Full Text Searchable PDF User Manual

ORIGINAL INSTRUCTIONS

USER MANUAL

Inverter welder PM-MMA-250SP /

PM-MMA-300S

1

Table of Contents

SYMBOLS WARNING / INFORMATION .............................................. ........................................... 2

APPLICATION EQUIPMENT ................................................ .................................................. ............... 2

TECHNICAL DATA ................................................ .................................................. ................................ 2

SAFETY ................................................. .................................................. ................................ 3

GENERAL THOUGHTS ................................................ .................................................. .................................... 3

Safety during welding ............................................... .................................................. 3 ....

Electromagnetic field ................................................ .................................................. .................. 5

Pacemakers ................................................ .................................................. ............................... 5

DESCRIPTION OF THE DEVICE ................................................ .................................................. ................................. 6

DESCRIPTION OF SYMBOLS ON THE LABEL ............................................. ....................................... 8

SIMPLIFIED INSTRUCTIONS FOR USE ............................................... ........................................... 8

INSRUKCJA INSTALLATION AND USE .............................................. .................................................. . 9

Place using the unit ............................................... .................................................. ........ 9

Current power and grounding. .................................................. .................................................. ............ 9

Welding service ................................................ .................................................. ............................ 10

Description welding process ............................................... .................................................. ..................... 10

One specific example of welding by means of electrodes. .................................................. ...................... 10

BASIC INFORMATION FOR WELDING .............................................. ........................... 11

FEATURE ARC FORCE ............................................... .................................................. ............................ 12

WELDING ELECTRODES IN PRACTICE .............................................. ................................................. 12

Electric arc welding ............................................... .................................................. ........ 13

Selection of appropriate electrode ............................................... .................................................. ........ 13

Correct welding position ............................................... .................................................. .......... 14

Tips arc ignition .............................................. .................................................. ..... 14

Proper arc length ............................................... .................................................. .................. 14

The correct welding speed ............................................... .................................................. ....... 15

Practice welding ................................................ .................................................. ........................... 15

Practical exercise ................................................ .................................................. ...................... 15

Base metals ................................................ .................................................. ...................... 16

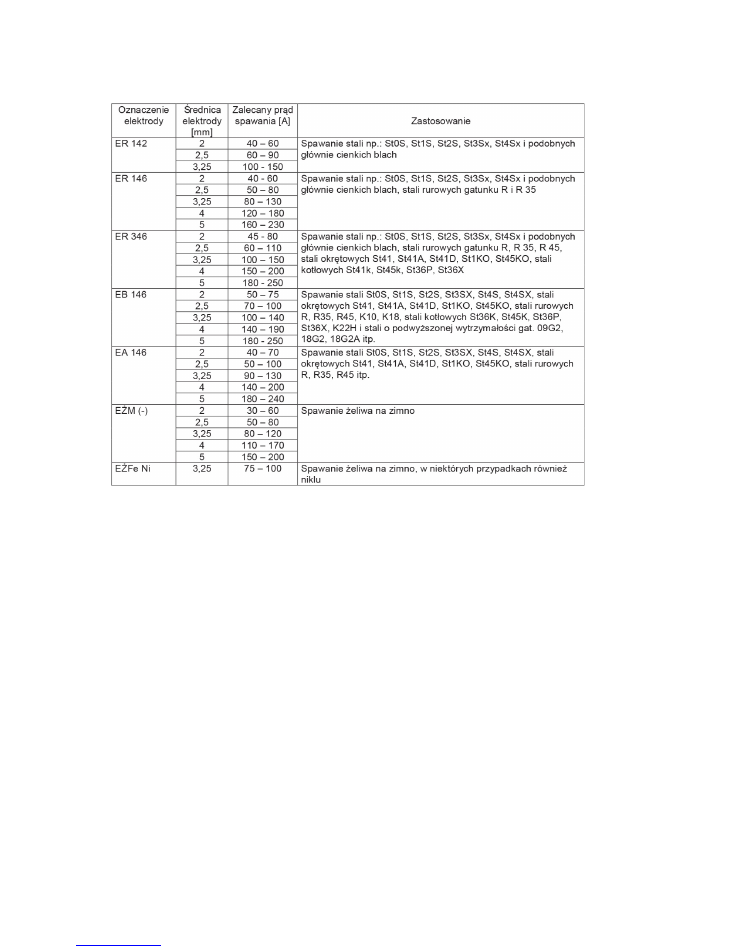

PARAMETERS TABLE PADS ............................................... .................................................. ...... 17

MAINTENANCE AND SERVICE ............................................... .................................................. ...................... 17

REMOVAL OF USED ............................................... .................................................. ....... 18

COMPANY INFORMATION ................................................ .................................................. ............................ 18

DECLARATION OF CONFORMITY ................................................ .................................................. .................... 19

2

SYMBOLS WARNING / INFORMATION

APPLICATION EQUIPMENT

The device is used for welding any type of welding electrodes. The product to which this manual is electronically

controlled inverter welding machine MMA. Electronics devices based on the IGBTs combine the advantages of two

types of transistors FET ease of operation and high breakdown voltage and switching speed of bipolar transistors.

The device is versatile, such as performing field work and all kinds of repair work inside buildings.

Use the equipment only for its intended purpose. Any other use than described in this manual is the improper use of

the device. For resulting from improper use damage or injuries responsibility of the user / operator and not the

manufacturer. Producer in order to improve its products reserves the right to possibility of differences in the above

mentioned product.

TECHNICAL DATA

Model

PM-MMA-250SP

PM-MMA-300S

Power

230V / 50Hz

230V / 50Hz

Open circuit voltage

66v

66v

Welding current range

20-250

20-300

In the field of welding

electrodes

1.6 - 4.0 mm

1.6 - 4.0 mm

Power consumption

7,1kVA

7,6kVA

Power

230V / 50Hz

230V / 50Hz

Rated welding current

250A

300A

Rated duty cycle

60%

60%

Welding current at duty cycle of

100%

193A

216A

WARNING:

Before using the device please read the instruction manual and safety instructions.

WARNING:

Before using the device please read the instruction manual and safety instructions.

Keep these instructions.

WARNING:

Keep a safe distance from bystanders during operation.

WARNING:

Keep a safe distance from bystanders during operation.

WARNING:

To protect the unit from rain and moisture.

WARNING:

To protect the unit from rain and moisture.

3

operating voltage

20,8- 30V

20,8- 30V

Protection class

F

F

insulation class

IP21S

IP21S

Weight

6,8kg

7,9kg

SECURITY

Before starting work carefully to become familiar with the manual. Keep them for future reference. For damages

resulting from failure to observe these instructions, the manufacturer is not liable.

The greatest danger is prohibited to perform the following steps:

and) Welders use for purposes other than those described in the manual.

and) Welders use for purposes other than those described in the manual.

b) Using a welder by people niezapoznane manual.

b) Using a welder by people niezapoznane manual.

c) Using welders without proper, protective clothing and footwear that supports

c) Using welders without proper, protective clothing and footwear that supports

protecting the foot.

d) The use of the device by a person under the influence of alcohol, drugs or other substances

d) The use of the device by a person under the influence of alcohol, drugs or other substances

drugs. And also by persons with reduced physical, sensory or mental capabilities, or lacking experience or

knowledge concerning the use of this type of equipment.

GENERAL THOUGHTS

Safety during welding

ELECTRIC SHOCK CAN KILL:

Welding apparatus produce a high voltage. Do not touch the torch,

ELECTRIC SHOCK CAN KILL:

Welding apparatus produce a high voltage. Do not touch the torch,

welding material connected when the device is turned on to the network. All the elements forming

the welding current circuit can cause electrical shock and should therefore be avoided

touching them with bare hands and by wet or damaged protective clothing. Never work on a wet surface, or use

damaged welding cables. NOTE: Removing the external time when the device is connected to the network, as well as

the use of the device with the covers removed is prohibited! Welding cables, ground cable, earthing terminal and

welding equipment should be kept in good condition, ensuring safety.

ARC RAYS CAN BURN:

It is not allowed to look directly at the eyes uncovered and exposed to an

ARC RAYS CAN BURN:

It is not allowed to look directly at the eyes uncovered and exposed to an

electric arc. Always wear a mask or helmets protected with a suitable filter. Bystanders, nearby,

protected with non-combustible, absorbing radiation screens. Protect

exposed parts of the body suitable protective clothing made of non-combustible material.

FUMES AND GASES CAN BE DANGEROUS:

In the welding process are produced noxious fumes

FUMES AND GASES CAN BE DANGEROUS:

In the welding process are produced noxious fumes

and gases hazardous to health. Avoid breathing these fumes and gases. Workplace should be

adequately ventilated and equipped with exhaust ventilation. Do not weld in confined spaces.

surfaces

the elements to be welded should be free from chemical impurities such

4

as degreasing agents (solvents) which decompose during welding to produce toxic gases.

ELECTROMAGNETIC FIELDS MAY BE DANGEROUS:

Electric current flowing through wires

ELECTROMAGNETIC FIELDS MAY BE DANGEROUS:

Electric current flowing through wires

Welding produces electromagnetic field around it. Electromagnetic fields can interfere with

pacemakers. Welding cables should be arranged in parallel, as close as possible to each other.

SPARKS CAN CAUSE FIRE:

Sparks generated during welding can cause fire, explosion and burns

SPARKS CAN CAUSE FIRE:

Sparks generated during welding can cause fire, explosion and burns

unprotected skin. When welding should be wearing welding gloves and protective clothing. Remove

or secure any flammable materials and substances from the workplace. Do not weld

closed containers or receptacles in which there were flammable liquids. Such containers or tanks should be rinsed

prior to welding in order to remove flammable liquid. Do not weld near flammable gases, vapors or liquids. Fire

extinguishing equipment (fire blankets and fire extinguishers powder or snow) should be located close to the

workstation in a conspicuous and easily accessible place.

POWER SUPPLY:

Disconnect the power supply before carrying out any work, repairs on the device.

POWER SUPPLY:

Disconnect the power supply before carrying out any work, repairs on the device.

Regularly check the welding cables. If you note any damage to the wire or insulation should be

removed immediately. Welding wires can not be overwhelmed,

touch sharp edges or hot objects.

WELDED MATERIALS CAN BURN:

Never touch the parts to be welded unprotected parts of the

WELDED MATERIALS CAN BURN:

Never touch the parts to be welded unprotected parts of the

body. While touching and moving the welding material, always use gloves and welding pliers.

Noise can damage hearing:

Noise-induced, some processes

Noise can damage hearing:

Noise-induced, some processes

or

devices can damage hearing. Wear hearing protection in situations of increased noise levels.

FIRE OR EXPLOSION:

Do not use the machine near flammable substances. Make sure that the

FIRE OR EXPLOSION:

Do not use the machine near flammable substances. Make sure that the

electrical network is properly configured to work with the welder. Overloading the power supply may

cause fire.

FALLING EQUIPMENT CAN BE DANGEROUS:

To move the machine, use the handle of transport.

FALLING EQUIPMENT CAN BE DANGEROUS:

To move the machine, use the handle of transport.

All the equipment necessary to lift the unit must have sufficient capacity and stable hook. When

moving the machine by forklift truck, the forks must be long enough to protrude beyond the device.

5

Overload can cause overheating:

Do not extend the cycle of welding, welding between cycles allow

Overload can cause overheating:

Do not extend the cycle of welding, welding between cycles allow

the device to cool. In the case of excessive heating of the device, shorten the cycle time of welding or

reduce the welding current.

STATIC DISCHARGE MAY DAMAGE THE PRINTED CIRCUIT:

Before touching the printed circuit

STATIC DISCHARGE MAY DAMAGE THE PRINTED CIRCUIT:

Before touching the printed circuit

boards and parts of the electrical system should be assumed grounding wrist-strap. Use of antistatic

packaging is storing and transporting electrical components.

READ INSTRUCTIONS:

Carefully read the manual and follow the information contained therein. For

READ INSTRUCTIONS:

Carefully read the manual and follow the information contained therein. For

any damage caused by failure to comply with the guidelines of this manual manufacturer is not

liable.

HIGH RADIATION

FREQUENCY:

high radiation

frequency radio signal can zakłucać, alarm systems, work computers and communications

equipment. User is obliged to ensure a qualified electrician correct the problems resulting from

zakłucenia electrical installation. Regularly check and maintain electrical installations. Use

grounding, shielding and anti-surge protection measures to minimize any zakłucenia.

ARC WELDING CAN CAUSE ZAKŁUCENIA:

Electromagnetic energy can interfere with electronic

ARC WELDING CAN CAUSE ZAKŁUCENIA:

Electromagnetic energy can interfere with electronic

equipment such as computers and computer-controlled equipment. Make sure that the hardware

devices in the work environment welders are electromagnetically compatible. To minimize the

potential for interference stick welding wires close to each other, as close to the ground. IN

If electrical noise sensitive spot welding should not be closer than 100m. The device must be connected and

grounded in accordance with this instruction. If noise still persists the user needs to take additional measures such as

changing jobs, the use of shielded cables, filters, linear and securing jobs.

Electromagnetic field

To reduce the amount of electromagnetic fields in the workplace include:

1. Keep cables close together (you can turn the tape or taped).

1. Keep cables close together (you can turn the tape or taped).

2. Organize the wires from one side of the operator as far as possible from him.

2. Organize the wires from one side of the operator as far as possible from him.

3. Do not wrap the cables around the body.

3. Do not wrap the cables around the body.

4. The power source and wires should be as far away from the operator as possible.

4. The power source and wires should be as far away from the operator as possible.

5. Connect the terminal welding seam as close as possible.

5. Connect the terminal welding seam as close as possible.

pacemakers

You should consult your doctor before welding and welding being in place. The doctor will explain the procedure if

any of the contact with the welding apparatus.

6

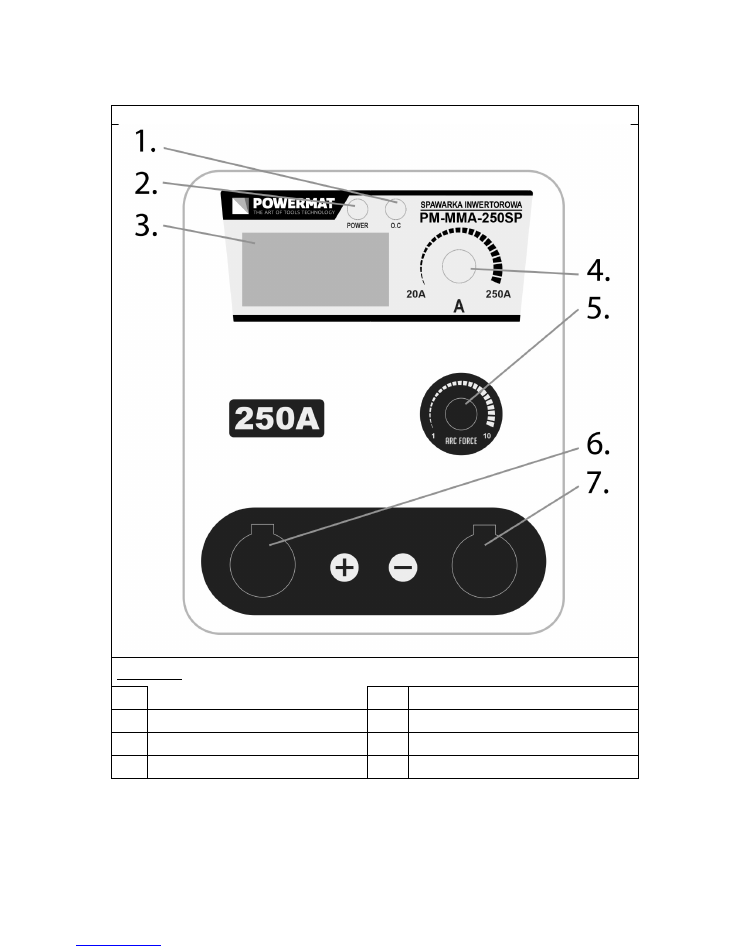

DESCRIPTION OF THE DEVICE

Model: PM-MMA-250SP

DESCRIPTION ELEMENTS

DESCRIPTION ELEMENTS

1.

LED indicating overload

5.

Knob Arc Force

2.

power LED

6.

The welding cable "+"

3.

Current meter

7.

Earth wire "-"

4.

potentiometer amperage

7

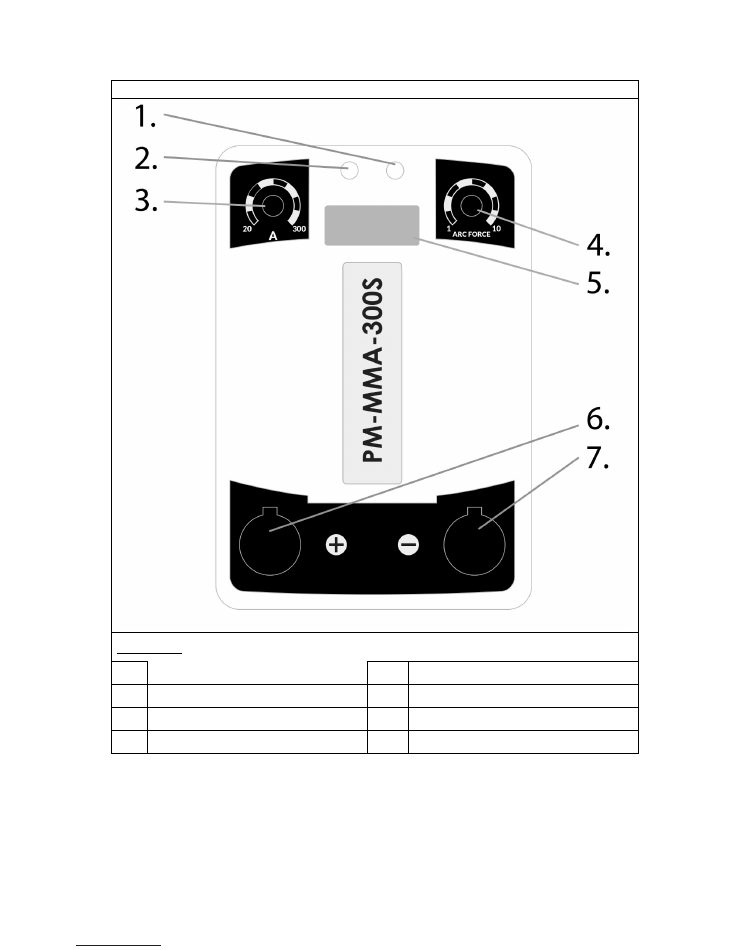

Model: PM-MMA-300SP

DESCRIPTION ELEMENTS

DESCRIPTION ELEMENTS

1.

power LED

5.

Current meter

2.

LED indicating overload

6.

The welding cable "+"

3.

potentiometer amperage

7.

Earth wire "-"

4.

Arc Force potentiometer

8

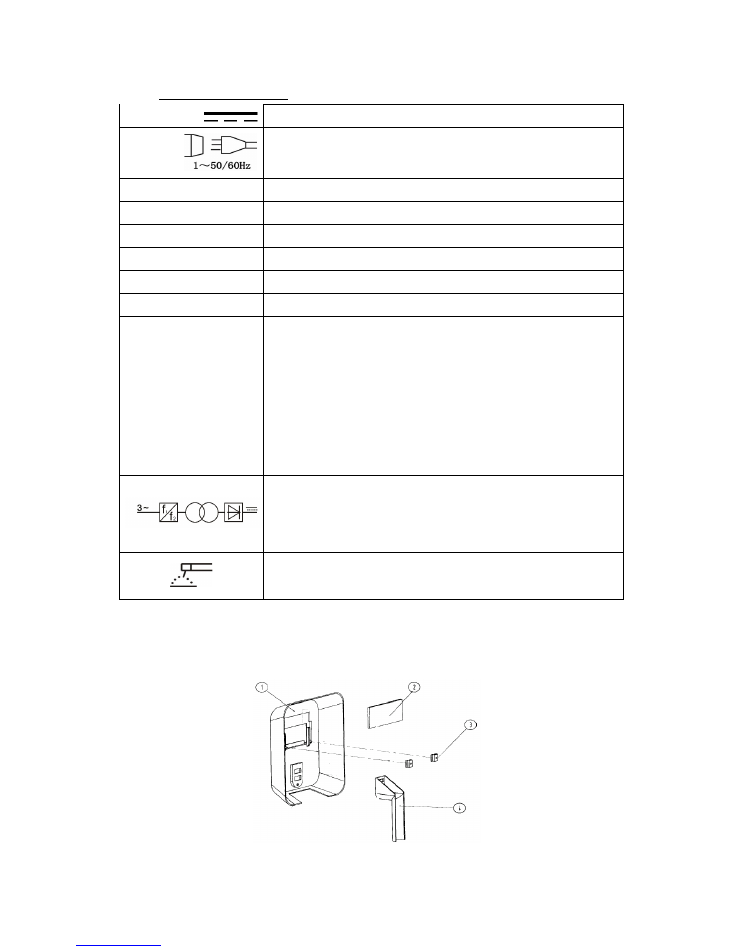

ABOUT MARKING THE PIS LABEL

ABOUT MARKING THE PIS LABEL

ABOUT MARKING THE PIS LABEL

Current (DC)

Symbol

single phase alternating current (AC) of the rated frequency 50Hz

and 60Hz operating frequency.

AT

1

Nominal input voltage (AC)

AT

1

Nominal input voltage (AC)

AT

1

Nominal input voltage (AC)

AND

1max

Maximum input current

AND

1max

Maximum input current

AND

1max

Maximum input current

AND

1EFF

Effective input current

AND

1EFF

Effective input current

AND

1EFF

Effective input current

AT

0

No-load voltage (load voltage)

AT

0

No-load voltage (load voltage)

AT

0

No-load voltage (load voltage)

AND

2

output current

AND

2

output current

AND

2

output current

AT

2

The output voltage under load

AT

2

The output voltage under load

AT

2

The output voltage under load

X

welding cycle

(This percentage ratio of working time under load to full duty cycle)

•

The value of 0-100%

• Standard for this device, one full cycle is 10 min. For example, 40% of the

cycle allows for continuous welding under load for 4 minutes. and the time

to "rest" should last 6 minutes. When the time under load the machine is

switched off by the thermal fuse.

The device welded single-phase DC

Welder is used for MMA welding

SIMPLIFIED INSTRUCTIONS FOR USE

Assembly welding mask

Welding mask assembly is performed according to the diagram.

9

1. Connect to the power welder, dial located at the rear of the unit.

1. Connect to the power welder, dial located at the rear of the unit.

2. Connect the ground wire to the quick and the workpiece.

2. Connect the ground wire to the quick and the workpiece.

3. Mount the electrode in the torch, and then connect the wire from the quick coupling.

3. Mount the electrode in the torch, and then connect the wire from the quick coupling.

4. Switch to the ON position and make sure the power LED indicator lights up

4. Switch to the ON position and make sure the power LED indicator lights up

yellow.

5. You can start the process of welding.

5. You can start the process of welding.

6. After welding is complete, move the electrode from the work piece and set

6. After welding is complete, move the electrode from the work piece and set

OFF switch in the OFF position.

Warning!

At the time of exceeding the cycle provided for the amperage thermal circuit breaker lock the device

Warning!

At the time of exceeding the cycle provided for the amperage thermal circuit breaker lock the device

(indicated by yellow LED Overload) until cool welding.

If your machine or its accessories will begin to work properly you should refrain from further work and contact a

qualified service center.

INSRUKCJA INSTALLATION AND USE

Installation of equipment

Only qualified personnel are allowed to install, use and service the welding machine.

Place of use of the device

The device can be used only in well-ventilated place.

Before working at the site of use should always take into account the guidelines for safety contained in the section

"GENERAL"

Welding cables must be connected to the output of the welding power source to the welding machine. Welder power cord

must be connected to a 230V AC power source.

Current power and grounding.

Only qualified personnel may perform installation and modification of the electricity grid.

Warning!

It is forbidden to use the device or completely dismantled the housing removed, it may cause electric shock

Warning!

It is forbidden to use the device or completely dismantled the housing removed, it may cause electric shock

and lead to severe injury. Do not touch the energized equipment.

Before installing the unit, check electrical network to which the device is connected meets the requirements placed on

the nameplate and that it meets all local and national standards. Keep in mind that different models of welding

machines may have different requirements for the electricity grid.

1. Before connecting check whether the network meets the requirements of the welding machine.

1. Before connecting check whether the network meets the requirements of the welding machine.

2. Connect the PE or green / yellow ground wire to the grounding system in accordance with the

2. Connect the PE or green / yellow ground wire to the grounding system in accordance with the

national regulations.

3. Connect the welding cables to the device, then the power cord to a single-phase network

3. Connect the welding cables to the device, then the power cord to a single-phase network

the electric voltage of 230V and frequency of 50Hz.

10

welding service

Welding current control is performed using the knob located on the top panel welder. Turning the knob (2)

right

welding

Welding current control is performed using the knob located on the top panel welder. Turning the knob (2)

right

welding

Welding current control is performed using the knob located on the top panel welder. Turning the knob (2)

right

welding

current increases, while traffic

left

current increases, while traffic

left

reduces welding current.

The current value of the welding current expressed in Amperes and presented on the display (1) located on the front

panel of the welder.

Description of the welding process

WARNING! The arc starts at the moment when the welding electrode to the welding point touch and then will

be moved to a distance the length of the arc.

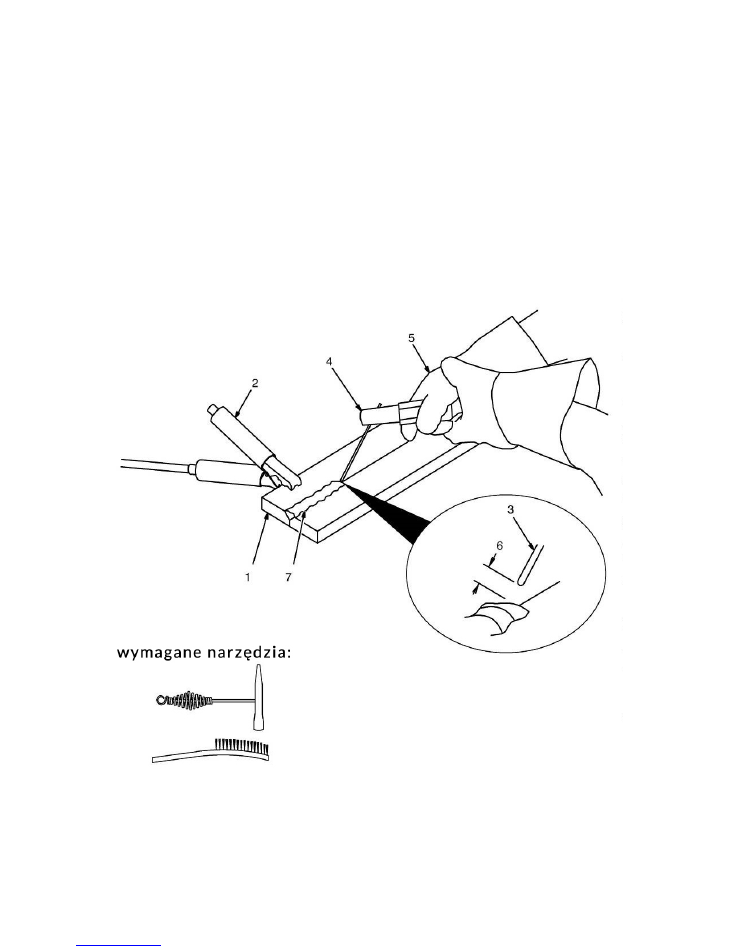

One specific example of welding by means of electrodes.

11

BASIC INFORMATION FOR WELDING

Otulinowymi welding electrodes (MMA) is a process in which metal is melted, and then combined, by heating it by

means of electric arc with consumable electrode coated metal wrapper flux. The electric current generates an electric

arc between the electrode and the material combined. During the welding electrode coating decomposes under heat

to form the gaseous substances which shield gas during the welding and slag.

If the electrode moves along a weld spot at the right speed deposited metal forms a layer called the seam.

Welding is powered by an AC source and can generate alternating current and constant. The best characteristics of the weld

obtained using a constant current.

In the circuit welding measured voltage and current. Voltage (V) is controlled by the arc length between the electrode and

welded surface and depends on the diameter of the electrode. It is a measure of the current in the welding circuit, and is

measured in amperes (A), is controlled by the dial. Setting the welding current is dependent on the diameter of the electrode

size and thickness of the welded material and the welding position. When welding materials with the same thickness,

materials with a small area is used lower electrode and a lower welding current than the larger

1.

Workplace

1.

Workplace

Make sure the work area is clean.

2.

earth wire

2.

earth wire

Clip the ground cable as close to the surface of the weld.

3.

Electrode

3.

Electrode

Before the electric arc ignition, place the electrode in the torch. With the electrodes of smaller diameter

to be operated at less than the current to the electrodes with a larger diameter. Follow the data on the

welding current provided by the manufacturer.

4.

Insulated welding gun.

5.

The correct position of holding the torch.

5.

The correct position of holding the torch.

6.

The length of the arc.

6.

The length of the arc.

The length of arc is the distance from the point of welding electrodes. In the case of a short arc of the

proper amperage and you hear sharp cracks. The appropriate length of the electric arc is similar to the

electrode diameter. Check the weld seam to determine if the arc is correct.

The length of the arc electrodes having a diameter of 1.6 mm and 2.4 mm should be greater than 1.6 mm, and the

electrodes 3mm and 4mm arc length should be greater than 3mm.

7.

Slag

7.

Slag

For removal of welding slag, use a hammer and brush. Remove slag and check weld bead before starting

a new weld.

12

surface. Thin metal requires less power, and smaller electrode requires less power.

It is recommended that during welding work in the horizontal and vertical positions. However, while we are forced to

weld in vertical or overhead should set the current lower than the level during operation. The best welds are obtained

while maintaining a short arc, smooth movement of the electrode and the electrode leading down at a constant speed

during melting. More detailed welding procedures are presented in the following pages Supported.

FEATURE ARC FORCE

ARC FORCE allows the arc. Shortening the length of the arc is accompanied by an increase in the welding current, which

results in stabilizing the arc. Reducing the value of the function gives a soft arc and a smaller depth of penetration, while

increasing the value of the function causes deeper penetration and the possibility of short-arc welding. At a set high value

ARC FORCE function you can be welded while maintaining the minimum arc length and a high melting rate of the electrode.

WELDING ELECTRODES IN PRACTICE

No one can learn to weld by reading the instruction manual or other literature on the subject. The ability to correct

welding can be purchased only through practice. The information contained in the attached manual to help you

understand those rules inexperienced welding with coated electrodes and make it easier to start learning. For more

information about welding can reach for a comprehensive literature deeply about.

Knowledge welding operator must go beyond information about the arc. User welders must know how to control the

arc, which requires knowledge of the circuit and the welding device that provides current during welding. The welding

cable starts in the torch, wherein the electrode is mounted, and the end on the connector, wherein the cable is

attached to the welding machine. Current flows through the wire to the welding electrode holder and then by the

electric arc. On the other side of the working arc current flows through the wire to the base metal mass, then back to

the device. The system must be closed. Mass holder to be stably mounted on the metal base cleared. Metal must be

cleaned of paint, rust, etc. It is necessary to obtain a good current flow. Connect the ground cable as close as

possible to the welding point. Avoid closing the circuit through the welding hinges, bearings, electrical systems and

other such items that may impede the flow of current in the system. The electric arc is formed in a space between the

work piece and the welding electrode tip mounted on the torch. The molten metal moves along the arc for the

combination of materials, forming a weld bond.

Electrode Welding requires a strong grip and a welding tip, stable hands, good vision and good mental health. The

operator controls the welding arc welding and thus, the quality of the weld created.

13

Electric arc welding

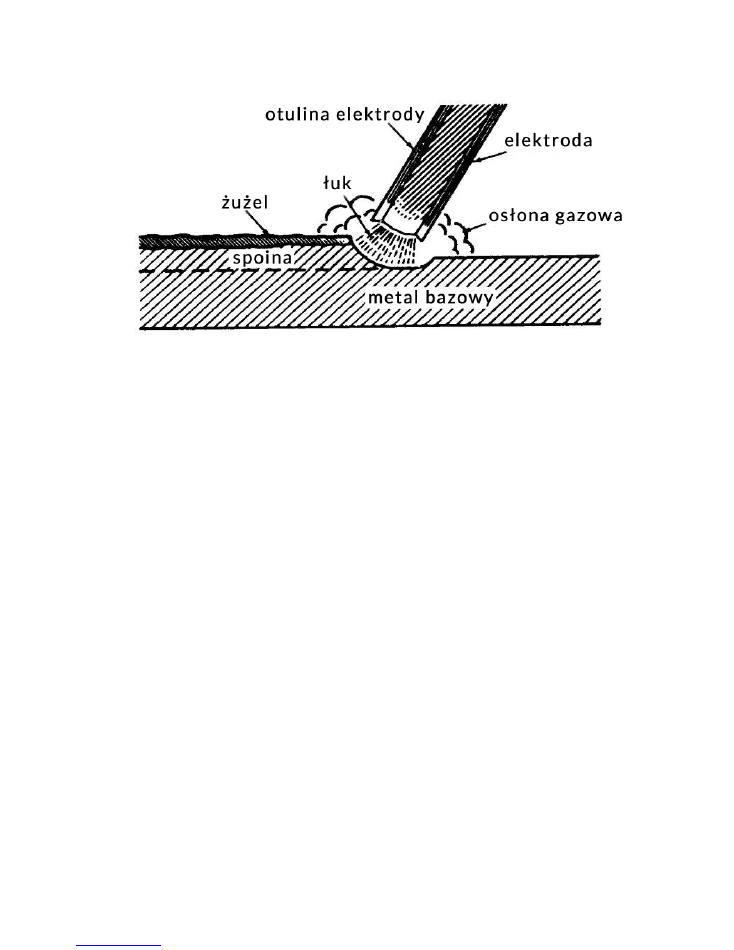

Fig. 1

Figure 1.

Presents phenomena occurring during arc welding, which is greatly enlarged what is seen by the welder.

Figure 1.

Presents phenomena occurring during arc welding, which is greatly enlarged what is seen by the welder.

Curved space is shown in a central position in the picture. Arc formed at a location between the electrode tip and the

base material. The arc welding reaches 3315

about

C, which is sufficient to melt the base metal. Since the arc is very

base material. The arc welding reaches 3315

about

C, which is sufficient to melt the base metal. Since the arc is very

base material. The arc welding reaches 3315

about

C, which is sufficient to melt the base metal. Since the arc is very

bright you can not look at him bare eyes, it can cause very painful burns of the retina or permanent eye damage.

They are designed for welding specialist welding masks and helmets protect the eyes during welding.

When working with an electric arc welder begins to "pull" handle, which is comparable to a stream of water from a

garden hose for use at the ground. The molten metal forms a lake or crater (small

area of the molten metal surface)

garden hose for use at the ground. The molten metal forms a lake or crater (small

area of the molten metal surface)

which follow for the electric arc. During the movement of the electrode puddle is cooled and solidifies. Slag emitted

during welding protects the weld during welding.

Selection of a respective electrode

The function of the covered electrodes is not only the transfer of power to the electric arc. The electrode is

constructed of a metal core and a cover. The metal core is melted in an electric arc to fill the gap between the two

pieces of combined metal. Lagging also melts or burns in an electric arc playing the same important functions in the

welding process. During the melting of the electrode decompose chemical compounds contained in the electrode

coating to form gaseous products, which stabilizes the electric arc cloud protects the molten metal from oxidation and

pollution in the atmosphere. Other chemicals get together with the molten metal from the core of the electrode to the

weld pool to form a slag that forms on the weld layer protecting from further oxidation during cooling.

The differences for the different types of electrodes refer mainly to the type of the buffer zone. Changing the outer coating

significantly affects the characteristics of welding. By understanding the differences in the types of buffer zones to gain

knowledge select the right electrode for the job.

14

When choosing the electrodes need to consider:

1. Implementation example. Steel, mild steel and stainless steel.

1. Implementation example. Steel, mild steel and stainless steel.

2. The thickness of the welded material.

2. The thickness of the welded material.

3. Position in which the weld is made.

3. Position in which the weld is made.

4. Technical state of the base metal.

4. Technical state of the base metal.

5. Own skills on using a welder.

5. Own skills on using a welder.

The first four points are necessary for the proper use of the welder without mastering their work will be hard and

tedious.

Correct welding position

The welding position presented is described for right-handed, in the case of left-handers will look exactly the opposite.

1. Catch the welding gun with his right hand.

1. Catch the welding gun with his right hand.

2. Put your left hand under your right hand.

2. Put your left hand under your right hand.

3. Put your left elbow to the left side of the body. If

3. Put your left elbow to the left side of the body. If

you can weld with both hands.

This will better control electrode.

Try to weld from left to right (if you're right-handed). You will see more precisely the welding area.

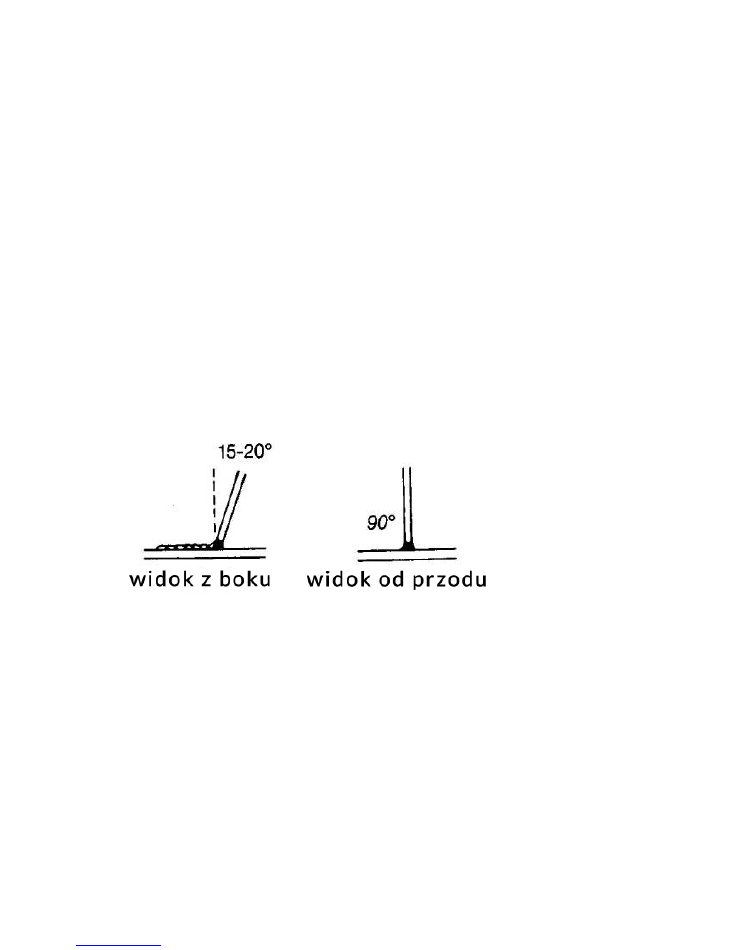

Fig. 2

Keep the electrode at a slight angle as shown in the figure.

Tips arc ignition

Make

out

that handle mass has good contact with the weld workspace.

Lower welding helmet and rub against metal electrode welding in place until you see sparks. While rubbing lift the

electrode at about 3mm to stabilize the arc.

Warning!

If you stop electrode while rubbing stick electrode.

Warning!

If you stop electrode while rubbing stick electrode.

Warning!

Most beginners trying to foment arc welders by tapping the electrode plate. As a result, the electrode or

Warning!

Most beginners trying to foment arc welders by tapping the electrode plate. As a result, the electrode or

sticks or the traffic is too fast and the arc is interrupted.

Proper arc length

Arc length is the distance from the end of the electrode to the workpiece. Once the arc is stabilized setting proper arc

length is very important. Arc should have

15

a length of approximately 1.5 - 3 mm. Due to the burning of the electrodes must be kept adjust the length of the arc.

Most simpler method of controlling arc is relying on its own hearing. The correct length of the arc is characterized by a

crackling sound like frying eggs patelce. Invalid too long arc is revealed empty hissing sound or a sound like blowing.

The correct welding speed

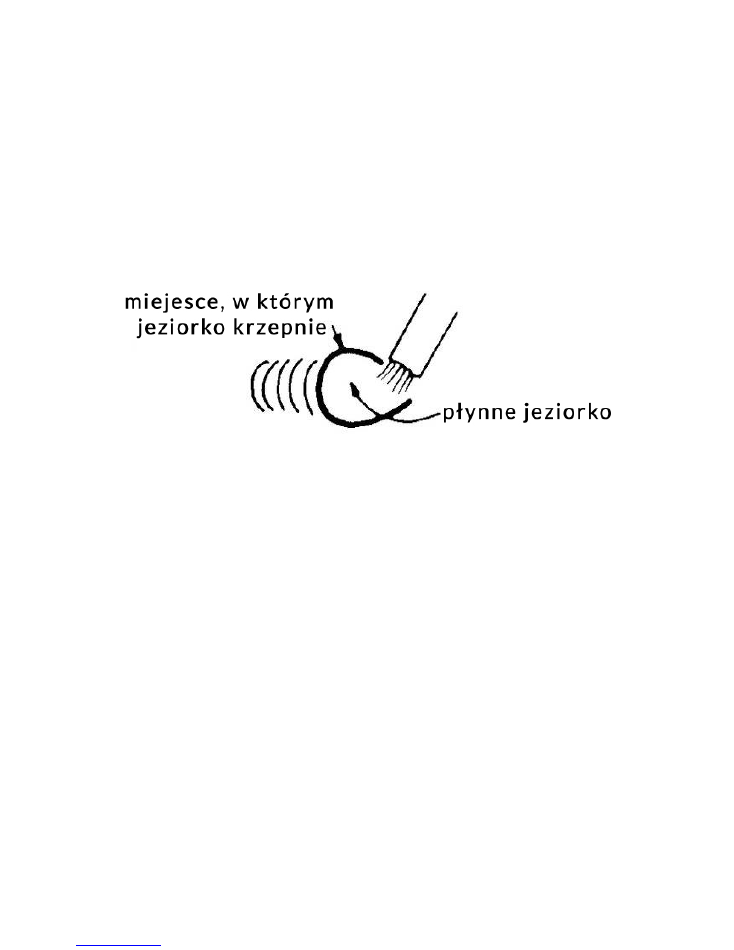

The important thing is to check whether the lake follows the arc.

Important can not look directly at the arc.

The

The important thing is to check whether the lake follows the arc.

Important can not look directly at the arc.

The

The important thing is to check whether the lake follows the arc.

Important can not look directly at the arc.

The

appearance of the weld puddle and back out of the solidification of the molten pool indicates a normal welding speed. The

appearance of the weld puddle and back out of the solidification of the molten pool indicates a normal welding speed. The

back surface should be formed about 10mm behind the electrode.

Fig. 3

Most people beginners tend to weld too fast, resulting in the effect of thin, similar to the "worm" thickening. This

happens when you do not observe the lake. Important. Welding is not necessary heave arc (side to side or front to

back). Weld a straight line at constant speed. It will be easier this way.

When the welding material of low thickness increase the speed of the electrode so as not to burn metal analogy

welding speed heavy materials should be smaller to increase the penetration of the weld.

practice welding

The best way to gain the skills of welding is practical exercise. During the exercise, remember to:

1. Proper welding position.

1. Proper welding position.

2. The proper way arcing arc.

2. The proper way arcing arc.

3. The correct length of the arc.

3. The correct length of the arc.

4. The correct speed.

4. The correct speed.

practical exercise

Will be needed:

1. Mild steel sheet: 5mm or thicker

1. Mild steel sheet: 5mm or thicker

2. electrode 3.2mm

2. electrode 3.2mm

3. Recommended setting: 100-120

3. Recommended setting: 100-120

16

and) Learn how to kindle a bow by rubbing on metal electrodes. Make sure that the angle of the electrode

and) Learn how to kindle a bow by rubbing on metal electrodes. Make sure that the angle of the electrode

It is correct and that you are using both hands.

b) When you learn to kindle practice a proper arc setting arc length using

b) When you learn to kindle practice a proper arc setting arc length using

sound that seems arc.

c) Once you have mastered this step, go to the proper welding. Watch and smooth lake

c) Once you have mastered this step, go to the proper welding. Watch and smooth lake

Search ridge, the place where the metal solidifies.

d) Do stitches on a flat metal surface. Do them in parallel to the upper edge (the edge

d) Do stitches on a flat metal surface. Do them in parallel to the upper edge (the edge

furthest from you). This will give you practical skills in running straight welds, and also allow you to

easily track your progress. You will notice that the tenth weld will look much better than the first. By

constantly checking their mistakes and correct them, your progress in welding technology will keep the

increase. Through regular exercise after some time welding will be a matter of routine.

Base metals

Most metals found in farms and small shops are low carbon steel, sometimes offered mild steel. Typical items made

with this type of steel is the most common metal plates, pipes, rolling, angles, beams. This type of steel can usually

pospawać without special precautions. However, some types of steel contain large amounts of carbon. Such steels

are most commonly used in the connecting rods, knives and cutting grinding, axles, shafts, plowshares. Carbon steels

in most cases can be welded with success, however, caution should be exercised in maintaining proper temperatures

in the earlier welding and reheating the material to be welded. In some cases, you must carefully control the

temperature during the welding and the welding process. For comprehensive information on identifying and welding

different types of steel and other metals we purchase and read the detailed literature devoted to welding. Regardless

of the type of material to be welded, it is important to clean it of any dirt (rust, paint, oil, dust, etc.), Which significantly

affects the quality of the weld.

17

PARAMETERS TABLE PADS

MAINTENANCE AND SERVICE

Maintenance

WARNING!

The electrical shock can cause serious injury or even death. Under no circumstances may touch parts

WARNING!

The electrical shock can cause serious injury or even death. Under no circumstances may touch parts

under voltage wiring such as terminals or the internal components of the device. Prior to the maintenance welder

must be disconnected from the mains.

The device should be cleaned with dry air of low pressure, thereby removing contaminants must be formed on the

housing and the vents. It is necessary for the proper functioning of the device.

An important aspect is the state of the external wiring, welding machines, which need to be checked regularly. In the

event of damage, contact a qualified service welding equipment. Changing the wiring on the other performed inside

the device it is not recommended and may result in denial of warranty. All changes to the wiring should be done by

changing the external wiring.

Changing the power wiring can be performed only by a welding equipment.

18

The most common fault

Warning!

Before any intervention in the welding machine, disconnect the unit from the mains. PROBLEM

Warning!

Before any intervention in the welding machine, disconnect the unit from the mains. PROBLEM

CAUSE

SOLUTION

No voltage outputs

devices

No voltage at the output terminal

After cooling unit,

try to weld.

Inclusion

security

overload

When the power switch device

does not turn on

Damaged

line

control

Please contact an authorized

service center

Defective control board

Service

Repair welding equipment should be carried out by qualified personnel using original spare parts. This ensures the

safety of the device.

REMOVAL OF USED

End of life do not dispose of this product by normal household waste, but take it to a

collection point and recycling of electrical and electronic equipment. This is indicated by the

symbol on the product,

user manual

or packaging. Thanks

re-use, material utilization or other forms of old appliances, you make an important

contribution to protecting our environment.

COMPANY DETAILS

PH Powermat TMK Bijak Sp. General Partnership Ul.

Defenders of the Gdansk Post 97 42-400 Zawiercie

19

DECLARATION OF CONFORMITY