Full Text Searchable PDF User Manual

1

© Wilks-USA

TX750 / TX750i

1

READ THIS MANUAL CAREFULLY BEFORE USE – FAILURE TO DO SO MAY RESULT IN INJURY, PROPERTY

DAMAGE AND MAY VOID WARRANTY. • KEEP THIS MANUAL FOR FUTURE REFERENCE. • Products covered by

this manual may vary in appearance, assembly, inclusions, specifications, description and packaging.

V 1.0

Gasoline Pressure Washer

TX750 . TX750i

2

© Wilks-USA

TX750 / TX750i

Contents

02 -

Contents

03 -

General Safety Instructions

04 -

Explanation of the symbols used in this Manual

05 -

Maintenance and Storage

Getting to know your petrol washer

06 -

Assembly

07 -

Operation and Use

08 -

Water Supply from the Water Mains

09 -

Adjusting the Spray Pattern

10 -

Using the Detergent Facility

Clearing a Blockage

Safety Instructions for the Engine

11 -

Pre-Operation Inspection

12 -

Fuel and Fuel Tank

Fuel Tank Filter

Oil Level Switch

Air

Filter

13 - Storage

Winter and Long Term Storage

14 -

Maintenance

Exhaust Control System

Maintenance

Replacement of Parts

Modifying

Problems Affecting Exhaust Emissions

Water Suction Filter Checking

15 -

Spark Plug Maintenance

Carburettor Idling Adjustment

16 - Transport

Storage

Prepare for Storage

17 -

Removal Fom Storage

Service Schedule

Engine Oil Replacement

18 -

Service Schedule Table

19 -

Troubleshooting

20 - Troubleshooting

21 -

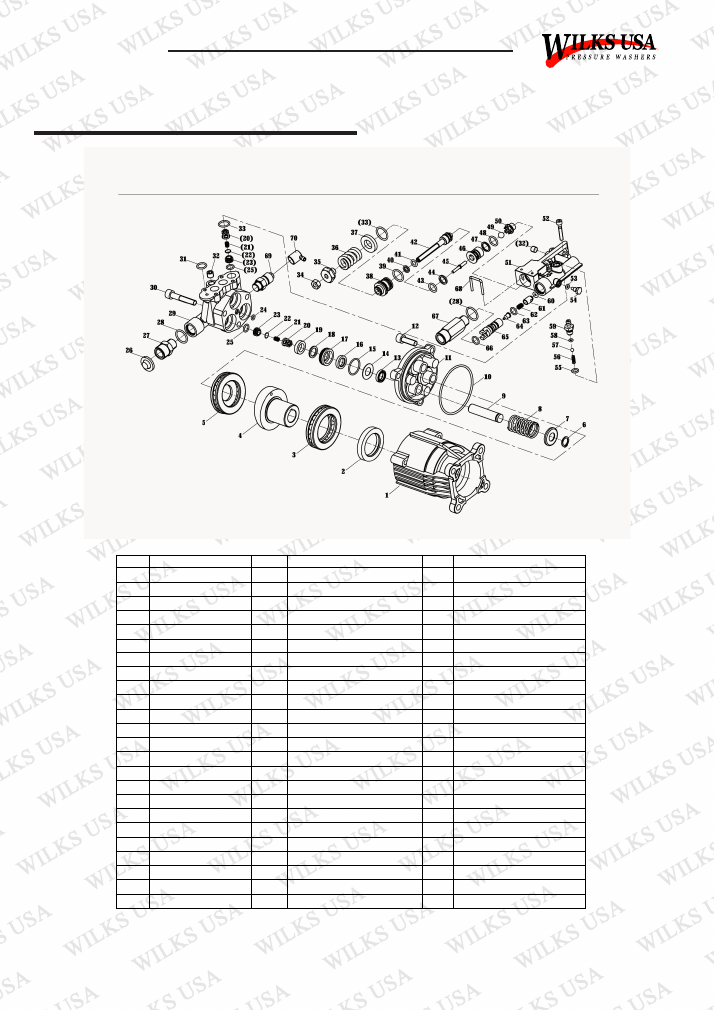

Pump Parts Diagram

22 -

CE Declaration of Conformity

3

© Wilks-USA

TX750 / TX750i

General Safety Instructions

•

GENERAL SAFETY INSTRUCTIONS

•

Read instructions carefully before operating this product.

•

Keep bystanders away.

•

This product is for outdoor use only.

•

Ensure the engine is stopped before carrying out adjustments, cleaning or maintenance.

•

Always turn off the engine and water supply when finished.

•

Do not use the product if found to be damaged.

•

Only use with detergents specified by the manufacturer. Other chemicals may compromise the safety of the product.

•

Do not direct the pressure jet towards mechanical parts containing lubricant grease. ■

•

Clean vehicle tyres from a minimum of 50cm to avoid damage by the high pressure jet. ■

•

Do not point high pressure jets at people, animals, live electrical parts or the product itself. ■

•

Do not use accessories such as hoses and connections that are not advised by the manufacturer.

•

Engage the high pressure safety catch located on the gun when not in use. ■

•

Do not step/stand on the high pressure hose.

•

Ensure the nozzle is securely attached before using the Product. High pressure can cause it to be fired from the lance

with considerable force, and could cause injury damage. ■

•

Be ready for the kick-back force and the sudden torque on the spray assembly when operating the trigger.

•

A high pressure jet can remove paint and other surface finish. It can also damage tarmac and grouting.

•

Switch off completely when not attended.

•

The hose is designed specifically for operation with high pressures. Take care to avoid damage that may prevent

correct operation of the product.

•

This product is not to be used by children or anyone with reduced capabilities.

•

Always completely unwind the high pressure hose prior to operation.

•

Make sure that the machine is switched off before unwinding the high pressure hose, and take care not to pull the

machine over.

•

Do not let the high pressure hose contact the hot engine exhaust.

•

Do not use this product indoors.

•

Keep exhaust emissions away from air intakes.

3

4

© Wilks-USA

TX750 / TX750i

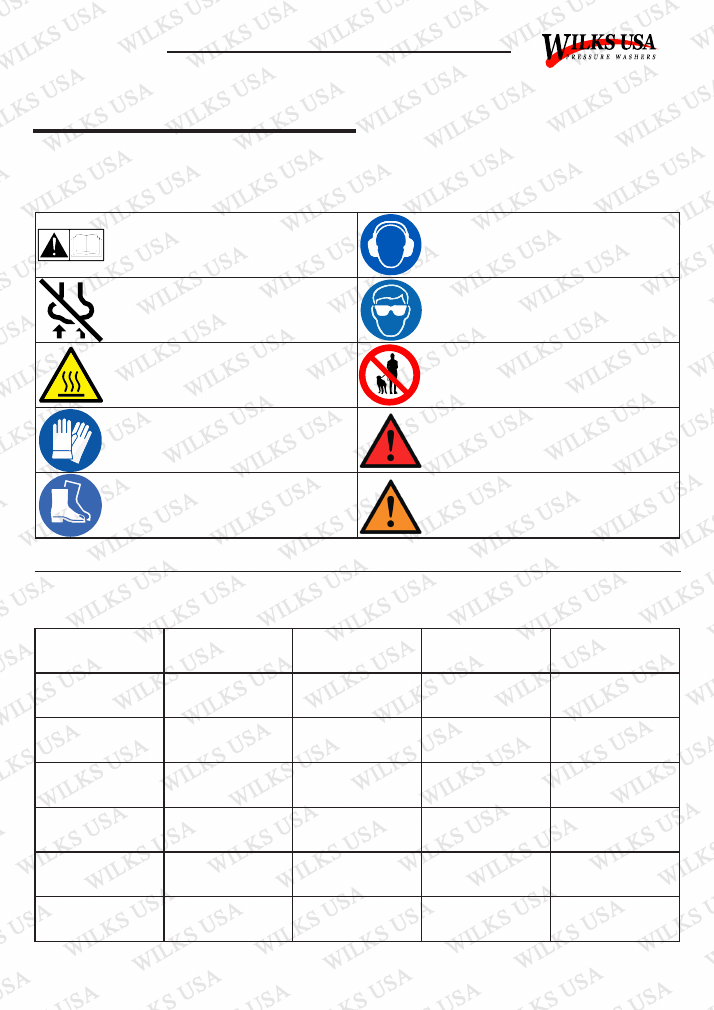

Explanation of the symbols used in this Manual

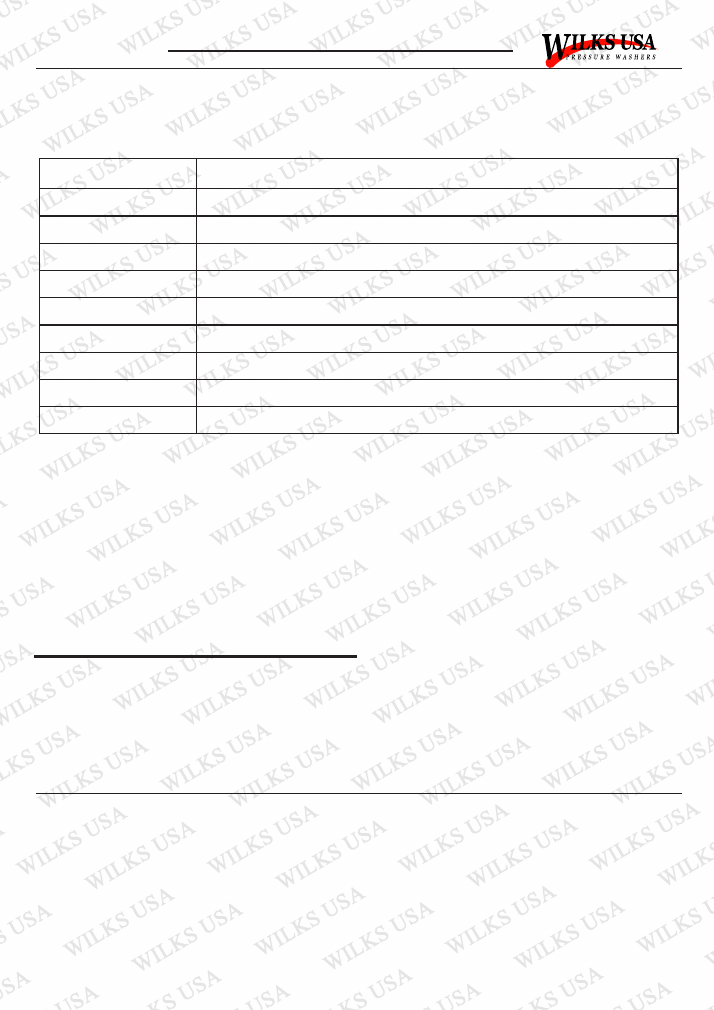

Technical Paramaters

Warning! Read the operating

Instructions before use!

Wear hearing protection!

Warning! Do not inhale exhaust fumes

Wear safety goggles!

Attention! Hot surfaces! Risk of burns!

High-pressure jets can be dangerous

if misused. Do not aim at animals,

electrical appliances or the machine itself.

Wear protective gloves

Warning! Risk of injury. Pay special attention

Wear safety shoes

Caution! Be aware of potential risks/hazards

Model

TX675

TX700

TX725

TX750

Max Pressure

13Mpa (1885 PSI)

17Mpa (2465 PSI)

18Mpa (2610 PSI)

27Mpa (3950 PSI)

Continuous

Pressure

10Mpa (1450 PSI)

15Mpa (2175 PSI)

16Mpa (2320 PSI)

22Mpa (3200PSI)

Max Flow Rate

9.2L/min

9.2L/min

9.2L/min

10L/min

Engine

2.5-4 HP

5.5 HP

6.5 HP

8 HP

Rated Rotation

Speed

3400 RPM

3400 RPM

3400 RPM

3400 RPM

Allowable

Temperature

0-60ºC

0-60ºC

0-60ºC

0-60ºC

5

© Wilks-USA

TX750 / TX750i

•

Do not attempt to modify the product In any way.

•

To ensure good operating conditions, range regular service from an authorized agent.

•

Only use replacement parts supplied by the manufacturer.

•

Only use fresh, clean and good quality fuel in the engine.

•

Never operate the engine without oil.

•

Never refuel in close proximity to naked flames, sparks or other sources of ignition e.g. cigarettes.

•

Do not refuel when the engine it hot.

•

Wipe up and correctly dispose of any fuel spillage immediately within public guidelines.

•

Move away from the refuelling areas before restarting the engine. Store fuel for short periods only in a suitable

container away from heat and direct sunlight.

•

Clean the pressure washer thoroughly after each use.

•

Regularly check external nuts and fixings to ensure vibration caused by normal caused y normal use has not loosened

them. Remove the spark plug ignition lead (HT Lead) from the back of the spark plug and position the lead to avoid

accidental reconnection.

•

Store the machine in a secure dry location out of reach of children.

•

Empty the fuel lank before storage.

Maintenance and Storage

Getting to Know Your Petrol Washer

Fuel Tank

Lance Nozzle End

Wheels

Hose Reel (TX750i)

Gun/Lance

Spare Hose

Nozzle Storage

Lance Extension

Lower Frame

Detergent Tank

6

© Wilks-USA

TX750 / TX750i

Note: Every Machine is tested during production, so there may be a few drops of water inside the pump

assembly

Assembly

To assemble the wheels (figs 1-2)

Insert the axle in to the axle tube

at the bottom of the frame, then

fix with M6 screws.

Fig.01

Fig.02

Assemble the wheel on the axle

and fix it with a nut.

In the direction of the arrow, fix

the hose reel on the frame (TX750i

only)

Fig.03

Fig.04

Fig.05

Fig.06

Fig.07

In the direction of the arrow, insert

the handle of the frame into the

frame, lock it by lock catch A.

In order to avoid the hose reel

moving, fix it with screw and nut

In the direction of the arrow, insert

the handle into the mounting hole

of the hose reel.

Assemble the panel as shown.

7

© Wilks-USA

TX750 / TX750i

Operation and Use

Warning:

The engine is not filled with oil. It is necessary to fill the unit before starting the engine. The engine

will not product a spark unless sufficient oil is inside.

Caution:

Do not run the engine with high or low oil level as this can cause engine damage.

Caution:

Only use unleaded gasoline.

Caution:

Avoid damaging your hose by ensuring it does not touch the hot exhaust during or after use.

Caution:

Avoid damaging your pump by ensuring the water supply is clean and free of any foreign objects

Caution:

Inlet water temperature must not exceed 40ºC and 20 PSI

Caution:

Never let the appliance operate for more than 2 minutes with the spray gun in the closed position

Caution:

Never operate the pressure washer with repeated and rapid on/off movements of the trigger

WARNING: The engine is not provided with oil. It is necessary to fill the unit before starting the

engine.

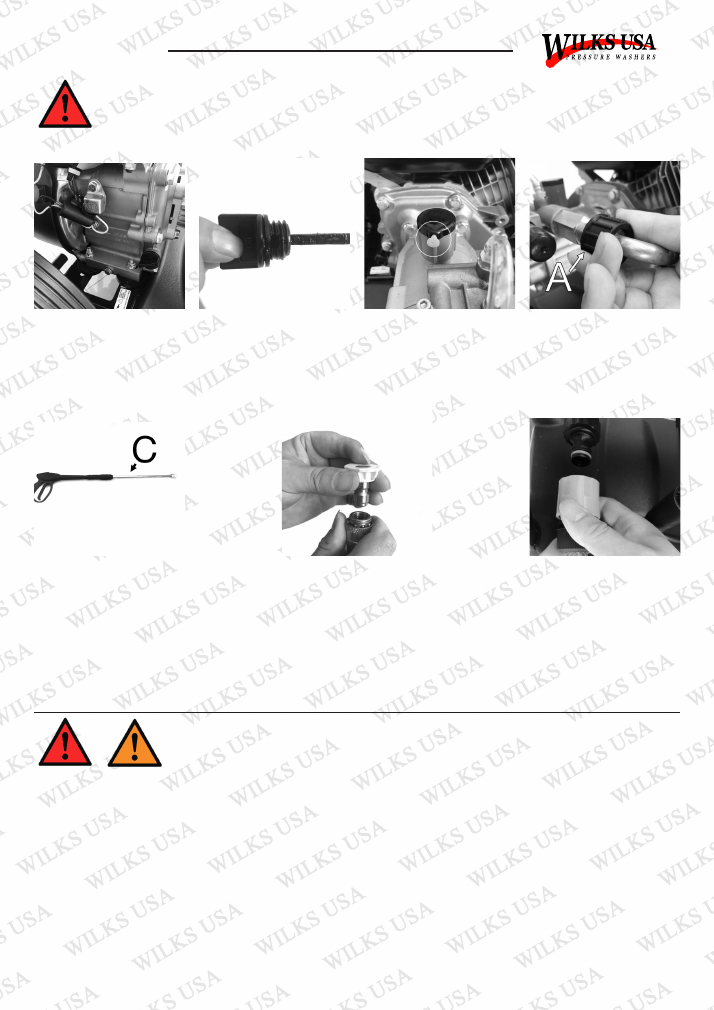

Fig.08

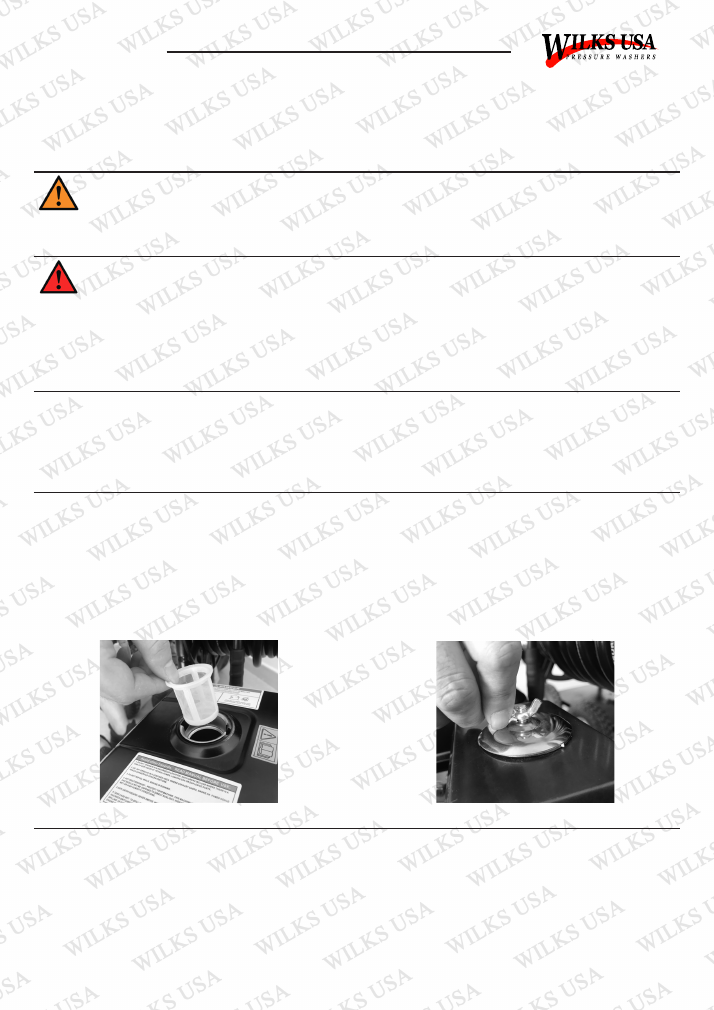

Engine Oil. (fig.08-09) Warning:

The engine is not provided

with oil. It is necessary to fill the unit before starting the engine.

The engine has two oil fill points at the front and back of the

engine. Remove the desired cap and fill with the engine oil

specified to the upper level mark or base of threads.

Fig.09

Pump Oil. (fig.10) Warning:

The YELLOW pin must be

removed from the RED

breather plug before use.

High Pressure Connection

(fig.11-14):

Connect the

high pressure hose A to the

units high pressure outlet.

Fig.10

Fig.11

Connect the High Pressure

Hose to the Trigger B:

Insert

the lance C into the gun

end. Press firmly and twist

the coupling into the locked

position.

Fig.12

Connecting the Hose:

Connect the hose to the

water inlet connector (MAX.

20PSI, MAX 40°C Temp)

and turn the water on

completely.

Fig.14

Inserting a Nozzle (fig.13):

To insert a nozzle, pull back

the locking collar at the end

of the lance, insert nozzle

and release the collar. This

will lock the nozzle in place.

Ensure the nozzle is inserted

correctly. If not it can fly

out and injure personnel or

damage property.

Fig.13

8

© Wilks-USA

TX750 / TX750i

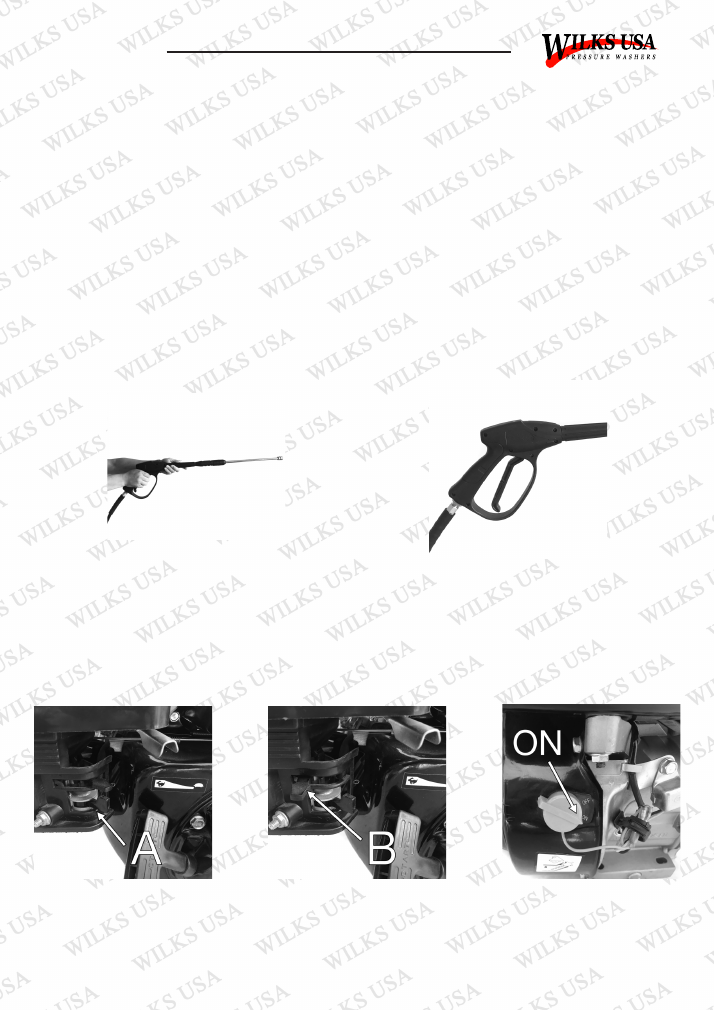

Pull the trigger to eliminate

trapped air and wait for a steady

flow of water to emerge from the

spray nozzle.

NOTE: In order to assist further

setup it is recommended to press

the trigger during the pulling of

recoil start handle.

Fig.15

To prevent accidental operation

the trigger is fitted with a locking

facility.

Fig.16

Starting the Engine (fig.17-20):

Push the fuel lever A to the right

(ON position)

Fig.17

Fig.18

Fig.19

Push the Choke lever B to the left;

closing the Choke for initial start-

up.

NOTE:

Do not use the Choke

if the engine or air temperature is

warm.

Turn the engine switch clockwise

to the ON Position.

•

Connect a water supply hose (not supplied) to the water inlet connection of the pressure washer

•

Turn on the water supply and pull the trigger until water is continually flowing out of the nozzle.

WATER SUPPLY FROM A CONTAINER / STANDING WATER

•

Unscrew the coupling part for the water inlet.

•

Screw the suction hose with filter (not Included) onto the water connection of the unit.

•

Hang the filter in the container.

•

Vent the unit before operation.

•

Unscrew the high pressure line at the high pressure outlet of unit.

•

Switch on the unit and let it run until water is free of bubbles at the high pressure outlet.

•

Switch off the unit and screw on high pressure hose again.

Water Supply from the Water Mains

9

© Wilks-USA

TX750 / TX750i

You have a choice of 5 different colour coded nozzles giving you different spray patterns/pressures to choose

from. See fig.25

0º Nozzle (Red)

This nozzle delivers a pinpoint stream and is extremely powerful. It covers only a small area for

cleaning. The nozzle should only be used on surfaces which can withstand the high pressure such as metal/

concrete.

15º Nozzle (Yellow)

This nozzle delivers a powerful 15 degree spray for intense cleaning of small areas. The

nozzle should only be used on surfaces which can withstand the high pressure

25º Nozzle (Green)

This nozzle is used where high pressure is still required, over a medium sized area.

Produces more power than White nozzle in a smaller area.

40º Nozzle (White)

This nozzle a less focused spray pattern, giving a wider area of cleaning with less power.

This is used for most cleaning applications

Low Pressure Nozzle (Black)

This is used for chemical application only. The nozzle created the required back

pressure to draw detergent from the tank.

Adjusting the Spray Pattern

Pull the black handle on the Recoil

Starter gradually until you feel

resistance; then make a rapid pull

Fig.20

Fig.21

Fig.22

Push the Choke lever B to the left;

closing the Choke for initial start-

up.

NOTE:

Do not use the Choke

if the engine or air temperature is

warm.

Turn the engine switch clockwise

to the ON Position.

Stopping the engine (fig. 23-24)

In an emergency turn the engine

switch anticlockwise to the OFF

position to stall the engine. To

stop the appliance normally, use

the following sequence:

Fig.23

Turn the engine switch

anticlockwise to the OFF position.

Then slide the fuel lever E to the

right OFF position. Caution: When

you have finished working, turn off

the engine. When the machine is

switched off, always discharge the

pressure by depressing the trigger

Fig.24

Attaching a nozzle to the quick-fit

end of the lance.

Fig.25

10

© Wilks-USA

TX750 / TX750i

Fill a suitable container with pressure washer detergent. Do not use washing up liquid as it contains salt. Please

follow the instructions on the container. Most automobile detergents are a combination of detergent and a wax

solution. Viscosity (thickness) of the detergent will increase in cold weather. It is recommended that this type of

detergent is diluted with water before filling the container. When using combination was and wax solutions, we

recommend that they are diluted before use. As a general guide we would recommend a dilution rate of 50/50.

Please follow the instructions of your detergent product for variations/specific requirements.

Note:

A thick viscous detergent will not flow freely from the detergent tank and the residue is likely to cause a

blockage in the system. After using the detergent facility it should be flushed thoroughly with clean water

to remove ANY trace of detergent. To activate detergent facility, fit the BLACK nozzle to the end of the lance.

Submerge the end of the detergent tank inlet hose in the container/solution. Suction and mixing will occur as

water flows through the pump. You may be required to fit the shorter of the supplied hoses in conjunction with

the black nozzle to create the required pressure to draw detergent.

Using the Detergent Facility

Before using the pressure washer to clean patio paving slabs it is advisable to test a small area first

as some paving slabs are manufactured from inferior materials and the use of a pressure washer

could damage the surface

If at any time the flow rate stutters or is inconsistent, release the trigger and switch OFF the machine. Squeeze

the trigger to release any pressure and check the jet end of the lance for any blockage. If a blockage is

suspected, use some wire (supplied to rear of instruction manual) to clean inside the nozzle.

Clearing a Blockage

Safety Instructions for the Engine

1. Before operating the engine, be sure to read all instructions carefully as injury or permanent damage to the

machine may occur.

2. Run the engine in a well ventilated area.

3. Ensure the appliance is at least 1 metre away from building walls or other equipment.

4. Keep the appliance away fro flammable liquids such as petrol.

5. Refuel in a well ventilated area with the engine switched off and avoid sparks or naked flames.

6. When refuelling, ensure that you do not over fill the tank.

7. If any fuel is spilled ensure it is cleaned up thoroughly before restarting.

8. Ensure the fuel cap is located securely.

9. The exhaust mufflers get very hot and will remain hot for some time after the engine is switched off.

10. Ensure the appliance is completely cooled before transporting or storing.

Fig.26

Fig.27

11

© Wilks-USA

TX750 / TX750i

Engine oil is a key factor in deciding the engine’s performance. Do not use engine oil with additives or 2-stroke

gasoline engine oil as they do not have sufficient lubricating properties, which may shorten the engine’s service

life.

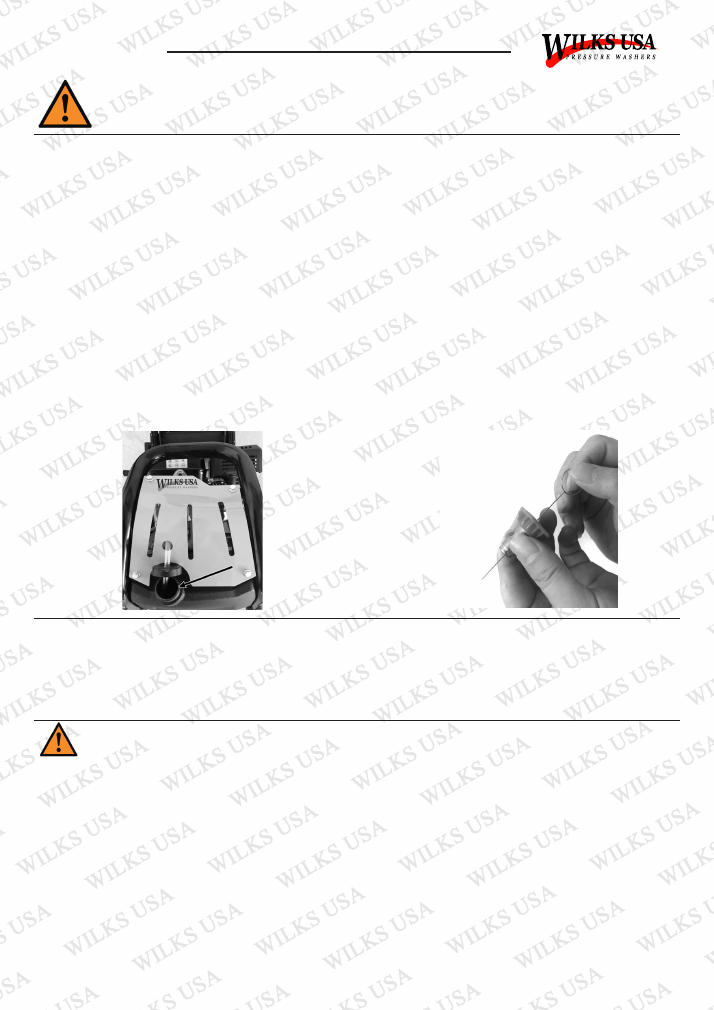

1. Check the engine is on level ground.

2. 10W-40 to 15W-30 is recommended for general all-temperature use.

3. Remove Dipstick and clean it.

(fig.28)

4. Re-insert the Dipstick into the oil filler port without screwing it in, lift out to check oil level.

5. If the oil level is too low, add the required amount of engine oil to the oil filler mark or to the lowest thread.

6. Replace the Dipstick securely.

Pre-Operation Inspection

Running with insufficient engine oil may damage the engine severely.

Caution

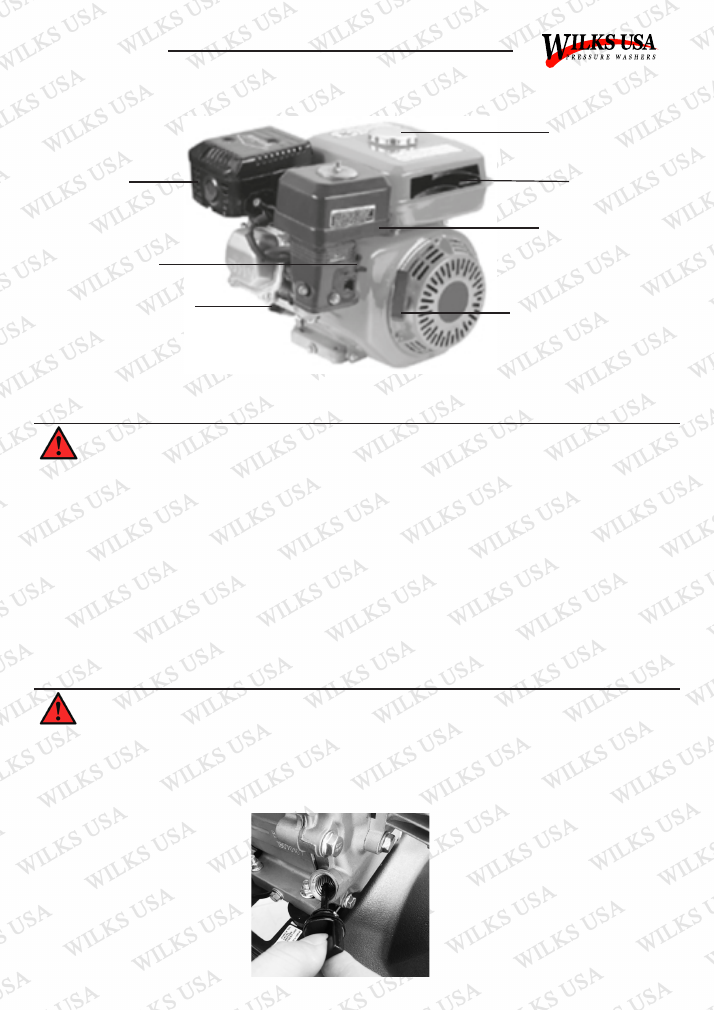

Exhaust

Choke Lever

Dipstick

Fuel Tank Cap

Fuel Tank

Air Filter

Recoil Starter Handle

Fig.28

12

© Wilks-USA

TX750 / TX750i

Fuel and Fuel Tank

Only use unleaded petrol or fuel with an octane number over 86. Using unleaded petrol or fuel will decrease the

possibility of producing carbon deposits and extend the engines service life. Never use old or polluted petrol or

fuel or a mixture of petrol and engine oil. Make sure the fuel is free of dirt and water.

Handle fuel with care because it can damage plastic and painted surfaces. Remove the fuel filler cap and check

the fuel level. If the fuel level is too low, refuel the tank taking care not to over fill.

Caution

Petrol is extremely flammable and is explosive under certain conditions. Refuel in a well ventilated area with

the engine stopped. Do not smoke or allow naked flames or sparks in the area where petrol is stored or where

refuelling is taking place. After refuelling, make sure the tank filler cap is returned securely. Be careful not to

spill the fuel when refuelling. Spilled fuel or vapour may ignite. If any fuel is spilled make sure the area is dry

before starting the engine.

Warning

After every 150 hours of running or every three months, the fuel tank filter should be removed and cleaned.

Remove the fuel tank filler cap and filter, clean thoroughly using environmentally friendly water based de-

greasing agent and re-fit.

Fuel Tank Filter (fig.29)

Oil Level Switch

Air Filter (fig.30)

The engine oil alarm is designed to prevent the operator starting the engine when the oil in the crankcase is

insufficient. Running with insufficient oil will damage the engine. Once the oil level in the crankcase is too low,

the engine oil alarm will stall the engine automatically to avoid damage while the engine switch is still ON.

Fig.29

Fig.30

After every 100 hours of running or every month, the air filter should be removed, examined for deterioration

and cleaned. Clean the air filter thoroughly using an environmentally friendly water based degreasing agent.

Allow to dry full then replace the air filter. Never run the engine without the air filter fitted.

13

© Wilks-USA

TX750 / TX750i

Storage

Winter and Long Term Storage

If the engine is not to be used or is to be stored for more than one month the following storage procedure

should be carried out:

1. Drain all the fuel from the fuel tank and the carburettor. Ensure that all fuel has been removed.

2. Remove the spark plug and pour approximately one table spoon full of clean engine oil into the spark plug

hole.

3. With the ignition turned OFF, gently pull on the recoil starter handle several times.

4. Re-fit the spark plug and continue to pull the recoil starter handle until the piston is on the compression

stroke (when resistance is felt) then stop pulling.

5. Store the pressure washer in a dry well ventilated place under a cover to prevent any dust or debris from

accumulating on the pressure washer.

If the pressure washer is not being used for more than three months or if there is any danger of ice or frost

where the unit is stored, especially during the Winter months, certain precautions must be taken to ensure no

damage occurs to your washer or gun. Follow the previous steps for storage by ensuring there is no water left

inside the unit. The pump may require insulated protection from freezing conditions. The gun must be drained

of fluids to avoid water expansion. This will damage your gun.

14

© Wilks-USA

TX750 / TX750i

Maintenance

With the engine running, carbon monoxide, nitrogen oxide and hydrocarbon are produced, and in certain

conditions nitrogen oxide and hydrocarbons will react together to make ‘photochemical smog’ which is toxic.

Therefore exhaust control is very important. The manufacturer decreases exhaust emissions by introducing

‘poor fuel’ carburettors and other devices to solve the problem. The keep the exhaust of your engine within the

standard exhaust emission values, pay attention to the following:

Exhaust Control System

Maintenance

Maintain the engine periodically in accordance with the maintenance schedule. The maintenance schedule is

made out on the basis of normal use in normal conditions. If using under heavy load, dusty or wet conditions

or in high temperatures, more frequent maintenance will be necessary.

Replacement of Parts

We recommend that you use parts that are supplied by the manufacturer or equivalent quality parts.

Replacement parts of an inferior quality may impair the effectiveness of the exhaust control system.

Modifying

Modifying the exhaust control system may make the exhaust emissions exceed statutory limits. Illegal

modifications are:

1. Dismantling or modifying any part of the air inlet or outlet system.

2.Modifying or removing speed adjustment controls or connections which may result in the engine running

outside its set parameters.

Problems Affecting Exhaust Emissions

1. Difficulty in starting or stopping.

2. Erratic idling.

3. Giving off black smoke or excessive fuel consumption

4. Poor ignition or spark

5. Ignition too advanced. If you have any of these problems please contact your dealer.

Caution:

Before carrying out any maintenance to the machine release any pressure and remove the water connection.

Water Suction Filter Checking

Check periodically in order to avoid deposits clogging it.

15

© Wilks-USA

TX750 / TX750i

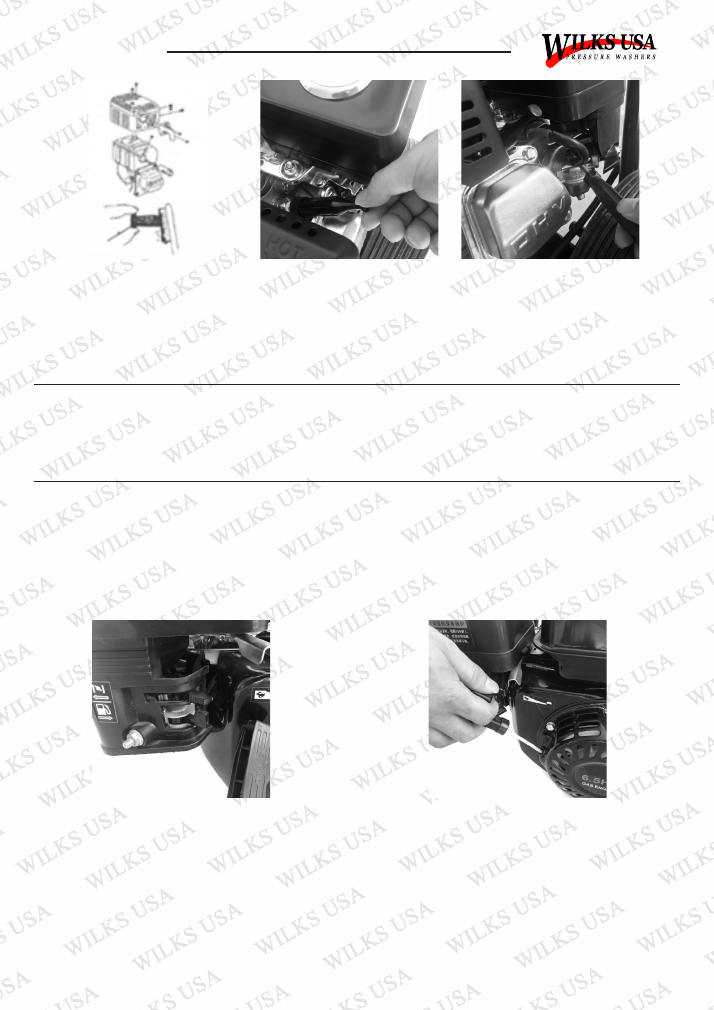

Spark Plug Maintenance

After every 50 hours clean the spark plug with a brush. If the insulator on the spark plug is damaged replace

it immediately. Check the spark plug gap with a feel gauge, the gap should be 0.7-0.8mm. If adjustment is

necessary bend the side electrode carefully. Check the spark plug gasket is in good condition or replace with a

new one. Screw in the spark plug to the bottom first by hand and then tighten by using a spark plug wrench. If

a new spark plug is used, twist a 1/2 more turn after impacting the gasket. If using the original gasket, twist 1-8

- 1/4 more turn.

Caution:

The spark plug eliminator should be serviced at least once every 100 hours of operation so as to keep it in good

condition.

Warning:

The muffler is very hot hen the engine is running and remains hot for a prolonged period after the engine has

stopped. Only service after the engine cools down completely.

Unscrew two nuts and remove the exhaust elbow from the engine body.

Unscrew five screws from the muffler guard and take it out.

Unscrew from the spark plug eliminator and separate the muffler.

Clean the spark eliminator mesh with a wire brush.

Reinstall the spark plug eliminator in reverse order of removal.

Caution:

Be careful not to damage the spark plug eliminator. Never use a damaged spark eliminator.

Carburettor Idling Adjustment

Start and pre-heat the engine until it reaches normal working temperature. Obtain standard idling by adjusting

the throttle fixing screw under the engine. Standard idling: 3400±300 RPM.

16

© Wilks-USA

TX750 / TX750i

Transport

Transport with the fuel switch in the OFF position. Ensure the engine is cooled so as to avoid the risk of burns

or fire.

Caution:

Do not tilt the engine to avoid spilling fuel. Spilled fuel or vapour will ignite.

Storage

If the engine is not to be used for a long period of time ensure it is stored correctly. Make sure the storage area

is dry and free of dust.

Prepare For Storage

Disconnect the spark plug. Put a spoonful of fresh engine oil into the cylinder and rotate the engine to distribute

the oil evenly. Replace the spark plug. Pull the recoil starter handle until you feel resistance and then keep

pulling so as to align the arrow of the starting sleeve with the hole of the starter: This will close both the inlet

and outlet valves to help prevent rusting inside. Cover the engine to keep it free of dust.

17

© Wilks-USA

TX750 / TX750i

Removal Fom Storage

Before re-using, service the engine in accordance with the instructions in the following table. Table for removal

from storage only. For full service schedule, see Page 18.

Storage Time

Service Item

Within One Month

No Service Needed

One - Two Months

Drain out the original fuel from the fuel tank and refuel

Two Months - One Year

Drain out the original fuel from the fuel tank and refuel

Drain out the original fuel in the carburettor

Empty the deposit cup

Above One Year

Drain out the original fuel from the fuel tank and refuel

Drain out the original fuel in the carburettor

Empty the deposit cup

Move the engine from the storage place and start up

1. Unscrew the drain plug and drain out the fuel in the carburettor.

2. Turn off the engine switch first, disconnect the deposit cup and empty it.

Note:

Do not dump oil containers or discard engine oil into the ground. For environmental protection take discarded

engine oil in a closed container to a recycling centre.

Warning:

Fuel is extremely flammable and explosive under certain conditions. Keep cigarettes, naked flames and sparks

away from the operating site.

Service Schedule

To keep the engine in sound condition, the user should maintain it according to the table below.

Caution:

Use parts that are supplied by the manufacturer, otherwise damage to the engine may occur..

Warning:

Stop the engine before servicing. If servicing is required with the engine running, ensure there is good

ventilation in the area. Exhaust emissions contain carbon monoxide which may cause injury or be fatal if

inhaled.

Engine Oil Replacement

Place the machine on a level surface and warm up the engine for several minutes. Then stop the engine.

Remove oil filler cap. Place an oil pan under the engine. Remove the oil drain plug so that oil can be completely

drained. You will need to use a tube or other similar device to prevent oil leaking onto the frame of the pressure

washer. Check the oil drain plug, gasket oil filler cap and O-ring - if damaged replace. Reinstall the oil drain

plug. Add the oil to the upper level of the dipstick or lower threads as required.

Note: Do not dump oil containers or allow oil into the environment. Always dispose oil at an appropriate

recycling centre.

18

© Wilks-USA

TX750 / TX750i

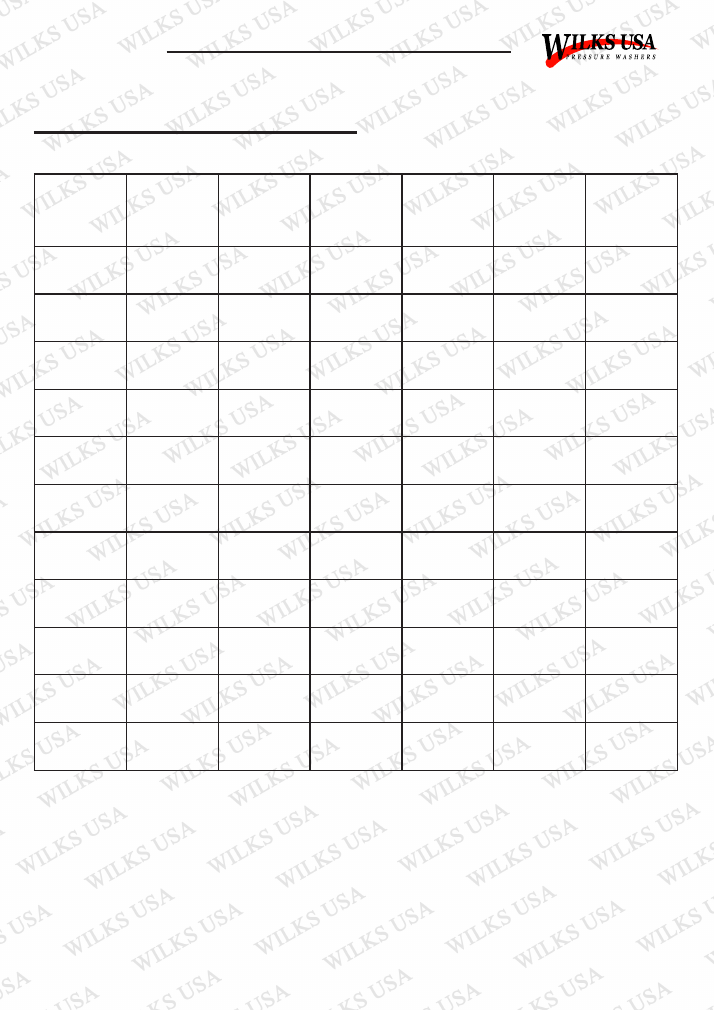

Component

/ Task

Every Use

After First 5

Hours Use

First Month

or 20 Hours

Use

Every 3

Months or

50 Hours

Use

Every 6

Months or

100 Hours

Use

Every Year

or 300

Hours Use

Engine Oil

Check

Replace

Replace

Oil Leaks

Check/repair

as necessary

Air Filter

Check

Clean

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Valve

Clearance

Adjust as

necessary

Combustion

Chamber

De-coke as

necessary

Idle Speed

Check/adjust

as necessary

Nuts & Bolts

Check/tighten

as necessary

Check/tighten

as necessary

Check/tighten

as necessary

Check/tighten

as necessary

Check/tighten

as necessary

Check/tighten

as necessary

Fuel Tank

Flush and

clean

Flush and

clean

Flush and

clean

Fuel Line

Check

Check/Clean

Replace as

necessary

Replace as

necessary

Replace as

necessary

Replace as

necessary

Fuel Filter

Check

Check/Clean

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Spark Plugs

Check/Clean

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Clean and

replace as

necessary

Service and maintenance tasks to be conducted by qualified technicians / authorized repair centres only.

Service Schedule Table

1. For the convenience of transport the Pump is not supplied with oil, and the Breather Plug is not installed

(Certain models only). Please add 15W-30 - 10W-40 Machine oil before using. Pump oil is to be topped up the

centre line of the sight glass, then install the breather plug.

2. After first 20 hours use, remove the pump oil. Add a similar level of kerosene and operate the machine

without load for 10-15 seconds. Shut off the machine, drain of kerosene and replace with new motor oil.

3. Please check the oil mass before using. If lower than the centre line on the spy glass, top up to the centre

line.

4. Accumulative use after 100 hours, change the oil in the same way. For every 100 hours use thereafter, repeat

the oil change/service. It is very important in order to extend the service life of the pump.

19

© Wilks-USA

TX750 / TX750i

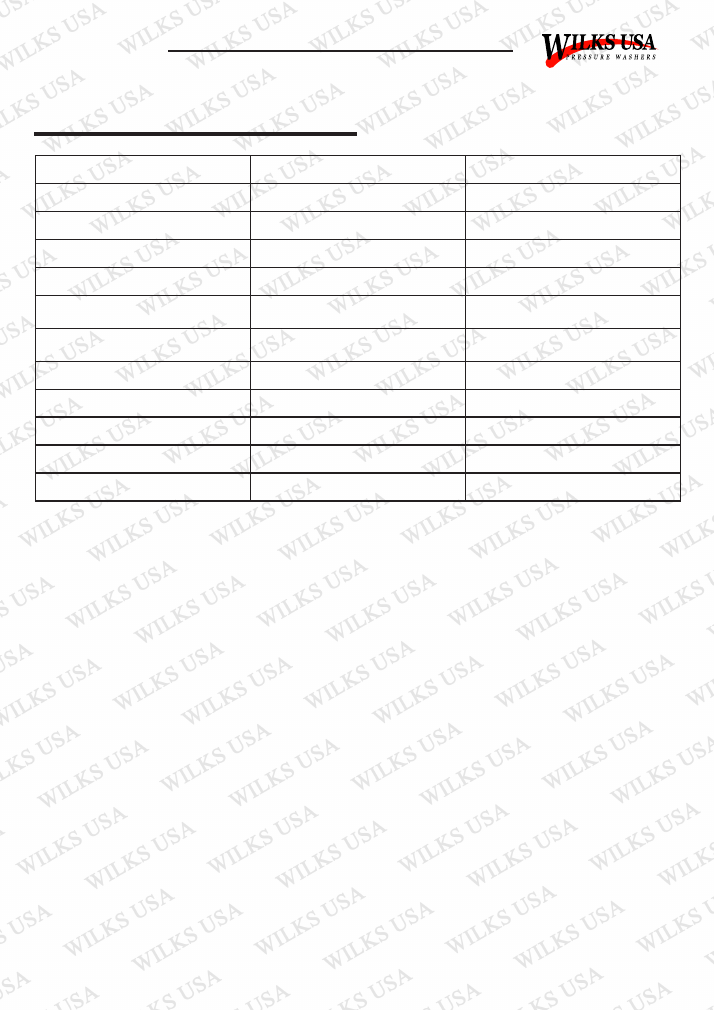

Troubleshooting

Trouble

Probable Cause

Remedy

Fluctuating Pressure

Pump sucking in air

Check connections are tight

Valves dirty, worn or seized

Contact customer helpline

Blocked jet

Remove blockage using jet cleaning tool

Water leakage from pump

Seals worn out

Contact customer helpline

The pump does not reach the required

pressure

Pump sucking in air from connections

or hose

Check tightness of all connections

Suction/delivery valves are clogged

Clear or replace valves. Have machine

checked by Service Centre

Unload valves are stuck

Loosen and re-tighten regulating screw

Lance or nozzle worn out

Check and/or replace

Pump is running but no water delivery

Kinked inlet and or pressure hose

Check, straighten and replace if required

Blocked inlet filter

Remove and clean filter

Blocked jet

Remove blockage using jet cleaning tool

20

© Wilks-USA

TX750 / TX750i

Fault

Probable

Cause

Repair

Engine

won’t start

Low

engine

output

Engine

runs

erratically

Insufficient

compression

Loose spark plug

Tighten plug

Loose cylinder head bolt

Tighten bolt

Damaged gasket

Replace gasket

Sufficient

compression

Fuel System Problems

No fuel supplied to

combustion chamber

Insufficient pulling speed for recoil starter

Pull rope sharply

Foreign matter in fuel tank

Clean tank

Clogged fuel line

Clean fuel line with suppliers

advice

No fuel in tank

Add fuel

Fuel tap not open

Open fuel tap

Fuel System Problems

Combustion chamber

(Poor spark)

Spark plug dirty with carbon or wet with

fuel

Remove carbon or dry spark plug

Damaged spark plug

Replace spark plug

Faulty magneto

Consult dealer

Combustion chamber

(Good spark)

Improper adjustment of carburettor

Insufficient pulling speed for recoil starter

Pull rope sharply

Wrong grade of fuel

used

Check grade of fuel

Overloading

Check working conditions

Overheating

Troubleshooting

21

© Wilks-USA

TX750 / TX750i

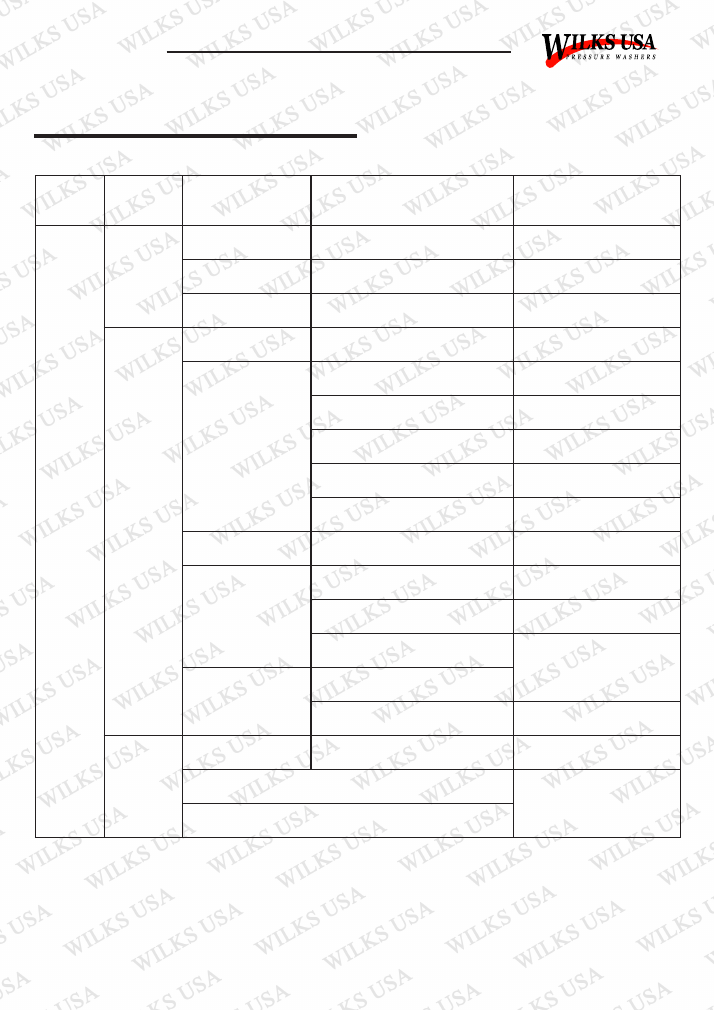

Pump Parts Diagram

Item

Name list

Item

Name list

Item

Name list

1

back housing

25

o-ring 9*1.8

49

φ7/9Cr18 steel ball

2

B35528 oil seal

26

inlet filter

50

lower seat

3

thrust bearing2

27

inlet connector

51

outlet valve body

4

wobble plate

28

o-ring 14*1.8

52

screw M5*30

5

thrust bearing1

29

manifold

53

o-ring 4*2

6

washer 12

30

screw M8*45

54

block 2

7

spring plate

31

o-ring 12*2

55

o-ring 7.65*1.78

8

piston spring

32

throat plug

56

small spring

9

piston

33

o-ring 14*2

57

steel ball φ3/16

10

o-ring 73*2.65

34

nut M6

58

o-ring 3.68*1.78

11

piston seat

35

regulating nut

59

fixed injector

12

screw 8*25

36

regulating pressure spring

60

o-ring 4*2.65

13

oil seal12*20*6

37

washer

61

unilateral valve core

14

washer

38

valve cover

62

unilateral valve spring

15

o-ring 22.4*1.8

39

o-ring 12.42*1.78

63

o-ring 9*1.8

16

seal washer 12*20*4

40

backup ring6.2

64

nozzle

17

packing supt.

41

o-ring 6.07*1.78

65

Venturitube

18

washer

42

valve rod

66

o-ring 10*1.8

19

washer seal 12*20*5

43

o-ring 8.5*1.8

67

outlet connector

20

valve boot

44

PTFE/8.7*11.6*1.25

68

pin

21

valve spring

45

pin

69

thermal relief

22

valve gasket

46

upper seat

70

TRV outlet protector

23

valve seat

47

PTFE/10.3*13*1.25

24

o-ring 4.5*1.8

48

o-ring 10*1.8

22

© Wilks-USA

TX750 / TX750i

CE Declaration of Conformity

EC Declaration of Conformity

with the

European Machinery Directive 2006/42/EC

We hereby certify that the machine detailed below complies with all relevant provisions of the EC

Machinery Directive 2006/42/EC and National Laws and Regulations adopting this Directive.

----------------------------------------

Declaration Ref. No.:-

Manufacturer:-

Manufactures Address:-

Authorised Representative (in EU):-

Authorised Representative’s Address:-

Name of the person authorised to compile the technical

file (in EU):-

Address of the person authorised to compile the

technical file (in EU):-

Product:-

Description:-

Type / Model No.:-

Procedure for assessment of conformity conducted by:-

We hereby declare that the machine detailed also

complies with all relevant provisions of the following

other EC Directives:-

Harmonised Standards Applied (in full):-

TX750 / TX750i

Union Mart Ltd

Unit 4, Mauretania Rd, Nursling Industrial Estate, Nursling,

Southampton SO16 0YS, UK

Union Mart Ltd

Unit 4, Mauretania Rd, Nursling Industrial Estate, Nursling,

Southampton SO16 0YS, UK

Michael S McQuaide

Unit 4, Mauretania Rd, Nursling Industrial Estate, Nursling,

Southampton SO16 0YS, UK

Petrol Pressure Washer Wilks-USA TX750 / TX750i

Petrol High Pressure Washer

Wilks-USA TX750 / TX750i

ISET S.r.l. Sede Legale e Uffici

(Note: Machinery is NOT referred to in Annex IV)

2006/42/EC Machinery Directive

2000/14/EC Noise Emission

2014/30/EU EMC Directive

EN 60335-2-79:2012

EN 1679-1:1998+A1:2011

EN 55012:2007/A1:2009

Person empowered to

draw up the declaration:-

Position:-

Place of issue:-

Michael S McQuaide

Managing Director

Unit 4, Mauretania Rd, Nursling Industrial

Estate, Nursling, Southampton SO16 0YS

Signature: -

Date:-

15.08.2018

----------------------------------------

This declaration relates exclusively to the machinery in the state in which it was placed on the market, and excludes

components which are added and/or operations carried out subsequently by the final user