Full Text Searchable PDF User Manual

Valve Series V2001

Globe Valve Type 3321

Mounting and

Operating Instructions

EB 8111/8112 EN

Edition February 2004

Fig. 1

⋅

Type 3321 Valve with mounted rod-type yoke for pneumatic or electric actuators (partial view)

Contents

Page

1

Design and principle of operation

. . . . . . . . . . . . . . . . . . . . . . 4

1.1

Technical data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2

Installation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1

Assembling valve and actuator . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2

Mounting position . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3

Strainer, bypass . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3

Operation

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

4

Maintenance – Replacing parts

. . . . . . . . . . . . . . . . . . . . . . . 7

4.1

Packing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

4.2

Plug . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

4.3

Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

5

Description of the nameplate

. . . . . . . . . . . . . . . . . . . . . . . . . 9

6

Dimensions and weights

. . . . . . . . . . . . . . . . . . . . . . . . . . . 9

7

Customer inquiries

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Contents

Note!

Non-electrical control valves, whose valve bodies are not lined with an

insulating material

coating

, do not have their own potential ignition source according to the risk assessment

stipulated in EN 13463-1: 2001, paragraph 5.2, even in the rare incident of an operating

fault. Therefore, such valve versions do

not

fall within the scope of Directive 94/9/EC.

Refer to paragraph 6.3 of EN 60079-14:1977 VDE 0165 Part 1 concerning connection to

equipotential bonding system.

2

EB 8111/8112 EN

General safety instructions

The control valve may only be mounted, started up or serviced by fully trained

and qualified personnel, observing the accepted industry codes and practices.

Make sure employees or third persons are not exposed to any danger.

All safety instructions and warnings in these instructions, particularly those con-

cerning installation, start-up, and maintenance, must be observed.

The control valve fulfills the requirements of the European Pressure Equipment

Directive 97/23/EC. Valves with a CE marking have a declaration of conform-

ity that includes information on the applied conformity assessment procedure.

The declaration can be viewed and downloaded on the Internet at

http://www.samson.de.

For appropriate operation, make sure that the control valve is only used in

areas where the operating pressure and temperatures do not exceed the oper-

ating values based on the valve sizing data submitted in the order. The manu-

facturer does not assume any responsibility for damage caused by external

forces or any other external influence!

Any hazards which could be caused in the control valve by the process me-

dium, operating pressure, signal pressure or by moving parts are to be

prevented by means of the appropriate measures.

Proper shipping and appropriate storage are assumed.

Important!

For installation and maintenance work on the valve, make sure the relevant

section of the pipeline has been depressurized and, depending on the process

medium used, drained as well. If necessary, allow the control valve to cool

down or warm up to reach ambient temperature prior to starting any work on

the valve.

When working on the valve, make sure that the supply lines for the air supply

as well as the control signal are disconnected to prevent any hazards that

could be caused by moving parts.

Special care is needed with pneumatic control valves when the actuator

springs are pretensioned. These actuators are labeled correspondingly and

can also be identified by three long bolts at the bottom of the actuator. Prior to

starting any work on the valve, you must relieve the compression from these

pretensioned springs.

Safety instructions

EB 8111/8112 EN

3

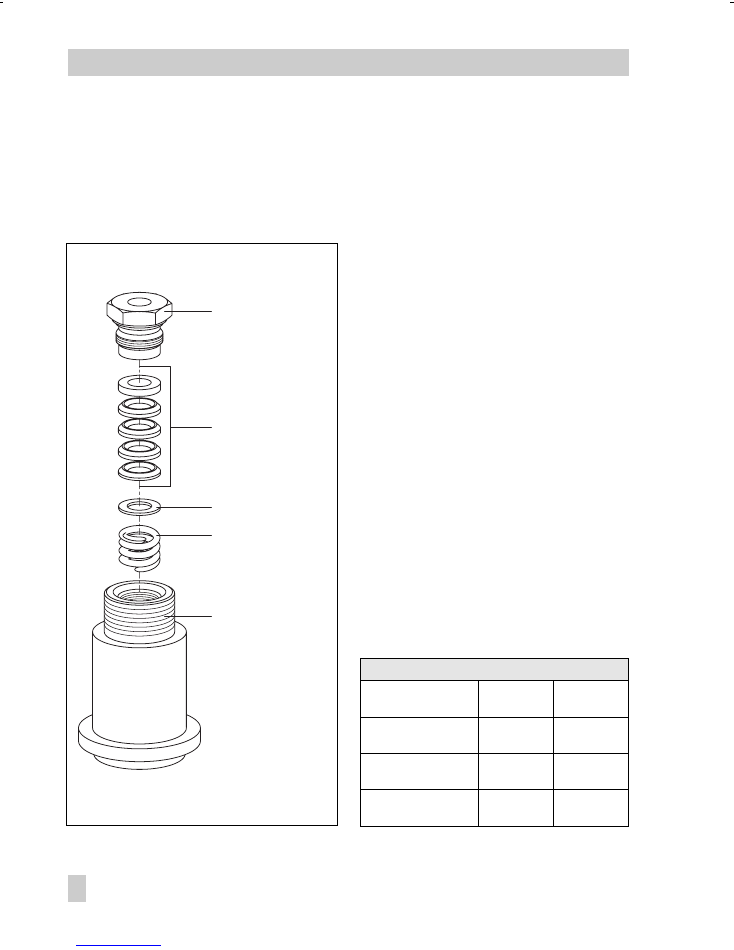

1 Design and principle of operation

The Type 3321 Single-seated Globe Valve

is based on the modular principle and can

be combined with pneumatic as well as elec-

tric actuators:

Type 3372-04xx Actuator attached to

the V 2001-P Pneumatic Control Valve

Type 3372-05xx Actuator attached to

the V 2001-IP Electropneumatic Control

Valve

Type 5824 or 3374 Actuator attached to

the V 2001-E1 or V 2001-E3 Electric

Control Valve (also refer to T 8111 EN).

The process medium flows through the valve

in the direction indicated by the arrow. The

valve plug position determines the cross-sec-

tional area of flow between the seat (2) and

the plug (3). The position of the plug is

changed by the control signal acting on the

actuator.

The plug stem is sealed by a spring-loaded

PTFE ring packing (4.2) and connected to

the actuator stem (8.1) by means of a stem

connector (7).

Fig. 2

⋅

Sectional drawing

1

Valve body

1.1 Nuts

1.2 Gasket

2

Seat

3

Plug

4.1 Spring

4.2 Packing

4.3 Washer

5

Valve bonnet

5.1 Flange

5.2 Threaded bushing

6

Nut

7

Stem connector

8.1 Actuator stem

8.2 Rod-type yoke

8.3 Rod nut

8.1

8.2

7

5.2

6

8.3

5

5.1

3

2

1

4.2

4.3

4.1

1.1

1.2

4

EB 8111/8112 EN

Design and principle of operation

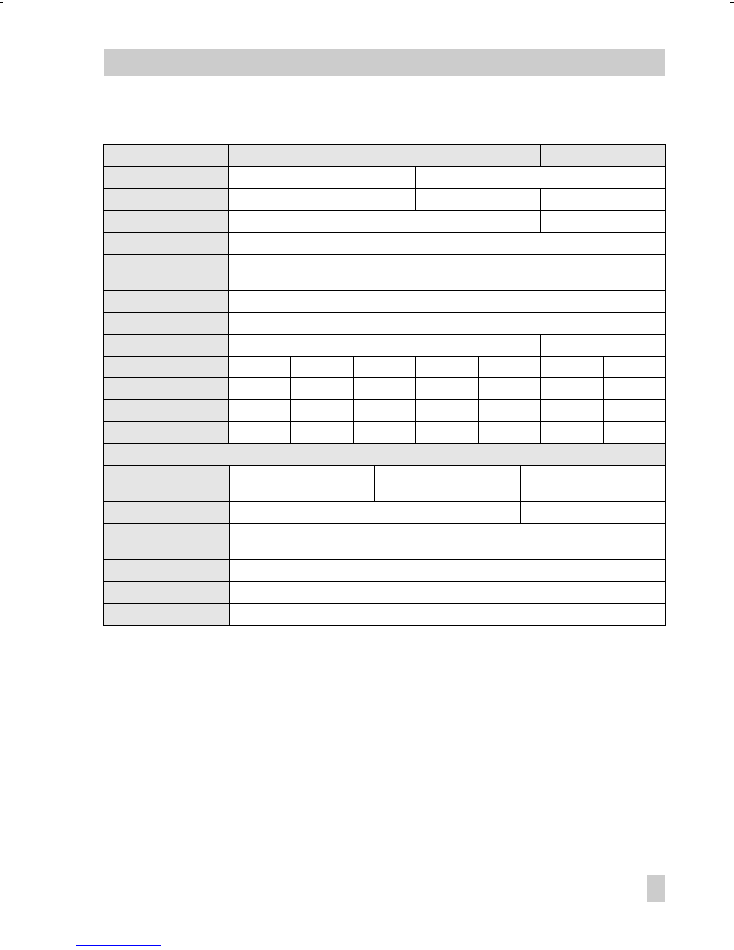

1.1 Technical data

Valve

DN 15 to 50

ANSI 1/2" to 2"

Material

Cast iron

Cast steel

Nominal pressure

10, 16

16, 25, 40

Class 150, Class 300

Flange connection

Type B1 EN 1092-1

Raised face

Seat-plug seal

Metal sealing or soft sealing:

Leakage class

acc. to IEC 534-4

Metal sealing: IV (0.01 % K

VS

)

Soft sealing: VI (bubble-tight)

Characteristic

Equal percentage

Rangeability

50 : 1

Temperature range

–10 to 220 °C

15 to 430 °F

DN

15 / 1/2"

1)

15 / 1/2"

20 / 3/4"

25 / 1"

32

40 / 1 1/2"

50 / 2"

K

VS

values

m

3

/h 0.63

⋅

0.25

1.6

⋅

4

2.5

⋅

6.3

4.0

⋅

10

6.3

⋅

16

10

⋅

25

16

⋅

35

C

V

values

0.75

⋅

0.3

2

⋅

5

3

⋅

7.5

5

⋅

12

12

⋅

30

20

⋅

40

Seat diameter

mm

6

⋅

3

12

12

⋅

24

12

⋅

24

12

⋅

32

24

⋅

38

32

⋅

48

Materials

Valve body

Cast iron

EN-JL1040 (GG-25)

2)

Cast steel

1.0619 (GSC25)2)

ANSI

A216 WCB

Valve bonnet

1.0460 (C 22.8)

2)

A105

Seat and plug

1.4305/for seats in DN 32 and larger: 1.4104

Sealing ring of the soft seal: PTFE with glass fiber

Guide bushing

1.4104

Packing

PTFE V-ring packing with carbon; spring: 1.4310

Body gasket

Metal graphite

1)

Special version

2)

Former material designation

EB 8111/8112 EN

5

Technical data

2 Installation

2.1 Assembling valve and actuator

The valve and the actuator are packed indi-

vidually and must be assembled on site.

To do this, proceed as follows:

1. Remove the nut (6) from the valve bon-

net.

2. Slightly retract the actuator stem (8.1)

and place the actuator with its rod-type

yoke on the valve bonnet. Secure with

the nut (SW 36). Observe a tightening

torque of min. 150 Nm.

3. Extend the actuator stem until it contacts

the plug stem.

4. Position the stem connector clamps and

screw tight.

Caution!

Under no circumstances must the rod nuts

(8.3) of the rod-type yoke be unscrewed.

For further details, refer to the mounting

and operating instructions of the respective

actuator.

2.2 Mounting position

The valve can be mounted in any position.

However, strictly observe the limitations re-

sulting from the type of actuator used.

Caution!

The valve must be installed free of stress

and free of excessive vibrations. If necess-

ary, support the pipelines near the connec-

tions. Do not install supports on the valve or

on the actuator. Thoroughly flush the

pipeline prior to installation of the valve.

2.3 Strainer, bypass

We recommend that you install a SAMSON

Type 2 Strainer upstream of the valve.

We also recommend that you install a shut-

off valve both upstream of the strainer and

downstream of the control valve as well as

a bypass line so that the plant need not be

shut down for maintenance routines.

3 Operation

As the operating instructions depend on the

actuator used, refer to the corresponding

mounting and operating instructions for de-

tailed information.

6

EB 8111/8112 EN

Installation

4 Maintenance – Replacing parts

The control valve is subject to wear espe-

cially at the seat, plug, and packing. De-

pending on the application conditions that

prevail, the valve must be inspected at ap-

propriately scheduled intervals to prevent

any problems before they occur.

If any leaks occur to the atmosphere, the

packing may have become untight.

If the valve does not seal properly, this may

be because tight shut-off is prevented by

dirt or other impurities between the seat

and plug or because the seating surfaces

have been damaged.

We recommend removing the parts, thor-

oughly cleaning them, and replacing them

with new parts, if necessary.

Caution!

If you intend carrying out mainten-

ance work on the valve, first relieve

the corresponding plant section of

pressure and, depending on the pro-

cess medium, drain it as well.

Let the plant section cool down to

reach ambient temperature, if

necessary.

Prior to starting any work, discon-

nect the electric or pneumatic con-

trol signal for the actuator. On pneu-

matic actuators, additionally remove

the signal pressure line.

As the process medium cannot drain

completely out of the valve, be

aware that some of the process me-

dium could still be in the valve.

We recommend that you remove the

valve from the pipeline.

Note!

The tightening torques and special tools re-

quired for installing and removing the seat

are listed in the table on page 8. For further

details, refer to the SAMSON Special Tools

WA 029 EN.

Important!

Always separate the actuator and the valve

prior to carrying out repairs! Separate the

actuator from the valve by removing the

stem connector clamps (7) and the nut (6).

Then lift the actuator off the valve. Note that

the rod nuts (8.3) of the rod-type yoke must

not be unscrewed under any circumstances.

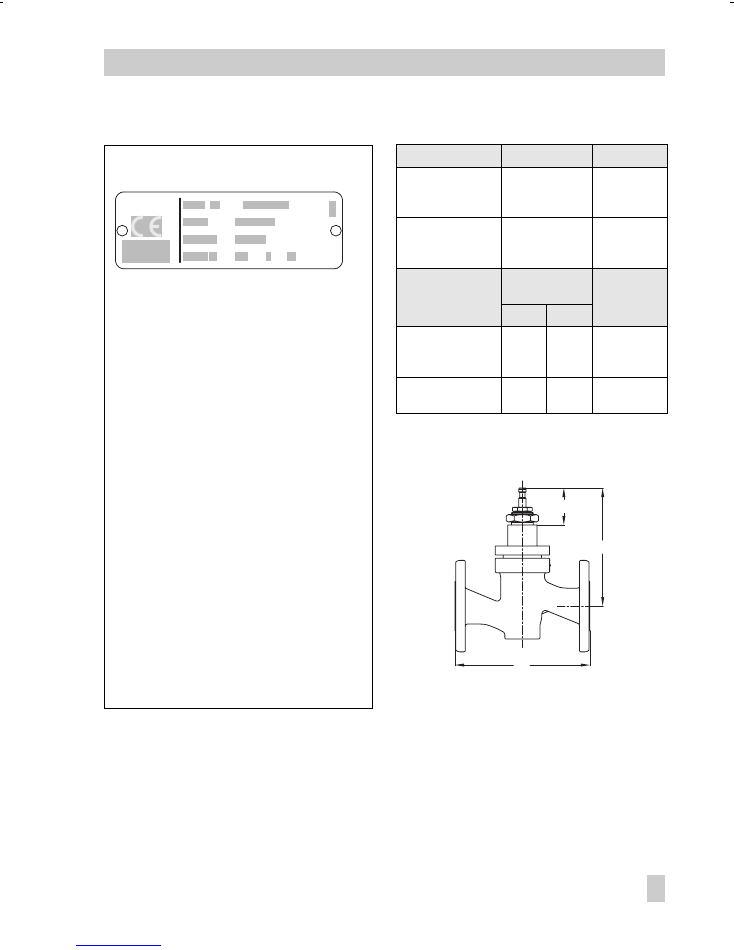

4.1 Packing

1. Unscrew the nuts (1.1) and remove the

valve bonnet (5) and flange (5.1).

2. Check the gasket (1.2) in the valve

body for damage. We recommend that

you replace the gasket.

3. Screw off the threaded bushing (5.2)

and pull out the plug (3).

4. Pull out the damaged packing (4.2)

using an appropriate tool.

Remove the washer (4.3) and spring

(4.1) and clean the packing chamber.

5. Apply lubricant (order no. 8150-0111)

to the individual parts of the new pack-

ing and the plug stem. Insert the

plug (3) in the valve bonnet (5).

6. Place the valve bonnet with flange on

the valve body and secure with

nuts (1.1). Observe the tightening tor-

ques given in the table on page 8.

EB 8111/8112 EN

7

Maintenance – Replacing parts

7. Insert the spring (4.1) and washer (4.3)

and carefully slide the new pack-

ing (4.2) over the plug stem into the

packing chamber. Screw in the threaded

bushing (5.2) and tighten.

4.2 Plug

When replacing the plug, you should also

replace the packing (4.2) and the gas-

ket (1.2).

To exchange the plug, carry out the same

steps as described in section 4.1. However,

install a new plug instead of the used one.

Apply lubricant (order no. 8150-0111) to

the plug stem prior to installation.

4.3 Seat

1. Unscrew the nuts (1.1). Lift the valve

bonnet (5) and flange (5.1) off the

valve body (1).

2. Unscrew the seat (2) using the appropri-

ate seat wrench.

3. Apply lubricant (order no. 8150-0119)

to the thread and the sealing cone of

the new seat and screw in.

4. Place the valve bonnet with flange on

the valve body and secure with nuts

(1.1). Observe the tightening torques!

Sockets / seat wrenches / tightening torques

DN (size)

15...25

(1/2...1")

32...50

(1 1/2...2")

Socket / seat wrench

Order no.

9932-3330

1280-3009

Seat thread in mm

Tightening torque

±

10 %

M32 x 1.5

170 Nm

M58 x 1.5

500 Nm

Body nuts (1.1)

Tightening torque +10 %

M10

10 Nm

M12

30 Nm

Fig. 3

⋅

Stuffing box parts

5.2

4.2

4.3

4.1

5

4.1 Spring

4.2 Packing

4.3 Washer

5

Valve bonnet

5.2 Threaded bushing

8

EB 8111/8112 EN

Maintenance – Replacing parts

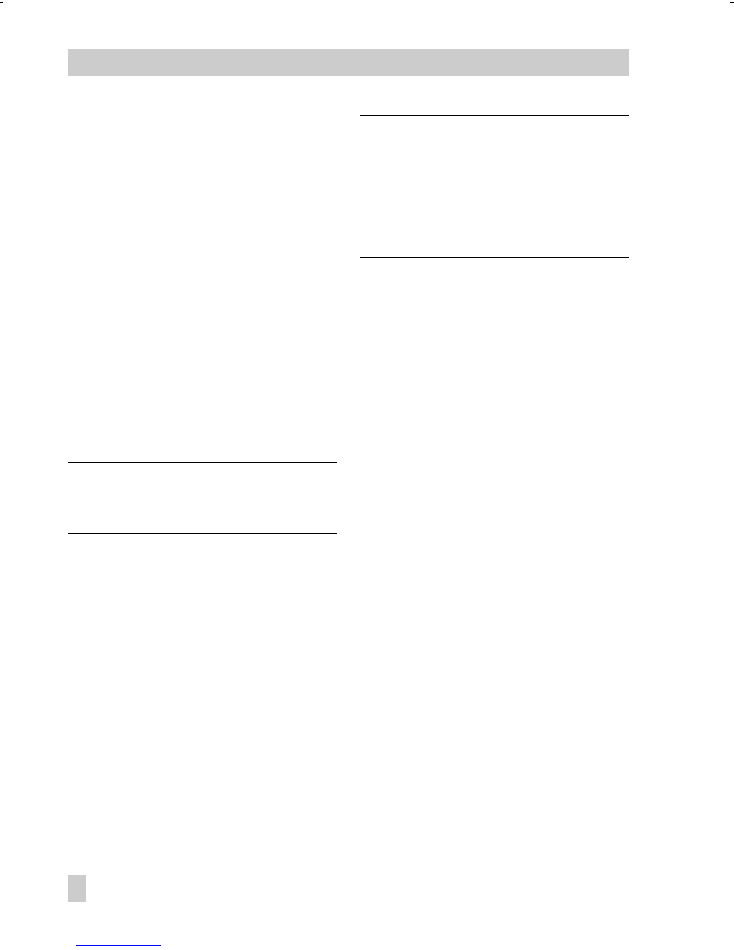

5 Description of the nameplates

6 Dimensions and weights

Fig. 4

⋅

Nameplate

DIN

DN (mm)

L mm

H mm

15

20

25

130

150

160

160

32

40

50

180

200

230

165

ANSI

Size (in)

L in

Class

H in

150

300

1/2"

3/4"

1"

7.25

7.25

7.25

7.5

7.62

7.75

6.3

1 1/2"

2"

8.75

10.0

9.25

10.5

6.5

1

CE marking or "Art. 3, Abs. 3" (see Article 3,

§3 of PED), where applicable

2

Identification number of notified body, fluid

group, and category, where applicable

3

Type designation

4

Modification index of valve

5

Material

6

Year of manufacture

7

Valve size DIN: DN, ANSI: Size

8

Permissible excess pressure at room temperature

DIN: PN, ANSI, CL

9

Order number with modification index

10 Item position in the order

11 Flow coefficient DIN:

K

VS

value, ANSI:

C

V

value

12 Characteristic:

%

Equal percentage,

Lin

Linear

DIN:

A/Z

, ANSI:

O/C

(open/closed)

13 Seal

ME

Metal,

ST

Stellited,

Ni

Nickel-plated,

PT

Soft sealing with PTFE,

PK

Soft sealing with PEEK

14 Pressure balanced DIN:

D

, ANSI:

B

15 Flow divider

I

or

III

H

50(1.96)*

L

* Valve CLOSED

3

4

5

9

10

7

8

11 12

13

14 15

2

1

6

SAMSON

Made in

Germany

-

EB 8111/8112 EN

9

Dimensions and weights

7 Customer inquiries

If you have any questions, submit the follow-

ing details:

Type designation and order number

(indicated on the nameplate)

Production number, nominal size, and

valve version

Pressure and temperature of the medium

Flow rate in m

3

/h

Bench range (signal pressure range, e.g.

1.4 to 2.3 bar) of the pneumatic actuator

Installation drawing

10

EB 8111/8112 EN

Customer inquiries

EB 8111/8112 EN

11

SAMSON AG

⋅

MESS- UND REGELTECHNIK

Weismüllerstraße 3

⋅

60314 Frankfurt am Main

⋅

Germany

Phone: +49 69 4009-0

⋅

Fax: +49 69 4009-1507

Internet: http://www.samson.de

EB 8111/8112 EN

S/Z

2004-

06