Full Text Searchable PDF User Manual

16

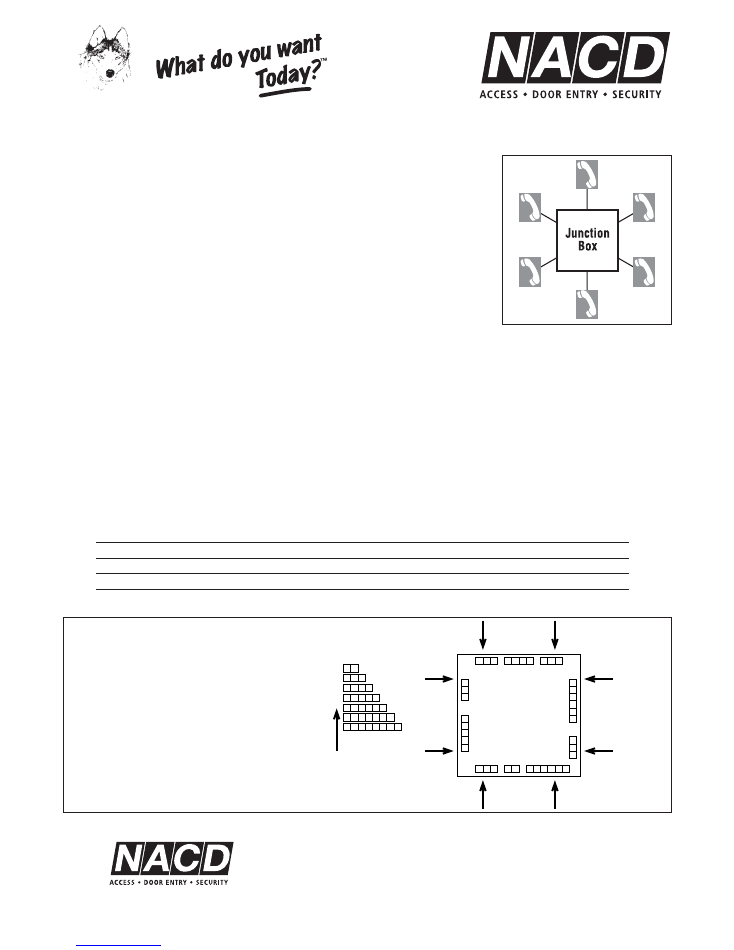

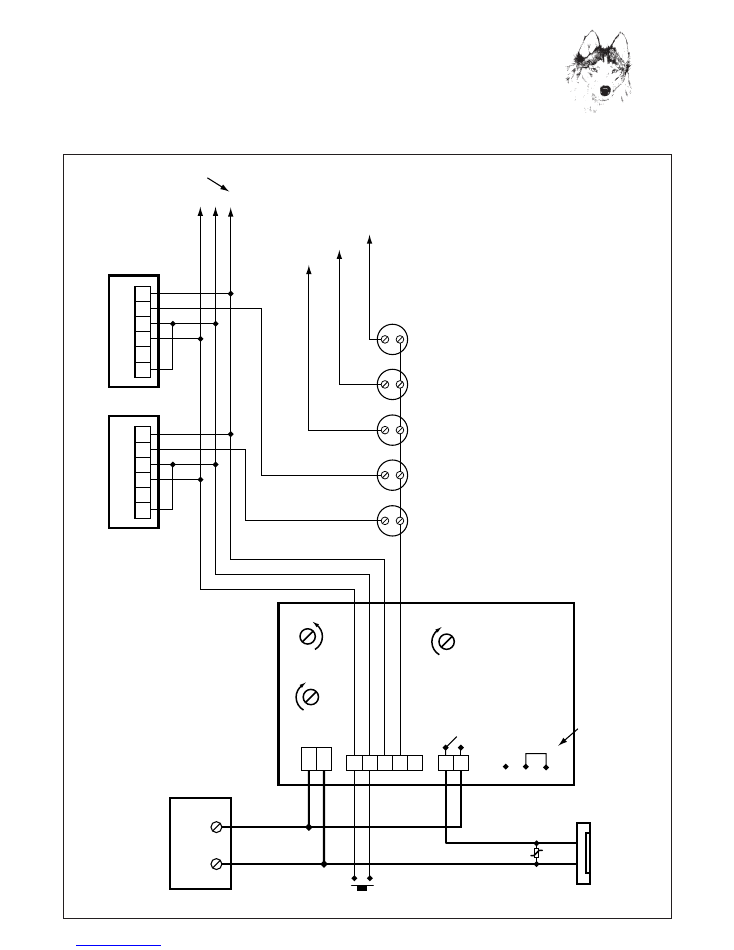

Cabling Audio Systems

1)

Cabling should be Star Configuration (Topology). ie. Each Handset cable should go back

to a junction box or central cabinet and NOT looped from one Handset to the next. This is

purely for maintenance reasons.

2)

It is recommended that 1mm diameter conductors are used from the power supply to the

(+) POSITIVE and (-) NEGATIVE of the speaker unit.

3)

It is recommended that 1mm (preferably 1.5mm) diameter conductors are used for the

lock circuit.

4)

Standard BT telephone cable is recommended (0.4mm per conductor) for reasons of

higher quality audio reproduction and because the pairs are twisted thereby providing a

powerful defence against interference.

5)

Standard alarm cable can also be used although there is a greater risk of interference.

Special care must be taken to ensure clean and neat terminations.

6)

All low voltage cabling must be run totally separated from high/mains voltage cables.

Please note that far better results are achieved using thicker conductors than combinations of

thinner conductors.

Power

Power the MIHP/6 Speaker using a 12V DC power source.

Amperage draw is dependent upon consumption characteristics of the locking used, the lengths of cable runs, the number of

handsets required to switch on simultaneously etc. As a general guide, allow 1 Amp per door. If unsure, please contact Noralsy.

Standby for Audio Systems

Simply add 12V battery to 12V DC power supply.

General Wire Diameter Guidlines – per conductor

Distance

Call/Speech/Release

Metres

CA, 2, 1, 9, 6

mm

50

0.4

100

0.8

200

1.0

300

1.6

For greater distances, please contact Noralsy for advice.

1 2 3

1

2

4

5

6

3

1

2

3

1

2

4

3

1

2

3

1

2

4

5

3

1

2

3

1

2

3

View Side-On

PCB Facing Up

View Side-On

PCB Facing Up

View Side-On

PCB Facing Up

View Side-On

PCB Facing Up

1 2

1 2 3

1 2

4

3

1 2

4 5

3

1 2

4 5 6

3

1 2

4 5 6 7

3

1 2

4 5 6 7 8

3

Direction of View

1 2

1 2

4 5 6

3

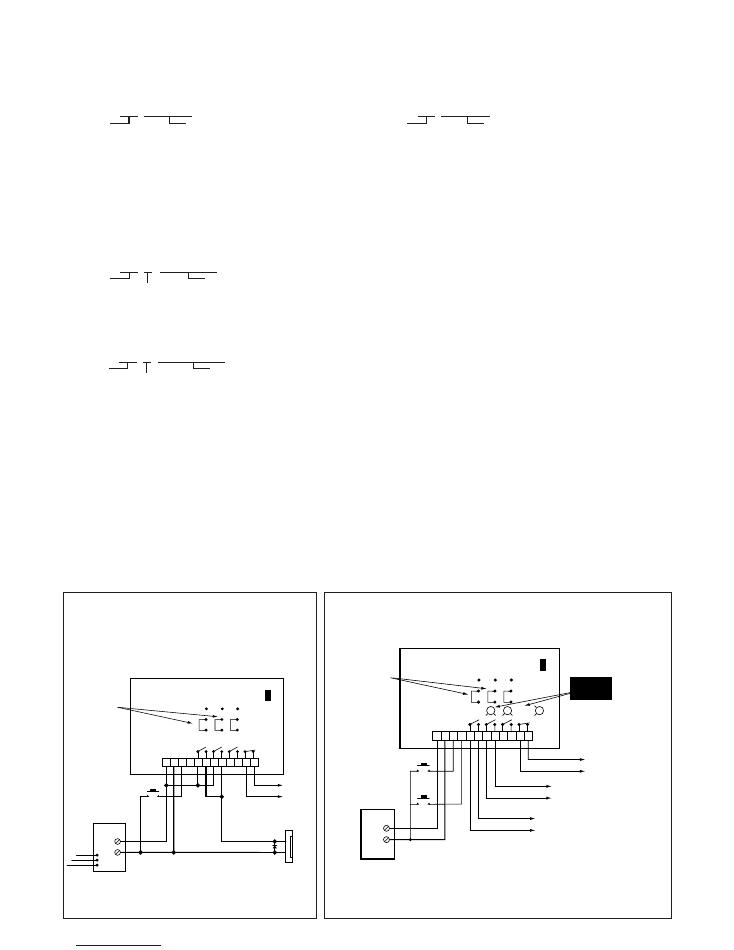

Any Noralsy

Control Unit

Door Controller

Speaker Unit

Access Pass Reader/Receiver

Keypad

Call Decoder

Module

Standardisation of

Terminal Numbering

Place Noralsy unit on a flat surface with

PCB facing skywards. View terminal blocks

from the outside looking in. Terminal No. 1

is always the first on the left of every

terminal block strip.

General Information

Our policy is one of continuous product improvement, we reserve the right to change specifications and prices without notice. All information is given in good faith. No responsibility can be accepted for errors, omissions or

incorrect assumptions. Picture reproduction of products are within the limitations of both colour and black and white printing and are intended as a guide only.

Star

Topology

N.A.C.D. LIMITED

UNIT 10, AVEBURY COURT, MARK ROAD, HEMEL HEMPSTEAD, HERTS HP2 7TA

TEL:

01442 211848

FAX:

01442 212776

EMAIL:

sales@nacd.co.uk

WEB:

http//:www.nacd.co.uk

NORALSY

™

MASTERING ACCESS CONTROL

™

™

12V

DC

Speak

er

I

NSTALLATION

I

NSTRUCTIONS

MIHP/6 S

PEAKER

Audio Entry

Single Entrance

Multiple Entrances with Automatic Switching

With

Fail Secure Locking

Fail Safe Locking

Automation

Keypad

Access Control

NORALSY

™

MASTERING ACCESS CONTROL

™

™

Contents

Page

General

3 -4

Single Entrance Audio System

5

2 Entrance Audio System

6

3 - 4 Entrance Audio System

7

5 - 6 Entrance Audio System

8

7 - 8 Entrance Audio System

9

Interfacing with a Keypad, Fail Secure Locking

10

Interfacing with a Keypad, Fail Safe Locking

10

“Volt Free” Automation

11

Interfacing with a Keypad, “Volt Free” Automation

11

Interfacing with Access Control, Fail Secure

12

Interfacing with Access Control, Fail Safe

12

Interfacing with Access Control, “Volt Free” Automation

12

Programming instructions for 30 Code/1 Relay Keypad

13

Programming instructions for 30 Code/3 Relay Keypad

14-15

Cabling Specifications

16

2

Audio Entry

Functional Systems

15

DELETING USER CODES

As all User Codes are stored in Slots, it is easy to delete a code from the keypad:

Enter the Master Code and wait for the beeps.

After a beep enter on the keypad:

or

To delete the User Code stored in Slot 01

To delete the User Code stored in Slot 17

A rapid series of beeps indicates that you have deleted successfully.

Now press B or # to escape from programming.

OVERWRITING / CHANGING USER CODES

You do not have to delete a User Code in order to change it. By programming a new User Code into a Slot that is currently in use,

you automatically erase the old User Code.

Enter the Master Code and wait for the beeps.

After a beep enter on the keypad:

The new User Code in Slot 01 is 700028. Whatever was in Slot 01 before has been erased.

Note: You change the Master Code in exactly the same way.

........to program Master Code 7767110 into Slot 30

Now press B or # to escape from programming.

LATCHING RELAY

The code stored in Slot 28 acts as the “ON” for Latching Relay no. 3.

The code stored in Slot 29 acts as the “OFF” for Latching Relay no. 3.

If you do not store a different code in Slot 29 to that stored in Slot 28, entering the code stored in Slot 28 will act first as

“ON” and then as “OFF”, then “ON” etc.

EMERGENCY CODE

The code stored in Slot 27 operates both Relay no. 1 and Relay no. 2 at the same time.

ANTI-TAMPER

An anti-tamper circuit (terminals 11 + 12 of J1) provides a normally closed contact, once the keypad is secured to the wall.

AUTOMATIC TIME-OUT - whenever programming accessed via Master Code

If you do not press B or # to escape from programming, the keypad will automatically revert to normal mode after 20 seconds.

30 7 7767110

Length of Code

Slot No.

Master Code

Itself

01 6 700028

Length of Code

Slot No.

User Code

17 A or

*

Slot No.

Delete Command

01 A or

*

Slot No.

Delete Command

+12v

0v

J1

SW1 SW2 SW3

L

E

N

INV

NOR

+

–

EX1

EX1 = Exit Button

1 2

+ -

3 4 5 6 7 8 9 10 11 12

Jumper Setting

COMMON - NOR

For Fail Safe Locking

move jumper to:

COMMON - INV

(+ wire relays 1 & 2

in series)

SW5

Alarm Circuit (NC)

POWER SUPPLY

12V DC

12V DC

ELECTRIC

RELEASE

D1

+

–

Single Door Installation

26 user codes / relay nos 1 & 2 in parallel.

+12v

0v

J1

SW1

RV3

RV1

RV2

SW2 SW3

Alarm Circuit (NC)

SW5

INV

NOR

To Automation Control Equipment No.2

To Automation Control Equipment No.1

+

–

Jumper Setting

COMMON - NOR

EX1

EX1 activates Relay 1.

EX2 activates Relay 2.

(EX = Exit Button)

EX2

POWER SUPPLY

12V DC

1 2

+ -

3 4 5 6 7 8 9 10 11 12

Automation Control

13 user codes / relay no.1 , 13 user codes / relay no. 2.

Gate/Barrier Automation Control No. 1 = Main Gate (for example)

Gate/Barrier Automation Control No. 2 = Pedestrian Gate (for example)

Cut-out varistor RV1 or RV2 if its corresponding relay

is controlling an automation system.

Latching relay no. 3 (terminals 9-10) can be used to

hold open an automated gate/barrier etc.

In this instance only, cut-out varistor RV3.

CUT OUT

When power OFF

✄

ELEC/INST/K304

ELEC/INST/K301

Noralsy™ Keypad 30 codes / 3 Relays

Noralsy™ Keypad 30 codes / 3 Relays

14

N

ORALSY

™ K

EYPAD

30 C

ODES

/ 3 R

ELAYS

TOP POINTS TO REMEMBER

■

Master ( Engineer) Code is always stored in Slot 30.

■

User Codes are stored in Slots 01, 02, 03, 04..........26.

■

Relay no. 1 is controlled by the User Codes stored in Slots 01 - 13.

■

Relay no. 2 is controlled by the User Codes stored in Slots 14 - 26.

■

The code stored in Slot Number 27 activates Relay no. 1 & Relay no. 2 simultaneously.

■

The code stored in Slot Number 28 turns Latching Relay no. 3 “ON”.

■

The code stored in Slot Number 29 turns Latching Relay no. 3 “OFF”.

TIP - WHEN YOU ARE IN PROGRAMMING

Enter the numbers in quick succession after a beep. Do not wait more than 2-3 seconds in between entering numbers. If you have

correctly programmed, you will hear a rapid series of beeps.

SET-UP ON INSTALLATION

Wire up according to appropriate electrical schematic for your installation, then power up the keypad. Flick Programming Switch SW5

and wait for the keypad to start beeping every 3 seconds.

STEP 1

Decide Now......for how many seconds do you want the door to open:

After a beep enter

The 2no. digits shown as underlined set the door open time in seconds for relay no.1. The last 2no. digits set the door open time for

relay no.2. A rapid series of beeps indicates that you have programmed successfully.

You must set the relay/lock command time for relay no. 2 even if you are not using relay no. 2. If you have linked relays 1 &

2 together, you must set the same open times for both.

STEP 2

Now set the Master Code of your choice.

This is the code that allows you to access programming mode

without having to open up the keypad and flicking switch SW5.

The Master Code is always stored in Slot 30.

The Master Code can be any length of digits/characters/symbols -

minimum 3, maximum 8.

After a beep enter on the keypad:

if you want your Master Code to be 2901

A rapid series of beeps indicates that you have programmed successfully.

STEP 3

Turn off programming switch SW5.

STEP 4

PROGRAMMING/ADDING USER CODES

User codes can be any length of digits/characters/symbols - minimum 3, maximum 8.

User codes are stored in Slots 01-26. Example: 01, 02, 03… 26.

Enter the Master Code you set in STEP 2 and wait for the beeps.

After a beep enter on the keypad:

..............to program User Code 494 into Slot 01

A rapid series of beeps indicates that you have programmed successfully.

.............to program User Code 5519 into Slot 02

A rapid series of beeps indicates that you have programmed successfully.

Now press B or # to escape from programming.

02 4 5519

Length of Code

Slot No.

User Code

01 3 494

Length of Code

Slot No.

User Code

30 4 2901

Length of Code

Slot No.

Master Code

Itself

00 05 05

Relay No. 1

Set Timer

Command

Relay No. 2

05

Example

Seconds

This is an example only.

SET THE MASTER CODE OF

YOUR CHOICE

NOTE:

Relays can be programmed

between 01 – 99 seconds.

J1

J2

J3

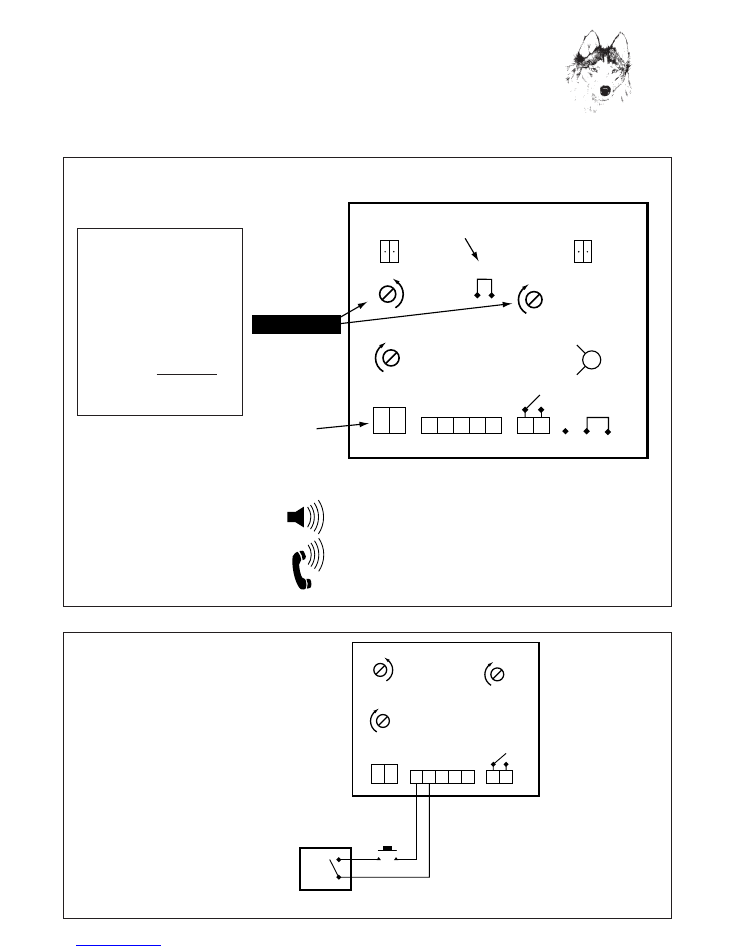

Speaker

MIHP/6

1 2

1 2

1 2

+ –

3 4 5

TR

TIME CLOCK

TR = Trades-Button

(Normally open contact)

P1

P3

P2

–

+

–

+

–

+

ELEC/INST/300B

Adding a Trades-Button

controlled via a Time Clock

3

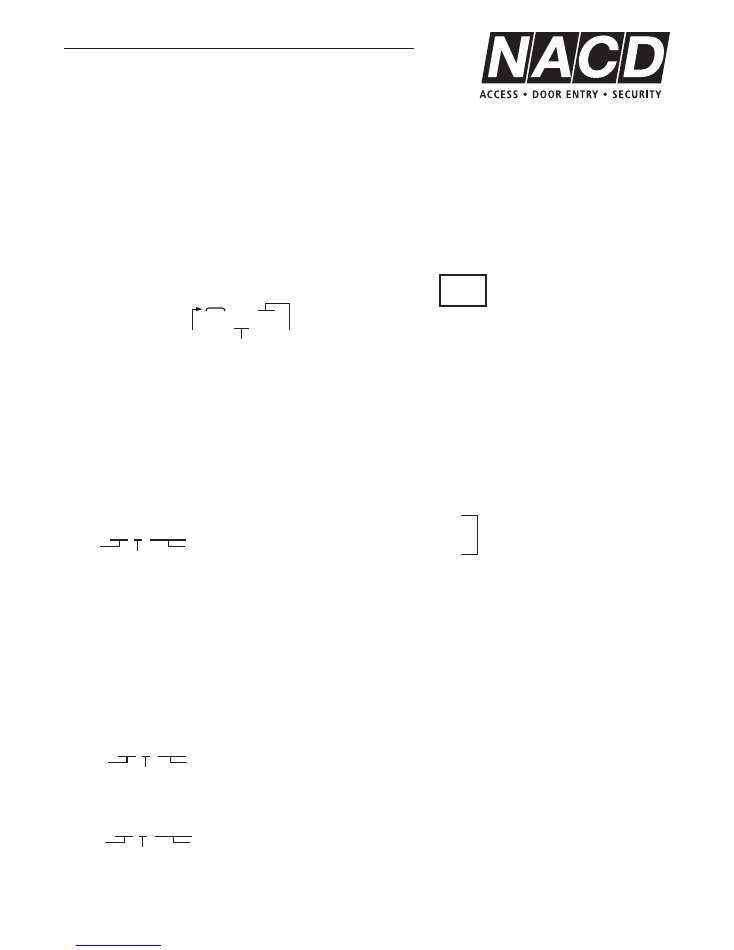

Noralsy Speaker MIHP/6

NORALSY

™

MASTERING ACCESS CONTROL

™

™

P1

J1

J5

J4

J8

J2

J3

J9

P3

P2

RV1

1 2

1 2

+ –

1 2 3 4 5

INV

NOR

Removing jumper reduces

gain of microphone

12V DC

Power Input

Speaker MIHP/6

–

+

–

+

–

+

Potentiometers

P2

= For adjusting speech/sound level

down to the external panel.

P3

= For adjusting speech/sound level

up to the handset(s).

Speech & Audio Settings

ELEC/INST/300

1. Turn P3 clockwise to

zero = No speech from

panel to handset.

2. Adjust P2 clockwise so

that speech level at

panel is at an acceptable

level. Do not increase

beyond this point.

3. Adjust P3 fractionally

anti-clockwise to “turn

on” microphone.

J4

= Prewired/connected to speaker (if not

connected simply plug in).

J5

= Prewired/connected to microphone (if not

connected simply plug in).

J8

= On short runs especially, removing the jumper

reduces the gain of the microphone.

4

Noralsy Speaker MIHP/6

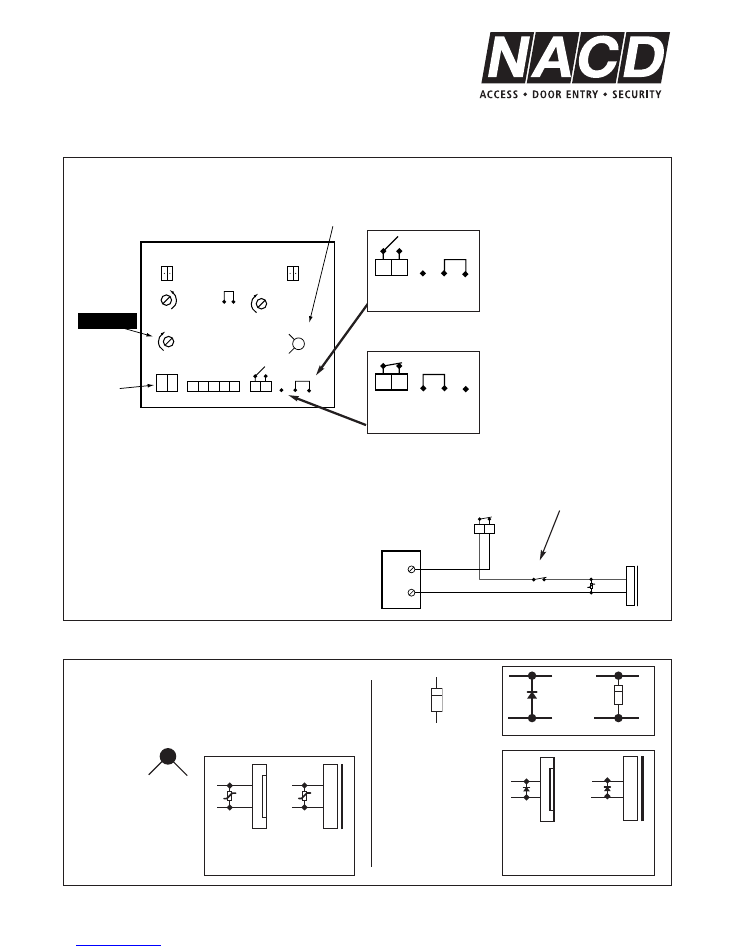

Common - NOR

= Relay closes (makes circuit)

when door release button on

handset or internal exit button is

pressed. This setting is used

when operating a fail secure

(locked) - power to unlock

electric release.

J1

J5

J4

J8

J2

J3

J9

RV1

1 2

1 2

+ –

1 2 3 4 5

INV

NOR

Potentiometer

12V DC

Power Input

If controlling an

automation system,

see note.

Speaker MIHP/6

P1

P3

P2

–

+

–

+

–

+

P1

= For adjusting relay J3 operating time (output

time) to lock or automation equipment.

RV1 = Cut out only if relay J3 is connected directly to

an automation system.

Common - INV

= Relay opens (breaks) circuit

when door release button on

handset or internal exit button is

pressed. This setting is used

when operating a fail safe (open)

- power to lock electro-magnet

or electric release.

EMEX

POWER SUPPLY

+12v

0v

Magnet

or Fail Safe

Release

1 2

J3

Varistor

If your fail safe locking requires an Emergency Break

Glass exit device ref. EMEX (normally closed contact) in

order to comply with relevant fire and safety regulations,

please fit as shown.

J3

1 2

J9

INV

NOR

J3

J9

1 2

INV

NOR

Fail Secure (N.O.)

Fail Safe (N.C.)

Jumper Settings J9 for Relay J3

ELEC/INST/300A

Protection Varistor or Diode

The use of a varistor or diode protects electrical equipment from

transient voltage spikes.

+

–

+

–

Diode

Varistor

DC release

Fail Secure or

Fail Safe

K = Cathode +

A = Anode –

Electro

Magnet

AC or DC

release

Electro

Magnet

Fit the diode ref. IN4001

close to the DC release

or electro-magnet.

Respect polarity of the

diode. Incorrect fitting of

a diode will cause a

short circuit.

Fit the varistor close to the

AC or DC release or the

DC magnet.

Varistor is polarity

insensitive.

+

–

K

A

–

K

A

+

+

or

D

D

D

D

V

V

or

–

Noralsy™ Keypad

30 Codes / 1 Relay

SET-UP ON INSTALLATION

Wire up according to appropriate electrical schematic for your installation, then power up the unit.

Flick the programming switch SW1 and wait for unit to start beeping every 3 seconds.

SET THE MASTER CODE. IT MUST BE STORED IN SLOT 06.

Example:

You want the following MASTER CODE: 74AB6

After a beep enter on the keypad:

06

5

74AB6

Master Code Slot Number

Length of Code

Master Code Itself

If you have correctly entered the Master Code you will hear 2no. series of rapid beeps.

Turn off Programming Switch SW1. You can now effect all programming simply by entering the Master Code and waiting for the

programming beeps.

TOP POINTS TO REMEMBER

1.

Up to 29 user entry codes available at any one time.

2.

Codes are stored in slots numbered 01, 02, ....05 and 07, 08......30.

3.

Master Code = Programming code and must be stored in Slot 06.

4.

Each code can be any mix of digits/letters from 3 to 8 in length.

TIP - WHEN YOU ARE PROGRAMMING

Enter the numbers in quick succession after a beep. Do not wait more than 2-3 seconds in between entering numbers as this will

confuse the keypad. If you have correctly programmed, you will hear a rapid series of beeps.

SETTING USER DOOR ENTRY CODES

Enter the Master Code onto the keypad and wait for the beeps.

Example: you want the following codes:

A94

= 3 digits

564B52

= 6 digits

After a beep enter on the keypad:

01

3

A94

Slot Number

Length of Code

Code Itself

02

6

564B52

Slot Number

Length of Code

Code Itself

NOTE CAREFULLY:

No codes into slot no. 06 as this is for the Master Code !

(Unless, of course, you want to change the Master Code).

Press B to escape from programming.

DELETING USER DOOR ENTRY CODES

As all door entry codes are stored in slot numbers 01 - 05 and 07 - 30, it is easy to delete a code from the system.

NOTE CAREFULLY

- Do not delete slot no. 06 unless you are going to input a new Master Code whilst still in programming mode !

Example - Your codes are:

A94

for Mr Smith

stored in Slot 01

564B52

for Staff use

stored in Slot 02

To delete Mr Smith’s code - A94 - from the system simply:

Enter the Master Code onto the keypad and wait for the beeps.

After a beep enter on the keypad:

01

A

Slot Number

Delete Command

Press B to escape from programming.

Note 1.

You do not have to know the actual code itself which needs to be deleted, only the slot in which it is stored.

Note 2.

Capacity is never reduced as a result of deleting codes. You can always add or change codes.

SETTING LOCK OPEN TIME

Enter the Master Code onto the keypad and wait for the beeps.

Lock open time can be set at

0.2

seconds or

01 - 99

seconds.

After a beep enter:

00 00

for 0.2 seconds (automation control)

00 05

for 05 seconds

00 10

for 10 seconds

00 19

for 19 seconds etc

Press B to escape from programming.

If you do not press B to escape from programming, the keypad automatically reverts to normal mode after 20 seconds.

13

NORALSY

™

MASTERING ACCESS CONTROL

™

™

12

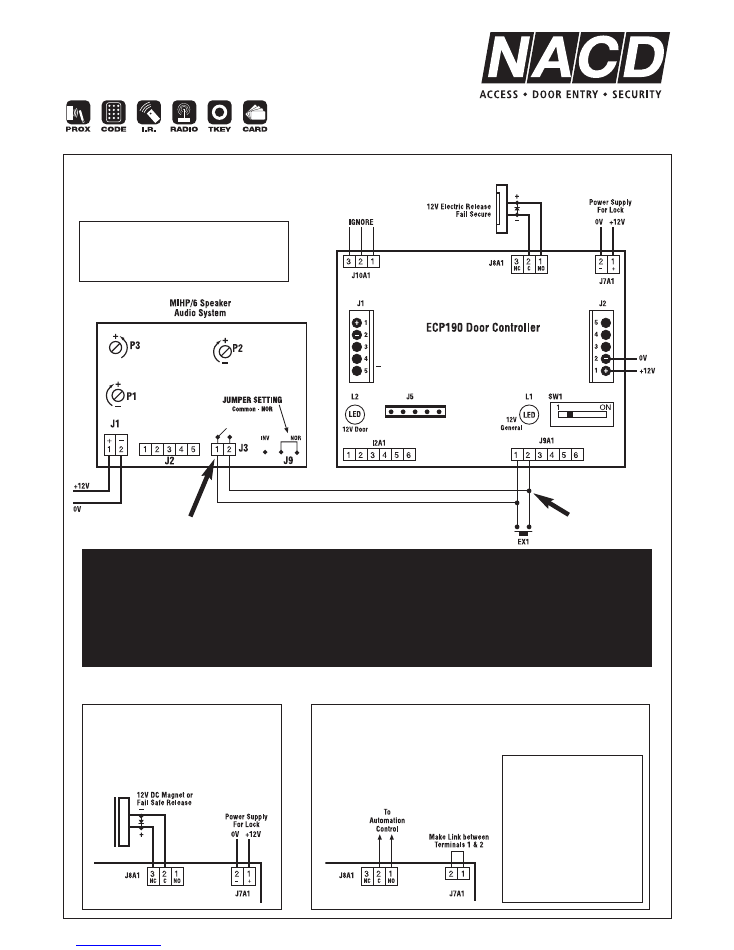

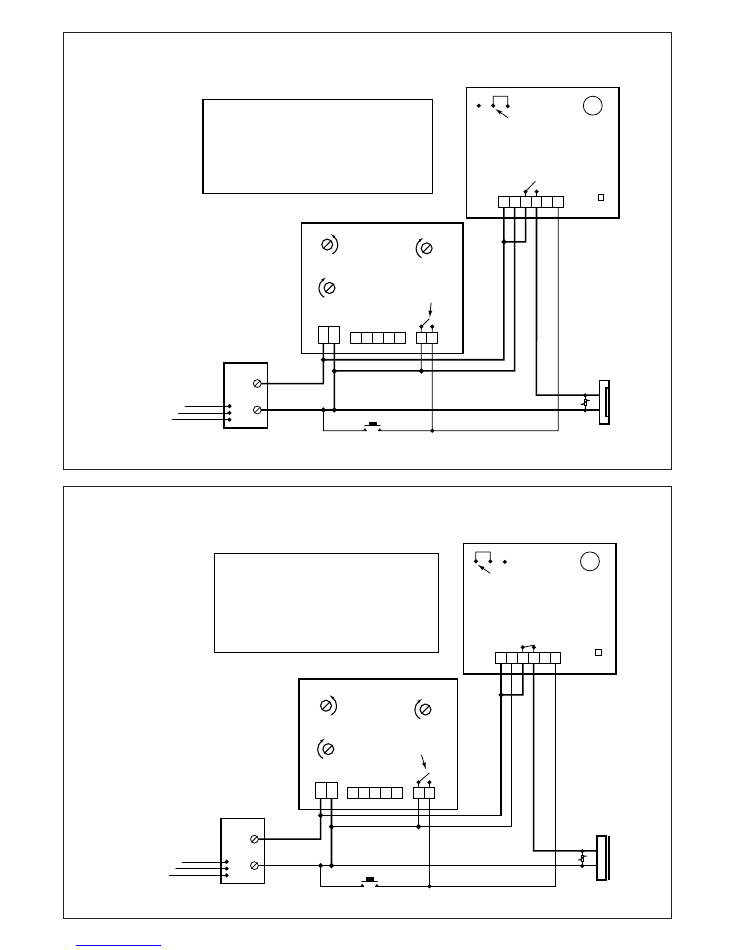

Audio System Interface

with Stand-Alone Access Control

Fail Secure (Locked) – Power to Unlock

ELEC/INST/309

Fail Safe (Open) –

Power to Lock

ELEC/INST/310

Automation Control / Volt Free

ELEC/INST/311

Set output time on speaker MIHP/6 (via

potentiometer P1) to slightly above

minimum. Program required lock

release time on ECP Door Controller.

Set output time on

speaker MIHP/6 (via

potentiometer P1) to

slightly above minimum

and program output time

on ECP Door Controller

to 01 seconds.

Program output time

accordingly if more time

is required to trigger

automation system.

Relay J3 used as a N.O. Volt Free change-over relay

to trigger relay (lock) output of ECP Door Controller

(Door Controller/Control Unit from 3rd party) via

standard internal exit button terminal connections.

Relay J3

EX1 = Internal Exit Button

Exit Button Input

Terminals

ECP Door Controller

ECP Door Controller

5

Noralsy Speaker MIHP/6

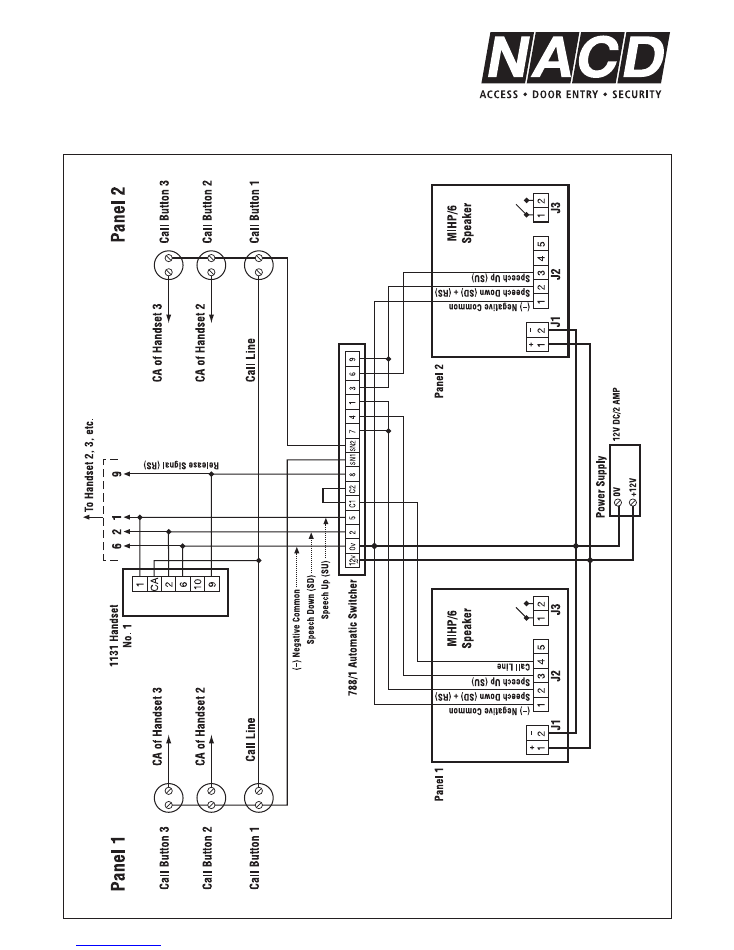

with 1131 Audio Handsets

ELEC/INST/301

(-) Negative Common

Speech Down (SD) + RS

Speech Up (SU)

(-) Negative Common

Speech Down (SD) + RS

Speech Up (SU)

Call line handset 1

Call line handset 2

Call line handset 3

Call line handset 4

Call line handset 5

POWER SUPPLY

12V DC

+12v

0v

J1

J2

J3

J9

Call Button 5

Call Button 4

Call Button 3

Call Button 2

Call Button 1

Speaker

MIHP/6

Handset 2

Handset 1

Handset 3

Handset 4

Handset 5

To Handset 3, 4, 5 etc.

ie. Terminal 1 of Handset

ie. Terminal CA of Handset

6 2 1

CA

CA

CA

12V

Electric

Release

Varistor

EX1

1 2

1 2

1 2

+ –

3 4 5

EX1 = Door release button

sited internally.

(Normally open contact)

RS = Release Signal

INV

NOR

JUMPER SETTING

(For fail safe locking

move jumper to

Common-INV)

6

10

9

2

CA

1

6

10

9

2

CA

1

P1

P3

P2

–

+

–

+

–

+

NORALSY

™

MASTERING ACCESS CONTROL

™

™

6

Noralsy Speaker MIHP/6

Audio Entry 2 Entrances

Automatic Switching

ELEC/INST/303

11

+12VDC

0V

J1

J2

J3

J9

Speaker

MIHP/6

1 2

1 2

1 2

+ –

3 4 5

INV

NOR

JUMPER SETTING

Common-NOR

To

Automation Control

RV1

CUT OUT

When power off

✄

Set output time on speaker

MIHP/6 (via Potentiometer

P1) to slightly above

minimum.

Adjust accordingly if more time

is required to trigger automation

system.

P1

P3

P2

–

+

–

+

–

+

Automation Control / Volt Free

MIHP/6 Speaker Audio System

J1

J2

J3

Speaker

MIHP/6

KEYPAD MODULE

30 Codes / 1 Relay

1 2

+ -

3 4 5 6

J1

SW1

KEYPAD

INV

NOR

INV

NOR

BUZZER

JUMPER SETTING

Common – NOR

1 2

1 2

1 2

+ –

3 4 5

JUMPER SETTING

Common-NOR

+12VDC

0V

To

Automation Control

Set output time on speaker MIHP/6

(via potentiometer P1) to slightly

above minimum and program output

time on keypad to 0.2 seconds.

Program keypad output time accordingly if more

time is required to trigger automation system.

RV1

CUT OUT

When power off

✄

P1

P3

P2

–

+

–

+

–

+

Automation Control / Volt Free

MIHP/6 Speaker Audio System + Keypad

ELEC/INST/307

ELEC/INST/308

10

POWER SUPPLY

12V DC

KEYPAD MODULE

30 Codes / 1 Relay

+12v

0v

L

E

N

J1

J2

J3

12V

Electric

Release

Varistor

EX1

Speaker

MIHP/6

1 2

+ -

3 4 5 6

J1

SW1

KEYPAD

INV

NOR

BUZZER

JUMPER SETTING

Common – NOR

1 2

1 2

1 2

+ –

3 4 5

EX1 = Door release button

sited internally.

(Normally open contact)

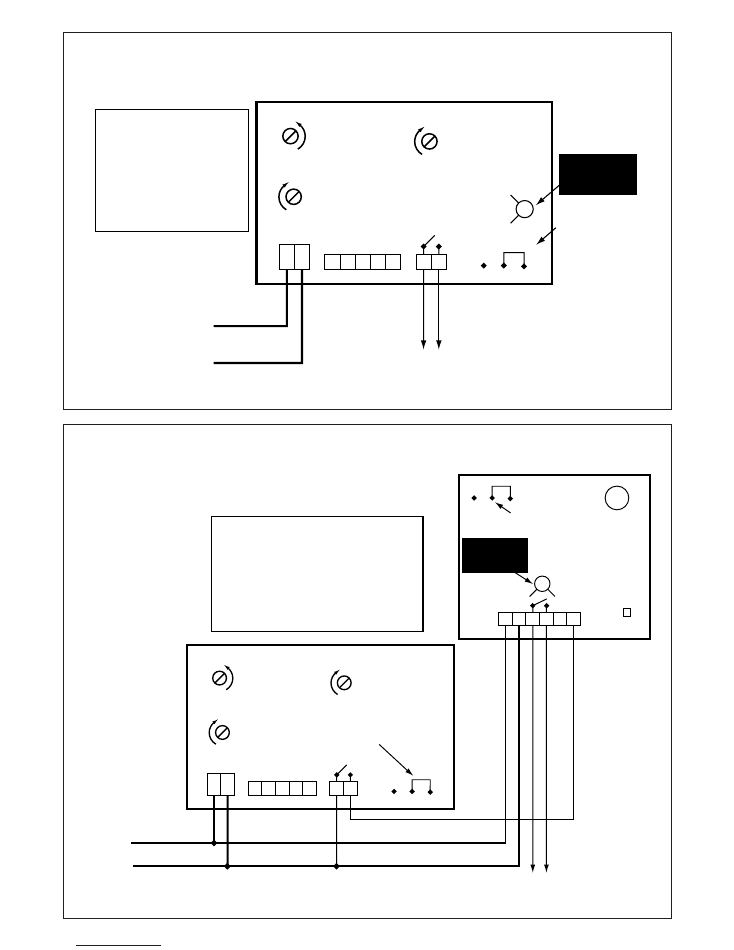

Fail Secure (Locked) - Power to Unlock

Fail Secure (Locked) -

Power to Unlock

Set lock release time on speaker

MIHP/6 (via potentiometer P1) to

slightly above minimum. Program

required lock release time on keypad.

JUMPER SETTING J9

Common-NOR

P1

P3

P2

–

+

–

+

–

+

Fail Secure Locking

MIHP/6 Speaker Audio System + Keypad

ELEC/INST/305

ELEC/INST/306

POWER SUPPLY

12V DC/1AMP

KEYPAD MODULE

30 Codes / 1 Relay

+12v

0v

L

E

N

J1

J2

J3

12V DC

Magnet

or

Fail Safe Release

Varistor

EX1

Speaker

MIHP/6

1 2

+ -

3 4 5 6

J1

SW1

KEYPAD

INV

NOR

BUZZER

JUMPER SETTING

Common – INV

JUMPER SETTING J9

Common-NOR

1 2

1 2

1 2

+ –

3 4 5

EX1 = Door release button

sited internally.

(Normally open contact)

Fail Safe (Open) - Power to Lock

Set lock release time on speaker

MIHP/6 (via potentiometer P1) to

slightly above minimum. Program

required lock release time on keypad.

Fail Safe (Open) -

Power to Lock

P1

P3

P2

–

+

–

+

–

+

Fail Safe Locking

MIHP/6 Speaker Audio System + Keypad

7

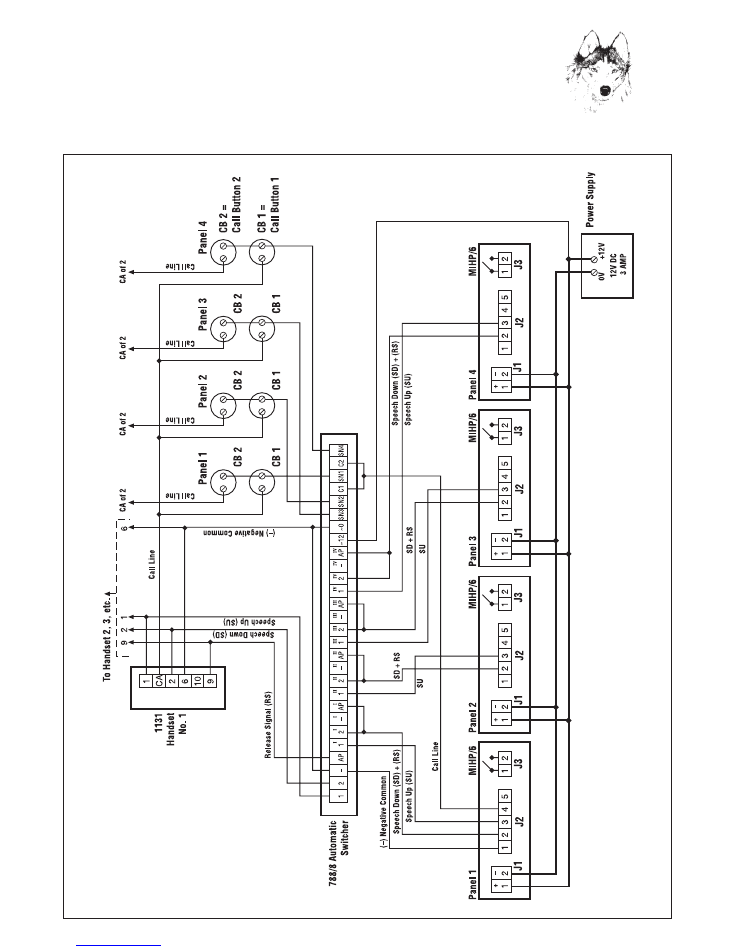

Noralsy Speaker MIHP/6

Audio Entry 3 or 4 Entrances

Automatic Switching

ELEC/INST/304

NORALSY

™

MASTERING ACCESS CONTROL

™

™

3

2

1

J3

J2

J1

3

4

1

7

SN1

9

10

6

2

1

CA

9

10

6

2

1

CA

5

2

11

8

C1

C2

5

2

11

8

C1

C2

1

I

2

I

_ I

AP

I

SN1

AP

2

1

1

III

2

III

_

III

AP

III

SN3

1

II

2

II

_

II

AP

II

SN2

1

IV

2

IV

_

IV

AP

IV

SN4

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 1

Call Buttons

SU

SD + RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 2

Call Buttons

SU

SD + RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 3

Call Buttons

SU

SD + RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 6

3

2

1

Call Buttons

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 5

3

2

1

Call Buttons

MIHP/6

Panel 4

Call Buttons

SU

SD + RS

SU

SD + RS

SU

SD + RS

6

3

9

~12 ~0

SN2

4

1

7

SN1

5

2

11

8

C1

C2

6

3

9

~12

~0

SN2

4

1

7

SN1

6

3

9

~12

DIP

E

+

+12 ~0

~0

C1

C2 ~12 ~0

–

SN2

788/8

788/1

788/1

788/1

SU

SD

RS

SU

SD

RS

CALL LINE 2

CALL LINE 1

CALL LINE 3

CALL LINE 3

CALL LINE 2

CALL LINE1

(–) Negative

Common

(–) Negative Common

1131 Handset No. 2

1131 Handset No. 1

S500 TNG

PSU 12VDC

6 AMP

To Handset 3, 4, etc.

8

Noralsy Speaker MIHP/6

Audio Entry 5 or 6 Entrances

Automatic Switching

ELEC/INST/304X

3

2

1

J3

J2

J1

3

4

1

7

SN1

9

10

6

2

1

CA

9

10

6

2

1

CA

5

2

11

8

C1

C2

5

2

11

8

C1

C2

1

I

2

I

_ I

AP

I

SN1

AP

2

1

1

III

2

III

_

III

AP

III

SN3

1

II

2

II

_

II

AP

II

SN2

1

IV

2

IV

_

IV

AP

IV

SN4

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 8

Call Buttons

SU

SD + RS

SU

SD

RS

SU

CALL LINE 2

CALL LINE 1

CALL LINE 3

(–) Negative

Common

SD

RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 2

Call Buttons

SU

SD + RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

MIHP/6

Panel 3

Call Buttons

SU

SD + RS

3

2

1

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

3

2

1

3

2

1

Call Buttons

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 7

3

2

1

Call Buttons

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 6

3

2

1

Call Buttons

J3

J2

J1

3

2

1

4

5

2

1

2–

1+

MIHP/6

Panel 5

3

2

1

Call Buttons

MIHP/6

Panel 4

Call Buttons

SU

SD + RS

SU

SD + RS

SU

SD + RS

SU

SD + RS

SU

SD + RS

6

3

9

~12 ~0

SN2

4

1

7

SN1

5

2

11

8

C1

C2

6

3

9

SN2

4

1

7

SN1

5

2

11

8

C1

C2

6

3

9

~12

~0

SN2

4

1

7

SN1

6

3

9

~12

DIP

E

+

+12 ~0

~0

C1

C2 ~12 ~0

–

SN2

788/8

788/1

788/1

788/1

788/1

1131 Handset No. 2

To Handset 3, 4, etc.

1131 Handset No. 1

~0 ~12

S500 TNG

PSU 12VDC

8 AMP

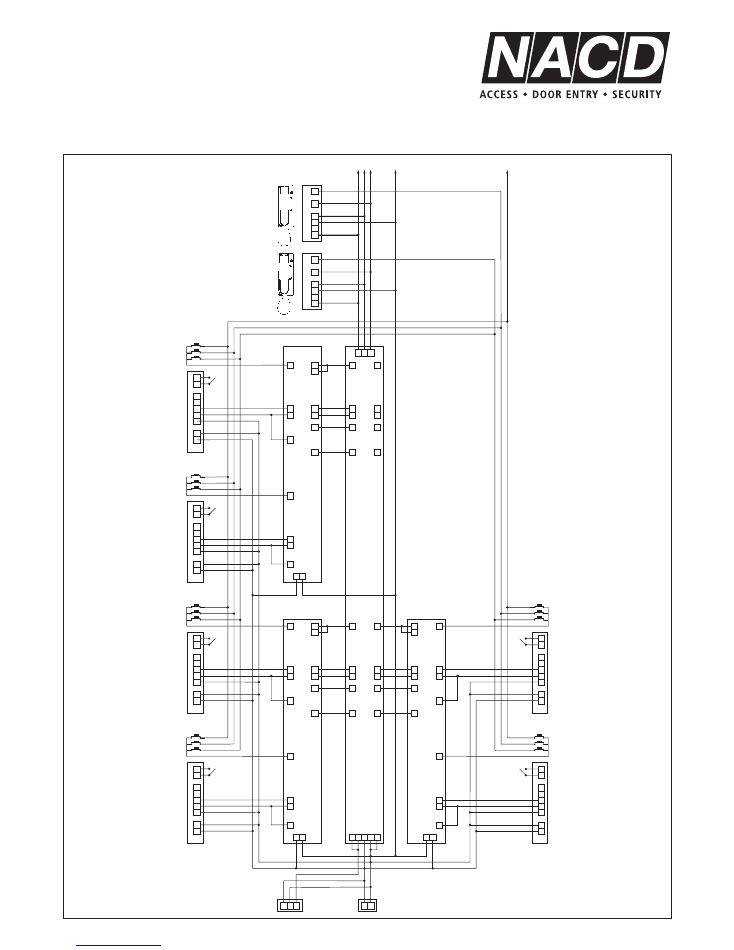

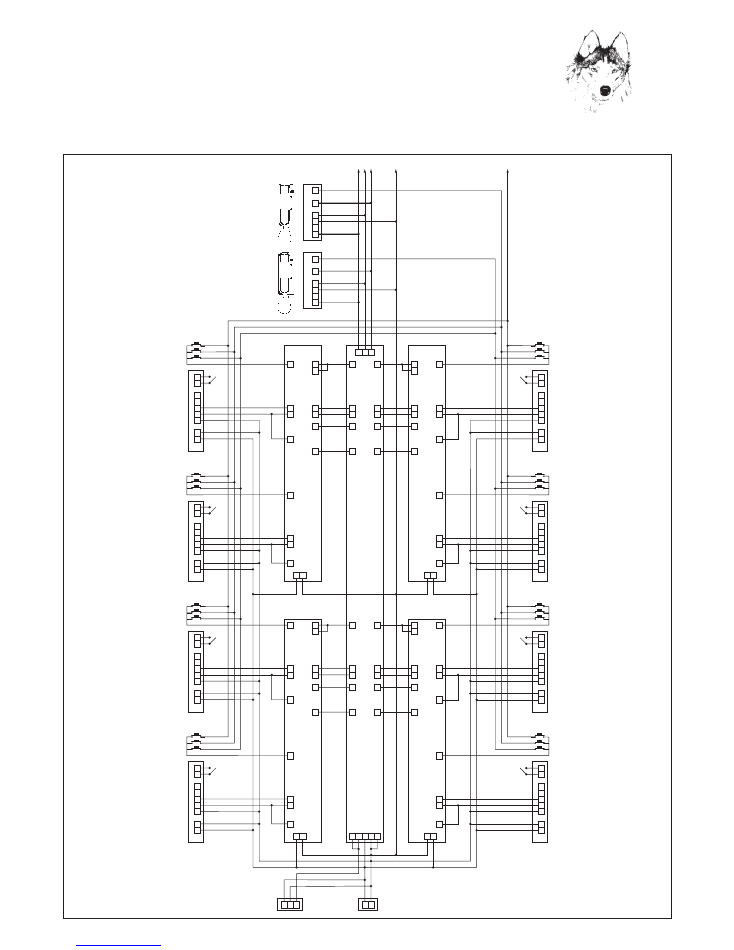

9

Noralsy Speaker MIHP/6

Audio Entry 7 or 8 Entrances

Automatic Switching

ELEC/INST/304Y

NORALSY

™

MASTERING ACCESS CONTROL

™

™