Full Text Searchable PDF User Manual

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 1 of 9

BUILT TO

ENJOY NATURE

BORN IN THE BLACK FOREST

Front Hub

MIG70

M A N U A L

as of May 2015

Number of holes

12, 16, 18, 20, 24, 28, 32

Disc mount

none

Build-in-with

100 mm

Axle diameter

17 mm

Colours

black, silver, red, gold, blue, green, orange, froggy-green

and white (powder-coated)

Bearings hub body

2 specific Tune grooved ball bearings (2 x 61803)

Sealing

dust cap, washer and rubber lip seal

Weight limit

none

Material:

Flange

aluminium, CNC machined

Axle

aluminium, CNC machined

Endcaps

aluminium, CNC machined

Inner sleve

aluminium, CNC machined

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 2 of 9

Instructions

General:

• Before every ride, make sure that your tune product is in a good condition and functioning properly. If there

seems to be any irregularities the product should not be used. Contact your retailer for help.

• The Quickrelease must be mounted properly.

• Never clean your Tune products directly with high water pressure (pressure cleaner) and do not use ag-

gressive detergents.

• Only use tires that suit the rim, pay attention not to exceed the maximum tire pressure of the rim and tire.

Maintenance:

The hub should be maintained at least once a year. If used in extreme conditions (rain, mud, salted streets,

transport in the rain) regularly, the hub should be maintained more often. A regular service supports the tech-

nical condition, as well as the durability of the hub.

What does the regular maintenance include?

•

The mounted hub should be cleaned. Afterwards it should be undertaken a detailed visual and technical

examination.

•

When disassembled, the bearings should be examined. The maintenance is described in detail below.

Lacing:

•

The hub is constructed for radial lacing or crossed lacing.

•

The 32 and 36 hole version has to be laced crossed.

•

If the MIG70 hub is gets laced radially the spoke heads have to face outwards.

•

The MIG 70 flanges have been designed to automatically distribute the tension among the spokes evenly

during the lacing process. There will be no more movement, of the flanges relative to each other, once the

spokes all have been tensioned (exerting an overall pulling force of several tons).

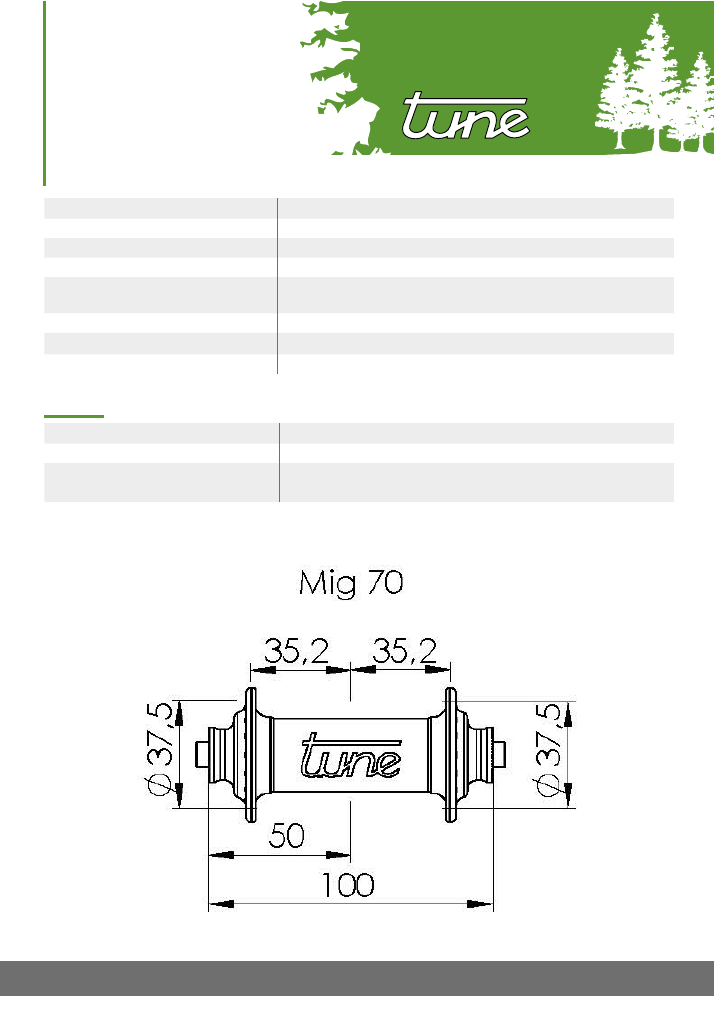

MIG70:

The highest permitted spoke tension is 1000 N.

Pitch circle diameter Ø

37.5 mm

Distance hub flange to wheel center line (l / r) 35.2 / 35.2 mm

Spoke hole diameter Ø

2.4 mm

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 3 of 9

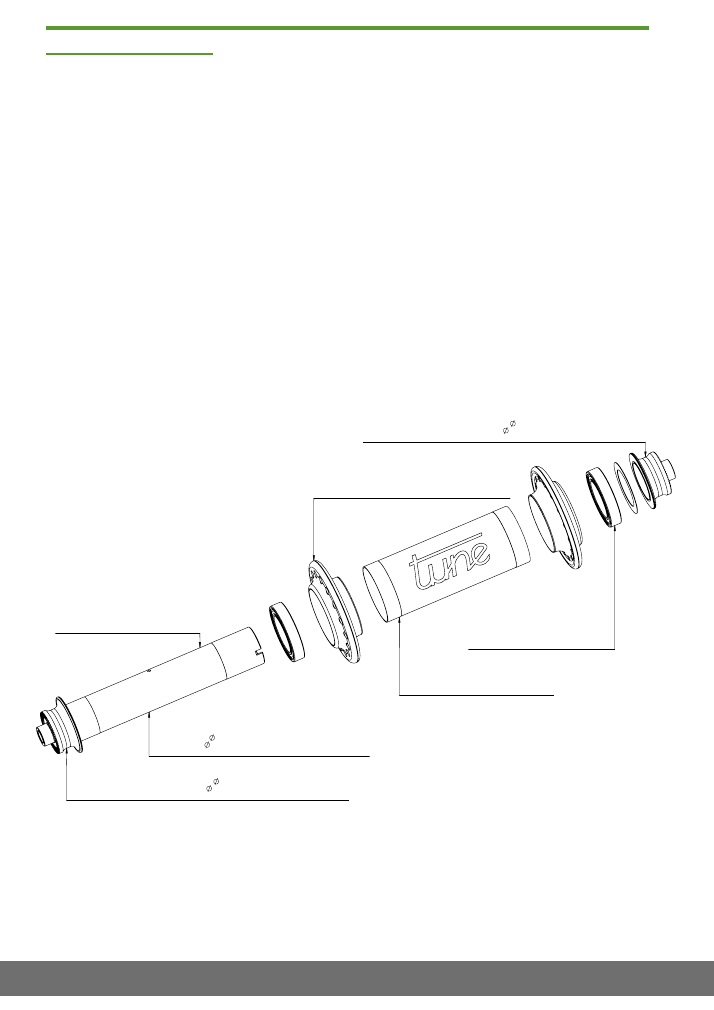

Maintenance

Construction of the hub:

This hub is built up from firmly connected parts, i.e. the axle goes all the way through, with endcaps at

both sides, and all parts are fixed exactly in place.

Tune uses specific bearings not available from any other manufacturer. The bearings distinguish

themselves by there unusual high amount of special grease and a radial play adjusted for the use.

The bearings have a double slid sealing, the hub therefore will run comparatively sluggishly when

new. This will change after the first rides, when the grease has been dispersed evenly in the ball-bear-

ings and the seals are working optimally.

Spare parts can be ordered through your local Tune retailer.

Aluröhrchen für Mig70 VR-Nabe, Farbe /

hub-body-bushing for Mig70 front-hub, color

VN01167(+Farbcode/color code)

Endkappe für King/Princess/Mig70/Dörte, 17mm, 10.0mm, links+rechts, schwarz

end-cap for King/Princess/Mig70/Dörte, 17mm, 10.0mm, left+right, black

NZ0304sw

Einreihiges Rillenkugellager 61803 2RS C3 /

single-row ball bearing 61803 2RS C3

NZ1509

Einreihiges Rillenkugellager 61803 2RS C3/

single-row ball bearing 61803 2RS C3

NZ1509

Endkappe für King/Princess/Mig70/Dörte, 17mm, 10.0mm, links+rechts, schwarz

end-cap for King/Princess/Mig70/Dörte, 17mm, 10.0mm, left+right, black

NZ0304sw

Aluminiumachse 17mm für King/Princess/Mig70/Dörte15, silber

aluminium-axle 17mm for King/Princess/Mig70/Dörte15, silver

NZ0002si

Mig70

BVN01 (+Lochzahl/number of spoke holes)(+Farbcode/color code)

Flansch für Mig70 VR-Nabe, Lochzahl, Farbe /

flange for Mig70 front-hub, number of spoke holes, color

VN001(+Lochzahl/number of spoke

holes)(+Farbcode/color code)

Stand: Oktober 2013

as of: October 2013

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 4 of 9

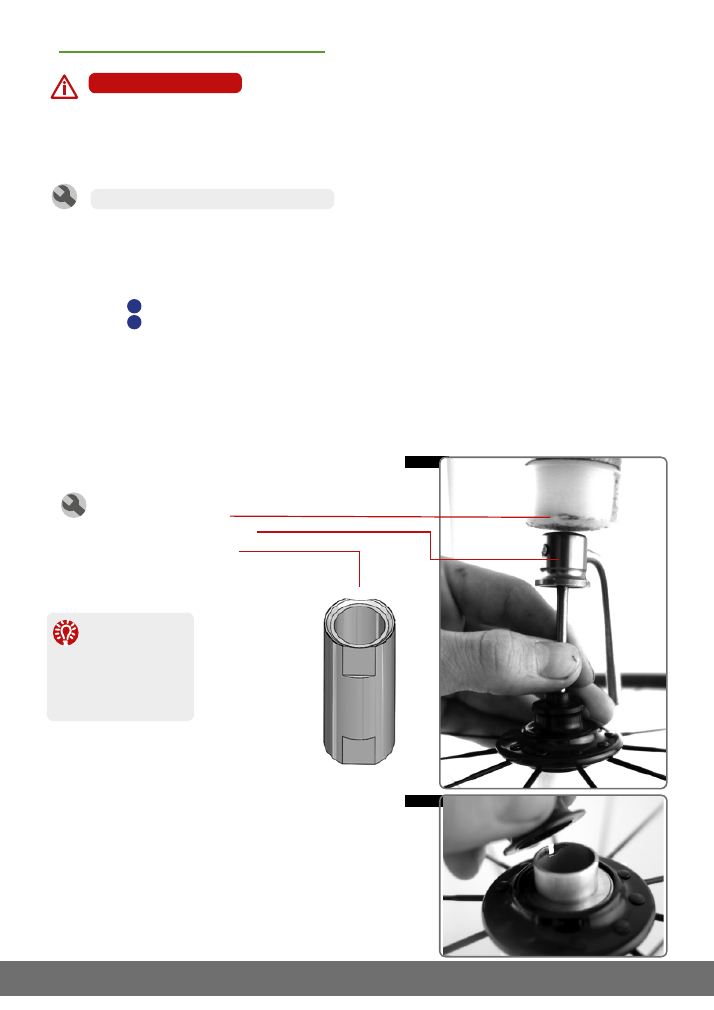

fig.1

Disassembly and assembly of the hub:

Important notes:

• All contact surfaces, except between the bearings and the hub body, should be greased.

• Always remember the exact position of all parts.

• Please contact your dealer, if you feel insecure, don´t have appropriate skills or the needed

equipment.

Needed tools / material:

• tool kit Tune Tool 08 (No. BWZ0000)

• plastic hammer

• an rob (old Quickrelease axle)

• hot air blower

• vernier caliper

•

1

Grease (we recommend Molykote Rapid Plus Paste, alternative bearing grease)

•

2

Glue (e.g. 3M Scotch-Weld TL-70, Loctite 641)

This manual leads you through the complete disassembly, assembly and adjustment of the hub. Not all

steps have to be carried out maintaining the hub.

If you only want to adjust the bearing play you can start with the first step

„Removing the endcap“

after-

wards you can continue with the step

„Setting the bearing play“.

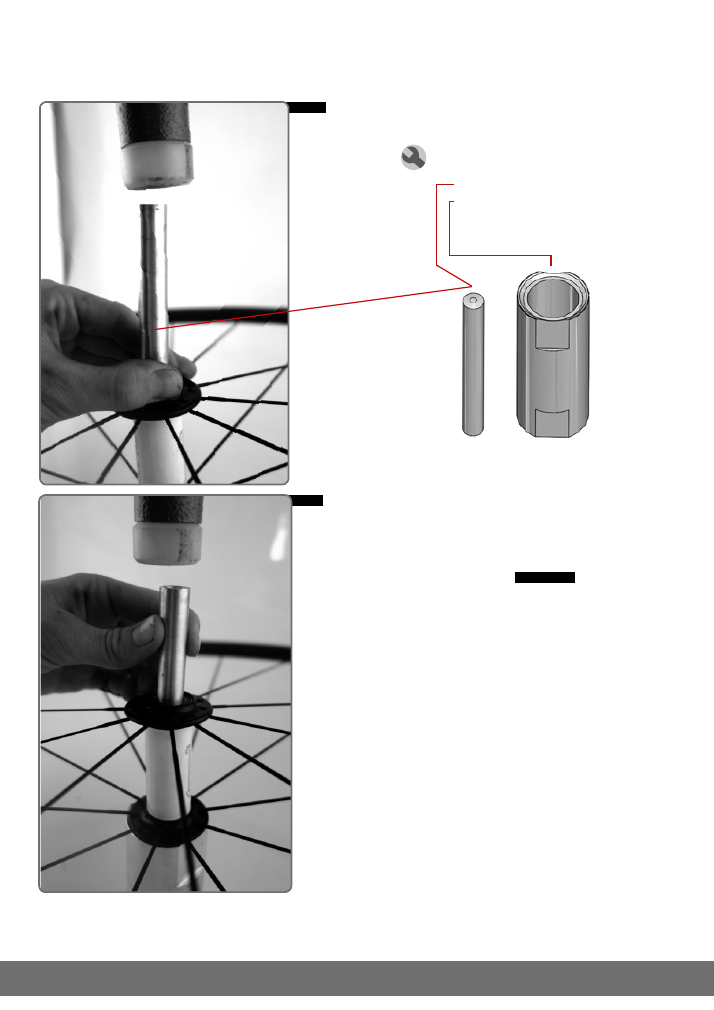

The hub gets placed on the main tool TT08.1.

An Quickrelease axle gets pushed through the

left endcap into the hub axle, so that it touches

the inner side of the right endcap.

The right end cap can now be pushed of the

axle by hitting the Quickrelease with the plastic

hammer.

Be careful to not loose the distances, which

are placed between the endcap and bearing.

Needed tools:

• plastic hammer

• old Quickrelease axle

• main tool TT08.1

1

Removing the endcap

fig.2

TT08.1

The right side of the

hub is next to the

“e” in the Tune logo.

(see graphic on p.3)

Tip:

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 5 of 9

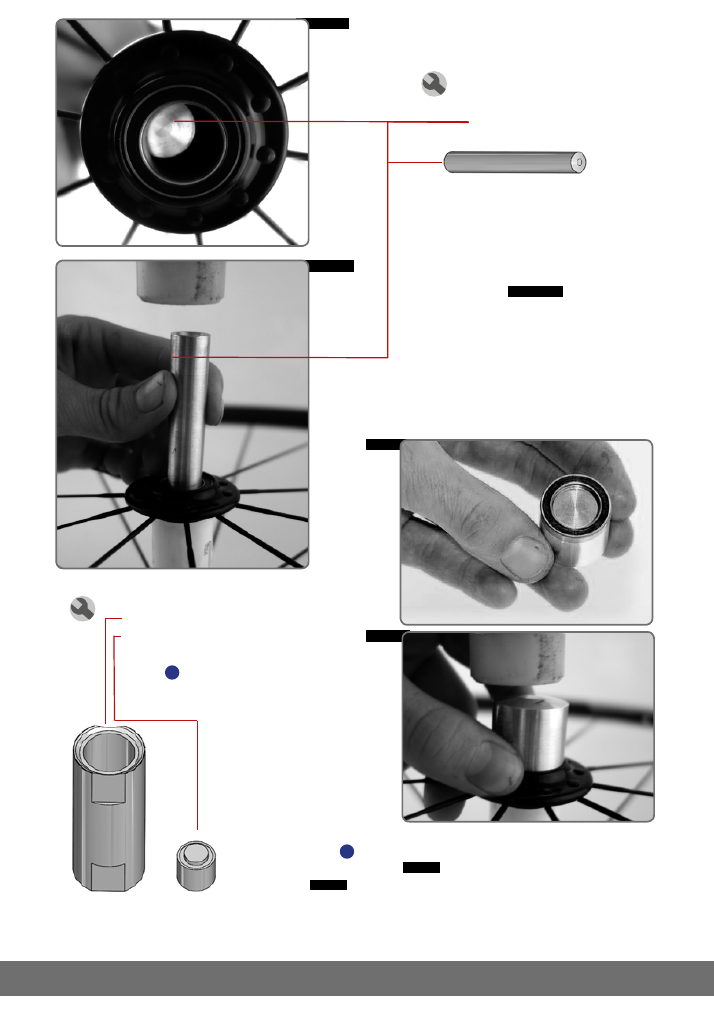

Place the hub on the main tool TT08.1.

Now the axle can be pushed out using the to the

Tool TT08.2 and a hammer.

fig. 3 & 4

If the hub is not laced, the flange (including the

pressed-in bearings) as-well as the inner sleeve

can be separated already.

fig.3

2

Removing the axle

Needed tools:

• plastic hammer

• TT08.2

article No.

WZ0202

• TT08.1

article No

.

WZ0200

fig.4

TT08.1

TT08.2

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 6 of 9

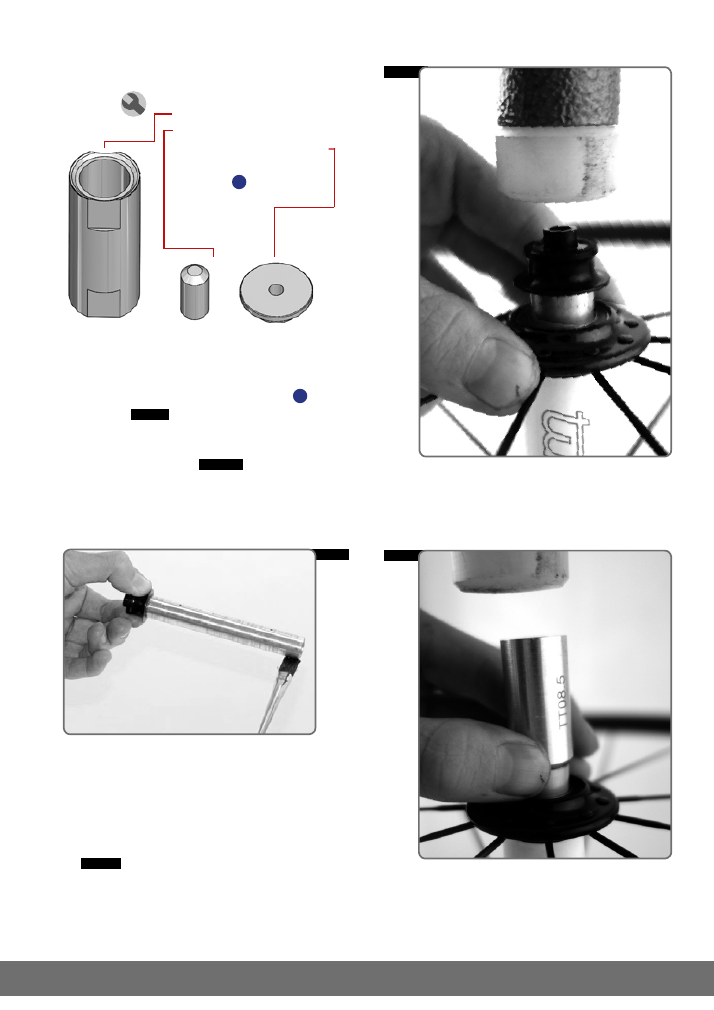

The cleaned bearing seat gets covered with a thin layer of

glue

3

. The bearing gets pressed in with some light hits

from a hammer

fig. 8

, using the correct sized fitting stamp

fig. 7

.

Pay attention to not cant the bearings and always only strain

the outer ring of the bearing.

5

Installing a new bearing

Needed tools:

• TT08.1

No. WZ0200

• TT08.14

No. WZ0209

• plastic hammer

• glue

2

fig.7

fig.8

TT08.1

TT08.14

fig.6

fig.5

4

Removing the bearings

Needed tools:

• TT08.1

• TT08.2

•

TT08.2

Place the hub on the main tool TT08.1.

Now the bearings can be pushed out us-

ing the tool TT08.2 and a plastic hammer.

Always dispense the force all around the

bearing to not damage both the bearing

and the hub body.

fig. 5 + 6

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 7 of 9

6

Reassembling the hub

Needed tools:

• TT08.1

article No. WZ0200

• TT08.5

article No. WZ0218

• TT08.9

article No. WZ0204

• plastic hammer

• grease

1

fig.10

fig.9

TT08.1

TT08.5

TT08.9

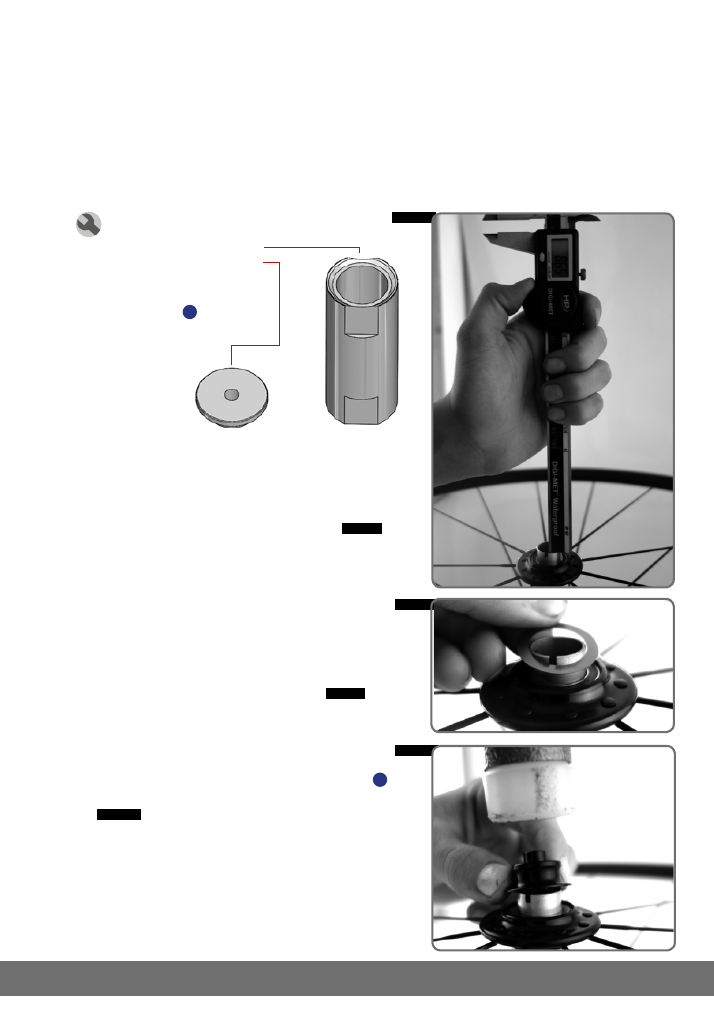

Release axle and bearings

Place the hub on the main tool with the extra attach-

ment TT08.9, that only the left endcap touches the tool.

Using the tool TT08.5 and a plastic hammer hit the axle

softly.

fig.11

By doing so, strain is taken of the axle

and the bearings.

fig.11

The axle gets slightly covered with grease

1

in the

contact areas.

fig.10

The hub gets placed on the main tool TT08.1. Using

the tool TT08.5 and a plastic hammer the axle gets

pushed back into the hub.

fig.9

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 8 of 9

fig.13

fig.12

Needed tools:

• TT08.1

No. WZ0200

• TT08.9

No. WZ0204

• plastic hammer

• vernier caliper

• grease

1

Now the open end of the axle on the right side has to be meas-

ured. With the depth gauge of a vernier caliper measure the

axle from the inner ring of the bearing to the end of the axle.

The measurement has to be extremely precise, we recom-

mend to repeat the measurement a couple of times.

fig.12

TT08.1

TT08.9

Reasons for bearing play can be worn bearings, a damaged axle or just the adjustment. A certain bearing

play is normal and enables a soft and smooth rotation.

The axial bearing play is adjusted with washers. These are available in 0,1mm (NZ1604), 0,15mm (NZ1605)

and 0,2mm (NZ1606) width. The washers are placed between the outer freewheel bearing and the right

endcap. We adjust the bearing play during production for every hub in manual labour. With wear, or when

new bearings are installed, the bearing play has to be readjusted.

7

Setting the bearing play

fig.14

From the measured length (e.g.: 8.4 mm) subtract the

depth of the endcap (8.0 mm). The difference is the axial

bearing play (here 8.4 - 8.0 = 0.4 mm).

The optimal axial bearing play amounts 0.15-0.20mm. The

difference between the measured open end of the axle

(e.g.: 8.4 mm) and the depth of the endcap (8,0 mm) has

to be adjusted to 0.15-0.20 mm using washers.

fig.13

The axial bearing play is adjusted perfectly, if the length, of

the open end of the axle, with washers is set to 8.15-8.20mm.

To finish of, the endcap is slightly covered with grease

1

on the inside. Now it can be pushed back on using a plastic

hammer.

fig.14

Now the wheel is usable again.

MANUAL

|

FRONT HUB MIG70

www.tune.de

As of May 2015

Page 9 of 9

© Tune U.Fahl e.K

.

BUILT TO ENJOY NATURE

BORN IN THE BLACK FOREST

Tune U. Fahl e.K.

Im Mittelfeld 18

|

79426 Buggingen

service@tune.de

www.tune.de

Outside of Germany please contact your local distributor.

Service

Warranty:

Tune grants a two year warranty from the date of purchase on material defects and production errors. On

bearings, rims and spokes we grant a one year Warranty, as these are wear parts. Claims can only be made

if a copy of an original dealer invoice is presented.

There is no claim for warranty services in case of:

•

normal wear

•

improper use or careless treatment

•

disregard of service instructions

•

inappropriate repair, assembly, or maintenance works or negligence

•

defects caused by wrong wheel building (spoke patterns, spoke crossings, spoke tension, etc.)

Warranty claims have to be sent to the local Tune distributor and are subject to the assessment of Tune.

Based on this warranty, the company Tune is not liable for compensation, especially not for indirect damage

caused by accidents, collateral damage and consequential damage. All anodized parts can bleach in sunlight.

Crash Replacement:

Tune offers a Crash Replacement in addition to the legal warranty. The service can be engaged if your Tune

product is damaged and not be ridable any more, due to a crash, accident or overload .

Conditions:

•

Due to our huge products variety, the discount we can give, is assessed individually for every case.

•

The damaged part is replaced by the same model. Tune reserves the right to replace the damaged part

with an equal alternative.

•

The damage has to affect the functionality of the component (optical damage is excluded).

•

Damaged parts pass into the ownership of Tune.

•

The Crash Replacement offer does not cover the costs of transport and labour.