Full Text Searchable PDF User Manual

TALISMAN

DYNAMIC LOOP AMPLIFIER SYSTEMS

_______________________________

INSTALLATION GUIDE

Publication Code TAL-DLS-3_TIG Issue 3

TAL/DLS1/3

TAL/DLS5/3

Part No. 7157106

Part No. 7157206

PLEASE NOTE: THIS MANUAL AND THE NOTES CONTAINED HEREIN, IS COPYRIGHT AND MAY NOT BE

REPRODUCED EITHER WHOLLY OR IN PART, IN ANY WAY WHATSOEVER, WITHOUT WRITTEN CONSENT

OF FEDERAL SIGNAL LIMITED.

PUBLICATION OF THIS INFORMATION DOES NOT IMPLY ANY AUTHORITY OR LICENCE FOR THE

UTILISATION IN ANY MANNER, IN ANY COUNTRY, OR ANY PATENTED OR REGISTERED DESIGN

FEATURES, MECHANICAL, ELECTRICAL OR AESTHETIC.

MILLBANK ELECTRONICS

is part of:

F

EDERAL

S

IGNAL

L

TD

Signal House, Charter Way, Hurdsfield Industrial Estate, Macclesfield, Cheshire, SK10 2NF, England

TEL: +44 (0) 1625 66 66 00 FAX: +44 (0) 1625 611 352 e-mail: millbank@fedsig.co.uk

In the interest of product improvement we reserve the right to change specification or design without notice.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 2

Designed by Millbank Electronics

Manufactured in the UK by Federal Signal Limited

Federal Signal Limited operate a Quality Management

System which meets the requirements of

BS EN ISO 9001 : 1994

Federal Signal Limited is registered by the Lloyds Register

Lloyds Register certificate of Registration No. 923077

Product Compliance to EC directives for Standard Products

All standard products conform to the relevant directives,

regulations and standards for electronic and associated apparatus.

The equipment is CE marked both on the apparatus and the packaging.

The Modular range of products for use in Mainframes must be used

in the configuration as described in the product literature.

Failure to use the modular products in the manner described

will invalidate the EC Compliance.

Our products meet the appropriate British and International standards. A product “Declaration of Conformity” Statement is

available for each of the product ranges (available on request). This covers both the EMC and Low Voltage Directives.

UNPACKING

While all Millbank equipment is carefully packed to prevent damage in transit, we recommend that

the equipment is unpacked and inspected immediately on receipt. If damage has

occurred please advise your carrier and your supplier who will arrange appropriate action.

If it is necessary to re-pack the equipment for onward shipping or returning to Millbank for service

PLEASE ENSURE THAT THE ORIGINAL PACKING OR EQUIVALENT IS USED.

For further technical information please contact

our Customer Services Department.

on + 44(0) 1625 666600

or E-mail: CustomerServices@fedsig.co.uk

KEEP THIS INFORMATION IN A SAFE PLACE

Equipment Serial No

........................................................................................................................

Supplied by

........................................................................................................................

........................................................................................................................

Date

........................................................................................................................

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 3

1.

INSTALLATION

1.1

Precautions

IMPORTANT: Before operating the PAC Amplifier please take note of the following points:

1.1.1

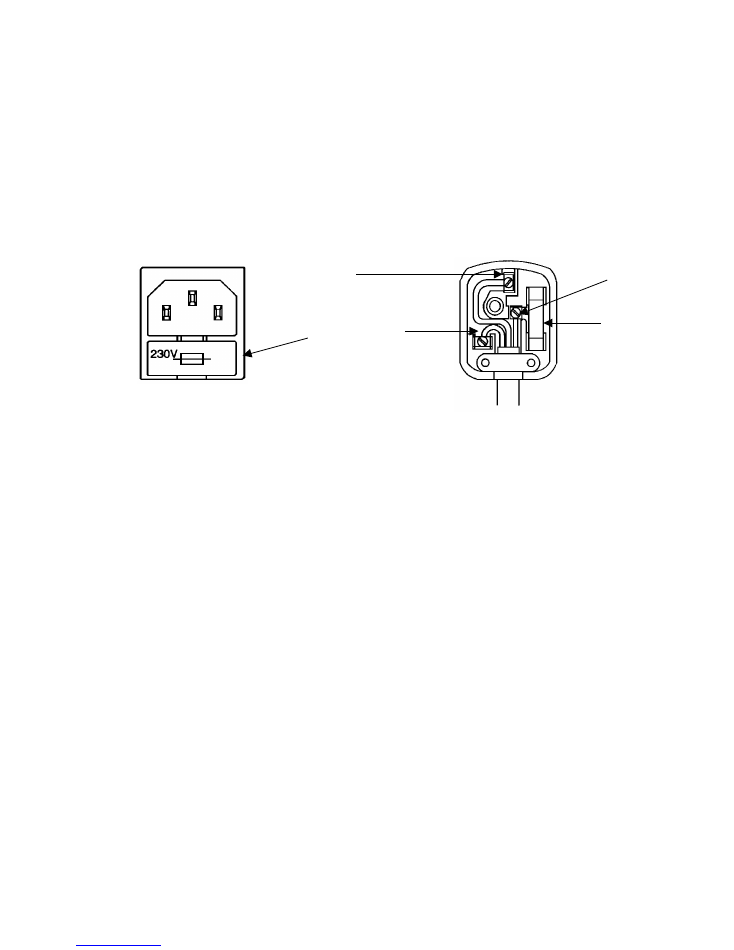

Ensure that the equipment is connected to a suitable mains supply. The equipment is supplied configured

for 230V 50/60Hz AC operation.

1.1.2

For mains connections other than the UK, refer to the local requirements for connections to supply.

1.1.3

Always ensure that the equipment is properly earthed (grounded). Operating without an earth is dangerous

and may cause high levels of audible hum from the loudspeaker outputs.

1.1.4

Avoid siting the equipment in locations exposed to direct sunlight, near heaters or other heat sources. Avoid

locations with high humidity or dust levels. Do not obstruct the ventilation slots in the amplifier case and, if

the amplifier is rack-mounted, ensure that a 1U ventilation panel is fitted above the unit.

1.1.5

Never remove the top cover of the amplifier with the AC mains supply connected. All internal servicing

should be performed by a competent / qualified engineer.

1.1.6

Never make an internal adjustment when the AC supply is connected.

Fuse Holder

IEC Mains Inlet Socket

13A Mains Plug Wiring (UK only)

Green/Yellow

Earth

Blue

Neutral

Brown

Live

Fuse

5A Max.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 4

2.

WHY INDUCTION LOOPS ?

2.1

Introduction

The problems faced by the hearing-impaired are rarely appreciated by those with normal hearing.

Unfortunately hearing aids give only partial restoration of hearing with the added disadvantage that the built-

in microphone cannot mimic the normal ear/brain ability to differentiate between distant, wanted sounds and

nearby, unwanted noises, and so to distinguish speech clearly from a combination of direct, reflected and

reverberant sounds. For instance a hearing aid user attending a concert or play may turn up the volume

control in an attempt to improve intelligibility, invariably resulting in an increase in interference from nearby

coughs, rustles, etc., sometimes to painful levels.

All these problems can be overcome by feeding microphone signals or the existing public address (PA)

system audio directly to the hearing-aid so that only the wanted sound (without auditorium reverberation,

audience noises, etc.) is reproduced.

This can be achieved by driving audio frequency currents around a large loop of wire to generate a magnetic

field (varying in sympathy with the PA program material) and which could be picked up by suitable

equipment. Specially designed headsets are available from a number of manufacturers such as Beyer,

Danavox and telex which have applications in high-noise environments for paging/life-safety and for silent

reproduction of commentary in museums and art galleries.

However, since 1974 all UK National Health Service hearing aids have had a switch to select M (internal

microphone) or T (telecoil pick-up), the T position being originally intended for use with telephone handsets

(later designs of telephone have proved unsuitable for this use). ‘AFILS’ (Audio Frequency Induction Loop

System) are designed to work efficiently, taking into account the positions and electromagnetic

characteristics of the internal pick-up coils normally fitted to hearing aids.

Now with a suitably installed AFILS the hearing impaired can appreciate and enjoy everything that those with

normal hearing do and, as mentioned above, the same type of system can be used to provide paging/life

safety communication in very noisy areas, secret paging for security staff, disturbance free audio for spoken

commentary systems or individual AFILS for booking offices, bank tellers etc.

2.1

The MILLBANK Dynamic Loop System

The dual purpose design allows for assisted listening of the hearing impaired and for applications such as

commentary systems in museums and art galleries.

The audio requirements for the two applications are different; a hearing impaired user requires tight control

of dynamic range and restricted bandwidth to enhance intelligibility by maximising perceived volume while

limiting maximum signal peaks and frequencies. A non hearing impaired user, however, may require less

dynamic range compression and a wider bandwidth.

The Talisman range of audio induction loop amplifiers is unique in that it provides switch selectable options

to cater for these alternative uses. The bandwidth may be set to either 5KHz or 10KHz high frequency roll off

and the dynamic range compression circuit is switchable either on a peak limiter (to prevent distortion in

wide dynamic range applications) or as a dual time constant compressor reducing the dynamic range to no

more than 9dB peak to average for assisted listening applications.

A combined voltage and current feedback technique is used to optimise drive into a wide range of loop

impedances. This system overcomes the disadvantages normally associated with amplifiers using voltage

feedback only. Radio frequency interference (R.F.I.) is prevented by amplitude limiting and low pass filtering

the signal prior to the driver stage. Unlike current feedback only designs, the TAL DLS output stage cannot

clip when driving inductive loads as voltage feedback takes over when the clipping threshold is approached.

Importantly, the feedback configuration means that the dynamic loop system is stable into highly inductive,

multi-turn loops.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 5

3.

TAL/DLS DESCRIPTION

The Talisman Dynamic Loop System is designed for the specific applications of the assisted listening for the

hearing impaired, by the users hearing aid, and for wire free sound distribution in museums, art galleries,

etc.

The unique Millbank Electronic design incorporates the results of many years of operational experience in

this field and offers superior performance.

Features include:

3.1

Dual purpose design

For the hearing impaired, especially contoured frequency curve.

For other audio induction loop applications, museum commentary, secret paging, etc., a wide range

frequency response.

3.2

Dynamic amplifier output allows

New flexibility in loop design.

Interference (R.F.I) free loop design.

3.3

Incorporates Frequency Contour Control

Adjusts performance to match exact requirements of the listener.

3.4

Switchable Automatic Gain Control

Compensates for differences between signal inputs (microphones for example), especially important for

hearing aid users.

3.5

Fast Acting Compression Circuitry

Controls signal peaks without audible distortion and prevents generation of interference within the

amplifier.

3.6

L.E.D. Display for optimum input levels and loop integrity

Allows optimum setting of signal processing circuits.

Provides visual reassurance of loop connection and operation.

3.6

Linear calibrated bargraph display of loop current

Continuous display of peak current in loop, confirms correct drive conditions.

3.6

Comply with existing and projected industry standards

Designed for loop systems to meet BS6083:Part4:1981.

Designed to meet interference regulation MPT1370.

Two models are available: a single input version to connect to an existing sound reinforcement system and a five input

version where no sound reinforcement system is to be incorporated and there is a requirement for sound from up to

five sources to be processed.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 6

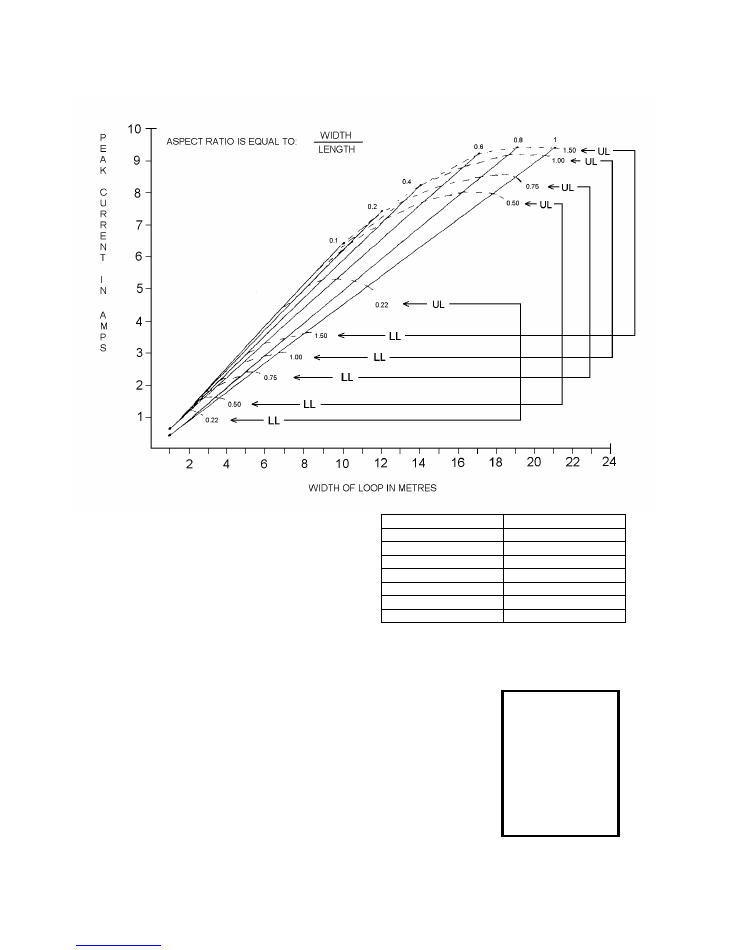

CONDUCTOR TYPE

COPPER AREA

1/0.8mm

0.5mm sq.

7/0.2mm

0.22mm sq.

13/0.2mm

0.4mm sq.

16/0.2mm

0.5mm sq.

24/0.2mm

0.75mm sq.

32/0.2mm

1.0mm sq.

30/0.25mm

1.5mm sq.

3.

CURRENT / CONDUCTOR GRAPH

Only a single turn loop of cable is normally required.

This assumes that the receiver is 1.5 metres above or

below the plane of the loop.

The graph corresponds to DLS use with the AGC

switched on.

Thus the maximum r.m.s. current in the loop is limited in

the event of fault conditions, such as feedback between

loop and microphone.

If the amplifier is to be used with the AGC switched off, a longer continuous current could be produced under fault

conditions and therefore care should be taken to allow for this in selecting conductor type.

Example:

Aspect ratio (W/L) = 0.8

From the graph: 16m intersects with 0.8 A.R.

n area bounded by upper (UL) and lower (LL) limits of

0.22 and 0.50 mm sq. So either 0.2mm sq. or 0.50mm

sq. may be used.

Current required = 7.8 Amps

20m

16m

L

W

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 7

4.

CHECK-LIST FOR SYSTEM DESIGN USING TAL/DLS

Refer also to setting up procedure on following pages

4.1

Before starting you will need the following:

a) Tape measure (at least 10m long).

b) Magnetic field strength meter.

c) AFILS receiver (headphones and hearing aid recommended).

d) Tape of continuous speech and tape-player, or a sympathetic assistant with a microphone.

4.2

Using the receiver(s) and field strength meter check the area to be covered for background magnetic noise.

Dimmers, power cabling, motors, etc., which can radiate powerful magnetic noise must be switched off

during this test. No standard currently exists but we recommend that the noise should be at least 26dB

below 0.1A/m and that the character of the noise is not objectionable (buzzes can sound worse than pure

hum).

4.3

Together with the customer decide on the most appropriate positioning for the wire loop and take the

dimensions so that an ‘ideal’ shape can be approximated (square or rectangle, etc.). Note the width

(shortest side of the loop), and calculate in metres the aspect ratio by dividing the width by the length.

4.4

Using the graph, find the width (shortest side) of the loop and move vertically up the graph until an

intersection is made with the appropriate ‘aspect ratio’ line.

4.5

The intersection of the loop width and ‘aspect’ ratio also determine the conductor area of the cable to be

used, taking into account both the current-carrying capacity and cable resistance.

The current demanded by this size of loop can be read – off the vertical axis. If the current indicated

is in excess of 9 Amps then separate loops should be employed, driven by separate amplifiers.

4.6

Temporarily install the loop as close as possible to its final position and test with the taped speech or

microphone and TAL DLS amplifier to confirm design parameters.

Hidden metalwork, etc., may cause reductions in field strength which can be compensated by

adjusting the master control during this test. In extreme cases the installation may prove totally

unsuitable for loop use and an alternative technology offered to the customer (e.g. Infra-Red

systems).

The frequency response should also be checked, losses of high frequencies may be recovered by

the use of the TAL DLS ‘Response’ control.

4.7

Assuming satisfactory test results, permanently install the loop wiring (not in metal conduit or trunking),

signal cabling (which should be routed as far as possible from the loop wire) and a.c. power supply. The

amplifier generates heat and must be located in a position with adequate ventilation.

4.8

Set all ‘input’ front panel gain controls to maximum, the ‘master’ control and ‘response’ control to mid

positions. Set the ‘response’ switch (located on the rear panel) to the required position – 5KHz for hearing-

aid use, 10KHz for other uses.

4.9

Depending on the use of the system, the AGC is set-up in two alternative ways:

4.9.1

AGC and limiting (for hearing aid use). Select the AGC mode by setting the ‘AGC’ switch (located

on the rear panel) to ON.

4.9.2

Limiting only (for non hearing aid use). Select the limiter only mode by setting the ‘AGC’ switch to

OFF (the switch is located on the rear panel).

4.10

The master control should now be adjusted to give the required current drive to the loop, indicated by the

bargraph display on the front panel. The field strength must be checked and the amplifier master control

adjusted if necessary.

4.11

Check the field strength over the entire area to be covered, note any areas of poor coverage and ensure

that hearing aid users are notified of such areas.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 8

3

2

4

5

6

7

8

Ser No:

TAL DLS1

England SK10 2NF

Cheshire

Macclesfield

Hurdsfield Industrial Estate

Signal House

Federal Signal Ltd

Dynamic Loop Amplifier System

Designed by Millbank on behalf of Federal Signal Ltd. Manufactured in R.O.C.

No user serviceable parts inside, refer servicing to qualified personel.

To avoid electric shock hazard, do not expose this appliance to rain or moisture.

AC 230V~240V, 50/60Hz

T3,15L 250V

WARNING

LOOP

High Voltage

DANGER

Input

Limiter

5kHz

Agc

10kHz

Response

Mode

1

2 3

4

5

4.12

Confirm that the ‘Loop Integrity’ LED functions by disconnecting the loop wire, the LED should extinguish in

about 5 seconds.

4.13

As a final check, the response control should be adjusted, if necessary, to achieve optimum frequency

response.

4.14

Set all unused input control to minimum.

4.15

The notice supplied with the equipment informing potential hearing aid users that the system is installed

should be clearly displayed.

4.16

Before leaving the installation it is most important that the owner and users of the system are familiar with its

operation and understand the need for regular checks to be carried out on the system – checking LED

indicators for input level, loop integrity and drive current and performing listening tests.

5.

CONTROLS AND CONNECTIONS

5.1

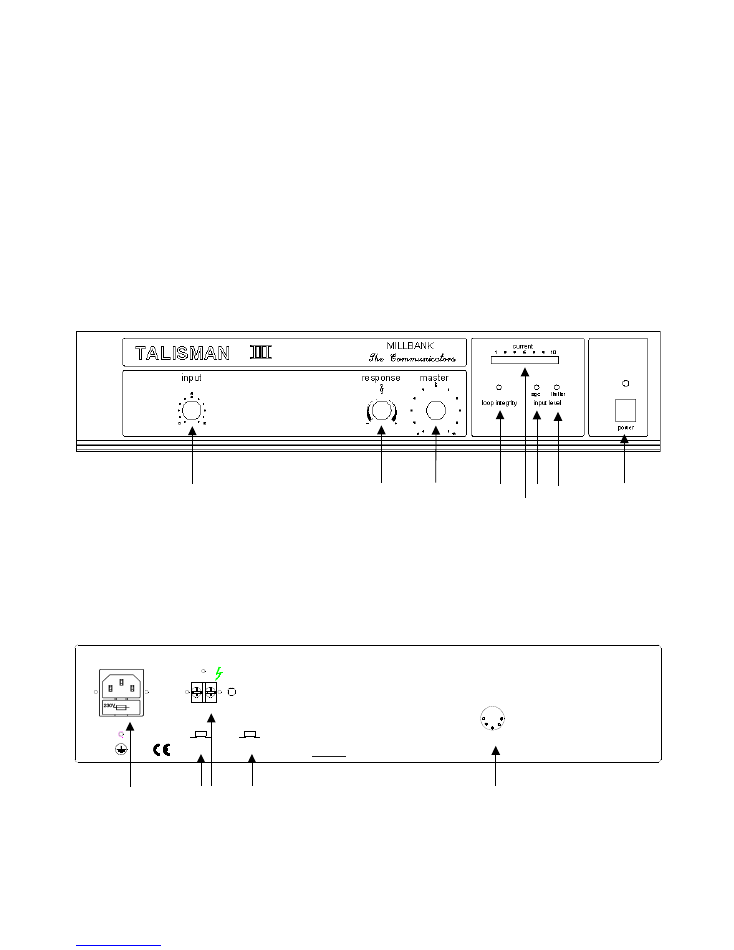

TAL/DLS1/3

1. Input Level Control.

2. Tone Control.

3. Master Level Control.

4. Loop Integrity Indicator.

5. Loop Current Indicator.

6. AGC Indicator

7. Limiter Indicator.

8. Power On/Off Switch.

1. Mains Input Socket and Fuse

2. Frequency Response Switch

3. Loop Connector

4. Mode Switch

5. Input Socket

1

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 9

Designed by Millbank on behalf of Federal Signal Ltd. Manufactured in R.O.C.

No user serviceable parts inside, refer servicing to qualified personel.

To avoid electric shock hazard, do not expose this appliance to rain or moisture.

AC 230V~240V, 50/60Hz

T3,15L 250V

WARNING

Tape out

LOOP

Aux 2

Aux 1

Mic 3

Mic 2

Mic 1

10kHz

Agc

5kHz

Limiter

Response

Mode

England SK10 2NF

Ser No:

TAL DLS5

Dynamic Loop Amplifier System

Hurdsfield Industrial Estate

Macclesfield

Cheshire

Federal Signal Ltd

Signal House

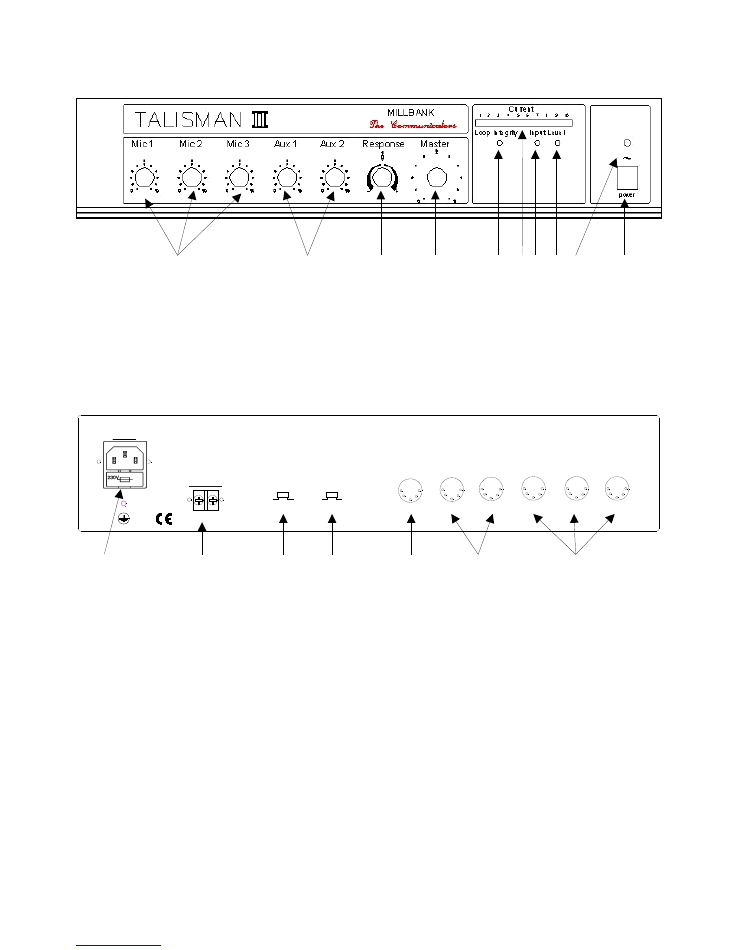

5.2

TAL/DLS 5/3

1. Microphone Input Level Controls

2. Auxiliary Input Level Controls

3. Tone Control

4. Master Level Control

5. Loop Integrity Indicator

6. Loop Current Indicator

7. Input Level AGC Indicator

8. Input Level Limiter Indicator

9. Power On Indicator

10. Power On/Off Switch

1. Mains Input Socket.

2. Loop Connector.

3. Response Switch.

4. Mode Switch.

5. Tape Output.

6. Auxiliary Inputs.

7. Microphone Inputs.

1

2

3

4

5

6 7

8 9

10

1

2

3

4

5

6

7

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 10

6.

SETUP PROCEDURE

6.1

Connections

6.1.1

Loop

Screw connections are provided for connection of the wire loop.

6.1.2

Microphones

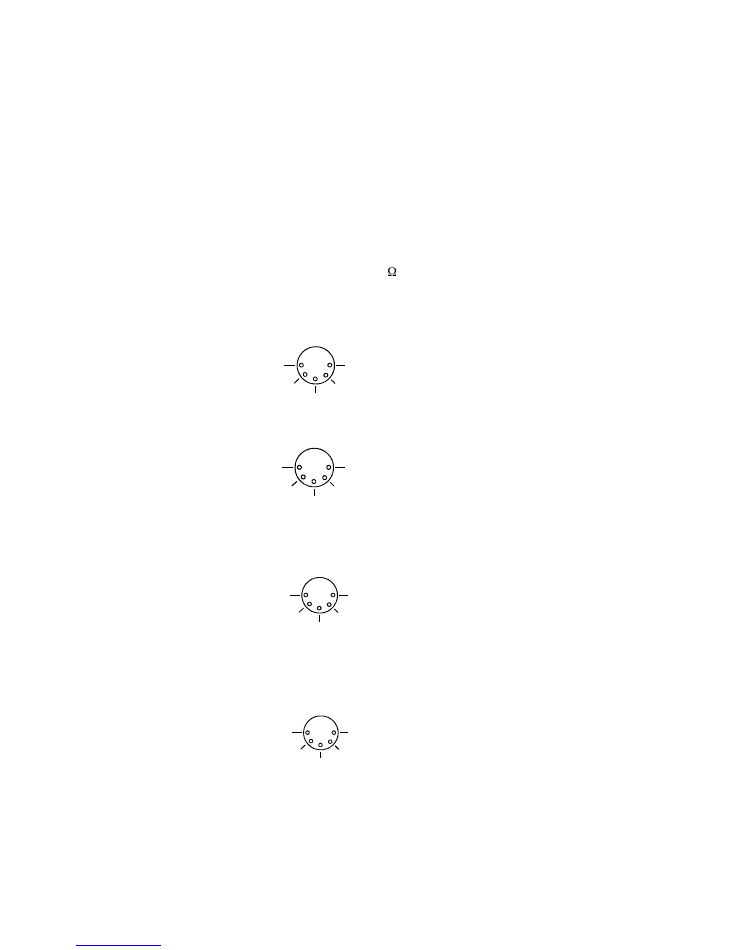

All connections to the microphone inputs are by 5 pin180° DIN connectors, which are supplied with the

equipment. Microphone 1 has the facility of priority, making it possible to mute all other inputs. To utilise this

feature the access pins 4 & 5 must be closed (shorted) during the announcement, this is normally done via

the PTT switch on the microphone to be connected.

If the priority function on Microphone Input 1 is not used, ALL inputs will be in mix-mode.

All microphone inputs are balanced with 200µV @ 200 sensitivity. Signal is connected to pin 1 and the

screen to pin 2.

Wiring Instructions for Microphone Input 1:

Wiring Instructions for Microphone Inputs 2 and 3:

6.1.3

Auxiliary

Up to two auxiliary input signals can be used, these can be from signal sources such as Cassette, Radio or

CD players, Two sensitivity levels are provided at 300mV (low) and 50mV (high). Pin 3 provides the high

sensitivity, pin 5 provides the low sensitivity and pin 2 is the screen connection.

Wiring Instructions:

6.1.4

Tape output (DLS 5 only)

The connector can be used for recording purposes or driving slave amplifiers. An output level of 550mv (at

full output) is provided on pin 1 and the screen or ground is on pin 2.

Wiring Instructions:

1

2

3

4

5

Hot

Cold

Priority

Priority

Screen

1

2

3

4

5

Screen

NC

NC

Low

High

1

2

3

4

5

Hot

Cold

Screen

NC

NC

1

2

3

4

5

Screen

NC

NC

550mV

Output

NC

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 11

6.2

Setup

6.2.1

Set the response switch to the desired frequency response, this should be set to 5KHz for hearing impaired

applications.

6.2.2

Set the mode switch to AGC (Automatic Gain Control) or the limiter position. In AGC mode (hearing

impaired applications), the AGC LED should flicker off during pauses in speech by setting the input level

using the input level controls located on the front panel. In the limiter mode, the input level should be set

such that the limiter LED only illuminates during signal peaks.

For hearing impaired applications.

Set the response switch to 5KHz, the mode switch to AGC.

The AGC input level LED should illuminate only whilst signal

is passing through the equipment.

For silent paging applications.

Set the response switch to 10KHz, the mode switch to Limiter.

The limiter LED should only illuminate during signal peaks.

Additional gain and frequency responses are programmable and further advise may be sought from the

Customer Services department of Federal Signal Limited – see details overleaf.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 12

IN CASE OF SERVICE REQUIREMENTS PLEASE CONTACT YOUR SUPPLIER

IN THE EVENT OF DIFFICULTY COMMUNICATE DIRECT TO:

FEDERAL SIGNAL LIMITED

MILLBANK ELECTRONICS Customer Service

Signal House, Charter Way, Hurdsfield Industrial Estate, Macclesfield, Cheshire SK10 2NF

Telephone: + 44 (0) 1625 666600 - Fax: +44 (0) 1625 611352 - Web-site: www.fedsig.co.uk

E-mail: CustomerServices@fedsig.co.uk or Repairs@fedsig.co.uk

7.

Service and Warranty

Federal Signal Ltd. guarantees this product against defects in either

materials or workmanship. The guarantee does not extend to damage

caused by improper installation, improper storage, misuse, or operation

outside stipulated conditions.

Our warranty covers only goods returned to our premises for either repair or

replacement as deemed appropriate by Federal Signal Ltd.

In order to expedite the process:

Contact your supplier and quote the model and serial number of your

equipment.

Should you require sending the goods directly to the manufacturer, please

contact Federal Signal Limited Customer Services, which will provide you

with a Return Goods Authorisation (RGA) number.

This RGA number should then be referenced on every related

correspondence.

If it is necessary to re-pack the equipment for onward shipping or returning

to Millbank for service or repair, PLEASE ENSURE THAT THE ORIGINAL

PACKING OR EQUIVALENT IS USED.

Talisman III Dynamic Loop Amplifier Systems (TAL/DLS1/3 & TAL/DLS5/3)

Publication Code TAL-DLS-3_TIG Issue 3

Page 13

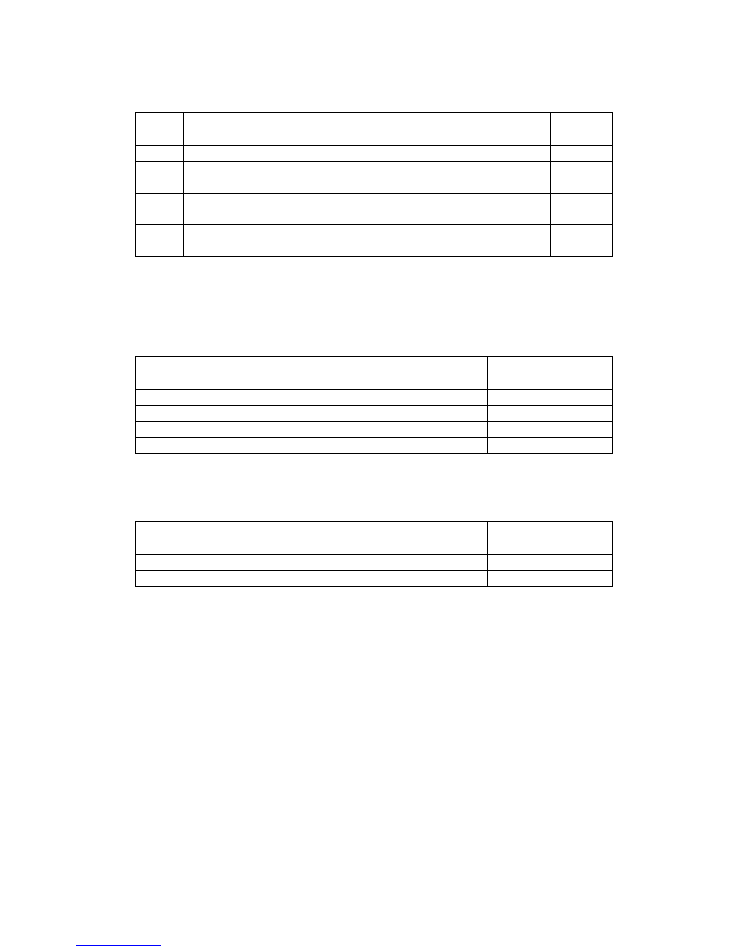

Document Change History

Issue

Details

Date

01

First Issue

Mar 00

02

Updated to include new standard clauses and company

details

May 01

03

Updates section 6 to include wiring details and referral to

additional programming features

Dec 01

03

Jumper setting investigated and recorded – See Customer

Services Department

Dec 01

Referenced Documentation

Title

Publication Code

Referenced Tools

Description

Part Number