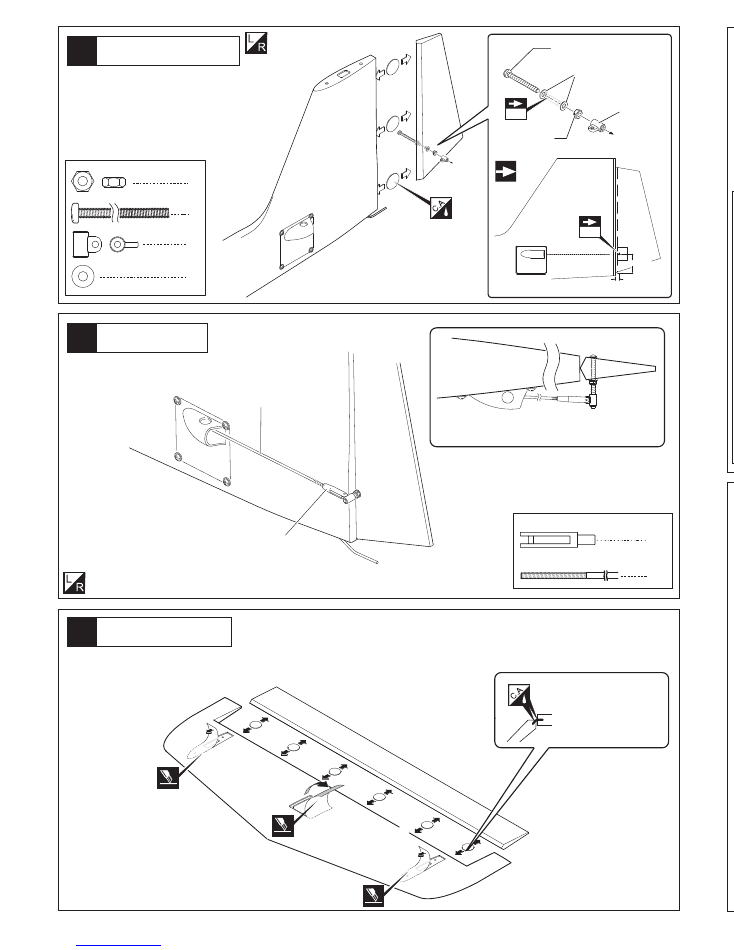

Aileron Servo installation

Outer wing panel

Centre Wing

When cutting away the film,for

the servo mount leave a gener-

ous overhang to allow for the

strong shrinkage of the Profilm

(Orocover) when you finally iron

it back in place.

A

B

Assemble left and right sides

the same way.

Assemble left and right sides

the same way.

Be sure to apply instant type CA glue to

both sides of each hinges.

(low viscosity type)

Cut away covering film.

Warning!

2.6 x12mm TP Screw

Be sure to glue securely.

This is Vital for safe flying!

11

23

22

For Retractable landing gear.

Noseleg Servo

Noseleg Mounting

“Trim the Cover Plate to clear the leg.”

8

2.6 x12mm TP Screw

2

2 x 100mm

Pushrod

2

Clevis

The nose leg length adjusted to give a

degree or two negative incidence or slightly

nose down attitude when Intro is standing on

a level surface. This will be easily overcome

on take off by the elevator authority and will

also help to eliminate bounce on landing.

2

2

4

2

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

3mm

Apply thin cyano top and bottom and

immediately tighten the 3mm. nut to

prevent the 3mm. bolt rotating.

2

Aluminium joiner

6 x 40mm

Aluminium joiners

6 x 40mm

Not Supplied.

Not Supplied.

2mm

Not Supplied.

4

2.6 x12mm TP Screw

2.6 x12mm TP Screw

2

Cut away part of the former at the

rear of the rails to allow the retract

unit steering arms to drop cleanly aft

of the retract mounting rails.

7

14

Rudder Servo installation

Cut away covering film.

8

2.6 x12mm TP Screw

2.6 x12mm TP Screw

Assemble left and right sides

the same way.

500mm. servo extension wires to rudder

servos in both booms. Alos 700mm.

extension wires to Elevator Servo in

Left hand boom only .(not supplied)

10

21

20

In order to save weight at the tail end, you

can use “Midi” servos for the rudders. If you

do this make up 6mm (1/4”) liteply plates to

raise the smaller servos and reduce the

standard spacing of the servo mountings

supplied. Remember to allow for the shrink-

age of the covering when cutting away for

the servo mounts.

Tail Assembly

3 x 20mm Bolt

4

3 x 20mm Bolt

3 x 20mm Bolt

Decrease size of top

exit hole after wires

are through to prevent

the connector falling

inside the fin.

Self-adhesive

4

Self-adhesive

13

12

Aileron Servo installation

Completed

Outer wing

Assemble left and right sides

the same way.

Assemble left and right sides

the same way.

2.5mm Hex Wrench

Lock

3 x 10mm Bolt

4

3x10mm Bolt

3x10mm Bolt

Wing Top

Wing Locking

3mm.(or 4/40)pushrods

and clevises (Supplied)

Supplied

8x285mm

Screw in the 8 X 285 mm alloy rods.

8

16

17

15

Rudder installation

Assemble left and right sides

the same way

Assemble left and right sides

the same way.

Rudder installation

9

19

18

Elevator Servo installation

Assemble left and right sides

the same way.

Right sides

Final Assembly

The tailskids are designed to swivel freely.

2

2 x 200mm Pushrod

2

Clevis

2

2

4

2

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

3mm

14mm

54mm

Completed

Apply thin Cyano to the 3 x 50mm.

Bolt after pushing it through the control

surface, and immediately tighten the nut

to prevent rotation.

3mm. or 4/40 pushrod and

clevises (supplied).

supplied

Completed

4

2.6 x12mm TP Screw

1

1

2

1

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

2.6 x12mm TP

Screw

3mm

Apply thin Cyano to the 3 x 50mm.

Bolt after pushing it through the control

surface, and immediately tighten the nut

to prevent rotation.

Supplied

3mm.(or 4/40)pushrods

and clevises (Supplied)

1

2 x 200mm Pushrod

1

Clevis

Tailplane/Stab

Be sure to apply instant

type CA glue to both

sides of each hinges.

(low viscosity type)

Cut away covering film.

Extension lead

1.5 metres (along booms to elevators)

Right boom shown.

Adjusting the Carbon Fibre Spars.

If it is necessary to adjust the fit of the C/F spars within the wings,

apply the Heatshrink supplied to the spars as shown.

The spars should be “snug”,but not tight.

Cut away the plywood

stays across the

fuselage and the hatch

where they are marked.

These are for packing

only, not structural to

the airframe.

Lightly iron the covering through a cloth with a warm iron before cutting away

covering film for the servo mount. Leave 3mm overhang all round the servo mounts

as per the wings.

8

16

17

15

Rudder installation

Assemble left and right sides

the same way

Assemble left and right sides

the same way.

Rudder installation

9

19

18

Elevator Servo installation

Assemble left and right sides

the same way.

Right sides

Final Assembly

The tailskids are designed to swivel freely.

2

2 x 200mm Pushrod

2

Clevis

2

2

4

2

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

3mm

14mm

54mm

Completed

Apply thin Cyano to the 3 x 50mm.

Bolt after pushing it through the control

surface, and immediately tighten the nut

to prevent rotation.

3mm. or 4/40 pushrod and

clevises (supplied).

supplied

Completed

4

2.6 x12mm TP Screw

1

1

2

1

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

2.6 x12mm TP

Screw

3mm

Apply thin Cyano to the 3 x 50mm.

Bolt after pushing it through the control

surface, and immediately tighten the nut

to prevent rotation.

Supplied

3mm.(or 4/40)pushrods

and clevises (Supplied)

1

2 x 200mm Pushrod

1

Clevis

Tailplane/Stab

Be sure to apply instant

type CA glue to both

sides of each hinges.

(low viscosity type)

Cut away covering film.

Extension lead

1.5 metres (along booms to elevators)

Right boom shown.

Adjusting the Carbon Fibre Spars.

If it is necessary to adjust the fit of the C/F spars within the wings,

apply the Heatshrink supplied to the spars as shown.

The spars should be “snug”,but not tight.

Cut away the plywood

stays across the

fuselage and the hatch

where they are marked.

These are for packing

only, not structural to

the airframe.

Lightly iron the covering through a cloth with a warm iron before cutting away

covering film for the servo mount. Leave 3mm overhang all round the servo mounts

as per the wings.

7

14

Rudder Servo installation

Cut away covering film.

8

2.6 x12mm TP Screw

2.6 x12mm TP Screw

Assemble left and right sides

the same way.

500mm. servo extension wires to rudder

servos in both booms. Alos 700mm.

extension wires to Elevator Servo in

Left hand boom only .(not supplied)

10

21

20

In order to save weight at the tail end, you

can use “Midi” servos for the rudders. If you

do this make up 6mm (1/4”) liteply plates to

raise the smaller servos and reduce the

standard spacing of the servo mountings

supplied. Remember to allow for the shrink-

age of the covering when cutting away for

the servo mounts.

Tail Assembly

3 x 20mm Bolt

4

3 x 20mm Bolt

3 x 20mm Bolt

Decrease size of top

exit hole after wires

are through to prevent

the connector falling

inside the fin.

Self-adhesive

4

Self-adhesive

13

12

Aileron Servo installation

Completed

Outer wing

Assemble left and right sides

the same way.

Assemble left and right sides

the same way.

2.5mm Hex Wrench

Lock

3 x 10mm Bolt

4

3x10mm Bolt

3x10mm Bolt

Wing Top

Wing Locking

3mm.(or 4/40)pushrods

and clevises (Supplied)

Supplied

8x285mm

Screw in the 8 X 285 mm alloy rods.

6

10

11

9

Aileron Servo installation

Outer wing panel

Centre Wing

When cutting away the film,for

the servo mount leave a gener-

ous overhang to allow for the

strong shrinkage of the Profilm

(Orocover) when you finally iron

it back in place.

A

B

Assemble left and right sides

the same way.

Assemble left and right sides

the same way.

Be sure to apply instant type CA glue to

both sides of each hinges.

(low viscosity type)

Cut away covering film.

Warning!

2.6 x12mm TP Screw

Be sure to glue securely.

This is Vital for safe flying!

11

23

22

For Retractable landing gear.

Noseleg Servo

Noseleg Mounting

“Trim the Cover Plate to clear the leg.”

8

2.6 x12mm TP Screw

2

2 x 100mm

Pushrod

2

Clevis

The nose leg length adjusted to give a

degree or two negative incidence or slightly

nose down attitude when Intro is standing on

a level surface. This will be easily overcome

on take off by the elevator authority and will

also help to eliminate bounce on landing.

2

2

4

2

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm

3mm Nut

3mm Washer

3mm Horn

3 x 50mm Bolt

3mm

Apply thin cyano top and bottom and

immediately tighten the 3mm. nut to

prevent the 3mm. bolt rotating.

2

Aluminium joiner

6 x 40mm

Aluminium joiners

6 x 40mm

Not Supplied.

Not Supplied.

2mm

Not Supplied.

4

2.6 x12mm TP Screw

2.6 x12mm TP Screw

2

Cut away part of the former at the

rear of the rails to allow the retract

unit steering arms to drop cleanly aft

of the retract mounting rails.

5

7

8

6

Main Landing Gear

Main Landing Gear

2

2

5.2mm Collar

3 x 4mm grub Screw

12

26

24

25

6

2 x 8mm TP Screw

Noseleg

Noseleg Cover Plate

2.6 x12mm

TP Screw

16

2.6 x12mm TP Screw

2.6 x12mm

TP Screw

Requires some modification

on main gear cover.

For Retractable landing gear

.

Not Supplied.

Not Supplied.

Not Supplied.

Main Landing Gear

Cut off shaded portion.

The main leg retracts should

be fitted about ½” inboard of

the centre wing tip.

2 x 8mm TP Screw

Trim the cover plate as required.

Fuselage/Wing joining

4mm

4mm Washer

4 x 50mm Bolt

NO:1007

2x8mm Screw

2

2

4 x 50mm Bolt

4mm Washer

2

NO:1007

2x8mm Screw

6

Cut away the covering from the slots on top of the centre wing. Place

the fuselage wing seat tabs into the slots. Mark the wingtop covering

along each side where the fuselage sits on the wing. Remove the

fuselage and carefully cut through the covering without damaging the

balsa abd strip off the the film between the marks you have made.

Now strip the covering carefully from the underside edge only of the

fuselage wing seat. Before finally gluing the wing to the fuselage, drill

and inset the alloy dowels to the front of the wing,. These will slip into

the parts No. 1007 supplied which should be epoxied to the former

using these dowels to adjust their position. Drill a 4mm hole through

the wing and plywood plate in the fuselage near the trailing edge and

fit the blind nuts on the topside of the ply. When satisfied with the fit,

epoxy the fuselage to the wing and tighten the bolts moderately with

washers to give a strong wing fix. The wing is not designed to be

removable.

Cut off shaded portion.

55mm

5.2mm Collar

3 x 4mm

grub Screw

For Retractable landing gear

Not Supplied.

NOTE;

Do not fix plastic wheel wells until the

servo wires and air lines are in place.

Level off the surface around the retract units.

The height of the landing gear should be

approximately as follows;

Noseleg 11cms. and mains 12cms.

from underside surfaces to the wheel axles.

Not Supplied.

4

4

To Make the Pushrods to the length required;-

(1)

Make a 90 degree bend in the wire at the length required

to meet the output hole in the servo arm with the servo

centred.

(2) Now make a second bend off at 90 degrees to the first one,

left or right, in the wire at approx. 3mm away from the first

bend.

(3) Straighten the wire by gripping each side of the “Z” bend

with pliers and slowly turning until the ends are in line. Now

cut off the excess wire. The output hole in the servo arm

may have to be drilled out to accommodate the “Z” bend

wire passing through it. Adjustment of the pushrod length

is carried out by adjusting the clevis along the threaded

part of the pushrod.

An extra pushrod is supplied to allow for possible error.

13

28

27

Fuel Tank etc

Pushrods

Cut

90

90

90

5

Flap control

Note hinge position and the control horn

Rearward to allow maximum 90 degree

downward movement for the flap.

Assemble left and right sides

the same way.

2mm.pushrods and clevises (Supplied)

Supplied

Air Intakes

Cut away covering film.

Cut away covering film.

A custom Sullivan 3.7 litre fuel tank made for this kit

is available from your Boomerang Jets dealer.

Otherwise it is possible to fit any container from 2

litres up by modifying the fuselage formers as

required. Ensure that the tank is well secured by

using long cable tie wraps through the formers. Do

not simply depend on the tank bay floor for this. A

full tank of fuel weighs anything up to 8 Lbs (4 Kilos)

and in a negative G manoeuvre can exert consider-

able upward pull.

Clean up the front opening of the air intakes as necessary. After carefully

stripping away covering film from the small cutouts in the supper fuselage use the

air intakes as a guide to how much covering to remove from each side of the

fuselage, opening up the airflow openings each side and leaving a bare wood

gluing surface just a few mm. smaller than the intakes all around ready to fix the

intakes using think CA glue. The air intake is glued to the fuselage only, not to the

wing.

3

1

2

3

Centre Wing

2.6 x12mm Screws

1

2 x 200mm

Pushrod

1

Clevis

4

Self-adhesive

Self-adhesive

Self-adhesive

Open the holes for

access to the wing

fixing bolts then apply

the self adhesive

rings.

Warning!

Cut away covering film.

Not supplied

Be sure to glue securely.

This is Vital for safe flying!

Apply thin Cyano glue to both

sides of hinges to ensure good

penetration.

Typical Servo Mount

Flap Servo Installation

14

29

30

Check Hatch fit

Canopy fix

1

Aluminum tube

Aluminum tube

Drill to suit your servos.

Not supplied

Not supplied

2.6 x12mm

TP Screw

Cut away covering film.

For Main Landing Gear

3mm

3mm

3mm Nut

3mm Washer

4

2.6 x12mm TP Screw

1

1

2

1

3 x 50mm Bolt

3mm Nut

3mm Washer

3mm Horn

3mm Horn

3 x 50mm Bolt

31

Decals

84

9

U.

S.

AI

R

FO

RC

E

SP

RI

NT

1

28

49

U.S

.A

IR

FO

RC

E

SP

RIN

T 1

284

9

84

9

849

USAF

USAF

USAF

S

P

R

I

N

T

Boo

m

e

r

a

ng

S

P

R

I

N

T

S

P

R

I

N

T

Boo

m

e

r

a

ng

S

P

R

I

N

T

Boomerang

S

P

R

I

N

T

S

P

R

I

N

T

Trim the hatch latch and if necessary adjust

the front peg to achieve a good sliding fit.

A small smear of grease

on the slots & alloy

buttons

will help the hatch to slide easily

into place.

Wingspan........ 75.5" (1920mm)

Length............. 73" (1850 mm)

Weight 14lb.( 6.35kg ) Dry.

Radio....... 5 to 7 Channels.

Designer Alan Cardash

E-Mail;-boomerangjets@aol.com

Website www.boomerangjets.com

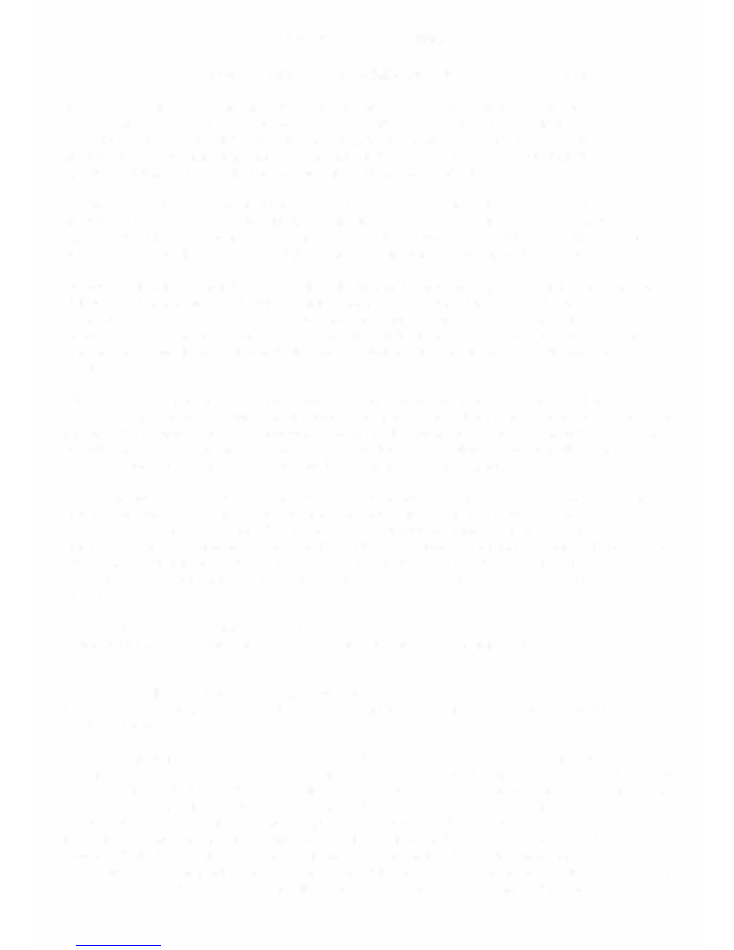

TRIMMING SET UP & FLYING NOTES

Boomerang SPRINT is not tricky or difficult to set up.

Set the Centre of Gravity no less than 10” (255 mm.) forward of the

Trailing Edge for the first flights.

Start with 5/8” up and ½” down Aileron (16 & 13 mm.). Elevators 5/8”

(16mm) up and down. Adjust later to your personal preferences.

The flap is very effective in slowing the glide speed. Set it up to drop

as far as possible, to act as an airbrake. If you can add crow braking

starting from half flap to full flap, to raise both ailerons about 15 to

20 degrees, the slow flight and the descent rate on the approach is

remarkable, with full control at very low airspeeds using slightly

open throttle allowing a high angle of attack with virtually no risk of

dropping a wing.

Mix in 10% down elevator with the flap movement to prevent the

nose rising as it is applied. If you have advanced mixing, this should

return to zero from half flap to full down flap.

SPRINT is capable of any aerobatics you care to try, including spins

both upright and inverted, snaps, tumbles, rolling circles and loops,

knife edge and very slow flight.

The fuel tank custom made by Sullivan for us will give up to 15

minutes of flying time. It can, of course, be only partially filled for

shorter flights if you prefer.

You should enjoy some good flying fun with the Sprint, just about

the most stress free jet flying you can get! Feel free to

provide

your feedback and comments to us

on our website:

www.

Boomerang-RC-Jets.com

SPRINT

Boomerang

Aerobatic Sport / Trainer Jet for 12 to 22 Lb. Thrust turbines

Almost ready to fly. Speed range from 18 to 150 MPH.

SAFETY PRECAUTIONS

The SPRINT turbine model is designed for experienced modellers. This model is not

recommended for beginners to R/C flying and should not be attempted by those with insuf-

ficient building and flying experience. This manual is for guidance only. If you are unsure of

any model building techniques, seek help from an experienced model builder or contact

Boomerang Jets Ltd for assistance. Jet models are dangerous if construction is carelessly

or incorrectly carried out. As the building assembly of this kit is out of our control after point

of sale, no liability is accepted by Boomerang Jets Ltd or Boomerang Jets USA Llc for any

accident or loss, however caused. Purchase of this kit implies acceptance of these condi-

tions by the purchaser. To decline these terms, return the unused kit to your supplier for full

refund.

S

P

R

I

N

T

Boomerang

S

P

R

I

N

T

IMPORTANT WARNING.

READ THROUGH BEFORE ASSEMBLING OR FLYING YOUR KIT.

Just as in any full size aircraft, any RIC model aircraft can be made to fail, be it a wing folding or a fuse

lage breaking under too high a load. Model RIC aircraft have a maximum safe G limit. Because you are

not in the plane it is difficult to judge the G during flight, and it is very easy to exceed the limits of the

aircraft. This is particularly important if you install a turbine larger or more powerful than the power band

specified for that particular kit. This negates any airframe warranty straight away.

All our designs are thoroughly test flown before the kit is released for sale. Turbine powered RIC model

aircraft are not manufactured to withstand unlimited G forces. When flying your Boomerang Jet, be

aware of the high loads which can be in excess of the airframes capability to handle. Respect the

airframe as you would when flying a full size aircraft. Fit a turbine only up to the specified power.

Understand that if you perfonn a snap roll, wall, blender, knife edge loop or any similar manoeuvre, or

pull hard on the elevator, particularly at high speed, you can over stress the airframe by up to15 G or

more. At 15 G, the 27 lbs (12.2 Kilo) model effectively weighs over400 lbs (184 kilo), and though it may

be for only a few seconds, the strain on the airframe is huge. Your model may survive those hard

manoeuvres a few times, but eventually the cumulative damage will tell and airframe break up can

occur.

It is common practice for any manufacturer not to replace an airframe which breaks in the air or upon

landing. Manufacturers may replace airframes when they have noticed many incidences of the same

failure and it is detennined that there was a design fault or repeated manufacturing error. If you break

an airframe, and you are the only one to do so, then it is highly unlikely to be the fault of the manufac

turer. Fly safely, and avoid full throttle operation other than at low airspeeds.

RIC model jets are not toys! If misused, they can cause serious bodily hann and property damage. Fly

only in open areas, and AMA (Academy of Model Aeronautics) or BMFA (British Model Flying Associa

tion) or your country's approved flying sites. Follow all manufacturer instructions included with your

plane, radio, servo's, batteries and engine. Each kit is guaranteed to be free from defects in both mate

rial and workmanship at the date of purchase. Warranty does not cover any component assembled by

the customer. All parts of high stress must be inspected and reinforced if necessary by a competent

builder.

Some parts should be examined, and if necessary, glued again. High stress areas such as firewalls,

motor mounts, wing mounts, landing gear mounts, etc., are areas of high concern. Seek help if neces

sary.

In no case shall Boomerang RC Jets, LLC. warranty cover any product which is not manufactured by

Boomerang RC Jets, LLC. The liability to the manufacturer cannot exceed the original cost of the

purchased item.

Further, Boomerang RC Jets, LLC. reserves the right to change or modify this warranty without notice.

In that Boomerang RC Jets, LLC. has no control over the assembly or materials used by the builder of

the model during final assembly, no liability shall be assumed nor accepted for any damage resulting

from the use of the final user-assembled product. By using the user assembled product, the user

accepts all resulting liability. The kits manufacturers have provided you with a top quality, thoroughly

tested kit and instructions, but ultimately the quality and flying ability of your finished model depends on

how you build it. Therefore, we cannot in any way guarantee the performance of your completed

model, and no representations are expressed or implied as to the performance or safety of your com

pleted model. It is the use�s responsibility to inspect each component for airworthiness.