Full Text Searchable PDF User Manual

XP1M

V1.0X

Networked Access Control Panel

Installation Guide

i

X P 1 M A C C E S S C O N T R O L S Y S T E M

Installation Guide

Document Ref: PLAN XP1M Installation Guide V4(G)2010

Access Control Services Limited

20-26 High Street, Greenhithe, Kent. DA9 9NN

Phone 01322 370777 • Fax 01322 370076

www.xplan.com

email: support@xplan.com

LIMITED WARRANTY.

i) Access Control Services Limited (ACS) warrants that, if properly installed and correctly operated in conjunction with compatible peripheral equipment and

software (running on a computer for which it was designed) the xP1M control panel will perform substantially in accordance with the accompanying

documentation for a period of five (5) years from the date of purchase from ACS.

ii) Due to the inherently complex nature of computer software and firmware, ACS does not warrant that the panel firmware, PC software or the

documentation is error free, will operate without interruptions, be compatible with all equipment and software configurations, or will otherwise meet your

needs.

iii) Your sole remedy and Access Control Services entire liability will be, at our discretion, either repair or replacement of the equipment, or return of the

price paid.

All rights reserved. Copyright© Access Control Services Limited, Greenhithe, Kent 2002.

COPYRIGHT

The contents of this manual and the associated PLAN software applications are the property of Access Control Services Limited and are copyrighted. Any

reproduction in whole, or part, is strictly prohibited.

The manufacturer observes a policy of continuous product development and reserves the right to alter or change any aspect of the system specification or

documentation without notice.

i

Table of Contents

Introduction __________________ 2

General Description ____________ 3

Product Overview ______________ 3

Technical Specification _________ 4

Features summary _____________ 4

Installation Procedure __________ 5

XP1M Control Panel location ____ 5

Mounting _____________________ 5

Connecting up _________________ 5

Mains Power ____________________ 5

Standby Batteries _________________ 6

External 12vDC Power ____________ 6

Readers ________________________ 6

Door Egress Switch (DR input) ______ 7

Door Monitoring Alarm (MC Input) __ 8

Locks __________________________ 8

Extended Alarms _________________ 9

Fire Alarm override _______________ 9

Networking _____________________ 9

Commissioning Procedure _____ 11

Powering up the unit __________ 11

Setting the station ID __________ 11

X P 1 M I N S T A L L E R G U I D E

2

Introduction

Introduction to the scope of this document and conventions used

throughout the manual.

his manual assumes very little understanding of PLAN access control

systems specifically, however, some aspects of the panel installation

and commissioning process (such as mains connection, lock and reader

termination and PC networking) will require a degree of experience in

security systems installation and a basic knowledge of computers and the

Microsoft Windows operating system.

Note: This guide is not intended to be a definitive installation manual for

installing access control systems. The installer is expected to have a

level of installation expertise and experience appropriate to the scale and

complexity of the project at hand.

At all times the prevailing local safety regulations and codes of practice

should take precedence and be applied to the installation of this system.

This document is intended for guidance on the installation and commissioning

of the X

P1M Access Control Door controller

only. The manual is intended

for installation personnel, project managers and people with similar

responsibilities.

For speed and ease of understanding the XP1M will be referred to in this

document as the ‘System’, and the engineering personnel who carry out the

installation of the system will be referred to as ‘installers’ or ‘users’.

The XP1M is expected to operate as part of an on-line system - connected to a

PC running appropriate PLAN software. For detailed guidance on the use and

operation of the the Software, please consult the relevant user manual (supplied

separately).

T

Note:

Tips, notes, or

definitions are occasionally

printed in the left-hand

margin (like this). These

provide

additional

information which is related

to the subject being discussed

in the main text.

X P 1 M I N S T A L L E R G U I D E

3

General Description

Product Overview

The XP1M controller is designed to be a flexible 1 door access control system,

capable of standalone or networked operation. The system can control up to

50,000 personnel (expandable), has 128 time profiles and alarm monitoring

options with separate alarm output relays.

Each unit features 3 extended alarm inputs for monitoring third party

equipment and standard alarm input devices (such as door contacts and PIRs).

The built in real time clock and system memory are both battery backed on the

circuit board and using the built-in PSU charger option (if fitted) all systems are

also backed up against mains failure. Mains supplies are filtered and suppressed

to protect against spurious noise and surges.

When off-line from the main PC, events are logged in the system RAM and the

last 2000 transactions will be buffered until they can be up-loaded to the host

system when comms is restored.

The XP1M controller is housed in a steel cabinet with provision for cable entry

through the rear panel or side walls. All external connections to the main board

utilise demountable terminal blocks.

The system is compatible with most types of card reader; technologies

supported range from Mag-stripe, Wiegand Swipe and Proximity through to

the more sophisticated Biometric and Contactless Smart Card solutions. The

controller has built-in enhanced support for the latest in multiple-reading long

range RFID tagging.

X P 1 M I N S T A L L E R G U I D E

4

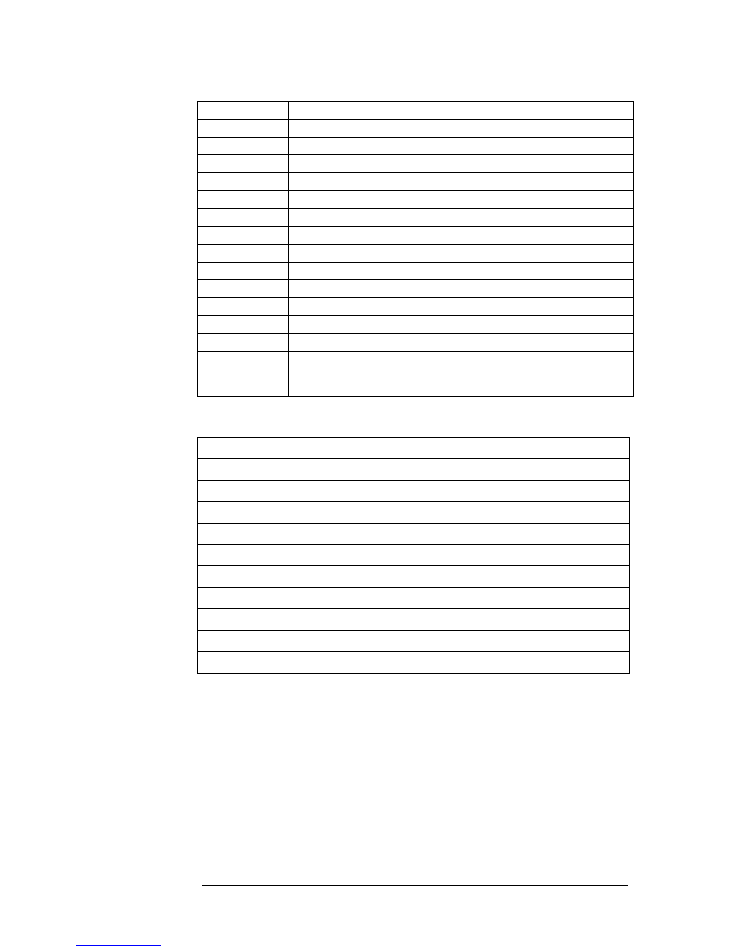

Technical Specification

Enclosure

Construction

Powder coated steel cabinet

Dimensions

320 x 260 x 95mm (H x W x D)

Weight

3.20 Kg

Power

Input

100

– 250v ~ 2.3A 50/60/440 Hz or DC 120-300v 1.5A

Output

Integral 12vDC PSU/Charger unit fused @ 3.15 Amps

Environmental

Operating Temp

0

o

C to +40

o

C

Storage

-10

o

C to +50

o

C

Humidity

10% to 80% (non-condensing relative humidity)

Interfaces

Communications

RS422/RS485/TCP-IP** WiFi*

Reader Interface

Wiegand or ‘Clock and Data’

Protection

Isolated communication, over voltage protection and

transient suppression on all inputs.

* Using appropriate plug-in module.

Features summary

2 card reader inputs (with RTE and Alarm Monitoring facility)

3 extended alarm inputs

50,000 Card holders *

2,000 Event Cyclical Transaction Memory

Fire Alarm override input (jumper configurable)

128 Time Profiles

Shut-down profiles

AES 128 bit encrypted communications

1 x General alarm relay output

Built-in PSU charger Option

TCP/IP LAN and WiFi wireless communications option

* Cardholder capacity may vary depending on card format configuration

X P 1 M I N S T A L L E R G U I D E

5

Installation Procedure

XP1M Control Panel location

The control panel is supplied in a wall mounting enclosure. Care should be

taken to ensure that the mounting surface and the fixings used are appropriate

for the weight of the panel. The following additional notes and observations

should be considered when choosing a location for the unit.

1)

The unit is not designed to be mounted externally unless it is fitted within

a suitably rated secondary enclosure.

2)

Sufficient free space around the unit (approx 35mm) should be left clear

for the purpose of removing the outer doors.

3)

The unit must be fitted in an upright orientation (hinges to the left).

4)

Do not use the XP1M enclosure to house additional equipment (other

than devices specifically designed to be fitted inside the box).

The unit should always be mounted in an accessible location - ideally on the

secure side of the doors that are controlled by the panel.

Mounting

Remove and retain all packaging and documentation that was shipped with the

unit. The precise fixing methods will vary from application to application,

however, as a general guide…

1)

Before fitting the back-box to the wall, establish the preferred route for

cable access into the enclosure; the box is supplied with a number of

25mm holes to the rear and several 20mm ‘knock-out’ access points to

the top, bottom and side walls. Use a hammer and punch to remove

any of ‘knock-outs’ and drill any additional holes that are required

before fixing the box to the wall.

2)

There are four fixing holes in the rear of the enclosure. If necessary,

use the back-box as a template to mark the fixing holes on the wall -

note that the top two fixings are ‘key-holed’ to enable easier single

handed installation.

Connecting up

Mains Power

The XP1M controller unit can be supplied with an integral 13.8vDC

PSU/charger. This unit is fitted into the rear of the back-box and must be

powered from a continuous mains supply. Ideally the mains supply will be

isolated through a dedicated un-switched, fused spur. The length and type of

cable that is used to connect the charger unit to the mains supply should

Note:

Always install at

least one manual access

override if a controller is

located within an area that

has no other means of entry

(i.e other than through a

controlled door).

X P 1 M I N S T A L L E R G U I D E

6

conform to local regulations and be appropriate to the termination method

used in the XP1M (e.g. Fused screw terminal block).

The controller should be earthed and the mains (L&N) polarity should be

observed when making this connection.

Do not apply mains power to the

unit until the readers and other peripheral equipment are fully installed

and connected.

Please see the technical specification indicated on the PSU for further

information about the mains supply voltage and frequency.

Standby Batteries

Space is available inside the enclosure for a single 7Amp/Hr. sealed lead acid

battery, this must be connected to the ‘BATT’ output on the PSU/Charger

(observing the correct polarity). One set of standard battery leads is provided

with each panel – although an additional pair will be provided on request.

Do

not connect the batteries to the unit until the readers and other

peripheral equipment are fully installed and connected.

External 12vDC Power

The control unit can optionally be powered by an external third party 12vDC

PSU. Please see the connection diagrams for further information.

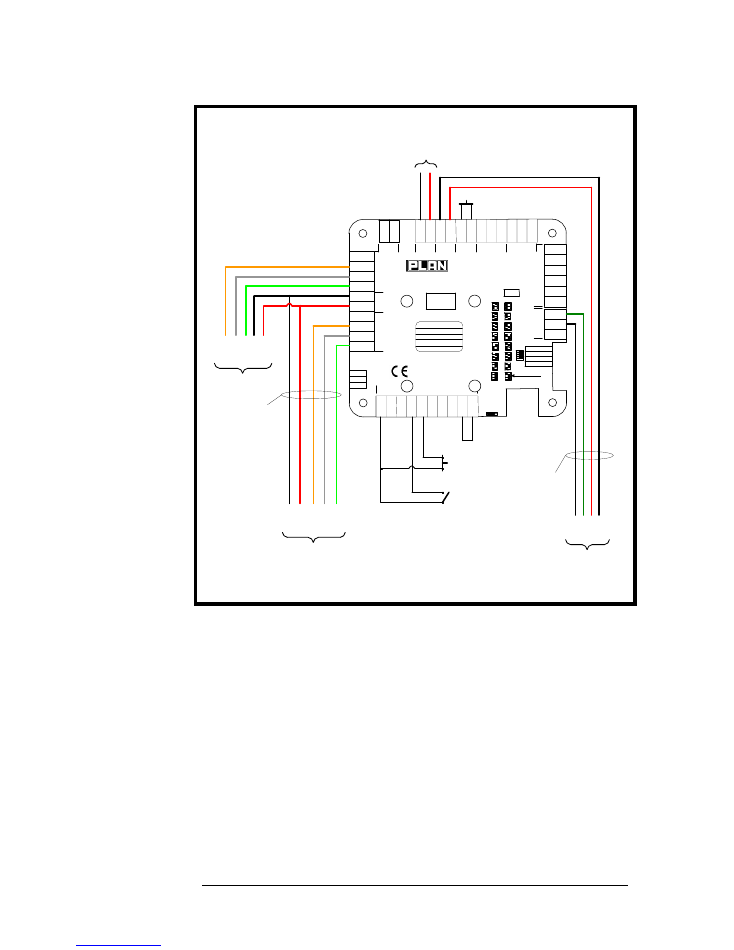

Readers

The system is compatible with most types of card reader; technologies

supported range from Mag-stripe, Wiegand Swipe and Proximity through to

more sophisticated Biometric and Contact-less Smart Card solutions. For

Asset Matching and Long range hands free, the system utilises the latest in long

range RFID tagging.

For connection purposes, all of the above reader options can be split into two

general interface types: ‘Wiegand’ and ‘Clock and Data’. Generally, the

Wiegand interface is used for all proximity readers and ‘Clock and Data’ is used

for Mag-stripe devices.

The documentation provided with the readers should be consulted for

installation guidance and cable requirements, however, the diagram below

indicates how the most common types of reader should be connected into the

XP1M reader ports.

X P 1 M I N S T A L L E R G U I D E

7

S T A N D A R D W I E G A N D R E A D E R T E R M I N A T I O N

RX+

RX-

TX+

TX-

2#

1#

A (A+)

B (A-)

GND

L2 RED

L1 GRN

D1/CLK

D0/DATA

- 0V

+ 12V

L2 RED

L1 GRN

D1/CLK

D0/DATA

G

N

D

R

D

_

T

A

U

X

1

T

a

m

p

A

U

X

2

M

C

D

R

S

E

C

P

R

I

G

N

D

S

ta

ti

o

n

I

D

Fire alarm shunt

5V

RX

TX

C

O

M

N

O

N

C

C

O

M

N

O

N

C

F

A

R

T

N

1

2

V

+

G

N

D

1

2

V

+

G

N

D

Program Socket

CM/RS422

SW 3

SW 2

SW 1

Lock

Relay

Alarm

Relay

Master

Reader

Slave

Reader

Fire

Alarm

Power

In

Power

Out

Network

RS422

Subnet

RS485

Reader

Power

0

9

1

0

1

1

1

2

1

3

1

4

1

5

1

6

o

n

1

2

3

4

Program

A

U

X

3

A

U

X

4

XP1M

AUX

www.xplan.com

Com’s Module

0

1

0

2

0

3

0

4

0

5

0

6

0

7

0

8

Designed and built in the UK

Access Control Services LTD

SW2 SW3 Speed

ON ON 1200

OFF ON 4800

ON OFF 9600

OFF OFF 57600

Cable Spec. Belden 9536

(Max Run 100m)

Tamper Link

(N/C) Monitoring Circuit

(N/0) Exit Button

Master Reader

D

A

T

A

0

D

A

T

A

1

G

R

N

L

E

D

1

2

v

0

v

Cable Spec.

Screened Twisted Pair

Belden 9502

(Max Run 100m)

B

A

1

2

V

G

N

D

Message Display

Unit

Slave Reader

D

A

T

A

0

D

A

T

A

1

G

R

N

L

E

D

1

2

v

0

v

+

-

12v DC @ 2A

A

la

rm

P

o

in

t 1

*

A

la

rm

P

o

in

t 2

*

A

la

rm

P

o

in

t 3

*

A

u

x

in

p

u

t 2

A

u

x

in

p

u

t 1

N/C

Door Control

Relay Output

(max. 1.25A)

Door Egress Switch (DR input)

As can be seen in the diagram above, an input (DR) is provided on each reader

port for a normally open ‘momentary operation’ egress switch. Whenever the

DR (Door Release) input is pulsed low (via the RTE switch) the lock output

will be switched for the pre-selected lock delay time.

The RTE is generally used in the following circumstances…

to provide an exit signal in the case of alarmed doors.

to allow a means of exit for doors with no mechanical override (e.g.

Mag-locks).

to allow the location of a remote override button.

X P 1 M I N S T A L L E R G U I D E

8

to provide an interface point between third party systems (such as

required by telephone entry systems).

Door Monitoring Alarm (MC Input)

Using the MC input, the system can monitor for Door Forced or Door Ajar

alarms.

Door Forced:

If the MC input is open circuit without there first having been a

valid card or RTE, then a Door Forced alarm will be generated.

Door Ajar:

If the MC input remains open circuit for longer than the allocated

door ajar delay then a Door Ajar alarm will be generated.

To use the door monitoring feature, connect a normally closed alarm circuit

between MC and 0V (this input would usually be derived from an integrated

contact within the locking device).

Note:

In addition to the door state monitoring for reader controlled doors, the

System features an additional 3 extended alarm inputs… please see ‘Extended

Alarms’ for more information.

Locks

The XP1M provides the installer with a volt free SPCO relay o/p for

connection of locking devices or third party control equipment (such as vehicle

barriers or powered doors).

For locking devices that draw up to 1.25 Amps, the lock feed can be switched

directly by the relay o/p. For locks that draw above 500mA, the source power

should not be drawn from the 'on-board' XP1M 12v power, but direct from

the PSU fitted in the rear of the enclosure - or from an additional PSU fitted

adjacent to the controller.

An optional ‘Break-Glass’ fire alarm override switch can be fitted in such a way

that it breaks either the positive, or, depending on local codes of practice, both

poles.

Under no circumstances should the emergency override be

installed so that it is only switching the negative supply.

The Break Glass device would normally be required if the controlled door

prevented access or egress to a nominated Fire Exit.

Please note that some

local authorities will require the use of a Double Pole break glass call

point (configured to disconnect power to both poles of the locking

device).

It is advisable to separately fuse the individual lock feeds using 'in-line' fuses as

shown.

The specific arrangement and connection of the locking device will be

dependent on the type of equipment used. In all cases reference and

X P 1 M I N S T A L L E R G U I D E

9

consideration should be made to the lock supplier’s documentation before

connection.

IMPORTANT NOTE:

For enhanced safety and flexibility the XP1M

controller firmware features the option to select Fail Safe or Fail Secure mode

from within the software. When set into Fail Safe mode the selected lock relays

will reverse their operation. This should be taken into consideration when

connecting a Fail Safe locking device because the panel default is for Fail

Secure.

Extended Alarms

Each XP1M features 3 extended alarm inputs for monitoring third party

equipment and standard alarm input devices (such as door contacts and PIRs).

Fire Alarm override

In addition to the local Break Glass Points fitted at each door, the System

can accept door override signals from a Fire Alarm system using the

configurable Fire Alarm Input.

At all times, this input must detect a closed contact ‘

safe

’ signal from an

evacuate relay controlled by the fire alarm system. If the fire alarm link is

removed, or the fire panel is activated, the selected doors will open.

The doors that will open in the event of an evacuation signal are selected

by means of a jumper (JP1) as shown above.

NOTE:

The Fire Alarm override input will only activate doors that have

been set to Fail Safe in the door configuration menu.

Since this facility does not depend on the microprocessor to operate it can

be considered fail safe in operation.

Networking

The PLAN system offers the installer a high degree of networking flexibility.

Direct cabled ‘star’ and ‘daisy chain’ topologies can be used. Using the field

upgradeable plug-in Ethernet module, client LAN/WAN infrastructure can be

utilised, as well as a wireless Ethernet (WiFi) option. All of these can be mixed

in a single installation.

As standard, the panel is shipped with the relevant jumpers set for direct cabled

systems, this presumes that XP1Ms are linked together using dedicated twisted

paired cables and connected to the Host PC via an RS422 interface.

Network cable should be minimum 7/0.2mm shielded two twisted

pairs. Recommended cable is Belden 8723 or equivalent. Maximum

cable distance between any two panels is 5,000m.

X P 1 M I N S T A L L E R G U I D E

10

Normal precautions to avoid possible causes of harmful interference

should be employed… e.g. avoid running with heavy duty mains cables

or adjacent to fluorescent lighting etc.

A maximum of 16 door controllers (XP1Ms PLAN200s or

PLAN400s) can be connected to any single comms port.

Care should be employed when using twisted pair cables that include

multiple ‘black’ conductors. ‘Crossing’ the black conductors between

panels will cause spurious faults that may be difficult to track down.

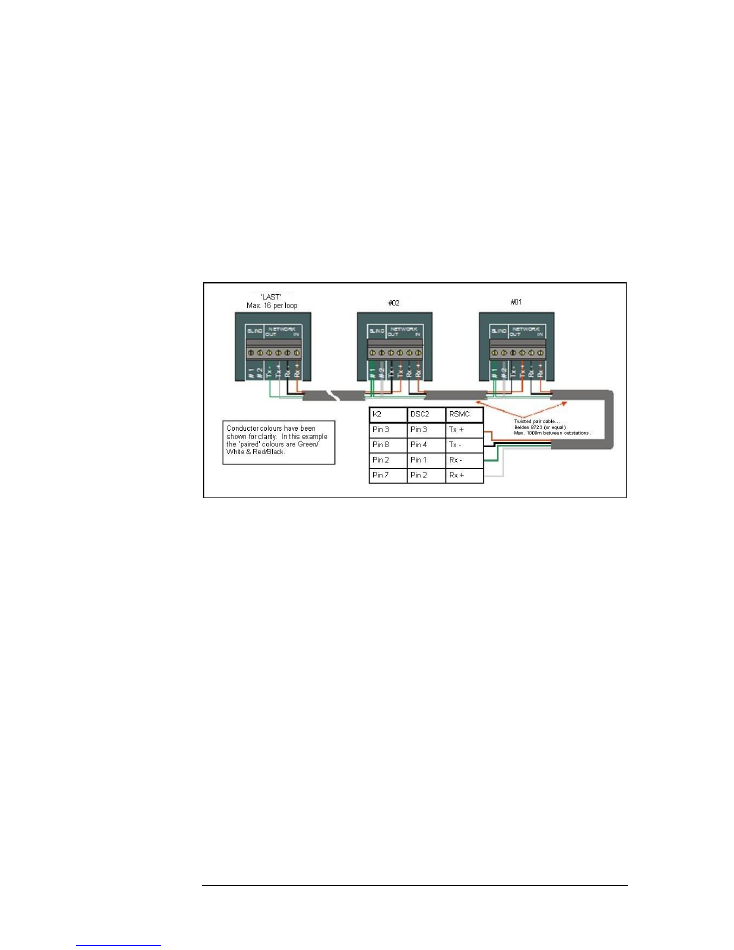

P L A N N E T W O R K C O N N E C T I O N D I A G R A M

Note above that the ‘BLIND’ terminals have been used to link the ‘through’

pair in the IN and OUT cables. These termination points have no connection

to the panel electronics and are provided solely for the purpose of linking the

‘straight-through’ pairs. The Blind terminals are not used in controllers situated

at the end of a chain.

X P 1 M I N S T A L L E R G U I D E

11

Commissioning Procedure

Powering up the unit

Before applying mains power to the XP1M, make a final check that all

connections are made off and terminated correctly. It is important that these

checks are carried out at the panel

and

at the door location. Ensure that all

unused conductors and foil shielding is insulated and made ‘safe’ as necessary

to prevent short circuits when the panel is closed.

To initiate the first time power-up sequence apply mains power to the

PSU/charger. Check that the LED on the PSU is displaying Green and that

the “5vDC” and LED on the xP1M is illuminated. If the LEDs are on,

connect the stand-by batteries to the PSU charger.

For direct cabled applications ensure that the ‘Comms Select’ jumpers are set

for RS422. For alternate communications configurations such as WiFi or

Ethernet, please refer to the relevant paperwork.

Setting the station ID

If the XP1M is connected in a network to other PLAN400s or PLAN200s,

then each unit must be given a Station-ID in the range 01-16. To Set the

Station ID for this panel simply use the dip switches as indicated on the PCB

overlay.

The control panel is now ready to be tested on-line. Refer to the

software manual for further instruction.