Full Text Searchable PDF User Manual

EUP11

Instantaneous gas water heater

User, Installation and Maintenance Manual

2

This appliance is certified to be placed in the following countries in relation to gas type and pressures:

-

Cat. I3+ (G30/G31 Butane/Propane @ 28-30/37 mbar): Belgium (BE), Spain (ES), France (FR), Great Britain (GB), Italy (IT), Ireland (IE).

-

Cat. I3P (G31 - Propane @ 37 mbar): Belgium (BE), Spain (ES), France (FR), Great Britain (GB), Italy (IT), Holland (NL), Ireland (IE).

-

Cat. I3B (G30 Butane @ 30 mbar): Belgium (BE), Spain (ES), France (FR), Great Britain (GB), Ireland (IE).

-

Cat. I3P (G31 Propane @ 50 mbar) Germany (DE), Austrian (AT)

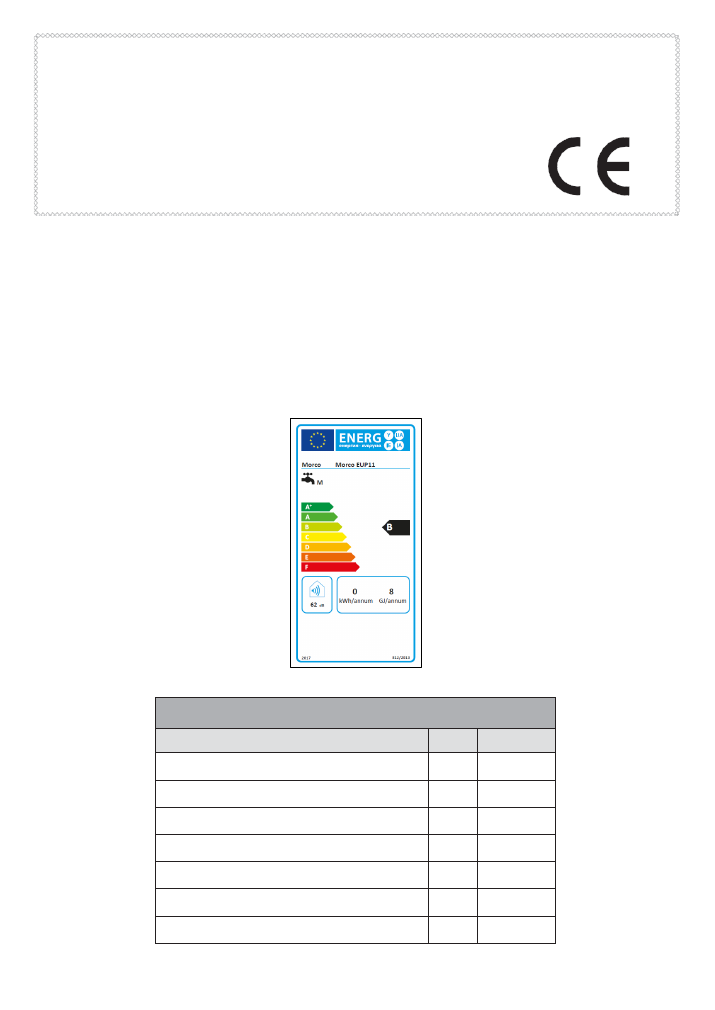

The appliance complies with the Regulation (EU) 2017/1369 setting a framework for energy labelling.

The energy label carries the information regarding the product’s energy efficiency characteristics.

In this way the end consumer can identify and compare similar products and can make informed choices regarding high efficiency

appliances.

PRODUCT DATASHEET

Morco

EUP11

Declared load profile

M

Indoor sound power level

dB(A)

62

Water heating energy efficiency class

B

Water heating energy efficiency class

%

58

Annual fuel consumption

GJ

8

Annual consumption of electric energy

kWh

0

Nitrogen oxide emissions (G30-G31)

mg/kWh

61-20

The device is well built in accordance with the current legislation.

The CE sign positioned on the product indicates that it conforms to the following European Directives:

• Regulation Gas Appliance (UE) 2016/426

• European Standard: gas-fired instantaneous water heaters for the production of domestic hot water

EN 26:2015

• Directive 2009/125/EC Ecodesign requirements for energy-related products

• Regulation (EU) 2017/1369 setting a framework for energy labelling

• Delegated regulation (EU) no. 812/2013

• Delegated regulation (EU) no. 814/2013

3

Gas Safety (Installation and Use) Regulations 1998

In the interest of safety, it is the law that all gas appliances are installed and serviced by a competent person in accordance

with the above regulations, building regulations, codes of practice and byelaws of the local water authority.

Failure to comply with the regulations may lead to prosecution. It is in your interests and that of your safety that the law is

complied with.

Related documents

The following British Standards, Codes of Practice and other Regulations must be observed in the installation of the water

heater.

The Gas Safety Regulations (Installation and Use) 1998

The Model Water Byelaws

Byelaws of the Local Water Undertaking

The Building Regulations (Permanent Buildings) England and Scotland.

BS 5482 Part 1 Installations in Permanent Dwellings

BS 5482 Part 2 Installations in Caravans and Non-Permanent Dwellings

BS 5482 Part 3 Installations in Boats

BS EN 1949 Installation of LPG System for Habitational Purposes in Leisure Accommodation Vehicles

BS EN 721 Leisure Accommodation Vehicles - Ventilation Requirements

BS EN ISO 10239 2008 Small Craft LPG Systems

CONTENTS

GENERAL SAFETY WARNINGS

page 4

DESCRIPTION OF THE APPLIANCE

page 4

1

OPERATION

page 5

1. a Function

page 5

1. b Usage

page 5

2

TECHNICAL CHARACTERISTICS

page 8

2. a Technical Data

page 8

3

INSTALLATION

page 9

3. a Regulations

page 9

3. b Wall mounting

page 9

3. c

Room ventilation

page 9

3. d Gas Connection

page 9

3. e Water connection

page 10

3. f

Flue gas

page 10

4

MAINTENANCE

page 11

4. a Removing the casing

page 11

4. b Troubleshooting: Problems and solutions page 11

FOR THE ENGINEER

Starting up the appliance and final checks

page 12

WINTERISATION

page 13

WARRANTY

page 14

WARNING

This booklet contains information relevant to the user as

well as the installer.

When the product has reached the end of its

serviceable life, it shall be disposed of in an

environmentally friendly way and disposed of

according to the regulations in force.

Separate collection and recycling of the product

avoid negative impact for environment and health,

and allows recovery of materials, in order to obtain

energy and resources saving.

4

GENERAL SAFETY WARNINGS

The User, Installation and Maintenance Manual is an integral part of the

product and so must be carefully preserved in order to accompany

the product; if it is lost or damaged another copy can be requested

from Morco Products Limited on 01482 325 456 or visit our website

www.morcoproducts. co.uk.

The installation of the device and any other repairs or

maintenance must be performed by a Gas Safe Engineer or

other qualified personnel according to the law in force, in

compliance with the installation regulations including any

revisions.

A Gas Safe Engineer or other qualified personnel must

commission this device.

The device must be used according to the manufacturer

specifications. The manufacturer cannot be held

contractually or otherwise responsible for damage caused to

persons, animals or objects as a result of incorrect

installation, repair or maintenance or improper usage.

The product’s safety or automatic regulation devices must

not be modified unless performed by the manufacturer.

This device is intended for heating water and therefore must

be connected to a water distribution network whose flow and

pressure are compatible with the product.

If water leaks are observed, turn off the water supply and

advise a Gas Safe Engineer or other qualified personnel.

If the appliance is not used for prolonged periods turn off the

gas supply. If there is a risk of the water freezing, empty the

water heater. Please see “frost and freezing” on page 5.

If the machine breaks down or does not function properly,

deactivate it, do not attempt to perform any repairs and

contact a Gas Safe Engineer or other qualified person.

The appliance should be maintained at least once a year.

When the product has reached the end of its serviceable life,

it shall be disposed of in an environmentally friendly way;

ensuring that the majority of the product is fully recycled.

When using the device the following safety rules must be applied:

Do not use the machine for purposes other than those

intended by the manufacturer.

Do not block the intake, flue or the ventilation openings in

the area where the device is installed with

rags, paper or any other materials.

If a gas leak is detected, do not switch on any electrical

devices, telephones or any other objects that could produce

a spark. Ventilate the area by opening the doors and

windows and switch off the gas supply.

Do not place objects on top of the device.

Do not leave flammable containers or substances in the

area where the device is installed.

Children or inexperienced persons should be prohibited from

using the device.

DESCRIPTION OF APPLIANCE

The Morco EUP11 is an open flued 11 litre instantaneous gas water heater. The air for combustion comes from the external

vents in the cupboard that the heater is placed in and hence very careful attention must be paid to providing sufficient

ventilation. See section 3.c. Room Ventilation. The appliance is suitable for use in dedicated boiler cupboards in caravan

holiday homes. We do not recommend this appliance for use outside of a dedicated cupboard or in boats, motorhomes or

rooms in which habitation takes place. The appliance relies on a pilot flame to ignite the main burner once a hot tap is

opened. The appliance does not store hot water. The flow of the water through the appliance can be adjusted from 5.5 to 11

litres per minute and this corresponds to the temperature of the incoming water being increased by 50°C or 25°C

respectively. This adjustment is made via the water temperature adjustment knob and during winter months it is advisable to

move the knob fully anticlockwise to ensure hot water of an acceptable temperature.

In parts of the manual the following symbols are used:

WARNING

= for actions that require caution and adequate preparation

PROHIBITED

= for actions that MUST NOT be performed

The water heater package contains:

2

Two knobs to attach to the control panel after

installation

1

Water filter to insert in the water valve pipe

fitting

5

1.

OPERATION

1.a. Function

The water heater is designed to produce instantaneous hot water. The hot water is delivered to several outlets around the home. If more

than one outlet is used at any one time the delivery of hot water will be reduced at each outlet. The Water heater has 2 main controls:

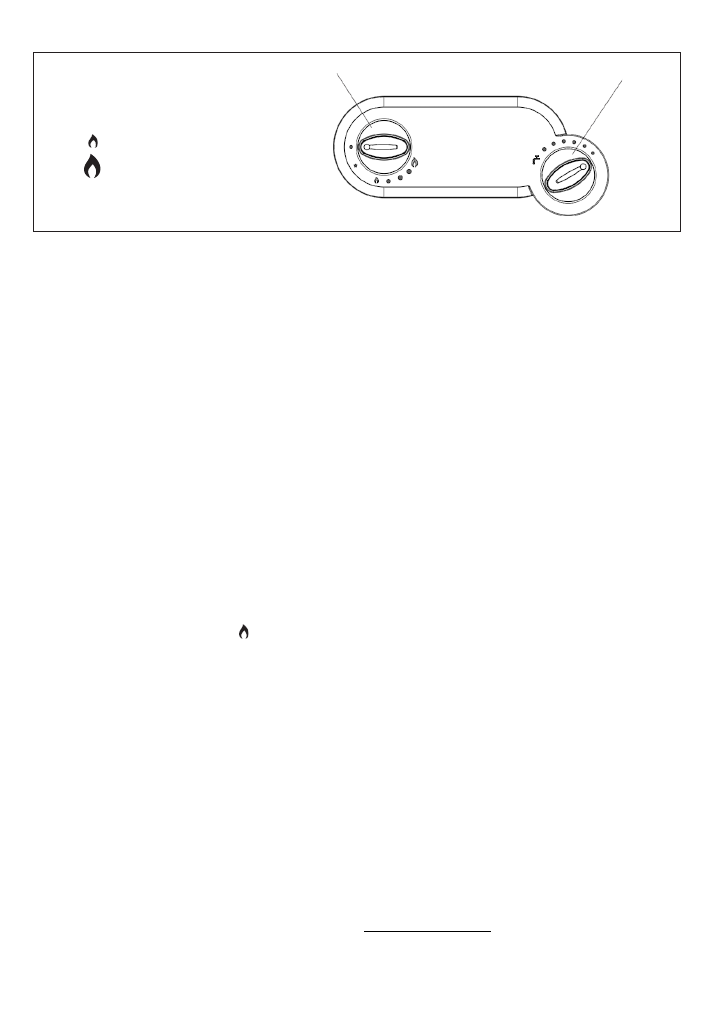

- A gas control knob - “A” in fig 1

- A water temperature control knob – “B” in fig 1

The minimum gas level in fig. 1 will provide approximately 50% of the available power. Turning the gas control knob counter- clockwise will

increase the power level between 50% and 100%. This function may be useful to vary the temperature of the water supplied.

The water temperature selector allows water to be supplied anywhere between 50% and 100% of the water heater’s capability. In effect the

selector reduces the water flow through the heater to the taps to increase the water temperature and correspondingly increases the water

flow to reduce the water temperature.

In the UK the normal positions for the controls are:

- Gas control – always set to 100% (fully counter clockwise)

- Water control set to 100% (fully clockwise) during the winter months

- Water control set to between 100% and 50% during the summer months to suit the customer’s preference for hot water temperature

1.b Usage

Ensure that the appliance gas isolation valve and all water taps are switched off

- Turn on the main external gas supply on the bottle or tank

- Light other gas appliances such as the cooker hob or fire and allow them to run for 30 seconds- this is to purge the gas system of air

- Open the appliance gas isolation valve, placed immediately below the water heater on the gas input pipe

- Rotate knob A to the on position (

), press the knob down all the way and keep it pressed

- Press the piezo electric button that is located under the water heater on the left-hand side until the spark ignites the pilot flame. The flame

can be seen through the viewing window on the front of the heater. When it ignites, keep the gas control knob (“A” in fig 1), pressed for

20-30 seconds. If the pilot does not stay lit when the knob is released, repeat the procedure

- Rotate Knob A towards the large flame ( ), during rotation it is necessary to keep the knob pressed down lightly until the final position

is reached

- From this moment the device is able to produce hot water on request. Opening the hot water tap causes the main burner to be ignited,

and inversely, by closing the hot water tap the main burner is switched off; but the pilot flame remains switched on for future requirements

- If the main burner or pilot flame is accidentally turned off, the gas valve automatically blocks the output of gas within 60 seconds so to

avoid any danger. To return the device to an operational mode, repeat the steps above

The machine is switched off by rotating knob

A

to the OFF position (●).

When the water heater is not used for long periods close the appliance gas isolation valve or the LPG gas valve on the bottle/tank.

For the best operational results it is recommended to have a Gas Safe Engineer or other qualified personnel service the machine at least

once a year.

PRECAUTIONS TO BE TAKEN AGAINST FROST AND FREEZING CONDITIONS

If there is a possibility that the area where the appliance is installed could reach below 0°C, the device must be emptied of all water.

During cold spells, if your appliance is located in a place exposed to frost and freezing conditions, it must be drained down in the following

way:

- Turn off the home’s water inlet stop tap.

- Disconnect the water supply pipe from the home

- Open any drain cocks located on the hot/cold water pipework under the home

- Turn on all hot and cold water taps

- Turn appliance water temperature selector fully anticlockwise

- Disconnect the cold water inlet to the water heater

-

Full details of winterisation can be found under “troubleshooting” at www.morcoproducts.co.uk

-

A summary can be found on page 13 of this manual

To use the appliance again reverse the above procedure

maximum gas level

B = Water temperature selector

fig. 1

B

A = Gas control on/off

● off position

activation position

minimum gas level

A

6

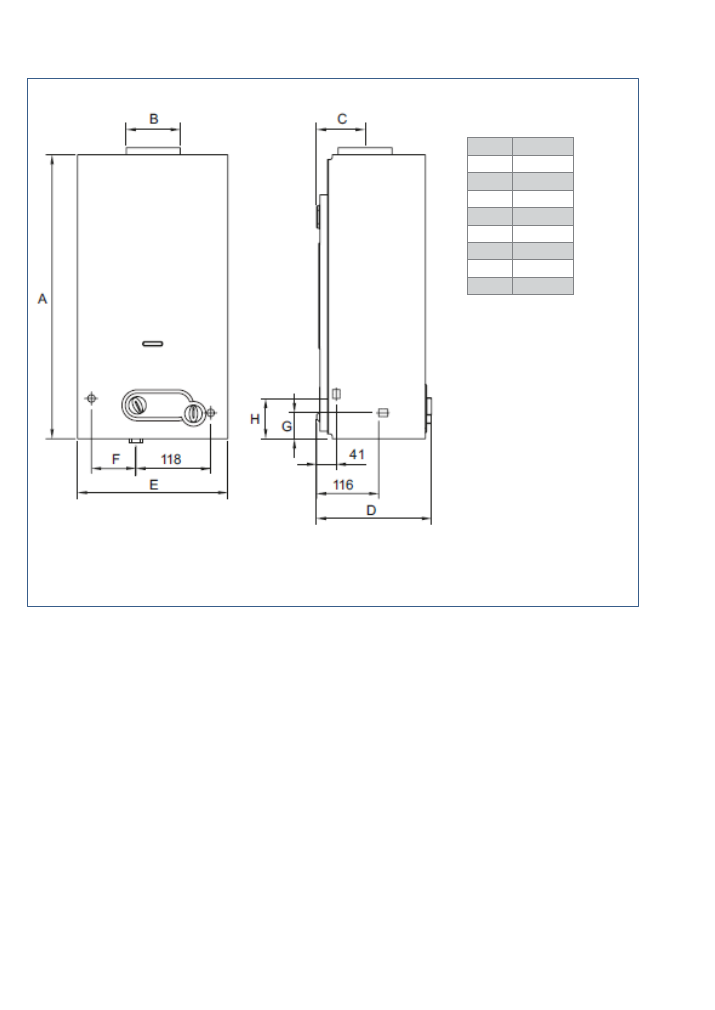

Fig. 2

11

A

592

B (Ø)

110

C

101

D

245

E

314

F

97

G

54

H

83

7

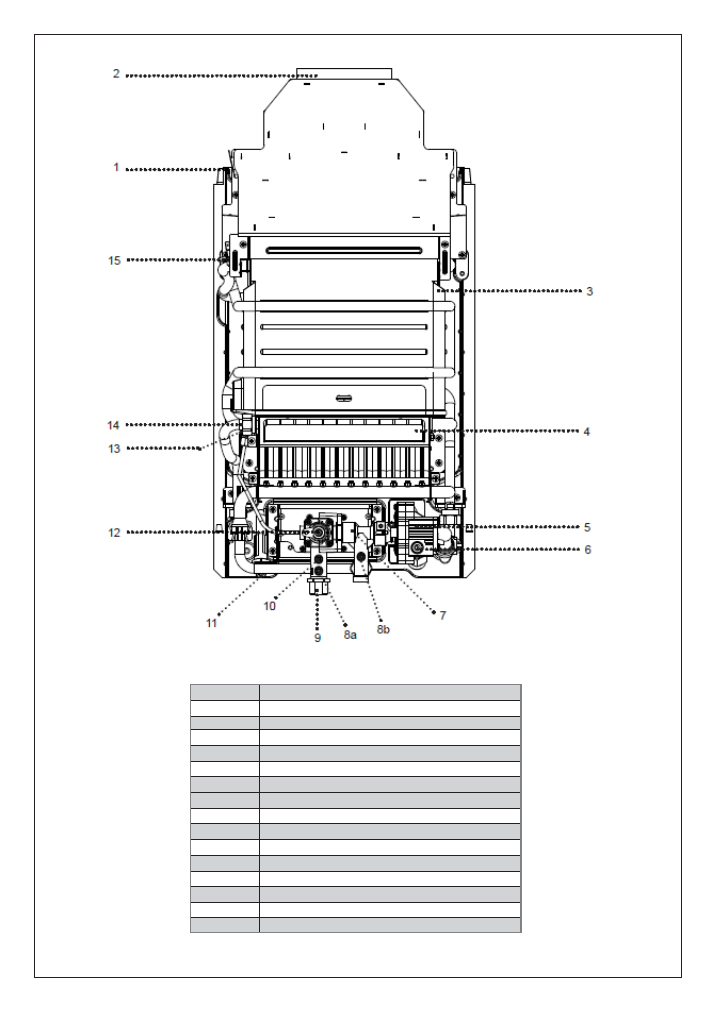

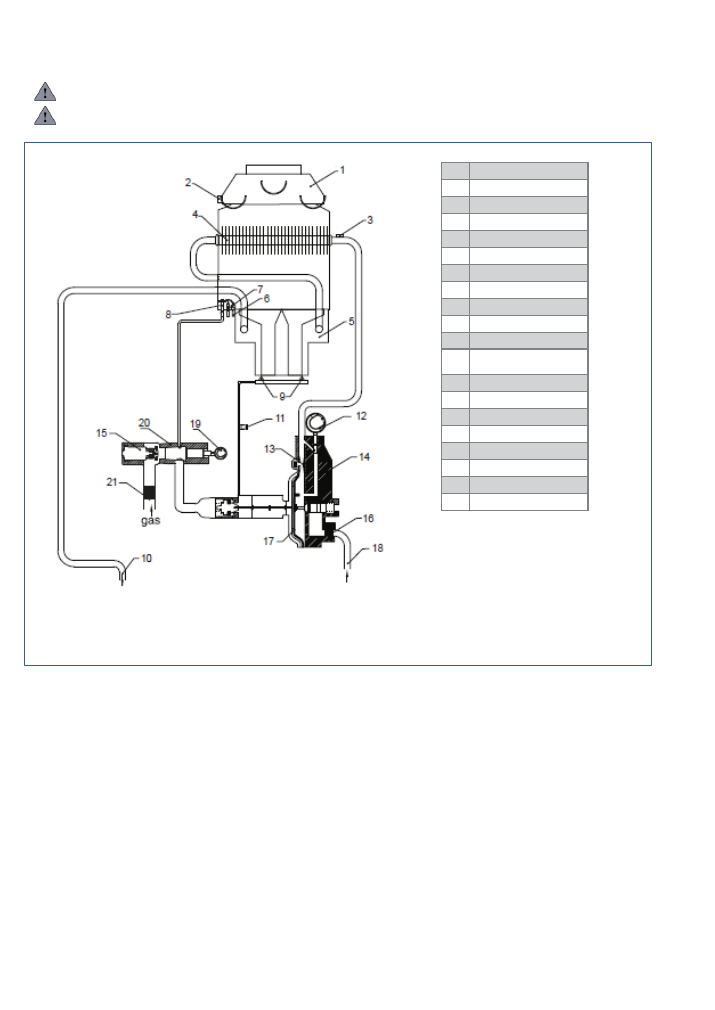

fig. 3

1

Combustion products safety sensor

2

Flue diverter hood

3

Heat exchanger

4

Burner

5

Water control assembly

6

Water temperature adjustment knob

7

Gas valve

8a

Gas Inlet point

8b

Burner pressure test point

9

Gas input

10

Gas adjustment screw - should not be adjusted

11

Piezoelectric pilot ignition button

12

Gas adjustment knob

13

Pilot burner

14

Ignition electrode

15

Hot water limit thermostat

8

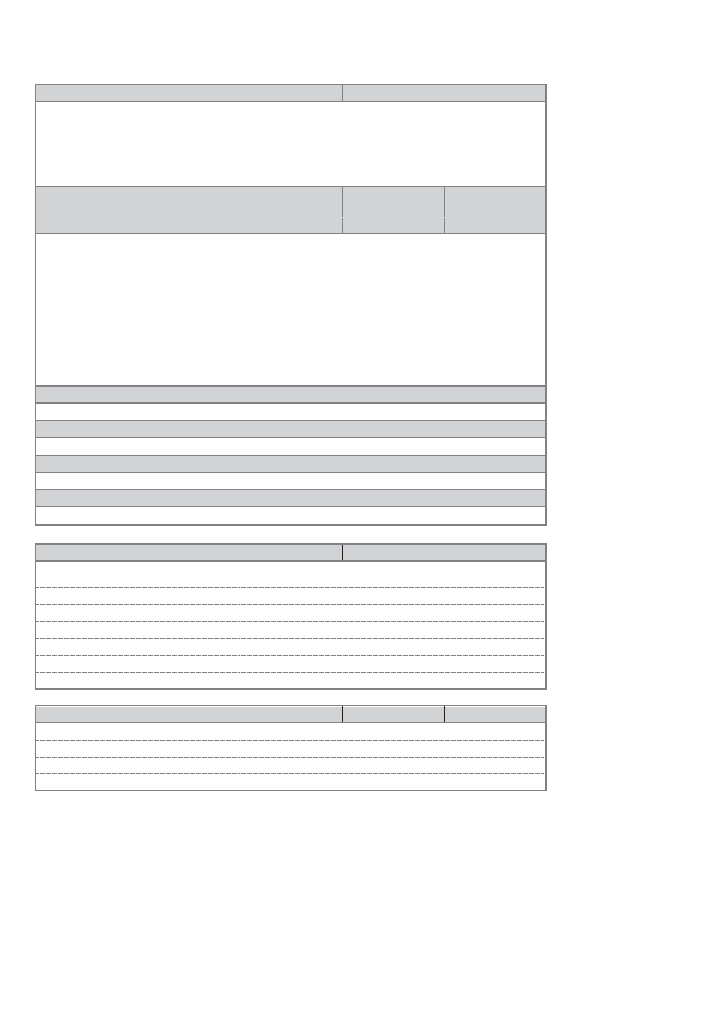

2.

TECHNICAL CHARACTERISTICS

2.a

Technical Data

11

kW - kcal/h

Nominal power usage (Pn)

19,4 - 16.665

Nominal Thermal range (Qn)

21,7 - 18.662

Minimal power usage (Pm)

9,6 – 8.260

Minimal Thermal range (Qm)

10,8 – 9.288

GAS TYPE

BUTANE

PROPANE

G30

G31

P.C.I. (15° C 1013 mbar)

MJ/m

3

116,09

88

WI (15° C 1013 mbar)

MJ/m

3

80,58

70,69

Consumption

kg/h

1,71

1,69

Burner Pressure

mbar

26,40

35,10

Nr/Ø main burner injector

Nr/mm

18x0,48+6x0,50

Ø pilot flame injector

mm

0,23

Ø gas connection

1/2”

Flue gas load (max-min)

g/s

11,80-9,75

12,48-10,29

Flue gas temperature (max-min)

°C

157-110

173-118

BE – FR – GB – IE – IT - ES

Category - Nominal feed pressure

I3+ - G30: 28/30 mbar G31: 37 mbar

BE – FR - GB – IE – IT – ES - NL

Category - Nominal feed pressure

I3P - G31: 37 mbar

DE- AT

Category - Nominal feed pressure

I3P - G31: 50 mbar

BE – FR - GB – IE – ES

Category - Nominal feed pressure

I3B - G30: 30 mbar

WATER

11

Input range

l/min

Minimum 5

l/min

Maximum

10.8 l/min

Water temperature lift

°C

approx. 50

approx. 25

Minimum pressure

bar

0,2

Nominal pressure

bar

2

Maximum pressure

bar

10

Ø Water connections

inch

1/2”

Ø flue spigot diameter

mm

110

DIMENSIONS AND WEIGHTS

DEVICE

PACKAGE

Height

mm

592

655

Length

mm

314

361

Depth

mm

245

280

Weight

Kg

10,60

11,80

Note: relative cold water temperature of 15 °C

9

3.

INSTALLATION

3.a

Regulations

The use of gas devices is controlled by precise regulations.

Installation of liquified petroleum gas (L.P.G) must comply with all

the manufacturer’s requirements and those of the regulations.

3.b

Wall mounting

Warning

Do not install this device in an area that contains dust, greasy

vapour and/or corrosive elements.

- The device must be installed on a suitable wall surface that

allows the fitting of a vertical exhaust gas flue

- It is vital to leave the minimal distances around the device as

shown in fig 4 to allow for maintenance operations to take place.

Location

The water heater requires a plentiful supply of fresh air for correct

operation. Fixed ventilators or air inlets should not be obstructed.

Do not install the water heater in a location where incomplete

combustion is foreseeable such as bathrooms or bedrooms unless

specifically allowed by national legislation.

The minimum low and high level free ventilation areas are stated

on this page and must be observed.

The water heater must be fixed to a load bearing wall in a vertical

plane.

3.c

Room ventilation

The installation of the water heater must comply with regulations in

force including any updates. See page 3

Warning: This device can only be installed in venues that are

permanently ventilated according to regulation in force.

• COMBUSTION GAS REMOVAL

A single wall vertical flue pipe of Ø110mm must be used and when

it passes through combustible materials, a metal sleeve of

Ø170mm must be used to allow an air gap of 25 mm. Part code

FTFCTG101.

Flue pipes and terminals should comply with BS 715. Terminals

shall not be sited within 300 mm. of a ventilator or open window. In

the U.K. full details of flueing requirements are given in BS EN 1949.

The overall length of the flue must be 600mm from the bottom of

the terminal louvres to the top of the water heater. At least 250mm

of this length must be external to the roof through which it is fitted.

• AIR SUPPLY FOR COMBUSTION

Air requirements: Reference is made to BS 5482 (BS EN 1949) and

EN 721 covering ventilation requirements for permanent dwellings,

caravans and boats.

Fixed ventilation should be provided to avoid draughts as far as

possible without impairing the free area of ventilation, even in ad-

verse weather conditions. If the heater is positioned in location

which may be subjected to strong draughts i.e. close to a window

or opening then strong draughts or gusts of wind may extinguish the

pilot.

All permanent openings for ventilation should be designed to pre-

vent the entry of vermin. Where screens are provided, they should

not have apertures of less than 6 mm. or greater than 9 mm. in any

direction, and they should be accessible for cleaning. Fine mesh screens

shall be avoided as they are liable to become blocked with dust.

The location of vents and the method of cleaning them should be

stated in the Owners Handbook (Caravans and Boats).

As a guide, the minimum effective free area of vents is stated below

in connection with this water heater. Additional appliances burning

gas in the same area would require additional ventilation.

If the appliance is installed in an enclosed cupboard in a Caravan

Holiday Home the required ventilation is that specified in BS 5482

part 2 and BS EN 1949, i.e. 10 cm² per kilowatt input rating divided

between high and low. Each of the high and low vents should

therefore be 109 cm² of free area.

3.d

Gas Connection

The water heater should be connected to the gas supply via a

15mm diameter copper gas pipe. A gas isolation valve must be fit-

ted to the gas inlet on the water heater.

When installing or commissioning the water heater the following

must be observed:

- The diameter of the gas pipe between the supply bottle or tank

must be in accordance with the regulations in force

- The regulator size and pressure specification are correct for the

application

- The correct gas (LPG) is being supplied

- All the required gas pressure and tightness tests are carried out

as part of the commissioning process.

- Gas joints downstream of the magnetic gas valve must be

checked

with leak detection fluid while the heater is running

- Gas jointing paste should not be used when connecting the gas

isolation valve

Do not obstruct the area’s ventilation openings where the device is

installed to avoid dangers such as the build-up of toxic and explosive

gases.

ATTENTION

: if the appliance is supplied with G31@50 mbar,

remove the protective cap (pos. 10 water heater components pag.

7) and regulate the pressure screw so that the burner reaches the

pressure indicate in the technical data.

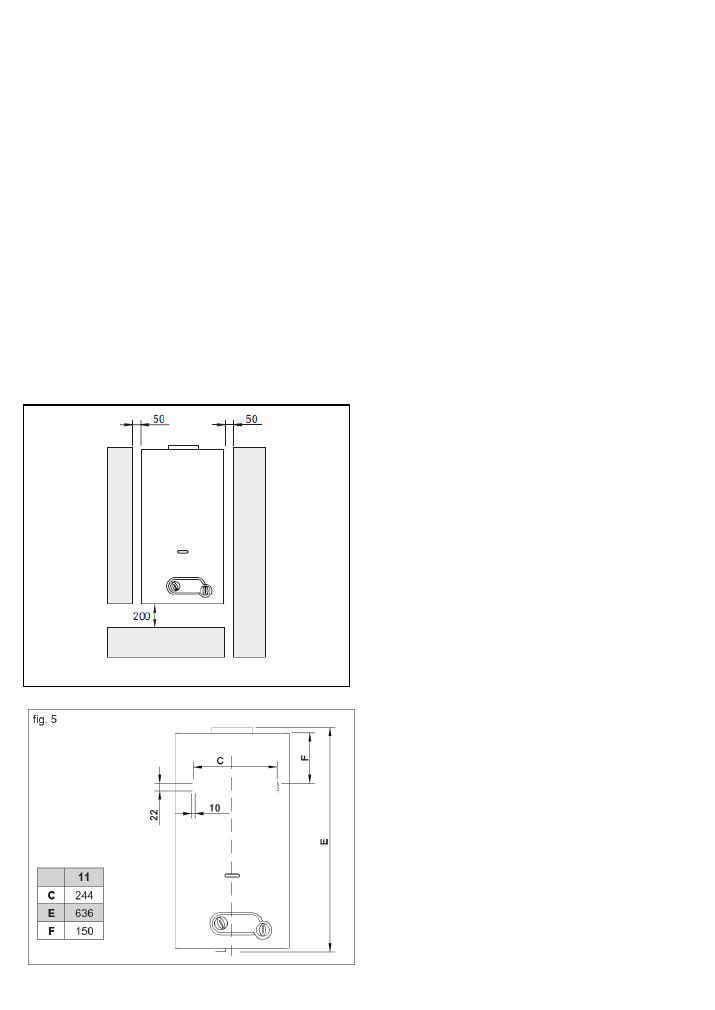

fig. 4

10

3.e

Water connection

Connect the water heater to the water supply.

From the front, the cold water input is on the right and the hot water output is on the left.

Insert the filter into the water valve input fitting.

Remove the plastic cap from the water outputs fitting before connecting it to the water supply.

3.f

Flue Gas

For output of flue gases refer to the regulations in force including

any updates. See page 3.

The water heater must be connected to a suitable flue terminal. The

following must be observed:

- The flue must be installed vertically – through the roof of the

holiday home

- The diameter of the flue terminal must match that of the water

heater (110mm)

- The overall flue length from the top of the water heater to the top

of the external flue must be at least 600mm. The distance from

the external roof surface to the top of the external flue must be at

least at least 250mm.

Flue gas safety device

This product is equipped with a flue gas safety device. The device

ensures the flue gases leave the water heater safely via the flue. The

flue safety device marked as 2 in Fig.6 is a flue gas safety device

that will interrupt the flow of gas to the water heater burner and pilot

light in the event that there is a total or partial blockage in the flue

that does not allow the

flue gases to leave safely. The device will also

operate if the design or length of the flue is not correct. This stat will

reset when it has cooled down due to the technical issue being resolved

thus allowing the water heater to operate as normal.

If the flue gas safety device is faulty it will need to be replaced

before the water heater will function again. The stat must not be

removed or altered in any way otherwise the operation of the water

heater may become dangerous.

1

Flue diverter hood

2

Flue gas safety device

3

Hot water limit thermostat

4

Heat exchanger

5

Burner

6

Ignition electrode

7

Thermocouple

8

Pilot burner

9

Main burner injectors

10

Hot water output

11

Burner pressure test point

12

Water temperature

selector knob

13

Venturi

14

Water control assembly

15

Magnetic valve

16

Water filter

17

Diaphragm

18

Cold water input

19

Gas adjustment knob

20

Gas valve

Fig. 6

11

4.

MAINTENANCE

To maintain the machine at maximum efficiency, have Gas Safe

Engineer or other qualified personnel perform a maintenance

check at least once a year.

Before cleaning or performing maintenance, opening or

disassembling the panels, switch off the device and turn off the gas

supply. Check the main burner and the pilot flame, the ignition

electrode, the safety valve and that there is no gas or water

leakage. Check that there is nothing obstructing the passages

within the heat exchanger or flue.

To clean the outside of the panels utilize a cloth with soap and

water. Do not use solvents, powders or abrasive sponges.

Do not clean the device and/or its parts with flammable materials

(e.g. petrol, alcohol, diesel etc.).

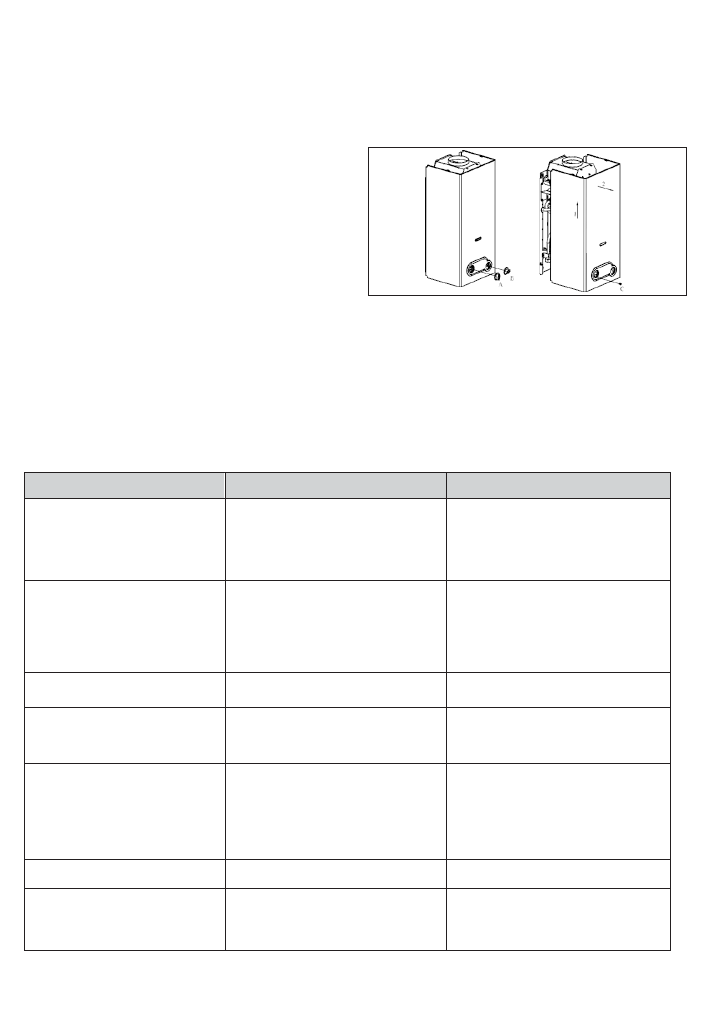

4.a

Removing the casing

To remove the outer casing follow the steps below:

- Remove the selector knobs (A and B)

- Remove the screws (C)

- Shift the casing upwards to free it from the upper and lateral hooks

- Shift the casing forwards

- To reinsert the casing, follow the above steps in reverse order.

4.b

Troubleshooting: problems and solutions

For the best functioning of the water heater, to prolong its lifetime

and ensure that it is always safe, it should be inspected at least once

a year by a gas safe engineer. The gas safe engineer is to perform

the following maintenance operations:

- Remove any rust from the burner

- Remove any deposit from the electrodes

- Clean the combustion chamber

- Check the ignition, switching off and general functionality of the

appliance

- Check that the gas and water pipes and connections are sealed

Warning: the following repair instructions are only to be performed

by Gas Safe Engineers or other qualified personnel.

PROBLEM

CAUSE

SOLUTIONS

There is no spark

- appliance spark wire is disconnected

- reconnect

- piezoelectric mechanism broken

- the electrode is damaged

- test, replace

- replace

The pilot does not switch on when

there is a spark

- pilot injector blocked

- clean by immersing in solvent or replace

- electrode activation position needs

changing

- adjust

- no gas supply

- open the appliance gas isolation valve

- air in the gas tubes

- purge air by turning on all gas rings on hob

for 30 seconds

The pilot does not stay on

- thermocouple faulty

- replace

- broken magnetic valve

- replace

Pilot on but the main burner does not

ignite

- insufficient water pressure

- Increase the external water supply

pressure

- rotate the knob B counter clockwise

- the diaphragm is broken

- replace

The burner does not switch off when

the water turns off

- contamination on the gas valve seat

- test, clean

- gas valve push rod is locked in the open

position

- Check the correct operation of the cold

water push rod , dis-assemble, clean or

replace

- check the gas pressure

- if the inlet gas pressure exceeds the

specification replace the pressure

regulator on the external bottle or tank

Delayed burner activation

- pilot burner flame is too far from main

burner flame or it is too short

- check inlet gas pressure, clean injector and

pilot

burner

The heat exchanger fins becomes

sooty in a small amount of time

- poor draught, adverse weather conditions

or dusty surroundings

- check the flue installation

- yellow flame

- check the gas type and clean the burner

- excess gas consumption

- check gas pressure and adjust

fig. 7

12

FOR THE ENGINEER

STARTING UP THE APPLIANCE AND FINAL CHECKS

Start the appliance by following the directions given in section 1b,

“Usage”, checking that the appliance is working correctly. Pay

special attention to the colour of the flames ensuring there is no

yellow- ness which would indicate burner venturis blocked by insect

matter.

Check the gas operating pressures with the heater under full power

at the inlet pressure nipple located on the right hand side of the gas

body valve stem. The pressure drop should not exceed 2.5 mb

below that specified in this manual.

Check the burner pressure with the heater at full load at the test

nipple located on the left hand side of the main gas valve body be-

low the main burner. These pressures must at least be equal those

specified in this manual in order to achieve the desired performance

specified in this manual.

These gas water heaters are set in the factory for use with the gas

they are intended to burn. The gas for which each appliance is set

is indicated on the packaging and on the data plate of the heater

itself

Check the flue for spillage: close all the doors and windows in the

room containing the water heater. If there are any fans or extractors

in the room then these must be turned on full. Light any other open

flued appliances such as fires of gas hobs. Turn the water heater

on by opening a hot tap on full burn and run for 5 minutes to allow

the flue to warm up.

Hold a smoke match to the side of the opening of the draught diver-

tor using an extended holder, making sure that the end of the match

is located centrally in the draught divertor.

The smoke should be pulled up the flue and not back into the room.

If spillage is detected, run the appliance for a further 10 minutes and

then repeat the test. If spillage is still detected then check the flue

for blockages, check that the correct flue terminal is fitted and that

the correct ventilation is fitted at a low and high level. Also check

the ventilation has not been blocked.

A.2.3. - LOOKING AFTER THE APPLIANCE

• PRECAUTIONS

– Against furring up (lime scale)

If the appliance is installed in an area with very hard water, with

time, the following may occur:

– A fall in the hot water temperature, or

– A reduction in the hot water flow.

This means that the heat exchanger may be furred up, creating the

above situations

Note: De-furring/descaling should be carried out using proprietary

agent or dilute hydrochloric acid. It is recommended to circulate the

descaling fluid around the heat exchanger in order to speed up the

process.

• MINIMUM ANNUAL MAINTENANCE

Gas water heaters are rugged pieces of equipment which are

designed to work for a long time with minimum maintenance

requirements. The only regular maintenance required is the

(annual) cleaning of the heating body and the burner. If the appliance

is installed in a caravan it is advised that this is done at the

beginning of each season.

•

CLEANING THE MAIN BURNER

To carry out the annual cleaning of the burner, proceed as follows:

– Turn off the gas supply, remove the cover and remove the burner.

– Clean the surface of the burner heads gently with a brush and

vacuum cleaner. Then blow through them to remove any particles

of dust loosened du- ring the brushing operation.

– Check the venturis i n t h e m a i n b u r n e r for contamination

from insects and spiders webs.

• CLEANING THE HEAT EXCHANGER

To carry out the annual cleaning of the heating body, proceed as

follows:

– Turn off the gas supply

– Turn off the supply of water to the appliance by turning off the

appliance water supply.

– Turn on all the hot water taps to empty all the pipes.

– Remove the heating body and clean it by gently brushing the fins.

Soot, if found, should be removed by washing, and the cause of

the sooting investigated.

• CLEANING THE PILOT

If the pilot light flame is yellow and the safety valve takes a long time

to open, this means that either the pilot injector or pilot burner is

partially blocked.

The pilot injector may be blocked with contaminants carried within

the gas, whilst the pilot burner is more likely to be contaminated by

insects (spiders / egg sacs)

N.B. No attempt should be made to clear blocked or partially

blocked pilot injectors by using wire. If blowing through the injector or

immersing in solvent fails to clear the restriction, then a new injector

should be fitted.

When the pilot is working normally the flame should be a stable blue

coloured cone shape. To clean the pilot burner, proceed as follows:

– Turn off the gas supply, remove the front cover. Remove the pilot

injector, by slackening the supply pipe nut first, and unscrewing

the pilot injector from the pilot burner

– Remove the contamination from within the pilot burner using

a pipe cleaner, and blow through to remove any further debris.

– Replace the pilot injector, ensuring that the washers are properly

fitted.

WINTERISATION

Winterisation of Holiday Homes That Have a Water Heater

Fresh water freezes at 0°C and expands by 9% with a significant force that will destroy:

•

Pipe work

•

Water heater components

•

Taps, and shower valves

DRAIN DOWN

If you leave fresh water in your caravan system over the winter you will run the risk of damage. This can only be avoided by

removing the fresh water from the system – we call this a “drain down”. You may wish to drain down the fresh water system

yourself using the procedure in the next section but we STRONGLY RECOMMEND that you have this carried out by an

experienced engineer as many caravan systems can only be completely drained by blowing the water out and this requires

specialist equipment. View the £50-£60 charge for a drain down as a mini insurance policy and always ask the engineer if he has

equipment to blow the water out. The two most common parts to be damaged by frost are the shower valve and the water control

assembly in a water heater and the costs to replace these are around £100 each.

Drain Down Procedure – without specialist equipment

•

Turn off the fresh water supply stop cock outside the Holiday Home

•

Disconnect the fresh water feed outside the home if possible as this protects from flooding due to stop cock failure

•

Open all hot and cold taps and shower valves and place the shower head in the tray

•

Use the Holiday Home Owner’s Handbook to locate all the fresh water drain cocks under the van – some of these may not be

obvious

•

Open these drain cocks

This procedure does not guarantee that all the fresh water will leave the system. Most modern homes have double check valves in

the TMV2 shower mixers and these trap fresh water and stop the flow of water around the system once the drain cocks and taps

are open. It may appear that all the water has left the system, but beware! This pitfall can be avoided by removing the shower

mixer valve/valves from the system after the cold water supply has been switched off and the drain cocks opened. Many

manufacturers provide access panels and these may make the removal of shower mixers easier. Removal of some shower mixers

requires the use of special tools.

In addition, pipe work layouts can cause air locks leaving water inside vulnerable components such as the water heater or shower

mixer.

Re-commissioning the home is a reverse of the above procedure.

This drain down procedure may work but the only way to be sure is to blow the water out using compressed air at 3 bar maximum

pressure.

WARRANTY

The water heater is guaranteed against manufacturing defects for one year from first commissioning date. However the guarantee

is subject to proof of commissioning in accordance with the gas safety (Installation and Use) act of 1998. The guarantee does not

cover defects caused by lack of maintenance.

Morco Products Ltd. warranty will cover parts and labour if the appliance has been fitted as part of the original equipment in a

caravan holiday home or leisure accommodation vehicle.

Appliances distributed as non original equipment either directly from Morco Products Ltd. or other merchants are subject to a return

to base policy for repair and return.

As an alternative to returning the appliance for repair we will supply spare parts and advice for defective appliances on the provision

that we can talk to the competent registered gas safe engineer involved in the fitting or repair of the defective appliance.

Under

this approach, no compensation will be offered for labour involved in the removal and refitting of the appliance or for any work /

travelling involved in the fitting of

spare parts.

Exclusions from warranty

- Damage caused by frost

- Scaling up of the heat exchanger

- Blocked pilot injectors

- Insect or debris in the burner or heat exchanger

- Blocked gas or water filters

- Incorrect operation caused by damaged mixer taps or shower TMV2

- Incorrect installation of the appliance or flue

- Low water pressure

Please note that proof of commissioning for the purposes of this warranty is a copy of the commissioning certificate

as filled out by the Gas Safe Engineer or other qualified personnel.

Supplied by Innovita Italy

Distributed in U.K. by:

MORCO PRODUCTS LTD

Morco House

Riverview Road

Beverley

East Yorkshire

HU17 0LD

ENGLAND

Telephone Number: 01482 325456

Fax Number: 01482 212869

Web Address: www.morcoproducts.co.uk