Full Text Searchable PDF User Manual

Dosing system

Commissioning and

maintenance manual

eco-PEN450

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

3 / 15

Contents

1

This manual

5

2

The dispenser

5

3

Safety

5

4

Starting up for the first time

6

4.1 Inserting the stator

6

4.1.1 Connecting the dosing unit to the drive unit

7

4.1.2 Supply and bleed the medium.

7

5

Connection options

9

6

Cleaning

10

7

Spare parts

11

8

Maintenance

12

8.1 Changing the stator

12

8.2 Troubleshooting

12

9

Disposal

12

10

Technical specifications

13

eco-PEN450

Commissioning and maintenance manual

4 / 15

Version 1.8

Copyright ©

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

5 / 15

1

This manual

Dear customer,

This manual forms part of the operating and maintenance manual for the dosing system

eco-CONTROL EC200. The operating and maintenance manual must have been read

and understood in full before commissioning or carrying out maintenance work on the

eco-PEN450.

2

The dispenser

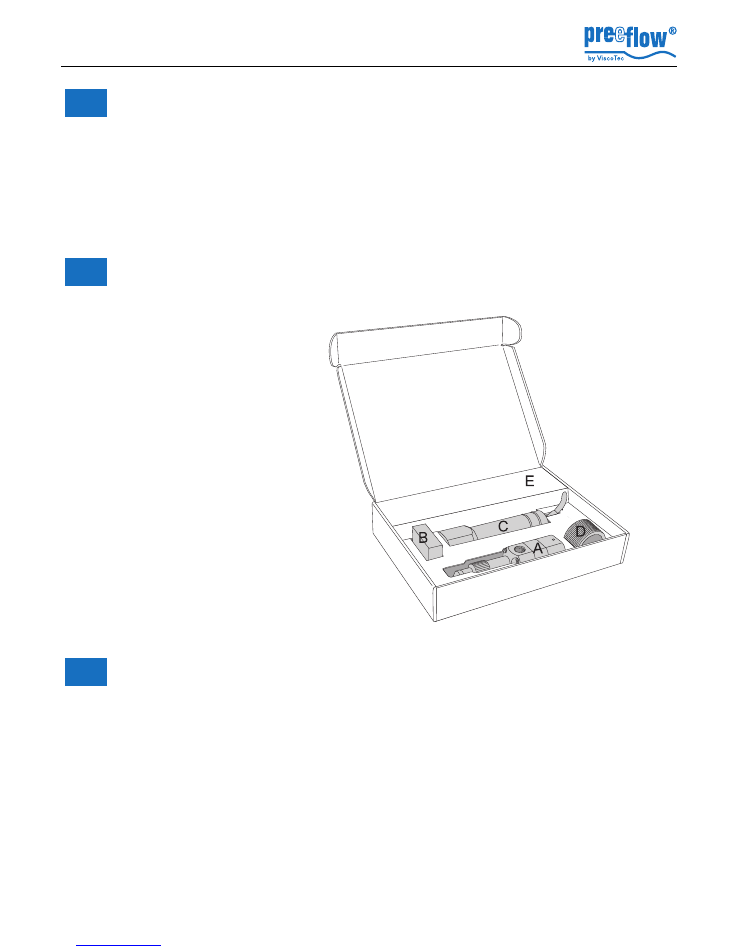

The dispenser is supplied with these components and accessories:

3

Safety

All instructions in the Safety section of the maintenance and operating manual for the

dosing system must be complied with and implemented.

fig. 1

A

Dosing unit

B

Stator

C

Drive unit

D

Assembly aid

E

Installation tool

(2 Allen wrenches)

F

Spraying device (without fig.)

eco-PEN450

Commissioning and maintenance manual

6 / 15

Version 1.8

Copyright ©

4

Starting up for the first time

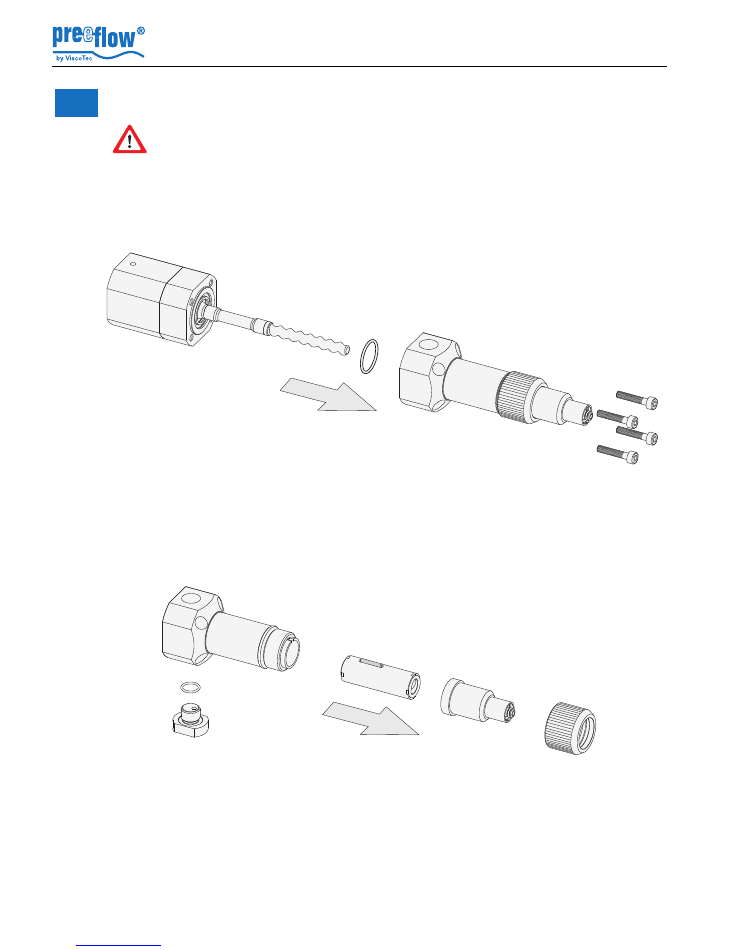

4.1

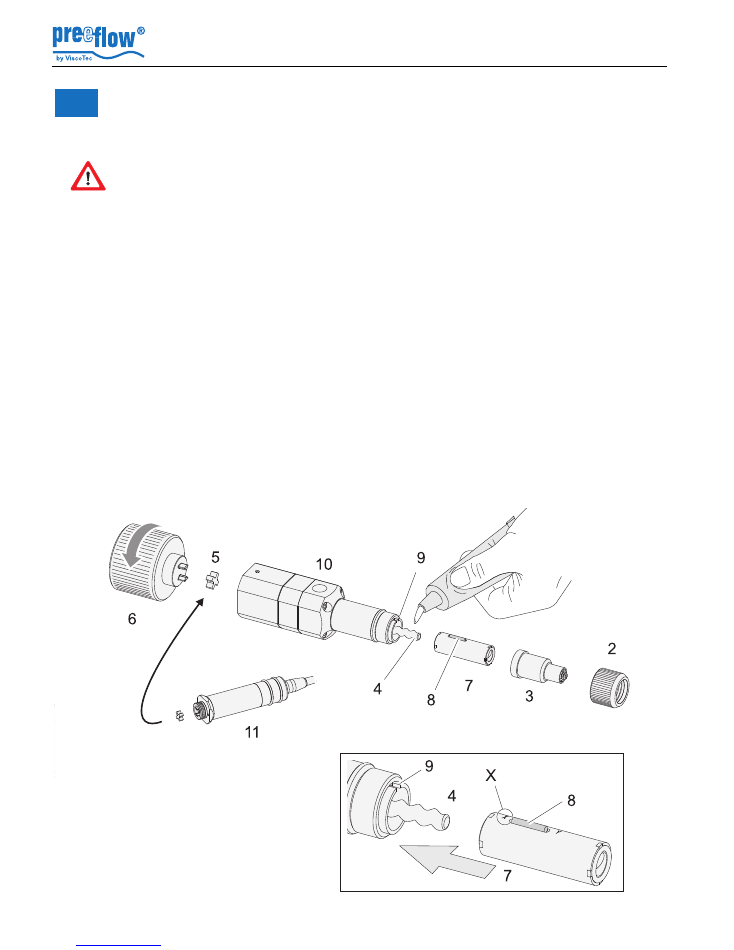

Inserting the stator

Preparation

: Unplug the power supply to the drive unit.

1. Undo the union ring (2).

2. Pull off the end piece (3).

3. Couple the assembly aid (6) to the dispenser housing (10)

(the star-shaped coupling (5) must be attached to the dispenser housing).

4. Wet the rotor (4) with the medium or a suitable lubricant.

5. Turn the stator (7) (on the bearing side, see Fig. A) on the rotor (4) until the dowel pin

begins to dip into the keyway (9).

6. Lightly press the stator in the direction of the dispenser housing (10) and turn the

assembly aid in the direction of the arrow until the stator has been guided into the

dispenser housing.

7. Uncouple the assembly aid, install the end piece and the union ring, and put in place

the required Luer-Lock needle.

Dispenser

Do not switch on

until medium has been delivered to it. Otherwise there is a

risk of

damage to the equipment. Even a brief period of dry running can lead to the

stator being destroyed.

Fig. A

Medium

fig. 2

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

7 / 15

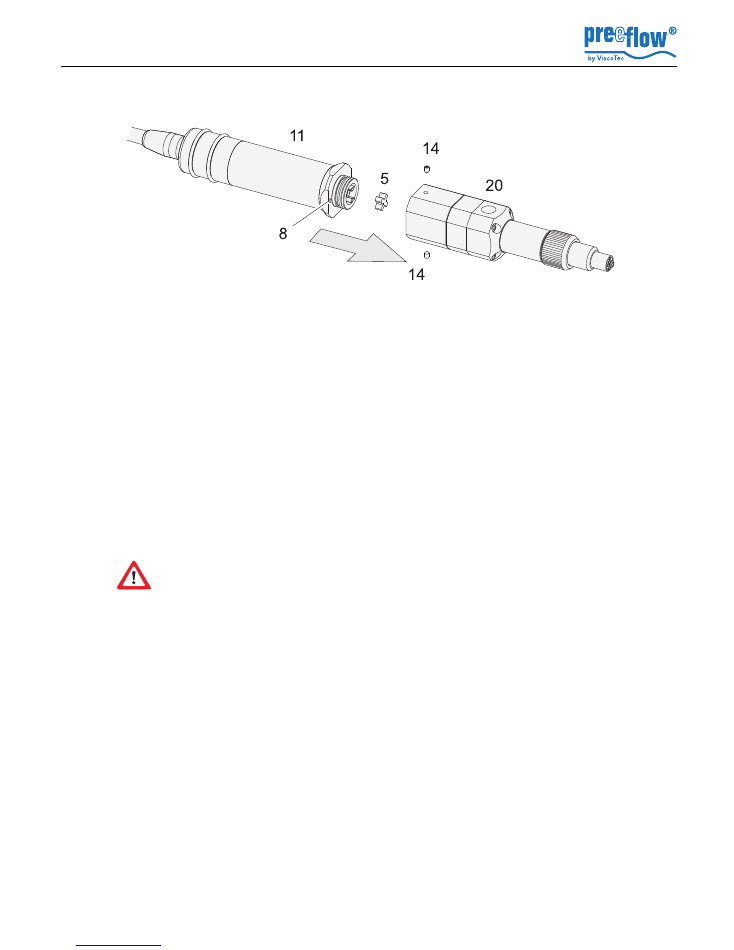

4.1.1 Connecting the dosing unit to the drive unit

1. Turn the set screws (14) in the thread such that they do not protrude into the coupling

area.

Danger of damage to the fit

.

2. Attach the star-shaped coupling (5) onto the coupling of the drive unit( 11).

3. Couple the drive unit (11) to the dosing unit (20) until there is a gap <1 mm between

the anti-rotation lock (8) and the dosing unit (20).

4. Set the anti-rotation lock (8) correctly in place by rotating the dosing unit (20).

5. Bring the drive unit (11) and the dosing (20) together completely.

6. Lightly turn the set screws (14), the drive unit (11) has now been centred properly.

4.1.2 Supply and bleed the medium.

• Connect the tank (supply line, cartridge) of the medium to the dispenser medium input

(12). (See section

10, Technical specifications,

, page

13

for details of the thread)

The Dispenser can be bled in one of two ways after the medium has been supplied.

Follow the safety stipulations and instructions of the manufacturer of the medium

to be used to fill the unit. If applicable, use the required protective equipment. If

the medium is being conveyed for the first time, there is a

danger

from

medium

spurting out

. Air bubbles can cause uncontrollable spurting out. Ensure that you stand

back a safe distance.

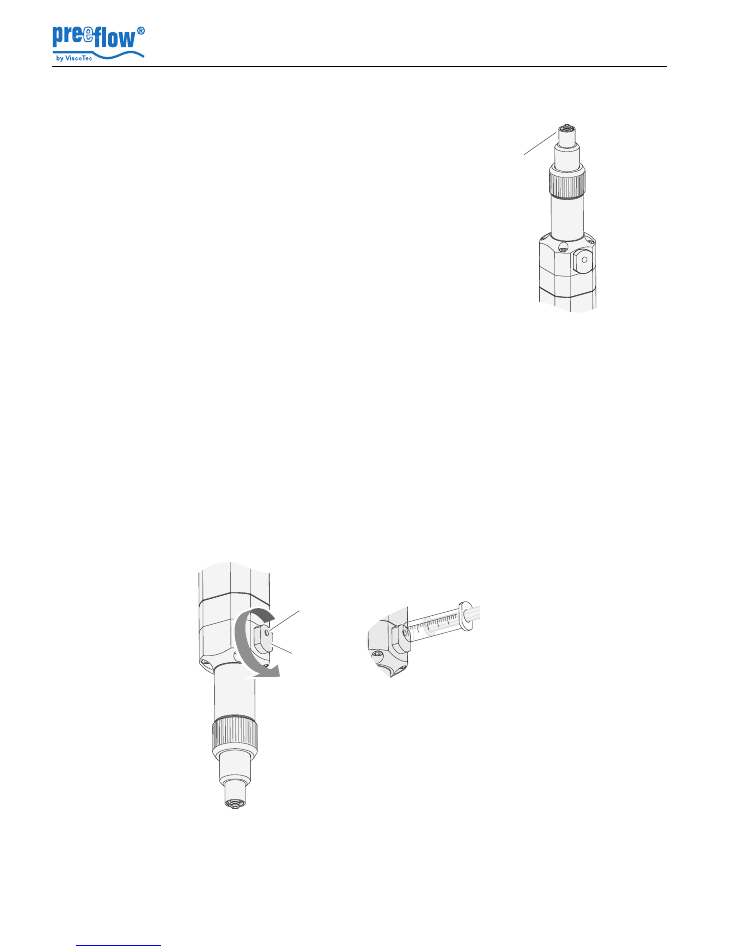

fig. 3

eco-PEN450

Commissioning and maintenance manual

8 / 15

Version 1.8

Copyright ©

Version B

(e.g. open cartridge, Dispenser fixed in place and supply of the medium under pressure)

• Turn the bleed screw (23) 180 degrees so that the bleed hole is in the position shown

(direction of the drive unit).

• wait until the medium emerges from the bleed hole free from air bubbles.

• Release (remove) the primary pressure on the medium and wait until no more medium

comes out of the bleed opening.

• Remove the ejected medium and close the bleed screw (23) again.

Connect the Dispenser to the power supply and convey the medium until there are no

more air bubbles in it and the outlet nozzle (with the Luer-Lock needle) comes out.

Alternatively, the air can also be extracted from the pump area with the syringe (9)

included in the scope of supply.

Version A

(e.g. supply via a hose, closed cartridge)

• Dispenser bring it into a position in which the end piece

(3) points upwards.

• Dispenser connect the unit to the power supply and

convey the medium until there are no more air bubbles

in it and the outlet nozzle (with the Luer-Lock needle)

comes out.

Tip

: Connecting a hose can protect the Dispenser from

being wetted with the medium.

3

fig. 4

23

8

9

fig. 5

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

9 / 15

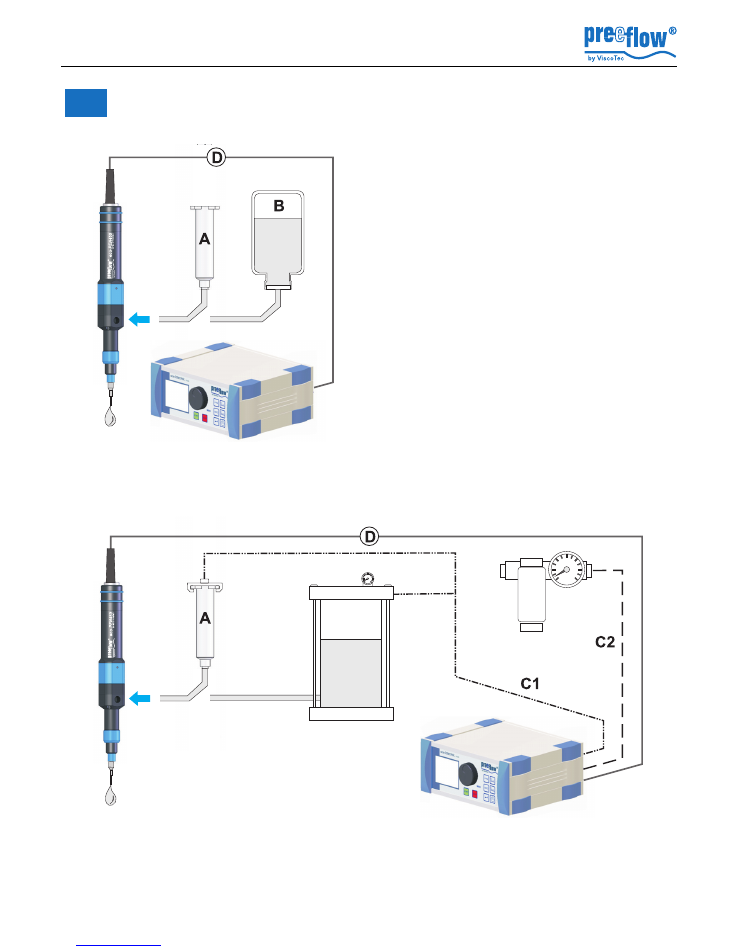

5

Connection options

Self-levelling liquid, low viscosity medium

Supply of the medium from a cartridge (A) or a

bottle (B).

D Power supply drive unit

Note

: Select the size of the hose to be such that

the liquid comes out by gravity and without any

air bubbles at the Dispenser.

Self-suction is possible.

Not a self-levelling liquid, medium/high viscosity medium

1. Cartridge (A) supplied with compressed air (C1), connected to the Dispenser.

2. Medium supply from the pressure tank (C).

fig. 6

C1

Compressed air, 0-6 bar,

regulated

C2

Compressed air, 7 bar, dry,

cleaned, oil-free

D

Power supply drive unit

fig. 7

eco-PEN450

Commissioning and maintenance manual

10 / 15

Version 1.8

Copyright ©

6

Cleaning

Preparation

:

Remove the dosing needle,

danger of injury!

Disconnect the power supply of the drive unit and uncouple it from the dosing unit (in the

reverse order to that described in

4.1.1, Connecting the dosing unit to the drive unit,

page

7

).

1. Undo the screws (18) and pull out the front dispenser housing (19) with the O-ring (22)

from the module (15) while turning it slightly.

2. Undo the union ring (2).

3. Pull off the end piece (3).

4. Pull the stator (7) out of the front dispenser housing (19).

5. Undo the bleed screw (23) and the washer (24).

6. Clean all the parts.

Assembly:

1. Attach the dispenser housing (19) with the O-ring (22) to the module (15) with the

screws (18) (do not exceed a tightening torque of 0.35 Nm).

2. Install the stator in accordance with work steps 4. to 7. described in section

4.1,

Inserting the stator,

page

6

.

3. Connect the dosing unit to the drive unit (see

4.1.1

, page

7

).

18

22

15

19

Note

: Do

not

rinse out the rotor

housing (15), because that could

damage the bearings! Clean it

with a cloth and brush.

fig. 8

23

24

3

2

19

7

fig. 9

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

11 / 15

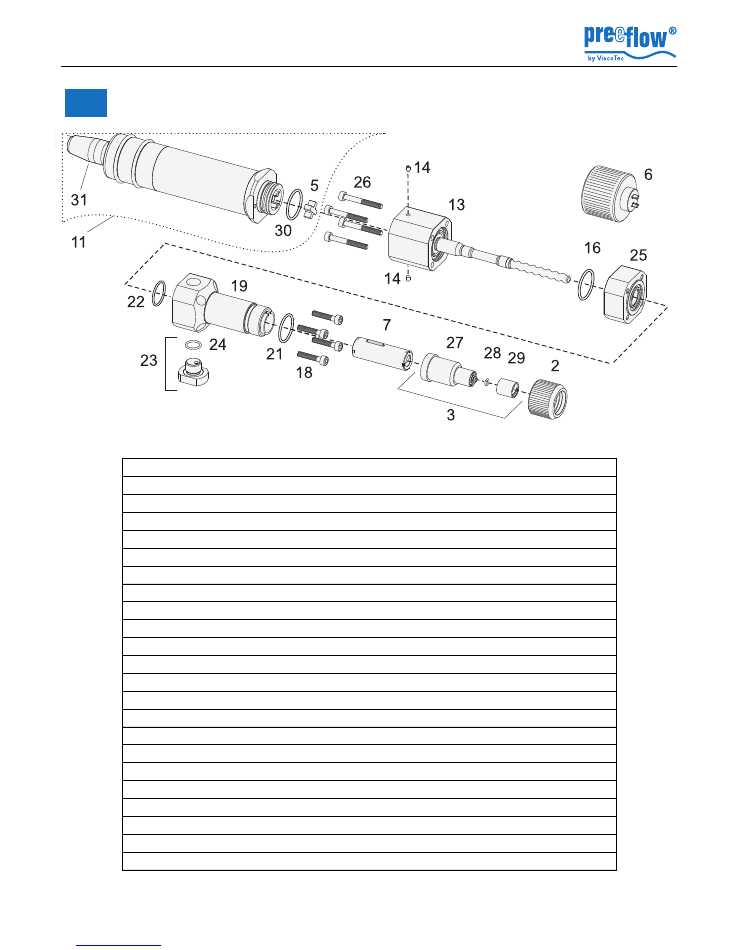

7

Spare parts

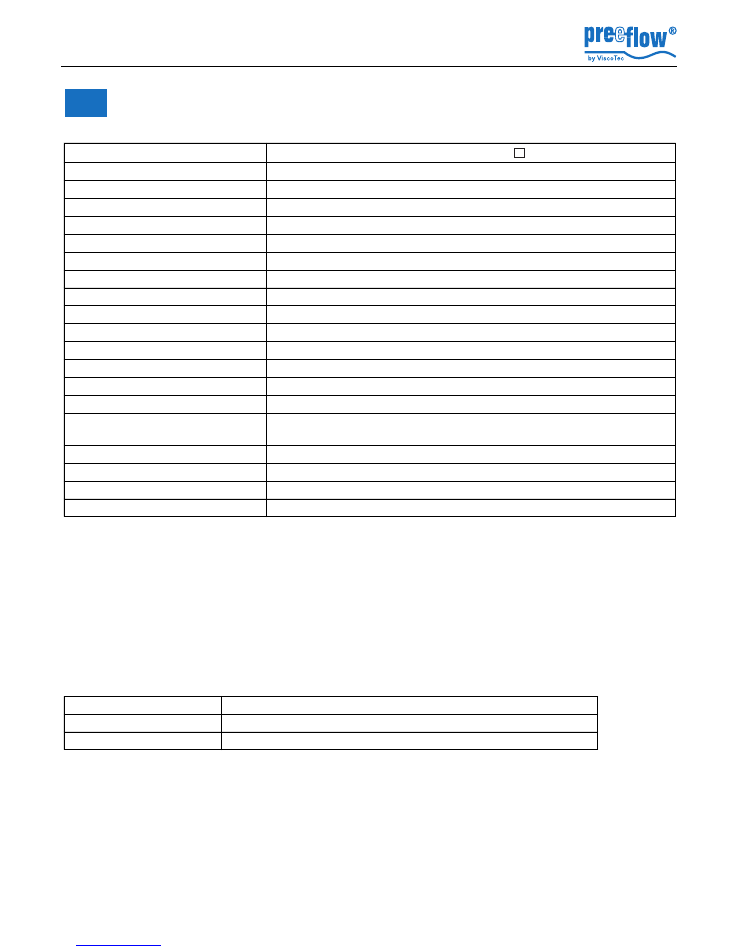

Item Part No. x Item name

Material

20091

Dosing unit eco-PEN450 cpl. (without 11)

2

20085

Union ring eco-PEN450

Aluminium

3

20075

End piece eco-PEN450 with Luer-Lock cpl.

POM

5

20050 x Star-shaped coupling

Elastomer

6

20108

Assembly aid

Aluminium

7

20001 x Stator cpl. eco-PEN450

VisChem

11

20081 x Drive unit eco-PEN450 cpl.

13

20149

Bearing housing with rotor set cpl.

14

20088

Set screw

A2

16

20007 x O-ring Ø 16

FKM

18

20089

Allen screw

A2

19

20083

Dispenser housing eco-PEN450

POM

21

20084 x O-ring Ø 15

FKM

22

20011 x O-ring Ø 13

FKM

23

20510

Bleed screw cpl.

POM

24

20513

O-ring

FKM

25

20148

Seal set with housing

26

20090

Allen screw

A2

27

20076

End piece eco-PEN450 with Luer-Lock

POM

28

20035 x O-ring

FKM

29

20021

Threaded sleeve Luer-Lock

Aluminium

30

20041 x O-ring Ø 17

NBR

31

20784

motor cable eco-PEN cpl.

x = recommended spare parts ad wearing parts

fig. 10

eco-PEN450

Commissioning and maintenance manual

12 / 15

Version 1.8

Copyright ©

8

Maintenance

8.1

Changing the stator

• Remove the defective stator (see section

6, Cleaning,

page

10

)

• Install the new stator (see "Assembly" in section

6, Cleaning,

page

10

)

8.2

Troubleshooting

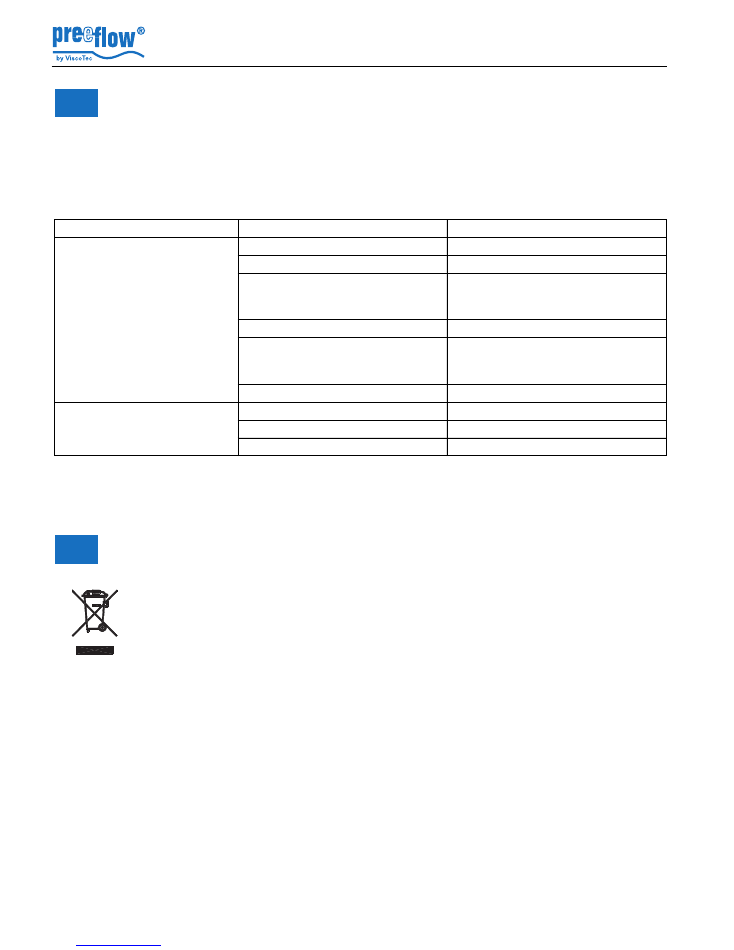

9

Disposal

Error

Possible cause

Correction

No or too little

medium conveyed

Needle blocked

Clean / replace the needle

Medium hardened

Dispenser clean

Needle too small or too long

Use a different needle cross-

section. Reduce the speed / flow

rate.

Stator swollen

Replace the stator

Inadequate supply of medium

Supply the medium, check the

hose, check the primary pressure

and increase it if necessary.

Motor not connected

Connect the motor

Dripping / running on of the

medium

Sucking back not set correctly

Set the sucking back

Air bubbles in the medium

Bleed the medium

Medium compressible

Degas the medium

The final disposal of the Dispenser is to be done in an environmentally-appropriate

way. All the materials and packaging must be handled in accordance with the

recycling stipulations.

Do not dispose of electrical parts in the household garbage. They are to be taken

to the appropriate collecting points. 2002/96/EU(WEEE)* EU DIRECTIVE

concerning used electrical and electronic equipment

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

13 / 15

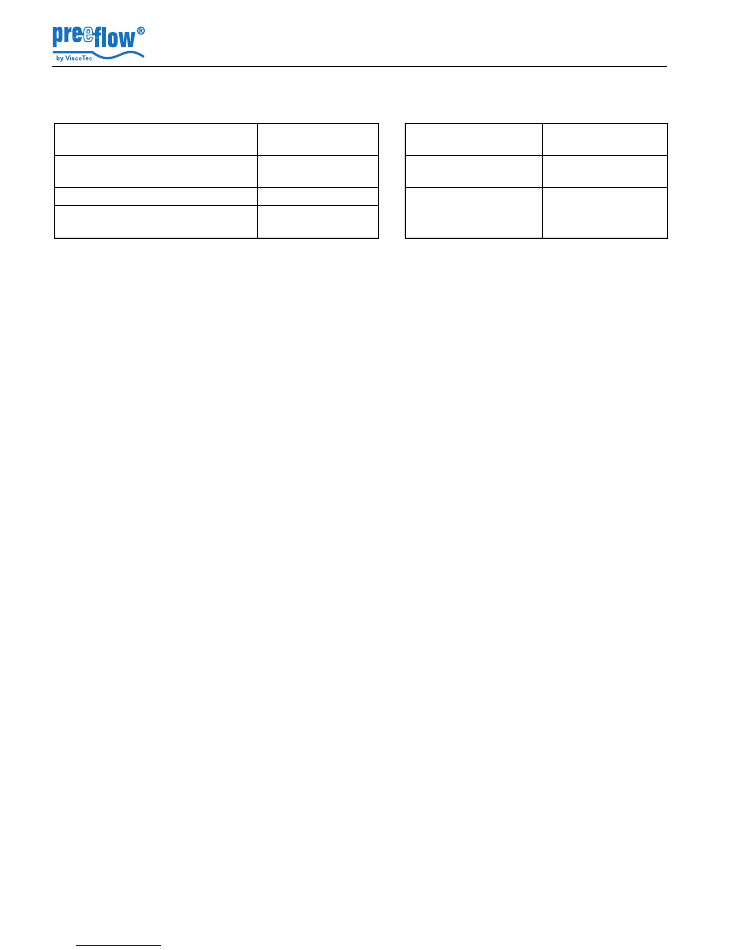

10

Technical specifications

Dimensions

Length 210 mm,

29 x 29 mm, ø 33 mm

Weight

approx. 410 gram

Material infeed

1/8“ cylindrical whitworth pipe thread DIN/ISO 228

Material outfeed

Luer lock with O ring, patented

Min. operating pressure

0 bar, self-levelling-fluid

Max. operating pressure

0 to 6 bar input pressure, non-self-levelling-fluid

Max. dosing pressure

16 to 20 bar

Intrinsic tightness *

approx. 2 bar (reference medium approx. 10mPas at 20°C)

Parts in contact with the media

HD-POM / stainless steel

Seals

High-molecular PE, VisChem

Static seals

Viton O ring (medium) NBR (dust)

Motor

18 - 24 V DC, incremental encoder, planetary gears

Operating conditions

+10°C to +40°C, air pressure 1 bar

Medium temperature

+10°C to +40°C

Storage environment

dry & dust-free, -10°C to +40°C

Approx. dosing volume per

revolution

0.05 millilitres per revolution

Accuracy of dosing **

± 1%

Repeat accuracy

> 99%

Min. dosing quantity

0.004 millilitres

Volume flow ***

0.5 to 6.0 millilitres per minute

* Max. dosing pressure and intrinsic tightness will decrease in direct proportion to a decrease in

viscosity and increase in direct proportion to an increase in viscosity. Consultation with the

manufacturer recommended.

** Volumetric dosing as absolute deviation in relation to one dispenser revolution. Depends on

the viscosity of the dosing medium.

*** Volume flow depends on viscosity and primary pressure.

Threads used

Medium input

1/8" cylindrical Whitworth pipe thread DIN / ISO 228

Bleed opening

Luer DIN EN 20594-1

Nozzle connection

LUER-LOCK DIN EN 1707 with O-ring, patented

eco-PEN450

Commissioning and maintenance manual

14 / 15

Version 1.8

Copyright ©

Materials used

Dispenserhousing, end

nozzles

POM black

Shaft sealing rings

Z80

Dispenserparts, motor housing Anodized

aluminium

O-rings

FKM

Screws, washers, etc.

Stainless steel A2

Drive shaft, rotor

Stainless steel A4

Stator elastomer, flexible shaft

covering

VisChem

eco-PEN450

Commissioning and maintenance manual

Copyright ©

Version 1.8

15 / 15

Notes

letzteSeite

info@preeflow.com

www.preeflow.com