Full Text Searchable PDF User Manual

10005246 00

MORCO MODELS D-61B,

D-61E

AND

G11E

INDEX

A.- ENGLISH

A.1. INSTRUCTIONS FOR USERS ..........................................................................

4

A.2. TECHNICAL INSTRUCTIONS FOR INSTALLATION ENGINEERS .............

7

A.2.1. TECHNICAL INFORMATION.................................................................

7

A.2.2. INSTALLATION INSTRUCTIONS........................................................... 11

A.2.3. LOOKING AFTER THE APPLIANCE...................................................... 15

A.2.4. SYMBOLS ................................................................................................. 16

A.2.5. WARRANTY .............................................................................................. 16

B.- FRANÇAIS

B.1. INSTRUCTIONS POUR L’UTILISATEUR.......................................................... 18

B.2. INSTRUCTIONS TECHNIQUES POUR L’INSTALLATEURS .......................... 21

B.2.1. DONNÉS TECHNIQUES ......................................................................... 21

B.2.2. NORMES D’INSTALLATION ................................................................... 25

B.2.3. INSTRUCTIONS POUR LA MISE EN MARCHE .................................... 30

B.2.4. MAINTENANCE....................................................................................... 32

B.2.5. SYMBOLES ............................................................................................... 33

B.2.6. GARANTIE................................................................................................ 34

C.- NEDERLANS

C.1. GEBRUIKSAANWIJZING.................................................................................. 36

C.2. TECHNISCHE INSTRUCTIES VOOR INSTALLATIE MONTEURS ............... 39

C.2.1. TECHNISCHE INFORMATIE.................................................................. 39

C.2.2. INSTRUCTIES VOOR DE INSTALLATIE................................................ 43

C.2.3. INSTRUCTIES VOOR HET BEDRIJFSKLAAR MAKEN VAN DE GEISER 48

C.2.4. ONDERHOUD.......................................................................................... 49

C.2.5. SYMBOLEN.............................................................................................. 51

MORCO MODELS D-61B, D-61E AND G11E

3

4

5

6

7

A.2.- TECHNICAL INSTRUCTIONS FOR INSTALLATION ENGINEERS

A.2.1. Technical information

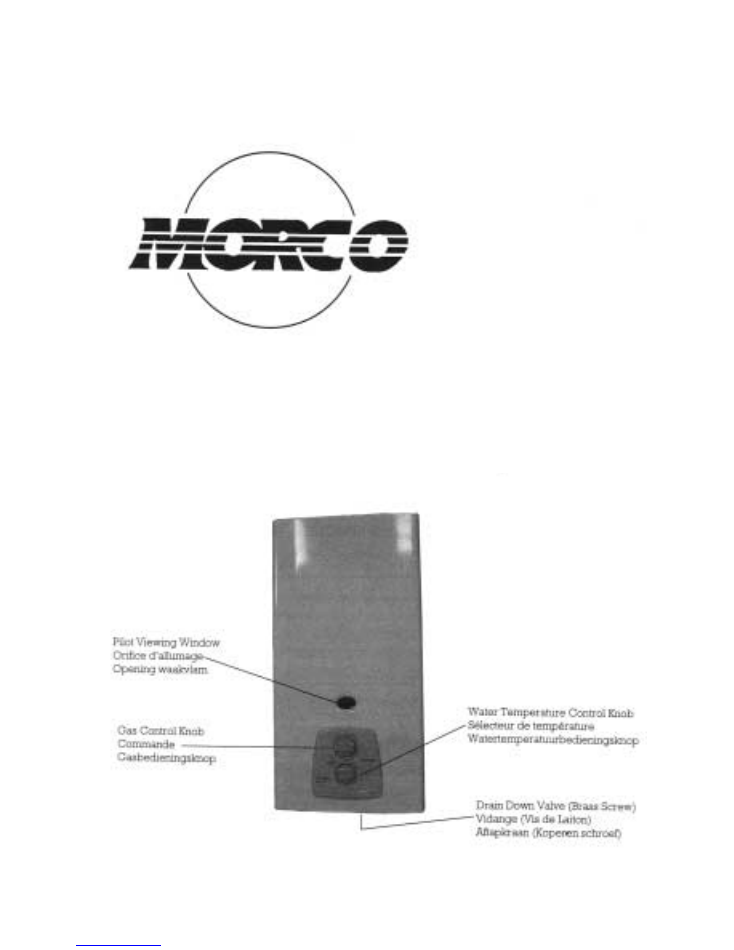

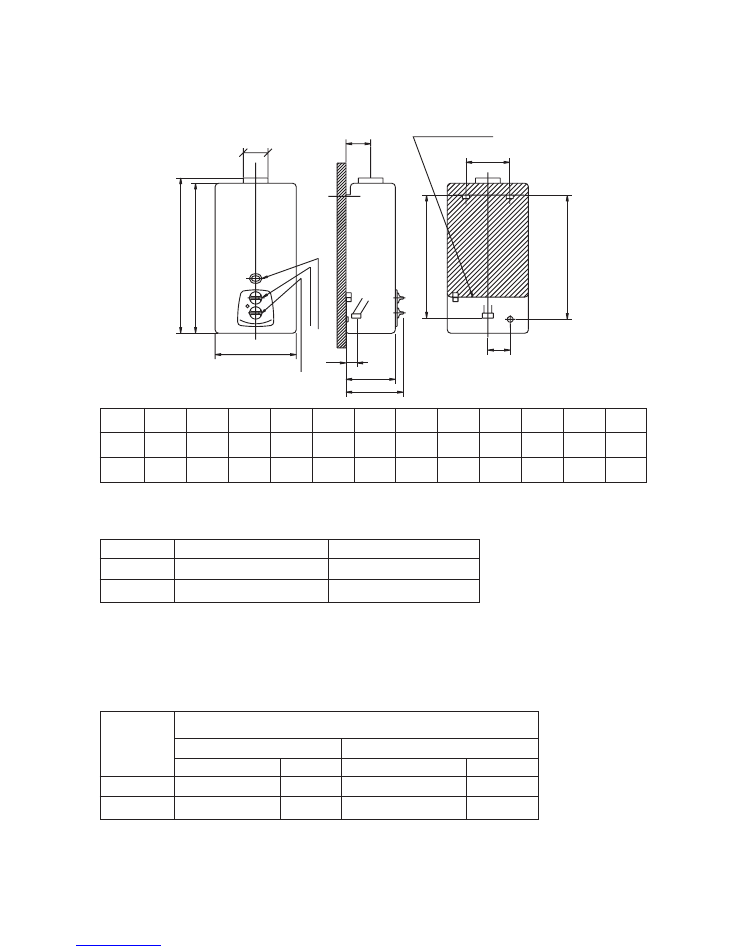

• Shape and outer dimensions

• SPECIFICATIONS

• Available calorific power

• Output in terms of a p.c.i. over 85%

• HOT WATER DELIVERY

The figures quoted are for the appliance at normal operating pressure at minimum

and maximum selector settings.

NOTE: Temperatures are in degrees rise above ambient.

• OPERATING PRESSURE

• Minimum

1bar

• Maximum

10 bar

• Water inlet pressure with the appliance working at normal pressure.

Lower of base

CW

GAS

WW

CW

GAS

WW

A

D

C

H

J

øE

F

B

M

Contr

ol knob

T

emperatur

e selector

Ignition window

G

I.

L

* WW, go connecting with one flexible pipe.

MODELS

D61B - D61E

G11E

Maximum

9,4 kW (135 kcal/min.)

19,2 kW (275 kcal/min.)

Minimum

5,6 kW (81 kcal/min.)

10 kW (145 kcal/min.)

B

A

C

D

E

F

G

H

I

J

L

M

634

310

230

276

110

660

115

235

464

50

456

45

G11E

573

266

190

236

90

589

97

120

350

50

344

45

D61B/D61E

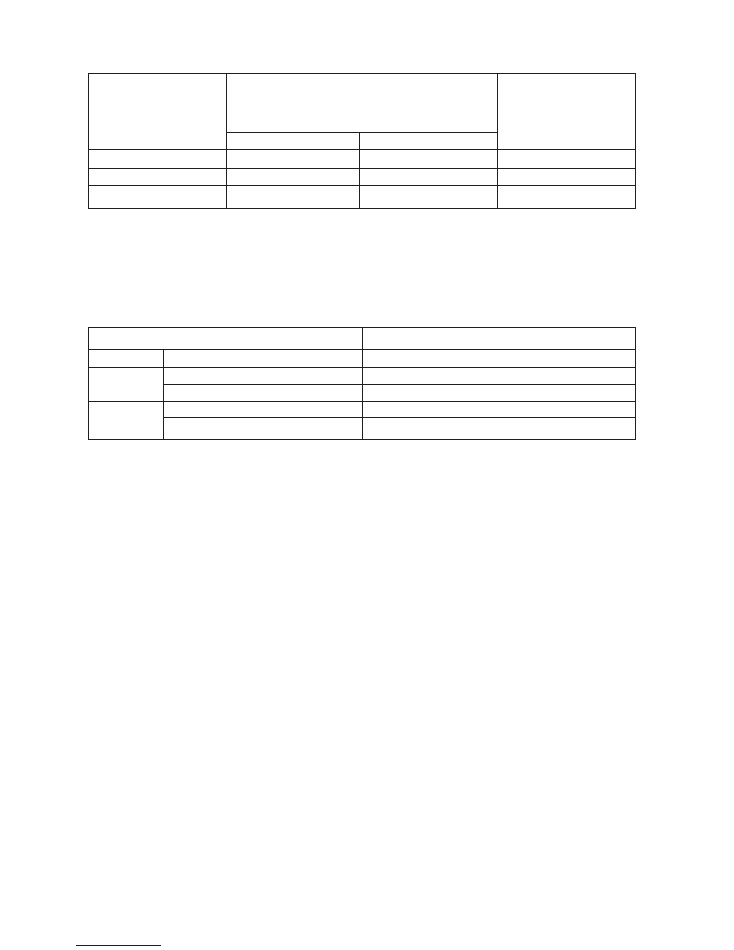

SELECTOR SETTING

MODELS

OPEN

CLOSED

Water flow

T

Water flow

T

D61B-D61E

5,4 litres/min.

25ºC

2,7 litres/min.

50ºC

G11E

11 litres/min.

25ºC

5,5, litres/min.

50ºC

8

• GAS CONSUMPTION

• BURNER PRESSURE

Butane gas: 27,5 mbar

Propane gas: 36,3 mbar

Natural gas: 16,4 mbar

• PIPE WORK DIAMETERS AND CONNECTION SIZES

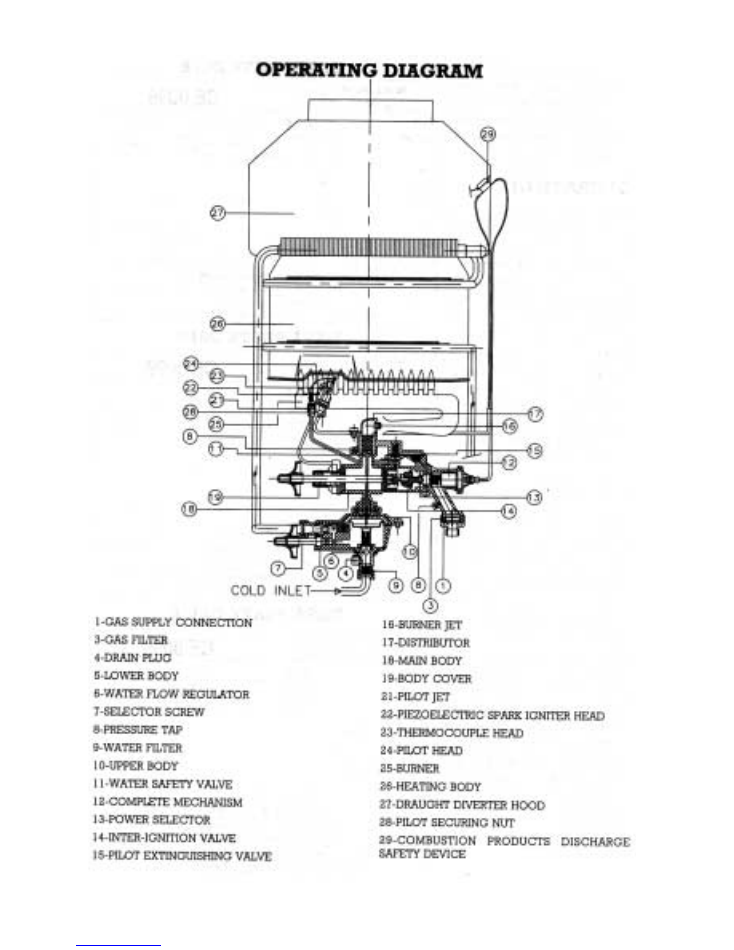

• DESCRIPTION AND OPERATION

These gas water heaters are equipped with:

• A stainless steel burner which can operate with Butane/Propane-Natural.

• A pilot which can be adapted to operate with Butane/Propane-Natural. It can be

taken apart easily for cleaning. Ignition is by piezoelectric spark ignition.

• A fully automatic progressive ignition system which needs no adjusting. This pre-

vents any black smoke being given off during the ignition process.

• A thermocouple safety valve which shuts off the gas supply to both pilot and main

burner in the event of accidental flame failure.

• An inter-ignition valve which cuts off the supply of gas to the burner during the

pilot ignition process, even if there is water circulating through the appliance.

• A total shut-off valve which shuts off the supply of gas to the burner and the pilot,

even during the response time before the safety valve closes.

• A water shortage safety valve which adapts the supply of gas to the burner to the

circulation of water through the appliance.

• A gas economy feature which enables the supply of gas to the burner to be

reduced by up to 60%, to adapt the operation of the appliance when the ambient

temperature of the water supply is high.

• An automatic water flow regulator.

• A temperature selector.

• A heat exchanger made from pure electrolytic copper.

• A draught diverter hood.

GAS PRESSURE AT

TIPE OF GAS

GAS FLOWAT 15ºC and 760 mm Hg

APPLIANCE INLET

(Standarised gases)

(mbar)

G11E

D61B-D61E

Butane

1,8 kg/h.

0,88 kg/h.

28-30

Propane

1,8 kg/h.

0,88 kg/h.

37

Natural

2,3 m

3

/h.

—

20-25

PIPE WORK

CONNECTION SIZES

GAS

Butane/Propane-Natural

3/8 or 15 mm.

WATER

Inlet (cold)

15 mm.

Outlet (hot)

15 mm.

Flueway

D61B and D61E

ø 90 mm.

G11E

ø 110 mm.

• A set of water inlet and outlet and gas inlet accessories, which make it easier to

connect the heater to the main water and gas supplies.

OPERATION

Once the appliance has been turned on following the indications given in section

A.2.3. “Instructions for starting up the appliance” gas is supplied to the burner

whenever a hot water tap is turned on.

What actually happens is that when a hot water tap is turned on, water starts to cir-

culate through the appliance and a valve, controlled by a diaphragm device which

operates by differential pressure, opens supplying gas to the burner.

When the hot water tap is turned off, the water pressure in the appliance is interrup-

ted, as is the differential pressure in the control device, automatically shutting off the

gas supply to the burner.

Whilst the appliance is in operation, even if there are pressure fluctuations in the

mains supply, the temperature of the water is maintained at all times at the tempe-

rature preset with the “temperature selector” thanks to the action of the “automatic

water flow regulator”.

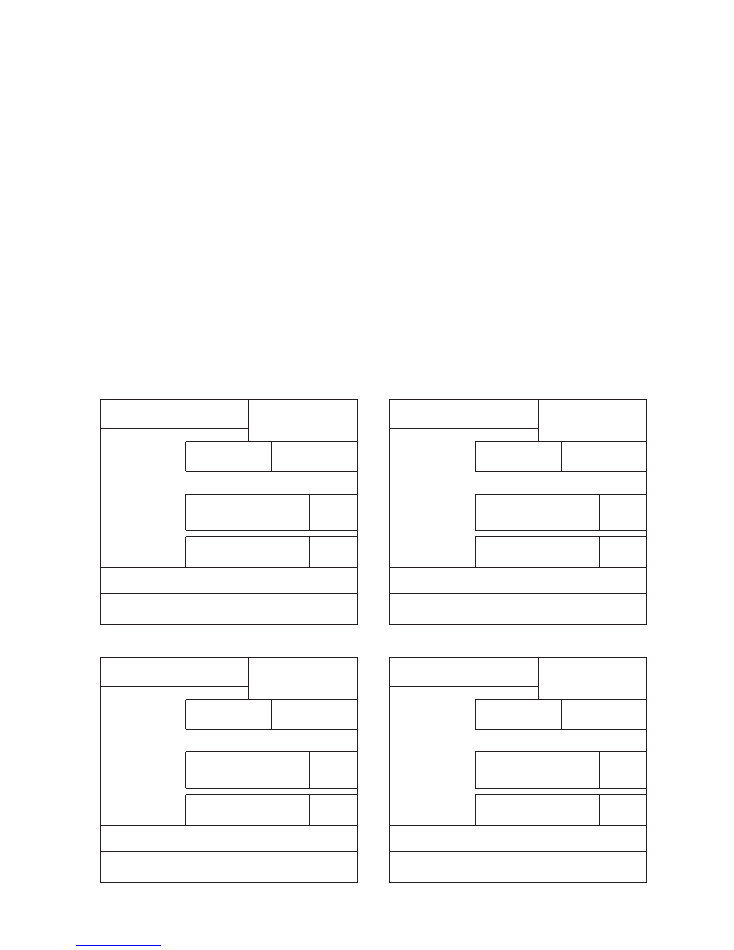

DATA PLATE D61B

DATA PLATE D61E

DATA PLATE G11E BUTANE/PROPANE

DATA PLATE G11E NATURAL

9

MORCO INSTANTANEOUS

GAS WATER HEATER

CE 0099

Mod. Nº:

G11E PROP

99BP819

Gas Type: G-30/G31 28-30mbar

Cat.

I

3+

30mbar Cat.

I

3B/P

G-30

37mbar

Type:

B

11BS

Qn (hi)

22,6 kW

Qm (hi)

11,8 kW R. Fab. 20/26210

Pn

19,2 kW SERIAL Nº

Pw

10 bar

Cat.

I

3+

I

3B/P

Country/Pays:

BE / ES / FR / GB / IE / IT / PT

NL

USE ONLY IN WELL VENTILATED ROOMS

NOT TO BE INSTALLED IN BATHROOMS

Manufactured in Spain exclusively for:

MORCO PRODUCTS LIMITED 59 Beberley Road HULL ENGLAND

MORCO INSTANTANEOUS

GAS WATER HEATER

CE 0099

Mod. Nº:

D61B

99AT507

Gas Type: G-30

28mbar

Cat.

I

3+

30mbar Cat.

I

3B/P

G-31

37mbar

Type:

B

11BS

Qn (hi)

11,1 kW

Qm (hi)

6,6 kW

R. Fab. 20/26210

Pn

9,4 kW

SERIAL Nº

Pw

10 bar

Cat.

I

3+

I

3B/P

Country/Pays:

GB / FR / IE / IT / ES / BE

NL

USE ONLY IN WELL VENTILATED ROOMS

NOT TO BE INSTALLED IN BATHROOMS

Manufactured in Spain exclusively for:

MORCO PRODUCTS LIMITED 59 Beberley Road HULL ENGLAND

MORCO INSTANTANEOUS

GAS WATER HEATER

CE 0099

Mod. Nº:

G11E NAT

99BP819

Gas Type: G-20

20mbar

Cat.

I

2H

20mbar

Cat.

I

2E+

G-20/G25

25mbar

Type:

B

11BS

Qn (hi)

22,6 kW

Qm (hi)

11,8 kW R. Fab. 20/26210

Pn

19,2 kW SERIAL Nº

Pw

10 bar

Cat.

I

2H

I

2E+

Country/Pays:

ES / GB / IE / IT / PT

BE / FR

USE ONLY IN WELL VENTILATED ROOMS

NOT TO BE INSTALLED IN BATHROOMS

Manufactured in Spain exclusively for:

MORCO PRODUCTS LIMITED 59 Beberley Road HULL ENGLAND

MORCO INSTANTANEOUS

GAS WATER HEATER

CE 0099

Mod. Nº:

D61E

99AT507

Gas Type: G-30

28mbar

Cat.

I

3+

30mbar Cat.

I

3B/P

G-31

37mbar

Type:

B

11BS

Qn (hi)

11,1 kW

Qm (hi)

6,6 kW

R. Fab. 20/26210

Pn

9,4 kW

SERIAL Nº

Pw

10 bar

Cat.

I

3+

I

3B/P

Country/Pays:

GB / FR / IE / IT / ES / BE

NL

USE ONLY IN WELL VENTILATED ROOMS

NOT TO BE INSTALLED IN BATHROOMS

Manufactured in Spain exclusively for:

MORCO PRODUCTS LIMITED 59 Beberley Road HULL ENGLAND

10

11

• COMBUSTION GAS REMOVAL

Flue:

A draught diverter is fitted to the top of the water heater. The nominal flue

size is 90 mm. (D61B, D61E) and 110 mm. (G11E). In exposed situations, twin-

walled flue pipe should be used. A minimum length of vertically rising flue of 600

mm. must be provided to ensure the water heater’s produts of combustion are

completely evacuated. If single wall flue pipe is being used which has to pass

through combustible materials, provide a metal sleeve of 115 mm. diameter which

allows an air gap of 25 mm.

The flue shall not run into chimmeys for removing combustion products from solid

or liquid fuels. Flue pipes and terminals should comply with BS 715. Terminals

shall not be sited within 300 mm. of a ventilator o open window. In the U. K full

details of flueing requirements are given in BS 5440 Part 1.

The flow rate of the combustion gases is 14 m

3

/h (G-30 and G-31), and the

temperature of the combustion gases at the exit draught diverter hood is

137ºC (Model D61E, D61B).

The flow rate of the combustion gases is 41,4 m

3

/h (G-30 and G-31), and 44,4

m

3

/h (G-20 and G-25). The temperature of the combustion gases at the exit

draught diverter hood is 160ºC (Model G11E).

This appliance is fitted with a device to monitor the removal of combustion

gases, which cuts off the supply of gas to the burner, thereby turning of the

appliance.

The function of this device is to prevent the combustion gases from getting into

the premises where the appliance is installed when there are problems with their

removal due to adverse weather conditions or incorret draught in the flueway.

It is a safety device to ensure that the combustion gases are removed properly.

This device should never be taken out of service, as this would mean a lack of

safety in the correct operation of the appliance.

Whenever any repairs are made to this device, only original parts should be fitted.

A check should always be made to ensure that the appliance works correctly. The

procedure is as follows:

a) Turn the appliance on.

b) If air does not blow back through the flueway due to bad weather conditions

(too much wind), the control device should not stop the appliance, at least

during 30 minutes of continouus operation.

If this test is carried out satisfactorily, the appliance is in perfect operating

condition.

If the appliance repeatedly turns off, this means that the combustion gases are not

being removed correctly. The problem should be resolved by taking the

appropriate steps.

• AIR SUPPLY FOR COMBUSTION

Air Requirements: Reference is made to BS 5482 (BS EN 1949) and EN 721

covering ventilation requirements for permanent dwellings, caravans and boats.

12

13

Fixed ventilation should be provided to avoid draughts as far as possible

without impairing the free area of ventilation, even in adverse weather conditions.

All permanent openings for ventilation should be designed to prevent the entry

of vermin. Where screens are provided, they should not have apertures of less

than 6 mm. or greater than 9 mm. in any direction, and they should be accessible

for cleaning. Fine mesh screens should be avoided as they are liable to become

blocked with dust.

The location of vents and the method of cleaning them should be stated in the

Owners Handbook (Caravans and Boats).

As a guide, the minimum effective free area of vents is stated below in connection

with this water heater. Additional appliances burning gas in the same area would

require additional air requirements.

1. If a D61B, D61E or G11E is installed in an enclosed space in a Caravan

Holiday Home the required ventilation is that as specified in BS 5482 part 2,

ie 10 cm

2

per kilowatt input rating divided between high and low. So the high

and low vents should be 55,5 cm

2

for D61B, D61E and 114 cm

2

for G11E.

2. Where a D61B or D61E is installed in an open bottomed cupboard in a

Caravan Holiday Home, i.e. in a kitchen, the ventilation requirements is as

stated in BS 5482 part 2. (EN 721).

A.2.2.B PUTTING AN APPLIANCE INTO SERVICE

Checks:

Check that the main water and gas supplies meet the specifications given on

the appliance’s technical specification plate. Take special care to ensure that the

water and gas pressures are correct. Also make sure that the bottle regulator is

large enough to allow sufficient gas to be supplied to the appliance, bearing in

mind the gas consumption of other appliances on the same meter.

• FIXING THE APPLIANCE

To do this you only need to remove the cover. Proceed as follows:

•

Remove the control knobs.

•

Remove the screw securing the front of the cover, hidden by the temperature

selector control button.

•

Remove the screw (2) which secures the cover to the base, at the bottom.

•

Remove the cover from the lugs which secures it to the top of the base.

Having selected a location for the water heater in accordance with the

requirements set out in this Manual, the water heater should be fixed to the wall

using the mounting holes on either side of the base plate.

• PUTTING THE APPLIANCE INTO SERVICE

•

Before connecting up the appliance, it is necessary to purge the water and gas

pipe work thoroughly, in order to remove filings and other waste material.

14

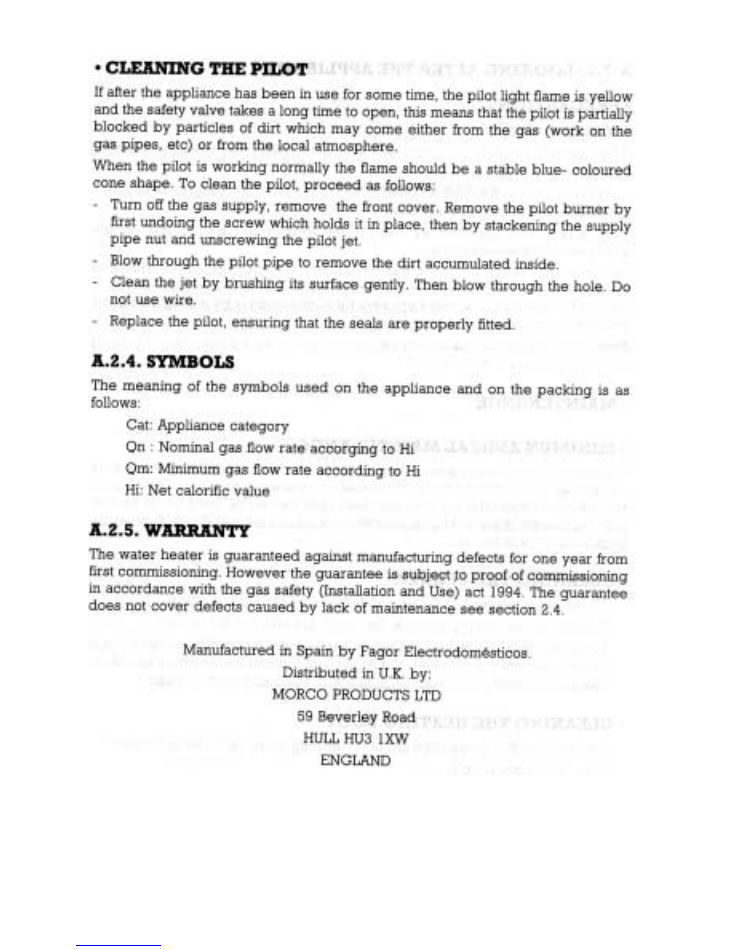

ø in mm.

MODELS

GAS

BURNER

PILOT

D61B-D61E

G.L.P.

0,72 (6)

0,19

G11E

G.L.P.

0,72 (12)

0,19

G11E

Natural

1,18 (12)

0,32

15

16