Full Text Searchable PDF User Manual

Distributed by:

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

JOF ONE

JOF 23

JOF 23-A (110V.)

OWNER’S MANUAL

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

2

Index

2) GENERAL SAFETY ........................................................................................................................5

2i: GENERAL SAFETY STANDARDS........................................................................................................

5

2ii:LOCATION REQUIREMENTS..............................................................................................................

5

3)

INSTALLATION…………………………………………………………………………………..5

3ii: MATERIALS AND CHILLING SOLUTIONS………………………………………………………..

6

3iii: ELEMENTARY SAFETY STANDARDS……………………………………………………………..

6

3iv: INSTALLATION INSTRUCTIONS……………………………………………………………..……

6

3v: CONNECTING TO THE POWER SUPPLY……………………………………………………….….

6

4) ADVICE FOR PROPER USE OF THE EQUIPMENT…………………………………………7

5) GENERAL OPERATION…………………………………………………………………………7

5v: CONSERVATION……………………………………………………………………….…………….

7

6) KEYPAD IDENTIFICATION.........................................................................................................9

7) USER FUNCTIONS........................................................................................................................10

8) FUNCTIONS OF THE BLAST CHILLER/BLAST FREEZER................................................13

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

3

10) COMPRESSOR WORKING HOUR CALCULATION

...........................................................

11i: REAL DAY AND HOUR SETTING

................................................................................................

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

4

1) INTRODUCTION

Thank you for choosing TECHFROST products. We are certain that you will be more than satisfied with their

performance. To help maintain efficiency and performance please follow the guidelines set forth in this manual

describing the correct use and maintenance of the Blast Chiller Freezer.

1i: TYPE OF USE AND LIMITATIONS

This Blast Chiller Freezer has been designed for chilling and preserving food. It rapidly lowers the temperature

of cooked food and specialty frozen desserts, preserving quality and assuring ultimate product freshness. Any

other use is considered improper and incorrect. This Chiller must not be installed outside and or in

environments subject to weather conditions. The manufacturer declines all responsibility for uses other than

those given in this manual.

1ii: CHARACTERISTICS OF THE MACHINE

The machine, to which this handbook refers, is a blast chiller/freezer which is completely constructed of

stainless steel AISI 304. It will continue working until reaching

-40 °F

. This machine is capable of quickly

tempering the heart of the cooked products from +158ºF to +37.4ºF during blast chilling and from +158ºF to -

0.40ºF during blast freezing. This thermal shock, keeps bacteria from spreading without altering the

organoleptic conditions or modifying the product’s quality. Through the use of this process, hygiene, security,

and product quality is maintained.

Features of the blast chiller include:

Indirect system of air circulation

Constant temperature from shelf to shelf

Advanced cooling system for a quick, cold penetration to the product’s core

Maintenance of a high humidity rate in the chilled product (80%-85%) thus avoiding drying or

dehydration, eliminating the risk of weight loss

Excellent thermic conditions during transfer to the conservation cell

A product is at peak quality at the point that it is taken from the oven, batch freezer or other production process.

The high temperatures reached by the oven act to destroy microorganisms without altering the product’s quality.

The molecular structure of a frozen dessert is at its best when first extracted from the production machine. You

can keep this high quality level unchanged by starting the chilling process immediately after production. The

blast chiller acts to lower the temperature rapidly, preventing external drying and early deterioration of your

product. These low temperatures also block bacterial proliferation.

The blast chiller is a professional instrument that closely follows regulations regarding the thermal treatment of

gastronomy, pastry, and ice cream products, before and after cooking. It facilitates application of the

HACCP

System

(Hazard Analysis Critical Control Point) and compliance with ISO9000 norms.

The passage to conservation at the pre-defined temperature follows the chilling or deep freezing cycle

automatically.

AIR STERILIZATION (accessory by request) is obtained by, the production of agglomerates of active oxygen

atoms. These atoms destroy bacteria, viruses, mildew spores, odor molecules, etc.

1iii: TESTING

Every Techfrost Chiller is thoroughly tested before shipping. Testing includes a visual inspection, an electric

test, and a functional test. Final testing is certified for the relevant documentation (please refer to the enclosed

appendixes).

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

5

2)

GENERAL SAFETY

2i: GENERAL SAFETY STANDARDS

The Chiller in question is manufactured conforming with the European Directives relevant to low tension

73/23-

93/68/EEC,

and electromagnetic compatibility 89

/336/EEC;

EN60335- 1, EN60335-2-24, EN55014, EN61000-

3-2, EN61000-3-3, EN55104.

2ii: LOCATION REQUIREMENTS

It is necessary that electrical supply to the freezer be provided as specified on the data plate of your Techfrost

freezer. Each freezer comes with electrical cord and power connector as required.

The chiller and its control board should only be operated by adults.

Installation and any other operation (including a possible extension of the power cable) must be carried

out by

authorized personnel

only.

Maintenance and service have to be carried out by qualified technicians. Only factory replacement

parts should be used for repairs.

Do not attempt to modify the chiller yourself; the operation could be dangerous.

In order to avoid the risk of over-heating of the compressor and consequent damage, it is crucial to

allow sufficient air circulation around the machine.

The chiller should be placed so that there remains sufficient space for air circulation in the back (at

least 10 cm or approximately 4in.).

While installing or transporting the unit, take care in ensuring that the cord is not crimped or kinked.

Before any cleaning or installing operation, remember to switch the machine off and disconnect the

plug. Make sure you do not pull the cord.

The deep-freezing system, placed on the back and inside the machine, contains a refrigerant solution.

Do not use sharp objects in the vicinity of the evaporator, cooling plate, or near the pipe coils (located

on the back and inside the chiller). The accidental perforation of the system could cause damage to the

unit.

Wait for at least 30 minutes before connecting the plug to the power point after sitting freezer in place.

If the chiller has been transported in the horizontal position, be sure to keep it vertical for at least four

hours. This allows the oil contained in the compressor to be transferred back to its original location.

WARNING! Do not keep explosive gases and liquids or glass bottles in the machine. Doing so may

result in damages to persons or things.

When the

“DEEP-FREEZING”

process has concluded, dry gloves or cloths should be used to remove

containers from the machine.

Do not open the machine door while executing its working cycle. Doing so may prevent cycle

completion.

The constructor is not liable for damages arising from improper use or installation, connection to non-

authorized equipment, use of non-original fittings, or tampering by non-authorized personnel.

CAUTION: The Blast Chiller/Blast Freezer must be connected to an electrical supply source that matches

the data plate on the machine. Make sure it is level and always use qualified personnel to install, repair

and service your Chiller.

3)

INSTALLATION

3i: INTRODUCTION

This manual aims to provide the user with all the necessary information to correctly use and maintain the chiller.

Before use, carefully read all the instructions given in this manual. The manufacturer shall decline all

responsibility for operations and use which disregard the instructions herein.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

6

3ii: MATERIALS AND CHILLING SOLUTIONS

The areas in contact with the product are made of stainless steel. The chilled coolant, found in this machine, is

used as permitted by current legislation and the HFC. The type and quality of gas used, are indicated on the data

plate.

3iii: ELEMENTARY SAFETY STANDARDS – RISKS

The chiller has no dangerous corners, sharp/cutting surfaces, or protruding parts. All safety guards on moving

parts or electrical components are properly attached to the cabinet. To prevent accidental contact with parts that

present risk to the user, always respect safety standards:

Do not touch the chiller with wet hands or feet

Do not use the chiller without proper footwear

Do not place any object between the safety guards mounted on the moving parts

Before cleaning or servicing the chiller, disconnect from the power supply

3iv: INSTALLATION INSTRUCTIONS

Carefully follow and adhere to the instructions given in this manual to guarantee working efficiency and safety

when the Chiller is in use.

CAUTION: When transporting or moving the Chiller to the installation site do not push or drag it. Lift it

and position it on a trolley to avoid overturning.

LOCATION

Locate the Chiller in a ventilated area distant from heat sources such as, radiators, air conditioning

units, deep-fryers, and ovens.

Make sure the Chiller is located at a distance not less than 4in. from the back wall and 4in. and 4in.

from the right side, to permit a good cooling effect for the various components.

To maintain the correct internal temperature, the ambient temperature must not exceed 85°F

Adjust height and level using the support feet.

o

If the Chiller is not perfectly level, working efficiency and condensation flow may be

affected.

Make certain that the door closes properly

Remove the PVC protective film.

Condensation Pan

Insert the condensation collector from the front part of the machine. Slide the collector along the runners

(located on the bottom of the machine) while pushing toward the rear.

Level positioning

The machine should be placed on flat and firm ground and all four feet are steadily in place. You can adjust the

feet yourself: make sure that the chiller does not lean against other machines.

The machine should be placed in a way that allows adequate space for air circulation.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

7

3v: CONNECTING TO THE POWER SUPPLY

Always connect blast chiller/freezer to an electrical supply that matches data plate. Connect the unit only to

energy sources that are properly grounded. Do not damage the power cord (danger of electric shock). If it is

damaged, it must be replaced immediately by a qualified electrician.

CAUTION: the manufacturer shall not be held responsible for damage or accidents caused by negligence

due to the non-observance of the recommendations and regulations given or of the local governing

standards and laws regarding electrical safety.

4) ADVICE FOR PROPER USE OF THE EQUIPMENT

Before using the Chiller remove all traces of glue using a detergent as there might be traces of condensate due to

final testing in the factory.

5)

GENERAL OPERATION

Efficiency when chilling and freezing depends on the following factors:

5i: PRE-COOLING

Simply turn the machine “ON” to the desired mode to precool the internal parts prior to use.

5ii: CORE PROBE (Optional)

The core probe shall be properly positioned in the core of the thicker portion of the product. Its point shall

neither come out nor touch the pan. The probe shall be cleaned before starting any cycle, in order to prevent

contaminations. *PLEASE NOTE, YOUR PARTICULAR MACHINE MAY/MAY NOT HAVE A CORE

PROBE*

5iii: LIDS AND CONTAINERS

Do not cover pans or other containers with lids or insulating films. The more the surface of the product is

exposed to the air circulating in the cell, the less it will take to chill and deep freeze it.

5iv: POSITIONING OF THE PRODUCT

Do not layer the products on top of one another

Make sure they are not thicker than 1.97in. thick.

Do not overload the unit beyond the quantity recommended by the manufacturer.

Allow a sufficient space between the pans in order to permit the proper air circulation

Do not put too many pans on one side of the unit. Distribute them evenly.

5v: CONSERVATION

The chilled and/or frozen product shall be covered and protected (film, airtight, hermetic sealing) after chilling

or freezing.

5vi:STANDARD USE INSTRUCTIONS

Functions of the blast chiller/Freezer:

Preliminary Instructions-

As soon as the machine is connected, it is in OFF position. Press and hold the ON/OFF Key to turn the machine

ON.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

8

You can select from the following functions:

-

BLAST CHILLING

*

-

BLAST CHILLING HARD

*

-

BLAST FREEZING HARD

***

Every function cycle can be preceded by pre-cooling; please check the paragraph 4.6 “Pre-cooling”. It

is used to cool down the internal room of the blast chiller to +5°C before placing product in the

machine. To activate the pre-cooling cycle, press and hold the

*

BLAST CHILLING key for 1 second.

Each selected program will pass automatically into the

CONSERVATION

phase

at the end of the

cycle. The conservation phase will reach +2°C when BLAST CHILLING and -20°C when BLAST

FREEZING.

The machine’s memory will store all the time and temperature parameters modified from default, even

if the machine has been unplugged.

Pressing the

*

BLAST CHILLING or

***

BLAST FREEZEING key during a normal cycle will

display the time remaining until cycle completion

BLAST CHILLING (0°C)

Make sure the device is "on"

Press the

*

BLAST CHILLING key. The LED will flash

You can modify the default temperature setting of 0°C by, pressing the key

▲ to

increase the temperature or

the key

▼

to decrease the temperature. (This option is active only

before

starting the program.)

Press the key ON/OFF to start the BLAST CHILLING

The BLAST CHILLING phase will last 90 minutes.

You can modify the

time

of the BLAST CHILLING phase by pressing the key

▲

to increase the time or the

key

▼

to decrease the time. (This option is active only

after

having started the program)

Once completing the 90 minute cycle, the device will pass into conservation (setpoint 2°C)

BLAST CHILLING HARD (-20°C)

Please make sure the device is "on."

Press the key

*

BLAST CHILLING: the LED will flash

Press the key HARD/SOFT: the LED HARD will flash

Press the key ON/OFF to start the BLAST CHILLING hard cycle

The phase of BLAST CHILLING phase will last 90 minutes.

I can modify the

time

of the BLAST CHILLING phase by, pressing the key

▲

to increase the time or the key

▼

to decrease the time. (This option is active only

after

having started the program)

Once 90 minute cycle has concluded, the device will pass into conservation (setpoint 2°C)

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

9

BLAST FREEZING (-40°C)

Make sure the device is "on."

Press the key

***

BLAST FREEZING: the LED

and the LED HARD will flash.

You can modify the default temperature setting of -40°C by, pressing the key

▲ to

increase the temperature or

the key

▼

to decrease the temperature. (This option is active only

before

starting the program)

Press the key ON/OFF to start the BLAST FREEZING phase

The BLAST FREEZING phase will last 240 minutes.

You can modify the

time

of the BLAST CHILLING phase by, pressing the key

▲

to increase the time or the

key

▼

to decrease the time. (This option is active only

after

having started the program)

Once the completion of the 240 minute cycle, the device will pass into conservation (setpoint -20°C)

WARNING: The BLAST FREEZING HARD phase is set by default. If the HARD key is pressed before

starting the cycle , HARD is stopped and the SHOCK FREEZING will cease even if in the BLAST FREEZING

phase w/ temperature setting of 0°C.

GELATO PROGRAM

To use the shock freezer for Gelato it is recommended to select a BLAST FREEZEING cycle and choose a

maximum time of 500 minutes. This way, the machine will always work at its maximum despite the continuous

door opening during gelato production.

Manual defrosting start

Make sure that the cycle is over and that no procedure is on.

Press and hold the key

▲

for 4 s: the LED DEFROSTING will switch on.

The defrosting will last 20 minutes. Leave the door open during the defrost phase.

6)

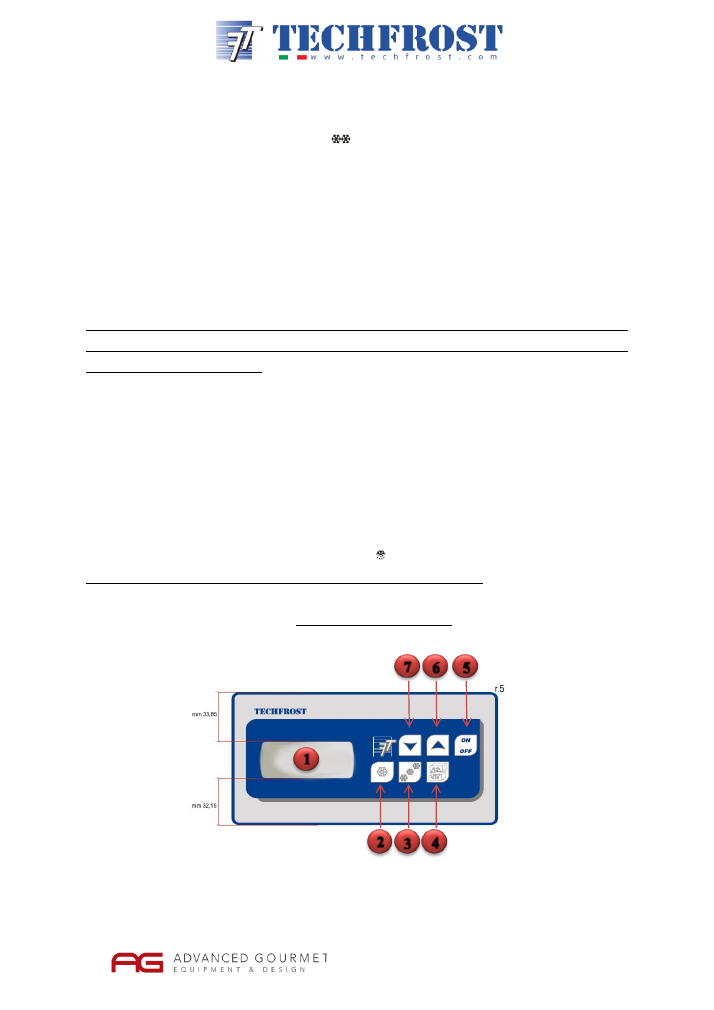

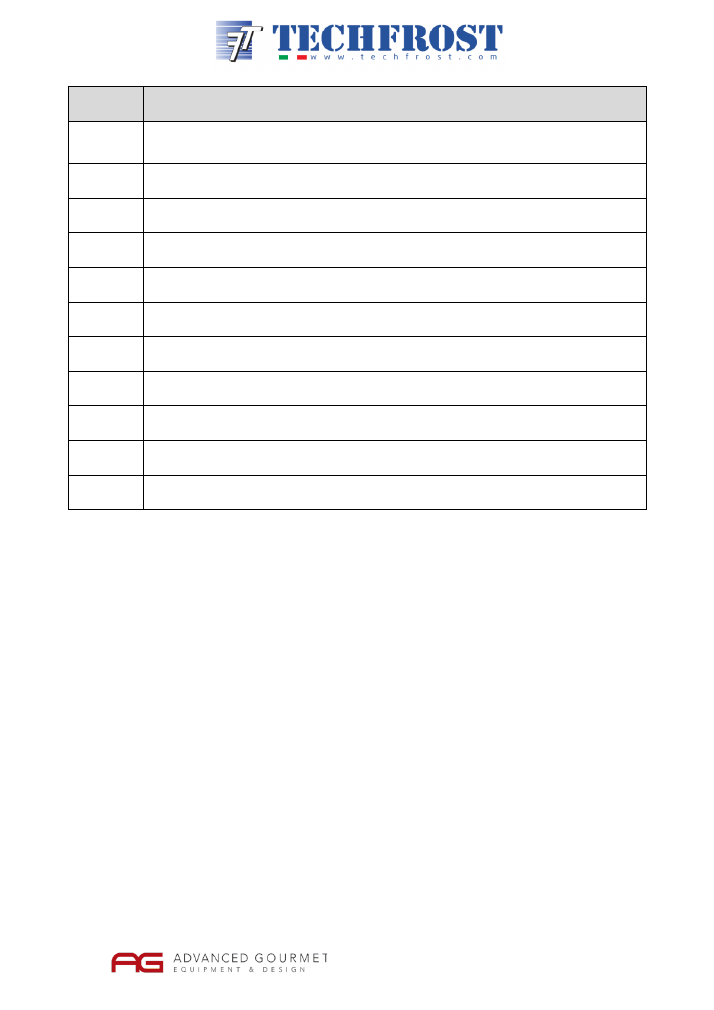

KEYPAD IDENTIFICATION

The drawing below is an illustration of the electronic panel

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

10

1 display

2 blast chilling key

3 blast freezing key

4 hard blast chilling or soft blast freezing key, then also named “HARD/SOFT key”

5 on/off/start/stop key, then also named “START/STOP key”

6 increase key, then also named “UP key”

7 decrease key, then also named “DOWN key”

For further information, please refer to the following chapters.

7) USER FUNCTIONS

a) Preliminary instructions

The following are the states of the machine:

the state "off" (the device is not fed).

the state "stand-by" (the device is fed and it is out).

the state "on" (the device is fed, you/he/she has turned on and it is waiting for the start of a cycle of

operation).

the state "run" (the device is fed, you/he/she has turned on and a cycle of operation is in progress).

the state “lighting of the device”, is the transition from the state “stand by” to the state “on”.

the state “turning of the device” is the transition from the state “on” to the state “stand by”.

If an interruption of the feeding occurs during the state "stand-by" or during the state "on", the restoration of the

feeding device will propose the same state.

If an interruption of the feeding occurs during the state "run", the restoration of the feeding device will work in

the following way:

if a temperature blast chilling cycle or a temperature blast freezing cycle was in progress, it will be

restarted from the beginning

if a time blast chilling cycle or a time blast freezing cycle was in progress, it will be restarted within 10

minutes of error occurrence

if a conservation cycle was in progress, the conservation cycle will start again.

b) Blast chiller switching on/off

If the blast chiller is turning on and shutting back off, please use the following steps:

1.

Please make sure that the keyboard is not jammed and that some procedure is not in progress.

2.

Please keep pressed the key START / STOP for 1 second: the LED will turn on and then back off.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

11

c) The display

During the state "off" and during the state "stand-by" the display is off.

During the state "on" the display shows the temperature of the cell.

During the state "run" the device will work in the following way:

if a time blast chilling cycle or a time blast freezing cycle is in progress, the display will visualize the

residual cycle time

if a maintenance is in progress, the display will visualize the temperature of the cell.

d) Cell temperature display

Please operate in the following way:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the key DOWN pressed for 1 second. The display will show the first available label.

3.

Press and release the UP or the DOWN key to select “PB1”

4.

Press and release the BLAST CHILLING key. The display will show the temperature of the cell

To leave the procedure, please operate in the following way:

5.

Press and release the BLAST CHILLING key or do not operate for 15 seconds. The display will again

read, “PB1”

6.

Press and release the UP key or the DOWN key until the display matches the state from paragraph 8iic or

do not operate for 60 seconds.

e) Evaporator temperature display

Please operate in the following way:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the DOWN key pressed for 1 second. The display will read out the first available label.

3.

Press and release the UP key of the DOWN key to select “PB3”

4.

Press and release the BLAST CHILLING key. The display will indicate the temperature of the

evaporator.

To leave the procedure, please operate in the following way:

5.

Press and release the BLAST CHILLING key or do not operate for 15seconds. The display will again

read “PB3”

6.

Press and release the UP key or the DOWN key until the display behaves as mentioned in paragraph 8iic

“the display”

f) Condenser temperature display

Please operate in the following way:

1.

Make sure the keyboard is not jammed and that a procedure is not in progress.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

12

2.

Keep the DOWN key pressed for 1 second. The display will show the first available label.

3.

Press and release the UP key or the DOWN key to select "Pb4."

4.

Press and release the BLAST CHILLING. The display will read the temperature of the condenser.

To leave the procedure, operate in the following way:

5.

Press and release the BLAST CHILLING key or do not operate for 15 seconds. The display will again

show "Pb4."

6. Press and to release the key UP or the key DOWN until the exhibits the suitable state from paragraph 8iic,

“the display

g) Manual defrosting starting

Please operate in the following way:

1.

Make sure that a maintenance cycle is in progress.

2. Make sure the keyboard is not jammed and that a procedure is not in progress.

3. Keep the UP key pressed for 4 seconds. The LED will switch on.

If the temperature of the evaporator upon starting the defrosting cycle, is not above that established with the

parameter d2, the cycle will not be activated. If the parameter P4 is set to 1, the defrosting cycle won’t begin.

h) Keyboard Block/unblock

To stop the keyboard, please operate in the following way:

1.

Please make sure a procedure is not in progress.

2.

Please keep the DOWN and the START / STOP key pressed for 1 second. The display will read "Loc"

for 1 second.

If the keyboard is jammed, the following operations won't be allowed:

Device switching on/off

Cell temperature display (per paragraph 8iid)

Evaporator temperature display

Condenser temperature display

Manual defrosting starting

Operation cycle start/stop

Lighting of the UV light for the cycle of sterilization

Alarms HACCP information display

Alarms HACCP information cancellation

Compressor working hours display

Compressor working hours cancellation

Formulation of the day and real time.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

13

To unlock the keyboard please operate in the following way:

1.

Make sure that a procedure is not in progress.

2.

Keep the DOWN key and the START / STOP key pressed for 1 second. The display will visualize "UnL"

for 1 second.

i)

Buzzer off

Please operate in the following way:

1.

Make sure that a procedure is not in progress.

2.

Press any key and release.

8) FUNCTIONS OF THE BLAST CHILLER/BLAST FREEZER

8i: PRELIMINARY INSTRUCTIONS

The following types of operation cycles can be managed:

Blast chilling and conservation

Hard blast chilling and conservation

Blast freezing and conservation

Hard blast freezing and conservation.

For further information please consult the following paragraphs.

Every cycle of operation can be preceded by a pre-cooling cycle. Please refer to paragraph 7i: "Pre-cooling."

8ii: BLAST CHILLING AND CONSERVATION

The temperature blast chilling and conservation cycle it is composed by the followings two phases:

blast chilling

conservation

When the first phase finishes the device automatically passes to the following one.

To start the cycle, please operate in the following manner:

1.

Make sure the device is “on”

2.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

3.

Press and release the BLAST CHILLING key: the LED will flash.

4.

4a. If the parameter r19 is set to 0, the display will show the work setting from the blast chilling cycle.

It is also possible to set this value through the parameter r7.

4b. If the parameter r19 is set to 1, the display will show the temperature taken at the end of the blast

chilling cycle. It is also possible to set this value through the parameter r3.

4c. Press and release the UP key or the DOWN key within 15 seconds to modify the value of the

parameter.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

14

8iii: HARD BLAST CHILLING AND CONSERVATION

The temperature hard blast chilling cycle and conservation are distinguished by the followings three phases:

hard blast chilling phase

blast chilling

conservation.

When the first phase ends the device automatically passes to the following one.

To start the cycle, please operate as follows:

1.

Make sure that the device is "on."

2.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

3.

Press and release the BLAST CHILLING key: the LED will flash.

4.

Press and release the HARD / SOFT key: the LED HARD will flash.

5.

5a. If the parameter r19 is set to 0, the display will show the work setting from the blast chilling cycle. It is

also possible to set this value through the parameter r7.

5b. If the parameter r19 is set to 1, the display will show the blast chilling end temperature. It is also

possible to set this value through the parameter r3.

5c. Please press and release the UP key or the DOWN key within 15 s to modify the value of the

parameter.

8iv: BLAST FREEZING AND CONSERVATION

The temperature blast freezing cycle and conservation cycle are distinguished by the followings two phases:

blast freezing

conservation

When the first phase ends, the device automatically passes to the following one.

To start the cycle, please operate as follows:

1.

Make sure that the device is "on."

2.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

3.

Press and release the BLAST FREEZING key: the LED

, the LED

and the LED HARD will

flash.

4

4a.

If the parameter r19 is set to 0, the display will show the work setting from the blast freezing cycle. It is

also possible to set this value through the parameter r8.

4b.

If the parameter r19 is set to 1, the display will show the end blast freezing temperature. It is also

possible to set this value through the parameter r4.

4c.

Press and release the UP key or the DOWN key within 15 seconds to modify the value of the

parameter.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

15

8v: SOFT BLAST FREEZING AND CONSERVATION

The temperature soft blast freezing cycle and conservation cycle are distinguished by the followings three

phases:

soft blast freezing

blast freezing

conservation.

When the first phase ends the device automatically passes to the following one.

To start the cycle:

1.

Make sure that the device is "on."

2.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

3.

Press and release the BLAST FREEZING key: the LED

, the LED

and the LED HARD will

flash.

4.

Press and release the HARD / SOFT key: the LED HARD will turn off.

5.1

If the parameter r19 is set to 0, the display will show the work setting from the blast freezing cycle; it is

also possible to plan this value through the parameter r8.

5.2

If the parameter r19 is set to 1, the display will show the end blast freezing temperature. It is possible to

set this value through the parameter r4.

5.3

Press and release the UP key or the DOWN key within 15 seconds to modify the value of the

parameter.

8vi: PRE-COOLING START

Every cycle of operation can be preceded by a pre-cooling phase.

To start the pre-cooling phase please operate in the suitable way:

1.

Make sure that the device is "on."

2.

Make sure that a procedure is not in progress.

3.

Keep the BLAST CHILLING key pressed for 1 second: the LED will flash.

To stop the pre-cooling phase:

4.

Keep the BLAST CHILLING key pressed for 1 second or start a cycle of operation.

The parameter r12 establishes the work setting from the pre-cooling phase.

When the cell temperature reaches the one established with the parameter r12 the pre-cooling phase continues,

the LED remains permanently turned on and the buzzer is activated for 1 second.

9) “HACCP” FUNCTION

9i: PRELIMINARY INSTRUCTIONS

Through the function "HACCP" it is possible to memorize up to 9 events for each of the 3 alarms HACCP, then

the most recent event is written on the older one.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

16

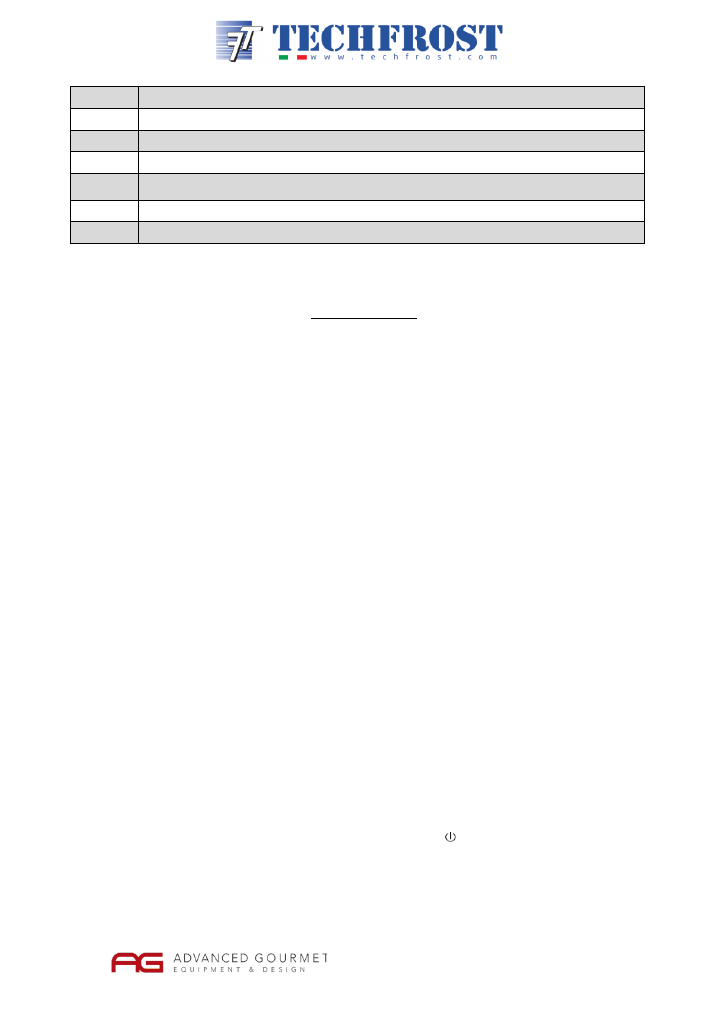

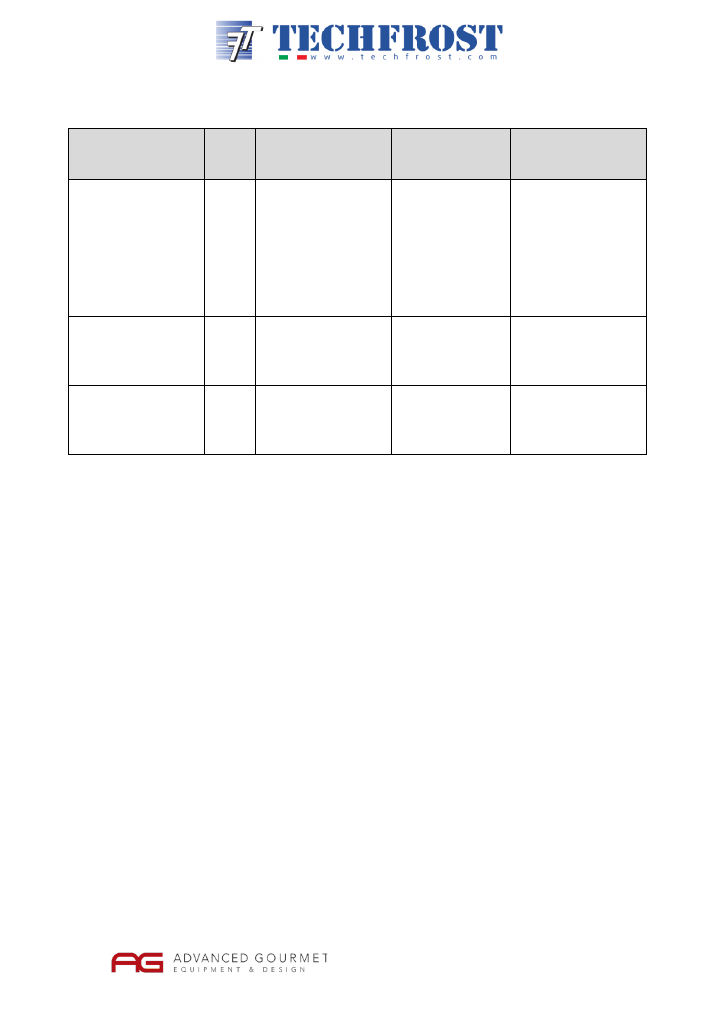

The following chart illustrates the information (related to the alarms HACCP) that the device is able to

memorize.

Alarm

Code

Critical Value

Date and hour of

event

Duration

alarm temperature blast

chilling or temperature

blast freezing not

concluded within the

maximum duration

Time

the temperature blast

freezing not concluded

within the maximum

duration

yes

from 1 min to 99 h and

59 min, partial if the

alarm is in progress

maximum temperature

alarm during the

maintenance

AH

cell maximum

temperature during the

alarm

yes

from 1 min to 99 h and

59 min, partial if the

alarm is in progress

alarm stop feeding

during the conservation

phase

PF

cell temperature during

the feeding restore

yes

from 1 min to 99h and 59

min

To avoid a continuous memorizing of feeding interruption alarms (code "PF"), please make sure the device is in

the state "stand-by" or in the state "on" before the feeding.

If the duration of the feeding interruption alarm (code "PF"), causes the clock error (code "rtc"), the device will

not memorize the date, the time when the alarm starts, or the duration of the alarm.

The LED HACCP gives information about the alarms HACCP memory state; please consult the paragraph 10.1

"signals."

9ii: ALARMS HACCP INFORMATIONS DISPLAY

Please operate in the following way:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the DOWN key pressed for 1 second. The display will show the first available label.

3.

Press and release the UP or DOWN key to select “LS”

4.

Press and release the BLAST CHILLING key. The display will show the code of the most

recent alarm or one of the codes from chart 10.1 “Preliminary Instructions”, followed by

number “1” (the greater the number, the older the alarm).

5.

Press and release the UP or DOWN key to select an alarm code (for example “AH3”)

6.

Press and release the BLAST CHILLING key: the LED HACCP will stop flashing and remain

permanently on. For example, the display will show, the following information in sequence:

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

17

Information Meaning

8.0

the critical value is 8.0 °C / 8 °F

StA the display is going to show the date and the hour when the alarm occurred.

y11 the alarm occurred in 2011 (continue…)

n03 the alarm occurred in March (continue…)

d26 the alarm occurred on March 26th 2011

h16 the alarm occurred in the16th hour (continue…)

n30 the alarm occurred at 16h 30m

dur the display is going to show the alarm duration

h01 the alarm went off for 1h (continue…)

n15 the alarm went off for 1 h 15 min

AH3 selected alarm code

The display shows the information for 1 second.

To end the display of information:

7.

Press and release the START/STOP key: the display will again show the code of selected alarm.

To leave the procedure:

8.

Conclude the display of information.

9.

Press and to release the UP key or the DOWN key until the display shows the appropriate state from

paragraph 8iic: “the display” or do not operate for 60 s.

9iii: CANCELLATION OF HACCP ALARM INFORMATION

Please operate as follows:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the DOWN key pressed for 1 second: the display will show the first available label.

3.

Press and release the UP key or the DOWN key to select "rLS."

4.

Press and release the BLAST CHILLING key: the display will read "0."

5.

Press and release the UP key or the DOWN key within 15 s to set it to "149."

6.

Press and release the BLAST CHILLING key or do not operate for 15 seconds: the display will

visualize "- - - - ", flashing for 4 s and the LED HACCP will turn off. The device will then

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

18

automatically end the procedure and the display will show the appropriate state from paragraph 8iic:

“the display”

If the device has not memorized any information about the HACCP alarms, the label "rLS" won't be visualized.

10) COMPRESSOR WORKING HOUR CALCULATION

10i: COMPRESSOR WORKING HOUR DISPLAY

Please operate per below:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the DOWN key pressed for 1 second: the display will visualize the first available label.

3.

Press and release the UP key or the DOWN key to select "CH."

4.

Press and release the BLAST CHILLING key: the display will show the compressor working hours.

To end this procedure:

5.

Press and release the BLAST CHILLING key or do not to operate for 15 seconds: the display will again

read "Pb2."

6.

Press and release the UP key or the DOWN key until the display shows the suitable state from paragraph

8iic: “the display”, or do not operate for 60 seconds.

10ii: COMPRESSOR WORKING HOURS CANCELLATION

Please operate in the following way:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Press the DOWN key for 1 second: the display will show the first available label.

3.

Press and release the UP key or the DOWN key to select "rCH."

4.

Press and release the BLAST CHILLING key: the display will read "0."

5.

Press and release the UP key or the DOWN key within 15 seconds to set it to "149."

6.

Press and release the BLAST CHILLING key or do not operate for 15 s: the display will show "- - - - ",

flash for 4 s, and the LED HACCP will turn off. The device will then automatically go out of the

procedure and the display will visualize the suitable size from paragraph 8iic: “the display”.

11) SETTING

11i: REAL DAY AND HOUR SETTING

Please operate in the following way:

1.

Make sure that the keyboard is not jammed and that a procedure is not in progress.

2.

Keep the DOWN key pressed for 1 second: the display will show the first available label.

3.

Press and release the UP key or the DOWN key to select "rtc."

To set the year:

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

19

4.

Press and release the BLAST CHILLING key: the display will read "yy" followed by the last two

numbers of the year and the LED will flash.

5.

Press and release the UP key or the DOWN key within 15 seconds to change the value.

To set the month, please operate in the following way:

6.

Press and release the BLAST CHILLING key during display of the year: the display will read "nn"

followed by the two numbers of the month.

7.

Press and release the UP key or the DOWN key within 15 seconds to modify the value.

To set the day of the month:

8.

Press and release the BLAST CHILLING key during the display of the month: the display will read "dd"

followed by the two numbers of the month.

9.

Press and release the UP key or the DOWN key within 15 seconds to modify the value.

To set the hour:

10.

Press and release the BLAST CHILLING key during the formulation of the day of the month: the display

will read "hh" followed by the two numbers of the time.

11.

Press and release the UP key or the DOWN key within 15 seconds to modify the value.

The time is display in the 24hour format.

To set the minutes:

12.

Press and release the BLAST CHILLING key during the display of the time: the display will read "nn"

followed by the two numbers of the minutes.

13.

Press and release the UP key or the DOWN key within 15 seconds to modify the value.

14.

Press and release the BLAST CHILLING key or do not operate for 15 seconds: the display will again

read "rtc" and the LED will turn off.

To end this process:

15.

Press and release the UP or DOWN key until the display shows the suitable sizes from paragraph 8iic or

do not operate for 60 s.

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

20

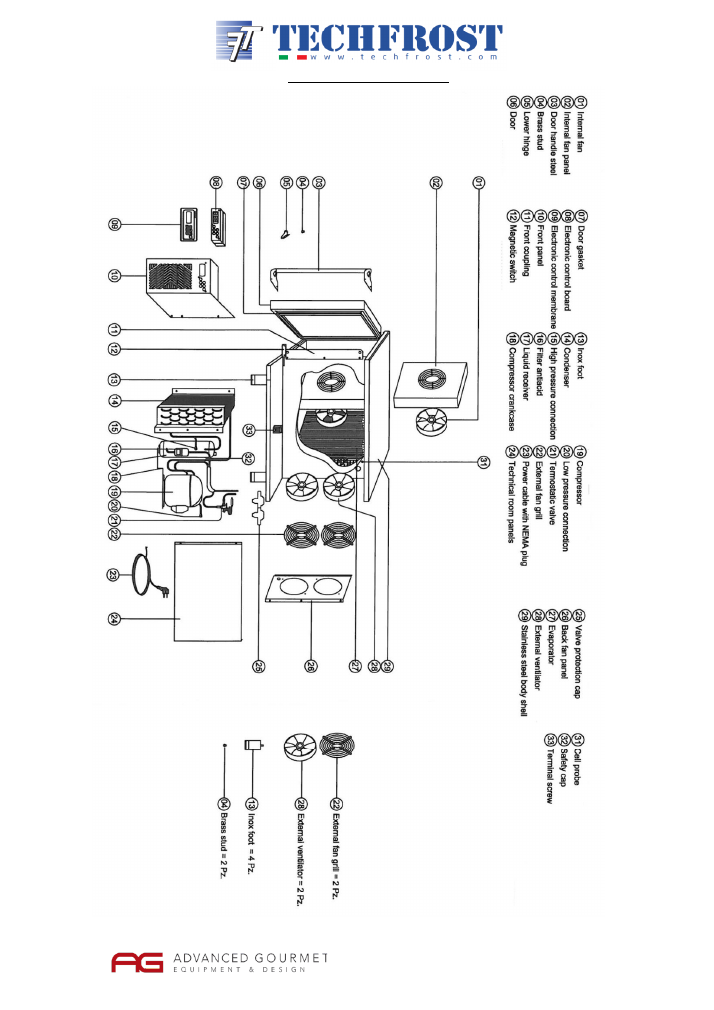

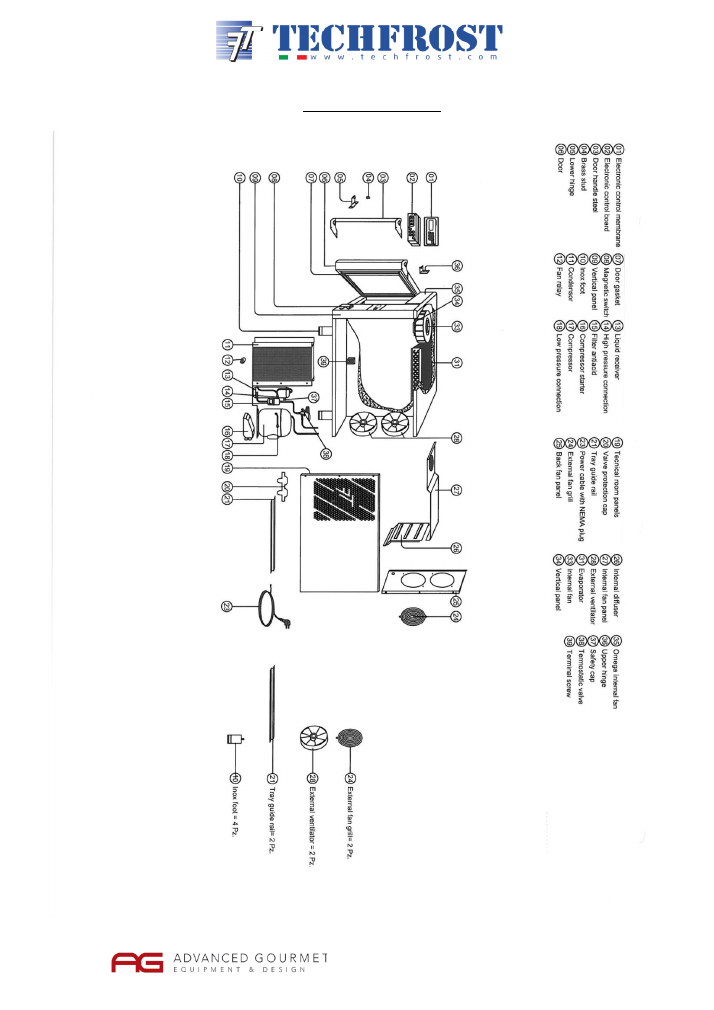

JOF 23/ 23-A EXPLODED VIEW

Street:5C Wendy Ct. Greensboro, NC 27409▪Mailing: PO Box 18542,

Greensboro, NC 27419▪P:336-856-2919▪F:336-217-8838

Email:Sales@AdvancedGourmet.com▪Web:www.AdvancedGourmet.com

Distributed By:

P a g e |

21

JOF ONE EXPLODED VIEW