Full Text Searchable PDF User Manual

rotowash

CAUTION

Do not operate this appliance

before reading the instructions

.

INSTRUCTION M ANUAL

Floor Cleaning M achine

Version 10/2009

DEAR

ROTOWASH

USER!

Your ROTOWASH is a valuable help in dealing with many

cleaning problems. Please read this manual through

carefully to enable you obtain the best results from your

ROTOWASH.

The following points must be observed before the ROTOWASH is used, also

during use or by service work:

The machine may only be used by persons who have been trained in its

use and who have been specially appointed as ROTOWASH Service Agents.

This machine is intended only for Dry Application and should not be used

or stored outdoors in wet conditions.

This appliance is suitable for commercial use for example in hotels,

schools, hospitals, factories, shops, offices and rental businesses.

This appliance is not suitable for picking up hazardous dust.

The specified voltage on the rating plate must match the voltage of the

power source.

The electrical connection must be made with a three contacts socket (with

earth ground).

It is not allowed to use this machine without earth ground.

All connections of mains supply cable must be protected at least against

water splashing.

The electrical plug must be disconnected from the main electricity supply

before cleaning and servicing the machine, before changing parts and

before changing over to another machine function.

Running over the mains cable can be dangerous.

Avoid damage to the mains supply cable by not running over it and by not

squashing ore pulling it etc.

The mains supply cable must be examined regularly for possible damage

or wear.

The machine must not be used if such damage is evident.

This substitute cable must be of an equivalent type (H05VV-F 3G1mm²) to

the cable fitted by the manufacturer or an original ROTOWASH spare part

must be fitted.

Use Only with the machine supplied, or in the parts list specified brushes.

The use of other brushes can compromise security.

When transporting the ROTOWASH in a lift ensure that the handle is placed

in such a position to avoid a possible jamming against the lift walls.

The water level on the floor must not exceed 3 mm. (approx. 2/16” ).

The use of cleaning fluids which foam excessively or contain Hydrochloride

based substances invalidates the guarantee.

Check before use, whether the brushes are suitable for the intended

application

This appliance is not intend for use by persons (including children) with

reduced physical, sensory or mental capabilities or lack of experience and

knowledge unless they have been given initial supervision to instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

KEEP THIS INSTRUCTION M ANUAL!!!

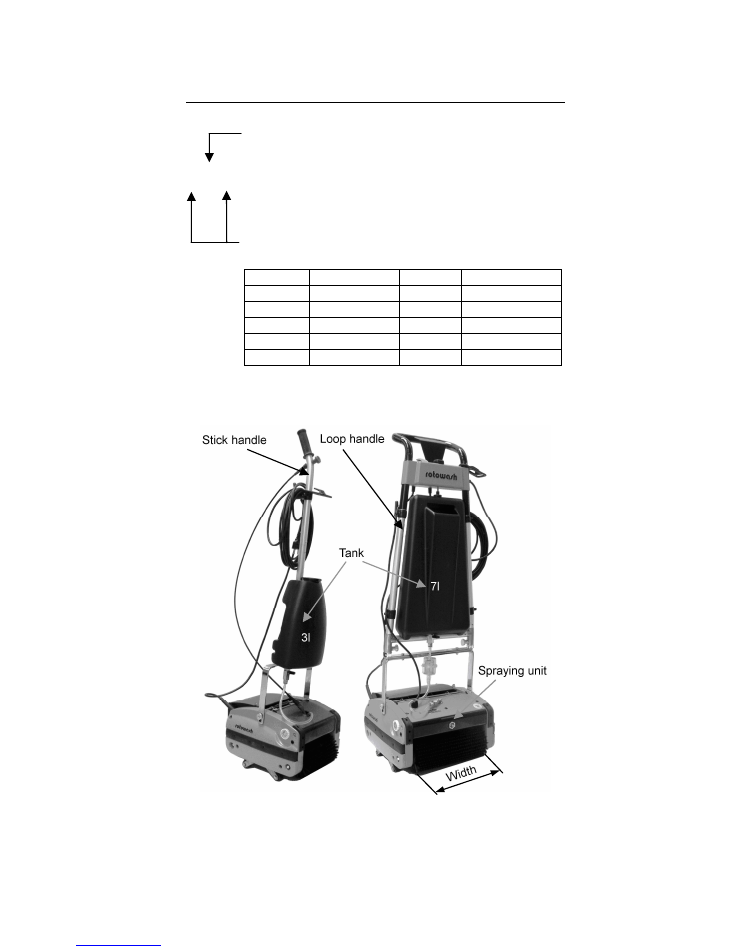

WHAT IT IS

This instruction manual is for following cleaning

machines:

X

is an indicator of the working width.

X = 20 stands for 200 mm working width

X = 30 stands for 300 mm working width

X = 45 stands for 440 mm working width

X = 60 stands for 600 mm working width

Y X Y

Y

indicator stands for:

Y

Handle:

Tank:

Spraying unit:

L /

Stick handle

without

no

T

Stick handle

3 litre

no

A

Loop handle

without

no

S

Loop handle

7 litre

no

B

Loop handle

7 litre

yes

e. g. 20T

e. g. 30B

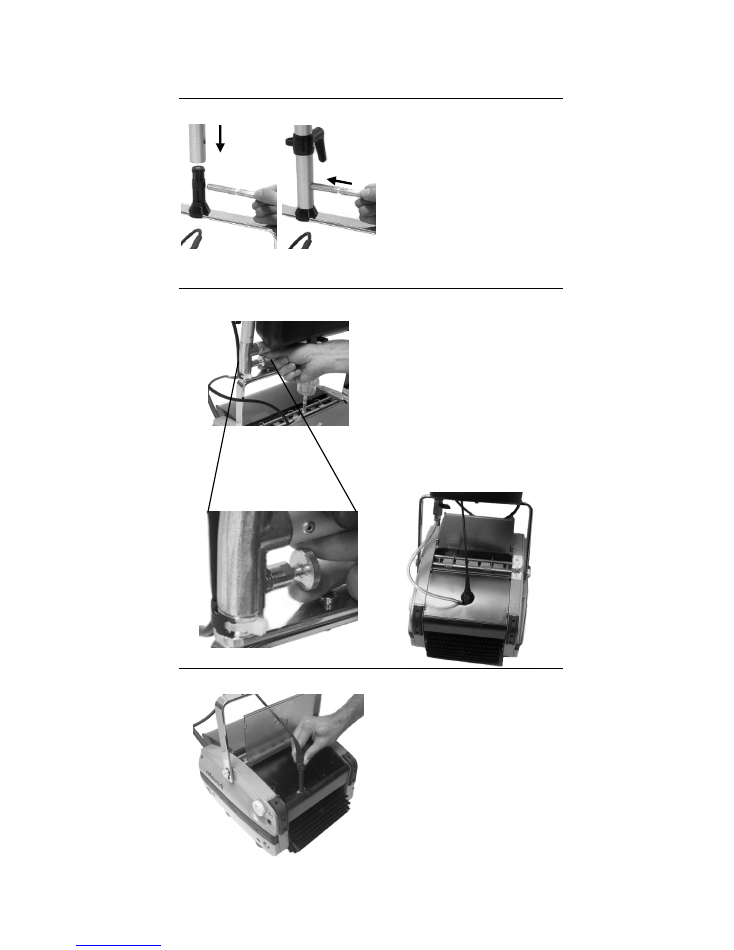

ASSEMBLY

Installing the stick handle for

L, T

Place the handle (1) on the plastic

handle connector on the fork and

push connecting pin (2) through to

locate handle.

Installing the loop handle for

A, B, S

Place the loop handle on the

aluminium handle connectors and fit

spring loaded bolts to locate.

Lead the plastic tube from the tank

water valve on model S into the clean

water tray, on model B connect to the

pump (spraying unit) inlet.

Installing the bowdencontrol for L, T,

A, S

Lead the bowdencontrol under the

handle into the cleanwater tray and

screw together the water valve tube

and the plastic nut.

Be careful not to twist the

bowdencontrol and test the ease of

operation by pushing the red button at

the top end of the stick handle.

1

2

Fitting the cables

A, S

Fit the electrical plug from machine

into the correct socket.

Machine

motor socket

B

Fit the electrical plugs from machine

and pump into the correct sockets.

Spraying unit

pump socket

Machine

motor socket

Pump Motor

Fixing the main cable

Push the mains cable into the

purpose-made hooks on the

handle. This will avoid the cable

being run over by the revolving

brushes

Cable safety

Place for an extra protection the

main cable in the cable safety.

Push the mains cable into the

purpose-made hooks on the

handle. This will avoid the cable

being run over by the revolving

brushes

Mains

supply

Spraying

unit

Machine

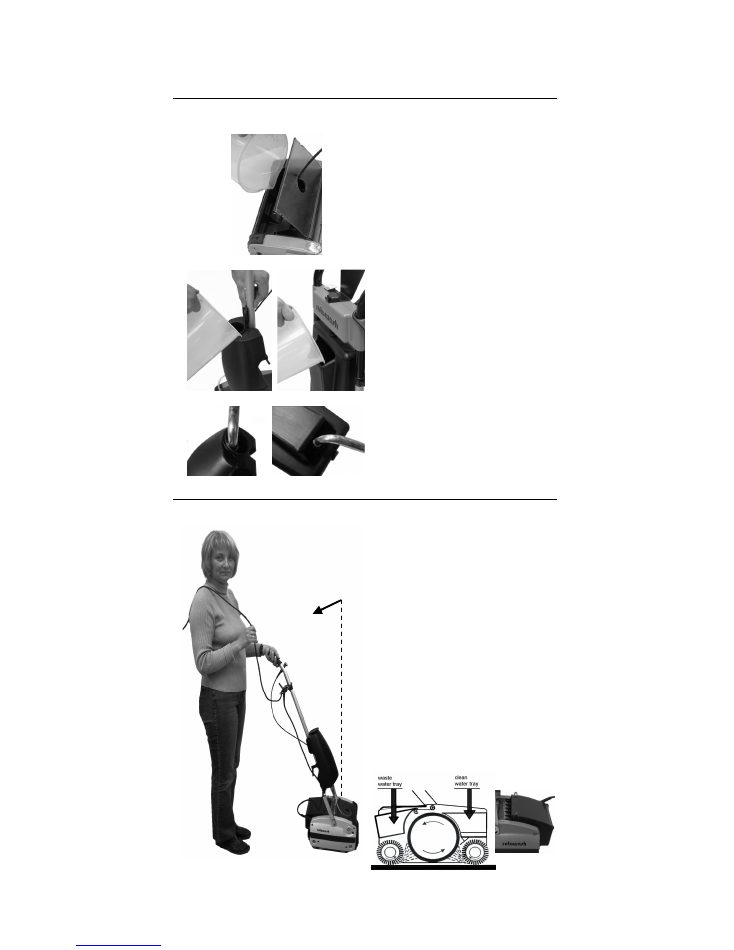

WORKING WITH

ROTOWASH

Cleaning liquid

Use only cleaning liquids which are

recommended by a cleaning expert.

If in doubt consult your ROTOWASH

dealer.

Tray capacity:

20 1,0 Litre (2 pints)

30 1,5 Litre (3 pints)

45 2,2 Litre (4 pints)

60 3,0 Litre (6 pints)

Pour the cleaning liquid into the

cleanwater tray (L, A) or in the case

of T, S, B into the tank. Test the

correct function of the watervalve by

activating the bowden control.

Tank capacity:

Tank for stick handle: 3 litre

Tank for loop handle: 7 litre

Starting

With machines with loop handle

only, place the on/off switch in

“ on” position.

By rocking the handle to the right

and pulling back the motor is

started, further pulling back will

lower the machine on to the

brushes.

Scrubbing

in lifted-up position

Wastewater tray is raised above

drum as shown

Start

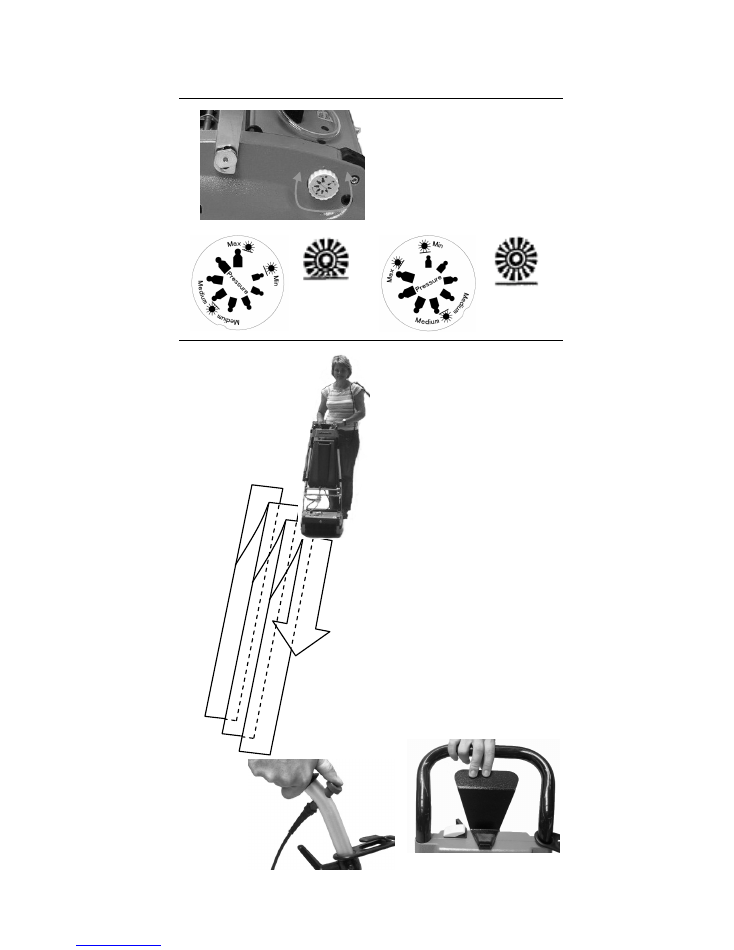

Setting brush pressure

The brush pressure can be adjusted

by turning the adjustment knob.

Position 1 is for hard floors, Position

2 is for carpets.

Position 1

Position 2

Manner of use

Move the machine in a forward

direction. By pushing the red

button near the handgrip of the

stick handle, or the pump

activating lever on the loop handle,

water is spread on to floor and

serves to clean the floor. When the

machine is moved backwards the

soiled water is collected in the

wastewater tray.

Model B is also suitable for

working in only one direction.

Machine moving forward:

Cleaning liquid should be sparingly

spread by activating the red

button/pump lever.

Machine moving backwards:

Soiled water is collected, if

necessary repeat operation.

WORKING WITH

ROTOWASH

Attention:

First remove mains plug

from socket

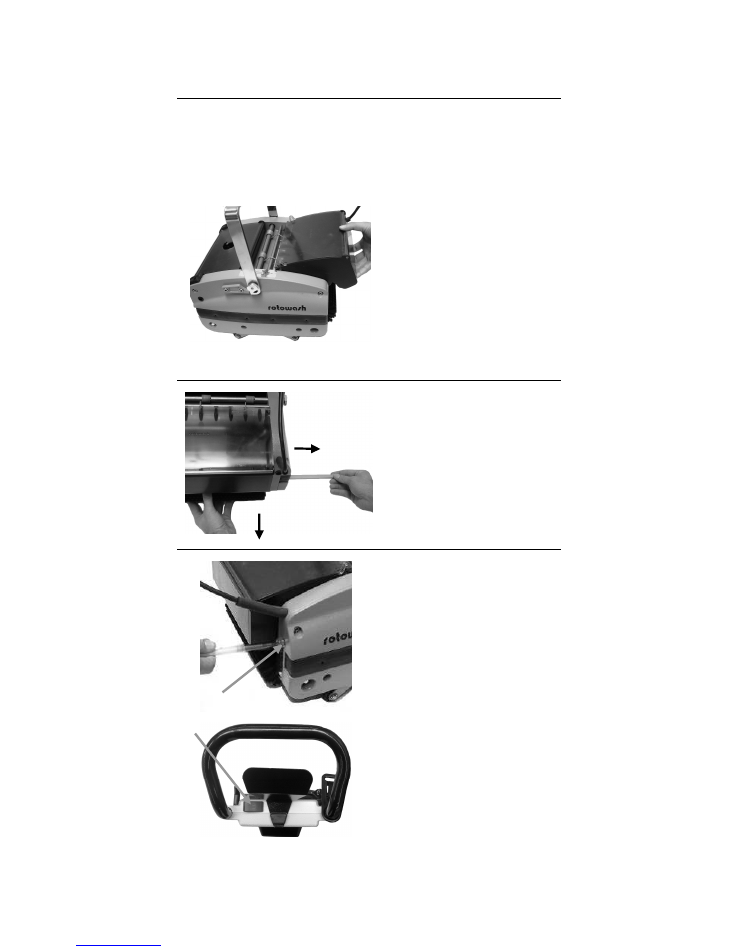

Emptying the soiled water

Lift out wastewater tray. When

refitting wastewater tray ensure that

springs are pressing on the tray.

Attention

Avoid touching the edge of the

stripperblade. It may cause injury.

Clean stripperblade regularly.

Stripperblade is removable and

should be renewed before it

becomes sharp and causes damage

to the drum through wear.

Changing brushes

Attention

:

First remove mains plug

from socket!

The brushes can be changed after

removing the brush axles.

Refit the brush axle from the cable

side of the machine

Thermorelay cut-out switch

Use the machine only with the

voltage supply stated on the type

plate. By overloading of the motor

the cut-out switch will interrupt the

mains supply. After approximately

30 seconds the cut-out button by

machine with stick handle and

on/off switch with thermo relay by

machines with loop handle can be

pushed in and the machine is again

ready for use.

On machines with a loop handle,

the On/Off switch is also the

Thermorelay, and can be reset

after 30 seconds by switching to

the “ On” position.

1

2

TRANSPORT, CLEANING AND CARE OF YOUR

ROTOWASH

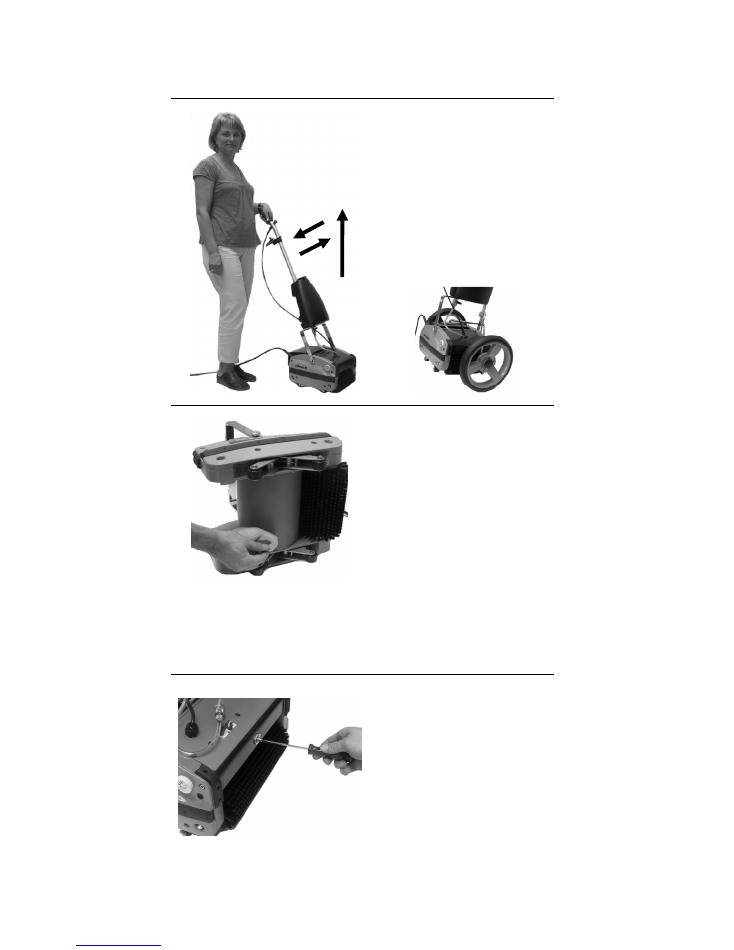

Transport

If you need to transport the machine

without carrying it, push the handle

slightly forward and lift it (1). Then

pull the handle back. This will enable

you to push the ROTOWASH along

on its transport rollers.

For long transportation use the

optional ROTOCART. Ask your

dealer for information.

Cleaning

Switch off and unplug before

cleaning.

The machine should be thoroughly

cleaned after completion of work.

The wastewater tray should be

emptied and cleaned.

To prevent a clogging of valves

and filters the machine should be

emptied of all cleaning liquid.

The transport rollers and the underside of the machine should be wiped with

damp cloth. The brushes should be rinsed through with clean water.

Pump for B

Empty the tank. Fill it with clean

water. Switch on the pump until

you are sure that is has been

completely rinsed through with

clean water. Unscrew the spray jet

at the front of the pump now and

again and clean it. Look for the

correct spray angle when refitting.

1

2

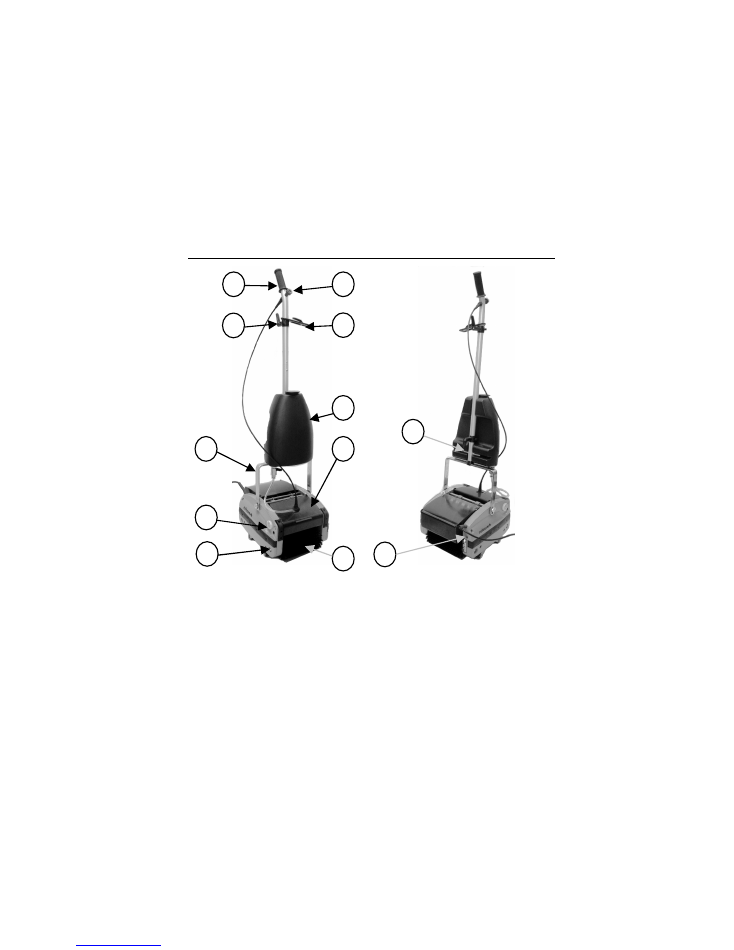

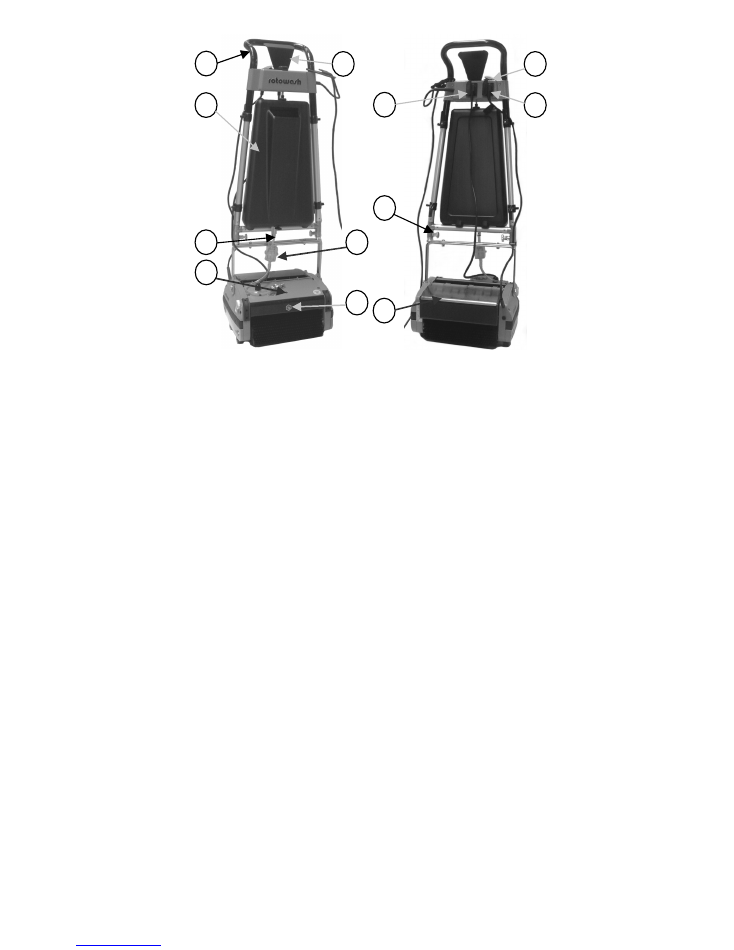

1.

Stick handle

2.

Bowdencontrol

3.

Cable safety

4.

Cable holder

5.

Tank 3l

6.

Connecting pin

7.

Fork

8.

Clean water tray

9.

Adjustment knob

10.

Thermo relay

11.

Brushaxle

12.

Brushes

13.

Loop handle

14.

Pump activating lever

15.

Combined On/Off switch and

Thermo relay

16.

Socket „ Pump”

17.

Socket „ Motor”

18.

Tank 7l

19.

Spring loaded bolt

20.

Water valve

21.

Water tube with filter

22.

Spraying unit

23.

Spray jet

24.

Waste water tray

4

9

1

11

3

2

8

7

6

5

12

10

21

18

14

13

20

15

16

19

17

22

23

24

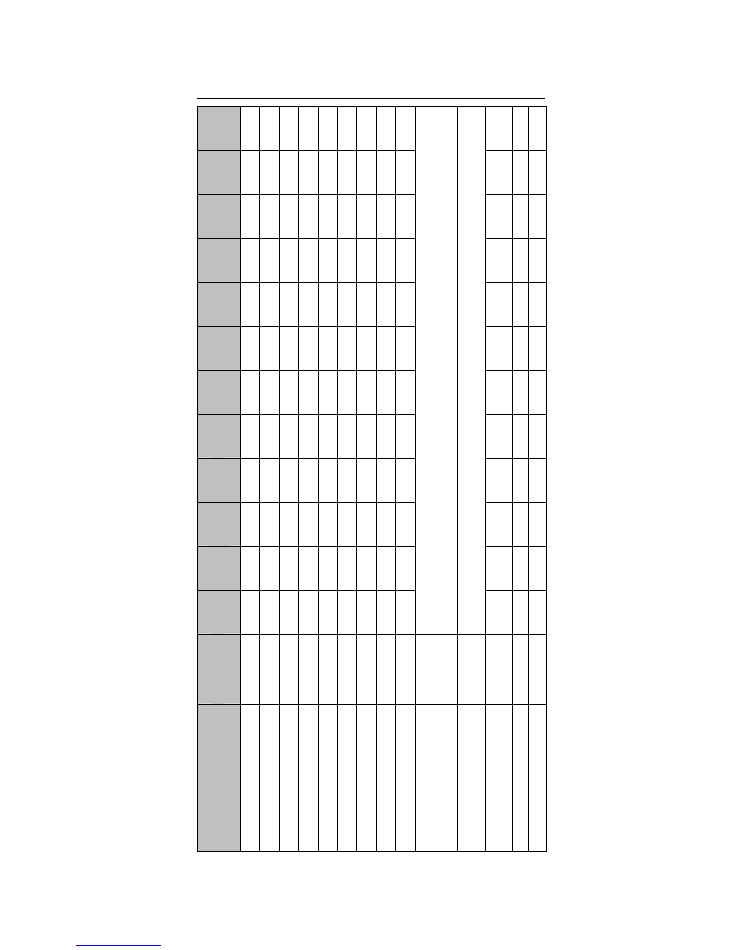

TECHNICAL DATA

>> WARNING – THIS APPLIANCE MUST BE EARTHED <<

R

6

0

B

1

1

5

0

6

5

0

6

0

0

7

3

5

3

6

6

x

7

0

5

2

0

5

1

2

1

0

1

8

4

5

9

2

0

R

6

0

S

1

1

5

0

6

5

0

6

0

0

7

3

4

3

6

6

x

7

0

5

2

0

5

1

2

1

0

8

9

0

4

3

0

R

6

0

A

1

1

5

0

6

5

0

6

0

0

3

,5

3

3

3

6

6

x

7

0

5

2

0

5

1

2

1

0

R

4

5

B

9

5

0

6

5

0

4

4

0

7

3

2

3

6

6

x

5

4

5

2

0

5

1

2

1

0

1

2

7

5

6

3

0

R

4

5

S

9

5

0

6

5

0

4

4

0

7

3

1

3

6

6

x

5

4

5

2

0

5

1

2

1

0

7

2

0

2

7

0

R

4

5

/

R

4

5

A

9

5

0

6

5

0

4

4

0

2

,5

3

0

3

6

6

x

5

4

5

2

0

5

1

2

1

0

R

3

0

B

5

5

0

6

5

0

3

0

0

7

2

4

,5

3

6

6

x

4

0

3

2

0

5

1

2

1

0

9

2

0

5

2

0

R

3

0

S

5

5

0

6

5

0

3

0

0

7

2

3

,5

3

6

6

x

4

0

3

2

0

5

1

2

1

0

4

3

0

1

7

0

R

3

0

T

5

5

0

6

5

0

3

0

0

3

2

1

,5

3

6

6

x

4

0

3

2

0

5

1

2

2

0

3

7

5

1

5

0

R

3

0

/

R

3

0

A

5

5

0

6

5

0

3

0

0

1

,5

2

0

,5

3

6

6

x

4

0

3

2

0

5

1

2

2

0

R

2

0

T

4

0

0

6

5

0

2

0

0

3

1

6

3

6

6

x

3

0

3

2

0

5

1

2

2

0

2

3

0

1

0

0

R

2

0

4

0

0

6

5

0

2

0

0

1

1

5

3

6

6

x

3

0

3

2

0

5

2

1

,6

5

m

ax

.

7

8

m

ax

.

U

n

it

W

at

ts

r.

p

.m

.

M

m

L

kg

m

m

m

m

m

m

m

/s

²

d

B

(A

)

u

p

t

o

m

2

/h

r

u

p

t

o

m

2

/h

r

T

E

C

H

N

IC

A

L

D

A

T

A

In

d

u

ct

io

n

M

o

to

r

2

3

0

V

/5

0

H

z

B

ru

sh

s

p

ee

d

B

ru

sh

w

id

th

C

le

an

w

at

er

c

ap

ac

it

y

W

ei

g

h

t

L

en

g

h

t

x

W

id

th

H

ei

g

h

t

w

it

h

o

u

t

h

an

d

le

H

ei

g

h

t

w

it

h

h

an

d

le

T

h

e

w

ei

g

h

te

d

r

.m

.s

.

ac

ce

le

ra

ti

o

n

va

lu

e

to

w

h

ic

h

t

h

e

o

p

er

at

o

r’

s

ar

m

s

ar

e

su

b

je

ct

ed

A

-w

ei

g

h

te

d

s

o

u

n

d

p

re

ss

u

re

l

ev

el

P

A

C

le

a

n

in

g

c

a

p

a

ci

ty

H

ar

d

f

lo

o

rs

C

ar

p

et

f

lo

o

rs

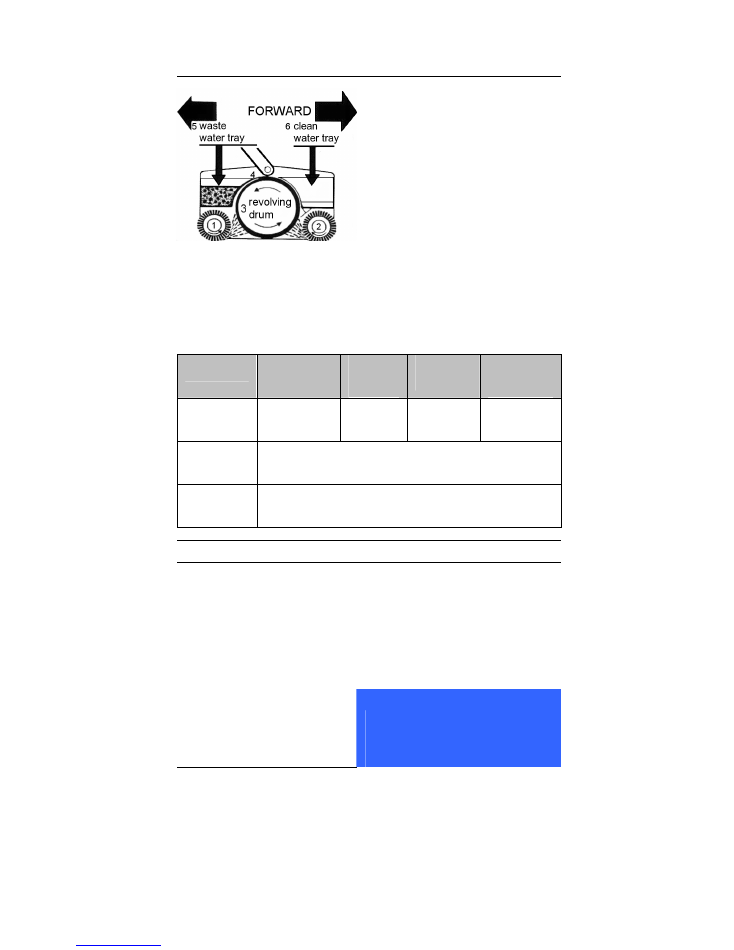

FUNCTION & USE

Two counter-rotating brushes (1 and 2)

throw the soiled water on to the

revolving drum (3), from there it is fed

into the waste water tray (5) by means

of a stripper blade (4).

This machine is suitable for use with

NON-FOAMING detergents having a pH

value ranging from 6.5 to 9.5.

The floor cleaning machine from Rotowash is intended for wet and dry

cleaning of hard floors, structural floors and textile floors. Prerequisite for the

success is the right choose of the brushes.

APPLICATION GUIDE

ROTOWASH

used as:

Maintenance

cleaning

machine

Primary

cleaning

machine*

Polishing

machine

Carpet

shampooing

machine * *

Type of brush

Standard

Standard

Hard

Abrasive

Soft

Soft

Brush

pressure

Depending on the type of floor; contact Rotowash

Cleaning and

Care liquids

According to the recom mendation of the floor manufacturer

* Wastewater tray in lifted-up position

* * Can also be used for applying im pregnation, disinfection and antistatic agents.

>> WARNING – THIS APPLIANCE HAS BEEN DESIGNED FOR THE USE

WITH BRUSHES SUPPLIED BY THE MANUFACTURER. THE FITTING OF

OTHER BRUSHES MAY AFFECT ITS SAFETY <<

rotowash

ALWAYS USE ORIGINAL SPARE

PARTS AND ACCESSORIES –

OTHERWISE NO WARRANTY!

Rotowash Reinigungsm aschinenfabrik Gm bH

Karl-Fink-Park 1 , A-8435 Wagna / Austria

Tel.: +43 3452 / 76611 – 0

Fax: +43 3452 / 76611 – 22

E-M ail: office@rotowash.at

Website: www.rotowash.at