Full Text Searchable PDF User Manual

MG-400

COMMISSIONING, OPERATING AND MAINTENANCE MANUAL

MODEL: MAVIGARD SERIES

SUB MODEL: CONVENTIONAL SYSTEM

COMBINED GAS AND FIRE ALARM CONTROL PANEL

KK-642.014 Rev.No:1 01.08.12 Page | 2

CONTENTS

1. INTRODUCTION ----------------------------------------------------------------------------------------------------------------------------------------------- 3

2- WARNING ------------------------------------------------------------------------------------------------------------------------------------------------------- 3

3- MOUNTING THE PANEL ------------------------------------------------------------------------------------------------------------------------------------- 3

4- PANEL INPUTS ------------------------------------------------------------------------------------------------------------------------------------------------- 4

4.1 Mains Power Supply ------------------------------------------------------------------------------------------------------------------------------------ 4

4.2 Batteries --------------------------------------------------------------------------------------------------------------------------------------------------- 4

4.3 Channel Inputs ------------------------------------------------------------------------------------------------------------------------------------------- 4

4.3.1 Fire detectors and MCPs ------------------------------------------------------------------------------------------------------------------------ 4

4.3.2 4-20mA input-------------------------------------------------------------------------------------------------------------------------------------- 4

4.3.3 Connections of 4-20mA converter card ----------------------------------------------------------------------------------------------------- 4

4.3.4 Two-wire detectors------------------------------------------------------------------------------------------------------------------------------- 5

4.3.5 Three-wire detectors ---------------------------------------------------------------------------------------------------------------------------- 5

4.3.6 Flame detectors ----------------------------------------------------------------------------------------------------------------------------------- 5

4.4 Remote control inputs --------------------------------------------------------------------------------------------------------------------------------- 5

5- PANEL OUTPUTS ---------------------------------------------------------------------------------------------------------------------------------------------- 5

5.1 Sounder outputs ----------------------------------------------------------------------------------------------------------------------------------------- 5

5.2 24V DC Power Supply (Aux) Output ---------------------------------------------------------------------------------------------------------------- 5

5.3 Relay Outputs -------------------------------------------------------------------------------------------------------------------------------------------- 5

5.3.1 Low alarm relay:----------------------------------------------------------------------------------------------------------------------------------- 5

5.3.2 High Alarm relay:---------------------------------------------------------------------------------------------------------------------------------- 5

5.3.3 Over-range Relay: --------------------------------------------------------------------------------------------------------------------------------- 5

5.3.4 Fault relay: ------------------------------------------------------------------------------------------------------------------------------------------ 6

6- CONTROL BUTTONS ------------------------------------------------------------------------------------------------------------------------------------------ 6

7- PANEL INDICATORS------------------------------------------------------------------------------------------------------------------------------------------- 6

8- FUSES ------------------------------------------------------------------------------------------------------------------------------------------------------------ 7

9- POWERING THE PANEL -------------------------------------------------------------------------------------------------------------------------------------- 8

9.1 Normal ----------------------------------------------------------------------------------------------------------------------------------------------------- 8

9.2 Alarm ------------------------------------------------------------------------------------------------------------------------------------------------------- 8

9.3 Fault -------------------------------------------------------------------------------------------------------------------------------------------------------- 8

10 PANEL MENUS ------------------------------------------------------------------------------------------------------------------------------------------------ 8

10.1 Visualization -------------------------------------------------------------------------------------------------------------------------------------------- 8

10.2 Access Level 2------------------------------------------------------------------------------------------------------------------------------------------ 11

11 – OPERATING WITH REPEATER PANEL AND RELAY MODULE ------------------------------------------------------------------------------------ 18

12- SPECIFICATIONS: ------------------------------------------------------------------------------------------------------------------------------------------- 18

12.1 Mechanical Features: -------------------------------------------------------------------------------------------------------------------------------- 18

12.2 Electrical Features: ----------------------------------------------------------------------------------------------------------------------------------- 18

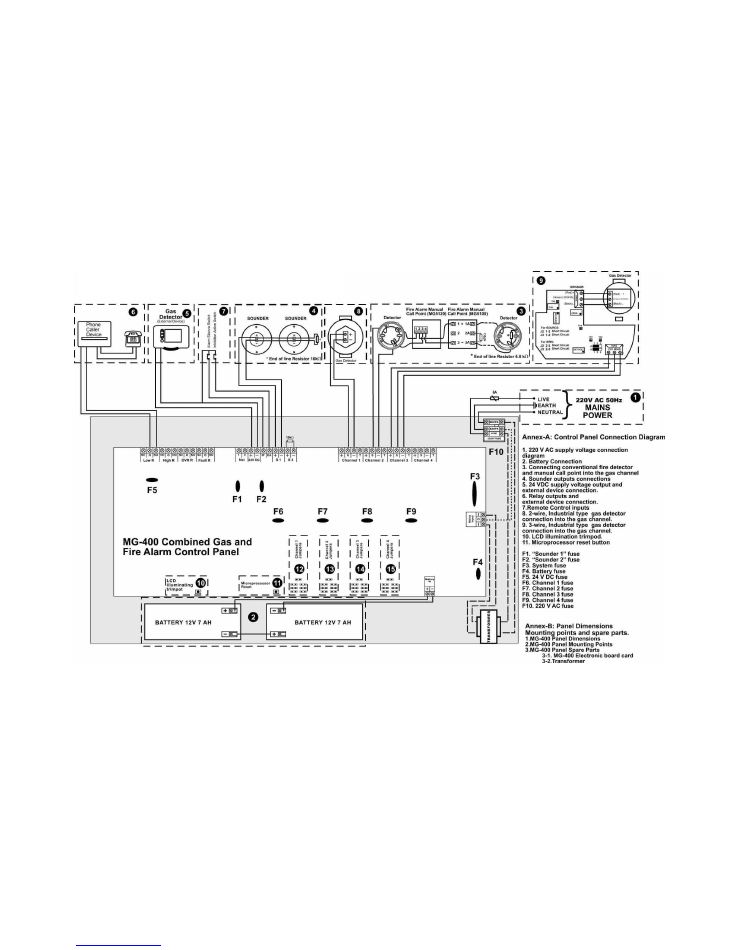

ANNEX-A CONNECTION SCHEME OF THE PANEL ----------------------------------------------------------------------------------------------------- 19

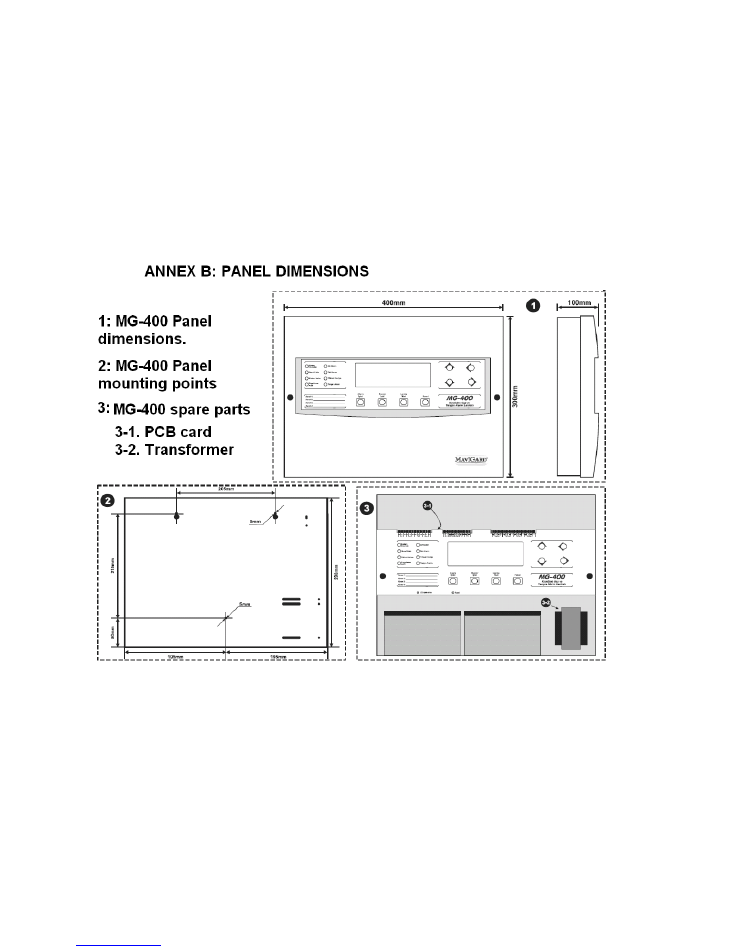

ANNEX-B PANEL DIMENSIONS -------------------------------------------------------------------------------------------------------------------------------- 20

KK-642.014 Rev.No:1 01.08.12 Page | 3

1. INTRODUCTION

MaviGard MG-400 is a 4 channel, 24 V DC operating voltage combined gas and fire alarm control panel.

Each channel can host 1 gas detector or 20 fire detectors with unlimited number of manual call points. Panel

power supply unit has an automatic battery charger and charging control circuit. Alarm and fault conditions are

showed on 8x40 character backlight LCD. Panel sounder outputs are supervised for open and short circuit

conditions. The panel has built-in buzzer. Settings to the panel are made by use of navigation buttons and

menu. The panel is microprocessor-controlled. Channels can be inhibited, sounder outputs and relays can be

tested,

Any channel can be disabled, sounder outputs and relays can be test. Gas detectors can be zeroed and

calibrated. These features are also told in the section of

“Panel Menu” in detail. The panel is equipped with 2

units of 24 V DC 500 mA sounder outputs and has 4 voltage-free changeover contact relay outputs (Low

alarm relay, High alarm relay, over-range relay and fault relay. Panel also has 24 V DC 500 mA auxiliary

power supply output. By use of remote control inputs, alarm can be silenced and all the channels in the panel

can be disabled.

Producer-

manufacturer or importer firms’ title, address, and telephone number

Manufacturer Firm:

MAVILI ELEKTRONIK TICARET VE SANAYI A.S.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/1-2-4 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 466 45 05 - +90 216 466 45 10

Service stations’ communication information that related spare parts have been provided

Authorized Services:

MAVILI ELEKTRONIK TICARET VE SANAYI A.S.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/1-2-4 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 466 45 05 - +90 216 466 45 10

TEKSIS TEKNIK ELEKTRONIK SIS.TIC. VE SAN. LTD. STI.

SERIFALI MAHALLESI, KUTUP SOKAK NO: 27/3 UMRANIYE / ISTANBUL / TURKEY

TEL: +90 216 313 60 60 - +90 216 313 47 49

Expected operation life which has been determined and announced by related ministry

This device’s expected operation life is 7 years.

2- WARNING

The equipment contains static-sensitive high quality electronic control equipment. Do not use the panel before

reading this manual. In case of any fault, only the technicians of the manufacturer or technicians authorized by

the manufacturer should repair or maintain the panel. Use the recommended cable types defined in this

manual for cabling of power supply, detection and sounder circuits. Do not remove any connections and do

not make any connections while mains power supply is connected. Pane

l’s earth connection must be made.

The cabinet must be connected to a suitable earth point.

Under no circumstances should voltage or current outside of the limits described in this manual be

used with system units. Otherwise, damage on panel may occur, which is not subject to maintenance

under warranty.

3- MOUNTING THE PANEL

MG-400; is not suitable for hazardous areas. Panels should be located into safe areas. With appropriate

protection material gas and fire detectors can be connected to the hazardous areas. To do that hazardous

areas should be checked and the protection material need to be select according to condition of this area.

While mounting the system in a hazardous area, experienced and educated technical team should be

assigned. Panel should be placed to an easy reachable, clean and dry place without forming any vibration.

The LCD on the panel should be located in flat wall on eye level and pay attention to mount inside of any

cabinet or near to high heat emitting devices. Screws or bolts of a minimum of 4mm diameter must be used

to mount the cabinet in 3 mounting points. Please check out Annex. B. Figure 2. Panel cable entries from

back and top of the panel are available for easy mounting.

KK-642.014 Rev.No:1 01.08.12 Page | 4

4- PANEL INPUTS

4.1 Mains Power Supply

The panel is designed to operate on 220 V AC 50Hz. Earth connections must be made to earth terminal and

earth resistor must be less than 10 Ohms. The mains power supply of the panel must be via an independent

self-resetting fuse rated 5A 220 V AC. This fuse must be separate from the other fuses and a caution note

should be written such as

“ATTENTION! GAS ALARM CONTROL PANEL FUSE. DO NOT REMOVE” to

ensure safe operation of the panel.

Recommended cable types are 3x2.5 NYM or 3x2.5 NYA. Connections should be same as Annex.A Figure1.

Do not connect or disconnect the loop, mains supply input and PCB connections while the panel is energized

to avoid an electric shock.

4.2 Batteries

Batteries provide continuity of operation during a failure of the mains power supply. The panel has an

automatic battery charger circuit. The panel uses 2 units of 12V DC 7Ah dry type batteries. Connection

diagram can be seen in Annex.A Figure-2.

4.3 Channel Inputs

These inputs provide power to the gas or fire detectors and transmit the status of gas/fire alarm, short circuit

and open circuit. In each channel input 4-20mA or conventional fire detector connection can be made.

4.3.1 Fire detectors and MCPs

For each zone line at most 20 units of detector and infinite number of button can be connected.

The characteristics of the cable are dependent on the length of the loop: for a loop of 0-500 metre long, use

1x2x0.8+0.8J-Y(st)Y cable, for a loop of 500-1500 metre long use 1x2x1.5+0.5J-Y(st)Y. A 6.8 k

Ω resistor

must be connected as an end-of-line element.

Channel jumper setting should be set as fire. If zener barrier will use, the jumper of zener barrier must be

adjust accordingly. Connections are seen as in Annex. A

– Figure-3.

4.3.2 4-20mA input

It provides 28V DC supply voltage for both fire and gas detectors. It follows 4-20 mA analogue current input

via 100 Ohms resistor. It is possible to mount 2- or 3- wire gas or flame detectors, in either sink or source

mode. Control panel can make the tracking of the analogue values between 4mA-21.5mA. When the

currents exceed 21.5 mA, panel gives the fault of

“OVERRANGE”. Connection can be seen from Annex. A

figure -9.

4.3.3 Connections of 4-20mA converter card

1- The jumper settings on both converter card and gas alarm control panel adjusted as

“SOURCE” or

“SINK”. The point here is both adjustments should be same.

2-

Before connecting 4-20 mA card to the panel, from the panel menu, channel device type must be

selected as

“det 4-20 srce” or “det 4-20 sink”.

3-

Before doing the signal connection of converter card to the panel, card is energized from the panel.

4-

Voltmeter

’s probes, are connected to (+) and (-) supply terminals of CON1 socket go to detector. Value

seen on Voltmeter is adjusted to 2V by using TP3(detector voltage potentiometer.) potentiometer.

5- Then converter card

’s energy is turned off. When all the connections are made, it is reenergized.

6- Voltmeter

’s probes are connected to the test points TP4 and TP3. Value seen on the voltmeter is

brought to zero by using TP4 (balance potentiometer)O. Make sure that 0 value see continuously.

7- Voltmeter

’s probes are connected to the test points TP2 and TP1. Value seen on the voltmeter is

brought to 40mV by using TP2 (zero potentiometer).

8-

After these settings applied, the measured value should be read as 0.

KK-642.014 Rev.No:1 01.08.12 Page | 5

4.3.4 Two - wire detectors

In Figure-8, Annex. A ; a sink current detector

’s connection is shown. Appropriate jumper settings should

be selected.

4.3.5 Three - wire detectors

In Figure-9 Annex-A; a 3-wire detector

’s connection is shown. Appropriate jumper settings should

be selected as sink or source.

4.3.6 Flame detectors

Jumper settings are adjusted according to detector is sink or source. Definitely do not select fire settings

4.4 Remote control inputs

Some of controls of gas alarm control panel can also be done remotely. These are:

·

Alarm Silence / Reset - As/R:

In case of alarm, to silence the sounders, switch is closed for one time.

If it is closed again, alarm situation is reset and system turns back to its initial position.

·Inhibiting All Channels - Inh:

Inhibits all channels. In this case panel keeps tracking detectors. Yet, if

there is an alarm from any fire or gas detectors, it shows the situation only from LCD panel.

Connections should be as in figure- 7 Annex. A. Screening table should be used.

5- PANEL OUTPUTS

5.1 Sounder outputs

The panel has 2 sounder outputs, each rated 24V DC 500mA. Current consumption more than 500mA will

cause a fault condition in sounder line. Sounder circuits are continuously monitored for open and short

circuit faults by connecting the end of line resistor on the last device on the circuit. 2x1.5 mm

² cable

should be used for cabling of sounder outputs. Connections should be made according to Annex-A

Figure-4. Polarised type sounders should be used. Otherwise, fire alarm control panel displays a fault

condition.

5.2 24V DC Power Supply (Aux) Output

The panel is equipped with an auxiliary 24V DC 500mA power supply output. The output is used to

energise external devices such as telephone dialler or gas detector. Overloading the output will cause

device malfunction or output fault respectively. Connections should be made according to Annex-A

Figure-5.

5.3 Relay Outputs

Panel has 4 volt free changeover relay outputs rated 1A at 30 V DC. These volt-free outputs, high alarm

relay (normally de-energized), low alarm relay (normally de-energized), over-range relay (normally de-

energized) and fault alarm (normally energized) relay. Connections should be made according to Annex-A

Figure-6.

5.3.1 Low alarm relay:

Low alarm relay is activated when the detectors channel low limit

value exceeds in the medium. Features of low alarm relay; threshold, latching/non-latching, NO/NC

operating is adjusted by the user.

5.3.2 High Alarm relay:

High alarm relay is activated when the detectors channel high limit

value exceeds in the medium. Features of low alarm relay; threshold, latching/non-latching, NO/NC

operating are adjusted by the user.

If channels include conventional fire alarm detectors, when detectors sends fire alarm signal, high

a

la

rm relay will be activated.

5.3.3 Over-range Relay:

If the gas level in the medium exceeds a fixed high limit (21.5 mA),

over- range relay is activated. Latching/non-latching, NO/NC operating is adjusted by the user.

KK-642.014 Rev.No:1 01.08.12 Page | 6

5.3.4 Fault relay:

When fault condition or panel

’s energy is cut off, it changes its position. When

the fault condition disappears, fault relay gets back to its initial position.

Important Note: Under no circumstances should voltage or current outside of 1A at 30 V DC used

with contacts. Otherwise, damage on panel may occur, which is not subject to maintenance under

warranty. If the relay outputs are used in an application requiring continuous high current, even

below the rated values, an appropriate contactor should be used between the device and the alarm

contacts. If not, main board of panel can blow or become damaged. Warranty excludes in this case.

6- CONTROL BUTTONS

Alarm silence

If there is a gas or fire alarm at the panel, pressing

“Alarm silence button” silences all sounder and relay

outputs which are programmed as latching. Buzzer keeps beeping discretely and the information of sounders

are silenced is seen on LCD screen.

Buzzer silence

Buzzer rings in case of alarm and fault situations, to silence buzzer, press

“Buzzer silence” button.

Lamp test

By pressing

“Lamp test” button, the control of all LEDs is made.

Reset

Reset button is used to reset the system when there is a gas or fire alarm situation in the system.

Up (+) and down (+) Buttons

“Up (+)” and “Down (-)” buttons, are used to make a pass through panel functions.

Enter Button

“Enter” button, is used to activate the selected function.

Exit Button

“Exit” button, is used to go back one menu up.

Microprocessor reset button

Microprocessor, is locked when it cannot run the system and

“System fault” in front panel is lit. In such case,

by pressing microprocessor reset button system is restarted. Also after changing system configuration, this

button helps to start new configuration. (Annex-A Figure 11)

LCD backlight:

LCD contrast could adjust by a trim pot. (Annex-A Figure 10)

7- PANEL INDICATORS

Power On

Under normal conditions only the green

“Power On” LED illuminates.

General Fault

If there is a fault on the system except for system faults,

“General Fault” LED Illuminates with related fault

LED.

System fault

The

“System Fault” LED will illuminate if the software of the panel configuration has not operated correctly.

Microprocessor button should be used.

Inhibit active

Light when channels are inhibited and which channels are inhibited on LCD screen.

Low Alarm

Low alarm shows detectors channel low limit value if exceeds and shows the low alarm relay is active.

High Alarm

High alarm shows detectors channel high limit value if exceeds and shows the high alarm relay is active.

KK-642.014 Rev.No:1 01.08.12 Page | 7

Over - Range

Shows the gas level in the medium exceeds a fixed high limit (21.5 mA), over-range relay is activated.

General Alarm

Shows if there is a gas or fire alarm from the detectors connected to the channels.

8- FUSES

Sounder 1 Fuse (F1)

F1 fuse; is self-resetting and activate on 500 m

А current overload.

Sounder 2 Fuse (F2)

F2 fuse; is self-resetting and activate on 500 m

А current overload.

System Fuse (F3)

F3; is self-resetting and activates

on 4А current overload or a short circuit

on panel PCBs. On activation of the fuse the SMPS 24 V output fault LED indicator illuminates.

Battery Fuse (F4)

F4; is self-resetting and activates on 500 m

А current overload or a short circuit on battery inputs. Illuminating

of the respective LED indicator on SMPS and silk screen label means the batteries are disconnected.

24 V DC Auxiliary Power Supply Output Fuse (F5)

F5; is self-resetting and activates on 500 m

А current overload. On the fuse activation the 24 V DC Fault LED

illuminates.

Channel Fuses (F6, F7, F8, F9)

They are 100 mA self-resetting fuses. It gets activated in case of any short circuit in channels inputs. In this

condition system takes energy from the batteries.

Mains Fuse (F10)

is glass type and activates on 2

А current overload, a short circuit or exceeding 220 V AC on mains supply

input. On the fuse activation, the POWER FAULT LED indicator on SMPS illuminates and power to the panel

is supplied from the batteries.

KK-642.014 Rev.No:1 01.08.12 Page | 8

9- POWERING THE PANEL

9.1 Normal

During normal mode, only green system is on LED lights. On the screen the gas levels read by channels is

9.2 Alarm

When the gas detectors exceed the levels of predetermined threshold levels in each channel, panel goes

into alarm mode. These alarms can be either low or high alarm level. In these situations each assigned output

is activated. Pressing Reset makes the system work in initial position.

9.3 Fault

In case of any fault condition at the panel leads to light

“General Fault” LED, rings the buzzer ad fault relay

changes its switch. When fault condition disappears, panel automatically turns back to its normal operating

status.

10- PANEL MENUS

In normal mode, access level of the panel is 1. In order to see the panel configuration and reach the functions

of access level 2, first you need to main menu. To do this, in normal operating mode press

“Enter” button.

Under the main menu there are 2 submenus. These are

“Visualization” and “Access level 2” menus. These

menus are selected by using

“Up (+)” and “Down (-)” buttons. Then, pressing “Enter” button results to enter the

selected submenu.

10.1 Visualization

When Visualization function is selected, pressing

“Enter” button pops up 4 sub visualization function.

To enter these sub-functions, function is selected by using

“Up (+)” and “Down (-)” buttons. Then, pressing

“Enter” button results to enter the selected sub-function.

*** Visualize ***

>

Relays status

Sounders status

Signal levels

Configuration

-----------------------------------------------------------------

-

Enter

– Ok

Exit

–Up

Menu

KK-642.014 Rev.No:1 01.08.12 Page | 9

10.1.1 Relay Activation Status

It enables to track the position of relay outputs of the panel.

*** RELAYS STATUS ***

Low Alarm Relay: Active

High Alarm Relay: Not Active

Over-range Relay: Not Active

Fault Relay: Active

-------------------------------------------------------------

-----

Exit

– Pre Menu

10.1.2 Sounder Activation Status

It follows whether sounder outputs are active or not.

*** SOUNDERS STATUS ***

Sounder 1 : Not active

Sounder 2 : Active

-------------------------------------------------------------

-----

Menu

Exit

– Pre

10.1.3 Signal Levels

Input of each channe

l’s signal level can be tracked.

*

SIGNAL LEVELS *

Channel 1 :

00.0 mA

Channel 2 :

05.5 mA

Channel 3 :

10.7 mA

Channel 4 :

25.5 mA

-------------------------------------------------------------

-----

Exit

– Pre Menu

10.1.4 Configuration

System operation is seen from the operating configuration of channels, sounders and relays. It is composed

of 4 sub-functions.

*

CONFIGURATION

*

> System

Common Relay settings

Sounder settings

Channel settings

Enter

–Ok

Exit

– Pre-menu

KK-642.014 Rev.No:1 01.08.12 Page | 10

10.1.4.1 System

In this menu, panel

’s language is shown.

*

SYSTEM

*

Language: English

Access Level 2 Password: Active

---------------------------------------------------------

----

Exit

– Pre-menu

10.1.4.2 Common relay settings

It is possible to check how pane

l’s relay works (latching or non-latching and N/O or N/C)

*COMMON RELAY SETTINGS*

Low

Alarm Relay : Latching / NO High

Alarm Relay: Non-latching / NC

Over-range Relay: Latching OK / NO

Fault Relay : Non-Latching / NO

---------------------------------------------------------------

---

Exit

– Pre-menu

10.1.4.3 Sounder settings

It is possible to check how pane

l’s sounder outputs operates (latching or non-latching)

*

SOUNDER SETTINGS

*

Sounder 1 : Latching

Sounder 2 : Non-latching

------------------------------------------------------------

Exit

– Pre-menu

10.1.4.4 Channel settings

Operating condition of all channels are monitored

*** CHANNEL SETTINGS

***

> Channel 1 configuration

Channel 2 configuration

Channel 3 configuration

Channel 4 configuration

Enter

– Ok

Exit

–Pre-menu

For example, if channel 1 is selected, then pressing

“Enter” makes to monitor all features of the channel.

KK-642.014 Rev.No:1 01.08.12 Page | 11

***

CHANNELS

*** Channel

1config

ıuration Detector

measurement range : Zero

forcing:

2 mA condition:

Warm-up delay :

-----------------------------------------------------------

Exit

– Pre-menu

*** CHANNELS ***

Channel 1config

ıuration

Fire Reset time :

1

st

Level Alarm position :

1

st

Level Alarm Entrance Value:

1

st

Level Alarm End Value :

------------------------------------------------------------

Exit

– Pre Menu

*** CHANNELS ***

Channel 1 Configuration

2

nd

Level Alarm Position Value :

2

nd

Level Alarm Entrance Value :

-------------------------------------------------------------

Exit - Pre Menu

10.2 Access Level 2

In order to get into the access level 2, person shall use the password

“1111”.Password display as the

following table.

*

ACCESS LEVEL 2

*

Enter Access Level 2 Password

****

------------------------------------------------------------

Exit

– Pre Menu

In this screen, first press to

“Up (+)” button and instead of the star “*”, number 1 comes to the end. Then by

pressing

“Enter “button 4 times makes the user to get in access level 2.

The screen of the

“Access Leve2” pops up, if correct password is entered, by the functions here control

panels operating features are programmed.

***

ACCESS LEVEL 2 ***

> Inhibit

Zeroing

Calibration

Test

Configure

------------------------------------------------------------

Enter

– Ok Exit – Pre

Menu

10.2.1 Inhibit

By use of Inhibit function, any channel or all channel of the control panel can be inhibited.

KK-642.014 Rev.No:1 01.08.12 Page | 12

***

INHIBIT***

> All

:Inhibition not active

Channel 1 :Inhibition not active

Channel 2 :Inhibition not active

Channel 3 : Inhibition Active

Channel 4 : Inhibition Active

------------------------------------------------------------

Enter

– Ok

Exit - Pre

Menu

Using

“Up (+)” and “Down (-)” buttons channel which wants to be inhibited is selected. The sign ‘>’ on the left

of the channel is moved). Then pressing enter selects the channel you want to be inhibited. (On the right

side of the channel the sign

‘<’ appears. In this position pressing ‘Down (-)’ button “Inhibited is active” text is

screened. Hence channel is inhibited. If the channel inhibited before, then selecting channel using

“Up(+)”

button changes the text

“Inhibited is active” into ““Inhibited is inactive” and channel is no longer inhibited.

10.2.2 Zeroing

When zero adjustment wants to apply channels, this function is used.

***

ZEROING***

Select the channel for zeroing

#1:Channel1

------------------------------------------------------------

Enter

–Ok

Exit

– Pre Menu

First of all the channel which want to be zeroed is selected. To do that

“Up (+)” and “Down (-)” buttons are

used and after determining the specific channel, press

“Enter” button to get into the zeroing submenu.

***

ZEROING***

#1:Channel1

Zeroing channel is inhibited!!!

When get ready press

“Enter”

0

-------------------------------------------------------------

Exit

– Pre Menu

To start zeroing, press

“Enter” once again and system performs zeroing of the related channel.

***

ZEROING***

#1:Channel1

Zeroing channel is inhibited!!!

20

Input fault

--------------------------------------------------------------

Exit

– Pre Menu

***

ZEROING***

#1:Channel1

Zeroing channel is inhibited!!!

0

Zeroing has been done

--------------------------------------------------------------

Exit

– Pre Menu

KK-642.014 Rev.No:1 01.08.12 Page | 13

10.2.3 Calibration

In order to make the calibration of the detectors, this function is used. It composes of 3 sub-functions.

***

CALIBRATION ***

> Calib. Channel.

Calib. Level:

Calibrate

------------------------------------------------------------

Exit

– Pre Menu

First of all the channel which want to be calibrated is selected. To do that the sign

“>” should be in the left

side of the sub-function

“Calib Channel”. Press “Enter”. (The sign “<” will be seen on the right side of the sub-

function

“Calib. Channel). Using “Up (+)” and “Down (-)” buttons channel name is found. By pressing “Enter

Butt

on” the related channel is selected.

After that calibration level shall be adjusted. To do this, again, using

“Up (+)” and “Down (-)” buttons

“Calibration level” sub-function is selected. When you press “Enter” button, on the right side of the

“Calibration Level” text the sign “<” is seen. In this position, calibration level value is adjusted between 25

and 100. To confirm the value press

“Enter Button”.

Once you done with these adjustments, calibration process can be started. For calibration

“Calibrate” sub-

function is selected and then

“Enter” is pressed. In such setting the screen is shown as:

Calibration process gets started by pressing

“Enter” button.

***

CALIBRATION ***

Calibrating channel is inhibited!!!

When get ready press

“Enter”

0

Calibration process gets started by pressing

“Enter” button.

a) IF CALIBRATION NOT SUCCEEDED

***

CALIBRATION ***

Calibrating channel is inhibited!!!

30

Input fault

------------------------------------------------------------

Exit-Ana Menu

b) IF CALIBRATION SUCCEEDED

***

CALIBRATION ***

Calibrating channel is inhibited!!!

50

Calibration has been done

Exit after gas level lowered

KK-642.014 Rev.No:1 01.08.12 Page | 14

10.2.4 Test

This function enable us test the relays and sounder outputs.

*** TEST ***

> Relay Test

Sounder Test

------------------------------------------------------------

Exit-Main Menu

10.2.4.1 Relay Test

In the Relay test function, the current status of the relays are monitored at the panel.

*** RELAY TEST***

>

Low Alarm Relay: Active

High Alarm Relay: Not Active

Over-range Relay: Active

Fault Relay: Not Active

-------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

On this screen, it is possible to select the relay which you may want to test, using arrow buttons. (On the left

‘>’ sign should be next to that relay.) By pressing “Enter” relay is selected. (On the left of the relay ‘<’ sign is

present.) After selecting relay, press

“Up(+)” button to test it.

10.2.4.2 Sounder Test

When you enter the sounder test function, the current condition of the sounders is monitored.

***

SOUNDER TEST***

> Sounder 1:

Active

Sounder 2:

Not Active

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

On this screen, it is possible to select the sounder output which you may want to test, using arrow buttons.

(On the left

‘>’ sign should be next to that sounder output.) By pressing “Enter” sounder output is selected.

(On the left of the sounder

‘<’ sign is present.) After selecting sounder output, press “Up(+)” button to test

sounder then press

“Down(-) button to exit from the test.

10.2.5 Configure

By using this function, system operating features are programmed.

***

CONFIGURATION

***

> System

Common Relay Settings

Sounder Settings

Channel Settings

-------------------------------------------------------------

Enter

– Ok

Exit

– Pre-Menu

KK-642.014 Rev.No:1 01.08.12 Page | 15

10.2.5.1 System

Panel: Network Address, communication rate, panel name, serial number and panel language are adjusted

by the help of system menu.

***

SYSTEM

***

> Language: English

Access Level 2 Password: Active

--------------------------------------------------------------

Enter

– Ok

Exit

– Pre Menu

10.2.5.2 Common Relay Settings

In this sub-function, relays operating structure are set as latching, non-latching or latching acceptance of

operating status and N/O or N/C is adjusted.

***

COMMON RELAY SETTINGS

***

> Low Alarm Relay

High Alarm Relay

Over-range Relay

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

On this screen, it is possible to select the relay which you may want to adjust setting, using

“Up(+)” and

“Down(-)”arrow buttons. (On the left ‘>’ sign should be next to that relay.) By pressing “Enter” relay is

selected. In this condition, this screen is monitored;

***

COMMON RELAY SETTINGS

***

Low Alarm Relay

> Relay Type: Latching

Normally :Open

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

“Relay Type” Sub-function:

By this sub-function, relay

’s operating conditions can be selected as latching

non-latching and latching acceptance operating status. These features can be defined as below:

-

Latching:

W hen the gas level in the medium, exceeds the pre-determined threshold value for that

channel, relay gets activated. The gas level even then lowers than the threshold value; relay does not get

back to its previous position. In order to make the relay turns back to its previous position,

“Alarm Silence”

button should be used.

-

Non-Latching:

When the gas level in the medium, exceeds the pre-determined threshold value for that

channel, The gas level even then lowers than the threshold value; relay gets back to its previous position

without any interfering to the system.

-

Latching Accept:

When the gas level in the medium, exceeds the pre-determined threshold value for that

channel. When system is in Alarm condition, it may possible to turn back the relay back its previous

condition. To do that

“Latching Accept” is selected and then press to “Alarm Silence” button. Additionally,

the operating condition of the relay whether normally Open or normally closed is set from tjis sub-function.

KK-642.014 Rev.No:1 01.08.12 Page | 16

10.2.5.3 Sounder settings

The sounder outputs of the control panel are adjusted.

***

SOUNDER SETTINGS

* **

> Sounder 1 : Latching

Sounder 2 : Non-latching

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

On this screen, it is possible to find the sounder output which you may want to adjust setting, using

“Up(+)”

and

“Down(-)”arrow buttons. (On the left ‘>’ sign should be next to that sounder output.) By pressing “Enter”

sounder output is selected. After selecting sounder output, pressing

“Up(+)” button enables to select the

sounder output as

“latching”, “non-latching” or “latching accept”. These operating features were just

described on section 10.2.5.2.

10.2.5.4 Channel settings

The operating features of the channels of the control panel are adjusted.

*** CHANNEL SETTINGS

***

> Channel 1 configuration

Channel 2 configuration

Channel 3 configuration

Channel 4 configuration

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

On this screen, it is possible to find the channel which you may want to adjust setting, using

“Up(+)” and

“Down(-)”arrow buttons. (On the left ‘>’ sign should be next to that channel.) By pressing “Enter” channel is

selected. In this condition, this screen is monitored as;

*** CHANNEL SETTINGS

***

Channel 1 configuration

> Device Type: DET 4-20 Source

Channel Name : Channel 1

Zone Name :Mavili Elektronik

Measuring Unit: % LEL

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

· Using “Type” function, detector type is selected. “Fire 4-20 Sink”, “Fire 4-20 Source”, “Detector 4-20

Sink

”, “Detector 4-20 Source”, “Fire Conventional”, “ESU” and “None” features can be selected.

·Using “Name” function, panel name can be written.

·Using “Zone” function, the zone name of the control panel can be given.

·Using “Unit” function, gas measuring unit can be selected as: “%LEL”, “PPB”, “PPM”, “%VOL” and “FIRE”.

After adjusting these settings press

“Down (-)” button to see the upcoming screen.

*** CHANNEL SETTINGS

***

Channel 1 configuration

> Detector Measuring Range: 9999

Zero Suppression: Active

2mA Status: Fault

Warm-Up Delay: 120 sec.

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

·By “Measuring Range” function, detector’s gas measuring range is estimated.

·By “Zero suppression” function, it is selected that zeroing process whether active or not.

KK-642.014 Rev.No:1 01.08.12 Page | 17

·By “2mA detection” function, in case of decreasing current which comes from detector or converter card, the

system response is determined. In this condition system may give fault warning, notification warning or

cannot be counted as a warning status.

·By “Warm-up delay” function, it is told to the control panel that, in the start –up session, the signals coming

from the detectors cannot be evaluated by the panel. This is because detector will have more stable values

after warm-up time. Hence they will measure accurate values.

After adjusting these settings press

“Down (-)” button to see the upcoming 3

rd

screen.

*** CHANNELS

***

Channel 1

configuration

> Fire Reset Time : Alarm

L1 Direction : Alarm L1

On Threshold: Alarm L1

Off Threshold:

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

·“Fire Reset Time”: Function that during fire alarm condition, when pressed to “Reset”, the determination of

interruption time of the energy of the channel which detector connected to that channel is adjusted.

· “Low alarm direction”: Function that estimates the sensitivity of low alarm warning as increasing or

decreasing level of the gas in the medium.

· “Low alarm opening level” Function that determines the threshold of gas level of the low alarm warning

value.

·“Low alarm closing level”: Function that determines the gas level, when panel pass from low alarm to

warning to normal status.

After adjusting these settings press

“Down (-)” button to see the upcoming 4

th

screen.

*** CHANNELS

***

Channel 1

configuration

> 2

nd

level Alarm Direction:

2

nd

level Alarm Input Value:

------------------------------------------------------------

Enter

– OK

Exit

– Pre Menu

·“High alarm direction” Function that estimates the sensitivity of high alarm warning as increasing or

decreasing level of the gas in the medium.

·“High alarm opening level” Function that determines the threshold of gas level of the high alarm warning

value.

KK-642.014 Rev.No:1 01.08.12 Page | 18

11 – OPERATING WITH REPEATER PANEL AND RELAY MODULE

MG-400 Series Control Panel has appropriate connections for repeater panel and relay module for each

zone output. Yet these features are not available to use currently.

12- SPECIFICATIONS:

12.1 Mechanical Features:

Dimensions (mm)

400 x 300 x 100 mm

Weight (excl. battery)

5.3 kg

Body

Panel Box; 1.2 mm front 1.5 mm DKP

Operating Temperature

(-10

ºC)- (+ 55ºC)

Relative Humidity

% 0 - 95

Mounting

Surface mounting

Cable Inputs

Upper and back inputs

12.2 Electrical Features:

Gas Channel

4

Operating Voltage

24 V DC

Battery

2 x 12 V 7Ah

Supply Voltage

220 V AC 50 Hz

Sounder Output

2 x (500 mA 24 V DC)

24V DC Output

500 mA 24 V DC

Extinguishant Output

500 mA 24 V DC

Low Alarm Relay

30 V DC 8 A, 250 V AC 10 A N/K

High Alarm Relay

30 V DC 8 A, 250 V AC 10 A N/K

Over-range Relay

30 V DC 8 A, 250 V AC 10 A N/K

Fault Relay

30 V DC 8 A, 250 V AC 10 A N/K

KK-642.014 Rev.No:1 01.08.12 Page | 19

ANNEX-A CONNECTION SCHEME OF THE PANEL

KK-642.014 Rev.No:1 01.08.12 Page | 20

ANNEX-B PANEL DIMENSIONS