Full Text Searchable PDF User Manual

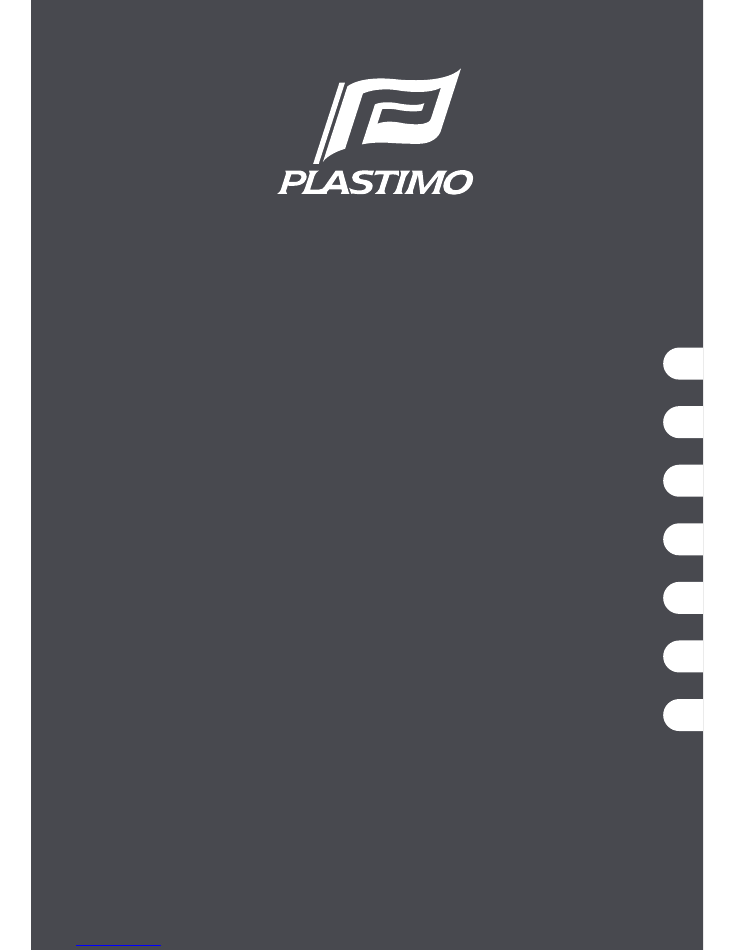

406-S 609-S 811-S

GB

D

NL

S

I

E

F

ROLLREFFANLAGE - AUFBLASBARE RETTUNGSWESTEN

ROLREEFSYSTEEM - GEBRUIKERSHANDLEIDING

RULLFOCKSYSTEM - INSTRUKTIONER OCH HANDHAVANDE

ENROLLADOR - GUIA DE UTILIZACION

JIB REEFING - OWNER'S MANUAL

AVVOLGITORE - MANUALE D'USO

ENROULEUR DE FOC - NOTICE D'UTILISATION

Plastimo - 15, rue Ingénieur Verrière - 56100 Lorient - FRANCE

PANTONE 425C

Couché moderne brillant 200g

58223_00 - Page 1/76

58223_00 - Page 2/76

PANTONE 425C

Couché moderne brillant 200g

I

D

F

GB

S

E

NL

latte

Terminal-

montage

chainplate

ridoir

turnbuckle

406-S

609-S

811-S

25722

25722

25722

25722

25722

25722

58202

58202

58202

58202

58202

58202

58204

58204

58204

58204

58204

58204

58204

25723

25723

25723

25723

25723

25723

25723

58203

58203

58203

58203

58203

58203

58203

ØA

ØB

étai : Ø4-7mm

Vorstag : Ø4-7mm

voorstag : Ø4-7mm

estay : Ø4-7mm

Förstags : Ø4-7mm

Strallo : Ø4-7mm

forestay : Ø4-7mm

ralingue :Ø6.5mm

Vorliek :Ø6.5mm

voorlijk :Ø6.5mm

relinga :Ø6.5mm

Lik :Ø6.5mm

ralinga :Ø6.5mm

luffrope : Ø6.5mm

811-S

407-S

609-S

C

6.20m

6.20m

6.20m

6.20m

6.20m

6.20m

6.28m

6.28m

6.28m

6.28m

6.28m

6.28m

6.28m

9.22m

9.22m

9.22m

9.22m

9.22m

9.22m

9.40m

9.40m

9.40m

9.40m

9.40m

9.40m

9.40m

11.05m

11.05m

11.05m

11.05m

11.05m

11.05m

11.05m

811-S

407-S

609-S

D

2

12m

2

12m

2

12m

2

12m

2

12m

2

12m

2

12m

2

25m

2

25m

2

25m

2

25m

2

25m

2

25m

2

25m

2

35m

2

35m

2

35m

2

35m

2

35m

2

35m

2

35m

E

811-S

407-S

609-S

65mm

65mm

65mm

65mm

65mm

65mm

150mm

150mm

150mm

150mm

150mm

150mm

150mm

115mm

115mm

115mm

115mm

115mm

115mm

285mm

285mm

285mm

285mm

285mm

285mm

285mm

220mm

220mm

220mm

220mm

220mm

220mm

220mm

811-S

407-S

609-S

F

5.82m

5.82m

5.82m

5.82m

5.82m

5.82m

5.82m

8.80m

8.80m

8.80m

8.80m

8.80m

8.80m

8.80m

10.49m

10.49m

10.49m

10.49m

10.49m

10.49m

10.49m

G

811-S

407-S

609-S

1 gorge

1 Nuten

1 zeilgroeven

1 relingas

1 likrännor

1 gole

1 groove

811-S

407-S

609-S

ØH

8.5mm

8.5mm

8.5mm

8.5mm

8.5mm

8.5mm

8.5mm

12.5mm

12.5mm

12.5mm

12.5mm

12.5mm

12.5mm

12.5mm

14.3mm

14.3mm

14.3mm

14.3mm

14.3mm

14.3mm

14.3mm

J

811-S

407-S

609-S

jonctions aluminium

+ vis

Verbindungen Alu-

minium +Schrauben

koppelstuk

alu + schroeven

Empalmes aluminio

+ tornillos

Kopplïngar alumi-

nium + skruv

Giunzione aluminio

+ vite

coupling units :

aluminium+screws

R

1

811-S

407-S

609-S

roulement Delrin

Kugellager Delrin

lagering Delrin

Rodamientos Delrin

Kullager Delrin

cuscinetti Delrin

bearing: Delrin

roulement Delrin,inox Kugellager Delrin,inox lagering Delrin,RVS

Rod. Delrin,inox

Kulla. Delrin,rostfritt cuscinetti Delrin,inox

bearing: Delrin,inox

roulement Delrin, Torlon Kugellager Delrin, Torlon lagering Delrin, Torlon

Rod. Delrin, Torlon

Kulla. Delrin, Torlon cusci. Delrin, Torlon

bearing: Delrin, Torlon

R

2

811-S

407-S

609-S

roulement Delrin

Kugellager Delrin

lagering Delrin

Rodamientos Delrin

Kullager Delrin

cuscinetti Delrin

bearing: Delrin

roulement

Delrin, Torlon

Kugellager

Delrin, Torlon

lagering

Delrin, Torlon

Rodamientos

Delrin, Torlon

Kullager

Delrin, Torlon

cuscinetti

Delrin, Torlon

bearing:

Delrin, Torlon

811-S

407-S

609-S

S

5.95m

5.95m

5.95m

5.95m

5.95m

5.95m

5.95m

8.94m

8.94m

8.94m

8.94m

8.94m

8.94m

8.94m

10.44m

10.44m

10.44m

10.44m

10.44m

10.44m

10.44m

Stagspanner-

montage

stevenplaa-

tuitvoering

spanschroe-

fuitvoering

placas

tensor

Landre

Arridatoi

1

2

0

C

D

4

5

ØA

ØB

Ø31

1

1

0

4

3

5

Ø145

ØH

F

E

406-S

609-S

811-S

S

R

1

R

2

J

S

4

5

R

1

Ø190

ØH

E

C

1

3

6

D

4

2

1

F

1

1

8

R

2

J

1

1

8

R

2

4

5

S

R

1

Ø200

ØH

E

3

6

3

C

6

0

5

F

D

- 3 -

58223_00 - Page 3/76

PANTONE 072C

Offset 80g

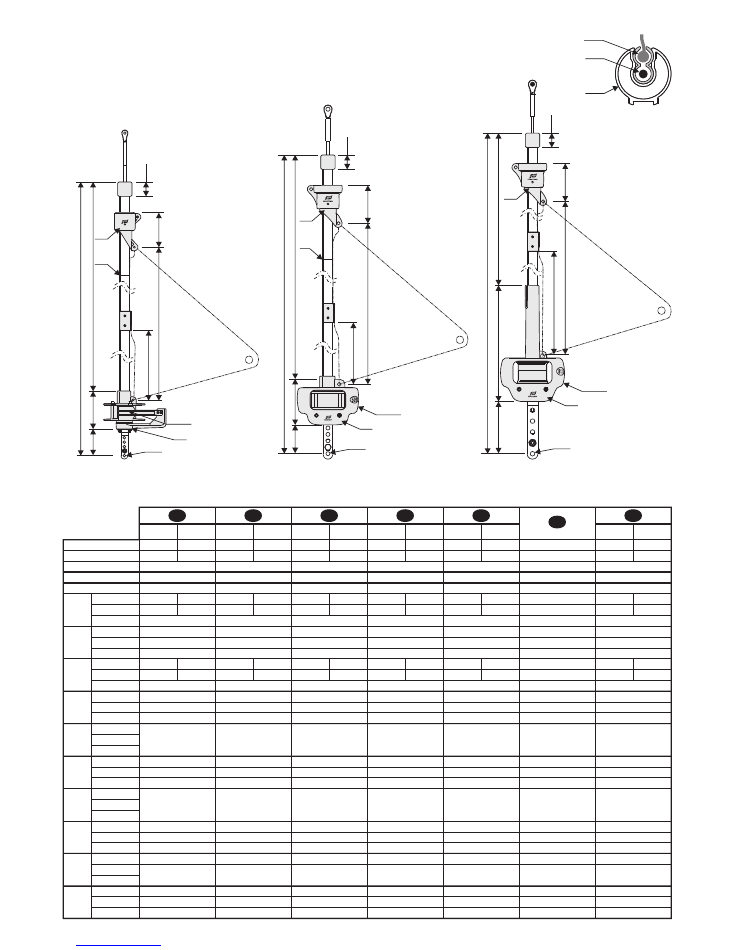

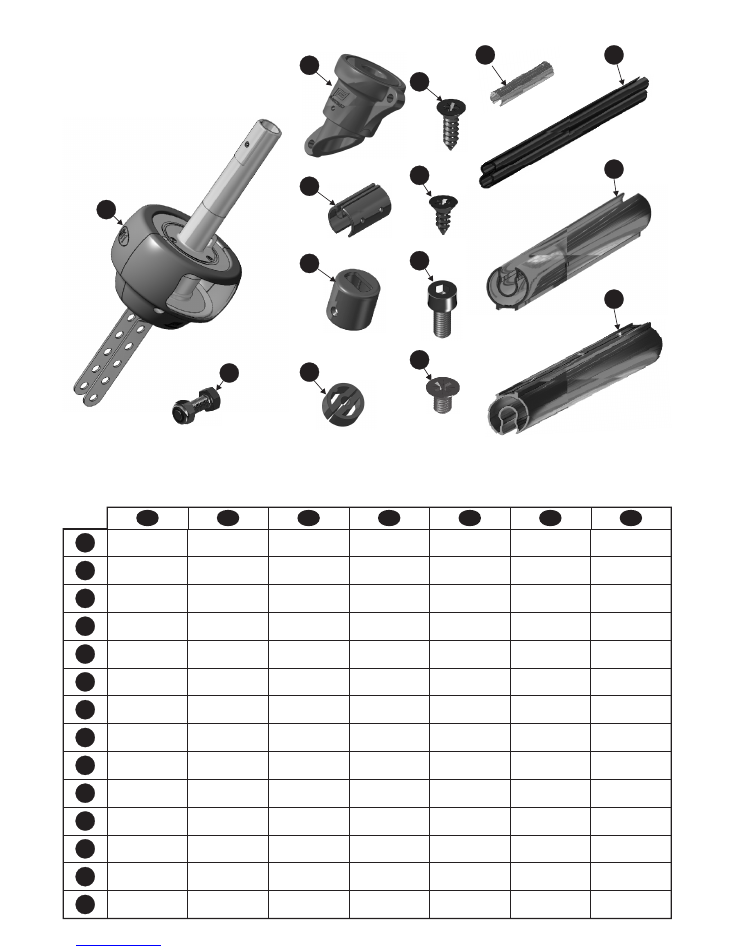

406-S

2

3

4

5

x2

6

7

x4

8

9

x8

x4

10

12

13

14b

1

11

x4

x3

14a

- 4 -

15

x15

D

F

GB

S

E

NL

4 Coupling sleeves

4 pièces de jonction

aluminium

4 Verbindungsstücke

4 koppelstukken

4 piezas de uniones

4 Skarvstycken

4 Pezzi di giunzione

4 PVC liners

4 profils PVC

4 PVC-Profile

4 PVC binnenprofielen

4 Perfiles PVC

4 Innerprofil i PVC

- plastrofil

4 Profilati PVC

1 base spar

1 profil aluminium

bas

1 unteres Profil

1 basisprofiel

1 perfil bajo

1 Bottenprofil

1 profilato basso

3 Intermediate spars

3 profils aluminium

intermédiaires

3 Zwischenprofile

3 standaardprofielen 3 Perfiles intermedios

3 Standard profiler

3 Profilati intermedi

1 screw+nut M8x35

=>chainplate

1 vis+écrou M8x35

modèle lattes

1 Schraube M8x35

Terminalmontage

1 bunten M8x35

stevenplaatuitvoering

1 tornillo M8x35

(placas)

1

M8x35

insex

1 Vite M8x35

Modello Landre

1 Shoudered clevis pin

Ø8 (=>turnbuckle)

1 axe épaulé Ø8

modèle ridoir

1 Bolzen, dick Ø8

Stagspannermontage

1 pen Ø8

spanschroefuitvoering

1 Bulón Ø8

(tensor)

1 Riggbult Ø8

1 Asse a testa Ø8

Modello arridatoi

15

15 PVC slide

(=>turnbuckle)

15 coulisseau plastique

modèle ridoir

15 PVC Rutscher

Stagspannermontage

15 PVC-leuver

spanschroefuitvoering

15 patin

(tensor)

15 Plasttravare

15 guida in plastica

Modello arridatoi

1 drum unit

1 ensemble tambour

1 Trommel

1 roltrommel

1 conjunto tambor

1 Trumma med

revlinematare

1 insieme tamburo

1 boltrope prefeeder

1 guide ralingue

1 Liekeinführung

1 voorlijkinvoer

1 guía relinga

1 Segelinmatare

1 guida ralinga

1 top end stop

1 embout profil

1 Profilansatzstück

1 top eind stuk

1 terminal tope

1 Toppdel

1 Terminale profilato

2 bearings

2 paliers de profil

2 Stopper

2 lagers

2 cojinetes

2 Lagringar

2 Supporti

4 screws Ø3.9x9.5

(prefeeder)

4 vis tôle TF Ø3.9x9.5

fixation guide ralingue

4 Schraube Ø3.9x9.5

(Liekeinführung)

4 schroeven Ø3.9x9.5

(voorlijkinvoer)

4 tornillos Ø3.9x9.5

(guía relinga)

4 spårskruv Ø3.9x9.5

(Segelinmatare)

4 viti lamiera Ø3.9x9.5

(guida ralinga)

1

Ø4.8x12.

(top end stop)

screw

1 vis tôle TF Ø4.8x12.

fixation embout profil

1

Ø4.8x12.

(Profilansatzstück)

Schraube

1 schroef Ø4.8x12.

(top eind stuk )

1 tornillo Ø4.8x12.

(terminal tope)

1 spårskruv Ø4.8x12.

(Toppdel)

1 vite lamiera Ø4.8x12

(terminale profilato)

1

M5x12

(base spar)

screw

1 vis Chc M5x12

fixation profil bas

1

M5x12

(unteres Profil)

Schraube

1

M5x12

(basisprofiel)

schroef

1 tornillo M5x12

(perfil bajo)

1 insex M5x12

(Bottenprofil)

1 vite a brugola M5x12

(profilato basso)

8

M5x8

(spar connections)

screws

8 vis TF M5x8

liaison profils

8 Schraube M5x8

(Verbindung der Profile)

8 bouten M5x8

(koppelstukken )

8 Tornillos M5x8

(unión perfiles)

8

M5x8

(profilkopplingarna)

insex

8 vite M5x8

(collegamento profilati)

1 halyard swivel

1 émerillon

1 Fallwirbel

1 valwartel

1 giratorio

1 Fallsvirvel

1 mulinello

I

2

3

4

5

6

7

8

9

10

12

13

14b

14a

11

1

58223_00 - Page 4/76

PANTONE 072C

Offset 80g

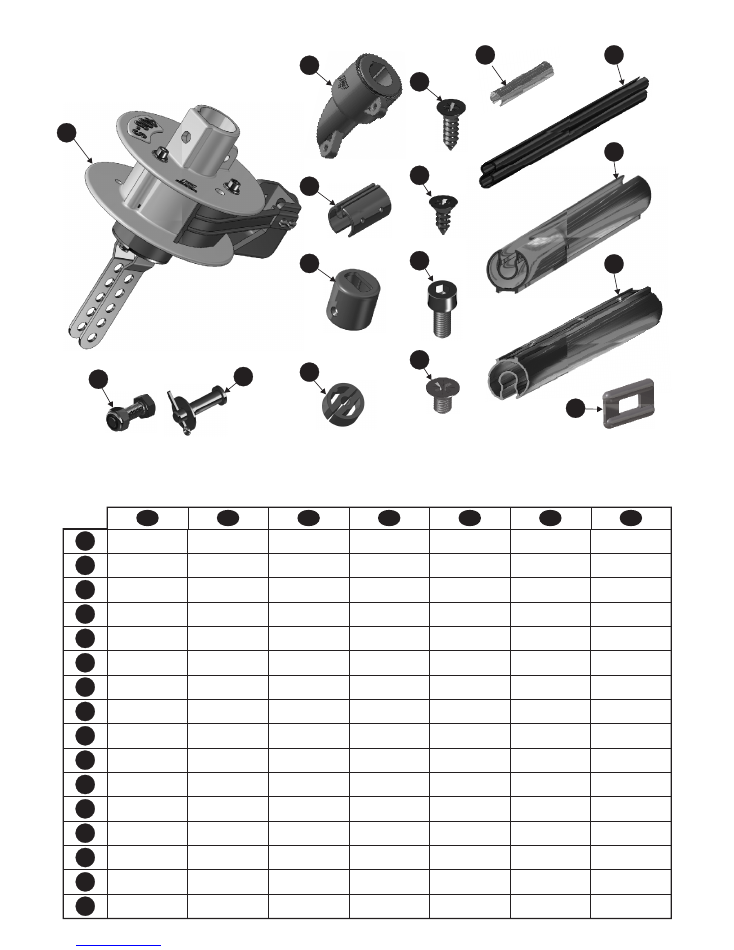

609-S

2

3

4

5

x2

6

7

x4

8

9

x12

x6

10

12

13

14b

1

11

x6

x5

14a

- 5 -

15

x15

D

F

GB

S

E

NL

6 Coupling sleeves

6 pièces de jonction

aluminium

6 Verbindungsstücke

6 koppelstukken

6 piezas de uniones

6 Skarvstycken

6 Pezzi di giunzione

6 PVC liners

6 profils PVC

6 PVC-Profile

6 PVC binnenprofielen

6 Perfiles PVC

6 Innerprofil i PVC

- plastrofil

6 Profilati PVC

1 base spar

1 profil aluminium

bas

1 unteres Profil

1 basisprofiel

1 perfil bajo

1 Bottenprofil

1 profilato basso

5 Intermediate spars

5 profils aluminium

intermédiaires

5 Zwischenprofile

5 standaardprofielen 5 Perfiles intermedios

5 Standard profiler

5 Profilati intermedi

1 screw+nut M12x35

=>chainplate

1 vis+écrou M12x35

modèle lattes

1 Schraube M12x35

Terminalmontage

1 bunten M12x35

stevenplaatuitvoering

1 tornillo M12x35

(placas)

1

M12x35

insex

1 Vite M12x35

Modello Landre

1 Shoudered clevis pin

Ø12 (=>turnbuckle)

1 axe épaulé Ø12

modèle ridoir

1 Bolzen, dick Ø12

Stagspannermontage

1 pen Ø12

spanschroefuitvoering

1 Bulón Ø12

(tensor)

1 Riggbult Ø12

1 Asse a testa Ø12

Modello arridatoi

15

15 PVC slide

(=>turnbuckle)

15 coulisseau plastique

modèle ridoir

15 PVC Rutscher

Stagspannermontage

15 PVC-leuver

spanschroefuitvoering

15 patin

(tensor)

15 Plasttravare

15 guida in plastica

Modello arridatoi

1 drum unit

1 ensemble tambour

1 Trommel

1 roltrommel

1 conjunto tambor

1 Trumma

1 insieme tamburo

1 boltrope prefeeder

1 guide ralingue

1 Liekeinführung

1 voorlijkinvoer

1 guía relinga

1 Segelinmatare

1 guida ralinga

1 top end stop

1 embout profil

1 Profilansatzstück

1 top eind stuk

1 terminal tope

1 Toppdel

1 Terminale profilato

2 bearings

2 paliers de profil

2 Stopper

2 lagers

2 cojinetes

2 Lagringar

2 Supporti

4 screws Ø3.9x9.5

(prefeeder)

4 vis tôle TF Ø3.9x9.5

fixation guide ralingue

4 Schraube Ø3.9x9.5

(Liekeinführung)

4 schroeven Ø3.9x9.5

(voorlijkinvoer)

4 tornillos Ø3.9x9.5

(guía relinga)

4 spårskruv Ø3.9x9.5

(Segelinmatare)

4 viti lamiera Ø3.9x9.5

(guida ralinga)

1

Ø4.8x12.

(top end stop)

screw

1 vis tôle TF Ø4.8x12.

fixation embout profil

1

Ø4.8x12.

(Profilansatzstück)

Schraube

1 schroef Ø4.8x12.

(top eind stuk )

1 tornillo Ø4.8x12.

(terminal tope)

1 spårskruv Ø4.8x12.

(Toppdel)

1 vite lamiera Ø4.8x12

(terminale profilato)

1

M5x12

(base spar)

screw

1 vis Chc M5x12

fixation profil bas

1

M5x12

(unteres Profil)

Schraube

1

M5x12

(basisprofiel)

schroef

1 tornillo M5x12

(perfil bajo)

1 insex M5x12

(Bottenprofil)

1 vite a brugola M5x12

(profilato basso)

12

M5x8

(spar connections)

screws

12 vis TF M5x8

liaison profils

12 Schraube M5x8

(Verbindung der Profile)

12 bouten M5x8

(koppelstukken )

12 Tornillos M5x8

(unión perfiles)

12

M5x8

(profilkopplingarna)

insex

12 vite M5x8

(collegamento profilati)

1 halyard swivel

1 émerillon

1 Fallwirbel

1 valwartel

1 giratorio

1 Fallsvirvel

1 mulinello

I

2

3

4

5

6

7

8

9

10

12

13

14b

14a

11

1

58223_00 - Page 5/76

PANTONE 072C

Offset 80g

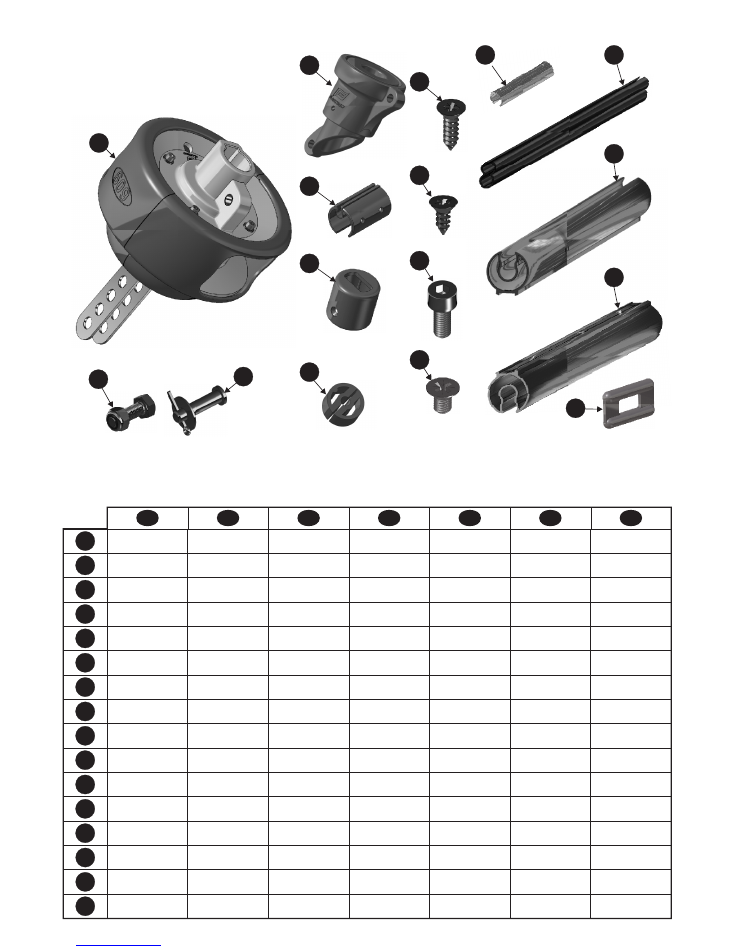

811-S

2

3

4

5

x2

6

7

x4

8

9

x14

x7

10

12

13

1

11

x7

x6

14

- 6 -

14

D

F

GB

S

E

NL

7 Coupling sleeves

7 pièces de jonction

aluminium

7 Verbindungsstücke

7 koppelstukken

7 piezas de uniones

7 Skarvstycken

7 Pezzi di giunzione

7 PVC liners

7 profils PVC

7 PVC-Profile

7 PVC binnenprofielen

7 Perfiles PVC

7 Innerprofil i PVC

- plastrofil

1 base spar

1 profil aluminium

bas

1 unteres Profil

1 basisprofiel

1 perfil bajo

1 Bottenprofil

1 profilato basso

6 Intermediate spars

6 profils aluminium

intermédiaires

6 Zwischenprofile

6 standaardprofielen 6 Perfiles intermedios

6 Standard profiler

6 Profilati intermedi

1 screw+nut M14x40 1 vis+écrou M14x40 1 Schraube M14x40

1 bunten M14x40

1 tornillo M14x40

1

M14x40

insex

1 drum unit

1 ensemble tambour

1 Trommel

1 roltrommel

1 conjunto tambor

1 Trumma

1 insieme tamburo

1 boltrope prefeeder

1 guide ralingue

1 Liekeinführung

1 voorlijkinvoer

1 guía relinga

1 Segelinmatare

1 top end stop

1 embout profil

1 Profilansatzstück

1 top eind stuk

1 terminal tope

1 Toppdel

1 Terminale profilato

2 bearings

2 paliers de profil

2 Stopper

2 lagers

2 cojinetes

2 Lagringar

4 screws Ø3.9x9.5

(prefeeder)

4 vis tôle TF Ø3.9x9.5

fixation guide ralingue

4 Schraube Ø3.9x9.5

(Liekeinführung)

4 schroeven Ø3.9x9.5

(voorlijkinvoer)

4 tornillos Ø3.9x9.5

(guía relinga)

4 spårskruv Ø3.9x9.5

(Segelinmatare)

4 viti lamiera Ø3.9x9.5

(guida ralinga)

1

Ø4.8x12.

(top end stop)

screw

1 vis tôle TF Ø4.8x12.

fixation embout profil

1

Ø4.8x12.

(Profilansatzstück)

Schraube

1 schroef Ø4.8x12.

(top eind stuk )

1 tornillo Ø4.8x12.

(terminal tope)

1 spårskruv Ø4.8x12.

(Toppdel)

1 vite lamiera Ø4.8x12

(terminale profilato)

1

M5x12

(base spar)

screw

1 vis Chc M5x12

fixation profil bas

1

M5x12

(unteres Profil)

Schraube

1

M5x12

(basisprofiel)

schroef

1 tornillo M5x12

(perfil bajo)

1 insex M5x12

(Bottenprofil)

1 vite a brugola M5x12

(profilato basso)

14

M5x8

(spar connections)

screws

14 vis TF M5x8

liaison profils

14 Schraube M5x8

(Verbindung der Profile)

14 bouten M5x8

(koppelstukken )

14 Tornillos M5x8

(unión perfiles)

14

M5x8

(profilkopplingarna)

insex

14 vite M5x8

(collegamento profilati)

1 halyard swivel

1 émerillon

1 Fallwirbel

1 valwartel

1 giratorio

1 Fallsvirvel

7 Profilati PVC

1 Vite M14x40

1 guida ralinga

2 Supporti

1 mulinello

I

2

3

4

5

6

7

8

9

10

12

13

11

1

58223_00 - Page 6/76

PANTONE 072C

Offset 80g

ASSEMBLY INSTRUCTIONS

FOR S-SERIES

406-S 609-S 811-S

- 7 -

I N D E X

1/ TECHNICAL SPECIFICATIONS 406-S, 609-S, 811-S

3

2/ DESCRIPTION OF SPECIFIC PARTS FOR EACH MODEL

2.1 - 406-S

4

2.2 - 609-S

5

2.3 - 811-S

6

3/ TOOLS NEEDED

7

4/ FLAT ASSEMBLY (forestay dismantled))

7

4.1 - Dismantling the forestay

8

4.2 - Assembly of the jib reefing system

9

4.3 - Assembling the last spar

9

4.4 - Assembling the top end stop

10

5/ IN SITU ASSEMBLY (directly onto the boat)

10

5.1 - Measuring the length of the forestay

10

5.2 - Cutting the last spar

11

5.3 - Assembling the top end stop

11

5.4 - Assembling the spars

11

5.5 - Assembling the base spar

12

5.6 - Cutting the PVC liner

12

5.7 - Assembling the boltrope prefeeder

12

5.8 - Assembling the drum unit

13

5.9 - Adjusting the reefing line feeders

13

6/ RECOMMANDATIONS

14

7/ OPTIONAL EXTRAS

15

8/ SPARE PARTS

8.1 - 406-S

72

8.2 - 609-S

73

8.3 - 811-S

74

3/ TOOLS NEEDED

Tools needed :

- Hammer

- Pliers

- Comfortable bosun's chair (Plastimo).

- Allen key (4)

- Electric or hand drill

- 1 Ø4 mm drill

- Hacksaw

- Tape measure

- Screwdriver

- Silicone filler.

4/ FLAT ASSEMBLY

- This method consists of fully dismantling the forestay and assembling the jib reefing system while the forestay is lying flat.

- We recommend this method as it is faster.

- In certain cases the top part of the forestay cannot be dismantled, in this case::

do an in situ assembly (see page 10)

contact a professional who can install a universal joint on the upper part of the forestay.

GB

58223_00 - Page 7/76

PANTONE 072C

Offset 80g

- 8 -

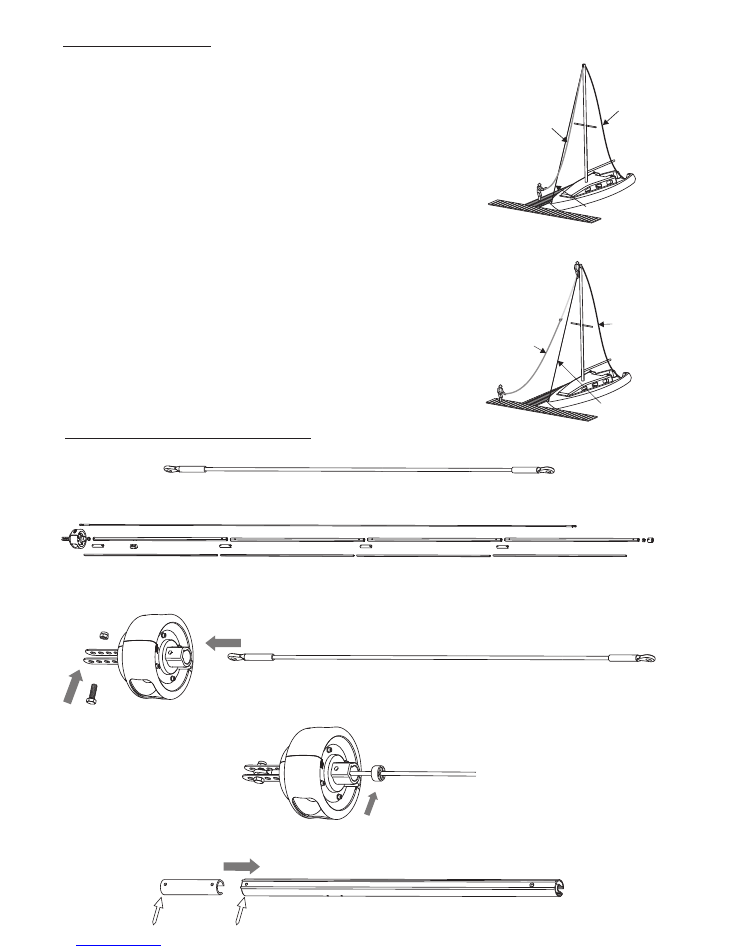

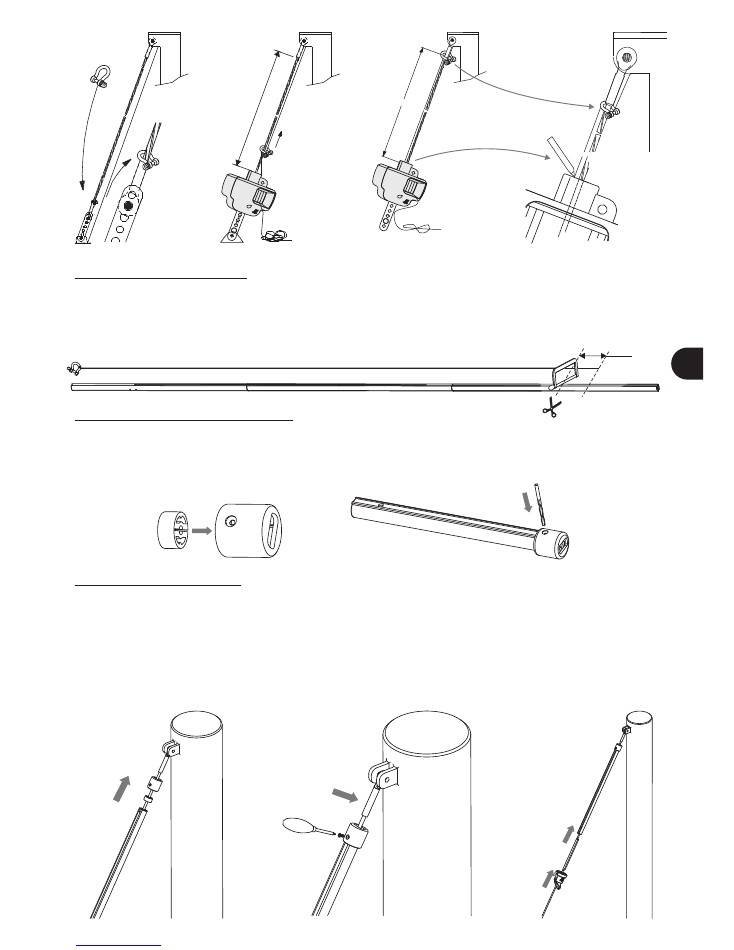

4.1 - Dismanting the forestay

4.1.1 - Lower part

- Slacken the backstay

- Secure the mast forward with 1 or 2 halyards

- Tigthen the halyards to relieve the strain on the forestay

- Dismantle the lower part of the forestay (this usually consists of removing a removing a

rigging screw pin, or a screw and a nut).

Note : it is important to measure the distance between the forestay eye and the hole of the

forward mounting plate in order to find the correct adjustments again.

For a turnbuckle assembly, measure the distance between the mounting plate and the blocking

nut of the turnbuckle.

4.1.2 - Upper part

- Send a person to the masthead (equipped with hammer and pliers)

- Dismount the upper part of the forestay

- Bring the person and the forestay down from the masthead

halyard to

secure the mast

forestay

slackened

backstay

halyard to

secure the mast

forestay

slackened

backstay

4.2 - ASSEMBLING THE JIB REEFING SYSTEM

- Lay the forestay flat

- Place the parts to be assembled alongside the forestay

- Assemble the drum unit on the forestay and put the rigging screw pin or screw and nut in place (select the chainplate hole that

corresponds to the initial forestay adjustment).

- Slide a bearing into the drum

- Insert a coupling sleeve into the base spar (ensure that the hole in the coupling sleeve is in line with the pre-drilled hole of the base

spar)

58223_00 - Page 8/76

PANTONE 072C

Offset 80g

GB

- 9 -

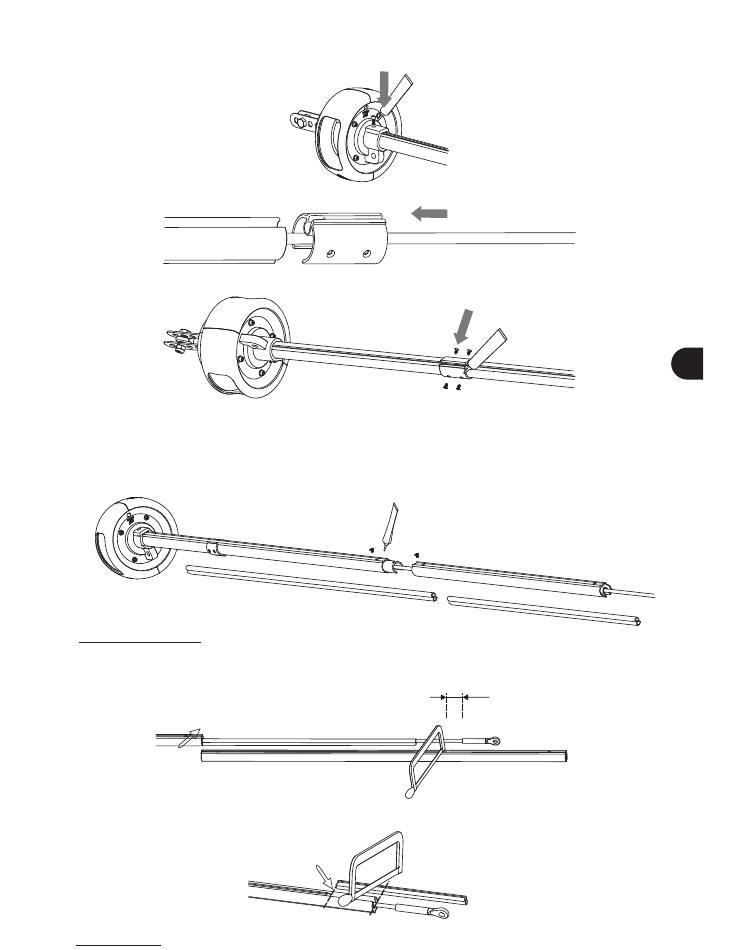

- Slide the base spar into the drum unit until the two holes are in line, insert the M5x12 screw (after putting some silicone filler in the

hole in order to reduce the stainless steel / aluminium electrolytic couple) and tighten.

- Secure with the 4 screws ø3.9x9.5

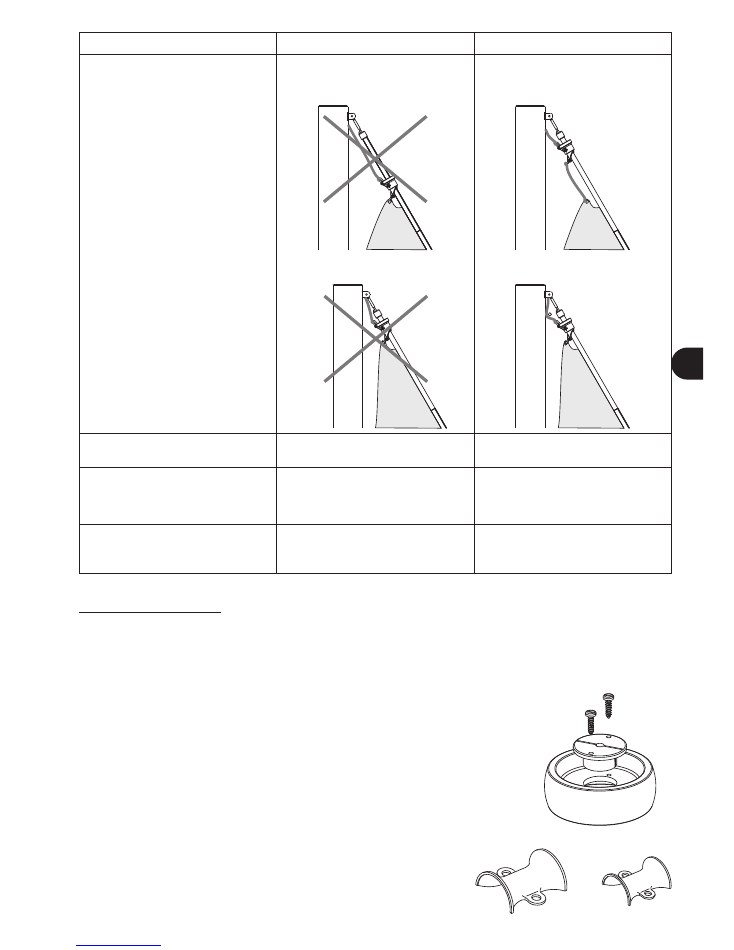

- Install the boltrope prefeeder; ensure it is the right way up, see diagram below.

- Insert an aluminium coupling sleeve, put some silicone filler into the hole and position a MSx8 screw (do not tighten or it will be

difficult to put the second screw in place).

- Put a second spar into position, put some silicone filler in the hole and position the screw (once the two screws are in position they

may both be tightened). Wipe off any excess filler with a cloth.

- Insert PVC liners as you go along (ensure they are flush against the prefeeder)

- Repeat the process until only one spar is left

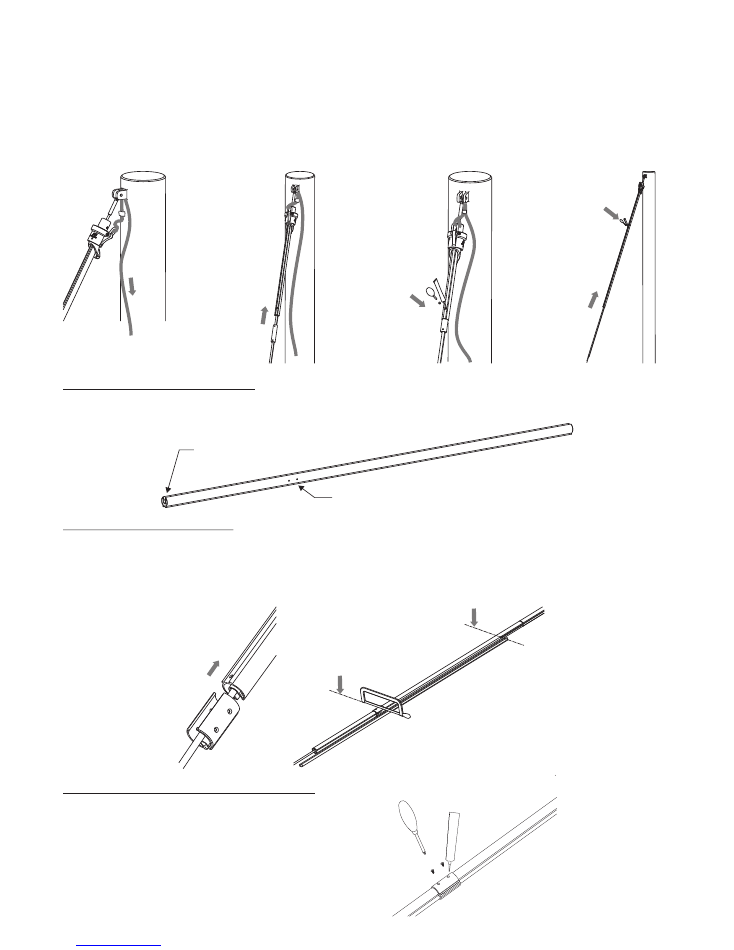

4.3 Cutting the last spar

- Position the last spar so that it lies flush against the previous spar but do not install it

- Measure a distance of 5 cm back from the sleeve of the forestay

- Mark and cut the spar with a hacksaw

- Put a coupling sleeve into position

- Insert the spar, then insert and tighten the screw

5cm

- Position the last PVC liner

- Mark the liner level with the end of the aluminium spar

- Cut and insert the PVC liner

58223_00 - Page 9/76

PANTONE 072C

Offset 80g

- 10 -

4.4 Installing the top end stop

- Slot the second bearing into the top end stop

- Slide the top end stop over the aluminium spar

- Drill a hole (with a Ø4 mm drill). IMPORTANT: refer to diagram for the positioning of the top end stop

- Before putting the screw into position, do not forget to slide the halyard swivel into place (ensure that the conical end of the halyard

swivel faces downwards)

- Put the top end stop back into position

- Put some silicone filler into the hole

- Insert and tighten screw Ø4.8 x 12.7

- Your jib reefing system is now assembled and can be put into position (hoist it up to the masthead with a halyard)

5/ IN SITU ASSEMBLY

Ø

this method of assembly may be carried out by one person

Ø

it is not necessary to dismantle anything at the masthead

5.1 - MEASURING THE LENGTH OF THE FORESTAY

In order for this jib reefing system to be perfectly adapted to your boat the length « X » needs to be known.

- Slide a small shackle around the forestay

- Ensure that it lies flush against the sleeve

- Slacken the backstay

- Secure the mast with a halyard

- Dismount the lower part of the forestay

- Assemble the drum unit

- Reassemble the lower part of the forestay

- Undo the halyard and tighten the backstay

- Attach a halyard to the shackle

- Attach a length of rope (or a tape measure) to the shackle

- Hoist the shackle until it touches the top sleeve of the forestay

- Mark the piece of rope level with the top of the drum unit

- Lower the shackle

58223_00 - Page 10/76

PANTONE 072C

Offset 80g

- 11 -

X

X

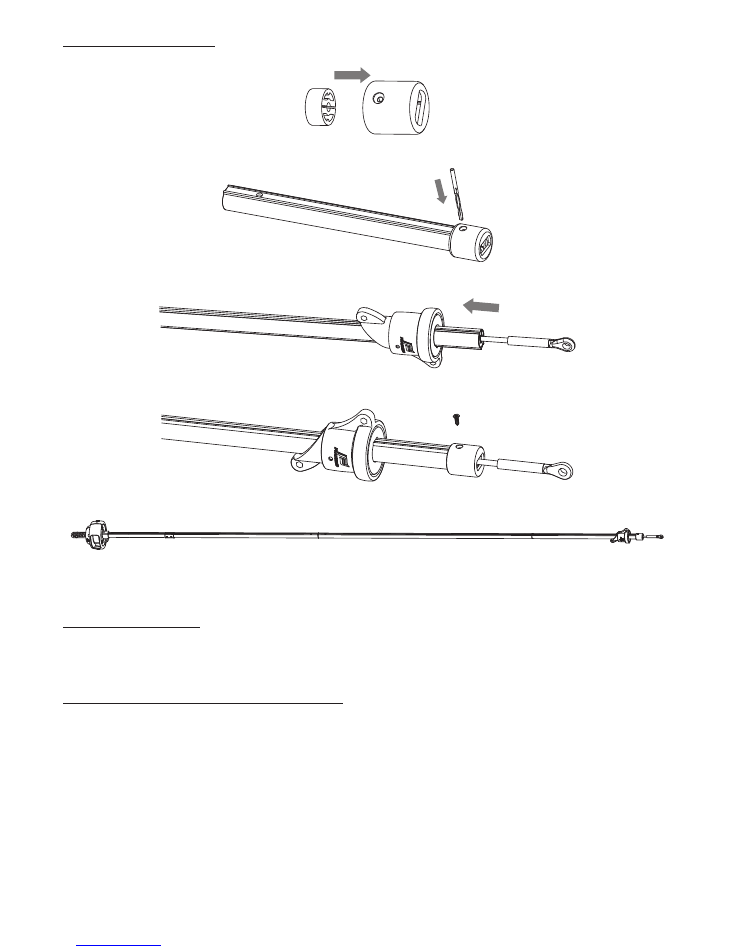

5.2 - CUTTING THE LAST SPAR

- Stretch out flat the piece of rope used to measure the length of the forestay

- Lay the aluminium spars parallel to the piece of rope (take note of base spar, see page 7)

- Mark the spar level with the mark on the piece of rope

- Cut the spar 3 cm (safety margin) below the mark

3cm

X

5.3 - ASSEMBLING THE TOP END STOP

- The top end stop should be assembled on the aluminium spar that has just been cut.

a) The second bearing is slotted into the top end stop

b) Slide the top end stop fully over the end of the spar (IMPORTANT: refer to diagram below for positioning of the hole in the top end

stop)

c) Drill a hole using a Ø4 mm drill

5.4 - ASSEMBLING THE SPARS

- Dismount the forestay from the stemhead fitting

- Install the following on the forestay :

Top end stop

Bearing

The spar that you have cut and drilled

1 screw Ø4.8x12.7

PVC liner

Halyard swivel (IMPORTANT: see drawing below for position of halyard swivel)

58223_00 - Page 11/76

PANTONE 072C

Offset 80g

GB

- 12 -

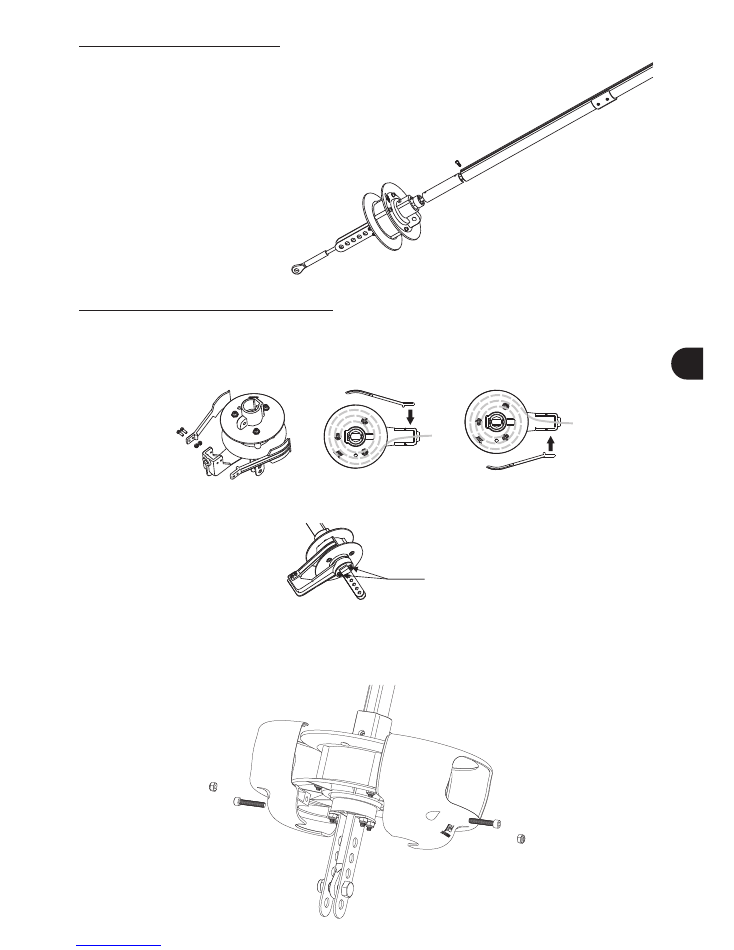

- Refasten the forestay

- Attach a halyard to the halyard swivel in order to support the spars as they are assembled

- Insert a coupling sleeve

- Put some silicone filler into the holes before tightening the screws (in order to reduce the electrolytic couple between the stainless steel

screw and the aluminium)

- Insert an M5 x 8 screw

- Wipe away any excess silicone with a cloth

- Slide another aluminium spar into position

- Insert a PVC liner (IMPORTANT: keep the base spar to one side; you will be assembling it last)

- Repeat the process as many times as necessary

5.5 - ASSEMBLING THE BASE SPAR

E

IMPORTANT: ensure the base spar is facing the right way (see diagram below)

holes to secure prefeeder

end to be inserted

into drum

5.6 - CUTTING THE PVC LINER

- Slide the prefeeder into position from the bottom of the spar until it is in line with the holes in the spar (IMPORTANT: ensure that the

prefeeder is the right way up)

- Insert a Ø3.9x9.5 screw

- Position a PVC liner, mark and cut to required length

- Remove the prefeeder and install the cut PVC liner

5.7 - INSTALLING THE BOLTROPE PREFEEDER

- Put the prefeeder back into position

- Put some silicone filler in the holes

- Insert and tighten the 4 Ø3,9x9,5 screws

- Wipe away any excess filler with a cloth

58223_00 - Page 12/76

PANTONE 072C

Offset 80g

- 13 -

GB

5.8 - ASSEMBLING THE DRUM UNIT

- Detach the forestay from its mounting plate on the boat

- Position the sleeve or turnbuckle* on the drum (*depending on model)

- Slide a bearing into the drum

- Insert a coupling sleeve into the base spar (ensure that the hole in the coupling sleeve is in line with the

pre-drilled hole of the base spar)

- Insert the base spar into the drum unit

- Put some silicone filler in the pre-drilled hole

- Insert the M5x12 screw

- Attach the jib reefing system to the forward mounting plate

- Lower the halyard swivel

- Tighten the backstay

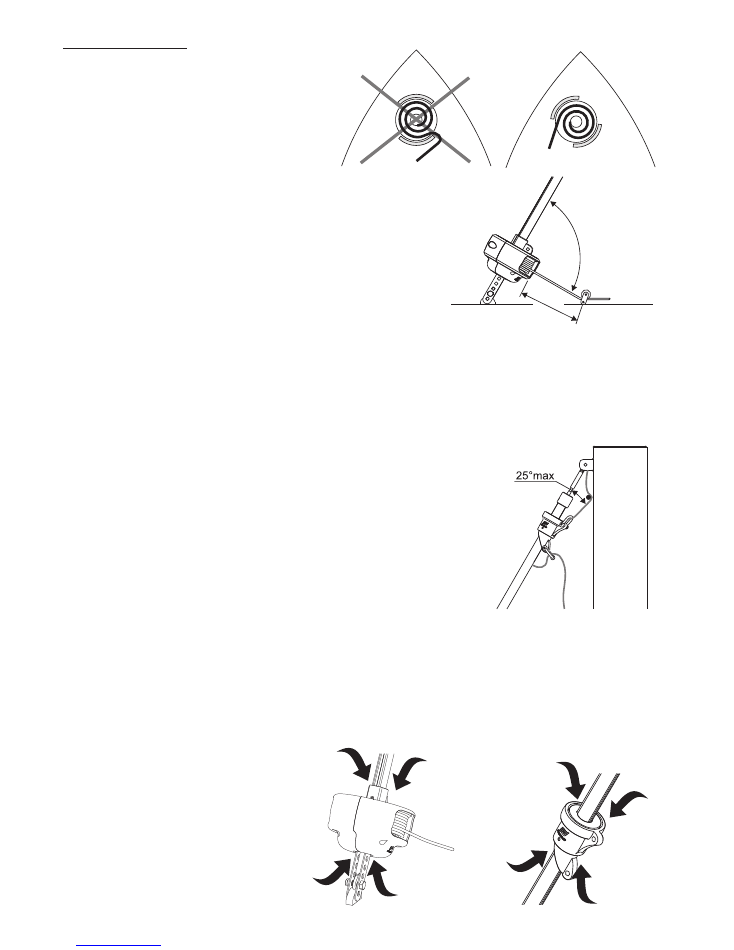

5.9 - ADJUSTING THE REEFING LINE FEEDERS

5.9.1 - 406-S model

- The reefing line feeder on the 406-S model is assembled either on the right or left hand side of the drum unit, depending on which

direction you prefer to reef.

- To fasten the reefing line feeder, use the two M4x12 nuts and bolts

5.9.2 - 609-S & 811-S models

- The angle of reefing line feeders on 609-S & 811-S models is adjusted by loosening the two nuts and bolts (see diagram below)

Screws

- The angle is adjusted by loosening the two screws that hold the chainplate.

port assembly

starboard assembly

58223_00 - Page 13/76

PANTONE 072C

Offset 80g

- 14 -

6/ Recommandations

A

Reefing line feeders

The angle of all the reefing line feeders may be adjusted.

IMPORTANT: they should be positioned in a way that best suits

the direction of pull on the line

A

Reefing line

The reefing line is wound around the drum. Only use pre-stretched rope in order to eliminate

any elasticity

Refer to diagram below for the position of the reefing line as it comes out of the drum

1m

90°

A

Reefing direction of the genoa

The genoa should be reefed in the same direction as the strands turn on the forestay.

A

When you are not sailing

Slacken the backstay in order to reduce undue strain on mechanical parts

A

About the drum

When your genoa is fully reefed and in order to avoid direct strain on mechanical parts and on the knot of the reefing line, there should be a

minimum length of one halyard turn on the drum.

A

Halyard/forestay angle

This angle should never be more than 20-25° as this makes it impossible to tauten and reef the sail.

What is more, this undue strain on the forestay could cause it to unravel and even dismast the boat.

A

When sailing

Ensure that the forestay is always taut. Not only will this make reefing easier but will avoid any danger of the forestay unravelling.

(We recommend putting a universal joint at the masthead)

A

Hauling on the genoa

The reefing line should never be used to haul on the sail.

A

Unfurling the genoa

When unfurling the genoa, ensure that it does not unfurl too quickly by winding the reefing line once round a winch and feeding it out

slowly in one hand and the genoa sheet in the other.

A

Maintenance

Rinse the drum unit and the halyard swivel once a year

with fresh water (no dismantling required).

No other special maintenance is needed.

Fresh water

58223_00 - Page 14/76

PANTONE 072C

Offset 80g

- 15 -

Genoa difficult to hoist

- Poor output from a sheave.

Halyard jammed

- Luffrope too large

- Try with a different halyard

- Change luffrope

PROBLEM ENCOUNTERED

CAUSES

SOLUTIONS

Halyard turns with the halyard swivel

- Forestay not taut enough

- Genoa halyard too slack

- Genoa too short, halyard swivel too low

- tighten the backstay

- tauten the genoa halyard

- Use a strop

- Genoa halyard too close to the forestay

- Fasten a halyard feeder to the mast or a

diverter to the forestay

The halyard tends to wrap itself around the

spar when the genoa is hoisted

- Halyard is worn and thus twists in the

direction of the rope strands

- Change the halyard

Reefing line fouls

- Wrong angle on reefing line.

First sheave too far from drum unit.

- Genoa unfurled too quickly

- Change position of first sheave

- Slow down the unfurling of the genoa by

winding the reefing line once round a winch.

7/ OPTIONAL EXTRAS

7.1 - HALYARD DIVERTERS

When the genoa is furled or unfurled, if the angle between the halyard and the forestay is too tight, the halyard risks being twisted round as

the halyard swivel turns.

2 options are available to solve this problem:

7.1.1 : Halyard diverter wheel

To install the diverter wheel, it is necessary to dismantle the forestay

7.1.2 : Halyard feeder

To install the halyard feeder, it is not necessary to dismantle the forestay

2 sizes are available:

- ref 25677 : 609 et 811 models

- ref 26140 : 406 model

Ref : 25720

Ref : 25677

Ref : 26140

GB

58223_00 - Page 15/76

PANTONE 072C

Offset 80g