Full Text Searchable PDF User Manual

April 2002

Sperre Industri AS

Tel +47 70 16 11 00

Fax +47 70 16 11 10

E-mail:industri@sperre.com

Sperre Rotterdam BV

Tel +31 180 463 299

Fax +31 180 463 264

E-mail:rotterdam@sperre.com

Sperre Asia PTE LTD

Tel +65 763 63 00

Fax +65 763 18 11

E-mail:asia@sperre.com

Sole suppliers of

genuine spare parts

GB

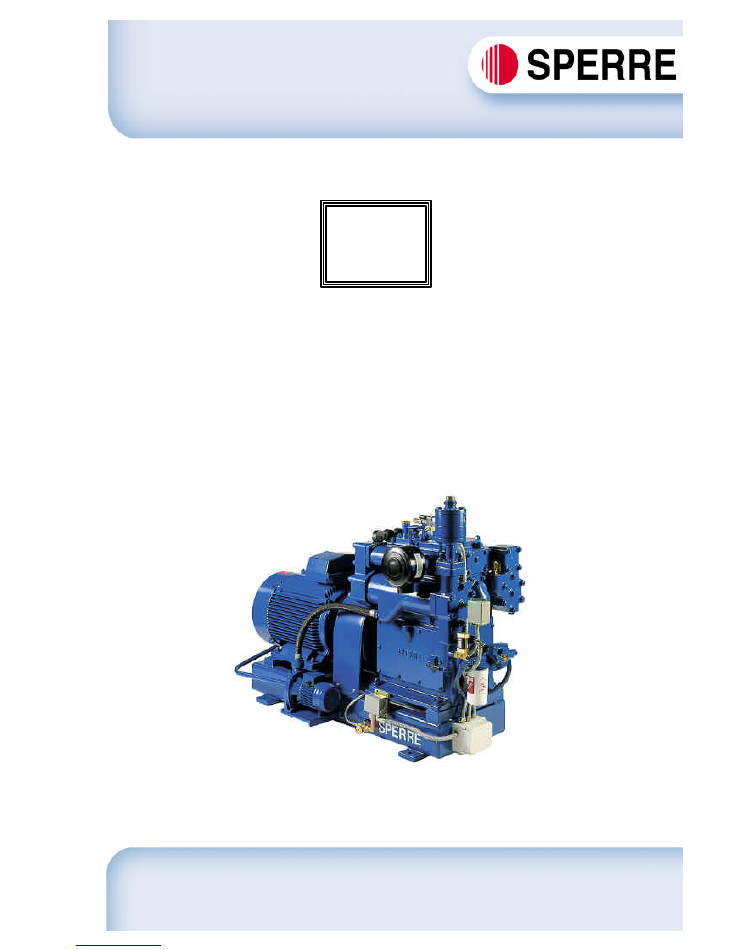

INSTRUCTION MANUAL

AIR COMPRESSOR

HV2/210

Water-cooled

Instruction manual for Water-cooled Air Compressor HV2/210 - 1 -

GB

INTRODUCTION

The purpose of this handbook is to describe the design and function of the compressor and to provide

basic instructions for inspection and maintenance of the equipment.

To ensure proper installation, operation and maintenance from the very beginning, it is essential that the

operator should read this handbook with care and attention.

The maintenance intervals and certain technical details given in this handbook ate mean values based on

experience. These values may vary depending upon the operating conditions of the individual

compressor.

The manufacturer disclaims liability for damage due to unskilled operation or improper maintenance of

the equipment.

Keep the compressor in good mechanical order, and remember that proper preventive maintenance of

the equipment will reduce the risk of damage and unnecessary shutdowns.

The manufacturer reserves the right to amend technical specifications without prior notice.

ELLINGSØY, April 2002

SPERRE INDUSTRI A/S

CONTENTS

Page

1. ORDERING REPLACEMENT PARTS ......................................... 2

2. DESCRIPTION OF COMPRESSOR............................................ 2

2.1. Design .................................................................................. 2

2.2. Safety equipment.................................................................. 3

3. INSTALLATION AND OPERATION ............................................. 3

3.1. Installation instructions ......................................................... 3

3.2. Cooling water system ........................................................... 3

3.3. Starting up ............................................................................ 4

3.4. Operation.............................................................................. 4

3.5. Stopping................................................................................ 4

4. FAULT TRACING ......................................................................... 5

5. INSPECTION AND MAINTENANCE............................................ 6

5.1. Maintenance schedule.......................................................... 6

5.2. Valves ................................................................................... 7

5.3. Lubricating oil system ........................................................... 8

5.4. Bearings ............................................................................... 8

5.5. Piston and piston rings ......................................................... 9

5.6. Flexible coupling................................................................... 9

5.7. Coolers ................................................................................. 10

5.8. Filters.................................................................................... 10

6. TECHNICAL DATA....................................................................... 11-12

7. REPLACEMENT PARTS LIST ..................................................... 13-14

8. ILLUSTRATIONS ......................................................................... 15-18

9. ILLUSTRATIONS FOR REPLACEMENT PARTS LIST ............... 19-20

Instruction manual for Water-cooled Air Compressor HV2/210 - 2 -

1. ORDERING REPLACEMENT PARTS

A list of replacement parts and drawings of the various components will be found at the end of this handbook.

The following information must be given when ordering spares.

A. COMPRESSOR TYPE

B. COMPRESSOR SERIAL NUMBER

C. PART NUMBER AND DESCRIPTION

D. QUANTITY ORDERED

E. RATED WORKING PRESSURE OF COMPRESSOR

The type designation (A) and serial number (B) are shown on the rating plate which is fixed to the crankcase.

The rating plate is shown in Fig. 1.

Pleace note that the manufactorer does not supply oversize or undersize parts, or unmachined parts for further

machining and fitting.

The manufactorer disclames all liability for damage due to the use of non-genuine replacement parts.

Order for replacement parts should be sent to:

Adress:

SPERRE INDUSTRI AS

E-mail:

industri@sperre.com

6057 ELLINGSØY

Web adress : http://www.sperre.com

NORWAY

Phone:

+ 47 70 16 11 00

Fax

+ 47 70 16 11 10

2. DESCRIPTION OF COMPRESSOR

2.1 Design

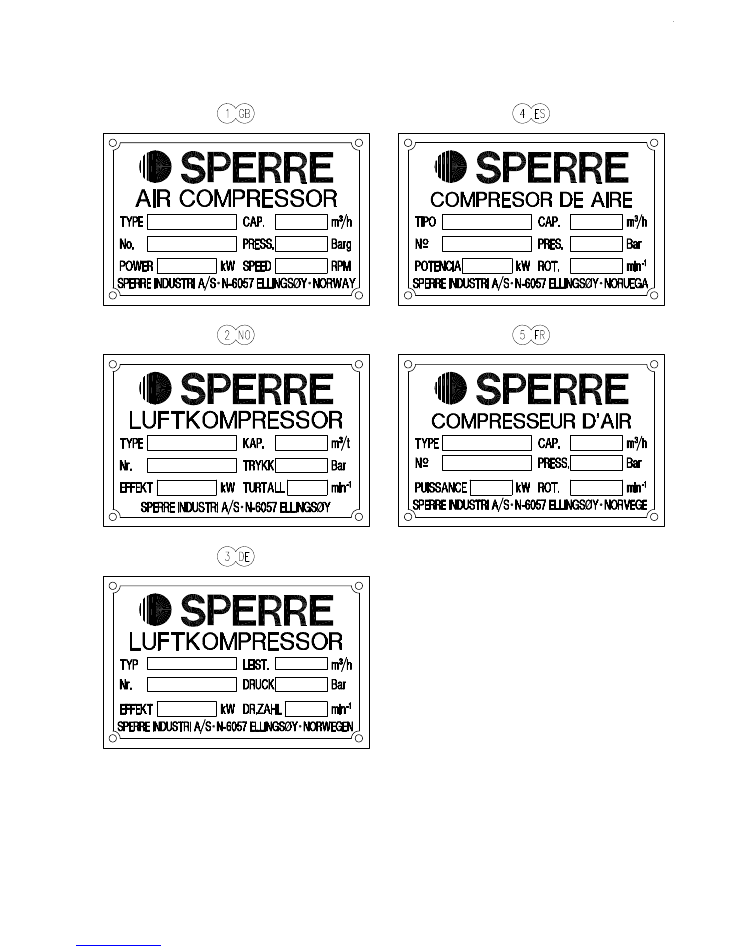

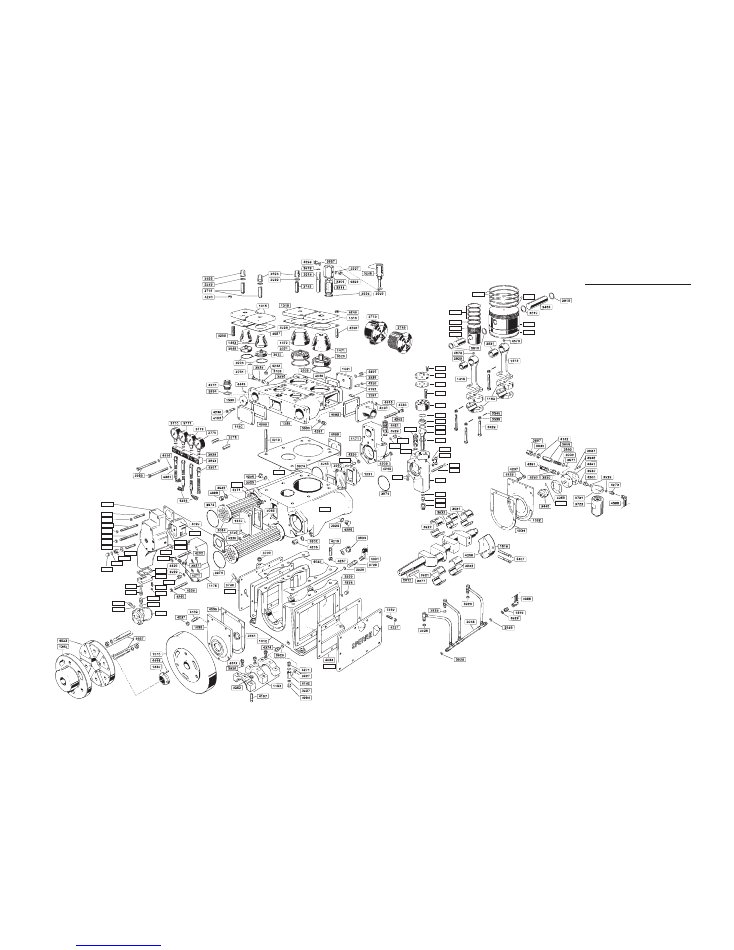

The machine coverded by this instruction book is a single cylinder, 2-stage single-acting watercooled air

compressor. The design principle is shown in the cross-sectional drawing Fig. 2.

The first stage of the compressor is the low-pressure stage (LP) and the second is the high-pressure stage (HP).

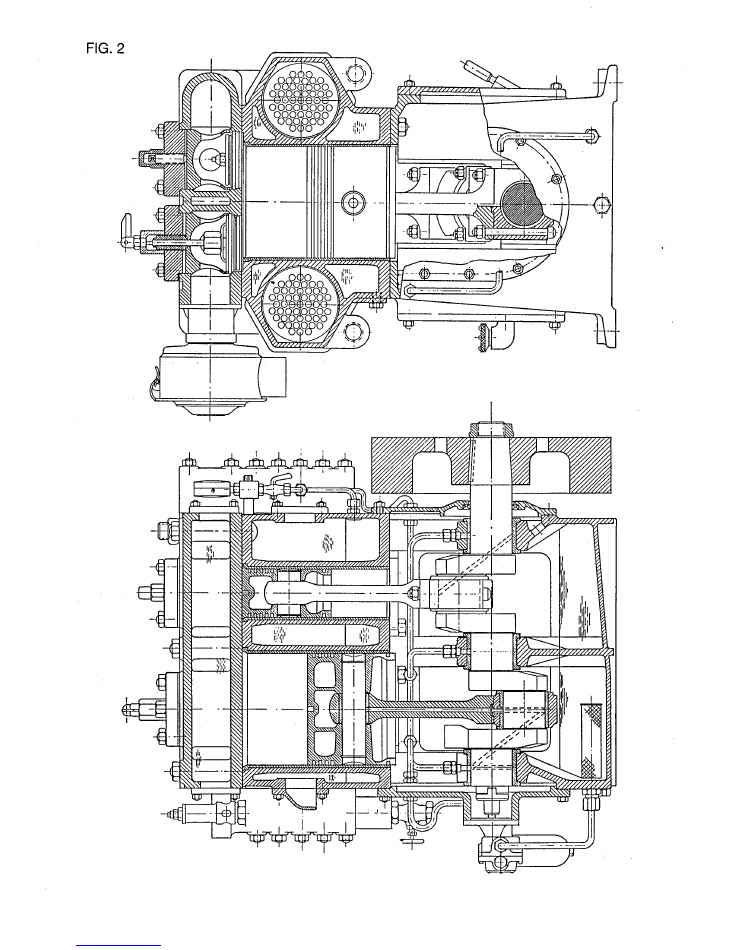

Air circulation through the compressor is shown in Fig. 3. The letters indicate:

A. Suction filter

B. LP suction valve

C. LP delivery valve

D. LP safety valve

E. LP cooler

F. HP suction valve

G. HP delivery valve

H. HP cooler

I. HP safety valve

All bearings are pressure lubricated by a gear pump fitted to the end of the crankshaft.

Two replaceable tube-type coolers are fitted in the compressor cylinder block. The first serves to cool the air after

first-stage compression, the second provides cooling after second-stage compression. The cooling water intake

and outlet are located so that the water circulates through the cylinder block and ensures efficient cooling of the

air and compressor cylinder walls.

The compressor compresses air from atmospheric pressure to rated pressure, with an upper limit of 35 bars.

The compressor is designed for installation together with an electric motor or other drive unit on a well-stiffended

base, with a flexible coupling between compressor and motor.

Every compressor is tested before delivery from the factory, and all compressor sets supplied with motor are

aligned before dispatch. See chapters 3.1. and 5.6.

This compressor is designed to supply compressed air for engine starting, and for the operation of air power

equipment and instruments. It complies with the requirements specified by the classification institutions.

Instruction manual for Water-cooled Air Compressor HV2/210 - 3 -

2.2. Safety equipment

The compressor is fitted with two safety valves, one after the first-stage compression and the other after second-

stage compression.

The safety valves, which are set at the factory in accordance with the working pressure specified by the

customer, ensure that the pressure does not exceed the limit for which the compressor and the compressed air

system are dimensioned.

The cylinder block cooling jacket is fitted with a safety plate which will be blow out if the cooling water is

subjected to excessive pressure. Use only manufacturer's genuine safety plates to replace blown plates.

A pressure switch is generally included in the automatic control system. This serves to stop the compressor if the

lube oil pressure falls belowe a predetermined minimum.

3. INSTALLATION AND OPERATION

3.1. Installation instructions

Every compressor unit is supplied complete with drawings and specifications showing its dimensions and

attachment points. The customer also receives installation instructions giving recommendations for the

installation of equipment and piping.

The compressor unit should be installed in a location where the air is not excessively warm. Warm intake air

reduces the capacity of the compressor. Normally, the ambient temperature for electrical equipment should not

exceed 45

o

C. The compressor unit bedplate should lie plane to its foundation. After the unit is installed, check

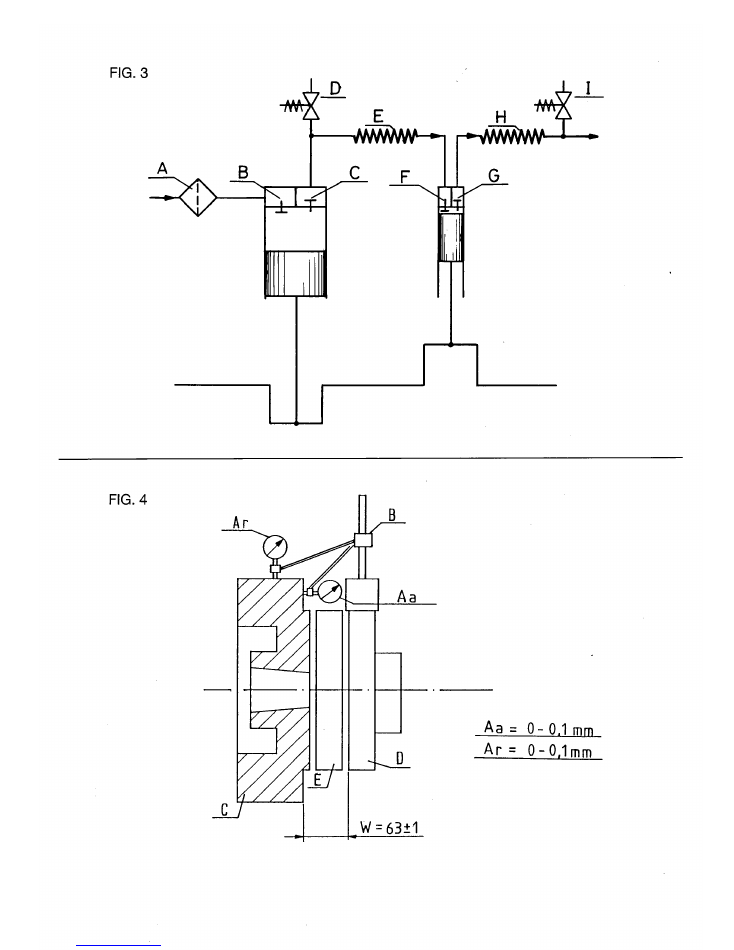

the alignment of compressor and motor. The procedure is shown in Fig.4.

Use vernier callipers or inside micrometer callipers to check the distance (W) (Fig.4). This should be the same

around the whole circumference of the coupling.

Using a micrometer (A), check the radial misalignment between the coupling halves as shown in Fig.4. The

maximum micrometer reading (A) should be as illustrated in Fig. 4.

Even if the unit has been installed on vibration dampers, an alignment check is to be recommended after

installation.

Piping should be so installed that there is no risk of water pockets.

Other equipment should not be installed around the compressor unit in such a way that inspection and

maintenance operations may be hampered.

3.2. Cooling water systems

It is of the greatest importance to the operation and life of the compressor that a good and reliable supply of

cooling water is ensured. The quantities of cooling water required are given in Table T.1. These specifications

apply to both seawater and freshwater cooling.

Whether the compressor is connected to a central cooling system or has its own separate cooling water pump, it

is important to ensure that the cooling water is circulating properly. In this connection it is not sufficient simply to

check that the compressor pressure gauge is registering cooling water pressure.

If the cooling water feed temperature is too low, increased internal condensation may result. If this is the case,

the cooling water temperature should be increased. If the temperature cannot be increased by recirculation,

condensation can be reduced by reducing the supply of cooling water.

The cylinder block cooling jacket is equipped with a thermometer for the monitoring of cooling water temperature.

Recommended cooling water temperatures are given in Table T.2

.

Instruction manual for Water-cooled Air Compressor HV2/210 - 4 -

3.3. Starting up

Before initial starting up and after long periods out of use, carry out he following operations:

A. Check the oil level.

B. Check that the quality of the oil has not been impaired by water or other foreign matter.

C. Check compressor valves and lubricate the cylinder with oil.

D. Turn over the compressor by hand, with the suction valve relieved by means of the manual valve opener.

E. Check cooling water circulation.

F. Check that the air line cock between the compressor and the air reservoir is open.

G. Open the manual drain cocks on the water trap.

H. Start the compressor.

I. If everyhing is operating normally, close the drain cocks and set the valve opener in the operating position.

Allow the compressor to run for a few minutes before loading it to maximum working pressure.

3.4. Operation

During normal operation, pressures and temperatures should be as shown in Table T.2. Some of the values,

which are directly affected by local conditions, may deviate slightly from the figures in the table.

Operation of the compressor is normally monitored by the automatic features of the starting equipment, e.g.

pressure switch monitoring of lube oil pressure and thermostat monitoring of cooling water temperature.

However, additional regular checking of operation and automatic functions is recommended.

Some water form the compressed air will always condence in the system. The compressor is fitted with drain

cocks after the HP and LP coolers. If these are not automatically controlled, they must be drained

regularly

by

hand. Also, the oil and water traps should be regularly drained by hand, unless this function is performed by an

automatic draining system.

Special water traps to collect condensate after the LP cooler can be supplied to order, by the manufacturer.

3.5. Stopping

Stopping the compressor manually for short periods:

A. Operate the manual valve opener to relieve the LP suction valve.

B. Open the water trap drain cocks.

C. Stop the compressor.

If the compressor is to be shut down for a long period, e.g. when a ship is to be laid up, the procedure is as

follows:

AA. Lubricate compressor valves, non-return valves, cylinder walls and exposed crankshaft surfaces with

corrosin-inhibiting oil, suitable for the envisaged period of shutdown.

BB. If there is any risk of frost, drain the cooling water from the compressor.

CC. Drain off old oil, clean the sump and refill with new oil.

DD. Set the manual valve opener in the horizontal position to relieve the load on the suction valve.

EE. Turn over the compressor manually once a month.

FF. The starter cabinet and other electrical equipment should also be protected from damage by corrosion.

Instruction manual for Water-cooled Air Compressor HV2/210 - 5 -

4. FAULT TRACING

The following are some of the faults that may arise in operation.

A. Compressor capacity is low and/or compressor

not supplying full pressure.

Possible cause

Remedy

Dirty, damaged or

Clean and check all valves.

worn valves

Replace defective parts.

Sticking piston rings

Dismantle rings.

Clean grooves and rings.

Replace defecive parts.

When reinstalling,

lubricate cylinder walls

with oil.

Leaking safety valves

Overhaul safety valves,

adjust to correct

lifting pressure.

Defective gasket

Replace gasket.

between crankcase

and sylinder block

Air filter blocked

Clean filter.

B. LP safety valve blows.

Possible cause

Remedy

HP valves damaged

Check and clean valves.

or dirty

Replace defective parts.

C. HP safety valve blows.

Possible cause

Remedy

Air line shut-off

Open shut-off cock.

cock closed.

Non-return valve

Remove and clean

blocked

non-return valve.

Replace defective parts.

D. Valves require maintenance too frequently.

Possible cause

Remedy

Overheating

Check cooling water

circulation and temp.

Inspect coolers and

clean if necessary.

Dirty intake air

Check suction filter.

Inferior lube oil

Change the lube oil type.

See list of

recommended types in

this handbook.

Manufactorer can

supply further

information.

Incorrect tightening of

Tighten valve

compressor valves

to specified torque.

clamping screws

to specified torque.

E. Overheating or knocking in crankcase.

Possible cause

Remedy

Defective bearings

Inspect bearings, check

clearances.

Insufficent lube oil or

Drain sump, clean and add

lube oil contaminated

new oil.

with water

Binding crankshaft

Check bearing clearances.

bearing

Replace defective parts.

F. Overheating and scoring of piston

.

Possible cause

Remedy

Piston or gudgeon pin

Replace defective

bearing incorrectly

parts, check piston

fitted

clearances, piston ring

clearances and

gudgeon pin bearing.

Deficient cooling

Check cooling

water circulation

and temperatures.

G. Excessive lube oil consumption

.

Possible causes

Remedy

Piston rings worn out

Replace piston rings.

Defective crankcase

Replace breather valve.

breather valve

Instruction manual for Water-cooled Air Compressor HV2/210 - 6 -

5. INSPECTION AND MAINTENANCE

IMPORTANT: PERSONAL SAFETY

Before starting any kind of work on the compressor, the

electricity supply must be switched off at the starters and also

at the main switchboard. Hang a notice on the switch on the

main switchboard to show that repairs are in progress

.

5.1. Maintenance schedule

Change the lube oil after approximately the first 200 hours of running in. Drain off the oil while it is warm, clean

the crankcase before refilling with new oil. When cleaning, it is important not to use rags that may leave threads

or fluff in the crankcase.

The following maintenance schedule is intended as a guideline for normal maintenance. However, compressor

operating conditions vary widely from installation to installation and it is therefore important to adapt the

maintenance schedule to the experience of the individual operator.

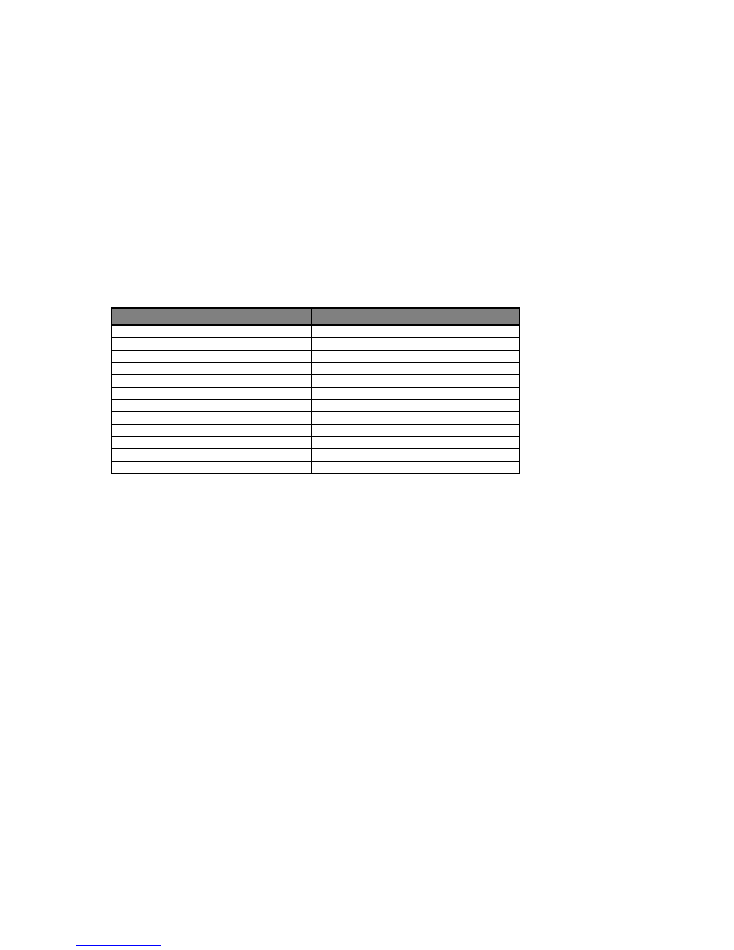

Maintenance

Maintenance

intervals

routine

Daily

A

Every 500 hours

B

Every 1000 hours

C

Every 3000 hours

D

Every 9000 hours

E

Every 12000 hours

F

Routine A

Check:

- Lube oil pressure

- Lube oil

- Cooling water circulation and

temperatures

- Automatic functions

- Drain condensate

Routine B

Check:

- LP delivery valve

- HP delivery valve

- Compressor bedplate bolts

Routine C

Check:

- LP suction valve

- HP suction valve

- Cylinder through valve apertures

- Pipe connections

Overhaul:

- LP delivery valve

- HP delivery valve

Replace:

- Lube oil after cleaning crankcase

- Lube oil filter

Routine D

Check:

- Big-end bearings

- Piston and cylinder walls through

valve apertures

- Flexible coupling

- Safety valves

Overhaul:

- LP suction valve

- HP suction valve

- Air filter (clean)

Routine E

Check:

- Coolers (clean)

Routine F

Check:

- Main bearings

- Piston, gudgeon pin and rings

- Gudgeon pin bearing

- Lub oil pump

Before ordering replacement parts, please read the

instructions for ordering parts.

Instruction manual for Water-cooled Air Compressor HV2/210 - 7 -

5.2. Valves

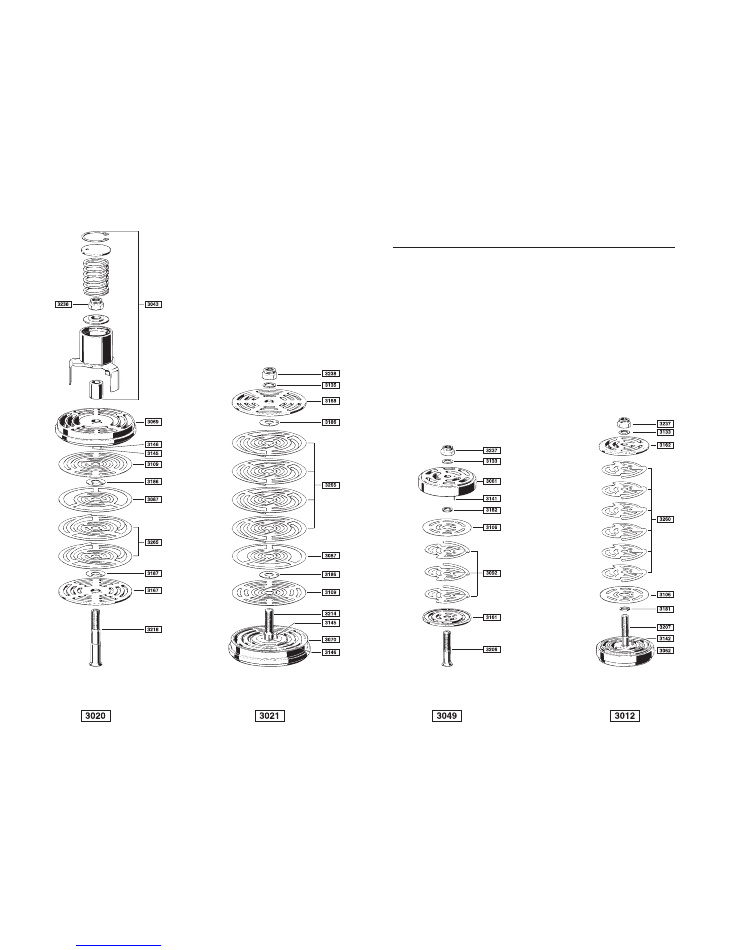

In the parts list and drawings each valve is shown complete, with its own part number, and also dismantled with

the part numbers of the individual components.

After overhaul or replacement of parts, assemble the valves in sequence as shown in the drawing of the

dismantled valve.

When assembling valves, lubricate the nut and valve bolt and tighten to the torques (in kpm) given below:

Dimension

Minimum

Maximum

M10

2.00

2.45

M12

3.60

4.40

M14

5.70

6.90

M16

9.00

11.00

IMPORTANT:

Before attempting to check compressor valves, loosen the clamping screw on the valve cover before removing

the cover.

After inspecting and overhauling valves, it is essential that the clamping screw, which bears against the valve

clamping piece and which keeps the valve in place on its seat, should be tightened with an unbrako key to the

torque shown in Table T.3.

Overhaul and mainenance of valves

Regular and careful maintenance of valves is essential to the capacity and reliability of the compressor. We

therefore recommend overhaul in accordance with the following guidelines:

A. When cleaning and dismantling the valve, never clamp the valve directly in a vice to loosen the centre bolt

nut. A special clamping jig for this purpose, suitable for all valves, is available from the factory on request. A

simple makeshift for clamping the valve is to set it in a vice between two pins which fit into the outermost seat

slots of the valve.

B. Clean the valve components and check them carefully.

IMPORTANT

: Never use sharp implements on sealing surfaces and plate parts.

C. Replace all parts that are worn or even slightly scored. Check that all guide pins are in order. Maximum wear

limit is 10% of the total thickness of components.

D. If a valve spring or spring plate shows signs of weak-ness, all springs must be replaced at the same time,

because damage can result if some springs operate longer than others. Replacement of all valve springs is

recommended after about 5000 hours running time, even if the springs do not look worn.

E. If there are signs of abrasion or scoring of the valve seat sealing ledges, these must be machined. Most

valves are drilled for guide pins, with spare holes for new pins. Guide pins can be driven out by means of a

suitable tool. If it proves impossible to remove a broken pin, use one of the spare holes.

F. To remove the valve centre bolt, mark the centre of the pin with a centre punch and then drill out the pin.

Remove the centre bolt. After refitting the bolt, drill a hole for the safety pin, drive the pin securely into place

and peen the end to prevent it from falling out.

G. After completion of machining and careful replacement of guide pins in their respective holes in the valve

seating and/or catch plate, check that the ends of the pins do not but against the bottom of the holes in the

matching parts.

Use

only

genuine replacement pins and parts.

Assembly of valves demands precision, care and forethought. Make sure that the various parts are correctly

located and that the right numbers are installed. Compare with the lists and drawings of parts to ensure that the

right number of parts is present. Total lifting heights of valve plates are given in Table T.4.

Instruction manual for Water-cooled Air Compressor HV2/210 - 8 -

5.3. Lubricating oil system

The lube oil pump is a gear pump which is normally capable of operating for long periods without maintenance.

The pump is directly driven from the end of the crankshaft, and oil pressure is controlled by means of a by-pass

valve in the pump. To overhaul, dismantle the mounting flange and pipe connections, and pull the pump out.

An easily replaceable lube oil filter is fitted between the delivery side of the pump and the compressor.

IMPORTANT:

Accumulation of condensate in the crankcase may present a serious problem under certain

operating conditions, and it is important that the operator should check from the very beginning

whether condensate in the lubricating oil is liable to become a problem.

Unless the condensed water emulsifies with the lubricating oil, it will separate out and there is a risk that the

compressor will be lubricated with water.

The choise of lube oil is of great importance to the reliable operation of the compressor. The manufactorers have

performed extensive tests of lube oils for the oil companies, and the following is a list of lubricants recommended

on the basis of these tests.

A list of recommended types of oil is affixed to the compressor on delivery.

Mineral oil

Syntetic oil

BP ENERGOL RC 68

BP ENERSYN RX 100

CASTROL AIRCOL PD 100

CASTROL AIRCOL SN 100

CALTEX RPM COMPR. OIL 68

CHEVRON HD COMPR. OIL 100

ESSO/ EXXON EXXCOLUB 77

DAPHNE MARINE COMPRESSOR 100

FINA EOLAN AC

ELF PRIMERIA SG 100

GENERAL COMPOL A 100

ESSO/EXXON ZERICE S 100

MITSUBISHI COMPR. OIL 100

ESSO/EXXON SYNTESSTIC 68

MOBIL RARUS 427

MOBIL RARUS 827

NYNÄS COMPR. OIL 68

NIPPON OIL CO. FAIRCOL SA100

PHILLIPS COMPR. OIL 68

SHELL CORENA AP 68

SHELL CORENA P 68

STATOIL COMPWAY S 100

TEXACO SYN STAR DE 100

Further information about lubricants is available on application to the manufacturer.

5.4. Bearings

The compressor has replaceable, two-shell plain big-end and crankshaft bearings. The middle crankshaft

bearings serves as an axial guide for the crankshaft.

The gudgeon pin bearings are single shell plain bearings, press-fitted into the little ends. Tolerances and

clearances for connecting rod, crankshaft and gudgeon pin bearings are given in Table T.4.

All plain bearings are pressure lubricated.

After inspection or replacement of the big-end bearings it is important to ensure that the bearing does not bind on

the crankshaft. It must be possible to turn over the compressor manually.

New two-shell bearings are coated with a running-in compound at the factory.

Dismantling the gudgeon pin bearing from the connecting rod.

A. Use a hydraulic press or extractor to remove the old bearing shell.

B. Press in the new bearing shell.

C. Adjust the fit of the bearing to the gudgeon pin in accordance with Table T.4.

Instruction manual for Water-cooled Air Compressor HV2/210 - 9 -

5.5. Piston and piston rings

Dismantle the piston as follows:

LP piston

A. Remove the cylinder head without dismantling the valves.

B. Remove the big-end bearing bolts and bearings.

C. Withdraw the piston and connecting rod from above.

Assembly sequence is the opposite of the above.

HP piston

AA. Remove the big-end bearing bolts and lower bearing shell. Turn over the crankshaft to top dead centre and

then back. The upper bearing shell can now be removed.

BB. Turn over the crankshaft to bottom dead centre, then withdraw the piston and connecting rod through the

crankcase door.

Assembly sequence is the opposite of the above.

5.6. Flexible coupling

The compressor flywheel serves as one coupling half.

Dismantle the coupling

A. Loosen the nuts on each coupling half and give each one a sharp tap with a hammer before removing them

completely. This will cause the bolts to loosen from their conical holes in the coupling halves.

B. Remove the bolts and take out the flexible coupling. Avoid spilling oil on the flexible coupling.

The coupling half on the motor is keyed and shrunk on to the axle.

Alignment

The prinsiple and values for checking alignment are shown in Fig. 4.

A. Micrometer/dial indicator

B. Magnetic base

C. Flywheel

D. Coupling half, motor

E. Flexible coupling

Check the angle (W) by means of inside micrometer callipers or vernier callipers. The distance (W) in mm should

be the same around the whole circumference of the coupling halves.

Check parallel misalignment (A) between coupling halves as shown, around the circumference of the coupling

halves (C). Values in mm for maximum parallel misalignment are given in Fig.4.

Instruction manual for Water-cooled Air Compressor HV2/210 - 10 -

5.7. Coolers

To ensure reliable operation of the compressor it is important to keep the LP and HP coolers free from deposis of

carbon and cooling water salts etc. Insufficient cooling causes excessive air temperature and progressively

increases the formation of carbon deposits.

The cooling tubes are roller expanded into tube plates at both ends.

The seals at the cooler ends are O-rings, type OF special quality. Use only manufacturer's spares. To remove

the tube bundle, first loosen the cooler covers at both ends. The whole bundle can then be withdrawn by means

of two guide rods, pushed through the tubes.

Assemble in opposite sequence.

Instal new seals.

If the cooling tubes show signs of severe corrosions or wear, the complete cooler should be replaced.

5.8. Filter

The air filter

should be cleaned by means of a good degreasing agent. Blow the filter clean with compressed air

and give it a thin coating of compressor oil.

The oil filter

should be replaced complete. Replacement every 1000 hours running time is recommended.

Instruction manual for Water-cooled Air Compressor HV2/210 - 11 -

6. TECHNICAL DATA

T.1. Coolant flows

Shaft speed rpm.

580

-

725

-

875

-

975

Coolant flow l/min. 7-10 bars................................ :

17

-

21

-

26

-

28

Pressure drop across compressor (mm.w.c.)....... :

110

-

180

-

280

-

350

Coolant flow l/min. 15-35 bars.............................. :

21

-

26

-

32

-

35

Pressure drop across compressor (mm.w.c.)....... :

180

-

280

-

440

-

550

T.2. Recommended pressures and temperatures

Recommended minimum inlet temperature Cooling water .................... : 30

o

C

Recommended maximum outlet temperature Cooling water ................. : 60

o

C

Recommended temperature difference.................................................. : 15 - 20

o

C

Recommended cooling water pressure.................................................. : 0.5 - 3.0 bars

Recommended lube oil pressure, warm compressor ............................. : 2.0 - 0.8 bars

Recommended limit switch setting for lube oil pressure/safety stop ...... : 0.8 bars

Normal working pressure one stage 0-10 bars ...................................... : 1.5 - 3.5 bars

Normal working pressure one stage 10-35 bars .................................... : 4.0 - 6.0 bars

Maximum working pressure.................................................................... : 35 bars

Safety valve setting over stage pressure................................................ : 10%

Normal temperature outlet air................................................................. : 30 - 65

o

C

T.3. Torque table

A - Thread diameter (mm)

B - Key width

C -Torque (kpm), clean and lubricated threads

* - Marker for unbrako screw

** - Marker for BSP threads

Component

A

B

C

Cylinder head ....................................................... :

M20

30

20

Cooler cover ......................................................... :

M16

24

15

Cooler cover ......................................................... :

M12

19

8

Valve cover HP and LP ........................................ :

M16

24

15

Valve clamping screw HP and LP ........................ :

*M20

10

12

Cap lock nut HP and LP ....................................... :

M20

30

10

Big end bearing bolts HP and LP ......................... :

**1/4

22

9-10

Main bearing studs ............................................... :

M12

19

8

Bearing housing, crankcase ................................. :

M10

17

4

Cylinder block to crankcase ................................. :

M22

32

25

Hand hole – Air intake manifold ........................... :

M12

19

8

Crankcase covers................................................. :

M10

17

4

Instruction manual for Water-cooled Air Compressor HV2/210 - 12 -

T.4. Clearances

Suction valve LP Lifting height

(mm)............. : 1.2

Pressure valve LP Lifting height

(mm)............. : 1.2

Suction valve HP Lifting height

(mm)............. : 1.1

Pressure valve HP Lifting height

mm) .............. : 1.4

Cylinder/piston clearance LP

(mm)............. : 0.35

Cylinder /piston clearanse HP

(mm)............. : 0.25

Piston/cylinder head clearance LP (mm)............. : 1.4 - 1.8

Piston cylinder head clearance HP (mm)............. : 1.4 - 1.8

Crankshaft/guide bearing end clearance (mm) .... : 0.3 - 0.5

Main bearing/shaft clearance

(mm)............. : 0.08 - 0.12

Crankshaft bearing play

(mm)............. : 0.08 - 0.11

Gudgeon pin bearing play

(mm)............. : 0.03 - 0.04

T.5. Piston rings

Pressure stage

LP

HP

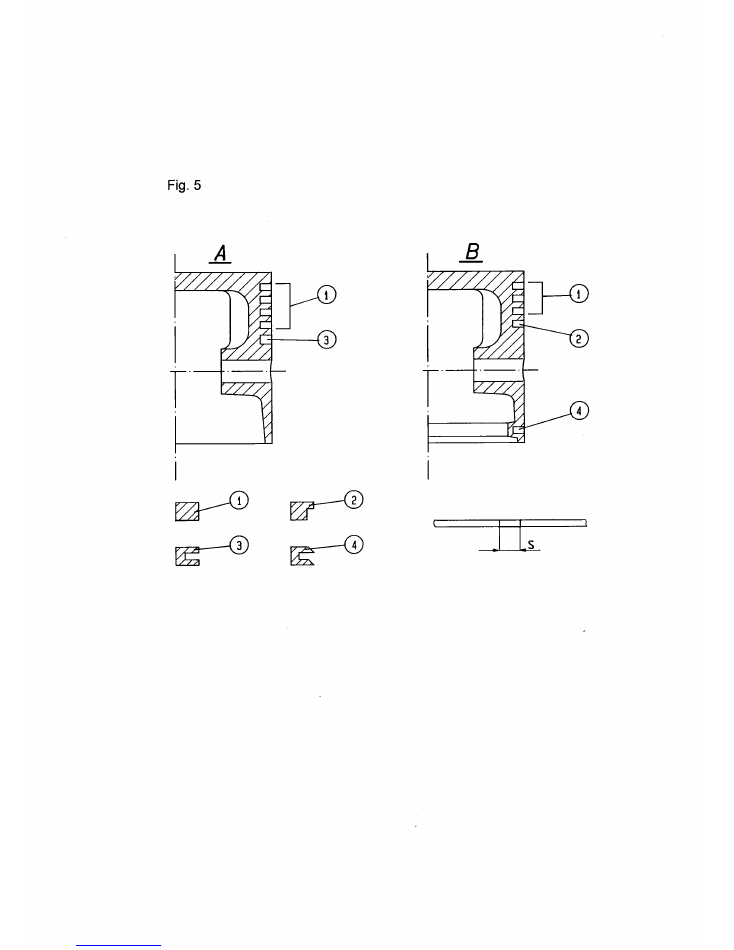

Piston illustration (F.5.)......................................... :

B

A

Number of compressor rings ................................ :

2

4

Number of scraper rings....................................... :

2

Number of oil rings ............................................... :

1

1

Min. end clearance S (mm) .................................. :

0.80

0.35

Max. end clearance S (mm) ................................. :

1.05

0.55

Wear limit S (mm) ................................................ :

2.05

1.55

T.6. General data

Number of cylinders

..................... :

2

Cylinder diameter LP

(mm) ............ :

210

Cylinder diameter HP

(mm) ............ :

93

Stroke

(mm) ............ :

110

Crankpin diameter

(mm) ............ :

63

Crankshaft diameter at bearing

(mm) ............ :

63

Gudgeon pin diameter LP

(mm) ............ :

40

Gudgeon pin diameter HP

(mm) ............ :

40

Number of valves LP

..................... :

2

Number of valves HP

..................... :

2

Oil capacity of sump

(litres) .......... :

8

Instruction manual for Water-cooled Air Compressor HV2/210 - 13 -

7. Replacement Parts List - Water Cooled Air Compressor - HV2/210

Part Qty. Description

No.

1012

1

Crankcase

1038

1

Crankcase cover

1041

1

Crankcase cover - dipstick side

1058

1

Bearing housing - flywheel side

1062

1

Bearing housing - lub. oil pump side

1076

1

Flywheel

1103

1

Cylinder block

1153

3

Main bearing shell cups

1163

4

Bearing shell cups, pair

1171

1

Cooler cover - Pos. 1

1175

1

Cooler cover - Pos. 3

1231

1

Frame - bursting plate

1255

1

Cylinder head

1297

1

Air filter duct

1316

2

Valve cover, HP

1318

1

Valve cover, LP suction side

1319

1

Valve cover, LP delivery side

1330

1

Flywheel nut

1366

1

Non return valve cover

1382

1

Coupling flange

1414

1

Connecting rod, LP

1415

1

Connecting rod, HP

1440

2

Inspection hole cover

1441

1

Inspection hole cover with 1/2" hole

1463

2

Clamping piece, HP valve

1471

1

Clamping piece, LP suction valve

1472

1

Clamping piece, LP delivery valve

1516

1

Counterweight

1530

1

Blind plate

2012

1

Crankshaft

2998

1

Non return valve

3245

1

Valve unloader, complete

3304

1

Unloader cover

3311

1

Unloader cylinder

3318

1

Unloader piston

3329

4

Big-end bearing bolt

3335

4

Big-end bearing nut

3340

4

Big-end bearing split pin

3384

1

Piston, LP

3398

1

Piston, HP

3446

1

Connector - pump

3465

1

Gudgeon pin, LP

3468

1

Gudgeon pin, HP

3486

2

Oil scraper ring, LP

3505

4

Compression ring, HP

3519

2

Compression ring, LP

3533

1

Oil ring, HP

3544

1

Oil ring, LP

3577

1

Ball - lub. oil pump

3583

1

Valve spring - lub. oil pump

3606

1

Adjusting screw - lub. oil pump

3634

1

Oil level gauge glas

3643

1

Pressure gauge board

3654

2

Cooler unit

3677

1

Key

Part Qty. Description

No.

3696

3

Cap nut - clamping screw

3697

1

Cap nut - lub. oil pump

3700

1

Breaher valve

3713

1

Air filter unit, complete

3718

1

Air filet insert

3722

1

Oil strainer

3728

1

Oil strainer mesh

3731

1

Oil strainer holder

3741

2

Clamping screw, HP

3742

1

Clamping screw, LP

3746

1

Dipstick

3770

2

Pressure gauge, C.W./lube oil

3771

1

Pressure gauge, LP

3773

1

Pressure gauge, HP

3775

2

Spacer

3781

1

Thermometer

3783

1

Nipple - thermometer

3810

4

Seeger ring

3821

1

Gudgeon pin bearing, LP

3822

1

Gudgeon pin bearing, HP

3832

2

Big-end bearing shell, pair

3852

1

Sealing ring - lub. oil pump

3861

1

Sealing ring - main shaft

3906

5

Valve gasket

3909

2

Valve gasket

3921

2

Main bearing end

3922

1

Main bearing guide

3925

4

Copper washer

3927

8

Copper washer

3928

5

Copper washer

3929 22

Copper washer

3930

6

Copper washer

3932

4

Copper washer

3934

2

Copper washer

3937

4

Lock washer

3946

4

Screw - lub. oil pump

3950

2

Screw - pressure gauge panel

3960

1

Bursting plate

3965

1

Internal lub. oil tube set

3974

4

O-ring - air coolers

3979

1

O-ring - valve unloader

4028

2

Gasket - crankcase / cylinder block

4033

2

Gasket - crank case cover

4034

1

Gasket - bearing housing, oil pump side

4035

1

Gasket - bearing housing, flywheel side

4053

1

Gasket - air outlet flange

4057

2

Gasket - HP valve cover

4058

2

Gasket - LP valve cover

4059

1

Gasket - lub. oil pump

4068

4

Gasket - bursting plate

4070

1

Gasket - cylinder cover

4085

1

Gasket - air filter duct

4099

3

Gasket - cooler cover

4132

1

Backnut

4142

1

T-joint

Instruction manual for Water-cooled Air Compressor HV2/210 - 14 -

Part Qty. Description

No.

4189 34

Stud - crank case covers

4192 16

Stud - inspection hole

4193

4

Stud - bursting disk

4197

6

Stud - main bearing housing

4198

1

Stud - LP separator

4202 10

Stud - cooler cover

4204

2

Stud - cooler cover

4208 16

Stud - valve cover

4209 12

Stud - cooler cover

4215

8

Stud - cylinder block / crank case

4219

6

Stud - cylinder top

4236

4

Nut - drain plate

4237 34

Nut - crank case cover

4238 32

Nut - inspection hatch, cooler cover

4240 44

Nut - cooler cover, valve cover

4242

6

Nut - cylinder top

4253

6

Locknut - main bearings

4257

8

Locknut - cylinder block / crank case

4268

1

Set screw - counter weight

4269

1

Nipple

4271

4

Nipple

4273

2

Nipple

4275

1

Nipple - c.w. inlet

4276

1

Nipple - c.w. outlet

4280

2

Nipple

4294

3

Plug

4296

7

Plug

4297

1

Plug

4298

1

Plug

4361

1

Pressure gauge tube

4364

2

Pressure gauge tube

4367

1

Pressure gauge tube

4372

3

Nipple

4374

1

Reduction nipple

4388

1

Lub. oil tube

4391

1

Lub. oil tube

4407

2

Screw - counterweight

4414

2

Washer - pressure gauge panel

4416

8

Washer - cooler cover

4420

1

Safety valve, HP

4421

1

Safety valve, LP

4433

4

Screw - non return valve cover

4441

1

Lub. oil pump

4446

1

Set screw

4447

1

Set screw

4449

2

Screw

4451

2

Connecting nipple

4471

2

T-joint

4487

6

Coupling bolt

4523

1

Coupling disk

4624

4

Screw - non return valve flange

4673

2

Screw - gudgeon pin bearing

7591

1

Cooler cover - Pos. 2

7593

1

Cooler cover - Pos. 4

7595

1

Separator

7609

1

Cyclone pipe

7620

6

Stud - cooler cover Pos. 2

7645

1

Drain plate

Part Qty. Description

No.

7648

1

Gasket - drain plate

7651

1

Drain trap

7654

1

Drain nipple

7655

1

Guide pin

7657

1

Plug

7659

1

Cap nut

7660

1

Gasket

7664

4

Stud - drain plate

7665

2

Swivel nipple

7747

6

Stud - cooler cover Pos. 4

7750

2

Plug

7754

1

Nipple

Valve parts:

3012

1

Delivery valve, HP complete

3020

1

Suction valve, LP complete

3021

1

Delivery valve, LP complete

3043

1

Valve gripper, LP complete

3049

1

Suction valve, HP complete

3061

1

Valve seat, HP suction

3062

1

Valve seat, HP delivery

3069

1

Valve seat, LP suction

3070

1

Valve seat, LP delivery

3087

2

Damping plate, LP

3092

3

Valve spring, HP suction

3106

2

Valve plate, HP valve

3109

2

Valve plate, LP valve

3133

2

Valve washer

3135

1

Valve washer

3141

1

Fixing pin

3142

1

Fixing pin

3145

2

Fixing pin

3146

2

Fixing pin

3161

1

Valve catcher, HP suction

3162

1

Valve catcher, HP delivery

3167

1

Valve catcher, LP suction

3168

1

Valve catcher, LP delivery

3181

1

Valve spacer ring

3182

1

Valve spacer ring

3186

3

Valve spacer ring

3187

1

Valve spacer ring

3206

1

Valve bolt, HP suction

3207

1

Valve bolt, HP delivery

3214

1

Valve bolt, LP delivery

3218

1

Valve bolt, LP suction

3237

2

Valve nut

3238

2

Valve nut

3260

6

Valve spring, HP delivery

3265

6

Valve spring, LP suction/delivery

Fig. 1

Instruction manual for Water-cooled Air Compressor HV2/

210

- 1

5

-

Instruction manual for Water-cooled Air Compressor HV2/

210

- 1

6

-

Instruction manual for Water-cooled Air Compressor HV2/

210

- 17 -

Instruction manual for Water-cooled Air Compressor HV2/

210

- 18 -

HV2/200 – HV2/210 – HV2/219

NOV. 2001

Low pressure

suction valve

Low pressure

delivery valve

High pressure

suction valve

High pressure

delivery valve

3927

4193

4447

4296

3929

4420

3929

7648

7645

7664

4236

3929

3929

3929

7654

4273

7651

7591

4271

3927

4416

7655

7595

4202

4238

4240

4198

7620

3932

7657

7660

7659

7665

4296

3519

3505

3533

3398

3468

3486

4204

4238

4624

3716

4053

4433

1366

3906

2998

7609

3906

4240

7747

7593

3932

7665

7750

3929

4296

3906

7754

3544

1038

1041

HV2/210

APRIL 2002

4070

1103

3384