Full Text Searchable PDF User Manual

30cc CURVED SHAFT TRIMMER

ELECTRIC START

OPERATOR’S MANUAL

RLT30CET

WARNING:

To reduce the risk of injury, the user must read and understand the operator’s man-

ual before using this product.

Your string trimmer has been engineered and manufactured to our high standard for

dependability, ease of operation, and operator safety. Properly cared for, it will give

you years of rugged, trouble-free performance.

ENGLISH

GENERAL SAFETY RULES

WARNING

Read and understand all instructions. Failure to follow all

instructions listed below may result in electric shock, fire

and/or serious personal injury.

READ ALL INSTRUCTIONS

n

For safe operation, read and understand all instructions before

using this product. Follow all safety instructions. Failure to

follow all safety instructions listed below, can result in serious

personal injury.

n

Do not allow children or untrained individuals to use this unit.

n

Never start or run the engine in a closed or poorly ventilated

area; breathing exhaust fumes can kill.

n

Clear the work area before each use. Remove all objects

such as rocks, broken glass, nails, wire or string which can be

thrown or become entangled in the cutting line or blade.

n

Wear safety glasses or goggles that are marked to comply

with EN 66 and AS/NZS337 standards when operating this

product.

n

A battery operated tool with integral batteries or a separate

battery pack must be recharged only with the specified charger

for the battery. A charger that may be suitable for one type

of battery may create a risk of fire when used with another

battery.

n

Use battery operated tool only with specifically designated

battery pack. Use of any other batteries may create a risk of

fire.

n

Use battery only with charger listed.

MODEL

BATTERY PACK

CHARGER

RLT30CET

BPH-25

BCAH-20-S (only

for British market)

RLT30CET

BPH-25

722850

n

Wear heavy, long trousers, boots and gloves. Do not wear

loose fitting clothing, shorts, sandals or go barefoot. Do not

wear jewellery of any kind.

n

Heavy protective clothing may increase operator fatigue,

which could lead to heat stroke. During weather that is hot and

humid, heavy work should be scheduled for early morning or

late afternoon hours when temperatures are cooler.

n

Never operate this unit on the operator’s left side.

n

Secure long hair above shoulder level to prevent entanglement

in moving parts.

n

Keep all bystanders, children and pets at least 5m away.

Bystanders should be encouraged to wear eye protection. If

you are approached, stop the engine and cutting attachment.

In the case of bladed units, there is the added risk of injury

to bystanders from being struck with the moving blade in the

event of a blade thrust or other unexpected reaction of the

tool.

n

Do not operate this unit when you are tired, ill or under the

influence of alcohol, drugs, or medication.

n

Do not operate in poor lighting.

n

Keep firm footing and balance. Do not overreach. Overreaching

can result in loss of balance or exposure to hot surfaces.

n

Keep all parts of your body away from any moving part.

n

To avoid hot surfaces, never operate the unit with the bottom

of the engine above waist level.

n

Do not touch area around the muffler or cylinder of the unit,

these parts get very hot from operation.

n

Always stop the engine and remove the spark plug lead before

making any adjustments or repairs except for carburettor

adjustments.

n

Inspect the unit before each use. Check for loose fasteners,

fuel leaks, etc. Replace any damaged parts before use.

n

The cutting attachment should never rotate at idle during

normal use. The cutting attachment may rotate at idle during

carburettor adjustments.

n

Mix and store fuel in a container approved for petrol.

n

Mix fuel outdoors where there are no sparks or flames. Wipe

up any fuel spillage. Move 0m away from refuelling site before

starting engine. Slowly remove the fuel cap after stopping

engine. DO NOT SMOKE when refuelling.

n

Stop the engine and allow to cool before refuelling or storing

the unit.

n

Allow the engine to cool; empty the fuel tank and secure the

unit from moving before transporting in a vehicle.

n

Wear protective equipment and observe all safety instructions.

For units equipped with a clutch, be sure the cutting attachment

stops turning when the engine idles. When the unit is turned off

make sure the cutting attachment has stopped before the unit

is set down.

SPECIFIC SAFETY RULES

n

Inspect before use. Replace damaged parts. Make sure

fasteners are in place and secure. Check for fuel leaks.

n

Replace cutting head if cracked, chipped or damaged in any

way. Be sure the cutting head is properly installed and securely

fastened. Failure to do so can cause serious injury.

n

Make sure all guards, straps, deflectors and handles are

properly and securely attached.

n

Use only the manufacturer’s replacement cutting line in the

cutting head. Do not use any other cutting attachment. To

install any other brand of replacement line or cutting head to

this line trimmer can result in serious personal injury. Never

use, for example, wire or wire-rope, which can break off and

become a dangerous projectile.

n

Never operate unit without the grass deflector in place and in

good condition.

n

Maintain a firm grip on both handles while trimming. Keep

cutting head below waist level. Never cut with the cutting head

located over 60cm or more above the ground.

n

Do not place battery tools or their batteries near fire or heat.

This will reduce the risk of explosion and possibly injury.

n

Always shut off engine before fuelling. Never add fuel to a

machine with a running or hot engine. Move at least 0m from

refuelling site before starting engine. Wipe up any fuel spillage.

DO NOT SMOKE. Failure to heed this warning could result in

serious personal injury.

n

Do not crush, drop or damage battery pack. Do not use a

battery pack or charger that has been dropped or received a

sharp blow. A damaged battery is subject to explosion. Properly

dispose of a dropped or damaged battery immediately.

n

Batteries can explode in the presence of a source of ignition,

such as a pilot light. To reduce the risk of serious personal

injury, never use any cordless product in the presence of open

flame. An exploded battery can propel debris and chemicals. If

exposed, flush with water immediately.

n

Do not charge battery tool in a damp or wet location. Following

this rule will reduce the risk of electric shock.

2

ENGLISH

SPECIFIC SAFETY RULES

n

For best results, your battery tool should be charged in a location where the temperature is more than 0°C but less than 38°C.

To reduce the risk of serious personal injury, do not store outside or in vehicles.

n

Under extreme usage or temperature conditions, battery leakage may occur. If liquid comes in contact with your skin, wash immediately

with soap and water, then neutralise with lemon juice or vinegar. If liquid gets into your eyes, flush them with clean water for at least 0

minutes, and seek immediate medical attention. Following this rule will reduce the risk of serious personal injury.

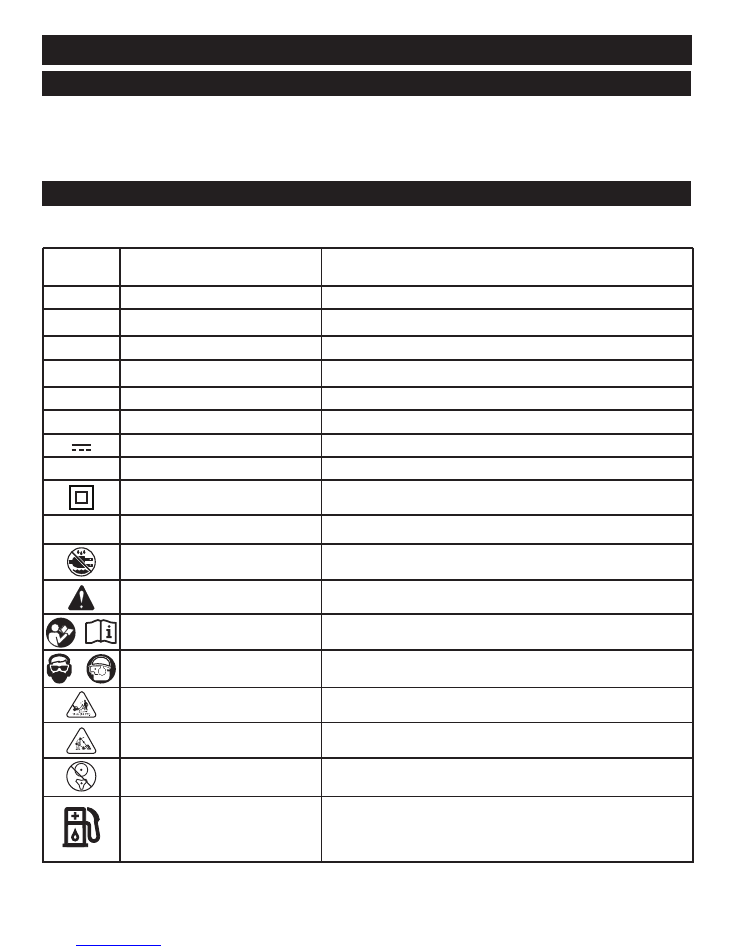

SYMBOLS

SYMBOL

NAME

EXPLANATION

V

Volts

Voltage

A

Amperes

Current

Hz

Hertz

Frequency (cycles per second)

W

Watt

Power

min

Minutes

Time

~

Alternating Current

Type of current

Direct Current

Type or a characteristic of current

n

o

No Load Speed

Rotational speed, at no load

Class II Tool

Double-insulated construction

.../min

Per Minute

Revolutions, strokes, surface speed, orbits etc., per minute

Wet Conditions Alert

Do not expose to rain or use in damp locations.

Safety Alert

Precautions that involve your safety.

Read the Operator’s Manual

To reduce the risk of injury, user must read and understand

operator’s manual before using this product.

Wear Eye and Hearing Protection

Wear eye protection which is marked to comply with ANSI Z87.

as well as hearing protection when operating this equipment.

Keep Bystanders Away

Keep all bystanders at least 50 ft. away.

Ricochet

Thrown objects can ricochet and result in personal injury or

property damage.

No Blade

Do not install or use any type of blade on a product displaying

this symbol.

Petrol and Lubricant

Use unleaded petrol intended for motor vehicle use with

an octane rating of 87 [(R + M) / 2] or higher. This product is

powered by a 2-stroke engine and requires pre-mixing petrol

and 2-stroke lubricant.

Some of the following symbols may be used on this product. Please study them and learn their meaning. Proper interpretation of these

symbols will allow you to operate the product better and safer.

3

ENGLISH

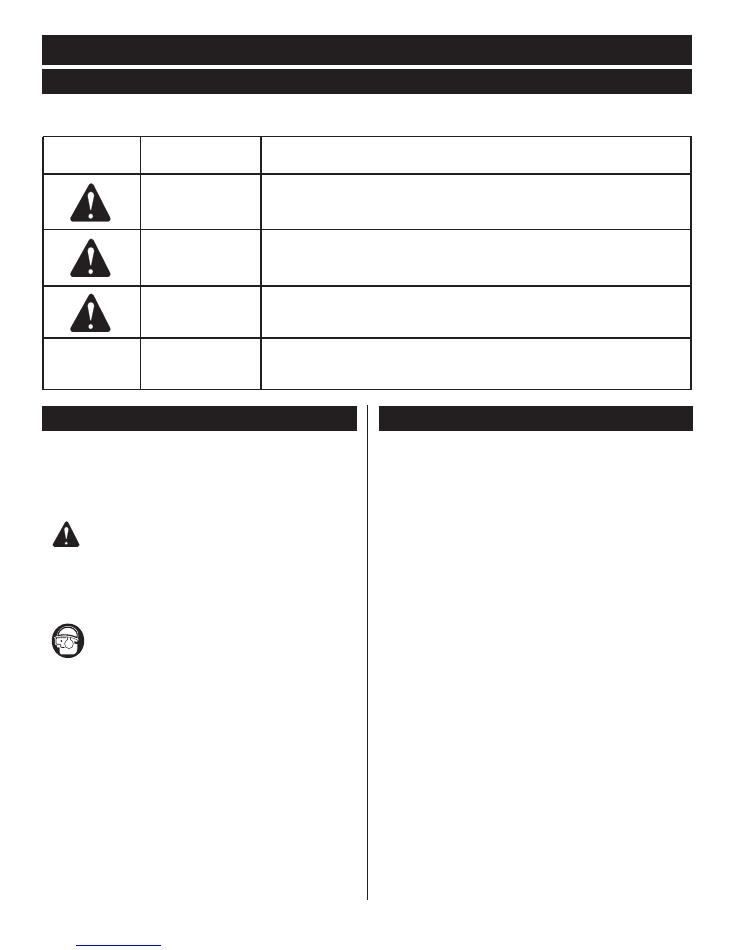

SYMBOLS

SYMBOL

SIGNAL

MEANING

DANGER:

Indicates an imminently hazardous situation, which, if not avoided,

will result in death or serious injury.

WARNING:

Indicates a potentially hazardous situation, which, if not avoided,

could result in death or serious injury.

CAUTION:

Indicates a potentially hazardous situation, which, if not avoided,

may result in minor or moderate injury.

CAUTION:

(Without Safety Alert Symbol) Indicates a situation that may result in property

damage.

The following signal words and meanings are intended to explain the levels of risk associated with this product.

SERVICE

Servicing requires extreme care and knowledge and should be

performed only by a qualified service technician. For service we

suggest you return the product to your nearest AUTHORISED

SERVICE CENTRE for repair. When servicing, use only identical

replacement parts.

WARNING:

To avoid serious personal injury, do not attempt

to use this product until you read thoroughly and

understand completely the operator’s manual. If you

do not understand the warnings and instructions in the

operator’s manual, do not use this product. Call Ryobi

customer service for assistance.

WARNING:

The operation of any power tool can result in foreign

objects being thrown into your eyes, which can result

in severe eye damage. Before beginning power tool

operation, always wear safety goggles or safety glasses

with side shields and, when needed, a full face shield.

We recommend Wide Vision Safety Mask for use over

eyeglasses or standard safety glasses with side shields.

Always use eye protection which is marked to comply

with EN 66 and AS/NZS337 standards.

SAVE THESE INSTRUCTIONS

INTRODUCTION

This product has many features for making its use more pleasant

and enjoyable. Safety, performance, and dependability have been

given top priority in the design of this product making it easy to

maintain and operate.

DESCRIPTION OF FIGURES

Figure

. Shoulder strap

2. Pro Cut II string head

3. Drive shaft

4. Coupler

5. Strap hanger

6. Ignition switch

7. Trigger lock

8. Rear handle

9. Primer bulb

0. Fuel cap

. Recoil starter

2. Throttle trigger

3. 2 Volt battery

4. Front handle

5. Wing screw

6. Grass deflection

7. Reel Easy Cutting head

8. Charger

9. Safety Switch

20. Latch

2. Choke lever

Figure 2

22. Trimmer attachment

23. Button

24. Guide recess

25. Power head shaft

26. Position hole

Figure 3

27. Hole

28. Hanger cap

29. Secondary hole

4

ENGLISH

DESCRIPTION OF FIGURES

Figure 4

30. Washer

3. Wing nut

32. Bolt

Figure 5

33. Slot

34. Tab

35. Wing screw

Figure 6

36. Hanger bracket

Figure 7

37. Red LED

38. Orange LED

Figure 8

39. Battery port

40. Battery

Figure 0

4. Direction of rotation

Figure

42. Dangerous cutting area

43. Best cutting area

44. Direction of rotation

Figure 2

45. Trimmer line cut-off blade

Figure 5a

46. Start position

Figure 5b

47. Run position

Figure 6

48. Drive shaft

49. Cutting head

50. Spool retainer

Figure 7

5. Pull lines from holes to remove

52. Slot

53. Hole

54. Slot

55. Hole

Figure 8

56. Idle speed screw

Figure 9

57. Latch

Figure 20

58. Latch

59. Filter screen

60. Air filter cover

Figure 2

6. Idle speed screw

62. Air filter cover

ASSEMBLY

UNPACKING

This product requires assembly.

n

Carefully remove the tool and any accessories from the box.

Make sure that all items listed in the packing list are included.

n

Inspect the tool carefully to make sure no breakage or damage

occurred during shipping.

n

Do not discard the packing material until you have carefully

inspected and satisfactorily operated the tool.

n

If any parts are damaged or missing do not operate this

product until the parts are replaced.

PACKING LIST

Trimmer Assembly

Pro Cut II

TM

Line Head

Spool Retainer

Shoulder Strap

2 Volt Battery

Charger

Front Handle

Wing Screw

Wing Nut

Bolt

Washer

Grass Deflector

Bottle of 2-Stroke Lubricant

Hanger Cap

Operator’s Manual

WARNING:

Do not attempt to modify this product or create

accessories not recommended for use with this product.

Any such alteration or modification is misuse and could

result in a hazardous condition leading to possible

serious personal injury.

WARNING:

To prevent accidental starting that could cause serious

personal injury, always disconnect the engine spark plug

wire from the spark plug and remove battery pack when

assembling parts.

INSTALLING THE POWER HEAD SHAFT TO THE ATTACHMENT

See Figure 2.

WARNING:

Never install, remove, or adjust any attachment while

power head is running. Failure to stop the engine can

cause serious personal injury.

The attachment connects to the power head shaft by means of a

coupler device.

n

Loosen the Wing Screw on the coupler of the power head shaft

and remove the end cap from the attachment.

n

Push in the button located on the attachment shaft. Align the

button with the guide recess on the power head coupler and slide

the two shafts together. Rotate the attachment shaft until the button

locks into the positioning hole.

NOTE:

If the button does not release completely in the positioning

hole, the shafts are not locked into place. Slightly rotate from side

to side until the button is locked into place.

n

Tighten the Wing Screw securely.

5

ENGLISH

ASSEMBLY

WARNING:

Be certain the Wing Screw is fully tightened before

operating equipment; check it periodically for tightness

during use to avoid serious personal injury.

REMOVING THE ATTACHMENT FROM THE POWER HEAD

For removing or changing the attachment:

n

Loosen the Wing Screw.

n

Push in the button and twist the shafts to remove and separate

ends.

ATTACHING THE HANGER CAP

See Figure 3.

There are two ways to hang your attachment for storage.

n

To use the hanger cap, push in the button and place the hanger

cap over end of the lower end attachment shaft. Slightly rotate

the cap from side to side until the button locks into place.

n

The secondary hole in the attachment shaft can be used for

hanging purposes as well.

ATTACHING THE FRONT HANDLE

See Figure 4.

n

Remove wing nut, washer, and bolt from the front handle.

n

Install the front handle onto the top side of the drive shaft housing.

NOTE:

The open side of the handle should face the operator.

n

Place the bolt through the front handle.

NOTE:

The hex bolt head fits inside the hex recess moulded into

one side of the handle.

n

Reinstall the washer and wing nut.

n

Tighten wing nut securely.

WARNING:

The line cutting blade on the grass deflector is sharp.

Avoid contact with the blade. Failure to avoid contact can

result in serious personal injury.

ATTACHING THE GRASS DEFLECTOR

See Figure 5.

n

Remove the wing screw from the grass deflector.

n

Insert the tab on the mounting bracket in the slot on the grass

deflector.

n

Align the screw hole in the mounting bracket with the screw hole

in the grass deflector.

n

Insert the wing screw through the mounting bracket and into

the grass deflector.

n

Tighten the screw securely.

Attaching the Shoulder Strap

See Figure 6.

Follow these steps to attach the shoulder strap.

n

Connect the latch on the strap to the hanger bracket.

n

Adjust the strap to a comfortable position.

FEATURES

PRODUCT SPECIFICATIONS

Engine Displacement..............................................................30 cm³

Cutting Path Diameter................................................7 in / 432mm.

String Diameter..............................................................2.4/2.7 mm.

Battery Voltage.......................................................................2 Volt

Mass (without fuel, cutting attachment and guard)................6.37 kg

Mass (without fuel with string head)..........................…............6.7kg

Volume (fuel tank)..................................................................45cm³

Maximum engine perform

(in accordance with ISO8893)................................................0.70kw

Maximum rotational frequency of the spindle...................2000/min

Engine speed (rotational frequency) at recommended max.

spindle rotational frequency..............................................2000/min

Engine speed (rotational frequency) at idling............2800-3500/min

Fuel consumption (in accordance with ISO8893)

at max. engine performance..............................0.48kg/h or 0.66 L/h

Specific fuel consumption (in accordance with ISO8893)

at max. engine performance.....................640 g/kw.h or 0.87 L/kw.h

Vibration levels for idling and racing (for idling and with wide open

throttle for grass trimmers) when measured in accordance

with 4.2Vibration level idling for Front handle and

Rear handle.....................................................3.5 m/s² and 3.3 m/s²

Vibration level racing for Front handle and

Rear handle.................................................4.5 m/s² and 0.4 m/s²

Sound pressure level

(in accordance with EN279)........................................00.7 dB (A)

Sound power level

(in accordance with ISO0884)........................................09 dB (A)

KNOW YOUR LINE TRIMMER

See Figure 1.

The safe use of this product requires an understanding of the

information on the tool and in this operator’s manual as well as a

knowledge of the project you are attempting. Before use of this

product, familiarise yourself with all operating features and safety

rules.

CHARGER

The charger has a key-hole hanging feature for convenient, space-

saving storage. Screws should be installed so that the centre

distance is .5cm

ELECTRIC START

The line trimmer has an electric start which can be used in place

of the pull start.

PRO CUT II

TM

LINE HEAD

The line trimmer is provided with an additional cutting head.

GRASS DEFLECTOR

The line trimmer includes a grass deflector that helps protect you

from flying debris.

SHOULDER STRAP

The line trimmer includes a shoulder strap that helps support the

product.

TOP-MOUNTED MOTOR

The top-mounted motor improves balance and is located away

from the dust and debris of the cutting area.

6

ENGLISH

OPERATION

WARNING:

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a second

is sufficient to inflict serious injury.

WARNING:

Always wear safety goggles or safety glasses with

side shields when operating power tools. Failure to do

so could result in objects being thrown into your eyes

resulting in possible serious injury.

WARNING:

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

FUELING AND REFUELING THE TRIMMER

HANDLING THE FUEL SAFELY

WARNING:

Check for fuel leaks. If any are found, correct them

before using the saw to prevent fire or burn injury.

Always handle fuel with care; it is highly flammable.

Always refuel outdoors, do not inhale fuel vapours.

Do not let petrol or lubricant come in contact with skin. If contact

does occur wash immediately with soap and plenty of water.

Keep petrol and lubricant away from the eyes. If petrol or lubricant

comes in contact with the eyes, wash them immediately with clean

water. If irritation is still present, see a doctor immediately.

Clean up spilled fuel immediately. Refer to Refuelling in the

Specific Safety Rules section of this manual for additional safety

information.

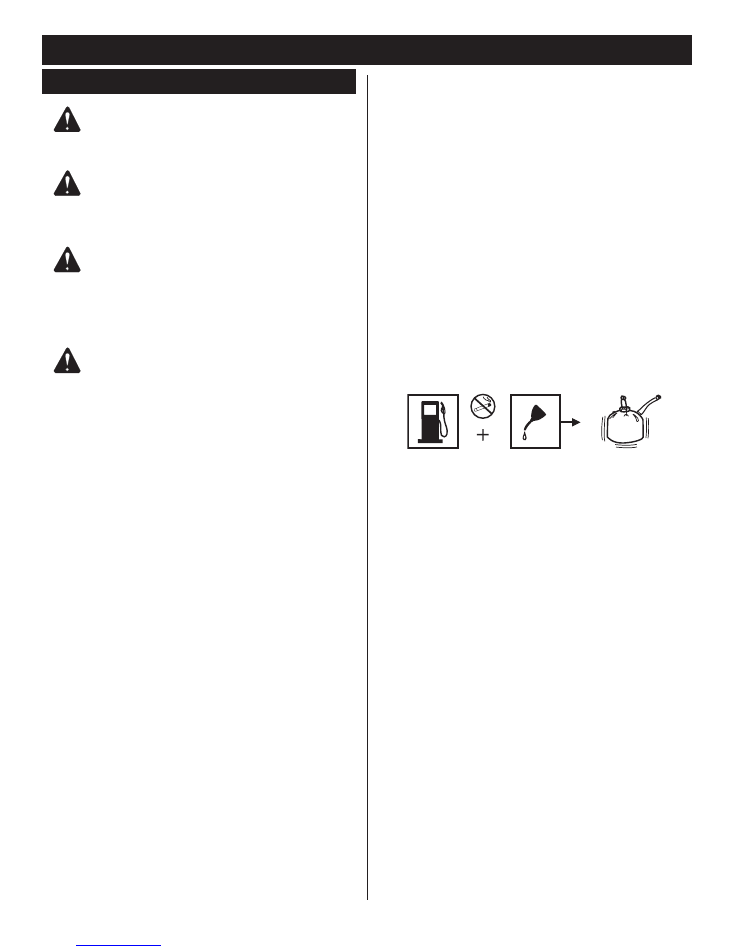

MIXING THE FUEL

This product is powered by a 2-stroke engine and requires pre-

mixing petrol and 2-stroke lubricant. Pre-mix unleaded petrol and

2-stroke engine lubricant in a clean container approved for petrol.

This engine is certified to operate on unleaded petrol intended for

automotive use with an octane rating of 9 or higher.

Do not use any type of pre-mixed petrol/lubricant from fuel service

stations; this includes the pre-mixed petrol/lubricant intended for

use in mopeds, motorcycles, etc.

Use a high quality 2-stroke self-mixing lubricant for air-cooled engines.

Do not use automotive lubricant or 2-stroke outboard lubricant.

Mix 2% lubricant into the petrol. This is a 50: ratio.

Mix the fuel thoroughly and each time before fuelling.

Mix in small quantities. Do not mix quantities larger than usable in

a 30-day period. A 2-stroke lubricant containing a fuel stabilizer is

recommended.

OXYGENATED FUELS

Some conventional petrol are blended with alcohol or an ether

compound. This type of petrol is collectively referred to as

oxygenated fuels.

If using an oxygenated fuel, make sure it is unleaded and meets

the minimum octane rating requirements. Before using an

oxygenated fuel, try to confirm the fuel’s contents. Some areas

require this information to be posted on the pump. The following

are the EPA approved percentages of oxygenates:

Ethanol (ethyl or grain alcohol) 10% by volume.

You may use

petrol containing up to 0% ethanol by volume. Petrol containing

ethanol may be marketed under the name “Gasohol.” Do not use

E85 fuel.

MTBE (methyl tertiary butyl ether) 15% by volume.

You may

use petrol containing up to 5% MTBE by volume.

Methanol (methyl or wood alcohol) 5% by volume.

You may use

petrol containing up to 5% methanol by volume as long as it also

contains co solvents and corrosion inhibitors to protect the fuel

system. Petrol containing more than 5% methanol by volume may

cause starting and/or performance problems. It may also damage

metal, rubber, and plastic parts of the product or your fuel system.

If you notice any undesirable operating symptoms, try another

service station or switch to another brand of Petrol.

NOTE:

Fuel system damage or performance problems resulting

from the use of an oxygenated fuel containing more than the

percentages of oxygenates stated previously are not covered

under warranty.

FILLING THE FUEL TANK

n

Clean the surface around the fuel cap to prevent contamination.

n

Loosen the fuel cap slowly.

n

Carefully pour the fuel mixture into the tank. Avoid spillage.

n

Prior to replacing the fuel cap, clean and inspect the gasket.

n

Immediately replace the fuel cap and hand tighten it. Wipe up

any fuel spillage.

NOTE

: It is normal for the engine to emit smoke during and after

the first use.

litre +

20 ml =

50:

2 litres

+

40 ml

=

50:

3 litres

+

60 ml

=

50:

4 litres

+

80 ml

=

50:

5 litres

+

00 ml

=

50:

CHARGING THE BATTERY PACK

The battery pack for this tool has been shipped in a low charge

condition to prevent possible problems. Therefore, you should

charge overnight prior to use.

NOTE:

Batteries will not reach full charge the first time they are

charged. Allow several cycles (operation followed by recharging)

for them to become fully charged.

n

Charge battery pack only with the charger assembly provided

(BPH-25 / 2V Ni-Cd).

n

Make sure power supply is normal household voltage, 230V/

240V~, 50 Hz.

n

Connect charger to power supply.

n

Place battery pack in charging stand. Align raised rib on battery

pack with groove in charging stand. (See Figure 8.)

n

Press down on battery pack to be sure contacts on battery pack

engage properly with contacts in charging stand.

n

The charge indicator light (LED), located on the charging stand,

will light up red when the charger is properly connected to power

supply. This light indicates the charger is operating properly. It

will remain on until battery pack is removed from charging stand

or charger is disconnected from power supply.

n

After normal usage, 3 hours or less of charging time is required

to fully recharge battery pack.

n

Do not leave the battery pack an charge for more than 3 hours,

any longer than 3 hours will cause permanent damage to the

battery which is not covered by warranty.

}

7

ENGLISH

OPERATION

n

If both red and orange LED indicators glow, the battery pack is

deeply or completely discharged, and 6 hours or longer of

charging time is required to fully recharge battery pack.

NOTE:

If charger does not charge battery pack or orange LED

continues to glow after more than 30 minutes of charging, return

battery pack and charging assembly to your nearest Ryobi

Authorised Service Centre for electrical check.

n

The battery pack will become slightly warm to the touch while

charging. This is normal and does not indicate a problem.

n

Do not place charger in an area of extreme heat or cold. It will

work best at normal room temperature.

n

When batteries become fully charged, unplug charger from

power supply and remove the battery pack.

OPERATING THE TRIMMER

See Figure 9.

WARNING:

Always position the unit on the operator’s right side. The

use of the unit on the operator’s left side will expose the

user to hot surfaces and can result in possible burn injury.

WARNING:

To avoid burns from hot surfaces, never operate unit with

the bottom of the engine above waist level.

Hold the trimmer with your right hand on the rear handle and your

left hand on the front handle. Keep a firm grip with both hands

while in operation. Trimmer should be held at a comfortable

position with the rear handle about hip height.

Always operate trimmer at full throttle. Cut tall grass from the top

down. This will prevent grass from wrapping

around the shaft housing and cutting head which could cause

damage from overheating. If grass becomes

wrapped around the cutting head, STOP THE ENGINE, disconnect

the spark plug lead, and remove the grass.

Prolonged cutting at partial throttle will result in lubricant dripping

from the muffler.

WARNING:

Always hold the line trimmer away from the body keeping

clearance between the body and the product. Any contact

with the housing or line trimmer cutting head can result in

burns and/or other serious personal injury.

TO ADVANCE THE CUTTING LINE - REEL EASY

Line advance is controlled by tapping the cutting head on grass

while running engine at full throttle.

n

Run engine at full throttle.

n

Tap the knob on ground to advance line. The line advances

each time the knob is tapped. Do not hold the knob on the ground.

NOTE:

The line trimming cut-off blade on the grass deflector will

cut the line to the correct length.

NOTE:

If the line is worn too short you may not be able to advance

the line by tapping it on the ground. If so, stop the engine, and

manually advance the line.

TO ADVANCE THE CUTTING LINE MANUALLY:

n

Stop the engine and disconnect the spark plug lead.

n

Push the knob in while pulling on line to manually advance the

line.

CUTTING TIPS

See Figures 9 - .

n

Avoid hot surfaces by always keeping the tool away from your

body. (Proper operating position shown in figure 9.)

n

Keep the trimmer tilted toward the area being cut; this is the

best cutting area.

n

The trimmer cuts when passing the unit from left to right. This

will avoid throwing debris at the operator. Avoid cutting in the

dangerous area shown in illustration.

n

Use the tip of line to do the cutting; do not force cutting head into

uncut grass.

n

Wire and picket fences cause extra line wear, even breakage.

Stone and brick walls, curbs, and wood may wear line rapidly.

n

Avoid trees and shrubs. Tree bark, wood mouldings, siding,

and fence posts can easily be damaged by the line.

LINE TRIMMING CUT-OFF BLADE

See Figure 2.

The trimmer is equipped with a line trimming cut-off blade on the

grass deflector. For best cutting, advance line until it is trimmed to

length by the cut-off blade. Advance the line whenever you hear

the engine running faster than normal, or when trimming efficiency

diminishes. This will maintain best performance and keep the line

long.

STARTING AND STOPPING

See Figures 3 - 5.

When starting the line trimmer for the first time or when the battery

voltage is low, it may be necessary to manually start the line

trimmer.

FOR MANUAL START:

To start a cold engine:

DO NOT

squeeze the throttle trigger until the engine starts and

runs.

n

Lay the trimmer on a flat, level surface.

n

PRIME -

Press the primer bulb at least 7 times, so fuel is

clearly visible.

n

SET

the start lever to the

START

position.

n

Ensure the ‘Ignition switch’ (item 6) is in the centre position.

n

PULL

the recoil starter until the engine starts.

n

Wait 6-0 seconds, then gently squeeze the trigger to run.

NOTE:

Squeezing and releasing the throttle trigger releases the

start lever to the RUN position.

To start a warm engine:

n

Make sure the ‘ignition switch’ is in the centre position.

n

PULL

the recoil starter until the engine starts.

To stop the engine:

n

Press the ‘ignition switch’ (item 6) to the stop “ O ” position and

the engine will stop.

FOR ELECTRIC START:

MAKE SURE THE BATTERY HAS BEEN FULLY CHARGED -

SEE CHARGING BATTERY

To start a cold engine:

n

DO NOT

squeeze the throttle trigger until the engine starts and

runs.

n

Install the battery onto the unit as shown in figure 8.

n

Lay the trimmer on a flat, level surface.

n

PRIME -

Press the primer bulb at least 7 times, so fuel is clearly

visible.

n

SET

the start lever (item 2) to the

START

position on the side

of the carburettor.

n

PRESS

the ‘safety switch’ (item 9) and the ‘ignition switch’ to

position 3 (item 6) at the same time.

8

ENGLISH

OPERATION

n

N.B. The safety switch is a rocker type switch and will

automatically reset it’s self once released.

n

N.B. The ignition switch is a 3 position switch. position 1

is ‘off’ position 2 is run, and position 3 is a rocker type switch

which will automatically reset it’s self to position 2 once

released.

n

RELEASE

the 2 switches after engine starts - they will revert

back to their resting place.

n

Wait 6-0 seconds, then squeeze the throttle trigger to run.

NOTE:

Squeezing and releasing the throttle trigger releases the

start lever to the

RUN

position.

To start a warm engine:

n

Lay the trimmer on a flat, bare surface.

n

PRESS

the ‘safety switch’ (item 9) and the ‘ignition switch’

(Item 6) at the same time.

n

RELEASE

the 2 switches after engine starts - they will revert

back to their resting place.

MAINTENANCE

WARNING:

When servicing, use only identical replacement parts.

Use of any other parts may create a hazard or cause

product damage.

WARNING:

Always wear safety goggles or safety glasses with side

shields during tool operation. If operation is dusty, also

wear a dust mask.

WARNING:

Before inspecting, cleaning, or servicing the machine,

shut off engine, wait for all moving parts to stop, and

disconnect spark plug lead and move it away from spark

plug. Failure to follow these instructions can result in

serious personal injury or property damage.

GENERAL MAINTENANCE

Avoid using solvents when cleaning plastic parts. Most plastics are

susceptible to damage from various types of commercial solvents

and may be damaged by their use. Use clean cloths to remove dirt,

dust, lubricant, grease.

WARNING:

Do not at any time let brake fluids, petrol, petroleum-

based products, penetrating lubricants, etc., come in

contact with plastic parts. Chemicals can damage,

weaken or destroy plastic which may result in serious

personal injury.

You can often make adjustments and repairs described here. For

other repairs, have the trimmer serviced by an authorised service

dealer.

INSTALLING PRO CUT II

TM

LINE HEAD

See Figure 6.

n

Stop the engine and disconnect the spark plug wire.

n

Remove currently installed line head.

n

Install the line head on the drive shaft until fully seated.

n

Install the spool retainer and turn counter clockwise.

n

Install cutting line as described in the next section of this manual.

INSTALLING CUTTING LINE IN PRO CUT II

TM

LINE HEAD

See Figure 7.

Use monofilament line diameter 2.4mm or 2.7mm. Use original

manufacturer’s replacement line for best performance.

n

Stop the engine and disconnect the spark plug lead.

n

Gather two of the pre-cut lengths of trimmer line provided or

cut two pieces of trimmer line, in 28cm lengths.

n

Insert the line into the slots located on the sides of the line head.

Line should be pushed in until approximately 2.5cm protrudes

from the holes on the top of the line head.

n

Remove old line by pulling it from the holes located on the top

of the line head.

CLEANING THE EXHAUST PORT, MUFFLER AND SPARK

ARRESTOR

NOTE:

Depending on the type of fuel used, the type and amount

of lubricant used, and/or your operating conditions, the exhaust

port, muffler, and/or spark arrestor screen may become blocked

with carbon deposits. If you notice a power loss with your petrol

powered tool, you may need to remove these deposits to restore

performance. We highly recommend that only qualified service

technicians perform this service.

The spark arrestor must be cleaned or replaced every 50 hours

or yearly to ensure proper performance of your product. Spark

arrestors may be in different locations depending on the model

purchased. Please contact your nearest service dealer for the

location of the spark arrestor for your model.

IDLE SPEED ADJUSTMENT

See Figure 8.

If the cutting attachment turns at idle, the idle speed screw needs

adjusting on the engine. Turn the idle speed screw counter

clockwise to reduce the idle RPM and stop the cutting attachment

movement. If the cutting attachment still moves at idle speed,

contact a service dealer for adjustment and discontinue use until

the repair is made.

WARNING:

The cutting attachment should never turn at idle. Turn

the idle speed screw counter clockwise to reduce the

idle RPM and stop the cutting attachment, or contact a

service dealer for adjustment and discontinue use until

the repair is made. Serious personal injury may result

from the cutting attachment turning at idle.

CLEANING AIR FILTER SCREEN

See Figures 9 - 20.

For proper performance and long life, keep air filter screen clean.

n

Remove the air filter cover by pushing down on the latch with

your thumb while gently pulling on the cover.

n

Brush the air filter screen lightly to clean.

n

Replace the air filter cover by inserting the tabs on the bottom

of the cover into the slots on the air filter base; push the cover

up until it latches securely in place.

FUEL CAP

WARNING:

A leaking fuel cap is a fire hazard and must be replaced

immediately.

The fuel cap contains a non-serviceable filter and a check valve.

A clogged fuel filter will cause poor engine performance. If

performance improves when the fuel cap is loosened, check valve

may be faulty or filter clogged. Replace fuel cap if required.

9

ENGLISH

SPARK PLUG REPLACEMENT

This engine uses a Champion RCJ-6Y or NGK BPMR7A spark plug with .025 in.(6.35mm) electrode gap. Use an exact replacement and

replace annually.

STORING THE PRODUCT

n

Clean all foreign material from the product. Store idle unit indoors in a dry, well-ventilated area that is inaccessible to children.

Keep away from corrosive agents such as garden chemicals.

When storing 1 month or longer:

n

Drain all fuel from tank into a container approved for petrol. Run engine until it stops.

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Engine will not start

. No spark.

. Clean or replace spark plug. Reset spark plug gap. Refer to Spark

Plug Replacement earlier in this manual.

2. No fuel.

2. Push primer bulb until bulb is full of fuel. If bulb does not fill, primary

fuel delivery system is blocked. Contact a service dealer. If primer

bulb fills, engine may be flooded, proceed to next item.

3. Engine is flooded.

3. Set the start lever to the START position. Squeeze the trigger and

pull the rope repeatedly until the engine starts and runs.

NOTE:

Depending on the severity of the flooding, this may require

numerous pulls of the rope.

Engine does not reach full

. Incorrect lubricant/fuel mixture. . Use fresh fuel and the correct 2- stroke lubricant mix. (50:).

speed and emits excessive

2. Air filter screen is dirty.

2. Clean air filter screen.

smoke

Refer to Cleaning Air Filter Screen earlier in this manual.

3. Spark arrestor screen is dirty.

3. Contact a servicing dealer.

4. Spark plug fouled.

4. Clean or replace spark plug. Reset spark plug gap. Refer to Spark

Plug Replacement earlier in this manual.

Engine starts, runs, and

Idle speed screw on carburettor

Turn idle speed screw clockwise to increase idle speed. accelerates

but will not idle

needs adjustment.

See Figure 2.

Line will not advance

. Line is welded to itself.

. Lubricate line with silicone spray.

2. Not enough line on spool.

2. Install more line. Refer to the applicable line replacement

section in this manual.

3. Line is worn too short.

3. Pull line while alternately pressing down on and releasing spool

retainer.

4. Line is tangled on spool.

4. Remove line from spool and rewind.

Refer to the applicable line replacement section in this manual.

5. Engine speed is too slow.

5. Advance string at full throttle.

Spool retainer hard to turn

Screw threads are dirty or

Clean threads and lubricate with grease - if no improvement, replace

damaged.

the spool retainer.

Grass wraps around

. Cutting tall grass at ground

. Cut tall grass from the top down to prevent wrapping.

driveshaft housing and

level.

cutting head

2. Operating trimmer at part

2. Operate trimmer at full throttle.

throttle.

IF THESE SOLUTIONS DO NOT SOLVE THE PROBLEM CONTACT YOUR AUTHORISED SERVICE DEALER.

MAINTENANCE

CALL US FIRST

For any questions about operating or maintaining your product, call the Ryobi® Help Line!

Your product has been fully tested prior to shipment to ensure your complete satisfaction.

LIMITED WARRANTY

TTI warrants this outdoor product to be free of defects in material or workmanship for 24 months from the date of

purchase by the original purchaser, subject to the limitations below. Please keep your invoice as proof of date of

purchase.

This warranty is only applicable where the product is used for personal and non-commercial purposes.

This

warranty does not cover damage or liability caused by / due to misuse, abuse, accidental or intentional acts by user,

improper handling, unreasonable use, negligence, failure by end user to follow operating procedures outlined in the

user’s manual, attempted repair by non-qualified professional, unauthorized repair, modification, or use of accessories

and/or attachments not specifically recommended by authorized party.

This warranty does not cover belts, brushes, bags, bulbs or any part which ordinary wear and tear results in required

replacement during warranty period. Unless specifically provided under applicable law, this warranty does not cover

transportation cost or consumable items such as fuses.

This limited warranty is void if the product’s original identification (trade mark, serial number, etc.) markings have been

defaced, altered or removed or if product is not purchased from an authorized reseller or if product is sold AS IS and /

or WITH ALL FAULTS.

Subject to all applicable local regulations, the provisions of this limited warranty are in lieu of any other written warranty,

whether express or implied, written or oral, including any warranty of MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE. IN NO EVENT SHALL WE BE LIABLE FOR SPECIAL, INCIDENTAL, CONSEQUENTIAL

OR INCIDENTAL DAMAGES. OUR MAXIMUM LIABILITY SHALL NOT EXCEED THE ACTUAL PURCHASE PRICE

PAID BY YOU FOR THE PRODUCT.

This warranty is valid only in the European Union, Australia and New Zealand. Outside these areas, please

contact your authorized Ryobi dealer to determine if another warranty applies.

CE DECLARATION OF CONFORMITY

We declare in sole responsibility that the product: - to which this certificate applies, conforms to the basic health and

safety requirements of the Machinery Directive 98/37/EC and other relevant directives, like EMC Directive 2004/08/

EC, Noise Emission Directive 2000/4/EC amended by 2005/88/EC, Battery Directive 2006/66/EC and Gas Emission

Directive 97/68/EC amended by 2004/26/EC.

To effect correct application of the health and safety requirements stated in the EEC directives, the following European

and/or national standards and/or technical specifications were consulted: ISO 806:997 / ISO 22868:2005 / ISO

22867:2004 / EN ISO4982:998.

We declare this product complies to the requirements of the Directive. 2000/4/EC, amended by 2005/88/EC.

RLT30CET

Measured Sound Power Level

07.6 dB (A)

Guaranteed Sound Power Level

09 dB (A)

Date of issuance

09 / 2008

Technical documents are kept by Homelite Far East Co., Ltd. 24/F, 388 Castle Peak Road, Tsuen Wan, N.T., Hong

Kong.

Declared in May 2008 by Homelite Far East Co., Ltd.

Machine:

ELECTRIC START CURVED LINE TRIMMER

Name of company: Homelite Far East Co., Ltd.

Address:

24/F, CDW Building,

388 Castle Peak Road,

Tsuen Wan, Hong Kong.

Type: RLT30CET

Name/Title: Andrew Eyre

Vice President, Engineering

Signature:

RYOBI TECHNOLOGIES (UK) LIMITED.

Medina House,

Fieldhouse Lane, Marlow,

Buckinghamshire,

SL7 TB,

UNITED KINGDOM

Tel: + 44 (0) 628 894400

Fax: + 44 (0) 628 89440

Technical Helpline : + 44 (0) 800 389 0305

RYOBI TECHNOLOGIES SAS

Immeuble Le Grand Roissy

Z.A. du Gué - 35 rue de Guivry

77990 LE MESNIL AMELOT FRANCE

Phone: + 33(0) 60 94 69 70

Fax: + 33(0) 60 94 69 79

RYOBI BELGIUM

Avenue des Pâquerettes, 55

Zoning artisanal - bâtiment 5

B - 40 Waterloo

BELGIQUE

Tel : + 32(0) 2357 840

Fax : + 32(0) 2357 849

RYOBI ITALIA

Via Vincenzo Borelli, 3

I - 400 Modena

ITALIA

Tel : + 39(0) 5923 8408

Fax : + 39(0) 5924 6960

RYOBI IBÉRICA

Avenidad de la Industria 52

28820 Coslada - Madrid

ESPANA

Tel : + 34(0) 9 627 93 26

Fax : + 34(0) 9 627 93 29

TECHTRONIC INDUSTRIES (ASIA) CO., LTD.

24/F, CDW Building,

388 Castle Peak Road,

Tsuen Wan, Hong Kong.

Tel : + 852 2402 6888

RYOBI TECHNOLOGIES GMBH

Itterpark 4

D-40724 Hilden

DEUTSCHLAND

Tel: + 49 (0) 203 2958-0

Fax: + 49 (0) 203 2958-29

RYOBI TECHNOLOGIES GMBH

Vertriebsbüro Österreich

Schinitzgasse 3

A-8605 Kapfenberg

Tel.: + 43 (0) 3862 23590-0

Fax: + 43 (0) 3862 23590-25

TECHTRONIC INDUSTRIES AUSTRALIA PTY LIMITED.

Building B, Rosehill Industrial Estate,

3 Shirley Street,

Rosehill NSW 242

AUSTRALIA

Tel: (02) 8892 800 or 300 36 505

Fax: 800 807 993

TECHTRONIC INDUSTRIES (NZ) LIMITED.

27 Clemow Drive, Mt Wellington

PO Box 2-806, Penrose, Auckland

NEW ZEALAND

Tel: + 64 (0) 9 573 0230

Free Call: +64 0800 279 624

Fax: + 64 (0) 9 573 023

A&M MIDDLE EAST FZCO

P.O.Box 6254

Jedel Ali, Dubai,

UNITED ARAB EMIRATES

Tel.: + 974 886399

Fax: + 974 886400

TECHTRONIC INDUSTRIES NORDIC

Stamholmen 47, 4. DK-2650 Hvidovre

DENMARK

Tel.: (+45) 43 56 55 55

Fax: (+45) 43 56 55 56

09/2008