Full Text Searchable PDF User Manual

Yingli Solar PV Modules, Installation and User Manual

page 1

This manual applies to photovoltaic modules (“PV modules”,

also commonly known as solar panels) manufactured by

Yingli Green Energy Holding Co. Ltd. (“Yingli Solar”), and

is explicitly written for qualified professionals (“Installer”

or “Installers”), including without limitation licensed

electricians and RAL Certified PV Installers.

I N T R O D U C T I O N

Thank you for choosing Yingli Solar as your PV module provider. We

appreciate your business! This manual contains important information

pertaining to the electrical and mechanical installation and maintenance

of PV modules, and contains safety information that you must read carefully

and be familiar with before handling, installing, and/or maintaining Yingli Solar

PV modules.

Yingli Solar does not assume responsibility and expressly disclaims liability for

losses, damages, or expenses arising out of, or in any way connected with this

Installation and User Manual. Yingli Solar assumes no responsibility for any

infringement of patents or other rights of third parties, which may result from

using Yingli Solar PV modules. No license is granted expressly or by implication

or under any patent or patent rights. The information in this manual is believed

to be reliable, but does not constitute an expressed or implied warranty. Yingli

Solar reserves the right to make changes to its PV modules and other products,

their specifications, or this manual without prior notice.

Yingli Solar and its subsidiaries are not liable for any damages caused by

inappropriate installation, use, or maintenance of Yingli Solar PV modules,

including without limitation damages, losses, and expenses caused by non-

observance of the instructions of this manual or caused by or in connection with

products of other manufacturers.

Yingli Solar PV modules are designed to meet the requirements for the standards

IEC 61215 and IEC 61730, application class A. Modules rated for use in this

application class may be used in systems operating at greater than 50 V DC

or 240 W, where general contact access is anticipated. Modules qualified for

safety through IEC 61730-1 and IEC 61730-2 and within this application class are

considered to meet the requirements for safety class II. In the course of the PV

module certification process, the compliance of this manual with the certification

requirements has been verified by an independent certification laboratory.

This Installation and User Manual is available in different languages. In cases of

discrepancy between versions, the English language version shall control.

Failure to comply with the requirements listed in this manual will invalidate the

Limited Warranty for PV Modules as provided by Yingli Solar at the time of sale

to the direct customer. Additional recommendations are provided to enhance

safety practices and performance results. Please provide a copy of this manual

to the PV system owner for their reference, and inform them of all relevant

aspects of safety, operation, and maintenance.

S A F E T Y

General

You must understand and follow all applicable local, state, and federal

regulations and standards for building construction, electrical design, fire,

and safety, and must check with local authorities to determine applicable

permitting requirements before attempting to install or maintain PV modules.

Rooftop PV systems should only be installed on dwellings that have been

formally analyzed for structural integrity, and confirmed to be capable

of handling the additional weighted load of PV system components,

including PV modules, by a certified building specialist or engineer.

For your safety, do not attempt to work on a rooftop until

safety precautions have been identified and taken, including

without limitation fall protection measures, ladders or

stairways, and personal protective equipment (PPE).

For your safety, do not install or handle PV modules under adverse conditions,

including without limitation strong or gusty winds, and wet or frosted roof surfaces.

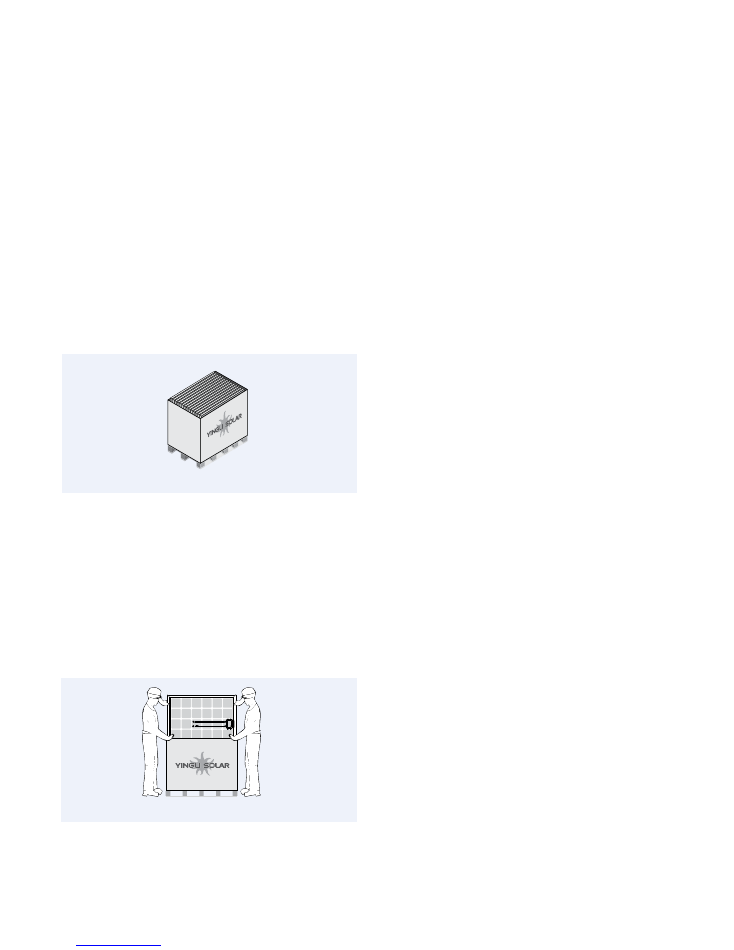

The flat-plate PV module construction consists of a laminated assembly

of solar cells encapsulated within an insulating material with a rigid

glass surface and an insulated substrate. The laminated assembly is

supported by an aluminum frame that is also used for mounting the

module. See Figure 1 for an illustration of the PV module components.

Figure 1: Module components and cross-section of the laminated assembly

Electrical

PV modules can produce current and voltage when exposed to

light of any intensity. Electrical current increases with higher

light intensity. DC voltage of 30 Volts or higher is potentially

lethal. Contacting the live circuitry of a PV system operating

under light can result in lethal electric shock.

Junction Box

Cable

Connector

Cell

Frame

1

1. Aluminum Frame

2. Glass

3. Encapsulating EVA

4. PV Cell

5. Backsheet

2

3

5

4

y i n g l i s o l a r . c o m

YINGLI SOLAR PV MODULES

Installation and User Manual

Revision Date Apr 19th, 2016 | Applicable for IEC certified products

File name: Corporate Logo with Tagline / Vertical.ai

Yingli Solar PV Modules, Installation and User Manual

page 2

De-energize PV modules by removing them entirely from light or by

covering

their front surface with an opaque material. Regard the safety regulations for

live electrical equipment when working with modules that are exposed to any

light. Use insulated tools and do not wear metallic

jewelry while working with

PV modules.

In order to avoid arcing and electrical shock, do not disconnect electrical

connections under load. Faulty connections can also result in arcing and

electrical shock. Keep connectors dry and clean, and ensure that they are in

proper working condition. Never insert metallic objects into the connectors, or

modify them in any way in order to secure an electrical connection.

Do not touch or handle PV modules with broken glass, separated frames or

a damaged backsheet unless the PV modules are first disconnected and you

are wearing proper PPE. Avoid handling PV modules when they are wet unless

cleaning the PV modules as directed in this manual. Never touch electrical

connections that are wet without protecting yourself with insulated gloves.

Transport and Handling

Yingli Solar PV modules must be transported in the supplied packaging only and

kept in the packaging until they are ready to be installed. Protect pallets against

movement and exposure to damage during transportation. Secure pallets from

falling over. Do not exceed the maximum height of pallets to be stacked, as

indicated on the pallet packaging. Store pallets in a cool and dry location until

the PV modules are ready to be unpackaged.

Figure 2: Pallet of PV modules

Yingli Solar PV modules are heavy, and should be handled with care. PV modules

shall be handled at the frame; never use the junction box or cables as a grip. Do

not exert mechanical stress on the cables. Never step on PV modules or drop

or place heavy objects on them. Be careful when placing PV modules on hard

surfaces, and secure them from falling. Broken glass can result in personal injury.

PV modules with broken glass cannot be repaired and must not be used. Broken

or damaged PV modules must be handled carefully and disposed of properly.

For unpacking PV modules from the Yingli Solar supplied packaging, first remove

the pallet lid (after removing securing straps, if provided). Remove PV modules

one at a time by sliding them up the channel in the package (see Figure 3). You

may need to secure the remaining PV modules in the pallet packaging to prevent

them from falling over.

Figure 3: Removing PV modules from a pallet

Check PV modules for damage due to transportation before they are installed;

do not install damaged modules. Contact the company you purchased the Yingli

Solar PV modules from in order to obtain information on making claims for

defective PV modules.

PV module surfaces are susceptible to damage that could affect the performance

or safety of the PV module; do not damage or scratch the PV module surfaces,

and do not apply paint or adhesive to any of the surfaces, including the frame.

For your safety, do not disassemble or modify Yingli Solar PV modules in any

way. Doing so may degrade performance or cause irreparable damage and will

void any applicable warranties.

If it is necessary to store PV modules prior to installation, the PV modules

should remain inside the packaging and protected from exposure that could

compromise the durability of the packaging.

Fire

Yingli Solar PV Modules have a Class C fire resistance rating in accordance with

the IEC 61730-2 certification. When PV modules are mounted on rooftops, the

roof must have a fire resistant covering suitable for this application. PV modules

are electrical generating devices that may affect the fire safety of a building.

The use of improper installation methods and/or defective parts may result

in the unexpected occurrence of an electrical arc during operation. In order to

mitigate the risk of fire in this event, PV modules should not be installed near

flammable liquids, gases, or locations with hazardous materials.

In the event of a fire, PV modules may continue to produce a dangerous voltage,

even if they have been disconnected from the inverter, have been partly or

entirely destroyed, or the system wiring has been compromised or destroyed. In

the event of fire, inform the fire crew about the particular hazards from the PV

system, and stay away from all elements of the PV system during and after a fire

until the necessary steps have been taken to make the PV system safe.

A P P L I C AT I O N I N F O R M AT I O N

Application Restrictions

Yingli Solar PV modules must be mounted on appropriate mounting structures

positioned on suitable buildings, the ground, or other structures suitable for PV

modules (e.g. carports, building facades or PV trackers). PV modules must not

be mounted on moving vehicles of any kind. Yingli Solar PV modules must not

be installed in locations where they could be submerged in water.

Yingli Solar PV modules must not be sited in locations where aggressive

substances such as salt or salt-water, or any other type of corrosive agent, could

affect the safety and/or performance of the PV modules. Although some types

of Yingli Solar PV modules have passed the IEC 61701 salt-mist corrosion test

with a salt concentration of 5% by weight, galvanic corrosion can occur between

the aluminum frame of the PV module and mounting or grounding hardware if

such hardware is comprised of dissimilar metals. Yingli Solar recommends that

only stainless steel and aluminum metal directly contact PV modules in seaside

installations to limit corrosion.

Artificially concentrated light must not be directed on Yingli Solar PV modules.

Design Recommendations

Yingli Solar recommends that PV modules be mounted at a minimum tilt angle

of 10 degrees to allow for proper self-cleaning from normal rain showers.

Partial or complete shading of a PV module or modules can significantly reduce

system performance. Yingli Solar recommends minimizing the amount of shade

throughout the year to increase the amount of energy produced by the PV

modules.

Lightning protection is recommended for PV systems that are to be installed in

locations with high probability of lightning strikes.

High system voltages could be induced in the event of an indirect

lightning

strike, which could cause damage to PV system components.

The open area of

wire loops should be minimized, as shown in Figure 4,

in order to reduce the risk

Series wiring (voltage additive)

Parallel wiring (current additive)

Fully engage and lock

Cap

+

–

Yingli Solar PV Modules, Installation and User Manual

page 4

Figure 7: Electrical circuitry of cells and bypass diodes

In the event of a known or suspected diode failure, installers or maintenance

providers should contact the company the PV modules were purchased from.

Never attempt to open the junction box of a Yingli Solar PV module yourself.

PV Array Grounding

For optimal performance, Yingli Solar recommends that the negative pole of the

PV array be connected to ground.

Equipment Grounding

The frame of the PV module, as well as any exposed non-current-carrying metal

parts of fixed equipment that are able to become energized by the PV system,

must be connected to the equipment grounding conductor (EGC) in order to

prevent electrical shock. Even when applicable regulations, code requirements,

and standards do not require safety-related grounding, Yingli Solar recommends

grounding all PV

module frames in order to ensure the voltage between

electrically conductive equipment and earth ground is zero in all circumstances.

Proper equipment grounding is achieved by bonding all exposed non-current-

carrying metal equipment continuously to one another using an appropriately

sized EGC or racking system that can be used for integrated grounding (see

Option B in Grounding Methods below).

Yingli Solar PV modules employ a coated aluminum frame for corrosion

resistance. In order to properly ground the module frame, the coating must be

penetrated.

The potential for corrosion due to the electrochemical action between dissimilar

metals in contact is minimized if the electrochemical voltage potential between

the dissimilar metals is low. The grounding method must not result in the direct

contact of dissimilar metals with the aluminum frame of the PV module that

will result in galvanic corrosion. An addendum to UL Standard 1703 “Flat Plate

Photovoltaic Modules and Panels” recommends metal combinations not exceed

an electrochemical potential difference of 0.5 Volts.

The frame rails have pre-drilled holes marked with a grounding sign, as

illustrated in Figure 8. These holes should be used for grounding

purposes and

must not be used for mounting the PV modules. Do not drill additional holes

into the frame rails.

Figure 8: Grounding hole detail

The following grounding methods are available:

Option A: Screw Assembly (see Figure 9)

1. A grounding screw assembly must be attached at a designated grounding

hole location using only stainless steel hardware. Insert an M5 stainless

steel screw first through the stainless steel cup washer, and then through the

grounding hole.

2. Loosely engage a stainless steel backing nut and toothed lock washer to the

screw.

Figure 9: Grounding screw assembly detail

3. Bend the EGC into an omega (Ω) shape to tightly fit between the partially

installed screw head and cup washer. The EGC shall be exclusively in contact

with stainless steel.

4. Tighten the screw to 2.3 N∙m torque. The toothed lock washer should be

visibly engaged to the frame.

5. Route the appropriately sized EGC in such a way as to avoid contact with the

aluminum module frame.

Option B: Racking Manufacturer Integrated

Grounding Methods

Yingli Solar PV modules can be grounded by bonding PV modules to a grounded

racking system. Integrated grounding methods must be certified for grounding

PV modules and must be installed in accordance with the specified instructions

of their respective manufacturers.

option c: additional Third-party grounding Devices

Yingli Solar PV modules can be grounded using third party grounding devices so

long as they are certified for grounding PV modules and the devices are installed

according to the manufacturer’s specified instructions.

M E C H A N I C A L I N S TA L L AT I O N

General

Yingli Solar PV Modules have been certified for a maximum static load on the

back of the module of up to 2400 Pa (i.e. wind load) and a maximum static load

on the front of the module of up to either 2400 Pa or 5400 Pa (i.e. wind and

snow load), depending on the module type (please refer to the data sheet for

this information).

Mounting structures and other mechanical parts must be designed and approved

to withstand the design wind and snow loads applicable for a particular site.

Yingli Solar PV modules must not be subjected to forces from the substructure,

including forces caused by thermal expansion.

The mounting method must not result in the direct contact of dissimilar

metals with the aluminum frame of the PV module that will result in galvanic

corrosion. An addendum to UL Standard 1703 “Flat Plate Photovoltaic Modules

and Panels” recommends metal combinations not exceed an electrochemical

potential difference of 0.5 Volts.

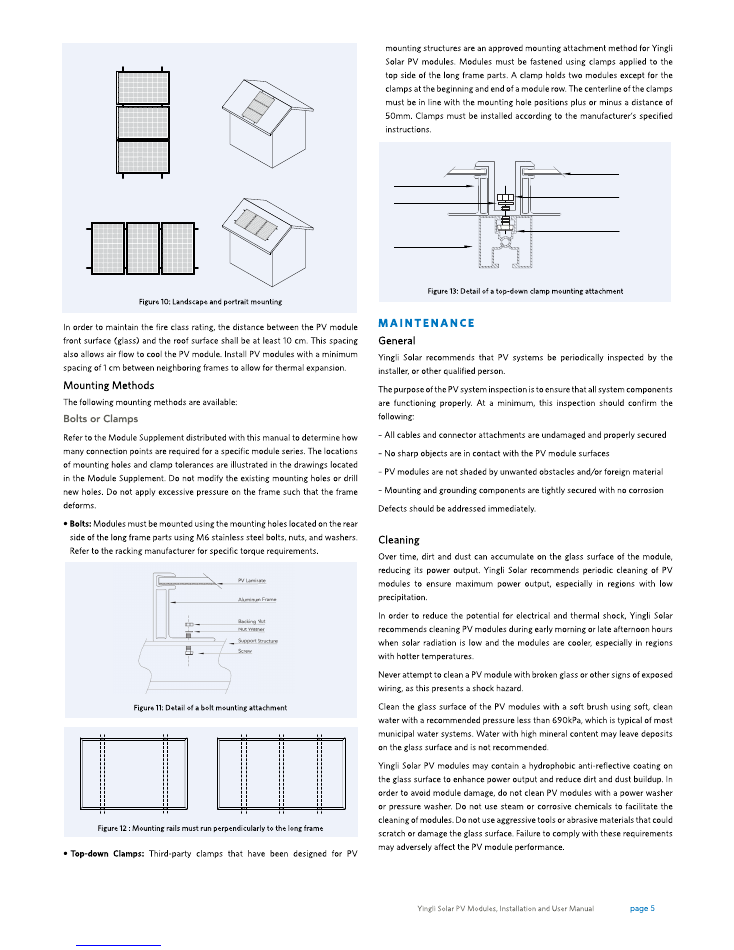

Yingli Solar PV modules can be mounted in landscape or portrait orientation, as

illustrated in Figure 10, provided that the mounting method follows one of the

acceptable methods listed below.

Grounding Holes

ø0.236in (6mm)

PV Laminate

Backing Nut

Toothed Lock Washer or KEPS Nut

Cup Washer

Aluminum

Frame

Screw

Equipment

Grounding

Conductor

Landscape Orientation

Portrait Orientation

Screw

Backing Nut

Nut Washer

PV Laminate

Mounting Rail

Aluminum Frame

Yingli Solar PV Modules, Installation and User Manual

page 6

Yingli Solar PV modules are designed to withstand high snow loads. However, if

removing snow is desired to enhance production, use a brush to gently remove

snow. Do not try to remove frozen snow or ice from PV modules.

D E CO M M I S S I O N I N G

The dismantling of PV systems must be performed with the same care and

safety precautions used during the initial installation. The PV system can

generate hazardous voltage even after the system has been disconnected.

Follow safety regulations for working with live electrical equipment.

R E C YC L I N G

Yingli Solar is a member of PV Cycle, the European association for voluntary

take back and recycling of PV modules. Please contact PV Cycle at www.

pvcycle.org for details regarding the recycling process.

© Yingli Green Energy Holding Co. Ltd.

InstallationManual_IEC_EN_20160419_V03

YINGLISOLAR.COM

NYSE:

YGE

Yingli Green Energy Holding Co., Ltd.

service@yingli.com

Service hotline:+86-312-2188055

Complaints hotline:+86-312-8922216

Yingli Solar PV Modules, Installation and User Manual

page 7

The information in this supplement is believed to be reliable, but does not constitute an expressed or implied warranty. Yingli Solar reserves the right to make

changes to its PV modules and other products, their specifications, or this supplement without prior notice.

This supplement to the installation manual does not contain information about some older module series no longer being manufactured by Yingli Solar. If you require

information about such modules, please contact Yingli Solar.

This supplement refers to modules of the following types:

Table 1: Module types

FAMILY

YGE 60 Cell Series 2

YGE 72 Cell Series 2

PANDA 50 Cell

Series

PANDA 60 Cell

Series 2

PANDA 72 Cell

NH Series

YLM 50 Cell

Series

YLM 60 Cell

40mm Series

YLM 72 Cell 40mm

Series

TYPE

YL250P-29b

YL300P-35b

YL220C-25b

YL260C-30b

YL310C-36b

YL215D-25b

YL260D-30b

YL315D-36b

YL255P-29b

YL305P-35b

YL225C-25b

YL265C-30b

YL315C-36b

YL220D-25b

YL265D-30b

YL320D-36b

YL260P-29b

YL310P-35b

YL230C-25b

YL270C-30b

YL320C-36b

YL225D-25b

YL270D-30b

YL325D-36b

YL265P-29b

YL315P-35b

YL235C-25b

YL275C-30b

YL325C-36b

YL230D-25b

YL275D-30b

YL330D-36b

YL270P-29b

YL320P-35b

YL240C-25b

YL280C-30b

YL330C-36b

YL235D-25b

YL280D-30b

YL335D-36b

YL275P-29b

YL325P-35b

YL245C-25b

YL285C-30b

YL335C-36b

YL240D-25b

YL285D-30b

YL340D-36b

YL280P-29b

YL330P-35b

YL250C-25b

YL290C-30b

YL340C-36b

YL345D-36b

YL285P-29b

YL335P-35b

YL295C-30b

YL345C-36b

YL290P-29b

YL340P-35b

YL300C-30b

YL350C-36b

YL345P-35b

YL355C-36b

YL350P-35b

YL360C-36b

YINGLI SOLAR PV MODULES

Module Supplement

Revision Date July 20th

,

2016 | Applicable for IEC certified products.

File name: Corporate Logo with Tagline / Vertical.ai

M O U N T I N G R E Q U I R E M E N T S

Mounting Method: Bolts and Clamps

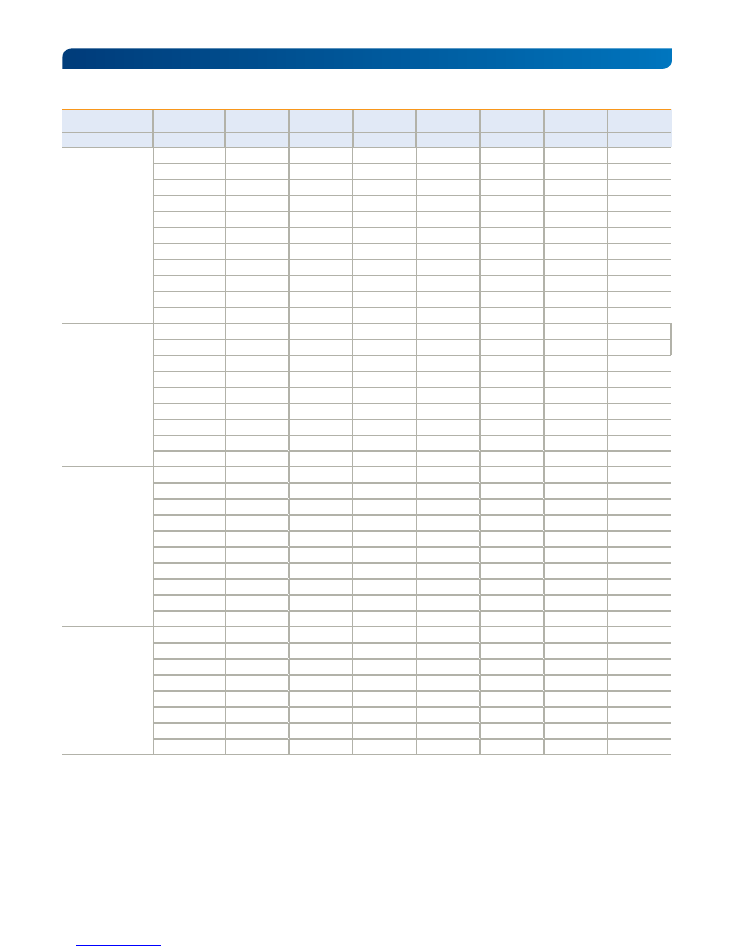

Table 2: Mounting requirements

Modules that Require

Four (4) Connection Points

Modules that Require

Six (6) Connection Points

YGE 60 Cell Series 2

YGE 72 Cell Series 2

PANDA 50 cell series

PANDA 72 Cell NH Series

PANDA 60 Cell Series 2

YLM 72 Cell 40mm Series

YLM 50 cell series

YLM 60 Cell 40mm Series

E L E C T R I C A L C H A R AC T E R I S T I C S

Nameplate ratings are average values. The electrical characteristics are within +/- 10 percent of the indicated values of Isc, Voc, and Pmax under Standard Test

Conditions (irradiance of 1000 W/m

2

, AM 1.5 spectrum, and a cell temperature of 25°C). Refer to module datasheets for specific power output tolerances. Note that

not necessarily all power classes are available for all module series given in the first column of Table 3. Please refer to Table 1 to see which power classes actually

exist for which module series.

Yingli Solar PV Modules, Installation and User Manual

page 8

Table 3: Electrical characteristics

Series

Module

P

max

V

mpp

I

mpp

V

oc

I

sc

Max. system

voltage

Max. series fuse

rating

[W]

[V]

[A]

[V]

[A]

[V]

[A]

YGE 72 Cell Series 2

YL350P-35b

350

47.2

9.51

38.2

9.17

1000

15

YL345P-35b

345

47.0

9.45

38.0

9.08

1000

15

YL340P-35b

340

46.7

9.40

37.8

9.00

1000

15

YL335P-35b

335

46.7

9.34

37.6

8.91

1000

15

YL330P-35b

330

46.4

9.29

37.4

8.84

1000

15

YL325P-35b

325

46.3

9.24

37.3

8.72

1000

15

YL320P-35b

320

37.0

8.64

46.0

9.18

1000

15

YL315P-35b

315

36.8

8.56

45.7

9.12

1000

15

YL310P-35b

310

36.3

8.53

45.6

8.99

1000

15

YL305P-35b

305

36.1

8.45

45.4

8.93

1000

15

YL300P-35b

300

35.8

8.37

45.2

8.86

1000

15

YGE 60 Cell Series 2

YL290P-29b

290

38.6

9.65

31.9

9.12

1000

15

YL285P-29b

285

38.4

9.55

31.6

9.02

1000

15

YL280P-29b

280

38.2

9.45

31.4

8.92

1000

15

YL275P-29b

275

37.9

9.35

31.0

8.90

1000

15

YL270P-29b

270

37.9

9.27

30.7

8.80

1000

15

YL265P-29b

265

30.5

8.70

37.8

9.18

1000

15

YL260P-29b

260

30.3

8.59

37.7

9.09

1000

15

YL255P-29b

255

30.0

8.49

37.7

9.01

1000

15

YL250P-29b

250

29.8

8.39

37.6

8.92

1000

15

PANDA 72 Cell

NH

Series

YL360C-36b

360

40.2

8.95

47.8

9.27

1000

15

YL355C-36b

355

39.8

8.92

47.6

9.26

1000

15

YL350C-36b

350

39.4

8.89

47.4

9.26

1000

15

YL345C-36b

345

39.0

8.85

47.2

9.26

1000

15

YL340C-36b

340

38.5

8.82

47.0

9.25

1000

15

YL335C-36b

335

38.1

8.79

46.8

9.25

1000

15

YL330C-36b

330

37.7

8.76

46.6

9.25

1000

15

YL325C-36b

325

37.3

8.72

46.4

9.24

1000

15

YL320C-36b

320

36.8

8.69

46.2

9.24

1000

15

YL315C-36b

315

36.4

8.65

46.0

9.23

1000

15

PANDA 60 Cell Series 2

YL300C-30b

300

32.7

9.16

40.1

9.66

1000

15

YL295C-30b

295

32.4

9.11

39.9

9.62

1000

15

YL290C-30b

290

32.0

9.06

39.6

9.58

1000

15

YL285C-30b

285

31.6

9.01

39.4

9.54

1000

15

YL280C-30b

280

31.3

8.96

39.1

9.5

1000

15

YL275C-30b

275

30.9

8.91

38.8

9.47

1000

15

YL270C-30b

270

30.5

8.85

38.6

9.43

1000

15

YL265C-30b

265

30.1

8.79

38.3

9.37

1000

15

Yingli Solar PV Modules, Installation and User Manual

page 9

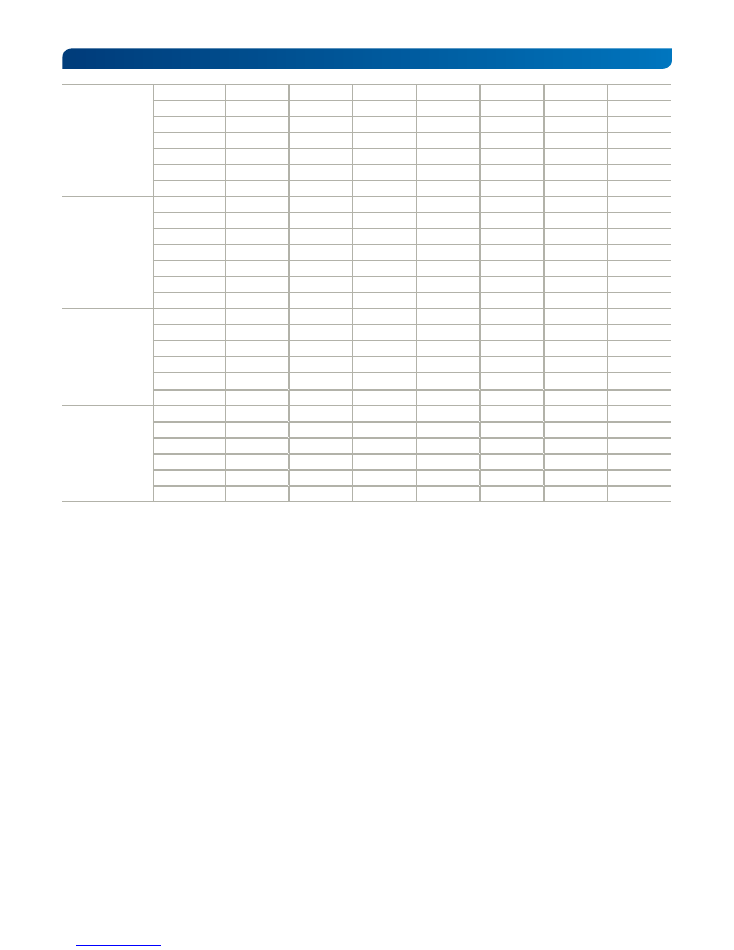

PANDA 50 Cell Series

YL250C-25b

250

27.6

9.06

33.3

9.73

1000

15

YL245C-25b

245

27.3

8.97

33.1

9.62

1000

15

YL240C-25b

240

26.9

8.92

32.9

9.50

1000

15

YL235C-25b

235

26.5

8.87

32.6

9.41

1000

15

YL230C-25b

230

26.1

8.81

32.4

9.34

1000

15

YL225C-25b

225

25.8

8.72

32.2

9.15

1000

15

YL220C-25b

220

25.6

8.59

32.0

9.03

1000

15

YLM 72 Cell 40mm

Series

YL345D-36b

345

38.3

9.02

47.7

9.38

1000

15

YL340D-36b

340

37.9

8.97

47.3

9.35

1000

15

YL335D-36b

335

37.6

8.91

46.9

9.32

1000

15

YL330D-36b

330

37.2

8.86

46.6

9.29

1000

15

YL325D-36b

325

36.9

8.81

46.2

9.27

1000

15

YL320D-36b

320

36.6

8.75

45.9

9.24

1000

15

YL315D-36b

315

36.2

8.69

45.5

9.21

1000

15

YLM 60 Cell 40mm

Series

YL285D-30b

285

31.7

9.00

39.6

9.41

1000

15

YL280D-30b

280

31.4

8.91

39.3

9.38

1000

15

YL275D-30b

275

31.2

8.82

38.9

9.34

1000

15

YL270D-30b

270

30.9

8.73

38.6

9.31

1000

15

YL265D-30b

265

30.7

8.64

38.3

9.27

1000

15

YL260D-30b

260

30.4

8.56

38.0

9.24

1000

15

YLM 50 Cell Series

YL240D-25b

240

27.1

8.87

32.9

9.41

1000

15

YL235D-25b

235

26.7

8.81

32.5

9.38

1000

15

YL230D-25b

230

26.3

8.75

32.1

9.34

1000

15

YL225D-25b

225

25.9

8.69

31.7

9.31

1000

15

YL220D-25b

220

25.5

8.63

31.3

9.27

1000

15

YL215D-25b

215

25.1

8.57

31.0

9.24

1000

15

Yingli Solar PV Modules, Installation and User Manual

page 10

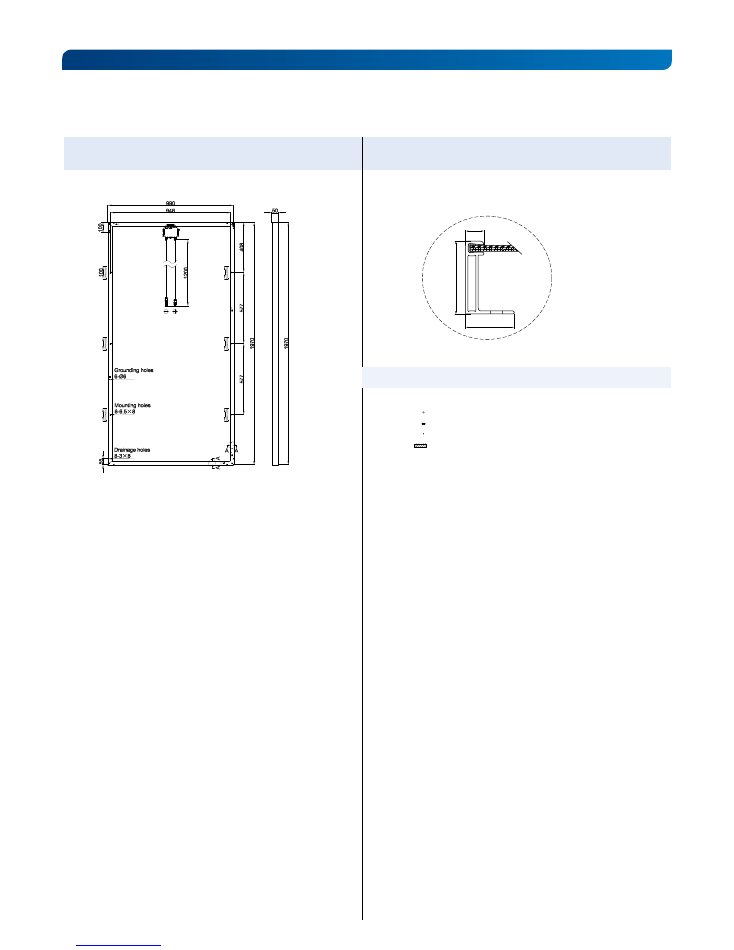

R E A R A N D S I D E V I E W D I M E N S I O N S O F M O D U L E S E R I E S W I T H 5 0 M M F R A M E

UNITS: mm

PANDA 72 Cell

NH

Series

Frame Cross Section

12

32

50

SECTION A–A

Frame P Cross Section A-A

Legend

Legend

Grounding holes

Mounting holes

Drainage holes

Mounting tolerance

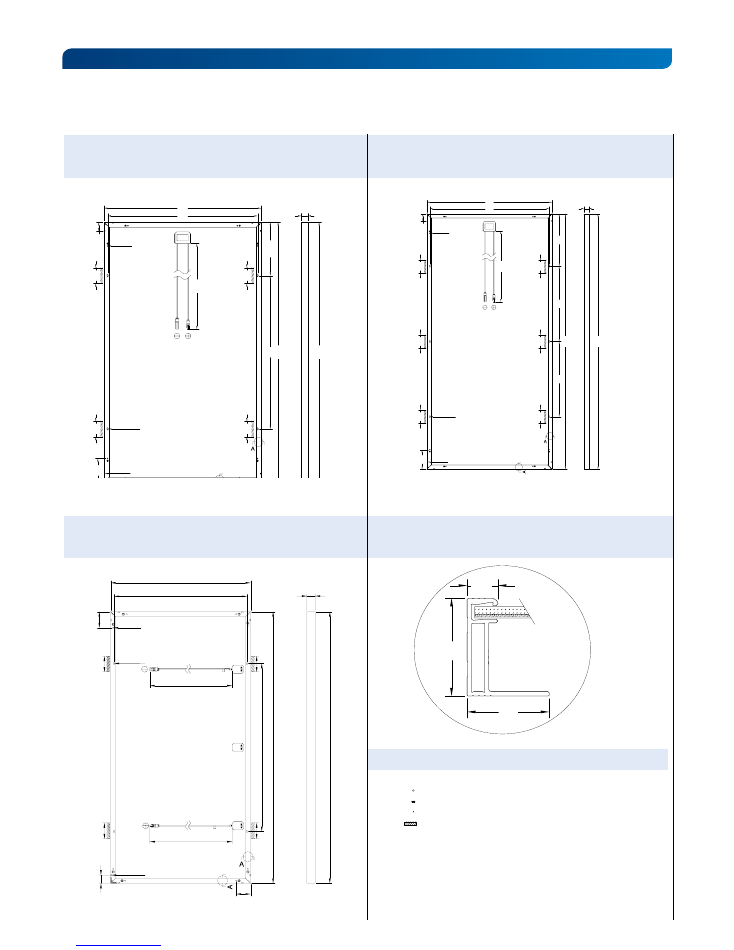

Yingli Solar PV Modules, Installation and User Manual

page 11

PANADA 50 Cell Series Frame Cross Section

(also valid for YLM 50Cell Series)

12

40

32

SECTION A-A

Legend

Legend

Grounding holes

Mounting holes

Drainage holes

Mounting tolerance

PANDA 60 Cell

Series2

YGE 72 Cell Series 2

(also valid for YLM 60Cell 40mm Series)

(also valid for YLM 72Cell 40mm Series)

R E A R A N D S I D E V I E W D I M E N S I O N S O F M O D U L E S E R I E S W I T H 4 0 M M F R A M E ( CO N T. )

UNITS: mm

1100

946

990

1960

150

55

A

A

403

40

1960

577

577

Grounding holes

8-

Φ

6

Mounting holes

6-6.5

×

8

Drainage holes

8-3

×

8

100

100

100

100

100

100

10

00

946

990

967 16

40

150

55

Drainage holes

8-3

×

8

Mounting holes

4-6.5

×

8

Grounding holes

8-

Φ

6

A

A

336.5

40

16

40

100

100

100

100

+

-

40

1

640

1

640

806

850

1

030

Mounting holes

4-6.5

×

8

Drainage holes

8-3

×

8

55

10

0

Grounding holes

8-Ø6

A

A

1000

1000

100

10

0

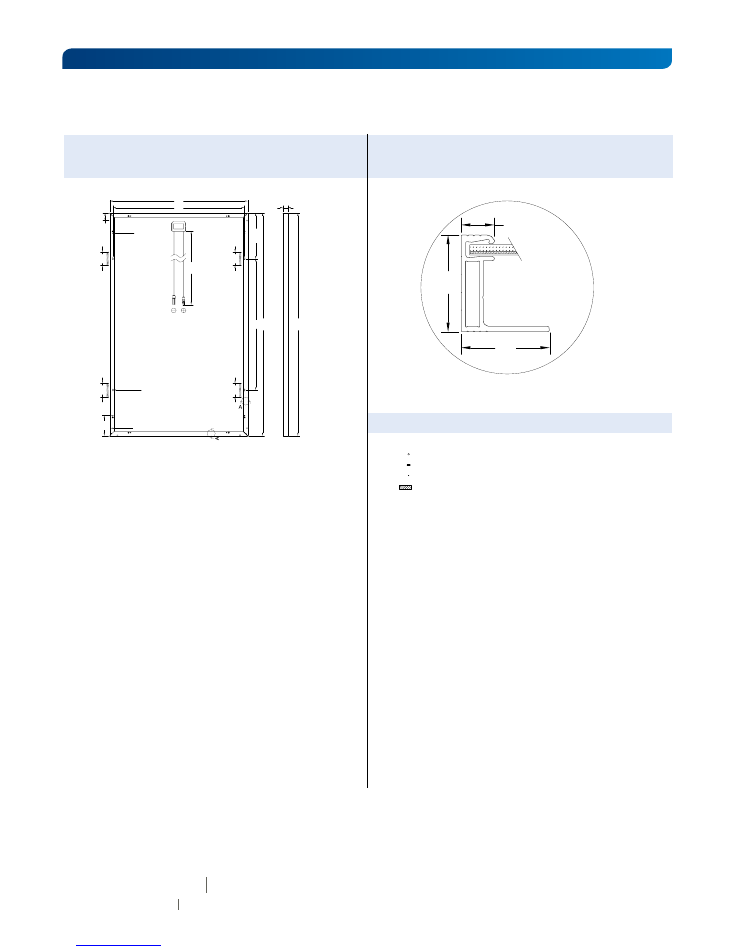

Yingli Solar PV Modules, Installation and User Manual

page 12

© Yingli Green Energy Holding Co. Ltd.

Module Supplement_IEC_EN_20160720_V03

YINGLISOLAR.COM

NYSE:

YGE

YGE 60 Cell Series 2 Frame Cross Section

R E A R A N D S I D E V I E W D I M E N S I O N S O F M O D U L E S E R I E S W I T H 3 5 M M F R A M E

UNITS: mm

1000

946

990

967 1640

150

55

Drainage holes

8-3

×

8

Mounting holes

4-6.5

×

8

Grounding holes

8-

Φ

6

A

A

336.5

35

1640

100

100

100

100

Legend

12

35

32

SECTION A-A

Legend

Grounding holes

Mounting holes

Drainage holes

Mounting tolerance

Yingli Green Energy Holding Co., Ltd.

service@yingli.com

Service hotline:+86-312-2188055

Complaints hotline:+86-312-8922216