Full Text Searchable PDF User Manual

2

26

28

22

18

24

23

25

27

19

20

21

6

8

3

1

4

2

7

5

9

11

10

13

15

12

14

16

17

23/02/2015 15:50

4

Model number:

TA235CSL

Input voltage:

220V - 240V AC, 50/60Hz

Input current:

10A

No load speed:

4500min

-1

Blade diameter:

235mm

Blade bore diameter:

30mm

Blade teeth:

40 TCT

Blade kerf:

2.2 – 3.5 mm

Bevel adjustment:

0° to 45°

Positive bevel stops:

0°, 15°, 22.5°, 30° and 45°

Cutting capacity at 90°:

82mm

Cutting capacity at 45°:

58mm

Insulation:

Net weight:

7.7kg

Laser:

Class 2

Wave length:

650nm

Output power:

≤1mW

Sound and vibration information

Sound pressure L

PA

:

97,1dB(A)

Sound power L

WA

:

108,1dB(A)

Uncertainty K:

3dB

Weighted vibration a

h

:

2,470m/s

2

Uncertainty:

1.5m/s

2

Thank you for purchasing this Triton tool. This manual contains information necessary for safe and effective operation of this product.

This product has unique features and, even if you are familiar with similar products, it is necessary to read this manual carefully to ensure

you fully understand the instructions. Ensure all users of the tool read and fully understand this manual.

Specification

Description of Symbols

V

Volts

~

Alternating current

A

Ampere

No load speed

Hz

Hertz

W, kW

Watt, kilowatt

/min or min

-1

(revolutions or reciprocation) per minute

The sound intensity level for the operator may exceed 85dB(A) and sound

protection measures are necessary.

As part of our ongoing product development, specifications of Triton

products may alter without notice.

WARNING

: Always wear ear protection where the sound level exceeds 85dB(A)

and limit the time of exposure if necessary. If sound levels are uncomfortable,

even with ear protection, stop using the tool immediately and check the ear

protection is correctly fitted and provides the correct level of sound attenuation

for the level of sound produced by your tool.

WARNING

: User exposure to tool vibration can result in loss of sense of touch,

numbness, tingling and reduced ability to grip. Long term exposure can lead to

a chronic condition. If necessary, limit the length of time exposed to vibration

and use anti-vibration gloves. Do not operate the tool with hands below a

normal comfortable temperature, as vibration will have a greater effect. Use

the figures provided in the specification relating to vibration to calculate the

duration and frequency of operating the tool.

Sound and vibration levels in the specification are determined according to

EN60745 or similar international standards. The figures represent normal use

for the tool in normal working conditions. A poorly maintained, incorrectly

assembled, or misused tool, may produce increased levels of noise and

vibration.

www.osha.europa.eu

provides information on sound and vibration

levels in the workplace that may be useful to domestic users who use tools for

long periods of time.

Wear hearing protection

Wear eye protection

Wear breathing protection

Wear head protection

Read instruction manual

Caution!

Class II construction

(double insulated for additional protection)

Toxic fumes or gases!

Laser

Be aware of kickback!

Always disconnect from the power supply when adjusting,

changing accessories, cleaning, carrying out maintenance and

when not in use!

Environmental Protection

Waste electrical products should not be disposed of with

household waste. Please recycle where facilities exist. Check

with your local authority or retailer for recycling advice.

Technical Abbreviations Key

n

o

23/02/2015 15:50

5

General Safety

WARNING Read all safety warnings and all instructions.

Failure to follow

the warnings and instructions may result in electric shock, fire and or serious

injury.

WARNING: This appliance is not intended for use by persons (including

children) with reduced, physical or mental capabilities or lack of

experience or knowledge unless they have been given supervision or

instruction concerning use of the appliance by a person responsible for

their safety.

Children must be supervised to ensure that they do not play with

the appliance.

Save all warnings and instructions for future reference.

The term “power tool” in the warnings refers to your mains-operated (corded)

power tool or battery-operated (cordless) power tool.

1) Work area safety

a)

Keep work area clean and well lit.

Cluttered or dark areas invite

accidents.

b)

Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust.

Power tools create

sparks which may ignite the dust or fumes.

c)

Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) Electrical safety

a)

Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power

tools.

Unmodified plugs and matching outlets will reduce risk of electric

shock.

b)

Avoid body contact with earthed or grounded surfaces, such as pipes,

radiators, ranges and refrigerators.

There is an increased risk of electric

shock if your body is earthed or grounded.

c)

Do not expose power tools to rain or wet conditions.

Water entering a

power tool will increase the risk of electric shock.

d)

Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp

edges or moving parts.

Damaged or entangled cords increase the risk of

electric shock.

e)

When operating a power tool outdoors, use an extension cord suitable

for outdoor use.

Use of a cord suitable for outdoor use reduces the risk of

electric shock.

f)

If operating a power tool in a damp location is unavoidable, use a

residual current device (RCD) protected supply.

Use of an RCD reduces

the risk of electric shock.

3) Personal safety

a)

Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired

or under the influence of drugs, alcohol or medication.

A moment of

inattention while operating power tools may result in serious personal

injury.

b)

Use personal protective equipment. Always wear eye protection.

Protective equipment such as dust mask, non-skid safety shoes, hard hat,

or hearing protection used for appropriate conditions will reduce personal

injuries.

c)

Prevent unintentional starting. Ensure the switch is in the off-position

before connecting to power source and/or battery pack, picking up

or carrying the tool.

Carrying power tools with your finger on the switch or

energising power tools that have the switch on invites accidents.

d)

Remove any adjusting key or wrench before turning the power tool

on.

A wrench or a key left attached to a rotating part of the power tool may

result in personal injury.

e)

Do not overreach. Keep proper footing and balance at all times.

This

enables better control of the power tool in unexpected situations.

f)

Dress properly. Do not wear loose clothing or jewellery. Keep your hair,

clothing and gloves away from moving parts.

Loose clothes, jewellery or

long hair can be caught in moving parts.

g)

If devices are provided for the connection of dust extraction and

collection facilities, ensure these are connected and properly used.

Use of dust collection can reduce dust-related hazards.

4) Power tool use and care

a)

Do not force the power tool. Use the correct power tool for your

application.

The correct power tool will do the job better and safer at the

rate for which it was designed.

b)

Do not use the power tool if the switch does not turn it on and off.

Any

power tool that cannot be controlled with the switch is dangerous and must

be repaired.

c)

Disconnect the plug from the power source and/or the battery

pack from the power tool before making any adjustments, changing

accessories, or storing power tools.

Such preventive safety measures

reduce the risk of starting the power tool accidentally.

d)

Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to

operate the power tool.

Power tools are dangerous in the hands of

untrained users.

e)

Maintain power tools. Check for misalignment or binding of moving

parts, breakage of parts and any other condition that may affect the

power tool’s operation. If damaged, have the power tool repaired

before use.

Many accidents are caused by poorly maintained power tools.

f)

Keep cutting tools sharp and clean.

Properly maintained cutting tools

with sharp cutting edges are less likely to bind and are easier to control.

g)

Use the power tool, accessories and tool bits etc. in accordance with

these instructions, taking into account the working conditions and

the work to be performed.

Use of the power tool for operations different

from those intended could result in a hazardous situation.

WARNING:

When used in Australia or New Zealand, it is recommended that this

tool is ALWAYS supplied via Residual Current Device (RCD) with a rated residual

current of 30mA or less.

5) Service

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power

tool is maintained.

Circular Saw Safety

Cutting procedures

a)

DANGER: Keep hands away from cutting area and the blade. Keep

your second hand on auxiliary handle, or motor housing.

If both hands

are holding the saw, they cannot be cut by the blade.

b) Do not reach underneath the workpiece.

The guard cannot protect you

from the blade below the workpiece.

c) Adjust the cutting depth to the thickness of the workpiece.

Less than a

full tooth of the blade teeth should be visible below the workpiece.

d) Never hold piece being cut in your hands or across your leg. Secure

the workpiece to a stable platform.

It is important to support the work

properly to minimise body exposure, blade binding, or loss of control.

e) Hold the power tool by insulated gripping surfaces only, when

performing an operation where the cutting tool may contact hidden

wiring or its own cord.

Contact with a “live” wire will also make exposed

metal parts of the power tool “live” and could give the operator an electric

shock.

f) When ripping, always use a rip fence or straight edge guide.

This

improves the accuracy of cut and reduces the chance of blade binding.

g) Always use blades with correct size and shape (diamond versus

round) of arbour holes.

Blades that do not match the mounting hardware

of the saw will run eccentrically, causing loss of control.

h) Never use damaged or incorrect blade washers or bolts.

The blade

washers and bolt were specially designed for your saw, for optimum

performance and safety of operation.

23/02/2015 15:50

6

Further safety instructions for all

saws

Kickback causes and related warnings

– kickback is a sudden reaction to a pinched, bound or misaligned saw blade,

causing an uncontrolled saw to lift up and out of the workpiece toward the

operator;

– when the blade is pinched or bound tightly by the kerf closing down, the

blade stalls and the motor reaction drives the unit rapidly back toward the

operator;

– if the blade becomes twisted or misaligned in the cut, the teeth at the back

edge of the blade can dig into the top surface of the wood causing the blade

to climb out of the kerf and jump back toward the operator.

Kickback is the result of saw misuse and/or incorrect operating

procedures or conditions and can be avoided by taking proper

precautions as given below.

a) Maintain a firm grip with both hands on the saw and position your

arms to resist kickback forces. Position your body to either side of the

blade, but not in line with the blade.

Kickback could cause the saw to

jump backwards, but kickback forces can be controlled by the operator if

proper precautions are taken.

b) When blade is binding, or when interrupting a cut for any reason,

release the trigger and hold the saw motionless in the material until

the blade comes to a complete stop. Never attempt to remove the

saw from the work or pull the saw backward while the blade is in

motion or kickback may occur.

Investigate and take corrective actions to

eliminate the cause of blade binding.

c) When restarting a saw in the workpiece, centre the saw blade in the

kerf and check that saw teeth are not engaged into the material.

If

saw blade is binding, it may walk up or kickback from the workpiece as the

saw is restarted.

d) Support large panels to minimise the risk of blade pinching and

kickback. Large panels tend to sag under their own weight.

Supports

must be placed under the panel on both sides, near the line of cut and near

the edge of the panel.

e) Do not use dull or damaged blades.

Unsharpened or improperly set

blades produce narrow kerf causing excessive friction, blade binding and

kickback.

f) Blade depth and bevel adjusting locking levers must be tight and

secure before making cut.

If blade adjustment shifts while cutting, it may

cause binding and kickback.

g) Use extra caution when sawing into existing walls or other blind

areas.

The protruding blade may cut objects that can cause kickback.

Lower guard function

a) Check lower guard for proper closing before each use. Do not operate

the saw if lower guard does not move freely and close instantly.

Never clamp or tie the lower guard into the open position.

If saw is

accidentally dropped, lower guard may be bent. Raise the lower guard with

the retracting handle and make sure it moves freely and does not touch the

blade or any other part, in all angles and depths of cut.

b) Check the operation of the lower guard spring. If the guard and

the spring are not operating properly, they must be serviced before

use.

Lower guard may operate sluggishly due to damaged parts, gummy

deposits, or a build-up of debris.

c) Lower guard may be retracted manually only for special cuts such as

“plunge cuts” and “compound cuts”. Raise lower guard by retracting

handle and as soon as blade enters the material, the lower guard

must be released.

For all other sawing, the lower guard should operate

automatically.

d) Always observe that the lower guard is covering the blade before

placing saw down on bench or floor.

An unprotected, coasting blade will

cause the saw to walk backwards, cutting whatever is in its path. Be aware

of the time it takes for the blade to stop after switch is released.

Additional circular saw safety

WARNING

:

Before connecting a tool to a power source (mains switch

power point receptacle, outlet, etc.) be sure that the voltage supply is the

same as that specified on the nameplate of the tool.

A power source with a

voltage greater than that specified for the tool can result in serious injury to the

user, and damage to the tool. If in doubt, do not plug in the tool. Using a power

source with a voltage less than the nameplate rating is harmful to the motor.

a) Do not allow anyone under the age of 18 years to operate this saw

b) When operating the saw, use safety equipment including safety goggles or

shield, ear protection, dust mask and protective clothing including safety

gloves

c) Hand-held power tools may produce vibration. Vibration can cause disease.

Gloves may help to maintain blood circulation in the fingers. Hand-held

tools should not be used for long periods without a break

d) Whenever possible, use a vacuum dust extraction system to control dust/

waste

e) Do not attempt to cut material thicker than detailed in the Specifications

section of this manual

f) Adjust the cutting depth to the thickness of the workpiece i.e. less than a

full tooth of the blade should be visible below the workpiece

g) Ensure work is correctly supported. Large panels may sag under their own

weight and bind the saw blade. Supports must be placed under the panel

on both sides, close to the line of cut and near the edge of the panel

h) Ensure all supports and power cables are completely clear of the cutting

path

i) Always secure the workpiece to a stable platform, ensuring body exposure

is minimised, avoiding blade binding, or loss of control

j) Always stand at an angle to the tool when operating

k) Be aware that the blade will project from the underside of the workpiece

l) Do not reach beneath the workpiece where the guard cannot protect you

from the blade

m) Note the direction of rotation of the motor and the blade

n) Inspect the workpiece and remove all nails and other embedded objects

prior to starting work

o) Do not apply any sideways or twisting force to the blade whilst cutting

p) If a cut does not extend to the edge of the workpiece, or if the blade binds

in the cut, allow the blade to come to a complete stop and lift the saw out

of the workpiece

q) Do not attempt to free a jammed blade before first disconnecting the

machine from power

r) Do not move the saw backwards at any time whilst cutting

s) Beware of projected waste. In some situations, waste material may be

projected at speed from the cutting tool. It is the user’s responsibility to

ensure other people in the work area are protected from the possibility of

projected waste

t) If you are interrupted when operating the saw, complete the process and

switch off before diverting your attention

u) Check the lower guard for proper closure before each use. Do not operate

the saw if the lower guard does not move freely and close instantly.

Never clamp or tie the lower guard into the open position. If the saw is

accidentally dropped, the lower guard may be bent. Raise the lower guard

with the retracting handle and make sure it moves freely and does not

touch the blade or any other part, in all angles and depths of cut

v) Always observe that the lower guard is covering the blade before resting

the saw on a surface after use. An unprotected, coasting blade will cause

the saw to move backwards, cutting whatever is in its path. Be aware of

the time it takes for the blade to stop after the trigger switch is released

w) Periodically check that all nuts, bolts and other fixings have not become

loose, and tighten where necessary

The tool must be used only for its prescribed purpose.

Any use other

than those mentioned in this manual will be considered a case of misuse.

The user, and not the manufacturer, shall be liable for any damage or injury

resulting from such cases of misuse.The manufacturer shall not be liable for

any modifications made to the tool nor for any damage resulting from such

modifications. Even when the tool is used as prescribed it is not possible to

eliminate all residual risk factors.

23/02/2015 15:50

7

Laser Safety

The laser used in this device is a Class 2 laser with maximum power of ≤1mW

and a wavelength of 650nm.

These lasers do not normally present an optical hazard, although staring at the

beam may cause flash blindness.

WARNING:

Avoid direct eye contact.

A hazard may exist if you deliberately stare into the beam, please observe all

safety rules as follows:

• The laser shall be used and maintained in accordance with the manufac

turer’s instructions

• Do not switch on the laser light until the tool is ready to cut

• Never aim the beam at any person, and particularly not into the eyes of any

person or animal, or any object other than the workpiece

• Always ensure the laser beam is aimed at a sturdy workpiece without

reflective surfaces. i.e. wood or rough-coated surfaces are acceptable.

Reflective sheet steel or similar is not suitable for laser use as the reflective

surface could direct the beam back at the operator

• Do not change the laser light assembly. Repairs must only be carried out by

the laser manufacturer or an authorised agent. DO NOT exchange with a

different type of laser

CAUTION: Use of controls or adjustments or performance of procedures other

than those specified herein may result in hazardous radiation exposure.

Please refer to the relevant EN standards, EN60825-1:2007 for more

information on Lasers.

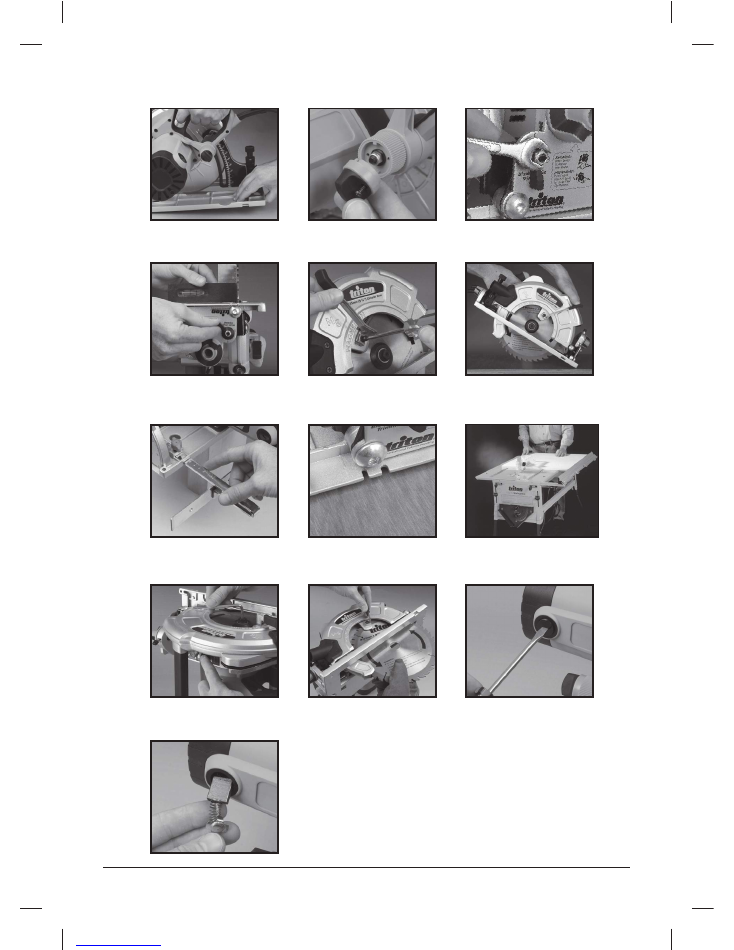

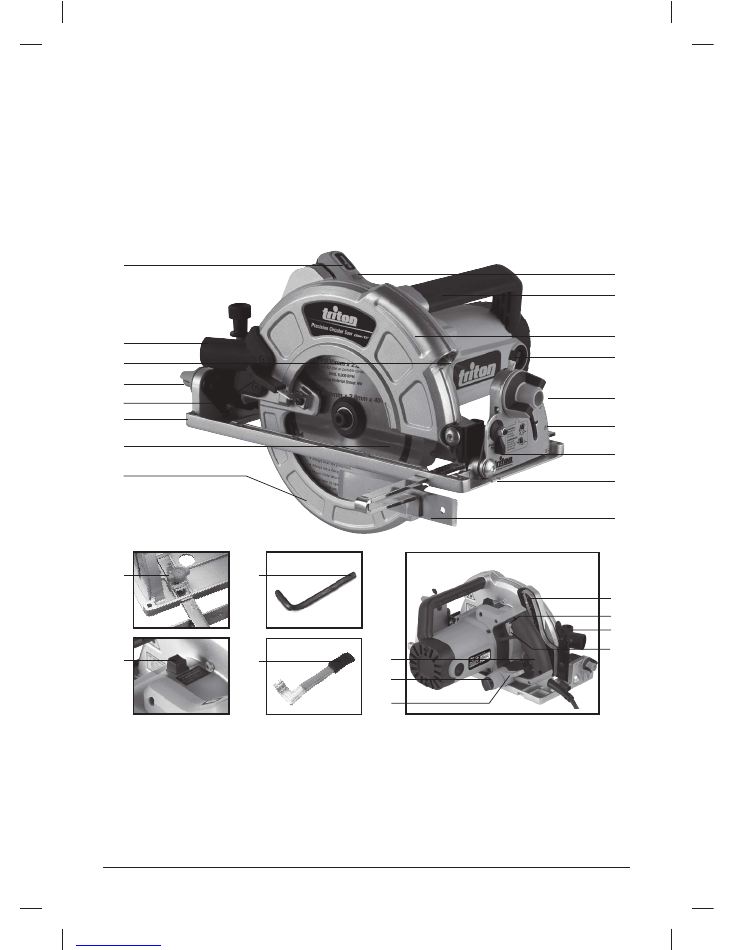

Product Familiarisation

1.

Laser Sight Switch

2. Dust Port

3. Laser Sight Assembly

4. Bevel Lock Knob (rear)

5. Short Blade Guard Lever (fitted)

6. Base Plate

7. 40 Tooth TCT Blade

8. Lower Blade Guard

9. Power-On Neon Light

10. Front Handle

11. Upper Guard

12. Bevel Detent Latch

13. Bevel Lock Knob (front)

14. Bevel Scale

15. Bevel Micro Adjustable Lever

16. 90° and 45° Blade Sight Notch

17. Rip Fence

18. Rip Fence Locking Knob

19. Spindle Lock Button

20. 6mm Hex Key

21. Long Blade Guard Lever

22. Main Handle

23. Rack & Pinion Adjustment Knob

24. Depth Adjustment Locking Lever

25. Depth of Cut Scale

26. Lock-Off Button

27. Micro Depth Adjustment Knob

28. Trigger Switch

Intended Use

Hand-held corded electric circular saw for cross, rip and bevel cutting of hard

and softwood timber and sheet material. This machine may also be used as a

table saw, mounted in the Triton Saw Table, the Triton Workcentre or a suitable

third-party stand.

WARNING:

This circular saw is only suited for cutting wood, MDF, chipboard

and similar materials; it is NOT suitable for cutting metal or wood with

embedded nails.

Unpacking Your Tool

Carefully unpack and inspect your tool. Familiarise yourself with all its features

and functions.

Ensure that all parts of the tool are present and in good condition. If any parts

are missing or damaged, have such parts replaced before attempting to use

this tool.

Before Use

WARNING:

Ensure that the tool is switched off and disconnected from the

power supply before making any adjustments or installing or removing blades.

Adjusting the cutting depth

1. Loosen the Depth Adjustment Locking Lever (24) and lift the back of the

saw away from the baseplate until the approximate depth is achieved

(Image A). Push down on the lever to lock the saw in position

2. For fine depth adjustments, lock the saw at the approximate depth and

then turn the Micro Depth Adjustment Knob for the exact depth. Turn the

Micro Depth Adjustment Knob in a clockwise direction to decrease the

depth of cut, turn in an anti-clockwise direction to increase the depth of

cut. The adjustment range is 6mm, if insufficient, reset the main depth

adjustment, and fine tune again. The micro-adjustment knob must be set to

full depth to achieve the 82mm maximum depth of cut

3. The circular saw also features a rack & pinion depth adjustment feature.

The rack & pinion depth adjustment is most useful when the saw is

mounted below a Triton Workcentre

4. To adjust the depth using the rack & pinion feature loosen the Depth

Adjustment Locking Lever (24) and then turn the Rack & Pinion Adjustment

Knob (23), to adjust the cutting height. Turn the knob in an anti-clockwise

direction to increase the cutting depth, turn in a clockwise direction to

decrease the cutting depth. Tighten the Depth Adjustment Locking Lever to

lock the saw in position

Adjusting the depth locking lever tension

If the Depth Adjustment Locking Lever (24) is not providing enough tension

adjust as follows:

1. Loosen and remove the two Phillips head screws that secure the Rack &

Pinion Adjustment Knob (23). Remove the adjustment knob; this will reveal

the locking lever tension nut (Image B)

2. Using a 10mm wrench tighten the tension nut in a clockwise direction to

increase the tension of the Depth Adjustment Locking Lever (24)

3. Once the locking lever is providing sufficient tension replace the

adjustment knob and secure using the two Phillips head screws

4. Check the operation of the locking lever before operating the saw

Adjusting the bevel angle

1. Bevel angles can be set anywhere within the range 0° to 47°. Pre-set

stops are available at 0°, 15°, 22.5°, 30° and 45° for quick, accurate bevel

settings

2. Loosen the Front and Rear Bevel Lock Knobs (13 and 4) and depress the

Bevel Detent Latch (12). Pivot the saw to the angle you require then release

the Bevel Detent Latch. A small movement of the saw motor will allow the

latch to pop up into the detent position. Tighten both Bevel Lock Knobs

3. For selecting other angles, leave the Bevel Detent Latch disengaged by

pushing it down and back towards the motor, where it has a ‘lock-out’

position. Firmly tighten both knobs at the required angle

23/02/2015 15:50

8

Fine tuning bevel angle and stops

1. You can fine-tune the calibration scale and the bevel detent positions by

+/-2˚

2. Make sure the saw is set at 0˚ and the Bevel Detent Latch is engaged

3. Loosen the rear Bevel Lock Knob (4), also loosen the Nyloc nut on the Bevel

Micro Adjustment Lever (15) using a 10mm spanner (Image C)

4. Adjust the trimmer to the left or right until the blade is square to the

baseplate or to the Triton table (Image D)

5. Tighten the rear Bevel Lock Knob and Nyloc nut after any adjustments

Note: For full trim range adjustment ensure the blade depth is set 2–3mm

(3/32”–1/8”) below maximum, for motor clearance. Full depth can be re-set

once the adjustment has been made.

Blade guard lever

For plunge or pocket cuts, use the Long Blade Guard Lever (21). To change the

lever follow the below instructions:

1. Loosen and remove the Phillips head screw holding the Short Blade Guard

Lever (5). Also remove the blade guard lever

2. Fit the Long Blade Guard Lever (21) into the same position

3. Replace the Phillips head screw and tighten to secure the Long Blade

Guard Lever in position (Image E)

4. The Long Blade Guard Lever can now be used to provide better control of

the lower guard when performing pocket cuts (Image F)

Rip fence adjustment

1. The Rip Fence (17) can be used on the left or the right of the blade (Image

G). Using the Rip Fence provides accurate cuts without the need to work

free-hand following pencil lines

2. Locate the Rip Fence into the mounting slots at the front of the Base Plate

(6) and tighten the Locking Knob (18) to lock it at the required cut width.

For greater width setting, the thumb screw can be repositioned to the inner

or outer clamp location

Sighting notches

1. Two sets of sighting notches at the front of the base plate provide guidance

when performing free-hand cuts following a pencil line

2. When viewed from the front of the saw use the left hand side notch for

90° cuts and the right hand sight notch for 45° cuts (Image H). Sight along

either edge of the notch, depending on which side of the line you wish to

cut.

3. Use the second set of notches, closer to the saw blade, to confirm the

alignment of your saw during the cut

Using the laser system

• Do not look directly at the laser beam

• Never aim the beam at any person or an object other than the workpiece

• Ensure that the beam is not directed towards others in the work area

• Ensure the laser beam is aimed at a sturdy workpiece without reflective

surfaces ie; wood or rough coated surfaces are acceptable. Bright shiny

reflective material is not suitable for laser use as the reflective surface could

direct the beam back at the operator

• Only turn on the laser beam when the tool is on the workpiece

1. 1Mark the line of the cut on the workpiece

2. Adjust the depth of cut and bevel angle as required

3. Rest the front edge of the base on the workpiece

4. Switch on the laser beam by pressing the Laser Sight Switch (1)

5. Line up the laser line with the pencil line on the workpiece

6. Start the motor by squeezing the Trigger Switch (28)

7. Make your cut ensuring that the laser line is kept in line with the pencil line

8. Switch off the laser beam by pressing the Laser Sight Switch

Saw bench guide

• Check that the saw bench is equipped with appropriate blade guarding and

ensure that it is properly adjusted and functioning correctly before

operating

• Ensure the saw is mounted securely to the bench. Refer to the

manufacturer’s instruction manual for mounting instructions

• Prior to starting work, manually run the saw along the table to ensure it

runs smoothly and is clear of obstructions

• Check that your saw bench is fitted with an anti-kickback device

• Make sure a suitable safety on/off switch is fitted to the saw bench. The

saw switch may then be locked on using a spring clamp, cable tie or

similar and then plugged into the safety socket on the saw bench. This

clamp MUST be taken off when the saw is removed from the saw bench

• Using all safety equipment make a test cut in an offcut piece of material

making sure all guarding is set up correctly before continuing with your

bench sawing (Image I)

Operation

WARNING:

ALWAYS wear eye protection, adequate respiratory and hearing

protection, as well as suitable gloves, when working with this tool.

Switching on and off

1. Connect the plug to the power supply.

2. To switch on the saw, press down the Lock-Off Button (26) and whilst

holding down the Lock-Off Button press down the Trigger Switch (28)

3. When you release the trigger, the saw turns off and the Lock-Off Button

re-engages. It will be necessary to press down the Lock-Off Button again

to turn the saw on

4. Allow the blade to come to a complete standstill before setting the saw

down

Operating

1. Rest the front of the base plate on the workpiece with your pencil mark

aligned with the correct sighting notch. Ensure the blade is not touching

the workpiece

2. Turn on the Laser Sight Switch (1) and align the laser line with the pencil

line

3. Hold the saw firmly with both hands, depress the Lock-Off Button (26) and

press the Trigger Switch (28). When the saw motor reaches full speed,

guide the saw smoothly along the cut line

4. Maintain a consistent feed rate - too fast may put excessive strain on

the motor, while too slow may burnish your workpiece. Avoid any sudden

movements of the saw

5. When cutting veneered board or wood less than 20mm thick, set the blade

to protrude 5-10mm through the work. This will reduce splintering. When

cutting thicker wood, set the blade to maximum depth to reduce kickback

6. For safety, use the parallel cutting guide or a clamped-on batten. If free-

hand cutting is unavoidable always mark out a straight cutting line as a

guide

7. Make sure the workpiece cannot move during the cut, using clamps

wherever possible. Never perform any cuts on a workpiece held in the

hand.

8. Large panels and long workpieces must be well supported close to

both sides of the cut to avoid pinching and kickback. Ensure the saw is

positioned with the wider part of the baseplate resting on the larger piece,

or on the piece with the best support

9. Prevent kickback by ensuring that you move the saw in a straight line.

Ensure that your blade is in good condition and that the cut does not close

in on the blade. (If necessary, use a small wedge or 3mm spacer in the

cut to prevent it closing in on the blade). Release the trigger if the saw

gives any sign of stalling but do not remove the saw until the blade stops

spinning

10. Avoid cutting any nails, screws etc. by inspecting your workpieces and

removing any fasteners prior to cutting

11. If any unusual noise or odour occurs during operation stop the saw

immediately and contact an authorised Triton Saw Repair Centre

23/02/2015 15:50

9

12. Do not operate the saw upside down unless securely mounted and guarded

in a reputable brand saw bench (eg. a Triton Workcentre or Triton Compact

Saw Table)

Accessories

A range of accessories are available for this power tool from your Triton dealer

including saw blades. Spare parts are available from your Triton dealer or

www.toolsparesonline.com.

Maintenance

WARNING:

Ensure that the tool is switched off and the plug is removed

from the power point before making any adjustments or maintenance

procedures.

• Inspect the supply cord of the tool, prior to each use, for damage or wear.

This advice also applies to extension cords used with this tool

• If the replacement of the supply cord is necessary, this has to be done by the

manufacturer or his agent in order to avoid a safety hazard.

• Regularly check that all the fixing screws are tight. They may vibrate loose

over time

• Regularly check that the saw arbors and arbor washer are clean, and free of

built-up gum deposits or caked-on sawdust. Check that the faces of the

arbor washers are smooth and free from burrs. Check that the blade

retaining bolt is correctly tightened

• Check the operation of the spring-loaded lower guard. It must close quickly

and without scraping anywhere. Remove the blade and clean accumulated

sawdust or wood slivers from the guard area

• Occasionally check the tension of the micro-adjustment knob, and if

necessary tighten or loosen the Nyloc nut

• The saw ventilation slots should be kept clean and clear of any foreign

matter. Use a lightly dampened cloth to wipe the saw clean - do not use

solvents

Replacing the saw blade

WARNING:

Ensure that the tool is switched off and disconnected from the

power supply before making any adjustments or installing or removing blades.

• Only use 235mm (9¼”) blades, with a kerf between 2.2 and 3.5mm,

designed for circular saws with a no-load speed rating of at least 5000rpm.

Never fit high speed steel blades or abrasive discs. Fitting of other purpose

or different sized blades could void the warranty

• Do not fit inferior blades. Regularly check the blade is flat, sharp and free of

cracks or defects

1. Ensure the saw is disconnected from power

2. Hold in the Spindle Lock Button (19) and use the 6mm Hex Key (20)

supplied to remove the arbor bolt (Image J) - turn in the direction of the

blade rotation. The shaft will turn slightly before locking, allowing the bolt

and outer arbor washer to be removed

3. Holding the Lower Blade Guard (8) fully back, carefully lift the worn blade

off the inner washer on the shaft and slide the blade through the baseplate

(Image K)

4. Now, keeping the Lower Blade Guard fully retracted, carefully slide the new

blade through the baseplate and position it onto the inner washer on the

shaft. The graphics should face out and the arrow on the blade should point

in the same direction as the arrow on the guard

5. Refit the outer arbor washer and, while depressing the Spindle Lock Button,

tighten the arbor bolt firmly into position – turn against the direction of

blade rotation

6. Ensure the blade sits flush between the inner and outer washers, then

tighten firmly with the Hex Key

Blade maintenance

• Regularly check that the blade is free from a build-up of gum resins or

sawdust. If necessary, clean with a solvent such as mineral turpentine

• Regularly check the saw blade for flatness. Use of the saw with a buckled

blade places excessive load on the motor and gearbox assembly, and may

affect your warranty rights

• The tungsten carbide teeth should be checked regularly for sharpness

and tooth breakages, and repaired or re-sharpened as required. Note that

when re-sharpening, the bevel angles on the front of the teeth should be

retained. The tungsten carbide teeth should be checked regularly for sharp-

ness and tooth breakages, and repaired or re-sharpened as required.

Contact the manufacturer

Cleaning

1. Keep the tool’s air vents unclogged and clean at all times

2. Remove dust and dirt regularly with a cloth or soft brush

3. Never use caustic agents to clean plastic parts. A damp cloth is

recommended. Water must never come into contact with the saw

4. Re-lubricate all moving parts at regular intervals

Brush replacement

• The carbon brushes are a consumable item which should be inspected

periodically and replaced when worn

• With the saw disconnected from power, unscrew the brush caps located

near the end of the motor (Image L). Remove the brushes by pulling care-

fully on the protruding springs (Image M)

• If either brush is worn to less than 6mm long, both brushes must be

replaced using genuine Triton replacement brushes - available from

Authorised Triton Saw Repair Centres

• Triton Precision Power Tools will not be responsible for any damage or

injury caused by mishandling or unauthorised repair of this tool

Power lead maintenance

If the power lead needs replacing, the task must be carried out by the

manufacturer, the manufacturer’s agent, or an authorised service centre in

order to avoid a safety hazard

Storage

• Store this tool carefully in a secure, dry place out of the reach of children

Disposal

Always adhere to national regulations when disposing of power tools that are

no longer functional and are not viable for repair.

• Do not dispose of power tools, or other waste electrical and electronic

equipment (WEEE), with household waste

• Contact your local waste disposal authority for information on the correct

way to dispose of power tools

23/02/2015 15:50

10

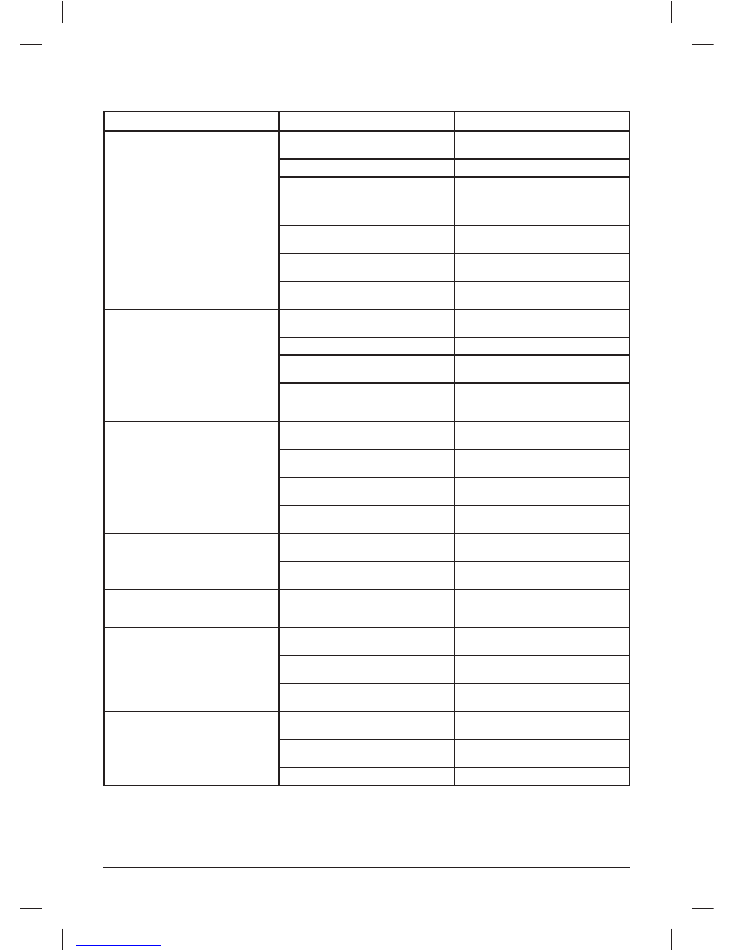

Problem

Possible cause

Solution

Saw will not operate

Power lead not plugged in

Ensure that the power lead is connected to the

power supply

Power fault, fuse or circuit breaker tripped

Check the power supply

Brushes worn or sticking

Disconnect power, open brush caps and ensure

brushes move freely in the holders. Check whether

brushes require replacing as outlined in the

maintenance section.

Lead damaged

Use authorised service centre** to repair or

replace the lead

Faulty switch

Use authorised service centre** to repair or

replace the switch

Faulty motor

Use authorised service centre** to repair or

replace the motor

Poor performance

Extension lead too long or undersized

Use extension lead heavy enough to carry the

current

Blunt or damaged blade

Re-sharpen or replace blade

Motor is overloaded

Reduce pushing force on saw. Ensure the cut isn’t

closing and pinching the blade.

Tool is overheating

Turn off the tool and let it cool down to room

temperature. Inspect and clean the ventilation

slots.

Vibration or abnormal noise

Accessory not secured

Ensure that the saw blade is fully tightened in the

arbor washers

Moving parts excessively worn

Use authorised service centre** to repair or

replace

Mechanical obstruction

Use authorised service centre** to repair or

replace

Armature has shorted sections

Use authorised service centre** to repair or

replace

Motor runs but blade won’t spin

Blade retaining nut is loose

Tighten blade retaining nut, ensure the arbor

washers are correctly fitted

Broken gear shaft or teeth

Use authorised service centre** to repair or

replace

Saw depth adjustment not holding

Depth Adjustment Locking Lever requires

tightening

Reposition the Depth Adjustment Locking Lever

as described in 'Adjusting the depth locking lever

tension'

Heavy sparking occurs inside motor housing

Brushes not moving freely

Disconnect power, remove brushes, clean or

replace

Armature short circuited or open circuited

Use authorised service centre** to repair or

replace

Commutator surface not clean

Use authorised service centre** to repair or

replace

Retractable guard will not close, or is slow to close

Return spring detached or broken

Re-attach or replace spring (use only genuine

Triton replacement parts)

Guard is bent

Straighten it or contact authorised service centre**

to repair or replace

Mechanism fouled by sawdust

Clean and lightly lubricate fouled mechanism

Troubleshooting

If a problem cannot be resolved using the above advice do not tamper with the saw - visit www.tritontools.com to find your nearest Triton office for assistance.

** Visit www.tritontools.com to find your nearest authorised service centre.

23/02/2015 15:50

11

Guarantee

To register your guarantee visit our web site at

www.tritontools.com* and enter your details.

Your details will be included on our mailing list (unless indicated other-

wise) for information on future releases. Details provided will not be made

available to any third party.

Purchase Record

Date of Purchase: ___ / ___ / ____

Model: TA235CSL Retain your receipt as proof of purchase

art pr

Triton Precision Power Tools guarantees to the purchaser of this product

that if any part proves to be defective due to faulty materials or workman-

ship within 3 YEARS from the date of original purchase,

Triton will repair, or at its discretion replace, the faulty part free of

charge.

This guarantee does not apply to commercial use nor does it extend to

normal wear and tear or damage as a result of accident, abuse or misuse.

* Register online within 30 days.

Terms & conditions apply.

This does not affect your statutory rights

oves to be defecti

Warranty

Our goods come with guarantees that cannot be excluded under the Australian

Consumer Law. You are entitled to a replacement or refund for a major failure and

for compensation for any other reasonably foreseeable loss or damage. You are also

entitled to have the goods repaired or replaced if the goods fail to be of acceptable

quality and the failure does not amount to a major failure.

This product is covered by a 36 month warranty.

This warranty will not apply:

(i) where this product has been subjected to misuse, abuse, accident or want of

care;

(ii) where this product has been used for a purpose for which it was not designed or

is not suited;

(iii) where the service of this product has been undertaken by a non-authorised

person or company or if non-approved parts have been used;

(iv) where this product has been used for industrial purposes.

Should service become necessary during the warranty period, the purchaser should

contact an Authorised Service Centre or White International. In order to obtain

warranty service, the purchaser must present the store receipt showing the name of

the retailer and the date of purchase.

The period of the warranty begins from the original date of purchase, notwithstanding

any subsequent repair or parts replacement.

Purchaser shall be responsible for all transport charges to and from the Authorised

Service Centre.

Damage in transit is not covered by this warranty. The purchaser should remove from

the product any liquids (if applicable) before sending the tool for service or repair. The

tool should be packed securely to prevent damage.

Warranty exclusions

Wear parts or service related parts required when performing normal and regular

maintenance of this product are not covered by warranty unless it is found to be

defective by an Authorised Service Centre. These include, but are not limited to: Blades

Distributed in Australia by White International.

PO Box 304 Milperra LPO, NSW Australia, 2214

Ph:1800 251 338

The White International Policy is one of continuous improvement and the company

reserves the right to alter designs, colours and specifications without notice

23/02/2015 15:50