Full Text Searchable PDF User Manual

CONTENTS

• PRODUCT SPECIFICATIONS ................................................................................................ 1

• DIMENSIONS .......................................................................................................................... 2

• WIRING DIAGRAM ............................................................................................................ 3 ~ 4

• REFRIGERATION CYCLE DIAGRAM..................................................................................... 5

• AIR CONDITIONER PERFORMANCE EVALUATION ............................................................ 5

• HOW TO INSTALL............................................................................................................. 6 ~ 7

• HOW TO OPERATE .......................................................................................................... 8 ~ 9

• TROUBLESHOOTING GUIDE .............................................................................................. 10

• CARE AND MAINTENANCE ................................................................................................. 11

• TECHNICAL DATA ............................................................................................................... 12

• EXPLODED VIEW ......................................................................................................... 13 ~ 14

• REPLACEMENT PARTS LIST .............................................................................................. 15

• ELECTRONIC CIRCUIT DIAGRAM ...................................................................................... 16

ORDER NO. MAC9604015C3

Panaso

nic

Panaso

nic

CW-C180BN

CW-A180BN

Service Manual

Room Air Conditioners

MODELS : CW-C180BN, CW-C240SN,

CW-A180BN, CW-A240SN.

© 1996 Matsushita Industrial Corp. Sdn. Bhd.

All rights reserved. Unauthorized copying and

distribution is a violation of law.

CW-C240SN

CW-A240SN

CW-C180BN

– 1 –

WARNING

This service information is designed for experienced repair technicians only and is not designed for use by the general

public. It does not contain warnings or cautions to advise non-technical individuals of potential dangers in attempting

to service a product. Products powered by electricity should be serviced or repaired only by experienced professional technicians.

Any attempt to service or repair the product or products dealt with in this service information by anyone else could result in serious injury

or death.

!

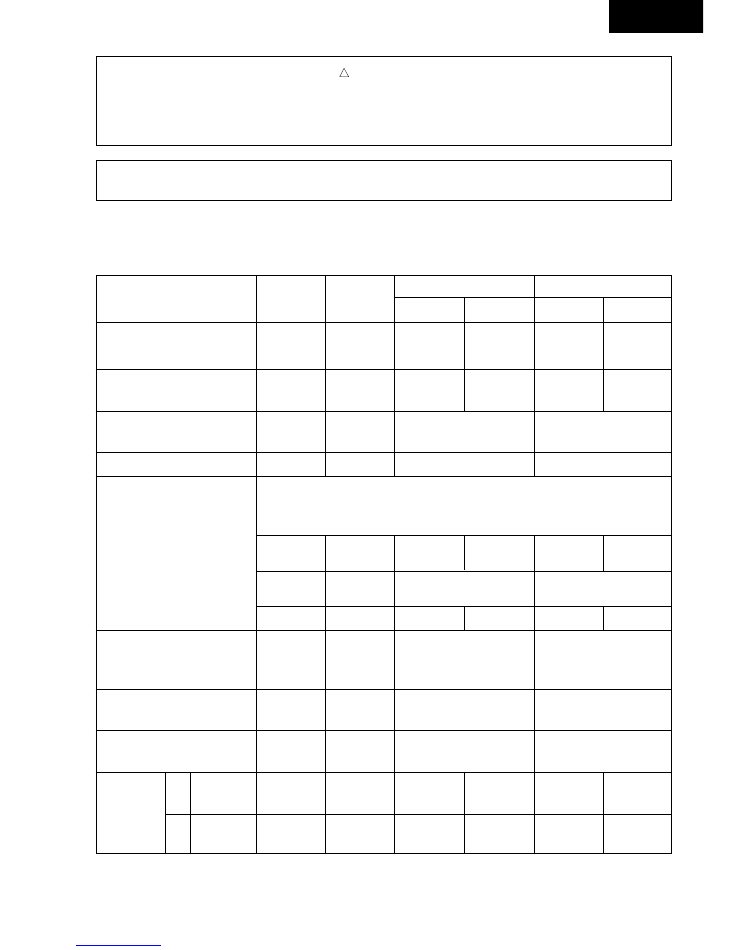

PRODUCT SPECIFICATIONS

MODELS

CW-C180BN

CW-C240SN

CW-A180BN

CW-A240SN

COOLING

HEATING

COOLING

HEATING

CAPACITY

(Btu/h)

17,900 – 17,700

22,700 – 22,510

15,690 – 15, 510

15,340 – 14,830

21,140 – 20,630

20,800 – 19,780

(W)

5,250 – 5,200

6,650 – 6,600

4,600 – 4,550

4,500 – 4,350

6,200 – 6,050

6,100 – 5,800

MOISTURE REMOVAL

(

s

/h)

2.9

4.0

2.5

––

3.4

––

(Pints/h)

6.1

8.5

5.3

7.2

AIR CIRCULATION

(m

3

/min)

14.0

17.0

14.0

16.0

(Cft/min)

490

600

490

560

COMPRESSOR OUTPUT

(W)

1,700

2,200

1,700

2,200

ELECTRICAL

Phase

Single

DATA

Cycle (Hz)

50

Voltage (V)

240 – 220

Running

Current (A)

11.6 – 11.2

15.2 – 15.4

11.7 – 11.0

9.9 – 8.9

14.8 – 14.6

13.6 – 12.8

Starting

Current (A)

50

60

50

60

Input (W)

2,360 – 2,230

3,100 – 3,050

2,450 – 2,300

1,950 – 1,700

3,150 – 3,050

2,800 – 2,650

CABINET

Height (mm)

16 – 7/8" (428)

16 – 7/8" (428)

16 – 7/8" (428)

16 – 7/8" (428)

DIMENSIONS

Width (mm)

26" (660)

26" (660)

26" (660)

26" (660)

Depth (mm)

25 – 7/32" (640)

28 – 3/4" (730)

25 – 7/32" (640)

28 – 3/4" (730)

NET WEIGHT

(kg)

59

72

59

74

(Ibs)

130

160

130

164

REFRIGERANT (R-22)

(g)

980

1,350

1,090

1,030

(oz)

34.6

47.7

38.5

36.4

NOISE LEVEL High

Indoor dB (A)

52 – 51

58 – 57

52 – 51

52 – 51

58 – 58

––

Outdoor dB (A)

60 - 59

67 – 66

60 – 59

61 – 60

68 – 69

––

Low

Indoor dB (A)

49 – 48

54 – 53

49 – 48

48 – 47

54 – 54

––

Outdoor dB (A)

56 – 55

66 – 63

57 – 56

59 – 58

65 – 65

––

* Specifications are subject to change without notice for further improvement.

All illustration shown inside caters for models CW-C180BN, CW-A180BN unless stated otherwise

CW-C180BN

– 2 –

Panasonic

Panasonic

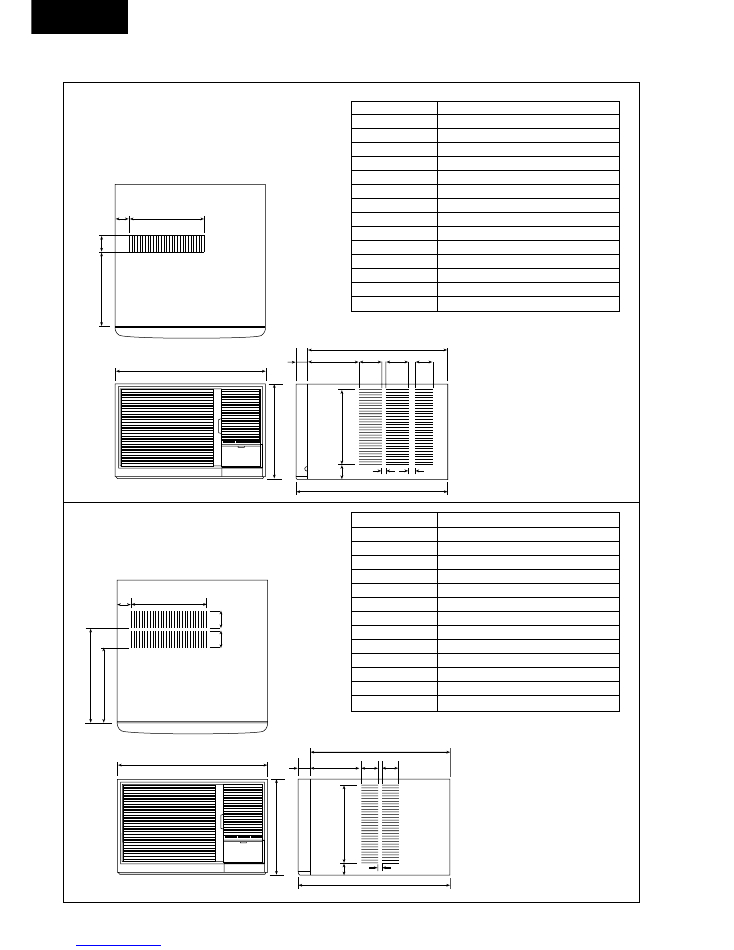

DIMENSIONS

CW-C180BN

CW-A180BN

CW-C240SN

CW-A240SN

FRONT VIEW

TOP VIEW

13-25/32"

(350)

J

N

SIDE VIEW

F

C

G

G

H

I

K

ITEM

CW-C240SN, CW-A240SN

A

Width

26"

(660)

B

Height

16 – 7/8"

(428)

C

Depth

28 – 25/32"

(730)

D

26 – 25/32"

(680)

E

1 – 31/32"

(50)

F

11 – 13/16"

(300)

G

2 – 3/64"

(75)

I

3/64"

(15)

J

10 – 13/16"

(288)

K

15 – 11/32" (389.6)

L

12 – 17/32"

(318)

M

3 – 5/32"

(80)

N

3 – 35/64"

(90)

ITEM

CW-C180BN, CW-A180BN

A

Width

26"

(660)

B

Height

16 – 7/8"

(428)

C

Depth

25 – 7/32"

(640)

D

23 – 7/32"

(590)

E

1 – 31/32"

(50)

F

10 – 15/16"

(220)

G

3 – 11/32"

(92)

H

3 – 1/32"

(77)

I

15 – 32"

(12)

J

10 – 15/16"

(278)

K

1 – 1/16"

(27)

L

12 – 17/32"

(318)

M

3 – 5/32"

(80)

N

3 – 35/64"

(90)

Unit : (mm)

Unit : (mm)

K

N

N

J

E

I

B

13-25/32"

(350)

2-3/32"

(53)

A

FRONT VIEW

SIDE VIEW

TOP VIEW

M

L

C

F

G

G

2-3/32"

(53)

M

L

A

E

D

D

B

CW-C180BN

– 3 –

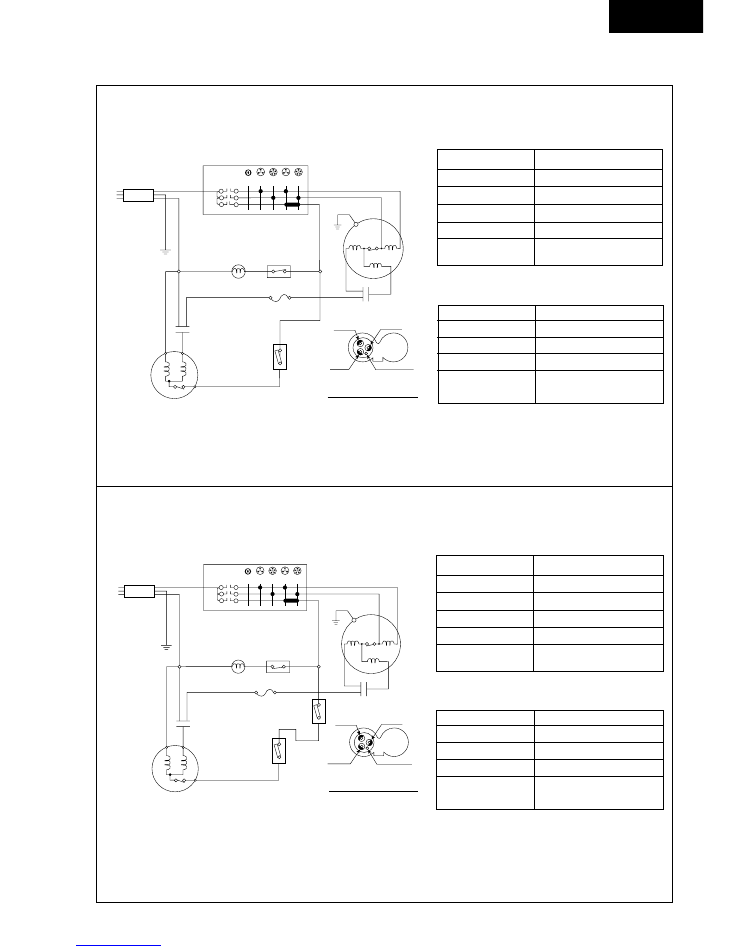

CW-C180BN

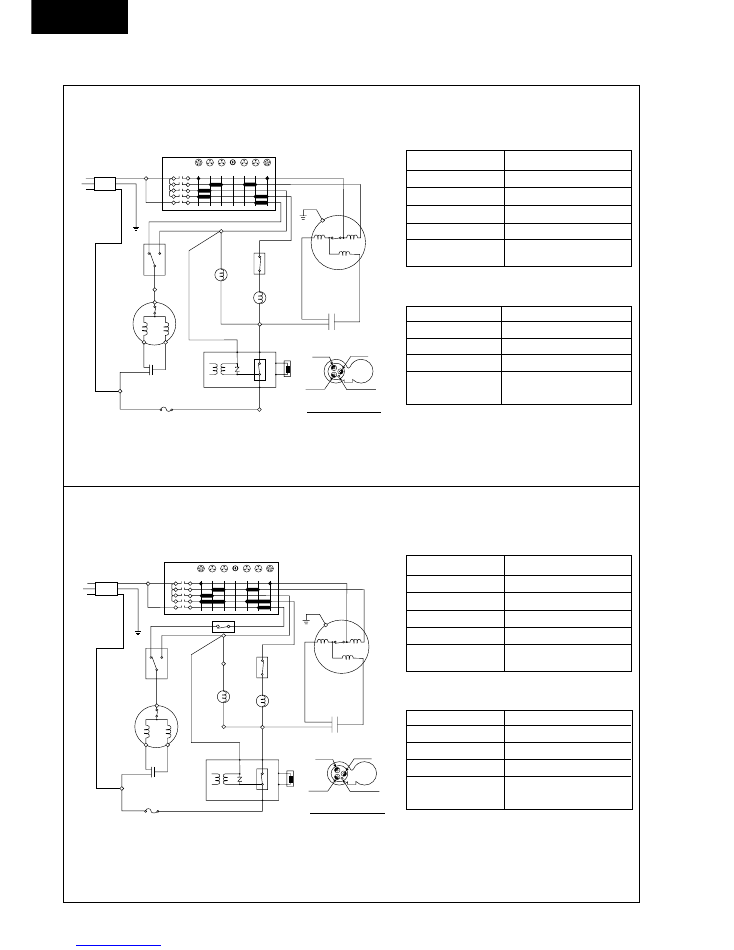

WIRING DIAGRAM

CW-C180BN

CW-C240SN

Connection

CWA92125

BLUE–YELLOW

18.8

Ω

YELLOW–ORANGE

6.25

Ω

RED–YELLOW

51.5

Ω

CWA31244

CAPACITOR

3µF, 400VAC

Resistance of Fan Motor windings and rated Capacitor

CW-C240SN

Connection

2JS442D4AA01

C-R

0.95

Ω

C-S

4.39

Ω

CAPACITOR

CWA31338

45µF, 370VAC

* Resistance at 20°C of Ambient Temp.

Resistance of Compressor windings and rated Capacitor

CW-C180BN

Connection

CWA95263

BLUE–YELLOW

47.9

Ω

YELLOW–ORANGE

25.2

Ω

RED–YELLOW

103.3

Ω

CWA31357

CAPACITOR

3.5µF, 450VAC

Resistance of Fan Motor windings and rated Capacitor

CW-C180BN

Connection

2JS350D6BA02

C-R

0.95

Ω

C-S

4.18

Ω

CAPACITOR

CWA31504

35µF, 370VAC

* Resistance at 20°C of Ambient Temp.

Resistance of Compressor windings and rated Capacitor

P O W E R S U P P L Y C O R D

P O W E R S U P P L Y C O R D

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

C A P A C I T O R

C A P A C I T O R

M A I N S W I T C H

M A I N S W I T C H

BROWN

BROWN

1

0

2

3

AIR SWING

AIR SWING

SELECT SWITCH

SELECT SWITCH

AIR SWING MOTOR

AIR SWING MOTOR

BLUEBLUE

BLUEBLUE

BLUEBLUE

BLUEBLUE

REDRED

REDRED

WHITEWHITE

BLACK

BLACK

WHITE

WHITE

WHITE

WHITE

YELLOW

YELLOW

YELLOW/GREEN

YELLOW/GREEN

YELLOW/GREENYELLOW/GREEN

YELLOW

YELLOW

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

ORANGE

ORANGE

1

2

R

S

C

FAN MOTORFAN MOTOR

C O M P R E S S O R

C O M P R E S S O R

THERMOSTATTHERMOSTAT

RED (RED)

RED (RED)

BLUE (BLU)

BLUE (BLU)

YELLOW (YEL)

YELLOW (YEL)

TRADE MARK

TRADE MARK

T H E P A R E N T H E S I Z E D L E T T E R I S

I N D I C A T E D O N T E R M I N A L C O V E R .

I N D I C A T E D O N T E R M I N A L C O V E R .

C O M P R E S S O R T E R M I N A L

C O M P R E S S O R T E R M I N A L

FUSE (5A)

FUSE (5A)

P

1

CAPACITORCAPACITOR

LOW

LOW

FAN

FAN

HIGH

HIGH

FAN

FAN

HIGH

HIGH

COOL

COOL

LOW

LOW

COOL

COOL

OFF

OFF

P O W E R S U P P L Y C O R D

P O W E R S U P P L Y C O R D

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

C A P A C I T O R

C A P A C I T O R

CAPACITORCAPACITOR

M A I N S W I T C H

M A I N S W I T C H

BROWN

BROWN

1

0

2

3

AIR SWING

AIR SWING

SELECT SWITCH

SELECT SWITCH

AIR SWING MOTOR

AIR SWING MOTOR

BLUEBLUE

YELLOW/GREENYELLOW/GREEN

BLUEBLUE

BLUEBLUE

BLUEBLUE

REDRED

REDRED

WHITEWHITE

WHITEWHITE

BLACK

BLACK

WHITE

WHITE

WHITE

WHITE

YELLOW

YELLOW

YELLOW/GREEN

YELLOW/GREEN

YELLOW

YELLOW

BLUE

BLUE

BLUE

BLUE

BLACK

BLACK

ORANGE

ORANGE

1

2

R

S

C

FAN MOTORFAN MOTOR

C O M P R E S S O R

C O M P R E S S O R

THERMOSTATTHERMOSTAT

(TEMP. CONTROL)(TEMP.

CONTROL)

THERMOSTATTHERMOSTAT

(LOW TEMP.)(LOW

TEMP.)

RED (RED)

RED (RED)

BLUE (BLU)

BLUE (BLU)

YELLOW (YEL)

YELLOW (YEL)

TRADE MARK

TRADE MARK

T H E P A R E N T H E S I Z E D L E T T E R I S

T H E P A R E N T H E S I Z E D L E T T E R I S

I N D I C A T E D O N T E R M I N A L C O V E R .

I N D I C A T E D O N T E R M I N A L C O V E R .

C O M P R E S S O R T E R M I N A L

C O M P R E S S O R T E R M I N A L

FUSE (5A)

FUSE (5A)

P

1

LOW

LOW

FAN

FAN

HIGH

HIGH

FAN

FAN

HIGH

HIGH

COOL

COOL

LOW

LOW

COOL

COOL

OFF

OFF

CW-C240SN

CW-C180BN

– 4 –

RED (RED)

RED (RED)

BLUE (BLU)

BLUE (BLU)

YELLOW (YEL)

YELLOW (YEL)

TRADE MARK

TRADE MARK

T H E P A R E N T H E S I Z E D L E T T E R I S

I N D I C A T E D O N T E R M I N A L C O V E R .

I N D I C A T E D O N T E R M I N A L C O V E R .

C O M P R E S S O R T E R M I N A L

C O M P R E S S O R T E R M I N A L

P O W E R S U P P L Y C O R D

P O W E R S U P P L Y C O R D

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

M A I N S W I T C H

M A I N S W I T C H

BROWN

BROWN

BROWN

BROWN

BLACK

BLACK

BLACK

BLACK

YELLOW

YELLOW

YELLOW/GREENYELLOW/GREEN

BLACKBLACK

BLACKBLACK

BLUE

BLUEBLUE

BLUEBLUE

BLUEBLUE

BLACK

REDRED

REDRED

YELLOW

YELLOW

YELLOW/GREEN

YELLOW/GREEN

ORANGE

ORANGE

1

0

2

3

AIR SWING AIR SWING

SELECT SELECT

SWITCHSWITCH

AIR SWING AIR SWING

MOTORMOTOR

BLACK

BLACK

BLUE

BLUE

BLUE

BLUE

BLUE

BLUE

RED

RED

BLUE

BLUE

BLUE

BLUE

RED

RED

RED

RED

GRAY

GRAY

GRAY

GRAY

FAN

FAN

MOTOR

MOTOR

FUSE

FUSE

(5A)

(5A)

4

2

B

A

H

C

L

C A P A C I T O R

C A P A C I T O R

C A P A C I T O R

C A P A C I T O R

C O M P R E S S O R

C O M P R E S S O R

T H E R M O S T A T

T H E R M O S T A T

COIL-REVERSING COIL-REVERSING

VALVEVALVE

E L E C T R I C D E I C E R

E L E C T R I C D E I C E R

1

2

5

1

P

3

4

6

Z N R

R y – D

R y – D

R

C

S

N C

C O M

OFF

OFF

LOW

LOW

HIGH

HIGH

HIGH

HIGH

COOL

COOL

HEAT

HEAT

LOW

LOW

FAN

FAN

FAN

FAN

CW-A180BN

Connection

CWA95263

BLUE–YELLOW

47.9

Ω

YELLOW–ORANGE

25.2

Ω

RED–YELLOW

103.3

Ω

CWA31357

CAPACITOR

3.5µF, 450VAC

CW-A180BN

Connection

2JS356D6DA01

C-R

0.86

Ω

C-S

3.45

Ω

CAPACITOR

CWA31506

45µF, 370VAC

* Resistance at 20°C of Ambient Temp.

Resistance of Fan Motor windings and rated Capacitor

Resistance of Compressor windings and rated Capacitor

CW-A240SN

Connection

CWA92125

BLUE–YELLOW

18.8

Ω

YELLOW–ORANGE

6.3

Ω

RED–YELLOW

51.5

Ω

CWA31244

CAPACITOR

3µF, 400VAC

CW-A240SN

Connection

2JS442D4AA01

C-R

0.95

Ω

C-S

4.39

Ω

CAPACITOR

CWA31506

45µF, 370VAC

* Resistance at 20°C of Ambient Temp.

Resistance of Fan Motor windings and rated Capacitor

Resistance of Compressor windings and rated Capacitor

CW-A180BN

CW-A240SN

RED (RED)

BLUE (BLU)

YELLOW (YEL)

TRADE MARK

T H E P A R E N T H E S I Z E D L E T T E R I S

T H E P A R E N T H E S I Z E D L E T T E R I S

I N D I C A T E D O N T E R M I N A L C O V E R .

I N D I C A T E D O N T E R M I N A L C O V E R .

C O M P R E S S O R T E R M I N A L

P O W E R S U P P L Y C O R D

P O W E R

S U P P L Y

C O R D

1 ø , 2 4 0 – 2 2 0 V , 5 0 H z

1 ø ,

2 4 0 – 2 2 0 V ,

5 0 H z

M A I N S W I T C H

M A I N

S W I T C H

BROWN

BROWN

BROWN

BROWN

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

BLACK

YELLOW

BLUE

BLUE

YELLOW/GREEN

BLUE

BLACK

RED

RED

YELLOW

YELLOW

YELLOW/GREEN

YELLOW/GREEN

ORANGE

ORANGE

1

0

2

3

AIR SWING

SELECT

SWITCH

AIR SWING

MOTOR

BLACK

BLACK

BLUE

BLUE

BLUE

BLUE

BLUE

RED

RED

BLUE

BLUE

BLUE

BLUE

RED

RED

RED

RED

GRAY

GRAY

GRAY

GRAY

BLACK

BLACK

FAN

FAN

MOTOR

MOTOR

FUSE (5A)

4

2

B

A

H

C

L

C A P A C I T O R

C A P A C I T O R

T H E R M O S T A T

T H E R M O S T A T

C A P A C I T O R

C A P A C I T O R

C O M P R E S S O R

C O M P R E S S O R

T H E R M O S T A T

T H E R M O S T A T

COIL-REVERSING

COIL-REVERSING

VALVE

E L E C T R I C D E I C E R

E L E C T R I C D E I C E R

4

4

1

1

P

3

2

S 2

S 2

S 1

S 1

Z N R

Z N R

R y – D

R y – D

R

C

S

N C

N C

C O M

C O M

OFF

OFF

LOW

LOW

HIGH

HIGH

HIGH

HIGH

COOL

COOL

HEAT

HEAT

LOW

LOW

FAN

FAN

FAN

FAN

CW-C180BN

– 5 –

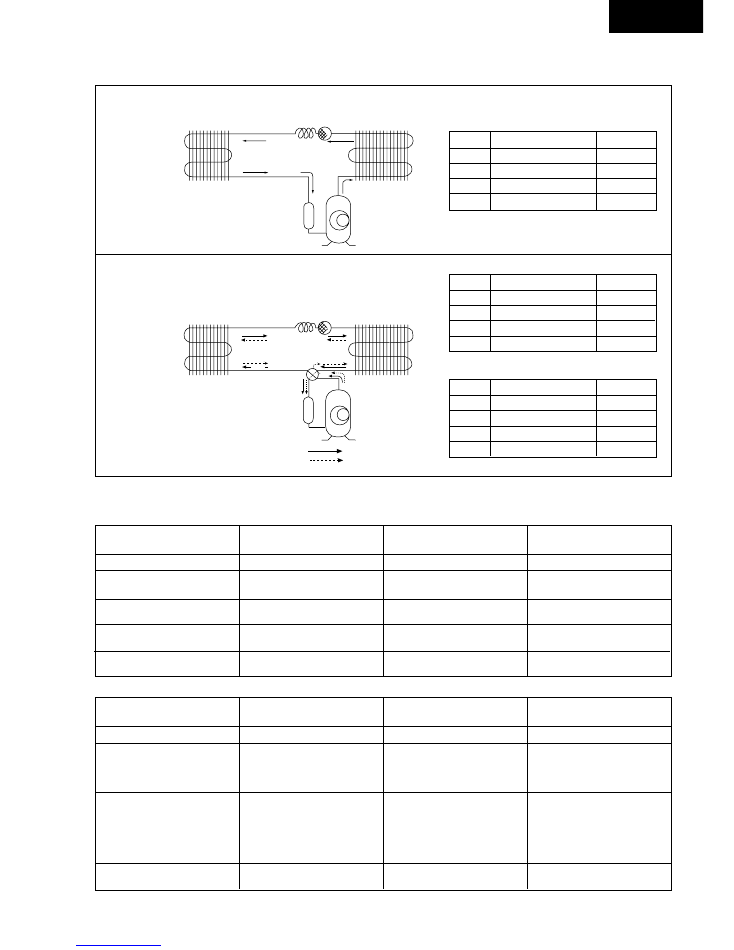

REFRIGERATION CYCLE DIAGRAM

2

6

B

C

A

5

D

CW-A180BN

CW-A240SN

ITEM

PRESSURE (kg/cm

2

)

TEMP. (°C)

A

15.5 ~ 19.0

55 ~ 70

B

4.0 ~ 4.5

0 ~ 5

C

15.0 ~ 18.5

37 ~ 47

D

15.4 ~ 18.9

45 ~ 55

* Indoor temp. at 21°C (DB), and Outdoor at 7°C (DB), 6°C (WB).

ITEM

PRESSURE (kg/cm

2

)

TEMP. (°C)

A

17.5 ~ 21.0

75 ~ 90

B

17.2 ~ 20.7

38 ~ 45

C

5.5 ~ 6.1

7 ~ 15

D

5.3 ~ 5.8

5 ~ 15

* Indoor temp. at 27°C (DB), 19°C (WB) and Outdoor at 35°C , 24°C.

1

4

3

SUCTION & DISCHARGE AIR

CURRENT

DETERMINATION

REMEDY

TEMPERATURE DIFFERENCE

12°C and over

As specified

• Nothing wrong

• None

12°C and over

Higher than specified

• Nothing wrong, outdoor temperature

• None

is high

• Something is preventing heat

• Clean air-filter

radiation at indoor heat-exchanger

Under 12°C

Lower than specified

• Nothing wrong, outdoor temperature

• None

is too low

• Something is preventing heat

• Improve heat radiation at outdoor

radiation at outdoor heat-exchanger

heat-exchanger

• Leakage of refrigerant

• Locate & repair leak

• Refrigerant system is blocked

• Flush refrigeration leak

Under 12°C

Higher than 150% of specified

• Compressor defect

• Replace compressor

• Compressor capacitor defect

• Replace compressor capacitor

1

Compressor

2

4-Way Valve

3

Evaporator

4

Capillary Tube

5

Strainer

6

Condenser

7

Accumulator

HEATING

COOLING

ITEM

PRESSURE (kg/cm

2

)

TEMP. (°C)

A

18.5 ~ 22.0

80 ~ 95

B

18.2 ~ 21.7

44 ~ 52

C

5.7 ~ 6.3

7 ~ 15

D

5.5 ~ 6.0

6 ~ 16

1

Compressor

2

Condenser

3

Strainer

4

Capillary Tube

5

Evaporator

6

Accumulator

CW-C180BN

CW-C240SN

3

4

2

7

6

C

A

1

B

5

D

HEATING

COOLING

* Note: Room air humidity is relatively higher, the Temp. difference will be smaller.

* Indoor temp. at 27°C (DB), 19°C (WB) and Outdoor at 35°C , 24°C.

SUCTION & DISCHARGE AIR

CURRENT

DETERMINATION

REMEDY

TEMPERATURE DIFFERENCE

8°C and over

As specified

Nothing wrong

• None

8°C and over

Higher than specified

Nothing wrong, outdoor temperature is

• Improve heat radiation

too high, heat radiation is not efficient

Under 8°C

Higher than specified but below

Something is preventing heat radiation

• Excessive amount of refrigerant

150% of specified

• Improve heat radiation

Under 8°C

Lower than specified

Leakage of refrigerant or refrigerant

• Locate repair leak

system is blocked

• Flush refrigeration cycle

Under 8°C

Higher than 150% of specified

Compressor defect or compressor

• Replace the compressor or

capacitor defect

compressor capacitor

HEATING

AIR CONDITIONER PERFORMANCE EVALUATION

COOLING

CW-C180BN

– 6 –

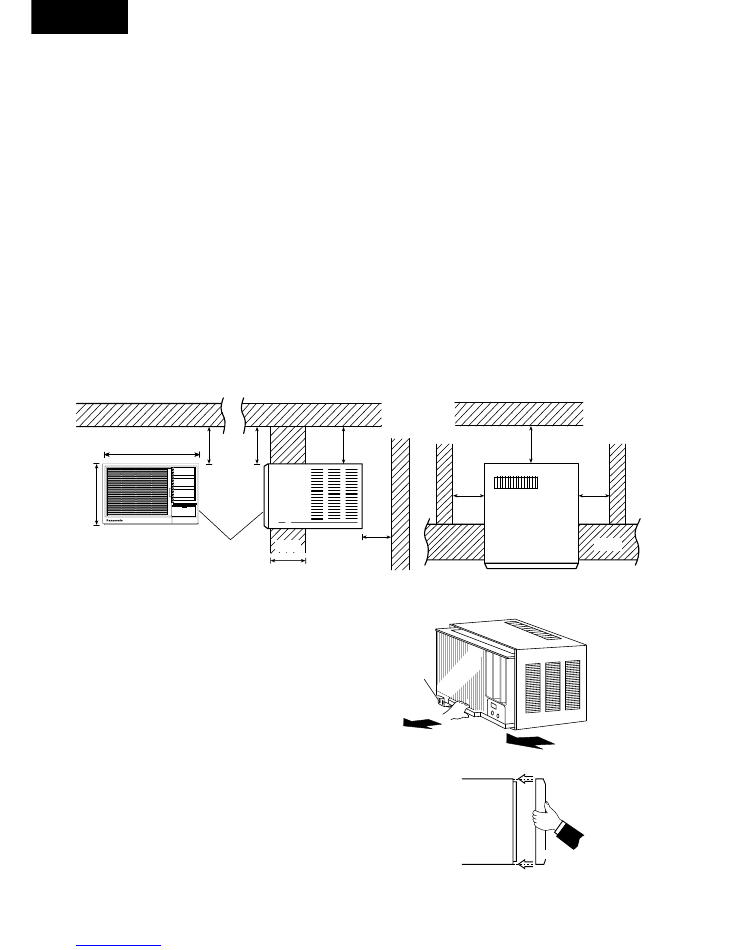

Over

15 cm

Over

15 cm

66 cm

43 cm

Front Grille

Less than

22 cm

Outdoor

(wall)

Over

50 cm

Fence or

likewise

Indoor

Ceiling

(TOP VIEW)

Outdoor

Over

15 cm

Over 50 cm

Over

15 cm

Indoor

(wall)

Fence or

likewise

(SIDE VIEW)

(FRONT VIEW)

Please read the following before installing the Air Conditioner.

Select the best location for the most efficient cooling.

Location

• The air conditioner should be installed in a dry place where there are no draughts.

• Condensation from the air conditioner must be drained to an appropriate location.

• Do not install in a location where flammable gas leaks are a possibility.

• Using in locations where the air is salty such as beside the sea or near hot spas, or

where sulphurous gas is generated, may lead to a malfunction. Please consult your dealer.

• Select a installation location which is rigid and strong enough to support or hold the unit and select a

location for easy maintenance.

How to install

• There should not be any obstacles surrounding the unit.

• Prepare the installation hole slightly bigger than cabinet size.

1) PREPARE CHASSIS

• Remove chassis locking bracket by loosening the screw.

• Slide the chassis out from the cabinet.

2) Place cabinet into opening and secure it by wood screws or

nails.

• The cabinet should be installed tilted slightly lower to the

rear for necessary condensate drainage. (Max. 10mm).

3) Slide Chassis into the cabinet which installed the above 2.

• The tubings or ducting part should not touch the cabinet

4) Lock the chassis into cabinet by chassis locking bracket.

5) Place FRONT GRILLE onto CABINET by screws.

• To place the grille, hook top of grille onto top of cabinet, push

bottom of grille in until it snaps into place. Secure the Front Grille

with the screws at the right, left and center of the grille.

Grille

Cabinet

To place the Grille

Chassis

Locking

Bracket

HOW TO INSTALL

CW-C180BN

– 7 –

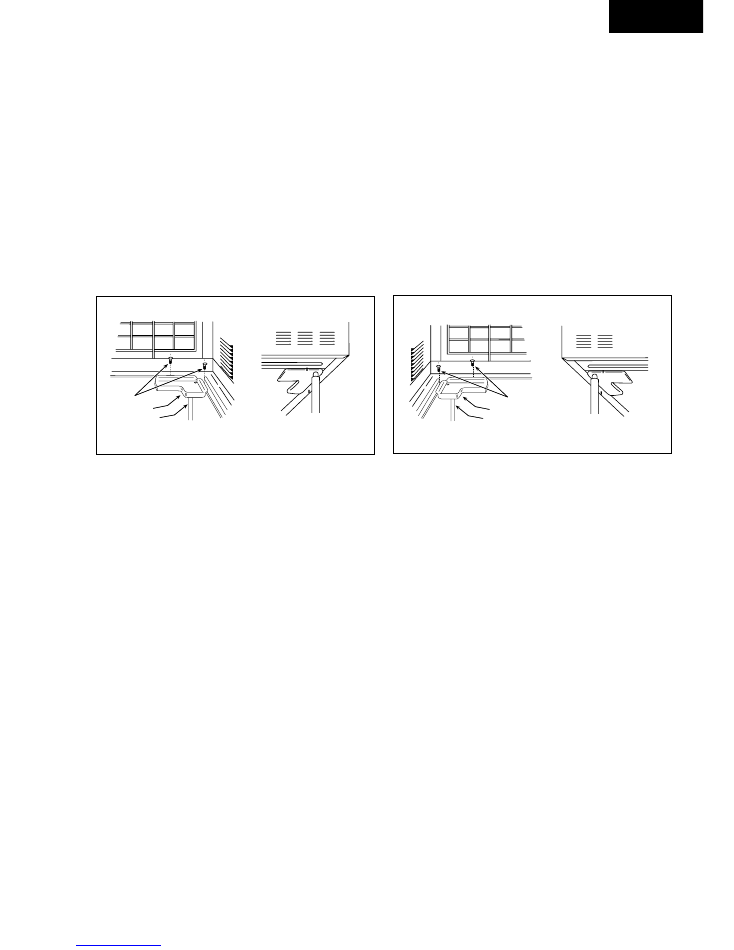

HOW TO INSTALL

3. Drain Water....

To get the maximum cooling efficiency this air conditioner is designed to splash the condensate on the condenser coil.

This method is called “Slinger-Up System”. (For cooling model only)

If the splashing sound annoys you, you can provide an outside drain by using the following procedure which may, however cause

a small loss of performance.

1. Slide out the chassis from the cabinet.

2. Remove the rubber plug from the body base plate. (For cooling model only)

3. Install the drain pan prepared in the accessory kit to the corner of the cabinet with 2 screws.

4. Connect the drain hose to the outlet on the drain pan bottom.

5. Slide the chassis into its original place in the cabinet.

Note: Drain hose or tubing can be purchased locally to satisfy your particular needs.

4. Plug line cord into wall receptacle.

<240–220V, 50Hz>

•

Power should be from independent circuit.

•

Nominal cross sectional area of power supply wire must be 3 core x 2.5 mm

2

or above.

EXTERNAL VIEW

INTERNAL VIEW

SCREWS

DRAIN PAN

DRAIN HOSE

Install drain pan at left corner of cabinet.

EXTERNAL VIEW

INTERNAL VIEW

Install drain pan at right corner of cabinet.

SCREWS

(CW-C180BN, CW-A180BN)

(CW-C240SN, CW-A240SN)

DRAIN PAN

DRAIN HOSE

CW-C180BN

– 8 –

°

C

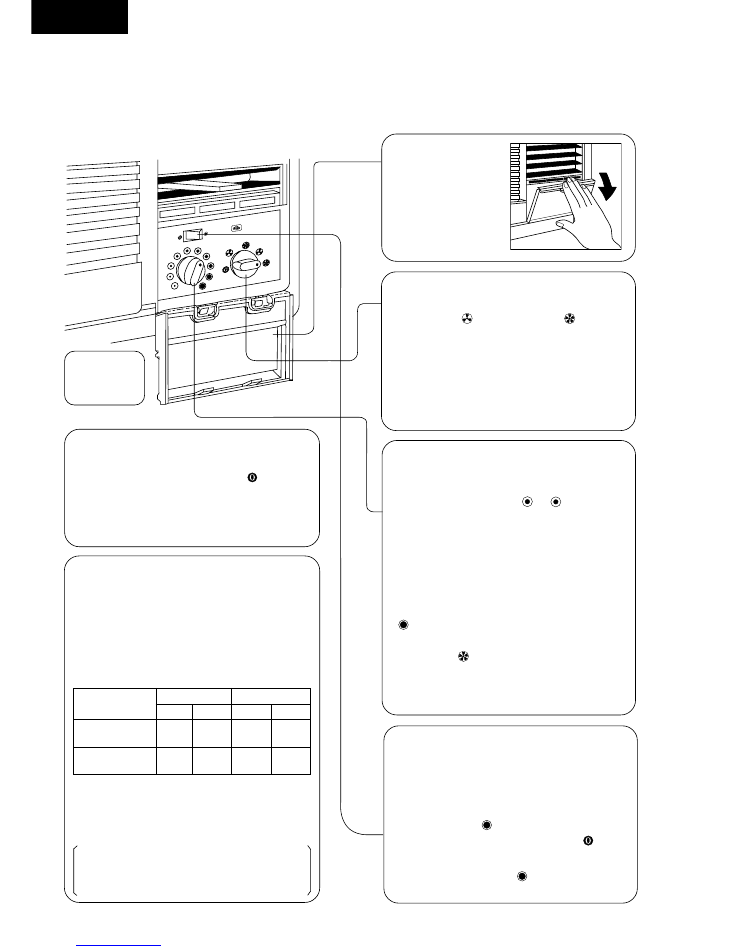

1

. Power Supply

Set the Main Control Knob to the “ ” OFF

position; confirm that the power supply cord is

connected to a proper AC outlet.

Recommended

Use the air conditioner under

the following conditions:

• Operating temperature range.

(unit in °C)

Indoor unit

Outdoor unit

D.B.T. W.B.T. D.B.T. W.B.T.

Maximum

Temperature

Minimum

Temperature

D.B.T.: Dry Bulb Temperature

W.B.T.: Wet Bulb Temperature

• Humidity does not exceed 90%.

Continuous operation at over 90% humidity

may create condensation and waterdrops on

the intake and outlet vents.

32

23

43

26

21

15

21

15

Illustration

only for

CW-C180BN

2

. Open the

cover

3

. Main Control Knob

Set to either “

” LOW COOL or “

” HIGH

COOL as required.

(FAN setting operates the fan only.)

* Caution: If the Main Control Knob is turned

off or changed to a fan setting from a cooling

operation setting, WAIT at least 3 minutes

before resetting to a cooling operation.

4

. Thermostat Control Knob

Set the Thermostat Control Knob at the

desired setting. (Usually “ ~ ” is a

recommended setting position.) If the room

temperature is unsatisfactory after a

reasonable amount of time, turn the control

knob clockwise to cool the room more, or

anticlockwise to cool the room less.

• When the Thermostat Control Knob is set to

“ ”, moisture may freeze onto the coils and

prevent effective cooling. If this happens, turn

the knob to “

” HIGH FAN, and the thermostat

control knob anticlockwise. This will quickly

defrost the cooling coil so that normal cooling

can be resumed.

5

. Air Swing Switch

(Airflow direction adjustment

Side-to-Side)

For fixed side-to-side air direction, set the Air

Swing Switch to “ ” ON until the desired air

direction is obtained, then move it to “ ” OFF.

For continuous side-to-side air circulation, set

the Air Swing Switch to “ ” ON and leave it

there.

HOW TO OPERATE

CW-C180BN, CW-C240SN (Cooling Only)

CW-C180BN

– 9 –

°

C

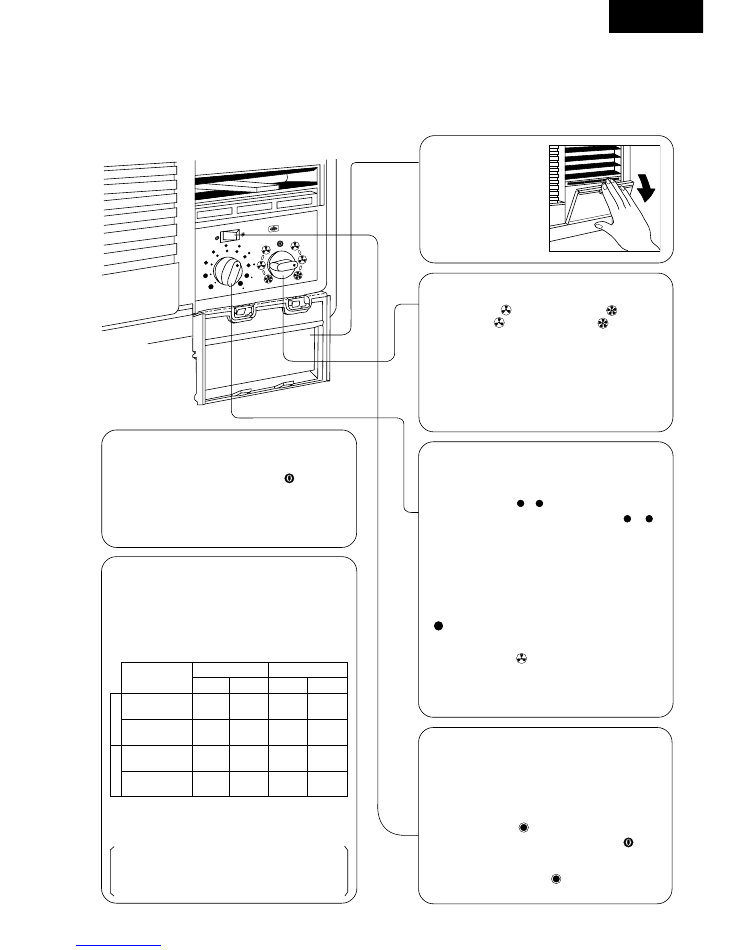

1

. Power Supply

Set the Main Control Knob to the “ ” OFF

position; confirm that the power supply cord is

connected to a proper AC outlet.

32

23

43

26

21

15

21

15

Recommended

Use the air conditioner under

the following conditions:

• Operating temperature range.

(unit in °C)

Indoor unit

Outdoor unit

D.B.T. W.B.T. D.B.T. W.B.T.

Maximum

Temperature

Minimum

Temperature

Maximum

Temperature

Minimum

Temperature

D.B.T.: Dry Bulb Temperature

W.B.T.: Wet Bulb Temperature

• Humidity does not exceed 90%.

Continuous operation at over 90% humidity

may create condensation and waterdrops on

the intake and outlet vents.

HEATING

COOLING

27

–

21

15

20

–

-5

-6

2

. Open the

cover

3

. Main Control Knob

Set to either “

” LOW COOL or “

” HIGH

COOL and “

” LOW HEAT or “

” HIGH

HEAT as required.

(FAN setting operates the fan only.)

* Caution: If the Main Control Knob is turned

off or changed to a fan setting from a cooling

or heating operation setting, WAIT at least 3

minutes before resetting to a cooling or

heating operation.

4

. Thermostat Control Knob

Set the Thermostat Control Knob to the desired

setting. (Usually “ ~ ” (Red) is a

recommended setting for heating and “ ~ ”

(Blue) for cooling.) If the room temperature is

unsatisfactory after a reasonable amount of

time, turn the control knob clockwise or anti-

clockwise to make the room cooler or warmer.

• When the Thermostat Control Knob is set to

“

” (Blue), moisture may freeze onto the coils

and prevent effective cooling. If this happens,

turn the knob to “ ” (Gray) FAN, and the

thermostat control knob anticlockwise. This will

quickly defrost the cooling coil so that normal

cooling can be resumed.

5

. Air Swing Switch

(Airflow direction adjustment

Side-to-Side)

For fixed side-to-side air direction, set the Air

Swing Switch to “

” ON until the desired air

direction is obtained, then move it to “

” OFF.

For continuous side-to-side air circulation, set

the Air Swing Switch to “

” ON and leave it

there.

HOW TO OPERATE

CW-A180BN, CW-A240SN (Cooling & Heating)

CW-C180BN

– 10 –

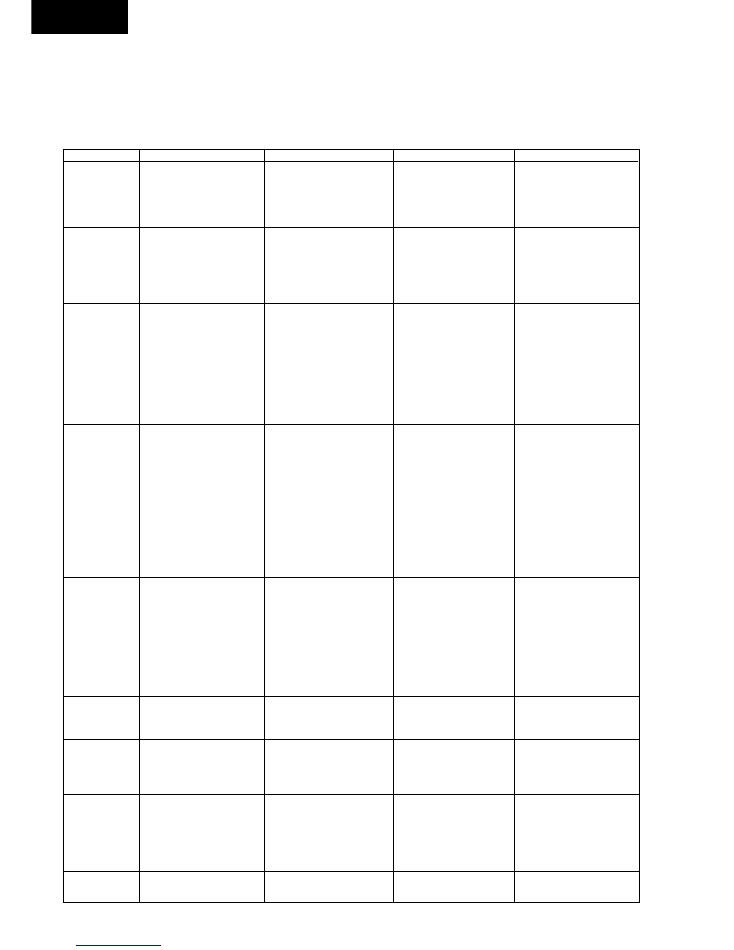

TROUBLE

CHECK

RESULT

CAUSE

REMEDY

Fan Motor and

1. Supply Voltage.

Less than - 10% by Rated.

Customer Restarted unit

Consult ELECTRICIAN.

Compressor

2. Fuse Box or Circuit Breaker.

Open Contacts.

immediately without

Repair Open Circuit.

won’t run.

waiting 3 minutes

WAIT FOR 3 MINUTES.

3. Power cord or Wiring Harness.

Pulled loose or Shorted.

Repair or Replace it.

4. Thermostat Setting.

Higher than ROOM TEMP.

Set it LOWER.

Fan Motor

1. Objects around Fan.

Locked Fan.

Fan Hitting Cowling or

Adjust Fan Position set screw.

won’t run

Foreign Materials.

Remove Foreign Materials.

Frozen Bearings.

Replace Fan Motor.

2. RESISTANCE between Wires.

Shorted/Open circuit.

Shorted or Burned out.

Replace Fan Motor.

3. Capacitor Fan Motor.

OHM Meter doesn’t Deflect.

Capacitor Defect.

Replace Capacitor Fan.

4. Main Control Switch.

No contacts at Position Shown.

Main Control Switch defect.

Replace Main Control Switch.

Compressor

1. Thermostat Setting.

Higher than ROOM TEMP.

Set it lower.

won’t run

2. RESISTANCE between

Shorted.

Winding Coil touched to the

Replace Compressor.

(Fan runs)

Terminal and the

Body.

Compressor Body.

3. RESISTANCE between

Shorted.

Rear Shorted or Burnt out.

Replace Compressor.

Terminals.

4. Overload Protector.

Infinity between Terminals.

Overload protector defect.

Replace Overload Protector.

5. Capacitor Compressor.

OHM Meter doesn’t deflect.

Capacitor defect.

Replace Capacitor Comp.

6. Thermostat.

No CLICK around position.

Thermostat defect.

Replace Thermostat.

7. Main Control Switch.

No contacts at Position shown.

Main Control Switch defect.

Replace Main Control Switch.

Insufficient

1. Thermostat Setting.

Higher or lower than ROOM TEMP.

Set it lower or higher.

cooling or

2. Ventilation Door open.

Open.

Reduces capacity.

Close Vent door.

heating

3. Air Filter dirty.

Clogged or Dirty.

Restricted air circulation.

Clean or Replace Air Filter.

4. Location of installation.

Sunlight hitting outdoor side

Restricted Heat Exchanger

Consider building an AWNING.

at cooling.

Obstacles.

Restricted Heat Exchanger.

Remove obstacles or

reinstall unit.

5. Evaporator/Condenser

Clogged or Dirty.

Restricted air circulation.

Clean by steam cleaner.

Coil obstructed.

6. Unit capacity for the room too

Not Satisfied.

Replace the Unit with

small.

bigger one.

7. Temp difference and

REFER PERFORMANCE

Leakage of refrigerant or

Locate repair leak.

Running Current.

EVALUATION.

refrigeration system is blocked.

Flush refrigeration cycle.

Noise

1. Source of Noise.

Vibration.

Faulty installation.

Reinstall unit or Reinforce

the installation.

Intermittent Noise.

Fan hitting objects.

Adjust Fan position or

remove Foreign Materials.

Refrigerant tubing touching

About 1/2" Clearance.

each other.

Fan splashing Drain Water.

Consider Attaching the Drain

Pan and pull plug in bottom

pan. (REFER INSTALLATION

INSTRUCTIONS)

No heating

1. Reversing Valve Coil.

Infinity between Coil.

Replace Reversing Valve coil.

(Fan and

2. Reversing Valve.

Resistance between Reversing

Replace Reversing Valve.

Compressor run.)

Valve Coil.

Water dripping

1. Unit Installation.

Tilted to inside room.

Restricted run off.

Tilt unit to outside slightly.

inside room

2. Drain Tray-STYROFOAM

Clogged.

Clogged or blocked.

Remove the foreign materials.

Pieces blocking Drain

(REFER OPERATING

Channel.

INSTRUCTIONS)

Frozen

1. Thermostat Setting

Set too low for ambient

Outdoor TEMP. Low

Set Main Control Switch to

Evaporator

conditions.

(Night time)

Fan to melt ICE and Set the Temp.

control to higher temperature

2. Air Filter/Evaporator.

Clogged or Dirty.

Restricted air circulation

Clean Air Filter/Evaporator.

3. Temp. difference and

REFER PERFORMANCE

Leakage of refrigerant or

Locate repair leak.

Running Current.

EVALUATION.

refrigeration system is blocked.

Flush refrigeration cycle.

Frozen

1. Outdoor ambient

Heating Operation at Low

Outdoor ambient temp.

Set Main Control Switch

Condenser

temp.

outdoor ambient temp.

is Low.

to Fan to melt ICE.

TROUBLESHOOTING GUIDE

WARNING: DISCONNECT UNIT FROM ELECTRICAL POWER SUPPLY BEFORE MAKING ANY ELECTRICAL

CHECKS.

DISCHARGE THE CAPACITOR BEFORE CHECKING IT.

CW-C180BN

– 11 –

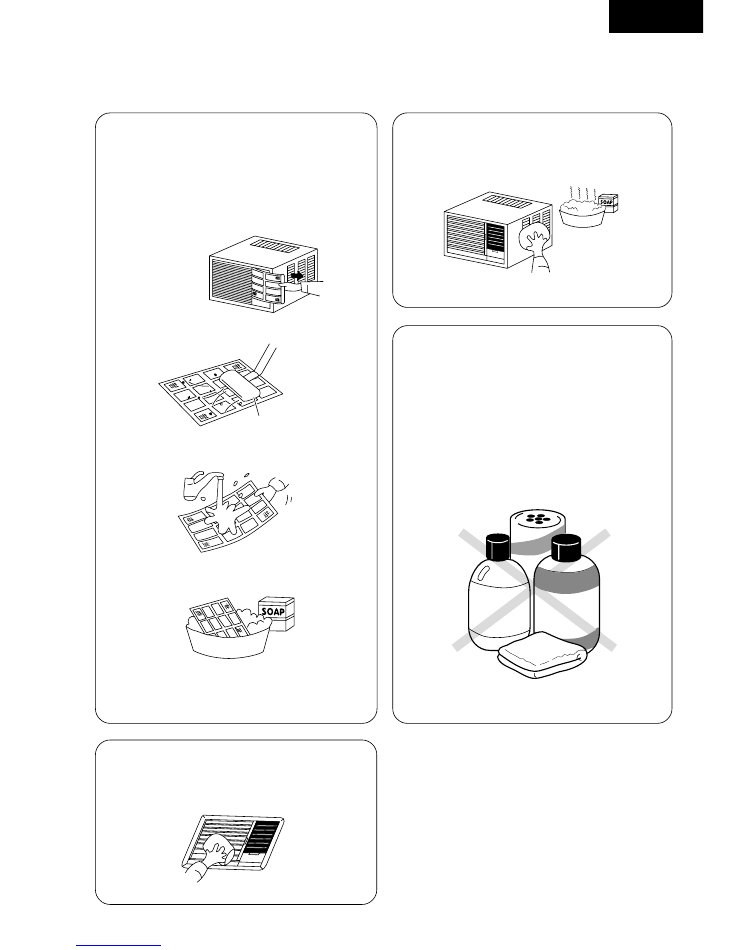

Always turn off the air conditioner and main power supply before cleaning to ensure safety.

CARE AND MAINTENANCE

Air Filter

The air filter behind the intake grille should be

washed at least every two weeks or as often as it

needs cleaning.

HOW TO CLEAN THE AIR FILTER:

1. To remove the air filter, grasp the tab on the filter

and pull to the right.

2. Vacuum the filter on the dusty side to remove

light dust.

3. Wash the filter, cleaner side up under gently flowing

water to wash out accumulated dust and lint.

4. If the filter is very dirty, use a mild household

detergent in the wash water.

Let the filter dry thoroughly before reinstalling it.

When reinstalling the filter, be sure the word “FRONT”

is facing you as you slide the filter back into place.

Front Grille

Clean the front grille with a clean cloth lightly

dampened with mild liquid dish-washing detergent.

Caution

Wipe off dirt with a soft, dry cloth (use a vacuum

cleaner to remove dust from the air intake.)

Use a cloth and water less than 40°C to remove

stubborn dirt (the cloth should be well-wrung).

Do not use the following cleansers as they cause

the paint to peel and lead to malfunctions:

Benzene, thinner, scouring powder, chemical-

soaked cloths, etc.

lukewarm water +

mild detergent

Vacuum cleaner

BENZENE

THINNER

Cabinet

Clean the cabinet with mild soap or detergent and

lukewarm water.

Annual check

* After long-term usage of room air conditioners, dust

and dirt will accumulate inside, lowering the perform-

ance. This may cause the generation of odour or may

impede the drainage of the dehumidifying water.

* Besides regular cleaning of the air conditioner, a

separate annual check is also recommended

(chargeable). Please request your dealer to carry out

these checks.

– 11 –

CW-C180BN

– 12 –

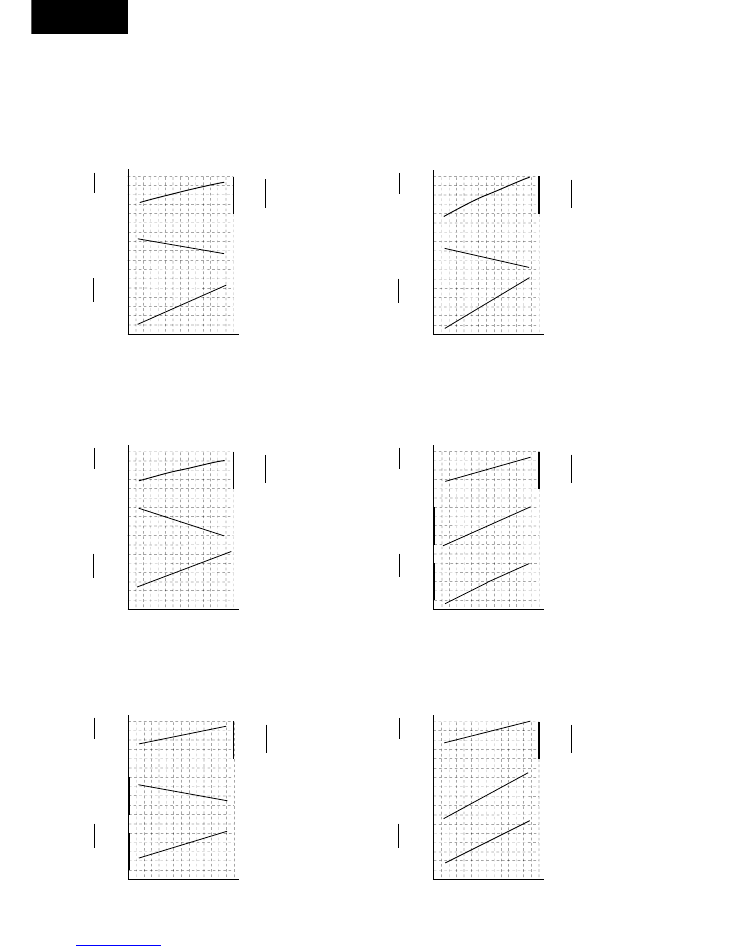

TECHNICAL

DATA

• Operation Characteristics

CW-C180BN

Cooling Characteristic

s

12.5

Voltage at 240–220V

11.5

10.5

s

O :

Outlet

Air Temperature (

o

C)

s

I

:

Current (A)

Q :

Cooling Capacity (KW)

30

35

40

Outdoor Air Temperature (

o

C)

Voltage at 240–220V

Voltage at 240–220V

CW-C240SN

Cooling Characteristic

CW-A180BN

Cooling Characteristic

CW-A240SN

Cooling Characteristic

Heating Characteristic

Heating Characteristic

s

50.0

Voltage at 240–220V

40.0

30.0

O :

Outlet

Air Temperature (

o

C)

I

:

Current (A)

Q :

Heating Capacity (KW)

-2

7

15

Outdoor Air Temperature (

o

C)

s

s

Voltage at 240–220V

s

11.5

Voltage at 240–220V

11.0

10.5

O :

Outlet

Air Temperature (

o

C)

Q :

Cooling Capacity (KW)

30

35

40

Outdoor Air Temperature (

o

C)

s

s

12.5

11.5

10.5

6.0

5.0

4.0

16.0

15.0

14.0

8.0

7.0

6.0

s

13.0

12.0

11.0

s

O :

Outlet

Air Temperature (

o

C)

s

I

:

Current (A)

Q :

Cooling Capacity (KW)

30

35

40

Outdoor Air Temperature (

o

C)

12.0

11.0

10.0

5.0

4.5

4.0

Q

O

I

s

O :

Outlet

Air Temperature (

o

C)

I

:

Current (A)

Q :

Cooling Capacity (KW)

30

35

40

Outdoor Air Temperature (

o

C)

s

s

7.0

6.0

5.0

Q

7.0

6.0

5.0

14.0

13.0

12.0

Q

O

I

s

50.0

40.0

30.0

O :

Outlet

Air Temperature (

o

C)

I

:

Current (A)

Q :

Heating Capacity (KW)

-2

7

15

Outdoor Air Temperature (

o

C)

s

s

5.5

4.5

3.5

11.0

10.0

Q

O

9.0

I

I

Q

O

O

Q

I

16.0

14.0

12.0

12.0

11.0

10.0

I

O

I

:

Current (A)

CW-C180BN

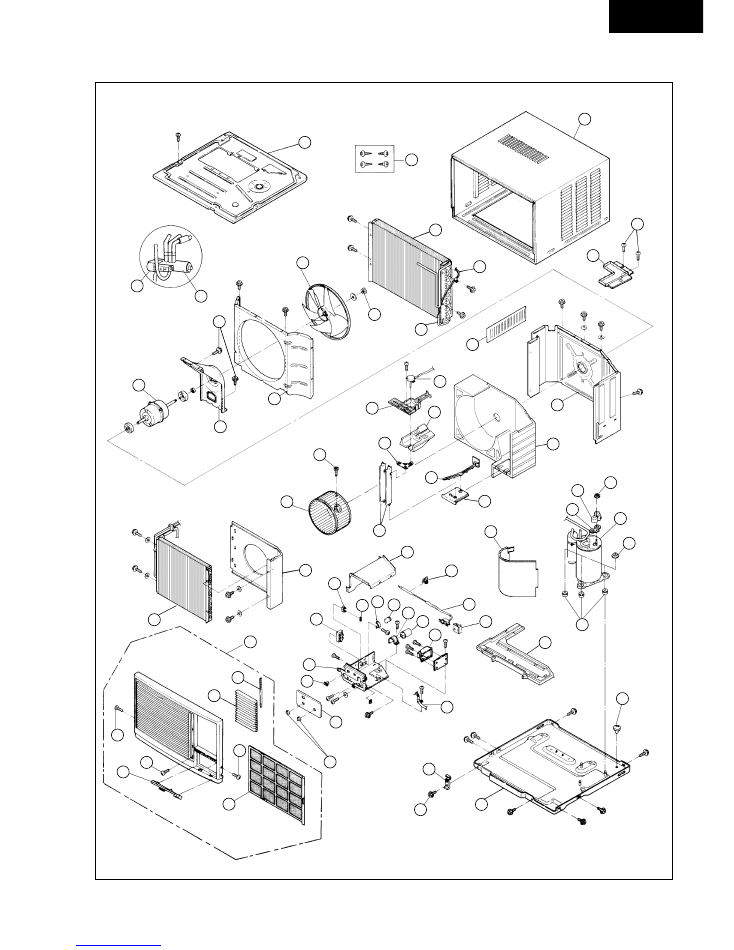

– 13 –

• The above exploded view is for the purpose of parts disassembly and replacement.

The non-numbered parts are not kept as standard service parts.

121

211

501

102

103

131

116

148

CW-C180BN, CW-A180BN

EXPLODED VIEW

CW-C180BE

106

712

210

212

122

217

323

300

703

312

146

610

710

145

123

120

135

101

207

200

202

144

147

128

308

304

109

129

311

306

125

508

509

507

500

220

707

502

505

100

130

600

117

112

205

203

310

329 126

326

303

124

302

711

201

702

707

707

613

CW-C180BN

– 14 –

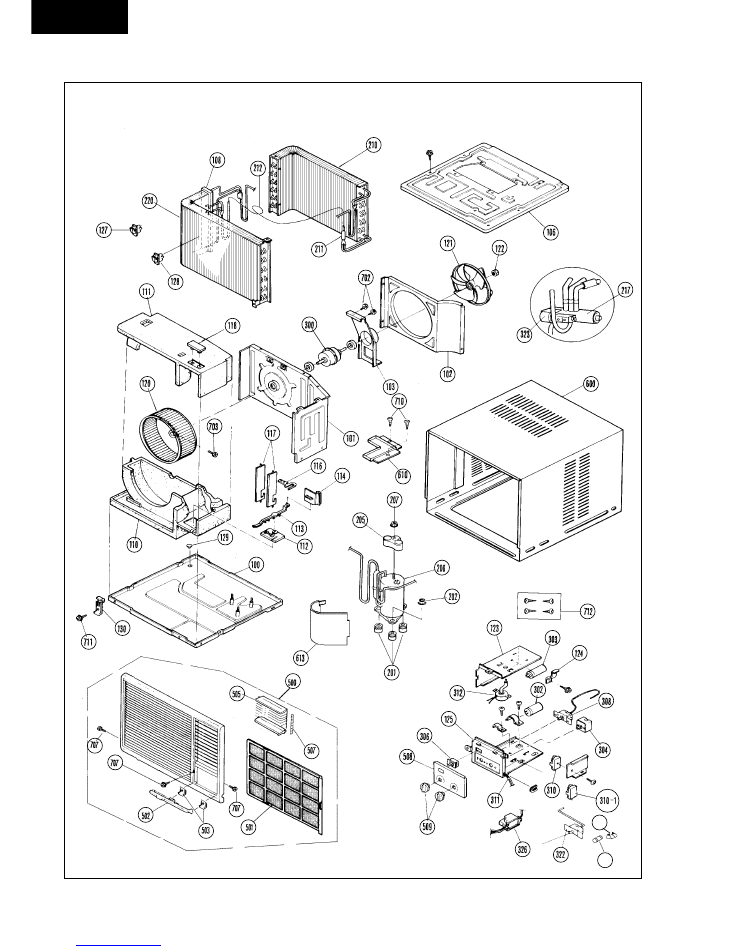

CW-C240SN, CW-A240SN

EXPLODED VIEW

EXPLODED VIEW

• The above exploded view is for the purpose of parts disassembly and replacement.

The non-numbered parts are not kept as standard service parts.

147

329

CW-C180BN

– 15 –

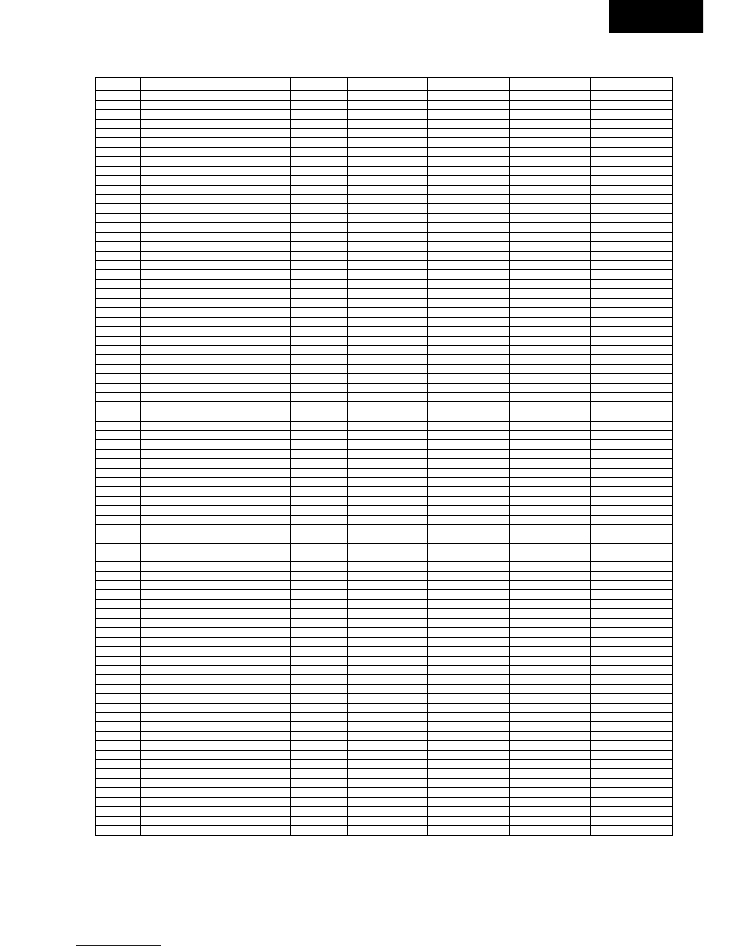

REF.NO.

DESCRIPTION & NAME

QTY

CW-C180BN

CW-A180BN

CW-C240SN

CW-A240SN

100

BASE PAN ASS'Y

1

CWD52K226A

CWD52K225A

CWD52K183A

CWD52K193A

101

BULKHEAD

1

CWD53K093

←

CWD53K087

CWD53K083

102

AIR GUIDER-PROPELLER FAN

1

CWD31092

←

CWD31K037

CWD31075

103

BRACKET-FAN MOTOR

1

CWD54091

←

CWD54142

←

106

TOP PLATE ASS'Y

1

CWD64K036

←

CWD64k029

←

108

COVER-EVAPORATOR

1

––

––

CWD11030

←

109

DRAIN TRAY-EVAPOPATOR

1

CWH40166

←

––

––

110

AIR GUIDER-B. WHEEL (BOTTOM)

1

––

––

CWD32099

←

111

AIR GUIDER-B. WHEEL (UPPER)

1

––

––

CWD32098

←

112

HOLDER-VENT. LEVER

1

CWD91021

←

CWD66156

←

113

VENTILATION LEVER

1

––

––

CWH22004

←

114

VENTILATION DOOR

1

––

––

CWH21012

←

116

CONNECTING BAR-A. SWING VANES

1

CWE26139

←

CWE26092

←

117

VANE-AIR SWING

2

CWE24314

←

CWC24210

←

118

GUIDER-A. SWING VANES

1

––

––

CWE26106

←

120

BLOWER WHEEL ASS'Y

1

CWH01K052

←

CWH01K056

←

121

PROPELLER FAN

1

CWH00009

←

←

←

122

NUT-P. FAN

1

CWH56033

←

←

←

123

CONTROL BOARD (AUX.)

1

CWD60384

←

CWH10K337

←

124

HOLDER-CAPACITOR (COMP.)

1

CWH30133

CWH30102

CWH30101

←

125

CONTROL BOARD (MAIN)

1

CWH10772

CWH10899

CWH10666

CWH10666

126

HOLDER-CAPACITOR (FAN)

1

CWH30132

←

––

––

127

HOLDER-SENSOR

1

––

––

––

CWH32048

128

HOLDER-SENSOR

1

CWH32085

CWH32086

CWH4690379

←

129

DRAIN PLUG-BASE PAN

1

CWH4611062

––

CWH4611062

––

130

CHASSIS LOCKING BRACKET

1

CWD93302

←

←

←

131

VENTILATION ASS'Y

1

CWH22007

←

––

––

135

AIR GUIDER-B. WHEEL

1

CWD32124

←

––

––

144

AIR GUIDER-B. WHEEL (FRONT)

1

CWD32126

CWD32126 (A)

––

––

145

RECTIFICATION PLATE

1

CWD21008

←

––

––

146

SPLASH WATER PROOF LOUVER

1

CWD91029A

––

––

––

147

FUSE HOLDER

1

XCSCW011

––

XCSCW011

←

148

BOX FOR AIR-SWING MOTOR

1

CWD66191

←

––

––

200

COMPRESSOR

1

2JS350D6BA02

2JS356D6DA01

2JS442D4AA01

←

(B09567)

(CWB09525)

(B09374)

201

BUSHING-COMP. MOUNT.

3

CWH50055

←

←

←

202

NUT-COMP. MOUNT.

3

CWH4582065

←

←

←

203

GASKET-TERMINAL COVER

1

CWH7070603

←

––

––

205

TERMINAL COVER-COMP.

1

CWH7070206

←

←

←

207

NUT-TERMINAL. COVER

1

CWH7080300

←

←

←

210

CONDENSER

1

CWB32604

CWB32484

CWB32C073

CWB32C095

211

STRAINER

1

CWB11025

←

←

←

212

CAPILLARY TUBE

2

CWB15491 (2)

CWB15363

CWB15315 (1)

CWB15589 (2)

217

4-WAY VALVE

1

––

CWB00003

––

CWB00003

220

EVAPORATOR

1

CWB30C049

←

CWB30C004

CWB30C015

300

FAN MOTOR

1

CWA95263

←

CWA92125

←

302

CAPACITOR-FAN

1

CWA31357

←

CWA31244

←

(3.5µF, 450VAC)

(3µF, 400VAC)

303

CAPACITOR-COMP.

1

CWA31504

CWA31506

←

←

(35µF, 370VAC)

(45µF, 370VAC)

304

MAIN CONTROL SWITCH

1

CWA07034

CWA07040

CWA07034

CWA07043

306

SWITCH-AIR SWING

1

CWA05024

←

←

←

308

THERMOSTAT ROOM

1

CWA15122

CWA15123

CWA15122

CWA15123

310

TERMINAL BOARD

1

CWA4711013

CWA4711060

CWA4711013

←

310-1

TERMINAL BOARD

1

––

––

––

CWA4711022

311

POWER SUPPLY CORD

1

CWA20C538

CWA20C643

CWA20C539

CWA20C481

312

AIR SWING MOTOR

1

CWA98K067

←

CWA98K046

←

322

SWITCH-LOW TEMP CUT

1

––

––

CWA15005

←

323

COIL-4 WAY VALVE

1

––

CWA43C365

––

CWA43C356

326

DEICER

1

––

CWA17004

––

CWA17004

329

FUSE

1

XBA2C50TR0

CWA16C158

XBA2C50TRO

←

500

FRONT GRILLE COMPLETE

1

CWE11C697

←

←

←

501

AIR FILTER

1

CWD00157D

←

←

←

502

GRILLE DOOR ASS'Y

1

CWE14K046

←

←

←

503

HINGE-G. DOOR

2

CWH61029E

←

←

←

505

VANE

14

CWE24301D

←

←

CWE24301D

507

LINK-VANES

1

CWE26136

←

←

←

508

CONTROL ESCUTCHEON

1

CWE311086

CWE311085

CWE311073

CWE311113

509

KNOB-TURNING

2

CWE17C076

←

←

←

600

CABINET COMPLETE

1

CWE00C121

CWE00C124

CWE00C120

←

610

DRAIN PAN

1

CWH40077

←

←

←

613

SOUND PROOF-COMP.

1

CWG30377

––

CWG30377

––

702

SCREW-BRACKET FAN MOTOR

4

CWH55039

←

←

←

703

SCREW-BLOWER WHEEL

1

CWH4580326

←

←

←

707

SCREW-F. GRILLE MOUNT.

1

CWH82C163

←

←

←

710

SCREW-DRAIN PAN

1

CWG86C733

←

←

←

711

SCREW-C. LOCKING BRACKET

1

XTT4+8B

←

←

←

712

SCREW-UNIT INSTALLATION

1

CWG86C280

←

←

←

OPERATING INSTRUCTIONS

1

F561189

←

←

←

All parts are supplied from MAICO, Malaysia (Vendor Code : 061).

• The above parts are kept for seven years in accordance with MEI service policy.

However, longer lead time will be taken in supplying the non-numbered parts.

REPLACEMENT PARTS LIST

CW-C180BN

– 16 –

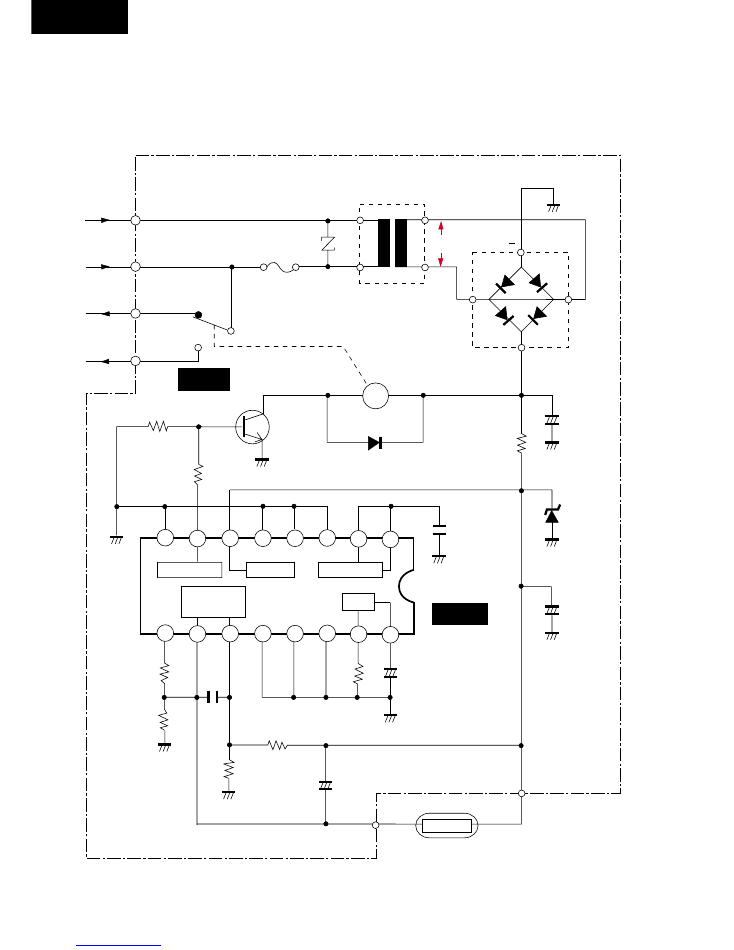

ELECTRONIC CIRCUIT DIAGRAM

•

CW-A180BN, CW-A240SN

(DEICER SCHEMATIC DIAGRAM)

D2

F14A

6.8

12.0

T

CWA40164

2 S C 1 3 1 8

DB1

SIVB10

10.0 VAC

ZNR

ERZC10DK471

IC

0.7

(0)

1 RED

2 BLUE

3 BLACK

4 YELLOW

NC

COM

NO

R2

6.8K

Ω

VCC

GND

AN6710

+C3

10V

33µF

R4

4.87K

Ω

R6

7.5K

Ω

+C4

16V

10µF

PIPING TEMP. SENSOR

~

~

7

9

0

(6.0)

C6

50V

4700PF

+C1

16V

470µF

R1

130

Ω

1W

POWER

OSC

PIPE

TEMP.

COUNTER

OUTPUT

+

Q

Ry

6

8

5

4

2

3

1

10

11

12

13

14

ZD

RD6. 8FB

16

15

R8

7.5K

Ω

R5

5.1K

Ω

R7

7.5K

Ω

R3

2.7K

Ω

0 (12.0)

+C2

10V

100µF

C5

50V

0.01µF

MAICO

Printed in Malaysia

F960500100TH