Full Text Searchable PDF User Manual

Version: 3.00 19-10-2016

Software-version: 2.35

→

a

User manual

Installation and User Guide

CTS 602

by Nilan

2

VPM 360

Modbus

All rights reserved

Side 1 af 16

The following information describes how to connect to Nilan CTS 602 controls by means of a

RS485 connection:

Table of Contents

Connection:

....................................................................................................................................................... 2

Setup:

................................................................................................................................................................ 2

Supported functions:

....................................................................................................................................... 2

Register layout:

................................................................................................................................................ 3

Register groups

........................................................................................................................................ 3

Input registers:

.......................................................................................................................................... 4

Holding registers:

..................................................................................................................................... 8

Communication example

.............................................................................................................................. 13

Alarm list

.......................................................................................................................................................... 14

See specification and user manual for each plant for a further description of alarms.

....................... 14

Connection diagram

...................................................................................................................................... 16

All rights reserved

Side 2 af 16

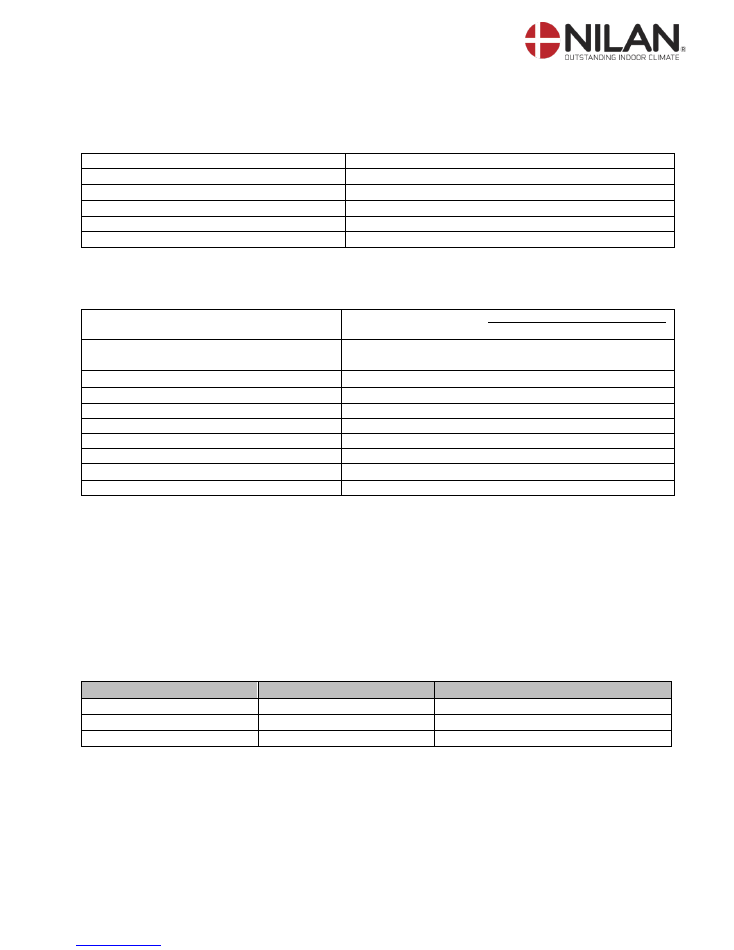

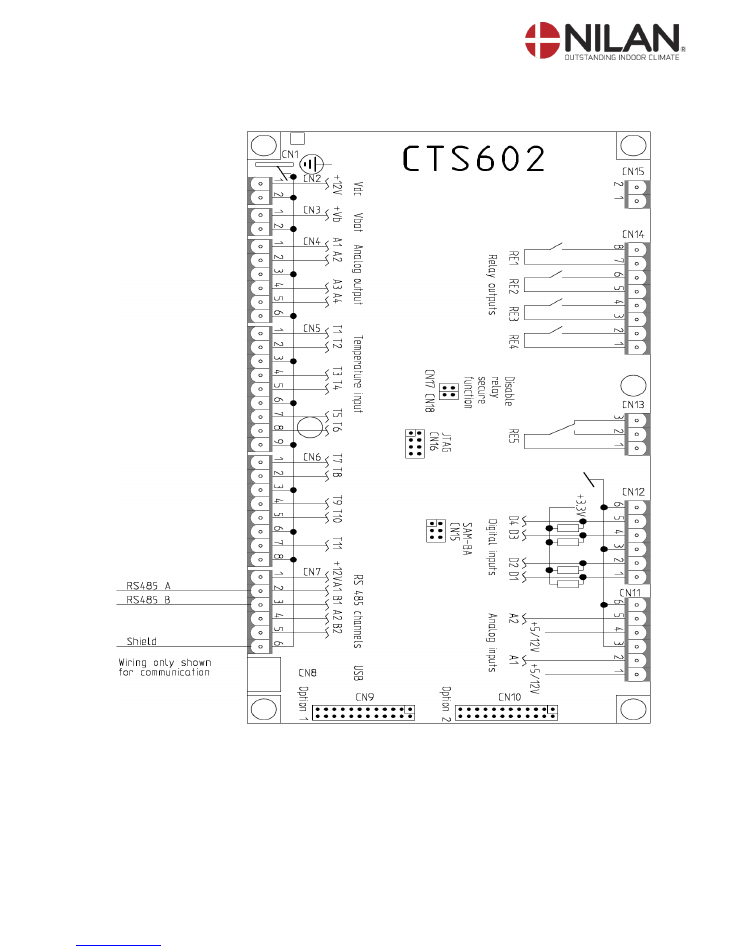

Connection:

The Modbus is connected to PIN 2,3,6 on CN7 placed next to the USB port of the printed circuit

board

Pin 1

12 VDC output

Pin 2

COM1 - RS 485 A - Modbus

Pin 3

COM1 - RS 485 B - Modbus

Pin 4

COM2 - RS 485 A - User panel

Pin 5

COM2 - RS 485 B - User panel

Pin 6

Ground

Setup:

Protocol

Modbus (RTU mode), see http://www.modbus.org/specs.php

Node address

Default 30, Address is selectable between 1 and 247

To be changed I SERVICE Menu.

Device type

CTS 602 is a Modbus slave

Baud rate

19.200

Databits

8

Stopbits

1

Parity

Even

Packet size

Max. 255 bytes

The communication speed and parameter can not be changed.

Supported functions:

Input and holding registers are supported.

All registers are 16 bit size.

The controller will respond to the below listed Modbus message functions only.

Please note that no other function codes are supported.

Function

Name

Description

03

Read Holding Registers

Read one or more holding registers

04

Read Input Registers

Read one or more input registers

16

Preset Multiple Registers

Write one or more holding registers

All rights reserved

Side 3 af 16

Register layout:

Register addresses are specified as decimal numerals.

Input registers are placed in the address area 30001..39999.

Holding registers are placed in the address area 40001..49999.

NOTE:

In the following tables, the register addresses applied in the MODBUS messages are without the

global offset. This means that if you read input register 100 with function code 04, you will get the

global address 30101.

NOTE:

All input registers can also be read as type holding register with function code 03 by adding the

offset value 10000 to the register address. No writes will be accepted in this range.

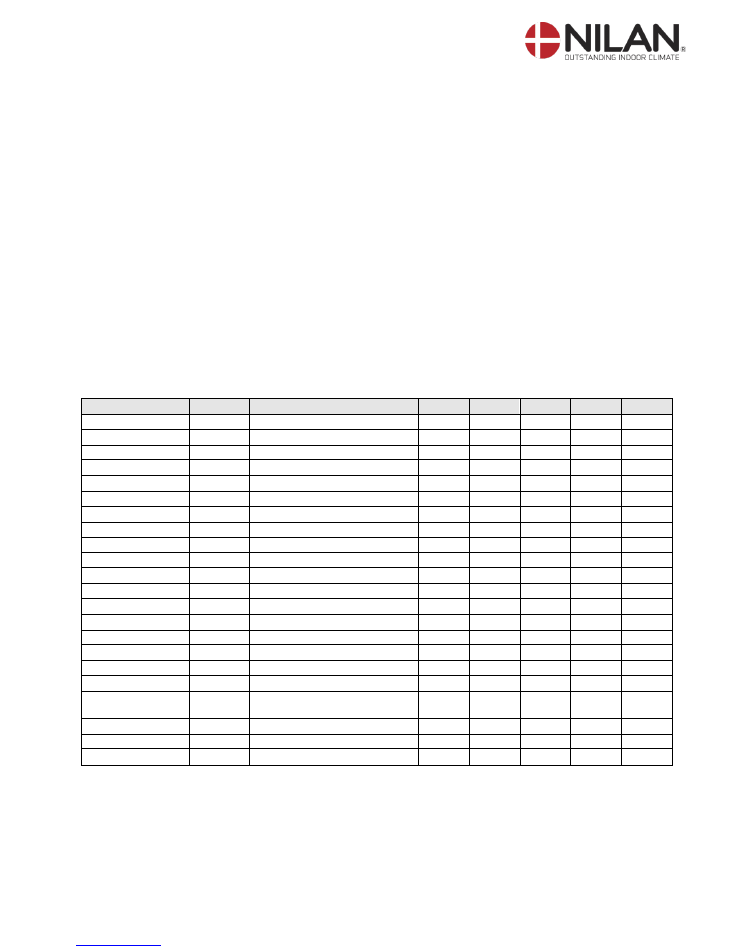

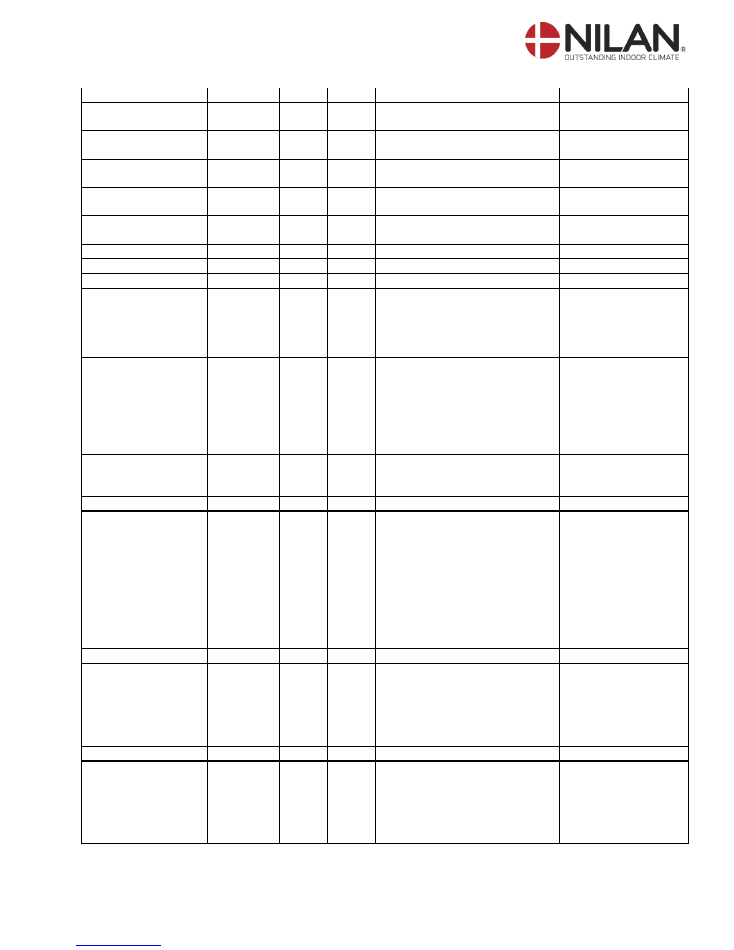

Register groups

The protocol data is grouped into the following address ranges with 100 registers in each group.

This applies to both input and holding register types:

Name

Address Description

VPM

VPL

VP

VGU

COMF

Device

000

Protocol and controller setup

x

x

x

x

x

Discrete I/O

100

Input / output bits (on/off)

x

x

x

x

x

Analog I/O

200

Input / output words

x

x

x

x

x

Time

300

Clock and calendar

x

x

x

x

x

Alarm

400

Alarm and message handling

x

x

x

x

x

Week program

500

Calendar based programming

x

x

x

x

x

User functions

600

User input function selection

x

x

x

x

x

--

700

--

--

800

--

--

900

--

Control

1000

System control and status

x

x

x

x

x

AirFlow

1100

Ventilation control

x

x

x

x

x

AirTemp

1200

Room temperature control

x

x

x

x

AirBypass

1300

Exchanger bypass control

x

x

AirHeat

1400

Inlet air heater control

x

x

x

Compressor

1500

Compressor operation control

x

x

x

x

Defrost

1600

Defrosting control

x

x

x

x

x

HotWater

1700

Hot water control

x

x

CentHeat

1800

Central water heat control

(EK)

x

x

AirQual

1900

Air quality control (RH, CO2)

x

x

x

x

x

User panel

2000

Display and keyboard

x

x

x

x

x

PreHeat

2100

Intake air preheat / earth tube

x

x

All rights reserved

Side 4 af 16

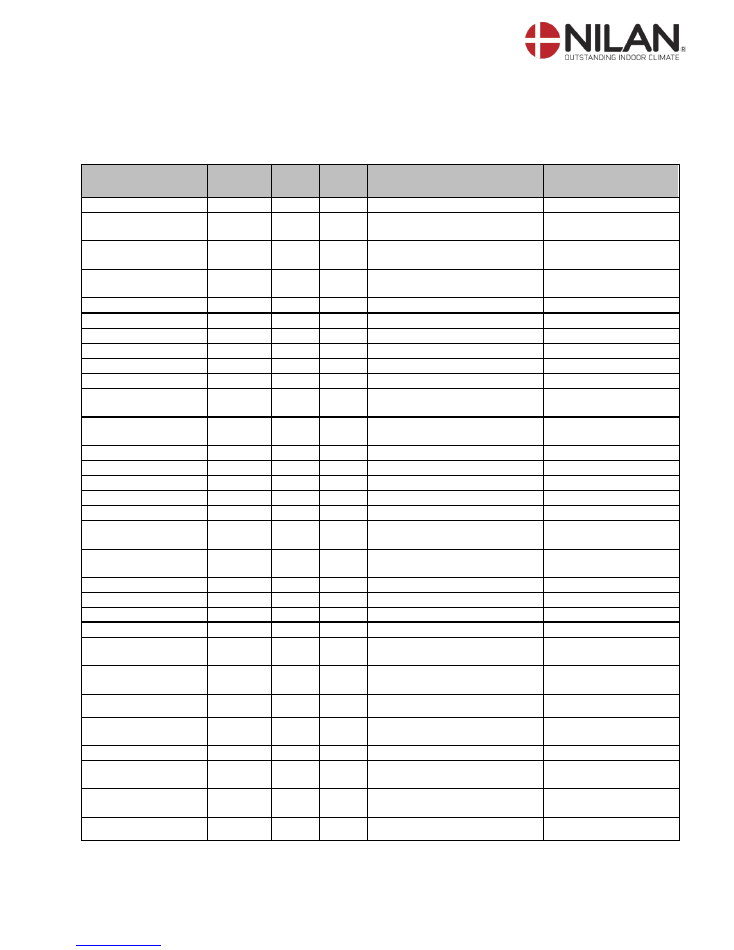

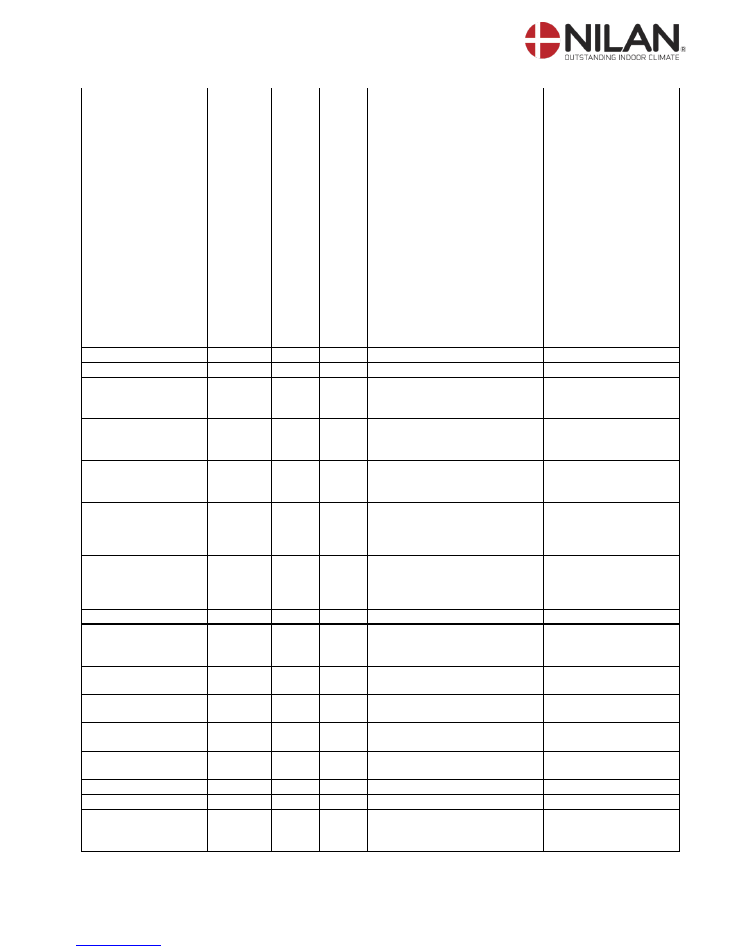

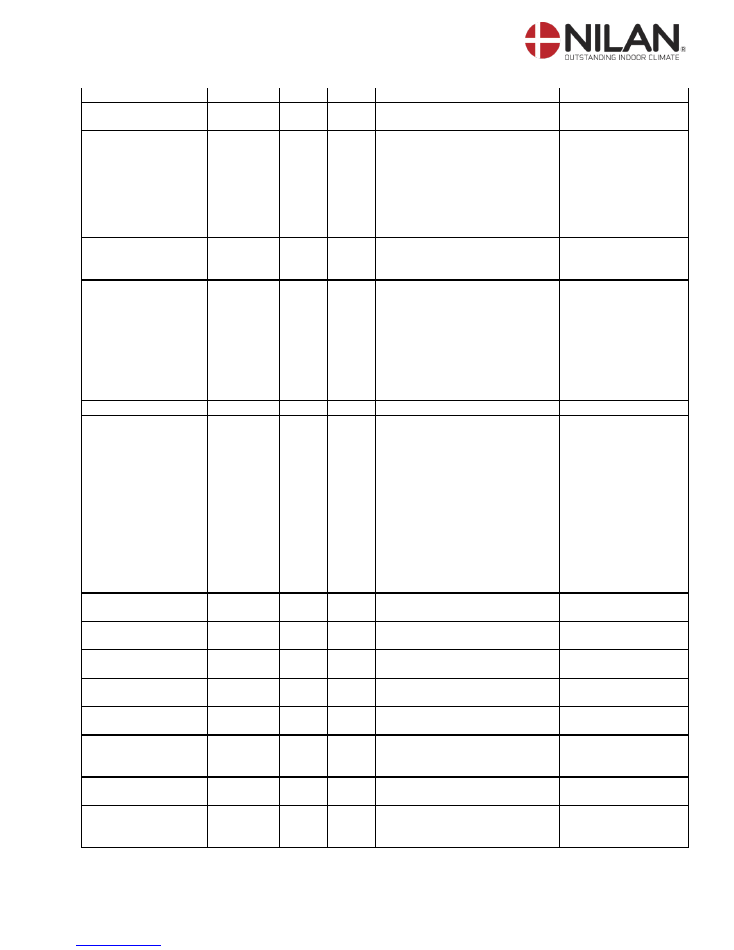

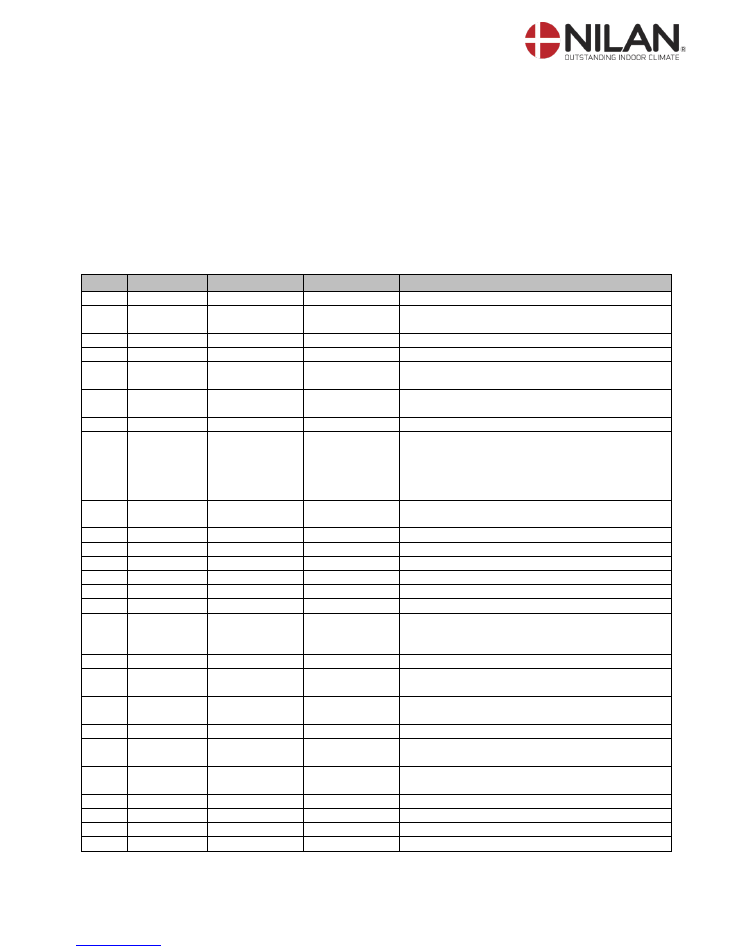

Input registers:

Name

Addres

s

Scale Unit

Description

Used to plant type

Bus.Version

000

Protocol version number

All plants

App.VersionMajor

001

text

Software version - major (2

character ascii text)

All plants

App.VersionMinor

002

text

Software version - minor (2

character ascii text)

All plants

App.VersionRelease

003

text

Software version - release (2

character ascii text)

All plants

Input.UserFunc

100

User function

All plants

Input.AirFilter

101

Air filter alarm

VPM-Comfort-Comforti

Input.DoorOpen

102

Door contact

VPM-Comforti

Input.Smoke

103

Fire/Smoke alarm

All plants

Input.MotorThermo

104

Motor thermo fuse

VPM-Comforti

Input.Frost_Overht

105

Heating surface frost /

overheat

VPL-VPM-Compact-

Comfort-Comforti

Input.AirFlow

106

Airflow monitor (guard)

VPL-VPM-Compact-

Comfort-Comforti

Input.P_HI

107

High pressure switch

All Plants

Input.P_LO

108

Low pressure switch

Not in use

Input.Boil

109

Hot water boiling

VGU-VP-Compact

Input.3WayPos

110

Hot water 3-way valve position

Not in use

Input.DefrostHG

111

Hotgas defrost type selection

Not in use

Input.Defrost

112

Defrost thermostat

VPL-VPM-VGU-VP-

Compact

Input.UserFunc_2

113

User function 2

VPL-VGU-VP-Compact-

Comfort

Input.DamperClosed

114

Air damper closed position

Comfort-COMFORTi

Input.DamperOpen

115

Air damper opened position

Comfort-COMFORTi

Input.T0_Controller

200

100

°C

Controller board temperature

All plants

Input.T1_Intake

201

100

°C

Fresh air intake temperature

VPL-VPM-VGU-VP-

Compact

Input.T2_Inlet

202

100

°C

Inlet temperature (before

heater)

VPL-VPM-VP-Compact-

Comfort-Comforti

Input.T3_Exhaust

203

100

°C

Room exhaust temperature

Comfort-Comforti

Input.T4_Outlet

204

100

°C

Outlet temperature

Compact-Comfort-

Comforti

Input.T5_Cond

205

100

°C

Condenser temperature

VPL-VPM-VP-Compact

Input.T6_Evap

206

100

°C

Evaporator temperature

VPL-VPM-VGU-VP-

Compact

Input.T7_Inlet

207

100

°C

Inlet temperature (after heater)

VPL-VPM-VP-Compact-

Comfort-Comforti

Input.T8_Outdoor

208

100

°C

Outdoor temperature

Comfort-Comforti

All rights reserved

Side 5 af 16

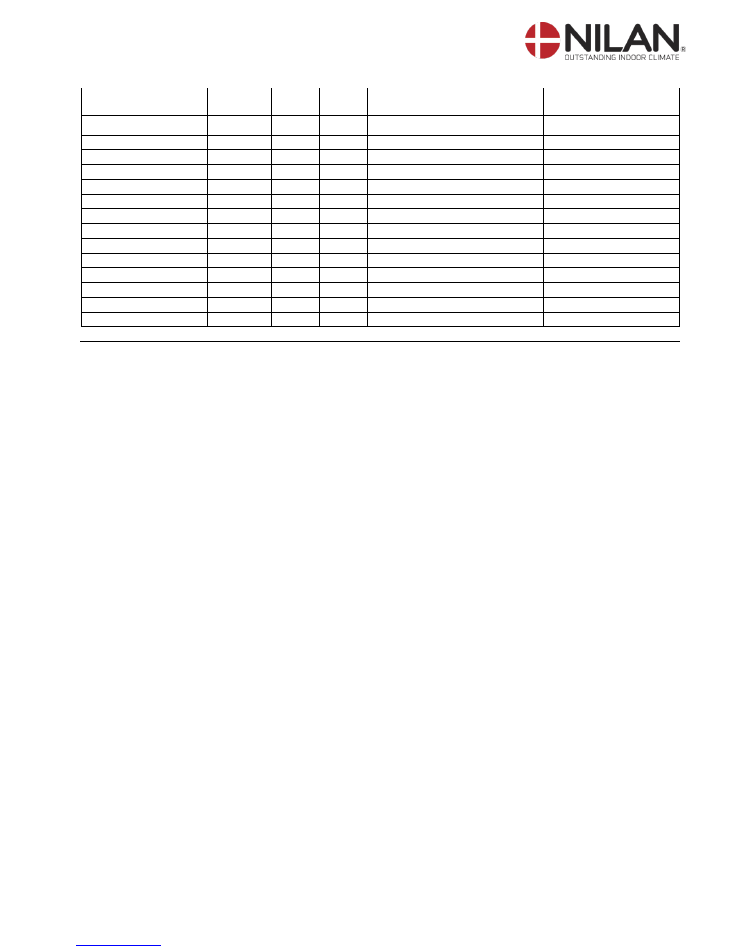

Input.T9_Heater

209

100

°C

Heating surface temperature

VPL-VPM-Comfort-

Comforti

Input.T10_Extern

210

100

°C

External room temperature

All plants

Input.T11_Top

211

100

°C

Hot water top temperature

VGU-VP-Compact

Input.T12_Bottom

212

100

°C

Hot water bottom temperature

VGU-VP-Compact

Input.T13_Return

213

100

°C

EK return temperature

VGU-VP

Input.T14_Supply

214

100

°C

EK supply temperature

VGU-VP

Input.T15_Room

215

100

°C

User panel room temperature

All plants

Input.T16

216

100

°C

AUX temperature (sacrificial

anode)

VGU-VP-Compact

Input.T17

217

100

°C

Preheater or earth tube air

intake temperature

--

218..220

(reserved)

Input.RH

221

100

%

Humidity

All plants

Input.CO2

222

ppm

Carbon dioxide

All plants

Alarm.Status

400

Alarm state bit mask

0x80 : Active alarm(s) present

0x03 : Nb. of alarms listed

All

Alarm.List_1_ID

401

Alarm 1

– Code

0x80 : (reserved future use)

0x7F : Display code 1..99

All

Alarm.List_1_Date

402

Alarm 1

– Date

Bit word packed in DOS date

format. Year 0 = 1980

15 8 7 0

HHHHHMMM MMMSSSSS

All

Alarm.List_1_Time

403

Alarm 1

– Time

Bit word packed in DOS time

format. Seconds are in scale 2

(0..29=0..58 seconds)

15 8 7 0

HHHHHMMM MMMSSSSS

All

Alarm.List_2_ID

404

Alarm 2 - Code

All

Alarm.List_2_Date

405

Alarm 2 - Date

All

Alarm.List_2_Time

406

Alarm 2 - Time

All

Alarm.List_3_ID

407

Alarm 3 - Code

All

Alarm.List_3_Date

408

Alarm 3 - Date

All

Alarm.List_3_Time

409

Alarm 3 - Time

All

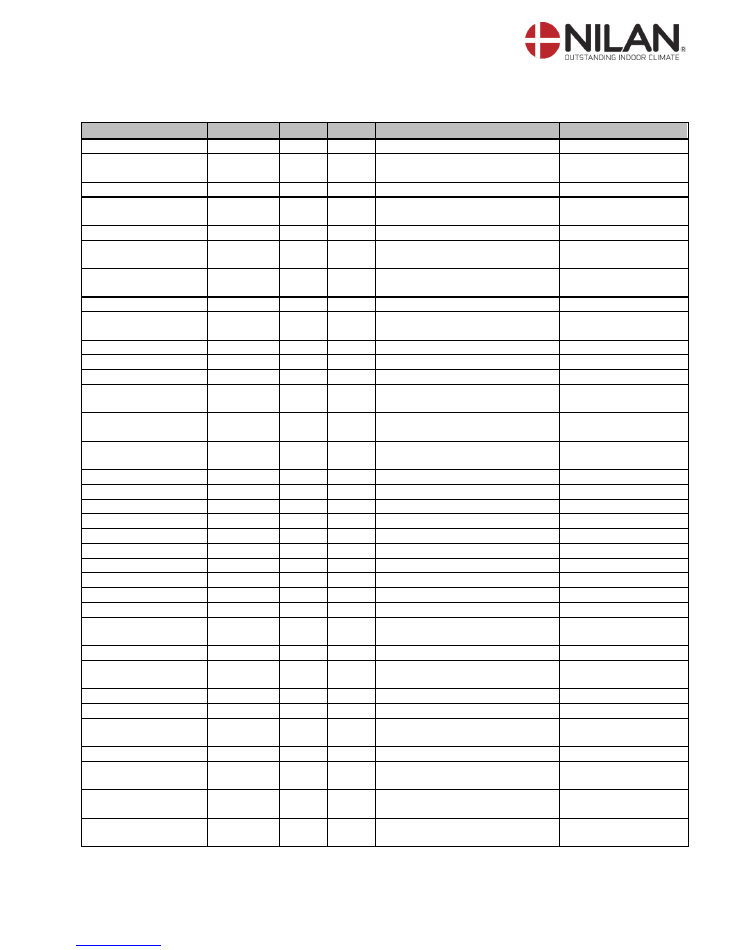

Control.RunAct

1000

Actual on/off state

0 : Off

1 : On

All

Control.ModeAct

1001

Actual operation mode

0 : Off

1 : Heat

2 : Cool

3 : Auto

4 : Service

All

All rights reserved

Side 6 af 16

Control.State

1002

Actual control state

0 : Off

1 : Shift

2 : Stop

3 : Start

4 : Standby

5 : Ventilation stop

6 : Ventilation

7 : Heating

8 : Cooling

9 : Hot water

10 : Legionella

11 : Cooling + hot water

12 : Central heating

13 : Defrost

14 : Frost secure

15 : Service

16 : Alarm

17: Heating + hot water

All

Control.SecInState

1003

Sec

Actual time in state

All

AirFlow.VentSet

1100

Step

Actual ventilation step set point

0 : Off

1..4 : Step number

All

AirFlow.InletAct

1101

Step

Actual ventilation step set point

0 : Off

1..4 : Step number

All

AirFlow.ExhaustAct

1102

Step

Actual ventilation step set point

0 : Off

1..4 : Step number

All

AirFlow.SinceFiltDay

1103

Days

Days since last air filter

change alarm

One day is measured as 24

hours of active running time

All

AirFlow.ToFiltDay

1104

Days

Days to next air filter change

alarm

One day is measured as 24

hours of active running time

All

AirTemp.IsSummer

1200

Summer state

0 : Off

1 : On

All

AirTemp.TempInletS

et

1201

100

°C

Inlet temperature request (T7

setpoint)

All

AirTemp.TempContro

l

1202

100

°C

Actual value for controlled

temperature

All

AirTemp.TempRoom 1203

100

°C

Actual room temperature (T15

or T10)

All

AirTemp.EffPct

1204

100

%

Passive heat exchanger

efficiency

Compact-Comfort-

Comforti

AirTemp.CapSet

1205

100

%

Requested capacity

All plants

AirTemp.CapAct

1206

100

%

Actual capacity

All plants

All rights reserved

Side 7 af 16

CentralHeat.HeatExt

Set

1800

100

°C

Actual setpoint for external

heating source

All plants

Display.LED_1

2000

User panel indicator light

All plants

Display.LED_2

2001

(reserved future use)

All plants

Display.Text_1_2

2002

ascii

Text line 1 character 1-2

All plants

Display.Text_3_4

2003

ascii

All plants

Display.Text_5_6

2004

ascii

All plants

Display.Text_7_8

2005

ascii

All plants

Display.Attr_1_8

2006

Text line 1 flags

All plants

Display.Text_9_10

2007

ascii

Text line 2 character 9-16

All plants

Display.Text_11_12

2008

ascii

All plants

Display.Text_13_14

2009

ascii

All plants

Display.Text_15_16

2010

ascii

All plants

Display.Attr_9_16

2011

Text line 2 flags

All plants

All rights reserved

Side 8 af 16

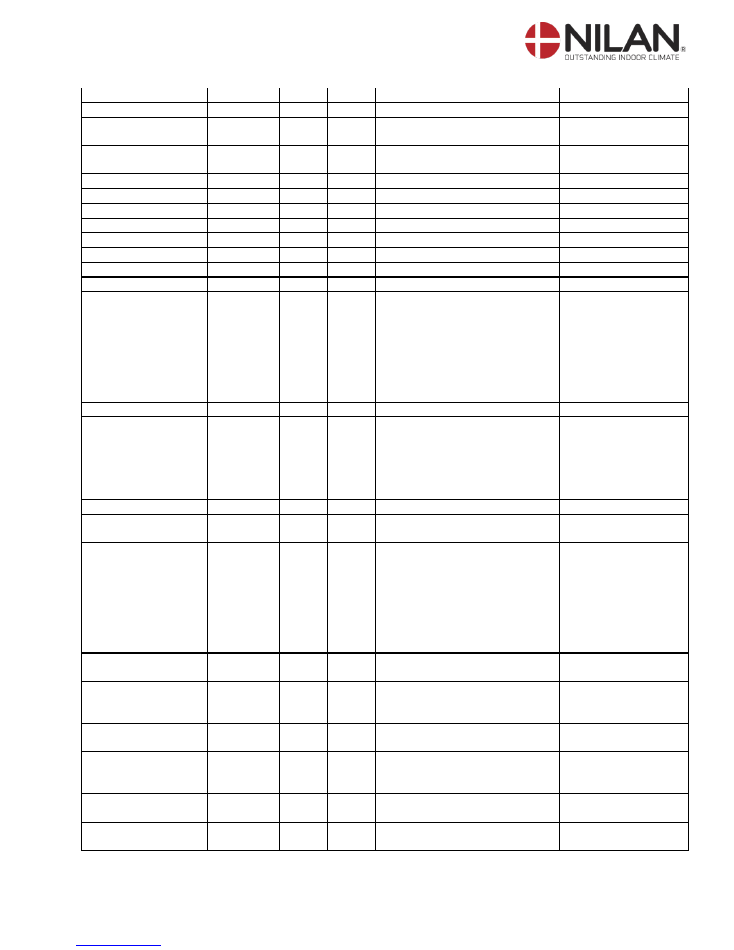

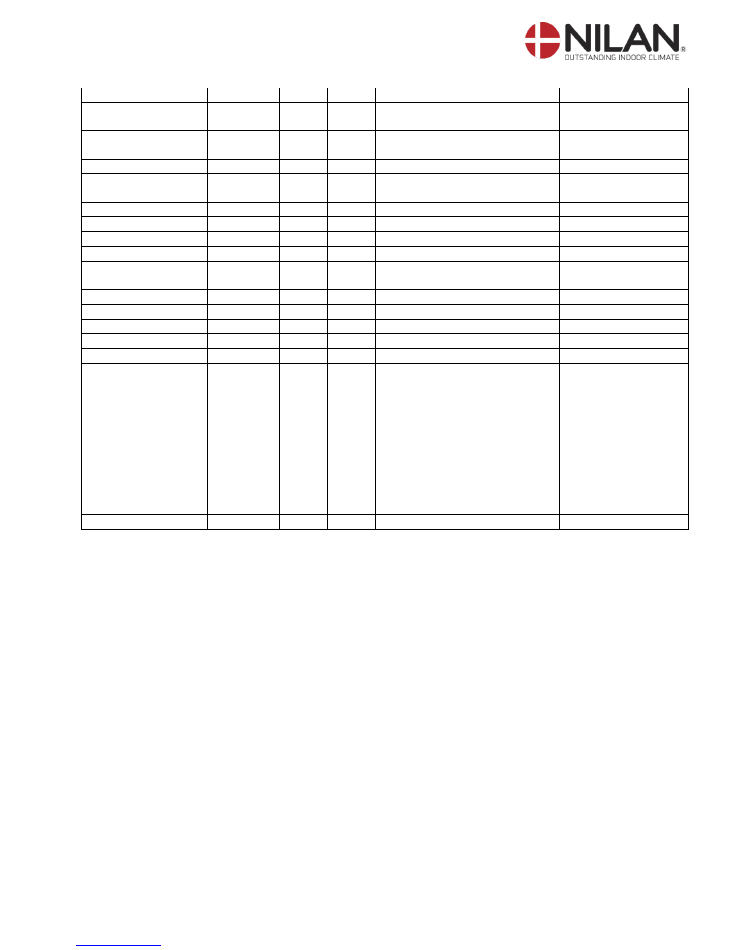

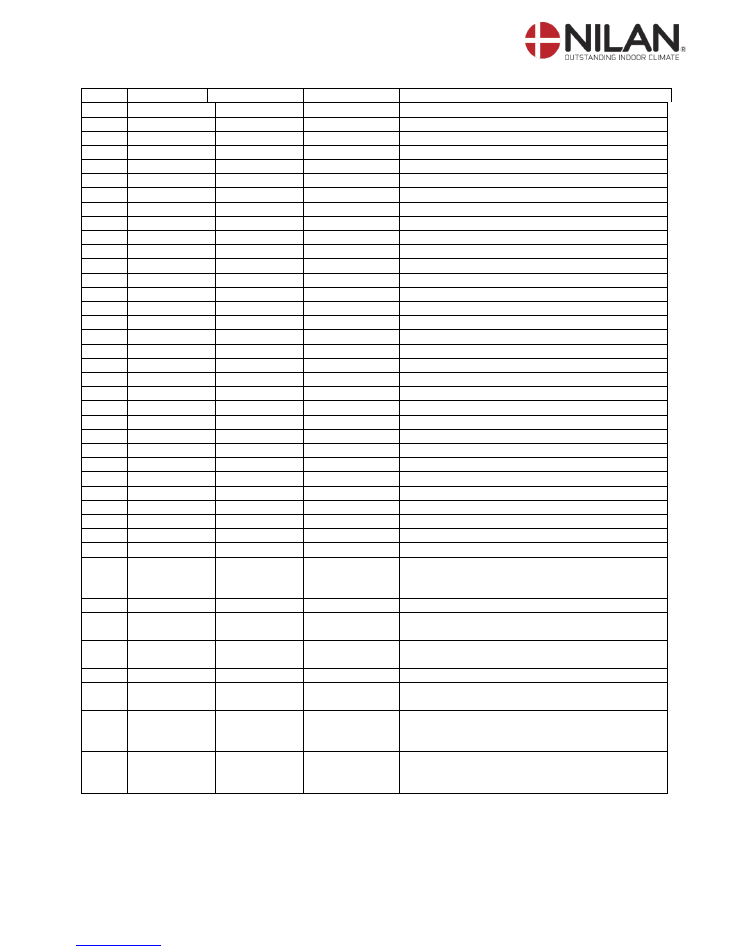

Holding registers:

Name

Address

Scale Unit

Description

Used to plant type

Bus.Address

0

Protocol node address (default =

30)

All plants

Output.AirFlap

100

Air flap

VPL-VPM-VGU-VP-

Comfort-Comforti

Output.SmokeFlap

101

Fire/Smoke flap

VPM-Comforti

Output.BypassOpen

102

Bypass flap open

Compact-Comfort-

Comforti

Output.BypassClose

103

Bypass flap close

Compact-Comfort-

Comforti

Output.AirCircPump

104

Air heat circulation pump

VPM-Comfort-Comforti

Output.AirHeatAllow

105

Air heating selected

VPL-VPM-Compact-

Comfort-Comfortit

Output.AirHeat_1

106

Air heater relays

VPM-Comforti

Output.AirHeat_2

107

--

VPM-Comforti

Output.AirHeat_3

108

--

VPM-Comforti

Output.Compressor

109

Compressor

VPL-VPM-VGU-VP-

Compact

Output.Compressor_

2

110

Compressor 2

Not in use

Output.4WayCool

111

4-way valve

VPL-VPM-VGU-

Compact

Output.HotgasHeat

112

Hotgas valve - heat

VPM

Output.HotgasCool

113

Hotgas valve - cool

VPM

Output.CondOpen

114

Air condenser active

Compact

Output.CondClose

115

Air condenser inactive

Compact

Output.WaterHeat

116

Hot water heater

VGU-VP-Compact

Output.3WayValve

117

Hot water 3-way valve

Not in use

Output.CenCircPump 118

EK circulation pump

VGU-VP

Output.CenHeat_1

119

EK heater relays

VGU-VP

Output.CenHeat_2

120

--

VGU-VP

Output.CenHeat_3

121

--

VGU-VP

Output.CenHeatExt

122

External radiator heat

VPL-VP-Compact-

Comfort

Output.UserFunc

123

User function active

All plants

Output.UserFunc_2

124

--

VPL-VGU-VP-Compact-

Comfort

Output.Defrosting

125

Defrost function active

All plants

Output.AlarmRelay

126

Alarm relay state

All plants

Output.PreHeat

127

Preheater or earth tube

activation

VPL-VGU-VP-Compact-

Comfort

Output.ExhaustSpee

d

200

100

%

Exhaust fan speed

All plants

Output.InletSpeed

201

100

%

Inlet fan speed

VPL-VPM-VP-Compact-

Comfort-Comforti

Output.AirHeatCap

202

100

%

Air heater capacity

VPL-VPM-Compact-

Comfort-Comforti

All rights reserved

Side 9 af 16

Output.CenHeatCap

203

100

%

Central heater capacity

VGU-VP

Output.CprCap

204

100

%

Compresor capacity

VPL-VPM-VGU-VP-

Compact

Output.PreHeatCap

205

100

%

Preheater capacity or earth tube

air intake fan speed

VPcCoB

Time.Second

300

ss

Second

All plants

Time.Minute

301

nn

Minute

All plants

Time.Hour

302

hh

Hour

All plants

Time.Day

303

dd

Day

All plants

Time.Month

304

mm

Month

All plants

Time.Year

305

yyyy

Year

All plants

Alarm.Reset

400

Clear one specific alarm code or

all

0 : No command

1..99 : (reserved internal

commands)

101..199 : Clear alarm display

code 1..99

255 : Clear all alarms

All plants

Program.Select

500

Week program nb. select

0 : None

1 : Program 1

2 : Program 2

3 : Program 3

4 : Erase

All plants

Program.UserFuncAc

t

600

User function active (See

“UserFuncSet”)

All plants

Program.UserFuncS

et

601

User function select

0 : None

1 : Extend

2 : Inlet

3 : Exhaust

4 : External heater offset

5 : Ventilate

6 : Cooker Hood

All plants

Program.UserTimeS

et

602

Min

Min User function period

All plants

Program.UserVentSe

t

603

Step

Step User function ventilation

0 : Off

1..4 : Step number

All plants

Program.UserTempS

et

604

100

°C

User function temperature

(Extend function only)

All plants

Program.UserOffsSet 605

100

°C

User function

temperature(Offset function

only)

All plants

Program.User2Func

Act

610

Same as user function 1 above

VPL-VGU-VP-Compact-

Comfort

All rights reserved

Side 10 af 16

Program.User2Func

Set

611

--

VPL-VGU-VP-Compact-

Comfort

Program.User2Time

Set

612

--

VPL-VGU-VP-Compact-

Comfort

Program.User2VentS

et

613

--

VPL-VGU-VP-Compact-

Comfort

Program.User2Temp

Set

614

--

VPL-VGU-VP-Compact-

Comfort

Program.User2OffsS

et

615

--

VPL-VGU-VP-Compact-

Comfort

Control.Type

1000

Machine type select

Do not use

Control.RunSet

1001

User on / off select (=ON/OFF

keys)

0 : Off (user functions can still

activate operation)

1 : On

All plants

Control.ModeSet

1002

User operation mode select

0 : Off

1 : Heat (no cooling active)

2 : Cool (no heating active)

3 : Auto

4 : Service (read only

– write to

register 1005)

All plants

Control.VentSet

1003

Step

User ventilation step select

0 : Off

1..4 : Step number

All plants

Control.TempSet

1004

100

°C

User temperature setpoint

All plants

Control.ServiceMode 1005

Service mode select

0 : Off

1 : Defrost

2 : Flaps

3 : Inlet

4 : Exhaust

5 : Compressor

6 : Heating

7 : Hot water

8 : Central heat

All plants

Control.ServicePct

1006

100

%

Service mode capacity

All plants

Control.Preset

1007

Request preset to factory

settings

0 : Ready

1 : Standard (to factory default)

2 : Backup (to user file)

3 : Restore (from user file)

All plants

AirFlow.AirExchMode 1100

Air exchange mode

0 : Energy

1 : Comfort

2 : Comfort Water

VPL-VPM-VGU-VP-

All rights reserved

Side 11 af 16

AirFlow.CoolVent

1101

Step

Cooling high ventilation step

VPL-VPM-VP-Compact-

Comfort-Comforti

AirFlow.TestSelect

1102

Select weekly air damper

position self-test

Once enabled, the

function cannot be

deactivated

0: Off

1: Wednesday 0400

2: Wednesday 1200

Comfort-Comforti

AirFlow.LastTestDay

1103

Date of last air damper position

test Bit word packed in DOS

date format (see IR 402 format)

Comfort-Comforti

AirFlow.TestState

1104

Actual air damper position test

state 0: Off

1: Standby

2: Start(Set to Start to run

manual test)

3: Closing

4: Opening

5: OK

6: Error

Comfort-Comforti

AirTemp.CoolSet

1200

100

°C

Cooling temperature setpoint

select

0 : Off (No cooling allowed)

1 : Set + 0 °C (User setpoint

plus 0 degrees)

2: Set + 1 °C

3: Set + 2 °C

4: Set + 3 °C

5: Set + 4 °C

6: Set + 5 °C

7: Set + 7 °C

8 : Set + 10 °C

VPL-VPM-VP-Compact-

Comfort-Comforti

AirTemp.TempMinSu

m

1201

100

°C

Inlet temp. min. summer

VPL-VPM-VP-Compact-

Comfort-Comforti

AirTemp.TempMinWi

n

1202

100

°C

Inlet temp. min. winter

VPL-VPM-VP-Compact-

Comfort-Comforti

AirTemp.TempMaxS

um

1203

100

°C

Inlet temp. max. summer

VPL-VPM-Comfort-

Comforti

AirTemp.TempMaxW

in

1204

100

°C

Inlet temp. max. winter

VPL-VPM-Comfort-

Comforti

AirTemp.TempSumm

er

1205

100

°C

Summer/winter limit

VPL-VPM-VP-Compact-

Comfort-Comforti

AirTemp.NightDayLi

m

1206

100

°C

Outdoor day temperature for

night cooling activation [0:Off,

20..40]

AirTemp.NightSet

1207

100

°C

Free energy night cooling room

setpoint [10..30]

All rights reserved

Side 12 af 16

HotWater.TempSet_

T11

1700

100

°C

Top temperature setpoint

(electric)

VGU-VP-Compact

HotWater.TempSet_

T12

1701

100

°C

Bottom temperature setpoint

(compressor)

VGU-VP-Compact

CentralHeat.HeatExt

ern

1800

100

°C

External heating offset from

room temperature setpoint

VPL-VP-Compact-

VPcCoB-

AirQual.RH_VentLo

1910

Step

Humidity low winter step select

All plants

AirQual.RH_VentHi

1911

Step

Humidity high step select

All plants

AirQual.RH_LimLo

1912

100

%

Humidity limit for low ventilation

AirQual.RH_TimeOut 1913

min

Humidity max. time on high

ventilation

All plants

AirQual.CO2_VentHi

1920

Step

CO2 high step select

All plants

AirQual.CO2_LimLo

1921

ppm

CO2 limit for normal ventilation

All plants

AirQual.CO2_LimHi

1922

ppm

CO2 limit for high ventilation

All plants

Display.KeyCode

2000

User panel keypress

Repeated if not cleared within

400 ms

Combined value with one bit for

each key

0x01 : ESCAPE

0x02 : UP

0x04 : DOWN

0x08 : ENTER

0x10 : OFF

0x20 : ON

All plants

All rights reserved

Side 13 af 16

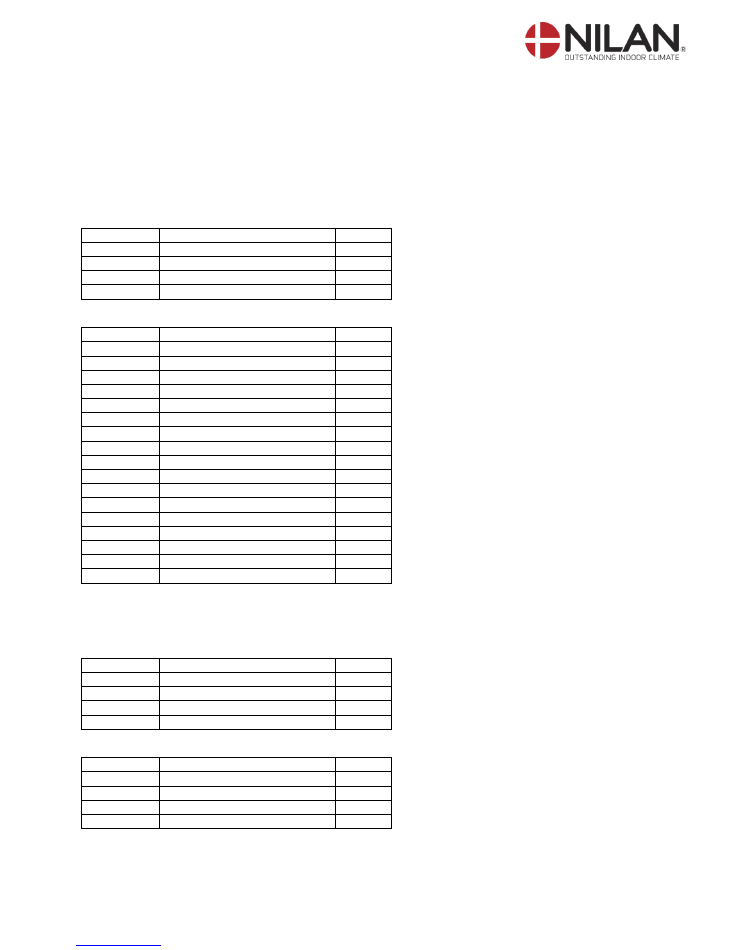

Communication example

The sample shown below is a general Modbus communication example, and is not specific for this

device.

Request: 0b041000000e75a4

Response: 0b041cffff0000095008b0e4a80014000b000108e108f1ffff000f0002fff39f8e

’

Request (Input register)

0x0b

Slave addr

1 byte

0x04

Function code

1 byte

0x1000

Start addr

2 bytes

0x000e

Quantity

2 bytes

0x75a4

CRC

2 bytes

Response

0x0b

Addr

1 byte

0x04

Function code

1 byte

0x1c

NB bytes of data

1 byte

0xffff

Value1

2 bytes

0x0000

Value2

2 bytes

0x0950

Value3

2 bytes

0x08b0

Value4

2 bytes

0xe4a8

Value5

2 bytes

0x0014

Value6

2 bytes

0x000b

Value7

2 bytes

0x0001

Value8

2 bytes

0x08e1

Value9

2 bytes

0x08f1

Value10

2 bytes

0xffff

Value11

2 bytes

0x000f

Value12

2 bytes

0x0002

Value13

2 bytes

0xfff3

Value14

2 bytes

0x9f8e

CRC

2 bytes

Request

0b03200000018f60

Response: 0b030200002045

Request (Holding register)

0x0b

Slave addr

1 byte

0x03

Function code

1 byte

0x2000

Address

2 bytes

0x0001

Quantity

2 bytes

0x8f60

CRC

2 bytes

Response

0x0b

Slave addr

1 byte

0x03

Function code

1 byte

0x02

Quantity

1 byte

0x0000

Value1

2 bytes

0x2045

CRC

2 bytes

All rights reserved

Side 14 af 16

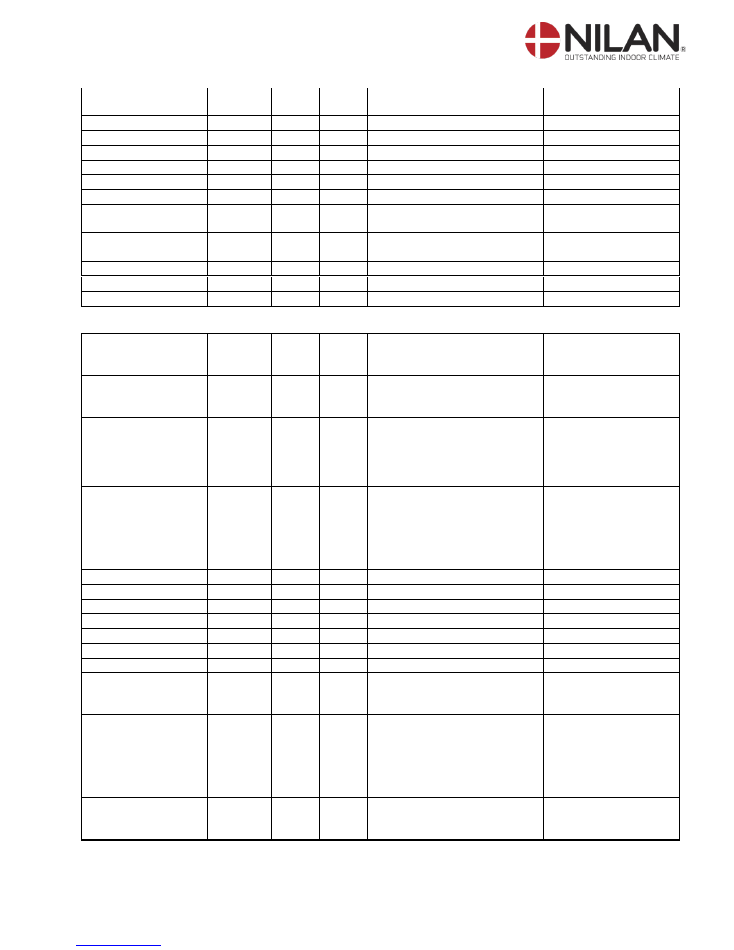

Alarm list

Alarms are divided into these categories:

LOG:

Information only visible in Alarm Log and Data Log

INFO:

Information can be confirmed with the same

WARNING: Warning, may become critical if the problem are not corrected

CRITICAL: Operation is stopped until the fault is corrected and the alarm is acknowledged

RS:

Restart (automatic restart when errors are OK, if selected by menu)

SC:

Self clearing (when receipted pending state again is OK)

See specification and user manual for each plant for a further description of alarms.

Code Text

Type

Subsystem

Function

0

NONE

NONE

System

No alarm

1

HARDWAR

E

CRITICAL

System

Electrical faults (eg, Ur-circuit)

2

TIMEOUT CRITICAL

System

A WARNING has been critically

3

FIRE

CRITICAL

AirFlow

Fire thermostat

4

PRESSURE CRITICAL +

RS

Compressor

High or low pressure pressure switch

5

DOOR

CRITICAL +

SC

AirFlow

Inspection door open

6

DEFROST INFO

Defrost

Defrosting time exceeded (compressor)

7

FROST

CRITICAL

AirTemperature Plants without T9 sensor:

- Water coil freeze thermostat triggered

Systems with T9 sensor

- Water surface could not reach 20 ° C within 6

min.

8

FROST

CRITICAL +

SC

AirTemperature Only plants with T9 sensor

- Water coil freeze thermostat triggered

9

OVERTEMP INFO + SC

CentralHeat

Kettle over temperature (TMax +10 ° C)

10

OVERHEAT INFO + SC

AirHeat

Electric reheating overheating

11

AIRFLOW INFO + SC

AirHeat

Electric reheating lack of air flow

12

THERMO CRITICAL

AirFlow

Ventilation Motor thermal switch

13

BOILING

CRITICAL

HotWater

DHW Water boiling

14

SENSOR

CRITICAL

AirTemperature Elected steered sensor is defect

15

ROOM LOW

CRITICAL

AirFlow

Room temperature below the set minimum.

Winter protection (reduced ventilation) is without

effect.

16

SOFTWARE INFO

System

Program startup / main loop

17

WATCHDO

G

INFO

System

Program execution errors

18

CONFIG

INFO

System

Database content changed - check settings

(eg after software update)

19

FILTER

INFO

AirFlow

Air filter pressure switch or timer

20

LEGIONEL

INFO

HotWater

Legionella Function not executed within the time

limit for the allowed number of attempts

21

POWER

INFO

System

Power outage longer than the backup time on

clock circuit

22

T AIR

INFO

AirTemperature Air temperature errors

23

T WATER INFO

HotWater

DHW temperature errors

24

T HEAT

INFO

CentralHeat

Central heating temperature errors

25

MODEM

INFO

System

Communication error modem (only CTS 600 G1)

All rights reserved

Side 15 af 16

27

T1SHORT

CRITICAL

System

Temperature sensor shorted

28

T1OPEN

CRITICAL

System

Temperature sensor disconnected

29

T2SHORT

CRITICAL

System

Temperature sensor shorted

30

T2OPEN

CRITICAL

System

Temperature sensor disconnected

31

T3SHORT

CRITICAL

System

Temperature sensor shorted

32

T3OPEN

CRITICAL

System

Temperature sensor disconnected

33

T4SHORT

CRITICAL

System

Temperature sensor shorted

34

T4OPEN

CRITICAL

System

Temperature sensor disconnected

35

T5SHORT

CRITICAL

System

Temperature sensor shorted

36

T5OPEN

CRITICAL

System

Temperature sensor disconnected

37

T6SHORT

CRITICAL

System

Temperature sensor shorted

38

T6OPEN

CRITICAL

System

Temperature sensor disconnected

39

T7SHORT

CRITICAL

System

Temperature sensor shorted

40

T7OPEN

CRITICAL

System

Temperature sensor disconnected

41

T8SHORT

CRITICAL

System

Temperature sensor shorted

42

T8OPEN

CRITICAL

System

Temperature sensor disconnected

43

T9SHORT

CRITICAL

System

Temperature sensor shorted

44

T9OPEN

CRITICAL

System

Temperature sensor disconnected

45

T10SHORT

CRITICAL

System

Temperature sensor shorted

46

T10OPEN

CRITICAL

System

Temperature sensor disconnected

47

T11SHORT

CRITICAL

System

Temperature sensor shorted

48

T11OPEN

CRITICAL

System

Temperature sensor disconnected

49

T12SHORT

CRITICAL

System

Temperature sensor shorted

50

T12OPEN

CRITICAL

System

Temperature sensor disconnected

51

T13SHORT

CRITICAL

System

Temperature sensor shorted

52

T13OPEN

CRITICAL

System

Temperature sensor disconnected

53

T14SHORT

CRITICAL

System

Temperature sensor shorted

54

T14OPEN

CRITICAL

System

Temperature sensor disconnected

55

T15SHORT

CRITICAL

System

Temperature sensor shorted

56

T15OPEN

CRITICAL

System

Temperature sensor disconnected

57

T16SHORT

CRITICAL

System

Temperature sensor shorted

58

T16OPEN

CRITICAL

System

Temperature sensor disconnected

70

ANODE

INFO + SC

HotWater

DHW tank anode corroded and needs replacing

(The alarm is deactivated by lice or

disconnection)

71

EXCH INFO

INFO

Defrost

Defrost time exceeded (exchanger)

72

EVAP LOW

CRITICAL

Compressor

Unexpected low evaporator temp T6, due to too

low airflow (only for Compact / Combi plants)

90

SLAVE IO

CRITICAL +

SC

System

(not relevant for the CTS 602)

91

OPT IO

INFO + SC

System

Options Module missing

92

PRESET

INFO

System

Error while writing or reload

installer settings (PRESET menu)

95

SW RJECT

INFO

System

Software update is rejected due to missing

Support for newer hardware in older software

Version (SW2.30+)

96

DAMPTEST

CRITICAL

Air Flow

Self-test of damper moving time has failed.

Check power for damper, opening/ closing

contacts and setting of operation time.

26

INSTABUS

INFO

System

Communication errors network (CTS 600 G1)

All rights reserved

Side 16 af 16

Connection diagram