Full Text Searchable PDF User Manual

ZETADYN 3 Series

Additional information for CANopen Lift

Brief instruction

Additional information for the operating instructions:

ZETADYN 3BF (R-TBA05_08)

ZETADYN 3C (R-TBA08_03)

ZETADYN 3C-MRL (R-TBA09_01)

ZETADYN 3BF009-1 (R-TBA08_02)

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

english

Content

1 General notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

1.1

Validity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

1.2

Structure ofthe operating instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

1.3

Exclusion ofliability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

2 Safety information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

3 Start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.1

Information for start-up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.2

Frequency inverter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.3

Bus-cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.4

Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3

3.5

Electrical connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

3.6

Activating the interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4

3.7

Operation mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5

3.7.1

Command- and Statusbits ofthe recorder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

4 Parameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

4.1

Parameter settings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

4.2

Inf o menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7

4.3

Network Management Status . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

5 Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

5.1

Error diagnosis in CANopen Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

5.2

Error list . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8

Briefinstruction

ZETADYN 3 Series

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

1/9

1 General notes

1.1 Validity

These operating instructions apply to:

Frequency inverter from the series: ZETADYN 3

1.2 Structure of the operating instructions

This instruction is a brief instruction with additional informations. It is valid only in connection

with the following operating instructions:

•

R-TBA05_08 (ZETADYN 3BF)

•

R-TBA08_03 (ZETADYN 3C)

•

R-TBA09_01 (ZETADYN 3C-MRL)

•

R-TBA08_02 (ZETADYN 3BF009-1)

The following informations, described in the operating instructions have to be followed:

•

Safety information

•

Product overview

•

mechanische Installation

•

Electrical installation

•

Service & maintenance

•

Transport

•

Storage duration:

•

Disposal & recycling

Before installation and start-up, read this manual carefully to ensure correct use!

1.3 Exclusion of liability

Concurrence between the contents ofthese operating instructions and the described hardware and

software in the device has been examined.

It is still possible that non-compliances exist; no guarantee is assumed for complete conformity. The

contents ofthis manual are put through periodic reviews. Necessary modi

cations are incorporated

into the next version.

Ziehl-Abegg AG is not liable for damage due to misuse, incorrect use, improper use or as a

consequence ofunauthorized repairs or modi

cations.

2 Safety information

The Safety informations , described in chapter 2 of the operating instructions R-TBA05_08,

R-TBA08_03, R-TBA09_01 or R-TBA08_02 or has to be followed!

Briefinstruction

ZETADYN 3 Series

General notes

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

2/9

3 Start-up

3.1 Information for start-up

Danger!

Defective connections can cause the motor to start unexpectedly or lead to uncontrolled motor

movements.

Reversed connections cause the motor to rotate in the wrong direction. That can cause serious

machine damage.

CAUTION!

Caution!

Incorrectly wired connections can destroy the electrical / electronic components.

Electrostatic discharges can be hazardous to the electronic components and lead to errors in the

software.

3.2 Frequency inverter

•

To operate the installation with CANopen, the frequency inverter must be equipped with

the optional board EM3-ENC-CAN-DCP (Art.-No.357107)!

•

Only devices with the CiA 417 pro

le are allowed.

•

All devices work in 11 bit - mode.

•

By implication, there can be one ZETADYN 3 connected to one bus-system.

•

When two ZETADYN 3 per bus-system are needed, please call Ziehl-Abegg before installing.

3.3 Bus-cable

•

A shielded bus-cable is not needed, but the data wires should be twisted.

•

The installation takes place in line structure. The seperate devices are connected to the bus with

short branch lines.

•

The bus should be terminated with a terminating resistor of120 - 150 Ohms, at both ends ofthe

bus.

•

The maximum length ofthe bus is 200 m and 6 m at the branch lines.

•

All devices normally work with a baud rate of250 kBit/s.

3.4 Wiring

•

The connection ofthe bus cable takes place at the slot "X-CAN" ofthe frequency inverter.

•

Take care ofthe maximum bus length.

•

Not correctly shielded motor- , brake chopper- or brake resistor cables can cause signi

cant

errors.

•

In case ofan error, check the shielding ofthe cables.

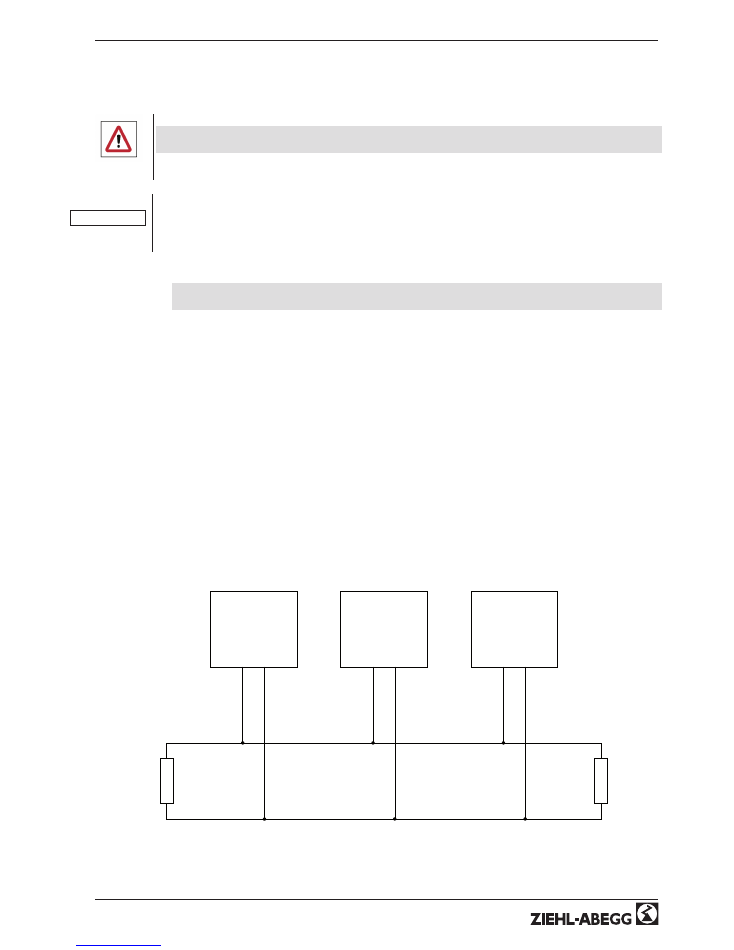

Steuerung /

Control system

Umrichter /

Inverter

Schachtgeber /

Encoder

120 - 150 Ohm

120 - 150 Ohm

Exemplary assembly ofa bus-system with CANopen

Briefinstruction

ZETADYN 3 Series

Start-up

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

3/9

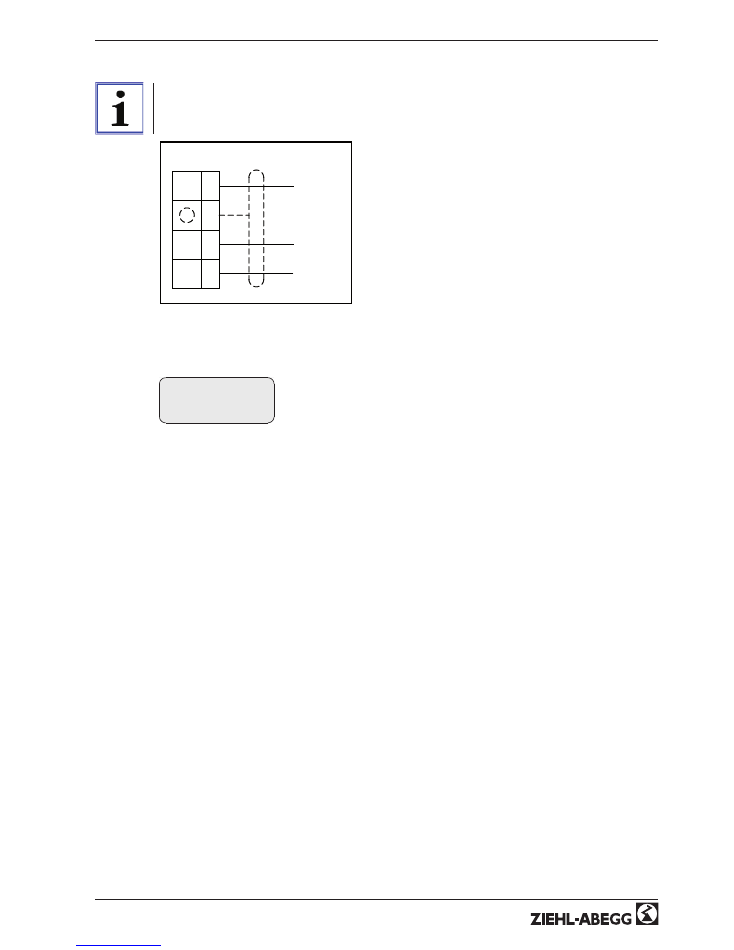

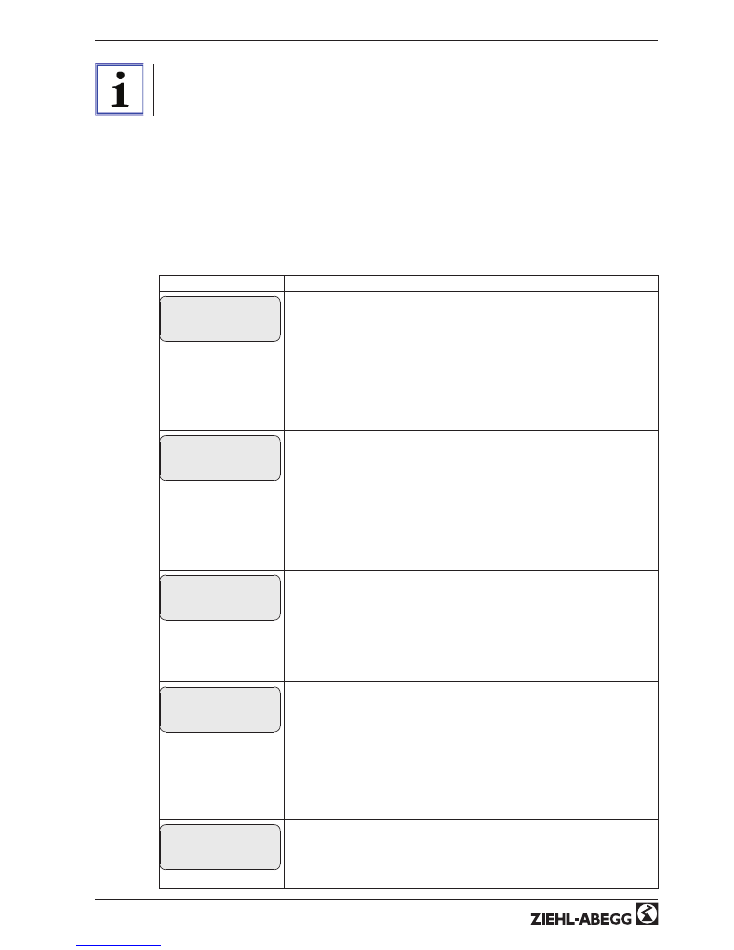

3.5 Electrical connection

Information

The connection ofthe bus cable takes place at the slot X-CAN ofthe frequency inverter.

X-CAN

CL

CH

0VC

CAN High (H)

CAN Low (L)

GND

(1)

(2)

(3)

(4)

Optionaler

Schirmanschluss

Connection CAN

3.6 Activating the interface

The activation ofthe CAN interface can be set in the menu

Control system/CONFIG

.

Control system

|

-

"

CONFIG 01:ZA_IO

|

-

"

02:ZA_CAN

Con

guration

The INFO menu shows CAN information at the pages 14 - 17 (Assumption: "CONFIG" = "02:

ZA_CAN").

Briefinstruction

ZETADYN 3 Series

Start-up

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

4/9

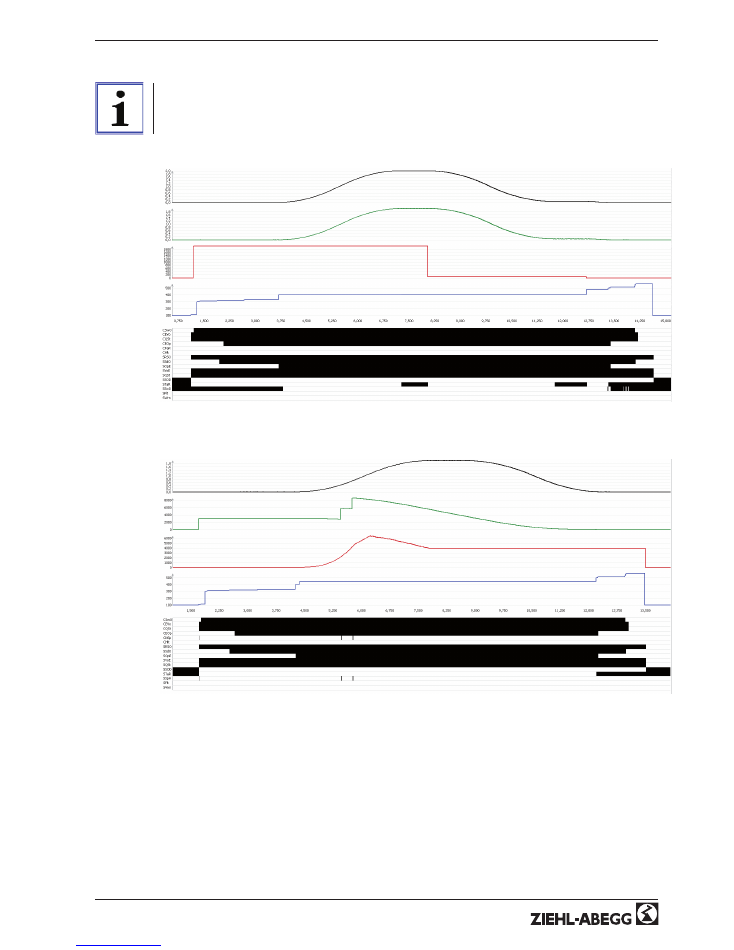

3.7 Operation mode

Information

There are two operation modes by using CAN:

•

Velocity Mode [pv]

Velocity Mode

•

Position Mode [pp]

Position Mode

Briefinstruction

ZETADYN 3 Series

Start-up

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

5/9

3.7.1

Command- and Statusbits of the recorder

•

Position Mode [pp] C&S / Velocity Mode [pv] C&S

•

C = Command = Command from the control system to the frequency inverter

•

S = Status = Status ofthe frequency inverter as reaction ofa command from the control system

Status- / Commandbit

Description

Comment

CSwO

Command Switch On

CEVo

Command Enable Voltage

CQSt

Command Quick Stop

CEOp

Command Enable Operation

CFaR

Command Fault Reset

CNSp

Command New Setpoint

only active in position mode

CHlt

Command Halt

SRSO

Status Ready to Switch On

SSdO

Status Switched On

SOpE

Status Operation Enabled

SVoE

Status Voltage Enabled

SQSt

Status Quick Stop

SSOD

Status Switch On Disabled

STaR

Status Target Reached

SS=0

Status Speed = 0

only active in velocity mode

SSpA

Status Setpoint Acknowledge only active in position mode

SFlt

Status Fault

SWrn

Status Warning

The used mode can be set in the menu "S8: CAN/MODE" ofthe ZETADYN 3. Generally the mode is

sent from the control system to the ZETADYN 3 shortly before start-up. Therefor you have to set the

operation mode in the control system.

When the ZETADYN 3 is operated in position mode, the shaft-encoder has to be connected to the

same bus as the ZETADYN 3.

The control system transmits the travel speed to the frequency inverter before every drive. If the

transmitted speed couldn't be reached, the frequency inverter initiates a pointed arch drive. Therefor

the maximum speed has to be entered in the control system.

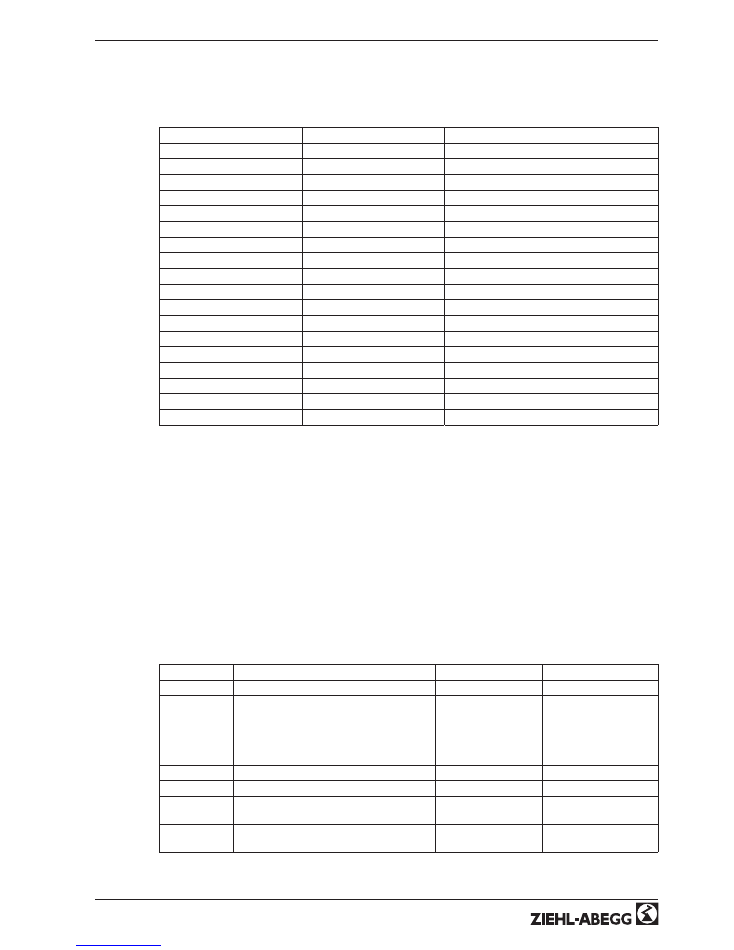

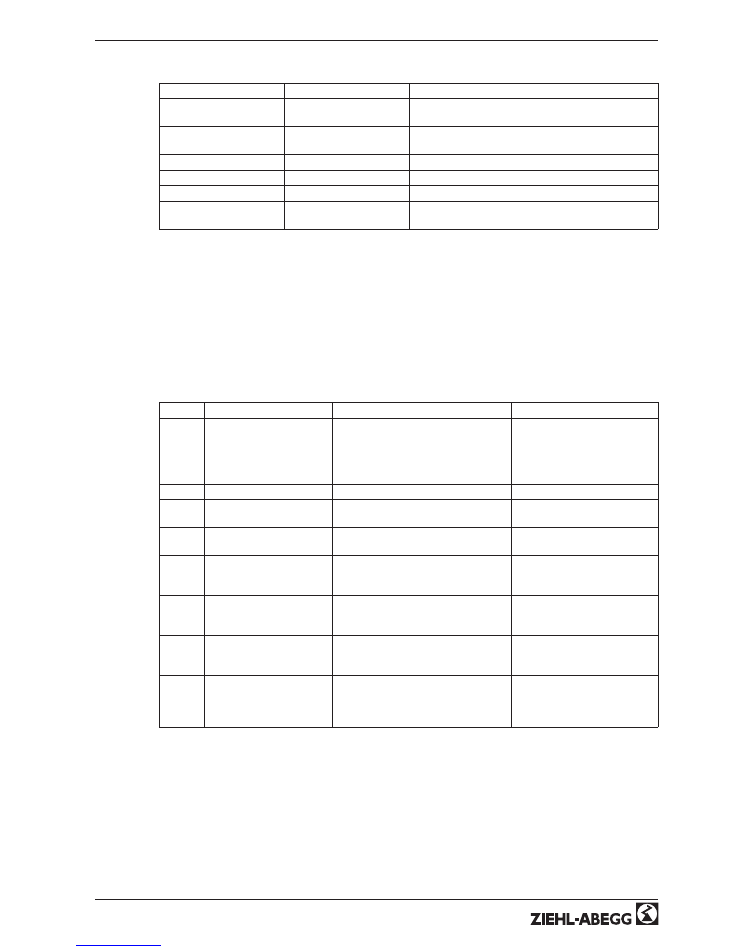

4 Parameter

4.1 Parameter settings

The seperate parameters for CAN operation can be modi

ed in the menu

S8:CAN

.

Parameter

Description

Value range

Factory setting

LIFT_NR

Enter the lift number

1 ... 2

1

NODE_ID

Node number,

normally:

Control system: 1

Frequency inverter: 2

Encoder: 4

1 ... 128

2

BD_RATE

Transfer rate (baud rate)

10 kBd ... 250 kBd

250 kBd

MODE

Operation mode ofthe ZETADYN 3

Position / Velocity

Position

T_CMD

Maximum waiting time for commands of the

control system

200 ... 3000 ms

1500 ms

T_MAX

Maximum processing time for the CAN mes-

sages per cycle.

0,1 ... 3 ms

0.8 ms

Briefinstruction

ZETADYN 3 Series

Parameter

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

6/9

Information

The in the ZETADYN 3 adjusted nominal travel speed V* has to be equal or higher than the speed

which is sent to the ZETADYN 3 by the control system. Otherwise no drive takes place.

4.2 Info menu

The INFO menu provides an easily accessible overview of:

•

Current measurements

•

Current operation conditions ofthe ZETADYN 3

•

Current switching states ofthe inputs and outputs

•

Inverter internal measurements

•

Information about the internal components

The individual pages are numbered for increased clarity.

This is a CAN speci

c instruction. Only the pages 14 - 17 will be described. A complete overview is

shown in the operating instruction ofthe particular inverter.

Display

Description

CAN--------------- -

14

Act

·

Mode: Velocity

T_max: 0 RErr:255

NMT:Preop./Warn.Lim:

Page 14: CAN

Operating information (normal view)

Line 2:

Act: A dot signalizes that the inverter operates with CAN

Mode: Operating mode (velocity or position)

Line 3:

T_max: Number ofcycles, which excessed the maximum process time

RErr: Recieve buffer - error counter

Line 4:

NMT: Shows the actual NMT status (see table 4.3)

CAN--------------- -

14

Act

·

Mode: Velocity

T_max:0.7ms TErr:255

NMT:Preop./Warn.Lim:

Page 14: CAN

Operating information (while pressing "Enter")

Line 2:

Act: A dot signalizes that the inverter operates with CAN

Mode: Operating mode (velocity or position)

Line 3:

T_max: Maximum time for processing the CAN messges per cycle, since switch-on

TErr: Transmit buffer - error counter

Line 4:

NMT: Shows the actual NMT status (see table 4.3)

CAN Velocity------ -

15

V_CAN: + 0mm/s

Contr.:Disable Volt.

Status:Sw. On Disab.

Page 15: CAN Velocity

Active in velocity mode

Line 2:

V_CAN: Travel speed, sent fron the control system to the ZETADYN 3.

Line 3:

Contr. Control-byte. Shows commands which are sent by the control system

Line 4:

Status: Status-byte. Shows CAN-status ofthe ZETADYN 3

CAN Position------ -

16

S_CAN + 0mm

Contr.:Disab. Volt.

Status:Sw.On Disab.

Page 16: CAN Position

Active in position mode

Line 2:

S_CAN: Relative target position, sent from the control system to the ZETADYN 3

Line 3:

Contr. Control-byte. Shows commands which are sent by the control system

Line 4:

Status: Status-byte. Shows CAN-status ofthe ZETADYN 3

After pressing the "Enter" button the display shows the maximum travel

speed, sent by the control system

CAN Calib. 1-------

17

AbsEnc mm: 5358

MotEnc mm:+ 4169

Offs:13081A/M 1.28

Page 17: CAN Calib.

Calibration

Lines 2 - 4:

For calibrating the distances which were sent by the motor encoder and the shaft

encoder.

Briefinstruction

ZETADYN 3 Series

Parameter

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

7/9

4.3 Network Management Status

Status:

BootUp:

ZETADYN 3 is switching to the bus

Stop:

ZETADYN 3 was stopped (normally by the control sys-

tem)

Preop.:

ZETADYN 3 can be parametrised, but before the it has

to be set to "operational".

Opera.:

ZETADYN 3 is ready, a drive can take place.

Controller state:

No Error:

No errors existent

Warn.Lim.:

Error counter exceed 127

Bus off:

Because of too many errors the device was switched

off the bus (Error counter > 255)

5 Error

5.1 Error diagnosis in CANopen Lift

For error diagnosis and elimination the operating instructions R-TBA05_08-D, R-TBA08_03-D, R-

TBA09_01-D and R-TBA08_02-D provide the chapter "Error diagnosis". In this chapter the errors and

the possibilities to eliminate them are described.

5.2 Error list

Error

Error text

Description

Condition

800

CAN: Timeout

Velocity Mode:

Heartbeat from control

system is missing or at wrong time

Position Mode:

In addition to the heart-

beat ofthe control system, the heart-

beat ofthe encoder is also monitored

Only during a drive

810

CAN: Quick Stop Det.

Control system activates a quick stop

Til software version 3.32

820

CAN: Illegal Status

Control system sends commands in

wrong order to the ZETADYN 3.

830

CAN: Timeout Enab. Op.

Controll system gives command "Ena-

ble Operation" not within T_CMD

Til software version 3.32

831

CAN: Timeout Dis. Op.

Control system gives command "Dis-

able Operation" not within T_CMD, hap-

pens at stop.

Not maskable, ifnecessary in-

crease T_CMD

832

CAN: Timeout Shutdown

Happens by closing the brakes, when

control system gives command "Dis-

able Operation" not within T_CMD.

Not maskable, ifnecessary in-

crease T_CMD

833

CAN: Timeout Dis. Vol.

Happens after drive, when control sys-

tem gives command "Disable Voltage"

not within T_CMD.

Not maskable, ifnecessary in-

crease T_CMD

840

CAN: Enc. Info missing

The object Encoder Info, which shows

how much encoder pulses are how

much mm distance wasn't programmed

by the control system

Only Position Mode / not mask-

able!

Briefinstruction

ZETADYN 3 Series

Error

R-TBA11_01-GB 1114

Part.-No. 00163371-GB

8/9

©

by

Ziehl-Abegg

-

-00163371-GB

-1

11

4

-

-Subject

to

technical

changes

HOTLINE

%

Tel.

+49 (0) 7940 16-308

Fax

+49 (0) 7940 16-249

email hotline.ra@ziehl-abegg.de

Ziehl-Abegg AG

Heinz-Ziehl-Stra

ß

e

·

D-74653 K

ü

nzelsau

·

Germany

Tel. +49 (0) 7940 16-0

·

Fax +49 (0) 7940 16-249

drives@ziehl-abegg.de

·

www.ziehl-abegg.com