Full Text Searchable PDF User Manual

CLICK TO CHANGE TEXT

1

BRUSH CUTTER

EN

OWNERS MANUAL

PGBC-5200

3

2

INTRODUCTION

CONTENTS

This manual has been produced by Parker Products Ltd. and should be kept with the

product and referenced for operation, maintenance and troubleshooting.

This manual contains an overall description of the product, together with all the

necessary information for using the product correctly and safely. It is highly

recommended that this manual is read prior to any operation or maintenance of this product.

The safety precautions and warnings are to ensure your safety and protect you from harm or

damage to the product.

All photographs and drawings in this manual are supplied by Parker Products Ltd. to help you

with the operation and maintenance of the product. The information contained in this manual

was accurate at the time of production, however Parker Products Ltd. may make modifications to

the product without notification.

GENERAL SAFETY ..................................................................................

4

SAFE OPERATION ...................................................................................

5-9

WHAT'S IN THE BOX .............................................................................

10-11

ASSEMBLY ....................................................................................................

12-13

INSTALLING THE 3 TOOTH BLADE

...............................................

14-15

INSTALLING THE SPOOL

.....................................................................

16

WEARING THE HARNESS

....................................................................

17

STARTING THE ENGINE

........................................................................

18-21

STOPPING THE ENGINE

.......................................................................

22

OPEN & REPLACE SPOOL WIRE

....................................................

24-25

ADJUSTING THROTTLE CABLE & IDLING SPEED ............

26

OPERATION .................................................................................................

28-31

TROUBLESHOOTING ...................................................................................

32-35

MAINTENANCE & CARE

.......................................................................

36-38

SPECIFICATIONS .....................................................................................

40

DECLARATION OF CONFORMITY .............................................

41

4

5

GENERAL SAFETY

•

WARNING

! Never allow children or anyone to fully understand the directions given in the manual to use the machine.

•

ALWAYS USE

safety equipment; appropriate footwear, eye protection, ear protection, head protection, trousers and gloves.

•

DO NOT

wear loose clothing, jewellery, short trousers, sandals, or go barefoot.

•

NEVER

start the engine inside a closed room or building.

•

NEVER

use the product when ground is slippery, at night, during rain storms, lightning storms, or at times of strong wind.

•

DO NOT

start the engine within 3m of the fuelling point.

•

REMOVE

all sources of sparks and flames before mixing and pouring fuel.

•

DO NOT

let anyone with in 15m of the product while in operation.

•

INSPECT

the entire unit for loose fasteners and fuel leakages, Make sure that the cutting attachment is properly installed.

•

DO NOT

start cutting until you have a clear cutting area and a secure footing.

•

ALWAYS

use the harness supplied while operating the machine.

•

NEVER

smoke while operating the unit or refilling its fuel tank.

•

ALWAYS

keep the handles dry, clean and free of oil and fuel mixture.

•

ALWAYS

shut off the engine before putting the product down.

•

MAKE SURE

all fuel is removed before transportation.

•

ALL MAINTENANCE

other than that listed in this manual should be carried out by professionally trained and certified personnel.

SAFE OPERATION

GLOVES

Gloves should be worn where appropriate.

HEARING PROTECTION

Hearing protection should be worn to prevent

damage to your ears. Ensure your hearing

protection provides adequate noise reduction.

EYE PROTECTION

Approved eye protection should be worn at all

times during operation.

BOOTS

Wear sturdy, non-slip boots.

CLOTHING

Appropriate clothing should be worn during

operation. Ensure clothing is made of strong

fabric and is not baggy or loose.

FUEL FILLER POINT

THE DIRECTION TO CLOSE THE CHOKE

THE DIRECTION TO OPEN THE CHOKE

ON

OFF

For safe operation and maintenance symbols are moulded in relief on the machine or shown on a label.

6

7

FOR SAFE OPERATION

FOR SAFE OPERATION

IMPORTANT

•

Read this manual carefully until you completely understand and can

follow all safety and operating instructions

•

Keep this manual handy so that you may refer to it later whenever

questions arise. Also note, if you have any questions which cannot be

answered herein, contact Parker Brand.

•

Always be sure to include this manual when selling, lending or other-

wise transferring ownership of this product.

•

Never allow children or anyone unable to fully understand the direc-

tions given in the manual to use the machine.

WORKING CIRCUMSTANCE

•

Never start the engine inside a closed room or building. Exhaust gas-

es contain dangerous carbon monoxide.

•

Never use the product

1. when the ground is slippery or when you can’t maintain a

stead posture.

2. at night, at times of heavy fog, or at any other times when

your field of vision might be limited and it would be difficult

to gain a clear view of the working area.

3. during rain storms, during lightening storms, at times of

strong gale-force winds, or at any other time when weath-

er conditions might make it unsafe to use the product.

WORKING PLAN

•

You should never use this product when under the influence of alco-

hol, when suffering from exhaustion or lack of sleep, when suffering

from drowsiness as a result of taking cold medicine or at any other

time when a possibility exists that your judgment might be impairs or

that you might not be able to operate the product properly and in a

safe manner.

•

When planning your work schedule, allow plenty of time to rest. Limit

the amount of time over which the product is to be used continuous-

ly to somewhere around 30-40 minutes per session, and take 10-20

minutes of rest between sessions. Also try to keep the total amount

of work performed in a single day under 2 hours.

•

If you don’t observe the working time or working manner repetitive

strain injury could occur,

•

If you feel discomfort, redness and swelling of your fingers or any

other part of your body, see a doctor before getting worse.

•

To avoid noise complaints operate product between 9am and 5pm.

BEFORE STARTING THE ENGINE

•

The area within a perimeter of 15m of the person using the product

should be considered a hazardous area into which no-one should

enter. If necessary, yellow warning rope and warning signs should

be placed around the perimeter of the area. When work is performed

simultaneously by two or more persons, care should be taken to con-

stantly look around or otherwise check for the presence and loca-

tions of other people working so as to maintain a distance between

each person sufficient to ensure safety.,

•

Check the condition of working area to avoid any accident by hitting

hidden obstacles such as stumps, stones, cans or broken glass.

•

Inspect the entire unit for loose fasteners and fuel leakage. Make

sure that the cutting attachment is properly installed and securely

fastened.

•

Be sure to attach the cutting attachment guard securely in place, or

you may injure yourself.

•

Always us the harness. Adjust the harness for comfort before start-

ing the engine. The harness should be adjusted so the left hand can

comfortably hold the handlebar grip approximately waist high.

STARTING THE ENGINE

•

Keep bystanders and animals at least 15m (50ft) away from the oper-

ating point. If you are approached, immediately stop the engine.

•

The product is equipped with a centrifugal clutch mechanism, so the

cutting attachment begins to rotate as soon as the engine is started

by putting the throttle trigger into the start position. When starting

the engine, place the product onto the ground in a flat clear area

and hold it firmly in place so as to ensure that neither the cutting at-

tachment nor the throttle trigger come into contact with any obstacle

when the engine starts.

•

After starting the engine, check to make sure that the cutting attach-

ment stops rotating when the throttle trigger is moved fully back to it’s

original position. If it continues to rotate even after the throttle trigger

has been moved fully back, turn off the engine contact Parker Brand.

i

i

i

i

i

8

9

FOR SAFE OPERATION

FOR SAFE OPERATION

USING THE PRODUCT

•

Grip the handles firmly with both hands using your whole hand. Place

your feet slightly apart (slightly further apart than shoulder width) so

that your weight is distributed evenly across both legs, and always

be sure to maintain a steady, even posture while working.

•

Keep cutting attachment below waist level.

•

Maintain the speed of the engine at the level required to perform cut-

ting work, and never raise the speed of the engine above the level

necessary.

•

If the unit starts to shake or vibrate, turn off the engine and check the

whole unit. Do not use until the problem has been properly corrected.

•

Keep all parts of your body away from rotating cutting attachment

and hot surfaces.

•

Never touch the muffler, spark plug, or other metallic parts of the en-

gine while the engine is in operation or immediately after shutting

down the engine. Doing so could result in serious burns or electrical

shock.

BE CAREFUL OF SURROUNDING PEOPLE

•

Guard against hazardous situations at all times. Warn adults to keep

pets and children away from the area. Be careful if you are ap-

proached. Injury may result from flying debris.

MAINTENANCE

•

In order to maintain your product in proper working order, perform

the maintenance and checking operations described in the manual

at regular intervals.

•

Always be sure to turn off the engine before performing any mainte-

nance or checking procedures.

•

In the event that any part must be replaced or any maintenance or

repair work not described in this manual must be performed please

contact Parker Brand.

•

Under no circumstances should you ever take apart the product or

alter it in any way. Doing so might result in the product becoming

damaged during operation or the product becoming unable to oper-

ate properly.

HANDLING FUEL

•

The engine of our product is designed to run on a mixed fuel, which

contains highly flammable gasoline. Never store cans of fuel or refill

the tank of the unit in any place where there is a boiler, stove, wood

fire, electrical sparks, welding sparks, or any other source of heat or

fire which might ignite the fuel.

•

Never smoke while operating the unit or refilling its fuel tank.

•

When refilling the tank, always turn off the engine and allow it to

cool down. Take a careful look around to make sure that there are no

sparks or open flames anywhere nearby before refuelling.

•

Wipe spilled fuel completely using a dry rag if any spillage occurs

during refuelling.

•

After refuelling, screw the fuel cap back tightly onto the fuel tank and

then carry the unit to a spot 3m or more away from where it was re-

fuelled before turning on the engine.

TRANSPORTATION

•

When hand-carrying the product, cover over the cutting attachment

if necessary, lift up the product and carry it paying attention to the

cutting attachment.

•

Never transport the product over rough roads or long distances by

vehicle without removing all fuel from the fuel tank. If doing so fuel

might leak from the tank during transport.

i

i

i

i

i

10

OPERATION

WHAT’S IN THE BOX

MAIN ENGINE

BULL HORN HANDLE BARS

LOWER SHAFT

+ SPOOL AND BLADE HUB

+ BRACKET FOR LOWER GUARD

TOOL KIT

+ SPARK PLUG WRENCH

+ ALLEN KEY WRENCH

WASHER ‘A’

WASHER ‘B’

3 TOOTH BLADE NUT

11

WHAT’S IN THE BOX

SAFETY HARNESS

THREE TOOTH BLADE

LOWER GUARD

SPOOL

Washers and nut are pre-installed on the

lower shaft.

i

12

13

ASSEMBLY

Attach the guard to the lower shaft using the

screws and tools provided.

Loosen the four screws on the upper cap and

place the bull horn handle inside.

Re-tighten the four screws to secure the handle in

position.

1

ATTACH THE LOWER GUARD

2

ATTACH THE HANDLE

Over-tightening the bolts can cause damage to the screw and/or the machine.

ASSEMBLY

1. Insert the locking knob into the shaft

connector.

2. Pull and hold the locating pin while securing

the lower shaft into the joint

3. Release the pin and rotate the lower shaft

until the joint is locked into position.

4. Secure the joint by tightening the knob.

1. Install the lower collar to the bottom of the

spool housing using the tools and screws pro-

vided.

2. Ensure the hole on the collar and spool

housing are aligned as illustrated above.

3

JOIN THE SHAFTS

4

INSTALL THE COLLAR

This step may already be complete.

i

14

15

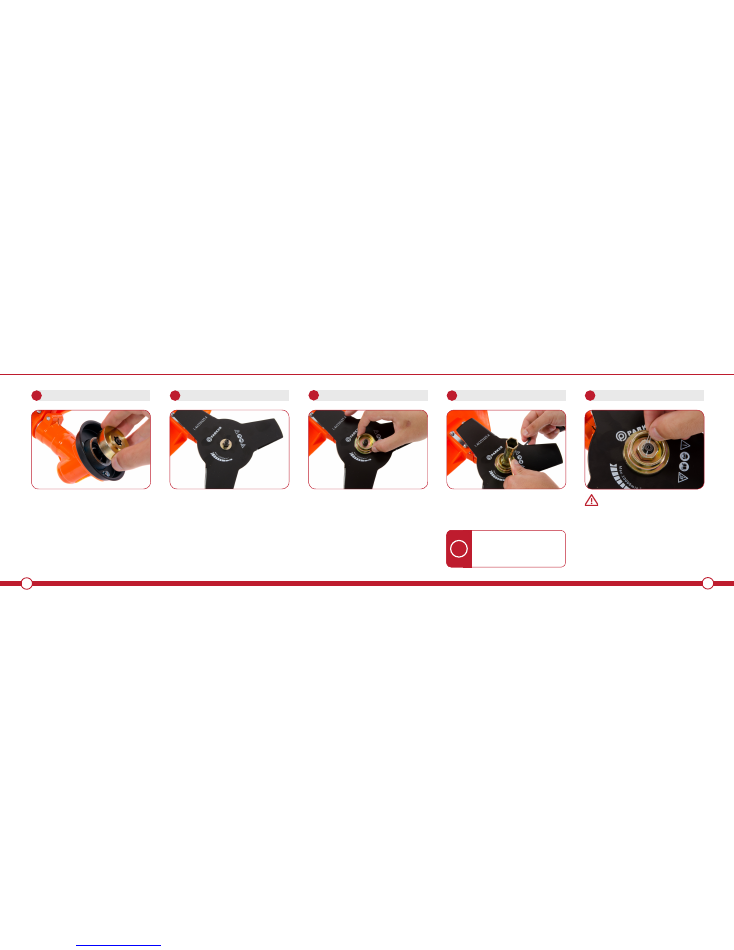

INSTALLING THE 3 TOOTH BLADE

Install washer “A” as illustrated above. Align the

hole in the washer with the hole in the spool collar.

Lock the axle by placing the allen key inside the

locating hole of the black collar and tighten the

locking nut in an anti-clockwise direction using the

wrench provided.

Place the three tooth blade so the centre hole sits

within washer “A”.

It is important that the blade sits correctly with-

in washer “A” and not in an off-centered position

which can cause excessive vibration and prema-

ture damage to the lower shaft.

1

INSTALL LOWER WASHER

2

ATTACH THE BLADE

3

INSTALLING THE 3 TOOTH BLADE

Install washer “B” as illustrated above to secure

the blade to the shaft.

Lock the axle by placing the allen key inside the

locating hole of the collar and tighten the locking

nut using the wrench provided, turning anti-clock-

wise until secured tightly.

IMPORTANT!

Place the split pin (where applicable) inside the

thread to prevent the nut coming loose.

4

SECURE UPPER WASHER

TIGHTEN LOCKING NUT

5

SECURE THE NUT

This is reverse threaded so to

tighten the nut you will have to turn

in an anti-clockwise direction and

clockwise to loosen.

i

16

17

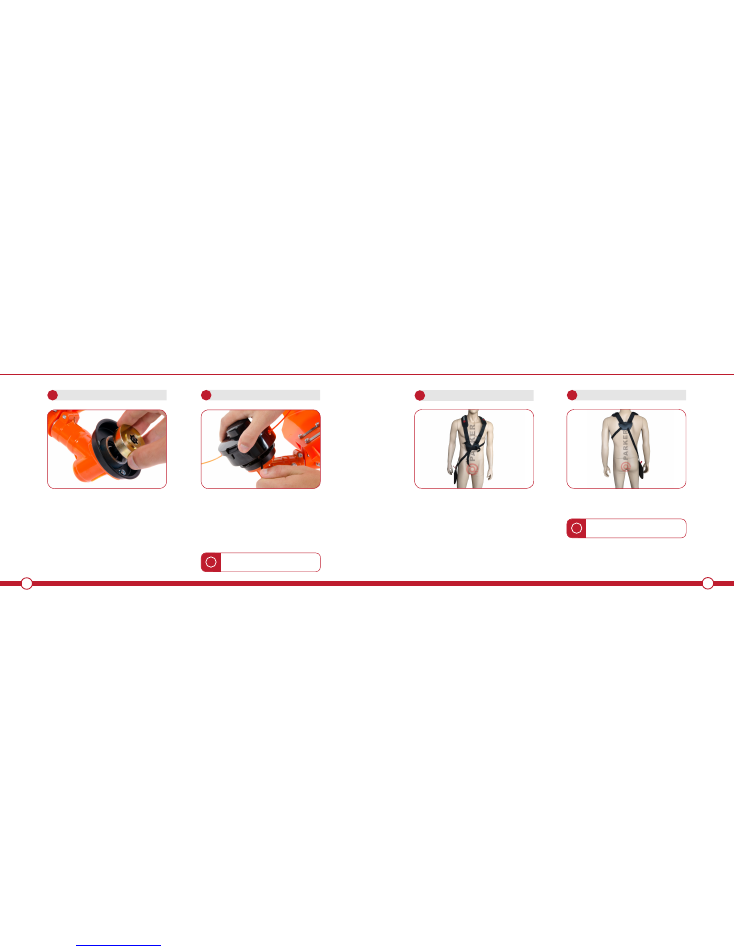

INSTALLING THE SPOOL

2

ATTACH SPOOL HOUSING

1

INSTALL LOWER WASHER

Install washer “A” as illustrated above. Align the

washer with the hole on the spool collar.

The purpose of this washer is to enable tightening

of the nut by locking the shaft, this is done by

inserting the allen key through the hole in the spool

collar and into the hole in washer “A”.

Lock the axle by placing the allen key inside the

locating hole of the collar and wind the spool onto

the thread by turning anti-clockwise.

Please ensure that the spool is secure and closed

correctly prior to use.

To remove the spool follow the above

directions in reverse.

i

WEARING THE HARNESS

1

PLACE OVER HEAD

2

ADJUST THE HARNESS

Your harness is designed to be worn with the

brush cutter hung on the right hand side.

Adjust the harness so it is secured against your

body.

Mannequin not included.

i

18

19

STARTING THE ENGINE

2

PRIME THE CARBURETTOR

1

FILL THE TANK

Remove the fuel cap and fill the tank to no more

than 80% capacity.

Fuel should be a mixture of unleaded petrol and 2 stroke

oil mixed at a ratio of 40:1 (Unless otherwise instructed).

Prime the carburettor by repeatedly pressing the

bulb located underneath the air filter housing.

The fuel cap must be secure and tight for the car-

burettor to prime.

STARTING THE ENGINE

3

CLOSE CHOKE (COLD START)

3

OPEN CHOKE (WARM START)

For cold engine starts close the choke by sliding

the lever upwards.

For warm engine starts open the choke by sliding

the lever downwards.

A

B

CHOKE CLOSED

CHOKE OPEN

The product is equipped with centrifugal clutch mechanism, so the cutting attachment begins to rotate as

soon as the speed of the engine is increased.

Fuel is highly flammable and care must be taken to avoid any spillages and contact with naked flames.

20

21

STARTING THE ENGINE

5

TENSION THE RECOIL

4

SWITCH ON

Enable power to the spark plug by placing the on/

off switch to position “I”

“I” has to be in downward position.

Place the unit on the ground and using your left

foot to secure the shaft to the ground while using

your right hand to pull the recoil starter handle

outwards until tension is felt.

Over-choking can make the engine hard to start due to excess fuel. When the engine failed to start after

several attempts, open the choke and repeat pulling the rope, or remove the spark plug and dry it.

i

STARTING THE ENGINE

6

START THE ENGINE (COLD START)

6

START THE ENGINE (WARM START)

B

A

Make sure that the choke is

CLOSED

1. Pull the recoil starter twice in quick

succession.

2. Proceed to Step 6B and follow instructions for

warm start.

1. Make sure that the choke is

OPEN

2. Pull the recoil starter in quick succession until

the engine starts.

Do not pull the starter cord to the end and avoid releasing the handle while fully extended.

Both of the above can cause premature damage to the mechanism.

22

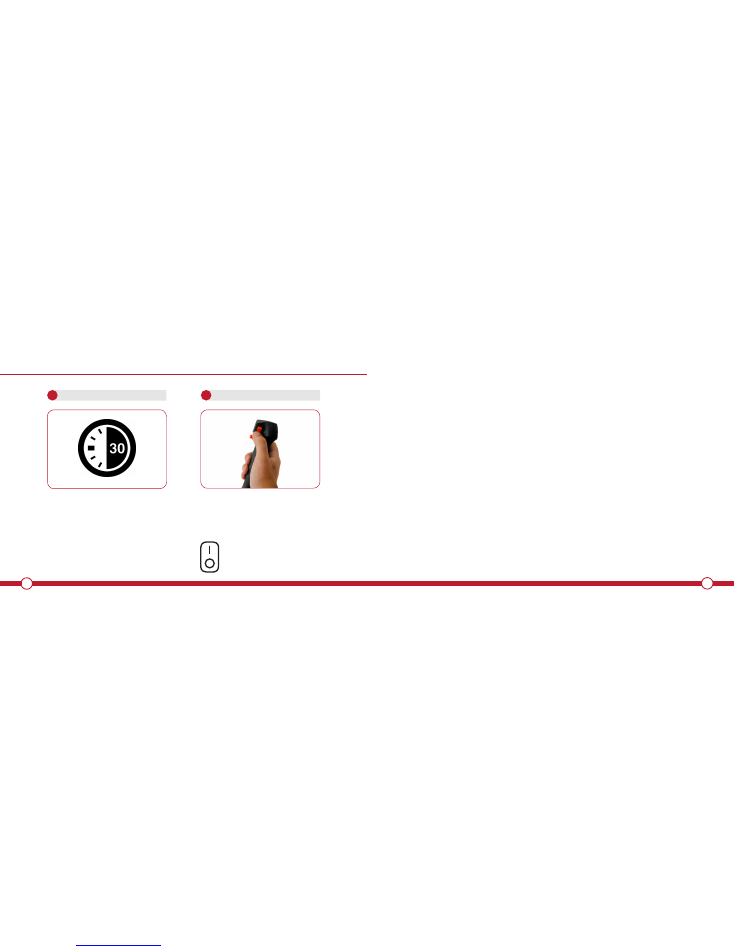

STOPPING THE ENGINE

2

SWITCH OFF

1

PREPARE TO STOP

Release the throttle trigger and let the engine idle

for 30 seconds.

This allows the engine to cool down and return to

optimum operating temperature.

Turn the engine off by placing the on/off switch to

position “O” as illustrated above.

When restarting the engine after immediately

stopping it, leave the choke open to prevent

flooding the engine.

THIS PAGE HAS INTENTIONALLY BEEN LEFT BLANK

23

ON

OFF

24

OPEN & REPLACE SPOOL WIRE

2

PREPARE WINDINGS

1

OPEN THE SPOOL

Open the spool by pressing one of the two clips

to loosen the cover. Once loose firmly press the

second clip and remove the spool cartridge from

inside the housing.

The cartridge consists of two windings which

need to be wound in the direction shown on the

body. Secure the replacement wire to the cartridge

as shown.

Replacement strimmer wire should be 2.4mm in diameter.

I

25

OPEN & REPLACE SPOOL WIRE

3

SECURE WINDING

4

REPEAT STEP 2 & 3

Secure the winding inside one of the two lugs to

grip the cord and prevent it unwinding.

Repeat steps 2 & 3 for the second winding and

thread back through the eyelets. Securing the

cover by repeating ‘Step 1’ in reverse.

26

27

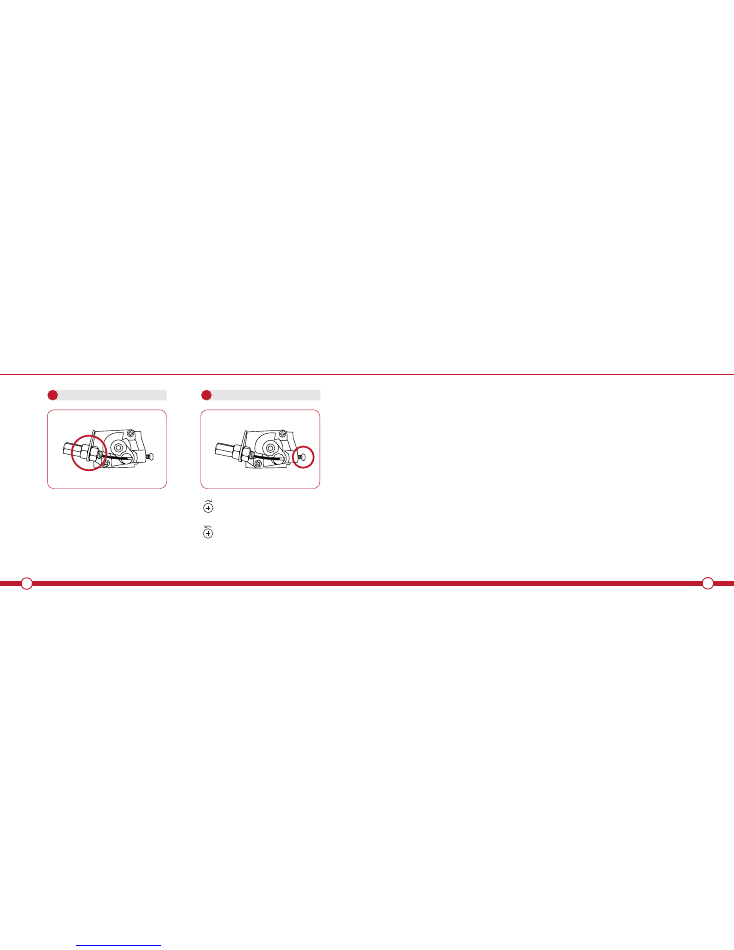

ADJUSTING THROTTLE CABLE & IDLING SPEED

2

ADJUSTING IDLING SPEED

1

ADJUSTING THROTTLE CABLE

Your throttle cable may become slack after

prolonged use and adjustment may be required.

To adjust the throttle cable loosen or tighten the

nuts illustrated above. Always allow 1-2mm of play

to ensure the cable is not under load at all times.

When the engine tends to stop frequently

at idling mode, turn the idle speed

adjuster clockwise.

When the cutting head keeps rotating

after releasing the trigger, turn the idle

speed adjuster counter clockwise

THIS PAGE HAS INTENTIONALLY BEEN LEFT BLANK

28

29

OPERATION

TRIMMING GRASS AND WEEDS

1. Hold the unit so the head is off the ground and is

tilted about 20 degrees toward the sweep

direction.

2. Sweep from left to right to avoid thrown debris.

3. Use a slow, deliberate action to cut heavy growth.

4. Never swing the unit hard as you are in danger of

losing your balance or control of the unit.

5. Try to control the cutting motion with your hip

rather than placing the full workload on your

arms and hands.

6. Take precautions to avoid wire, grass and dead,

dry, long-stem weeds from wrapping around the

shaft head.

Such materials can stall the head and cause the

clutch to slip, resulting in damage to the clutch

system if repeated frequently.

CUTTING METHOD

1. Use the front left side for optimal cutting.

2. Guide the blade from your right to left with it

tilted slightly to your left.

3. When mowing a wide area, start working from

your left end to avoid interference of cut grass.

4. The blade may be seized by weeds if the engine

speed is too low, or the blade cuts too deep into

weeds. Adjust the engine speed and cutting

depth according to the type of material being cut.

If grass or other object get caught in the blade,

or if the unit starts to shake or vibrate, turn off

the engine and check the whole unit. Change the

blade if it has been damaged.

Turn off the engine and make sure the blade has

completely stopped before checking the blade

and removing any object that has got caught in.

Always wear eye protection during operation. Never lean over rotating cutting head.

Never swing the unit hard as you are in danger of losing your balance or control of the unit.

OPERATION

CHOOSE THE BLADE

Choose the suitable recommended cutting attach-

ment according to the object to be cut

When replacing blade always be sure to use Parker

Brand products.

When sharpening, removing, or attaching the blade,

be sure to wear thick, sturdy gloves and use only

proper tools and equipment to prevent injury.

ADJUSTING THE LINE LENGTH

Your brush cutter is equipped with a semi-auto

type nylon trimmer head that allows the operator to

advance the line without stopping the engine. When

the line becomes short, lightly tap the head on the

ground while running the engine at full throttle.

Each time the head is bumped, the line advances

about 1 inch (25.4mm). For better effect, tap the head

on bare ground or hard soil. Avoid bumping in thick,

tall grass as the engine may stall by overload.

TWIN LINE SPOOL

Use this for light trimming.

3 TOOTH BLADE

Use this blade for dense growth.

9 TOOTH BLADE

Use this for extremely dense growth.

30

31

OPERATION

OPERATION

OPERATION

1. Check the bolt to fasten the blade and be sure

the bolt has no faults or damage.

2. Be sure that the blade and the holder have been

fastened according to instruction and that the

blade turns smoothly without abnormal noise.

The rotating parts fastened incorrectly may cause

serious injury to the operator.

Make sure that the blade is not bent, warped,

cracked, broken or damaged.

If you find any error to the blade, discard it and

replace with a new one.

Make sure to use the harness and cutting

attachment guard. If not, it is very dangerous when

you slip or lose your balance.

TRANSPORTING THE UNIT

• When you finish cutting in one location and wish

to continue work in another spot, turn off the

engine, lift up the unit and carry it, paying

attention to the blade.

• Never forget to place the protective cover over

the blades while transporting.

• When transporting the unit over long distances,

detach the blade and fasten the unit by ropes.

CONTROLLING BLADE THRUST

Blade thrust can cause serious personal injury.

Carefully study this section. It is important that you

understand what causes blade thrust, how you can

reduce the chance of it, and how you can remain in

control of the unit if blade thrust occurs.

What causes blade thrust:

• Blade thrust can occur when the moving blade

come in contact with an object that it cannot

cut. This contact causes the blade to stop for

an instant and then suddenly move or "bounce"

away from the object that was hit. The operator

can lose control of the unit and the blade can

cause serious personal injury to the operator, or

any person nearby if the blade contacts any part

of the body.

How you can reduce the chance of blade thrust:

• Recognise that the blade thrust can happen. By

understanding and knowing about blade thrust

you can help eliminate the element of surprise

• Cut fibrous weeds and grass only. Do not let the

blade contact materials it cannot cut such as

hard, woody vines, and bushes or rocks, fences,

metal etc.

• Be extra prepared for thrust if you must cut

where you cannot see the blade making contact

such as in areas of dense growth.

• Keep the blade sharp. A dull blade increases the

chance of thrust.

• Avoid feeding the blade too rapidly. The blade

can bounce away from material being cut if the

blade is fed faster than its cutting capability.

• Cut only from your right to your left.

How you can maintain control:

• Keep a good, firm grip on the unit with both

hands. A firm grip can help neutralise thrust.

Keep your right and left hands completely

around the respective handles.

• Keep both feet spread apart in a comfortable

stance and yet braced for the possibility that the

unit could bounce. Do not overreach. Keep firm

footing and balance.

32

33

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Engine will not start

No spark

To check for spark: Disconnect the spark plug wire. Reattach the spark

plug wire and lay spark plug on metal cylinder. Pull the starter rope and

watch for spark at spark plug tip. If there is no spark, repeat test with a

new spark plug

No fuel

Push primer bulb until bulb is full of fuel. If bulb does not fill, primary

fuel delivery system is blocked. Contact a service dealer. If primer bulb

fills, engine may be flooded (see next item)

Flooded engine

Remove spark plug, turn trimmer so spark plug hole is aimed at the

ground. Move choke lever to “RUN” and pull starter cord 10 to 15 times.

This will clear excess fuel from engine. Clean and reinstall spark plug.

Pull starter three times with choke lever at “RUN”. If engine does not

start, move choke lever to “CHOKE” and repeat normal starting proce-

dure. If engine still fails to start, repeat procedure with a new spark plug

Starter rope pulls harder now than

when new

Contact Parker Brand

Engine starts but will not

accelerate

Carburetor requires adjustment

Contact Parker Brand

Engine starts but will cut

out when the throttle is

pressed

Choke is in start/closed position

When the engine is running the choke should remain open (the down-

wards position)

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Engine starts but will

only run at high speed

at half choke

Carburetor requires adjustment

Contact Parker Brand

Engine does not reach

full speed and emits

excessive smoke

Check oil fuel mixture

Use fresh fuel and the correct 2-cycle oil mix

Air filter dirty

Clean air filter. Refer to “Replacing and

Cleaning Air Filter” earlier in this manual

Carburetor requires adjustment

Contact Parker Brand

Engine starts, runs,

and accelerates but

will not idle

Carburetor requires adjustment

Contact Parker Brand

Spool will not unwind

String welded to itself

Lubricate with silicone spray

Not enough string on spool

Install more string. Refer to “String Replacement”

earlier in this manual

34

35

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Spool retainer hard to

turn

Screw threads dirty or damaged.

Clean threads and lubricate with grease - if no improvement,

replace spool retainer

Oil drips from muffler

Operating trimmer at part

throttle

Operate trimmer at full throttle

Check oil/fuel mixture

Use fresh fuel and the correct 2-cycle oil mix

Air filter dirty

Clean air filter. Refer to “Replacing and Cleaning Air

Filter” earlier in this manual

Carburetor requires adjustment

Turn mixture needle clockwise 1/16 turn

Spool / Three Tooth

Blade does not rotate

when engine speed is

increased

Top and bottom shafts are not

correctly engaged.

Remove the bottom shaft and re-insert ensuring the joint is correctly

connected and engaged.

Excessive vibration

is felt when using the

three tooth blade

Top and bottom shafts are not

correctly engaged

Remove the bottom shaft and re-insert ensuring the joint is correctly

connected and engaged.

Three tooth blade is not installed

centrally

Reinstall the three tooth blade ensuring the blade is installed centrally

and with the correct washers

TROUBLESHOOTING

PROBLEM

POSSIBLE CAUSE

SOLUTION

Spool will not unwind

String welded to itself

Lubricate with silicone spray

Not enough string on spool

Install more string. Refer to “String Replacement”

earlier in this manual

Grass wraps around

shaft housing and

string-head

Cutting tall grass at ground

level

Cut tall grass from the top down

Operating trimmer at part

throttle

Operate trimmer at full throttle

36

37

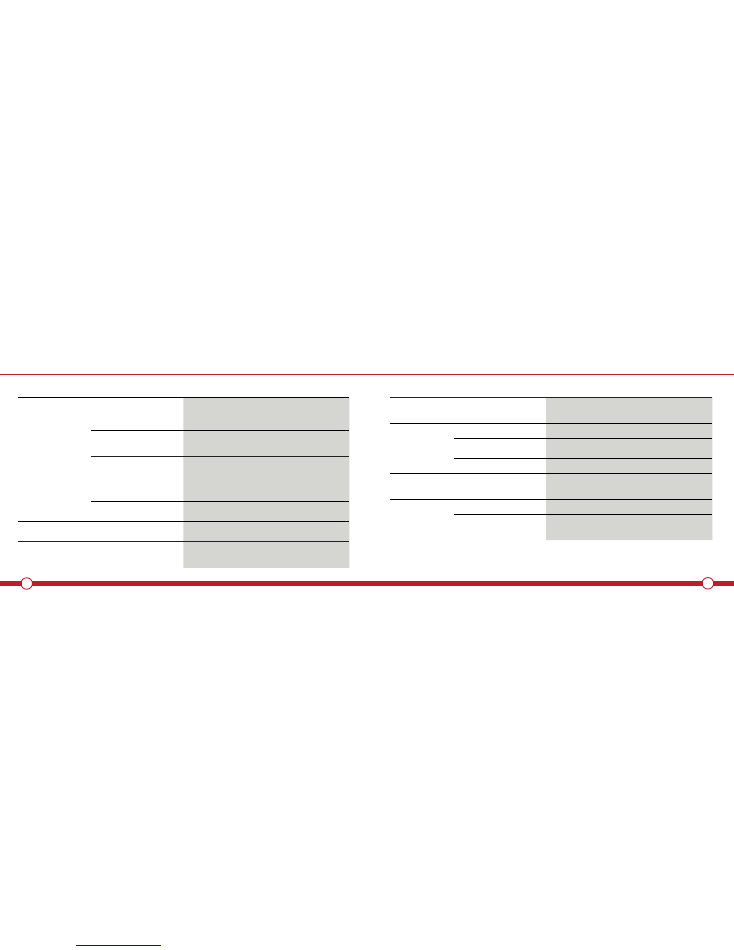

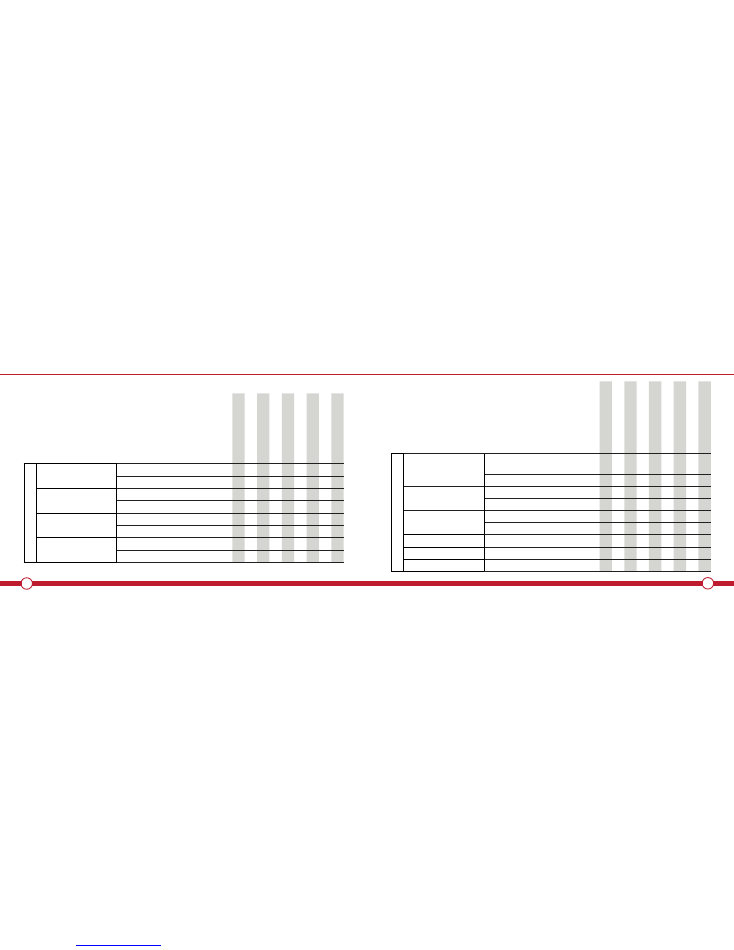

MAINTENANCE & CARE

MAINTENANCE & CARE

Be

fore s

tar

ting w

ork

Aft

er f

ini

shing w

ork or d

aily

Aft

er e

ach re

fuelling s

top

W

eekly

M

ont

hly

Ye

arly

If problem

If d

am

age

d

As re

quire

d

EN

GI

N

E

Air Filter

Clean

X

X

Replace

X

Manual fuel pump (if fitted)

Check

Have repaired by servicing dealer

Pickup body in fuel tank

Check

X

Replace

X

X

X

Gearbox Lubrication

Check

X

X

X

Replenish

X

Be

fore s

tar

ting w

ork

Aft

er f

ini

shing w

ork or d

aily

Aft

er e

ach re

fuelling s

top

W

eekly

M

ont

hly

Ye

arly

If problem

If d

am

age

d

As re

quire

d

EN

GI

N

E

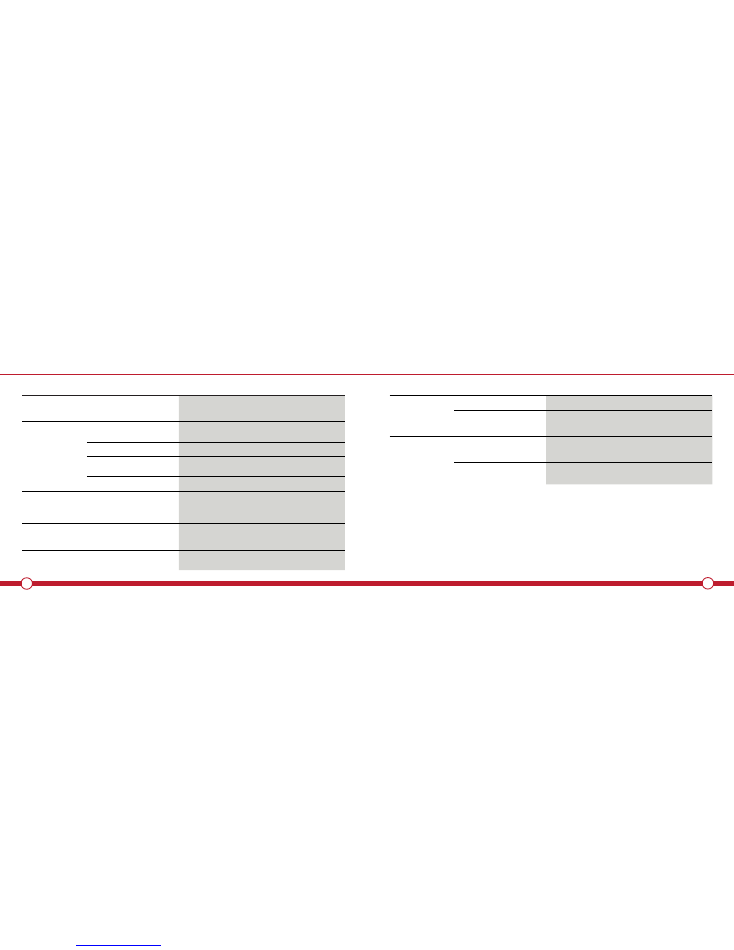

Carburetor

Check idle adjustment – the cutting

attachment must not rotate

X

X

Adjust idle speed

X

Spark Plug

Readjust electrode gap

X

Replace after every 100 operating hours

Cooling Inlets

Visual inspection

X

Clean

X

Fuel Tank

Clean

X

X

Air Filter

Clean

X

Fuel Filter

Clean

X

38

39

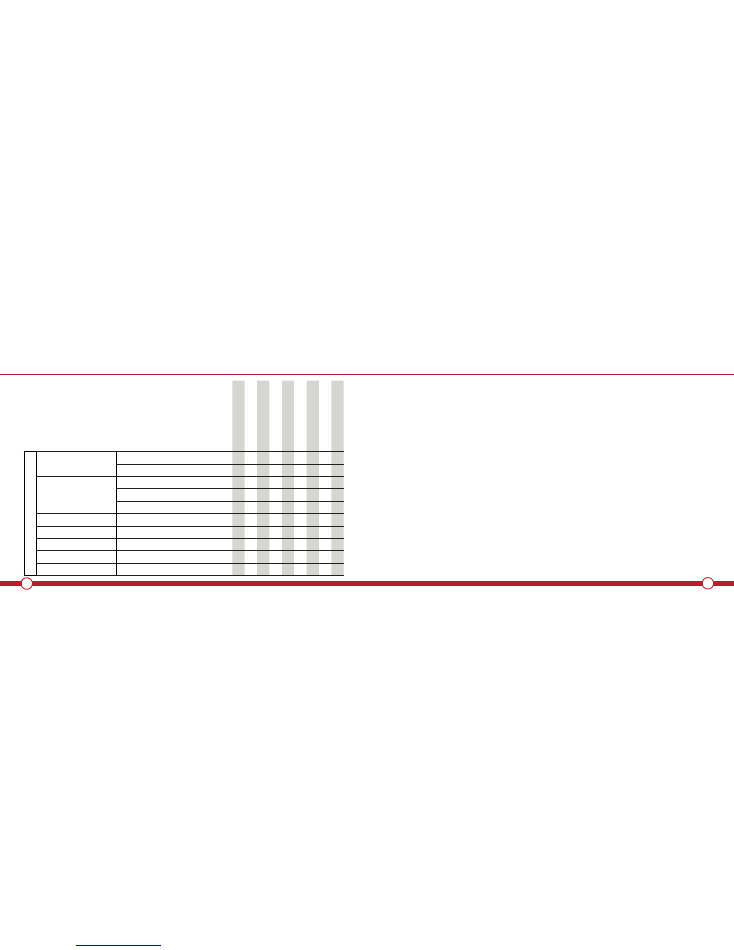

MAINTENANCE & CARE

Be

fore s

tar

ting w

ork

Aft

er f

ini

shing w

ork or d

aily

Aft

er e

ach re

fuelling s

top

W

eekly

M

ont

hly

Ye

arly

If problem

If d

am

age

d

As re

quire

d

O

TH

ER

Complete machine

Visual inspection (condition, leaks)

X

X

Clean

X

Cutting Attachment

Visual inspection

X

X

Replace

X

Check tightness

X

X

Cutting Attachment Guard

Attach

X

Control Handle

Check operation

X

X

Metal Cutting Attachment

Sharpen

X

X

All accessible screws and nuts

Re-tighten

X

X

Anti-vibration Elements

Check

X

X

X

THIS PAGE HAS INTENTIONALLY BEEN LEFT BLANK

41

40

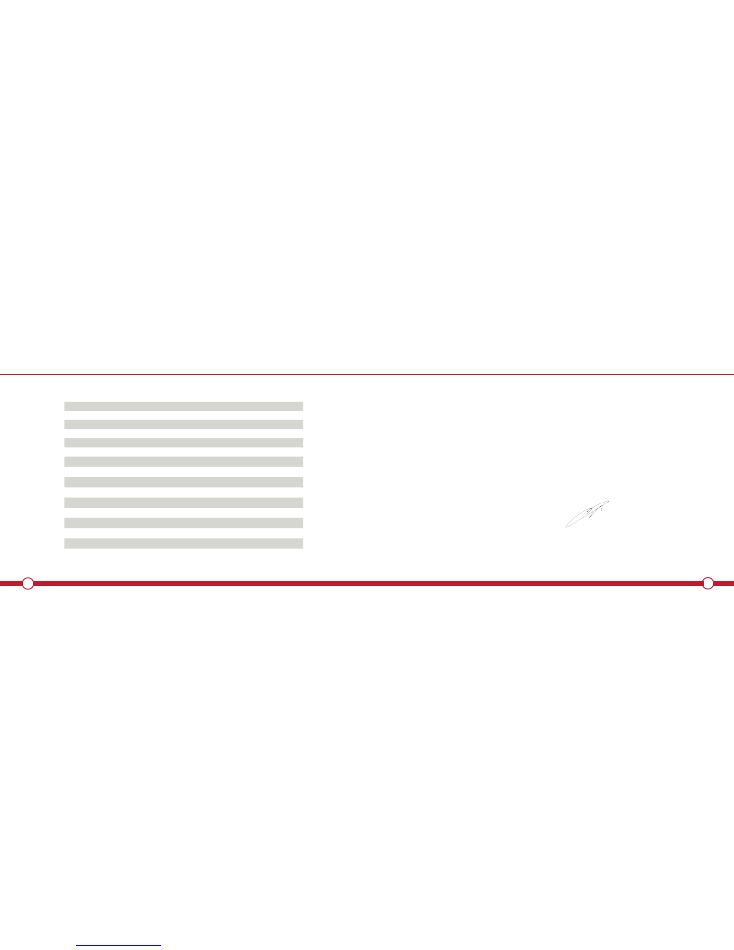

Engine:

10mm

Model

1E44F-5

Displacement

52,0cm3

Fuel

Mixture (Gasoline 40: Oil 1)

Carburetor

Diaphragm type

Ignition System

Transistor Controlled Flywheel Magneto

Spark Plug

LD BM6A

Fuel Tank Capacity (cm)

1.2 Litres

Starter

Recoil

Clutch

Centrifugal

Cutting Head Rotating Direction

Counter-Clockwise (Operator View)

3 Tooth Blade Size

1.4 x 255 x 254

Spool Wire Size

2.4mm

Overall size (L x W x H)

1860 x 610 x 520mm

Dry weight

8.5kg

SPECIFICATIONS

DECLARATION OF CONFORMITY

Description & Function:

52cc Petrol Brush Cutter

Model/Type:

PGBC-5200

Manufacturing Date/Serial Number:

2017

Conforms to the following Directives:

☑ 2006/42/EC Machine Directive (MD)

☑ 2004/108/EC Electromagnetic Compatibility Directive (EMC)

☑ 2000/14 EC & 2005 /88 EC Directive of Emission

☑ 2000/14 EC & 2005 /88 EC Directive of EU Noise

Manufacturer’s authorised representative within the EC:

Parker Products Ltd.

Richmond Park

Richmond Road

Louth

LN11 0FU

Conforms to the requirements of the Directives, as

indicated, and the following harmonised standard(s):

☑ EN ISO 11681 - 1:2011

☑ EN ISO 14982 - 2009

☑ EN ISO 3744 - 1995

☑ EN ISO 9207 - 1995

EC type-approved No:

e11*97/68SA*2010/26*2712*00 (EUII Emission)

Technical file complied by:

Parker Products Ltd

Being the responsible person appointed by the manufacturer.

Signed:

Date:

01/01/17

Name:

Jason Parker

Position:

Managing Director

WWW.PARKERBRAND.CO.UK

PGBC-5200

Rev 1.0

July 2017