Full Text Searchable PDF User Manual

ALL IN ONE

Heat Pump Water Heater

INSTALLATION AND OPERATION INSTRUCTIONS

Please read this user’s manual carefully before operate the unit.

CONTENTS

A. IMPORTANT REMARKS

-----------------------------------------------------------------------------------------------

1

B. DESCRIPTION OF HEAT PUMP

----------------------------------------------------------------------------------

2-3

C. INSTALLATION INSTRUCTION

-----------------------------------------------------------------------------------

4-6

D. OPERATION PANEL INSTRUCTION

---------------------------------------------------------------------------

7-11

E. MAINTENANCE AND SERVICE

--------------------------------------------------------------------------------

12-14

F. UNIT CIRCUIT DIAGRAM

----------------------------------------------------------------------------------------

15-16

G. ANNEX LIST

-------------------------------------------------------------------------------------------------------------

17

WARNING:

1. This unit must be installed by the professional persons, dealers or special installation

companies authorized. Or otherwise, accidents maybe possibly caused and use effect maybe

possibly be affected.

2. Be sure that the unit is STOP operation when disconnecting the power supply to the

unit .Disconnect all electric power supplies before servicing.

3. This appliance is not intended for use by persons (including children) with reduced physical,

or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

4. Children should be supervised to ensure that they do not play with the appliance.

5. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or

a similarly qualified person in order to avoid a hazard.

1

A. Important remarks

Thank you for choosing our products. Before installation, it is strongly recommended to read

this instruction firstly. This manual includes the information of installation, debugging,

running and maintenance of the products.

Every unit of products has passed strictly test to ensure safety and high efficiency operation.

The manufacturer of this product will not be held responsible if someone is injured or the unit

is damaged, as a result of improper installation, debugging, and unnecessary maintenance

which is not in line with this manual.

The installer should be an authorized technician, and install the system follow the diagram

on the equipment.

Please notice the following information during installation:

1. Applied working temperature of heat pump: -7~43

℃

.

2. Check whether the power supply and wire meet the standard of the unit.

3. Do not alter the power wire or socket and the metal parts should be connected to GND well. Do

not change the GND connection of the system.

4. The appliance shall be installed in accordance with national wiring regulations.

5. When the system is connected to a fixed power supply, a 3mm space switch should be equipped.

At the same time, must connect a power leakage protector. (30mA, 0.1sec.)

6. When finish all the wiring, check it again before power on.

7. Do not install the system in the warehouse where flammable gas may leak out.

8. Do not insert hands or object into the vent of the heat pump, it may cause the dangerous to

people or damage the system.

9. To make the system more efficiency, please install the main unit at a place with good ventilation.

10. Do not put (or install) the operating panel at a wet place, do not cut and reconnect the

connecting wire.

11. Before turn on the system at a first time, ensure the water tank is full filled with water.

12. The inlet of the water tank equips with a filter (detachable), clean it according to the water quality

and running condition of the system (the period should be 2~3 months)

13. While the water supply has been stopped or the system stops running for a long period in winter,

should be drain the tank water to avoid water system frost crack.

14. The highest temperature of outing water is 60

℃

, when using, tune up to a suitable temperature

(the most suitable temperature for human is 38

~

45

℃

, if the temperature is higher than 55

℃

, it

may cause the danger of scald). Normally, the setting temperature can be from 10

℃

- 55

℃

, the

model with Auxiliary heater can reach up to 70

℃

.

15. Move the main unit at max. 30 degree angle. Do not drop down or upend the unit.

16. Maintain the system by an authorized technician. And disconnect all power when servicing.

17. The water quality requirements for the heat pump: Chloride content in the water should be

<250mg/L; the PH of the water range is 6.5~8.5; the Calcium carbonate saturation index in the

water range is 1.0~0.4. Warranty does not apply to the heat exchanger, electrical heater and

water tank if it s connected to water quality out of the range.

18. Please provide the warrantee card and S/N No. enclosed with the product for after service.

2

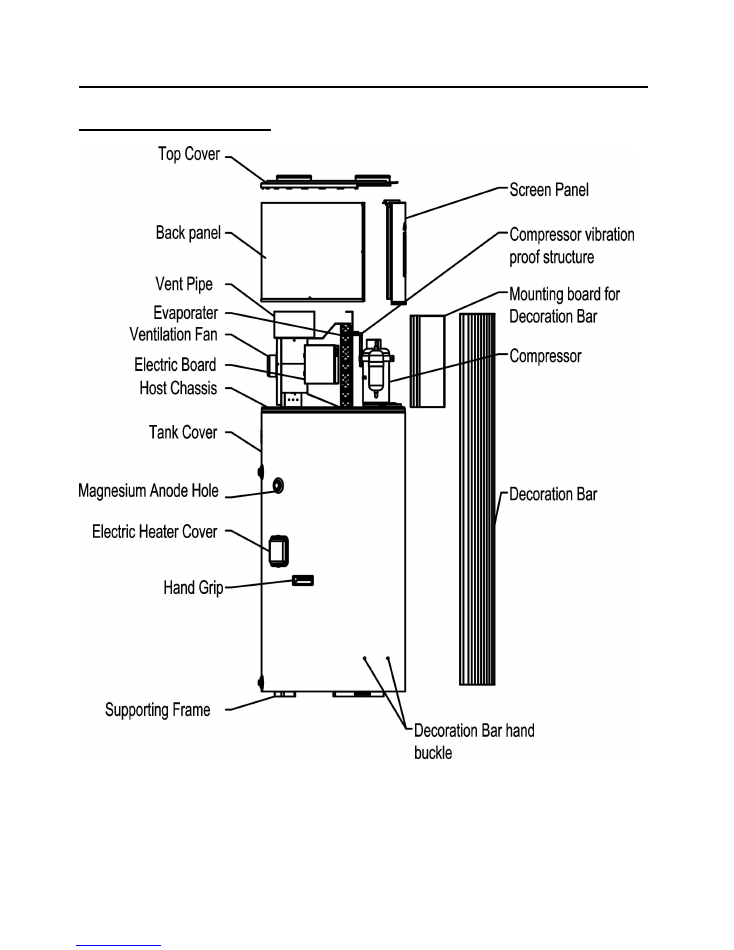

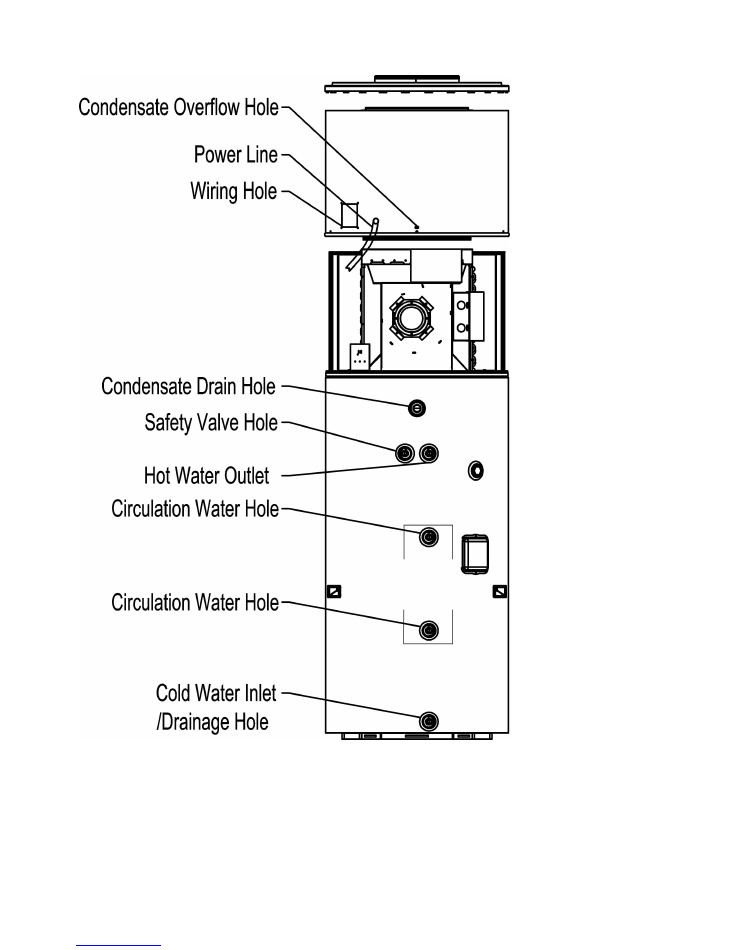

B. Description of heat pump

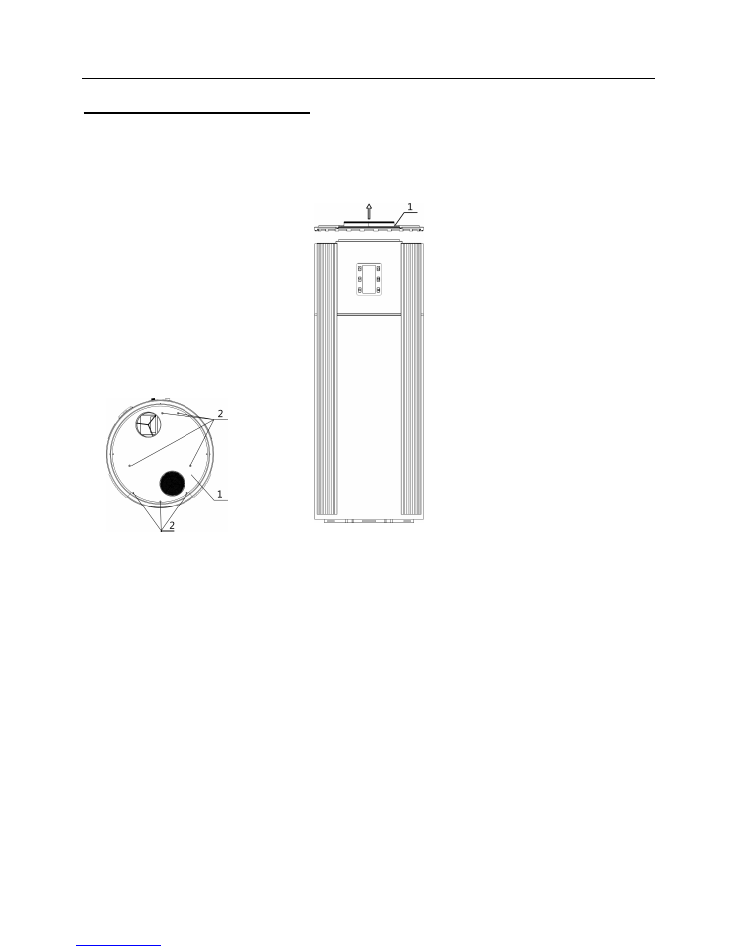

Unit constructions (outside):

3

Remark:

1. The above drawing is for reference to identify the name of each part. Details are subject to real unit.

2. The drawing of “Electric Heater hole” is only for the unit with Auxiliary heater models; other models

without auxiliary heater function are not available.

3. There are two “Circulation Water Hole” for optional connection. It can be available when the user

requests an external connection for hot water circulation. Normal models are without these holes.

4

C. Installation instruction

Note:

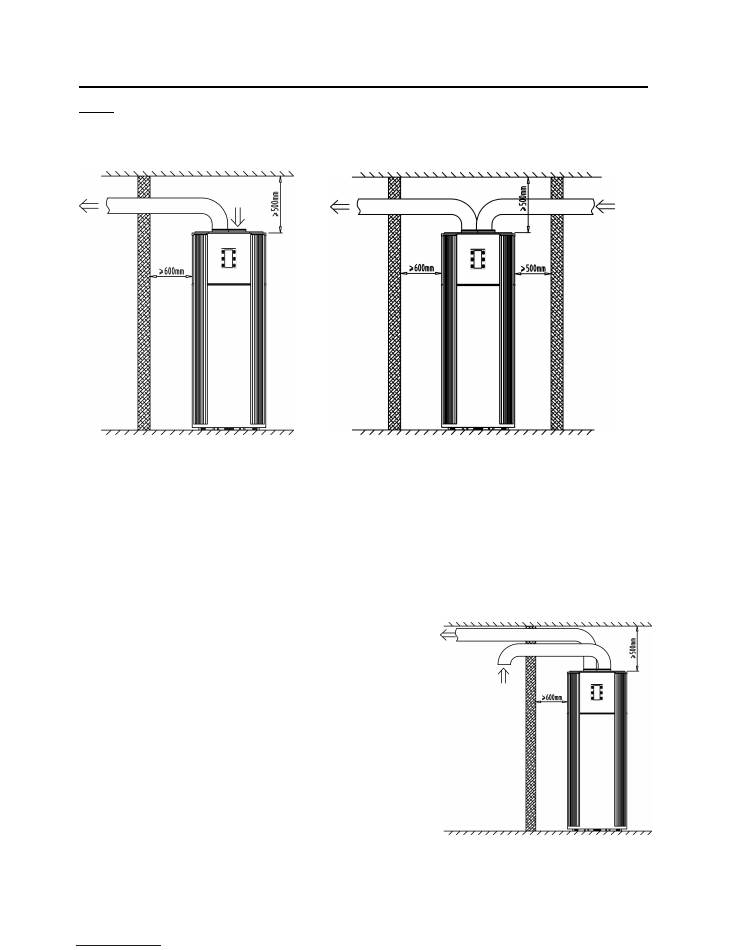

1. This heat pump unit can be installed at veranda, hallway or other place where is easy to install and

stable. The air inlet & outlet are at the top side, main unit should not be placed at an open air. Avoid the

rain or debris to enter the vents. The air inlet and outlet can connect the

φ

150mm air duct. As below,

(Fig.1)

(Fig.2)

2. When install as Fig.1, only connect the air inlet or outlet, the unit should be installed at a place of

ventilation, and the side connected with water pipes should has enough space. Then, if the unit is

installed besides the room, it can be connected the air outlet duct to the room for exchange fresh air

and cooling function; If the unit is installed in the room, it can be pulled out room’s air for ventilation

function.

3. If install as Fig. 2, the unit can be installed by the

middle of the wall, and connect the air inlet and

outlet pipe for air exchange. The distance of the unit and wall or other obstacle should not be too short.

Keep a certain distance.

4. If install as Fig. 3, the unit is installed outside the room, the air inlet and outlet is connected indoor for

air exchange (and cooling). In this way, the indoor air inlet and

outlet should have a distance

≥

2m to avoid mix air.

5. Because the air outlet comes with cooling air, the surface of

the pipe may have condensation water, it’s necessary to

insulate the indoor outlet pipe to prevent water leakage.

6. Heat pump water heater unit must be placed upright, and

installed on a solid place where can be able to withstand the

weight over 700kgs. Supporting surface should be evenness

(obliquity less than

2°)

7. When install the unit, there should has some measures of

sound insulation and shockproof in order not to affect

neighbors.

(Fig. 3)

5

C. Installation instruction

8. When unit operation, put the unit in a well-ventilated place and non-blocking the air vent, so that the

machine can be able to inhale and exhaust enough air, to achieve hot water supply function.

9. There should be with drain around the system unit for drainage. And the surrounding should have

enough space for maintenance. Because the top cover can be opened, at the top side of the unit

should have

≥

800mm space for maintain.

10. Nearby the system unit, there should be reserved a water supply pipe and hot water pipe interface

equipped with valves, the water inlet pipe should be with filter (for cleaning).

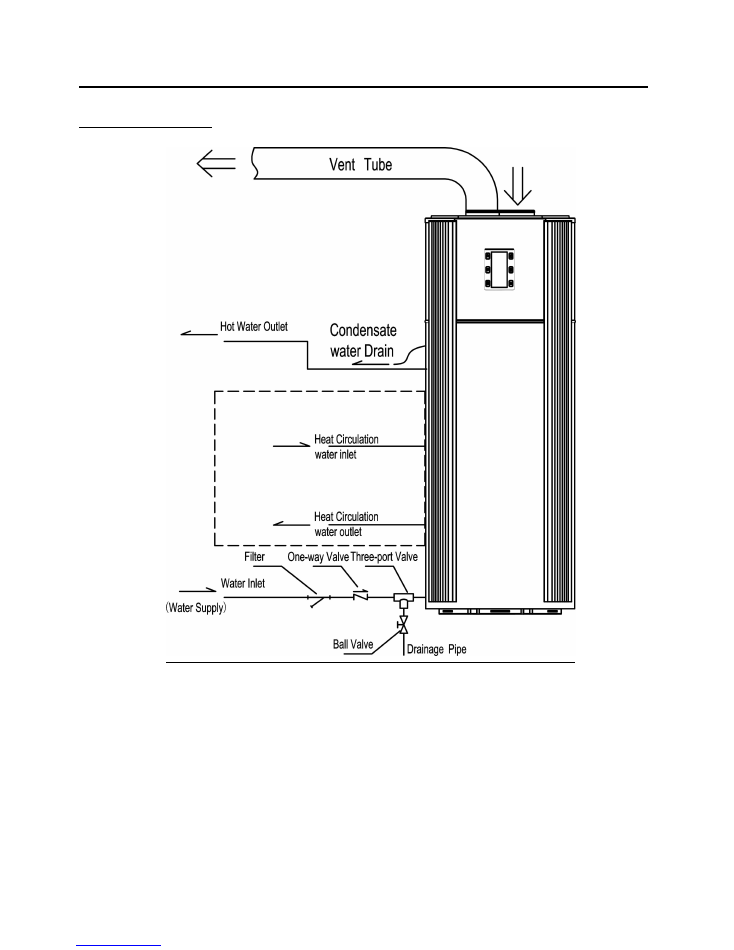

11. For waterway connection of this integrated unit, please refer to the following (Fig.4) “Waterway

installation diagram”. On the system unit, there should be installed Three-port valve, Safety valve and

Filter. Connect them to the water inlet and outlet of the unit.

12. If the Heat pump equip with

“Circulation Water Hole”

(optional), It can be connected with SOLAR

WATER HEATER, HEAT RECOVERY SYSTEM and other water heating equipment to heat the water

tank by circulation. Retain original if no need external connection.

13. The working pressure of this water heater tank must

≤

0.7MPa. Water inlet must connect the safety

valve, and its operation pressure is 0.7MPa, Connect another end of the safety valve to water supply

pipe. The safety valve should be connected by a small rubber pipe interlinked with atmosphere; this

pipe must not be blocked, in order to drain the water when the tank’s pressure exceeds 0.7MPa.

14. Water inlet pressure should >0. 1MPa, if the pressure is lower, can connect the pressure pump on

inlet pipe to get the high water flow.

15. Ensure the water tank is full fill with water before turn on the system: First, open the valve on the

water supply inlet, then switch on either valve of the water outlet, and then you can affuse water to the

tank until the water overflow the water outlet valve. After which you can turn off the water outlet valve

and check for leakage. Make sure there is no water leaking.

NOTE: For the first time use, ensure the water tank has been filled with water before turn on the

system.

16. In order to ensure the water tank filled with water, require a certain section of hot water outlet side

should be about 10cm higher than the water heater tank section.

17. The water heater temperature thermal sensor was put and sealed well in a tank by the factory before

launch to market. No need to install it when installation.

18. This water heater unit is filled with refrigerant by the factory, and no need to vacuumize or refill

refrigerant.

19. In the winter cold regions, the water heater unit can not turn off the power, if the system stops running

for a long period in winter, should be drain the tank water to avoid water pipe or tank frost crack.

Meanwhile, we should strengthen or check the external pipe to prevent the pipe frozen.

6

C. Installation instruction

Installation diagram:

(Fig.4)

Remark:

1. For the first time use, ensure the water tank have been filled with water before power on to prevent

burn out.

2. Follow with the water heater unit, there are some installation parts (see the annex detail list of parts).

As for other water system components, the user or installation company should provide by themselves.

3. Before installation, it’s better to reserve a water supply pipe interface, hot water outlet pipe interface

and drainage pipe interface. Among them, the water supply pipe and hot water outlet pipe should be

used in line with standards for drinking water pipes. (E.g. PPR pipe or stainless steel pipe, etc.), can

not use iron pipe or the rubber hose with odor for installation.

4. If the using place below 0

℃

, make sure to insulate the water pipes to prevent frozen.

5. Air inlet /outlet can connect the vent tube, but pipe should not be too long and less crankle.

7

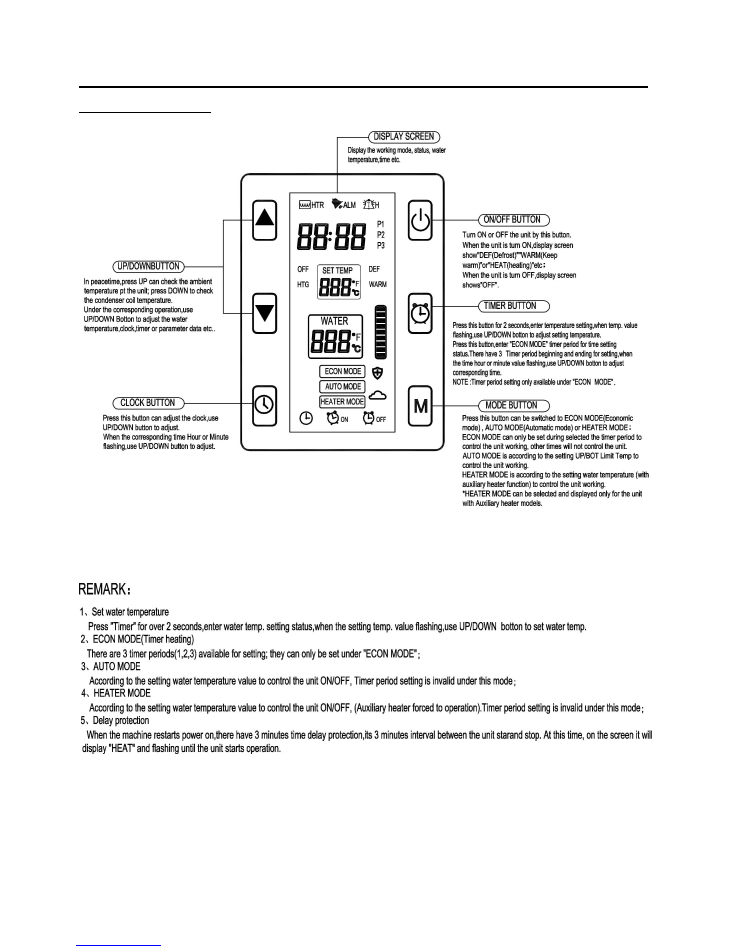

D. Operation panel instruction

1. Panel - Operation:

8

D. Operation panel instruction

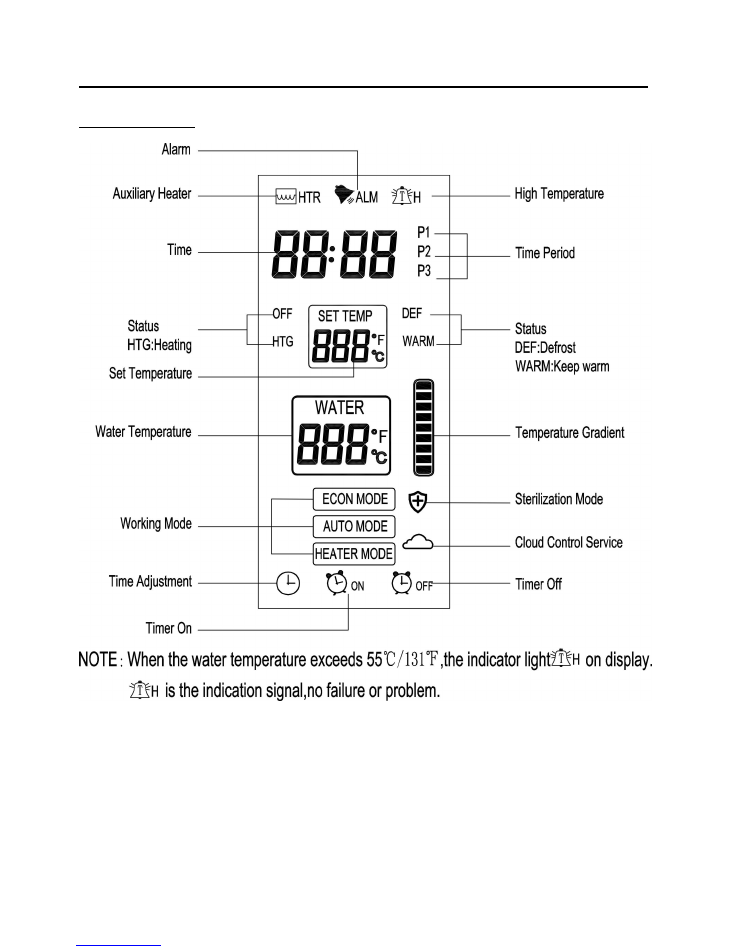

2. Panel - Display:

Cloud icon flashing during the connect with the internet,always lighting after connected with the

internet,no lighting means no cloud control function.

9

D. Operation panel instruction

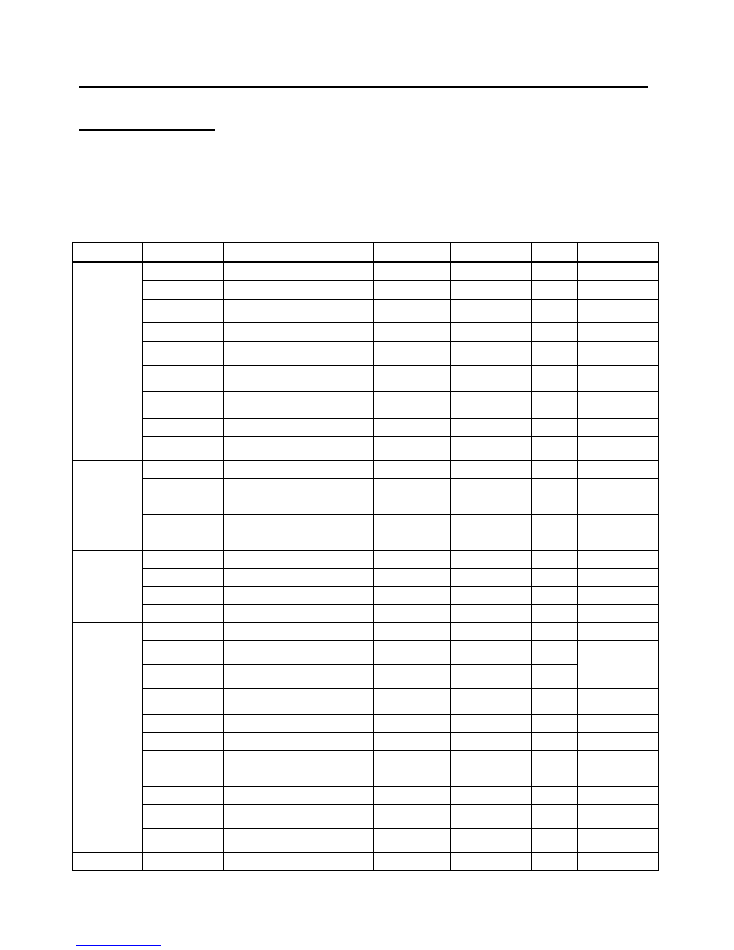

3. Parameter Setting:

Press “MODE” button for 5 seconds; enter the Parameter setting status, the main parameter code as

below sheet:

Type

Code

Parameter Name

Setting Range

Factory Setting

Unit

Remark

Temperature

Control

F11

Setting temperature

5-70

55

C

F12

Difference in Temp.

1 - 30

5

C

F13

Determine Heat pump stop

ambient temp.

-10 – 5

-7

C

F14

Highest temp. for heat pump

40 – 60

55

C

F15

Turn on or off electric

heater mode

0 - 1

1

-

F16

Ambient temp. for start electric

heating

-10 - 20

0

C

F17

Turn on or off electric heater

for sterilization function

0-1

1

F18

Sterilization cycle

1-990

336

hour

F19

Water thermal sensor

temp. amendment

-5 – 5

0

C

Compressor

F21

Compressor start delay

0 – 10

3

minute

F28

Econ mode turn on or off

electric heater

0 - 1

1

F29

Heat pumps working or not in

heater mode

0 - 1

1

Defrost

F31

Defrost start temp.

-20 – 20

-2

C

F32

Defrost finish temp.

0 – 50

25

C

F33

Defrost start time

1 – 999

30

minute

F34

Max. defrost time

Off, 1 – 99

5

minute

Alarm

F50

Low pressure alarm mode

0 - 2

2

-

F51

Auto resume times of low

pressure alarm

0 – 10

3

time

F52

Reset time of external alarm

auto resume times

0 – 999

60

minute

F54

Electric heater overheat

protection

0 - 2

2

-

F55

Overheat resume time

0-10

3

-

F56

Alarm resume time

0-999

60

C

F57

Exhaust temp. protection

mode

0 – 2

1

-

F58

Exhaust protect temp.

50 – 125

110

C

F59

Exhaust temp. protection

Return difference

1 – 30

10

C

F60

Condensate drain hole

blocked alarm

0-2

1

Function

F61

Memory status when power off

Yes/No

Yes

-

10

Remark:

When enter Parameter setting status, press “up” or “down” to choose parameter code; after choose one, press “Timer”

button to show this code’s setting value, and press “up” or “down” can set the value; After finish setting, press “Timer”

button to confirm and return to Parameter code status.

Setting

F69

Communication baud

24/48

24

-

Electronic

expansion

valve(EEV)

F70

EEV opening query

0–480

--

F71

EEV control mode

0–2

0

F72

Manually set EEV opening

100–480

350

F73

Set EEV superheat degree

-15–15

5

F74

Set EEV discharge temp

85–110

92

F79

Return gas temp.

--

System

Setting

F80

Password

OFF

0001 -- 9999

4321

-

“OFF” means no

password.

Set “0000” to

clear password.

F85

Display sterilization total time

-

-

hour

Testing

F98

Force defrosting (refrigeration)

Control panel

display “AdF”

Start compressor, 4-way

valve and fan motor. Press

any key to exit or 20 minutes

it will exit automatic.

11

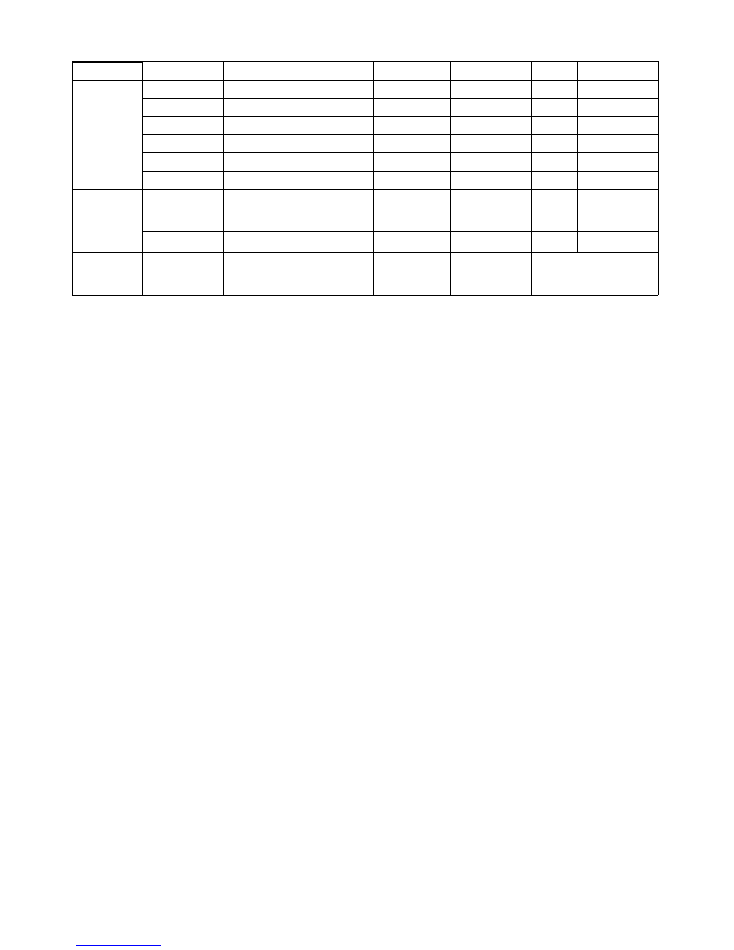

4. Error Handling:

ERROR

CODE

ERROR STATUS

REASONS

ERROR HANDLING

A1

Thermal sensor

alarm

Water temp. sensor open

circuit or short circuit.

1. Check the water temp. sensor

connection.

2. Change the water temp. sensor.

A2

Condenser coil

sensor alarm

Condenser coil temp.sensor

open circuit or short circuit.

1. Check the condenser coil temp.

sensor connection.

2. Change the coil sensor.

A3

Exhaust sensor

alarm

Exhaust temp. sensor open

circuit or short circuit.

1. Check the exhaust temp. sensor

connection.

2. Change the exhaust temp. sensor.

A4

Ambient temp.

sensor alarm

Ambient temp. sensor open

circuit or short circuit.

1. Check the Ambient temp. sensor

connection.

2. Change the ambient temp. sensor.

A5

Low /High pressure

alarm

1.1. High pressure protection

switch off.

1.2. Ambient temp. too high or

water heat exchanger dirty

block.

2.1. Low pressure protection

switch off.

2.2. Leakage of refrigerant.

1.1Check

or

change

the

high

pressure protector.

1.2. Check if the surround temp. is

too high, or clean the heat

exchanger of water tank.

2.1. Check or change the low

pressure protector.

2.2. Supply refrigerant and check if

there is any leakage.

A6

(Auxiliary) electric

heater protection

overheat alarm

1. Electric heater protection

switch off.

2. Tank water temp. too high.

1. Check if the water temp. is as LCD

display, or if water temp. is too

high.

2. Change the Electric heater.

A7

Exhaust temperature

too high

1. Lack of refrigerant.

2. Mix with air in system.

3. Lack of lubricating oil.

1. Supply refrigerant.

2.

Re-vacuumizing,

and

fill

in

refrigerant.

3. Change the lubricating oil of

compressor.

A8

Condensate drain

hole blocked

1.condensate pipe blocked

;

2.Machine drain hole blocked

;

1.Check condensate pipe is blocked

or not.

2.Check machine drain hole is

blocked or not.

A9

Return gas temp.

sensor alarm

Return gas temp. sensor open

circuit or short circuit.

1.Check the Return gas temp.

sensor connection.

2. Change the ambient temp. sensor.

- -

Screen no display or

display insufficiency

1. No plug in power.

2. Mainboard and operation

panel communication break

off.

1. Check the power line and voltage.

2. Reconnect the line of

mainboard and operation panel.

3.

Change

the

mainboard

or

operation panel.

NOTE:

1. When the unit has error, the buzzer of the operation panel will make an alarm sound, and there will

show “Alarm” on the screen panel.

2. “ERROR CODE” will show on temperature display location by alternately.

3. Part of the error alarm can be automatically restored (resumed). That is the appeared alarm can be

eliminated by electronically controlled self-test.

4. Some of the error alarm is caused by large fluctuation of the external power, by this, just power off and

restart the unit to clear the error.

5. When the machine has error alarm and restart still can not eliminated error, please contact the after

service as soon as possible for solution.

12

E. Maintenance and service

Examination before trial run

1. Check the water tank is filled with water, and open the water outlet tap till water flow out.

2. Check the water pressure is normal (0.15Mpa~0.7Mpa).

3. Check the air inlet or outlet is well connected; and the air outlet pipe heat insulation is completed.

4. Check the power supply voltage is normal, whether according with the nameplate requirement.

(Range ± 10%).

5. Check whether the equipped parts are screwed /locked well.

6. Check whether the wirings are according with the Circuit diagram, and the earth-wire is

connected.

7. Check whether the wind inlet and outlet has been cleaned up and no obstacle.

8. Check whether the condensate drain pipe is connected well and no blockage.

9. After power-ON, check the control panel display is normal.

Trial running

1. After the machine starts, to hear and determine whether there is abnormal sound or collision

during operation, if there is abnormal sound, stop the unit immediately and check for it until there

is no abnormal sound to continue operation.

2. For the first time power on, the compressor will have 3 minutes delay protection function.

3. Observe whether the drainage of condensate water is smooth, prevent the chassis stagnant or

spill water.

4. For the first time discharge hot water or start the units after a long time closure, the water tap of

outlet pipe may flow muddy water, this is a normal phenomenon, and continue to drain for a period

of time can be cleared.

5. After stop operation for a long time, there may have condensation water hereabout the air outlet or

pipe (especial in humidity weather), this is a normal phenomenon, use a dry washcloth to clean it

or by air dry.

6. The advance setting parameters of the operation panel has been set at the factory, users no need

to reset it, the maintenance person should be carefully set if needed.

Maintenance and service

1. After carry and move the unit by the first time installation, and connects the water pipes and filled

the tank with water. The machine should be rest for 1-2 hours before start trial running.

2. The water heater inlet filter needs to be cleaned once per 3 months. At the same time, per half

year we suggest draining all the storage water and repeatedly wash for 2-3 times to remove the

dirt and sediment.

3. To keep the unit in good heating performance, suggest cleaning the Air inlet /outlet filter net per

month, or using high pressure air tube to clean the Heat exchanger. Be careful not to damage the

copper tube.

4. Clean the Electric Heater per 6 months. (When clean the Electric Heater or Heat Exchanger must

cut off power supply.)

5. Change the Anode (Magnesium rod) per 6 months for better anticorrosion and antiscale.

According to different water quality, change the Anode rod when it’s expended.

6. When clean the Tank, Electric Heater, Heat Exchanger or Anode rod must cut off power supply.

7. If the supply cord is damaged, it must be replaced by the manufacturer or its service agent or a

similarly qualified person.

8. Special statement: for what does not in accordance with the requirements of above maintenance

and service work lead to the failure problem, does not apply to our warranty scope.

13

E. Maintenance and service

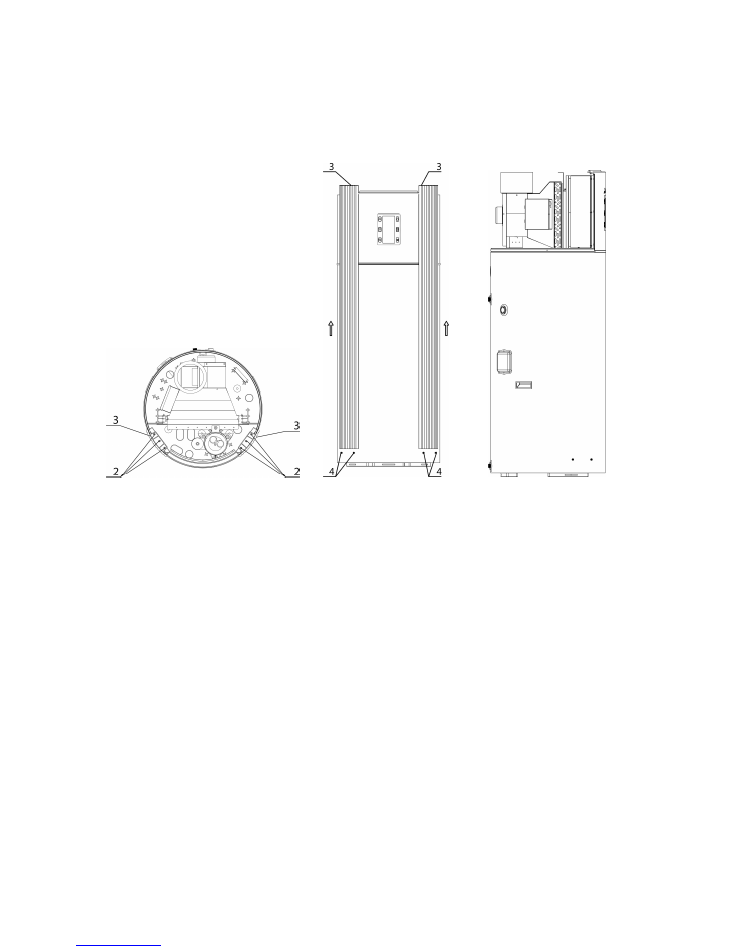

Heat Pump main unit disassembly

If want to check and maintain the top main parts of the unit,should disassembly the decoration

panel,back panel and top cover of the unit,follow the below steps(Fig.5,6)to process.

(Fig.5)

(Fig.6)

Top cover disassemble

Remove all the item-2 screws of the top cover-1,push up the top cover vertically by 15 to

20mm.Separate the top cover with the host,then you can have a preliminary review of the main

system and do maintenance.(View Fig.5,Fig.6)

14

(Fig.7)

(Fig.8)

(Fig.9)

Disassembly outside cover

1) When power off and disassemble the top cover,remove the decoration panel-3 by remove the

screws-2.Push up the decoration panel-3vertically by 150-200mm until it separate from the hang

buckle-4.(View Fig.7,Fig.8)

2) Loose the power wire from the terminal block,to avoid the wire get stuck when move up the top

shell.

3) Remove all the screws(item-2) from the Back panel(item-5),two sides decoration bar(item-6)and

tank shell(item-7).(View Fig.9)

4) At last,lift up the back panel(item-5)slightly can finish the disassembly.(View Fig.9)

5) After maintenance,make sure the air outlet of shell should be aimed at the fan outlet pearl cotton

when reinstall the shell.

15

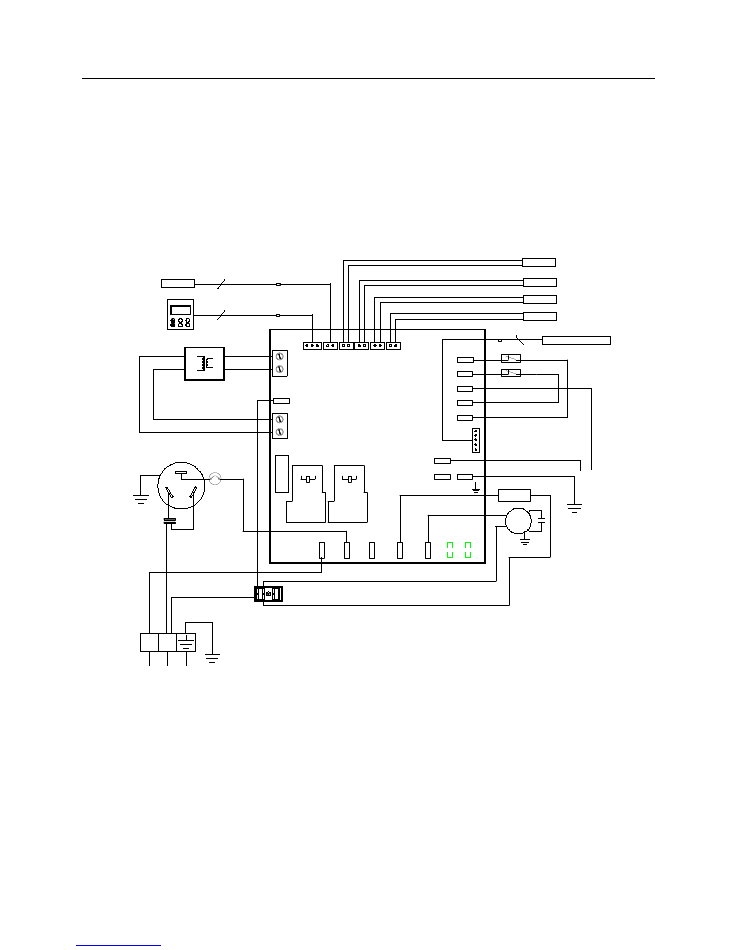

F. Unit circuit diagram

The following is a unit circuit diagram (for user’s reference); the unit practical connection should be as the

circuit /wiring diagram on the machine.

1). Heat pump

without

auxiliary electric heater:

2

1

Comp

Fan

Valve

Elect

R

S

C

开/关

时钟

定时

模式

BLACK/

12V

RED/

220V

5

COMPRESSOR

LOW

HI

B

X

S

N

LOW-PRESURE PROTECTOR

HI-PRESURE PROTECTOR

RETURN GAS TEMP. SENSOR

EXHAUST TEMP.SENSOR

COIL TEMP.SENSOR

AMBIENT TEMP.SENSOR

Electronic expansion valve

YELLOW/GREEN

FAN MOTOR

4-WAY VALVE

OPERATION PANEL

WATER TEMP.SENSOR

Transformer

YELLOW/GREEN

POWER SUPPLY

L

2

3

N

L

16

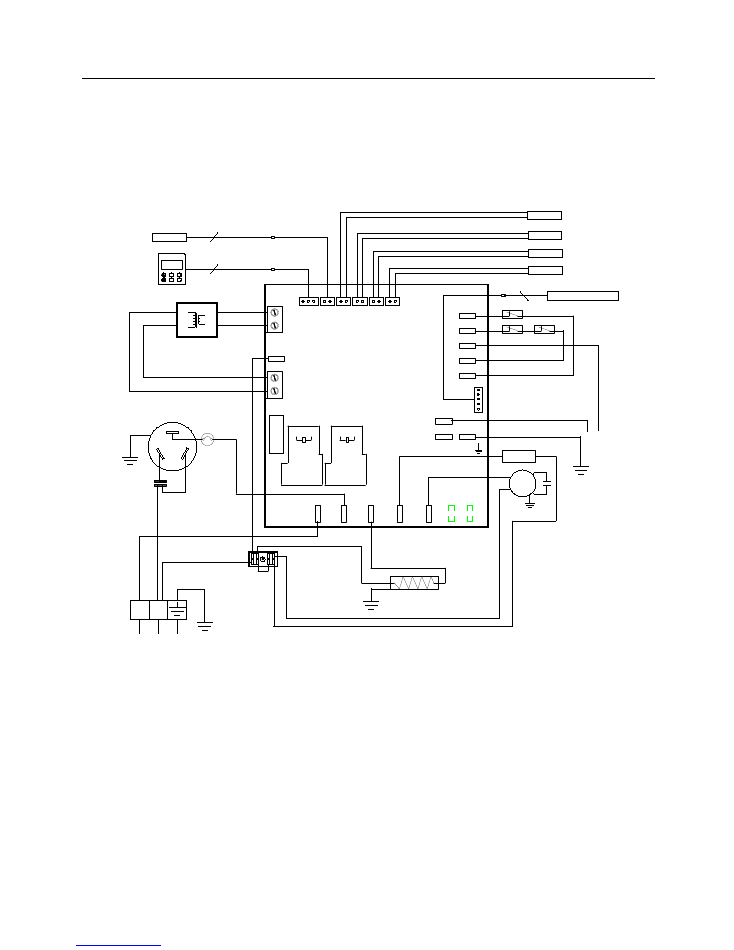

F. Unit circuit diagram

2). Heat pump WITH auxiliary electric heater:

BLACK/

12V

模式

定时

时钟

开/关

C

S

R

Elect Valve Fan

Comp

1

2

L N

3

2

L

POWER SUPPLY

YELLOW/GREEN

Transformer

WATER TEMP.SENSOR

OPERATION PANEL

ELECTRIC.HEATER

YELLOW/GREEN

4-WAY VALVE

FAN MOTOR

YELLOW/GREEN

ELECTRIC HEATER PROTECTOR

PRESURE PROTECTOR

Electronic expansion valve

AMBIENT TEMP.SENSOR

COIL TEMP.SENSOR

EXHAUST TEMP.SENSOR

RETURN GAS TEMP. SENSOR

N

B

X

S

HI

LOW

COMPRESSOR

5

RED/

220V

17

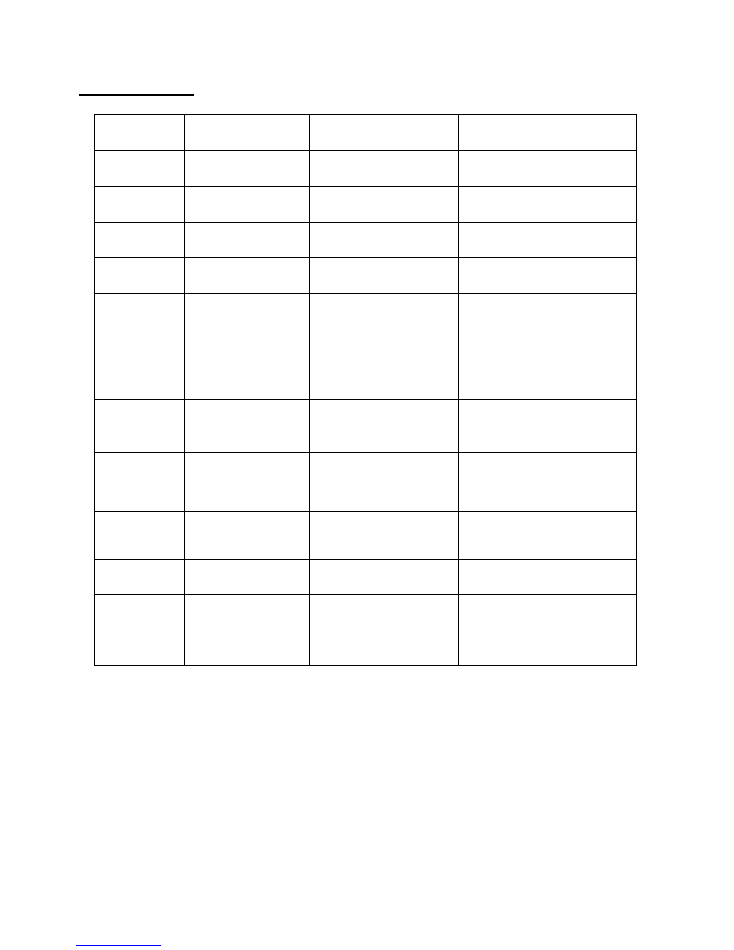

G. Annex list

ITEM

NAME

SPECIFICATION

QUANTITY

REMARK

1

Safety valve

1

2

Manual

1