Full Text Searchable PDF User Manual

Operating Manual

MELA

doc

Label Printer

Dear doctor,

With your purchase of MELAdoc, you have acquired a device which only a few years ago was not to be found in a

doctor's or dentist's practice. The majority of your colleagues would doubtless have dismissed it as a "bureaucratic

inanity.”

The situation has changed fundamentally.

Hygiene standards for doctor's and dental practices have become very strict. It is especially important to observe the

recommendations from the Robert Koch Institute "Hygiene requirements for the treatment of medical products," and

§4 clause.2 of the Medical Devices Operations Ordinance, which requires that the “operator“ (i.e. yourself)

“…prepares the instruments in a suitable and validated procedure which ensures its verifiable success…“

Compliance with these requirements will be verified. The Infections Protection Act gives government authorities the

right to subject practices to rigorous inspection without any grounds for suspicion. Health authorities, local authorities

etc. are making increased use of this right in the form practice inspections, usually announced in advance.

Using MELAdoc and the corresponding labels means that you are able to label sterile equipment in terms of its

sterilization date, expiry date, batch number and clearance of the sterilized product, and enables you to fulfil all the

valid legal requirements.

Your MELAG team

Operating Manual MELA

doc

Label Printer

MELAG Medical Technology

Geneststraße 7-10

10829 Berlin

Germany

E-mail: info@melag.de

www.melag.de

Document: BA_GB_MELAdoc.doc/ Revision: 0 – 09/1981

Operating Manual MELAdoc label printer

3

Contents

Chapter 1 – What does the MELAdoc do? ................................................................................................................ 4

Documentation of the procedure clearance................................................................................................................... 4

Documentation of the batch clearance .......................................................................................................................... 5

Labelling and clearance of the sterilized equipment...................................................................................................... 5

Storage.......................................................................................................................................................................... 6

Chapter 2 – Batch documentation ............................................................................................................................. 7

Post-application documentation .................................................................................................................................... 7

Chapter 3 – Commissioning....................................................................................................................................... 8

Overview – Assembly of the label printer ...................................................................................................................... 8

Inserting the label roll .................................................................................................................................................... 9

Removing jammed labels ............................................................................................................................................ 11

Setting the date ........................................................................................................................................................... 12

Inserting the inking roller ............................................................................................................................................. 12

Removing the inking roller........................................................................................................................................... 13

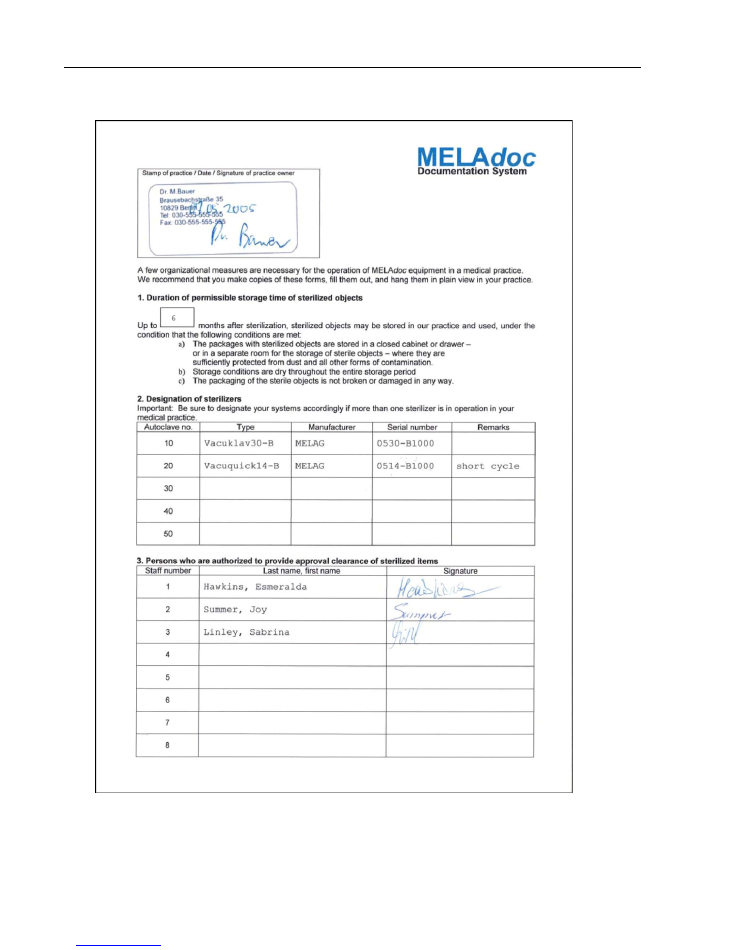

Measures for use - example........................................................................................................................................ 13

Measures for use - example........................................................................................................................................ 14

Glossary..................................................................................................................................................................... 16

Appendix - Accessories............................................................................................................................................ 17

Operating Manual MELAdoc label printer

4

Chapter 1 – What does the MELAdoc do?

MELA

doc

serves the:

Documentation of the clearance decision

Labelling the medical product

Traceability.

Clearance:

Instrument preparation ends with the documented clearance for storage and use

(according to RKI: “Hygiene requirements for the treatment of medical products”). The

respective clearance decisions may only be carried out by authorized and expert personnel and

must be documented. The clearance procedure consists of the steps procedure clearance,

batch clearance and clearance of the sterilized equipment.

1. Documentation of the procedure clearance

2. Documentation of the batch clearance

3. Labelling and clearance of the sterilized equipment

4. Storage

5. Post-application

documentation

Documentation of the procedure clearance

Daily routine inspection and commissioning of large steam sterilizers is described in DIN

58946-6:2002. The norm for the operation of small steam sterilizers is currently being

formulated. We recommend:

A visual inspection

Visual inspection of the autoclave chamber, the door seal, door lock, and where

necessary, further checks in accordance with the manufacturers instructions

Inspection of the operating materials

Quality of the feed water (automatically with MELAG Euroklav

®

, Vakuklav

®

and

Cliniklav

®

25),

Cooling water provision, electricity provision

Printer paper

Steam penetration test

For large steam sterilizers: Bowie&Dick test.

For small steam sterilizers of the class “B”: Helix test.

For small steam sterilizers of the class “S”: Follow manufacturer’s instructions.

For the MELAG Euroklav

®

, you can use a Bowie&Dick test on porous basis of e.g. 3M.

Background:

Daily routine inspection using a Bowie&Dick test is described in DIN 58946-

6:2002 (operating large steam sterilizers). The norm design for the operation of small steam

sterilizers is oriented around the norm for large steam sterilizers. Differing from this, for class “B”

autoclaves instead of the Bowie&Dick test, we recommend a Helix test according to EN 867-5.

Operating Manual MELAdoc label printer

5

Documentation of the batch clearance

Batch clearance assesses and documents the success of the sterilization procedure.

Assessing the success of the process

The success of the sterilization procedure is assessed using the protocol print out, the

autoclave display or a software output.

A log print-out requires written evaluation. The print-out can be signed or a label can be

affixed to the rear side.

Controlling the batch indicators added

The use of an indicator system increases process reliability. The MELAcontrol

®

Helix

test body can be used as a batch indicator for class “B“ autoclaves or large steam

sterilizers.

Batch indicators

can increase reliability.

For further validation of the success of the

sterilization procedure we recommend adding batch indicators (e.g. MELAcontrol). The

impossibility of making a certain prediction of the likely appearance of a successfully

coloured indicator after five or more years (return discolouration), means that it is

necessary to make a written record of the successful colour change. It is not necessary to

store the indicators.

Documentation of the (daily) procedure clearance in the batch control sheet, consisting of

label, entry and signature.

Labelling and clearance of the sterilized equipment

Every sterilization package must be controlled and cleared after successful sterilization.

Visual control

The transparent sterilization packaging must be undamaged and dry. The container

must be closed securely or sealed with sterilization tape, so that any early opening

during the storage time can be recognized easily. Also check the labelling of the

container (information regarding the contents).

Controlling the treatment indicators

The treatment indicators on the transparent sterilization packaging or the sterilization-

tape used must have coloured successfully.

Labelling the sterile equipment

The sterile equipment is cleared by adding a label. It is possible that individual items

in a batch cannot be cleared e.g. due to damage to the individual transparent

sterilization packaging.

Operating Manual MELAdoc label printer

6

Storage

Loss of sterility

is dependent less on the length of the storage time as from external

influences during storage, as well as transport and handling. When opening the

packaging, dust and microorganisms deposited on the packaging during the storage

time can fall on the instruments, thus contaminating them. An ideal storage time can

thus not be generally specified.

Specification

of a suitable storage time is to be taken from the hygiene plan.

Responsibility for the storage conditions and length rests with the practice operator.

Damage to the sterilization packaging

usually follows isolated events and is not a

factor of time. Primary and secondary packaging may only be opened immediately

prior to use. Remove all dust on the packaging before doing so.

Primary packaging

is the sealed packaging system surrounding the medical product

and holding it sealed from all germs (DIN EN 868-1:1997-05).

Secondary packaging

is the packaging containing one or more medical products,

each of which enclosed in its own primary packaging (DIN EN 868-1:1997-05).

Responsibility

for maintaining the specified storage requirements and times rests

with the facility operator.

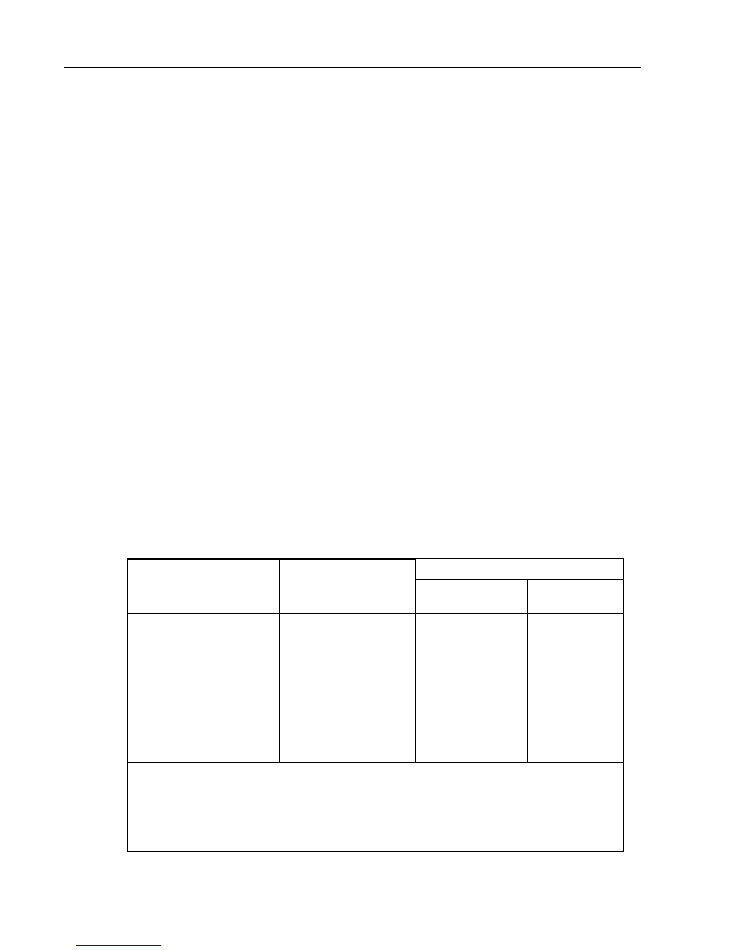

Storage length according to DIN 58953-8 from October 2003:

Storage period

Sterilized material

packaging

Packaging type

Unprotected

storage

1

Protected

storage

Paper bag in

accordance with DIN

EN 868-4 and heatable,

self-sealing transparent

bag and tubing of paper

and plastic composite

film in accordance with

DIN EN 868-5, or other

equivalent packaging.

Sterilized material in

primary or secondary

packaging

Serves provision

for immediate

use.

2

To be avoided

as method of

storage

6 months,

although no

longer than

expiry date

3

1)

On shelves in rooms which do not correspond with room class 1 as defined by DIN 1946-4

(Ventilation air conditioning) 1999-03, table 2

2)

Immediate use means application / use of the product within a maximum of 2 days / 48

hours.

3)

Experience has shown that exceeding the storage period when using this type of package

is not to be recommended for both practical and economical reasons.

Operating Manual MELAdoc label printer

7

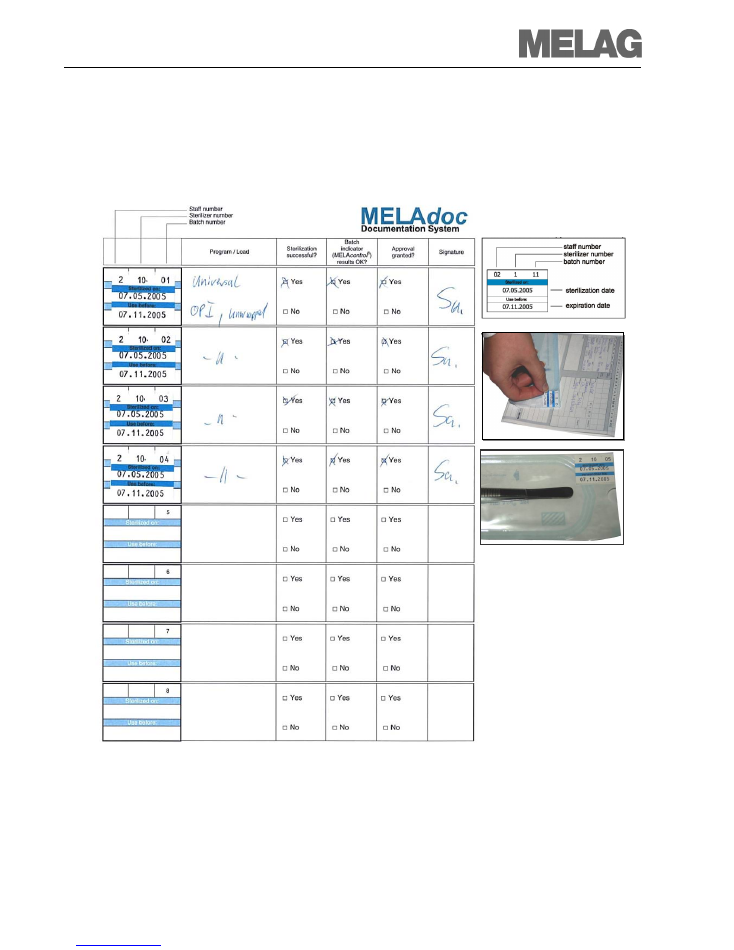

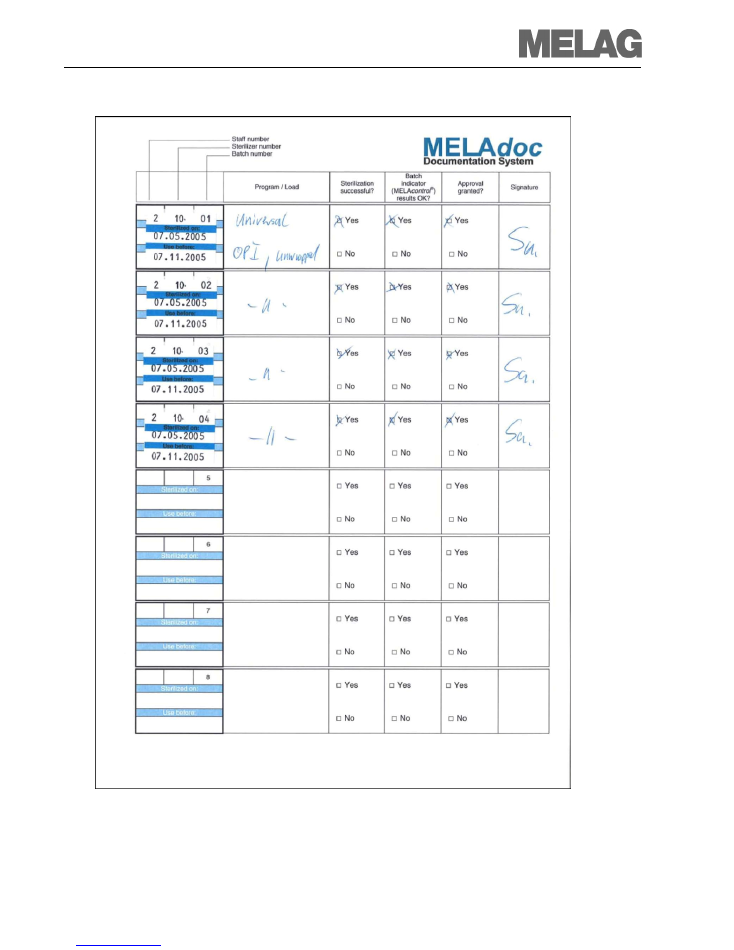

Chapter 2 – Batch documentation

Batch documentation completes the batch clearance.

The documentation in the batch control sheet is to be completed with a label, entries and a

signature. An unsuccessful clearance must also be documented.

Post-application documentation

After use of the medical product, the labels can be removed from the packaging and fixed to the

operation protocol or in the patient records. This enables traceability via the patient records from

the application to sterilization process.

Operating Manual MELAdoc label printer

8

Chapter 3 – Commissioning

Overview – Assembly of the label printer

E) Label printing

trigger

C) Label ejection

B) Release

button to open

A) Setting wheel for

setting date

D) Hinged top

section

Operating Manual MELAdoc label printer

9

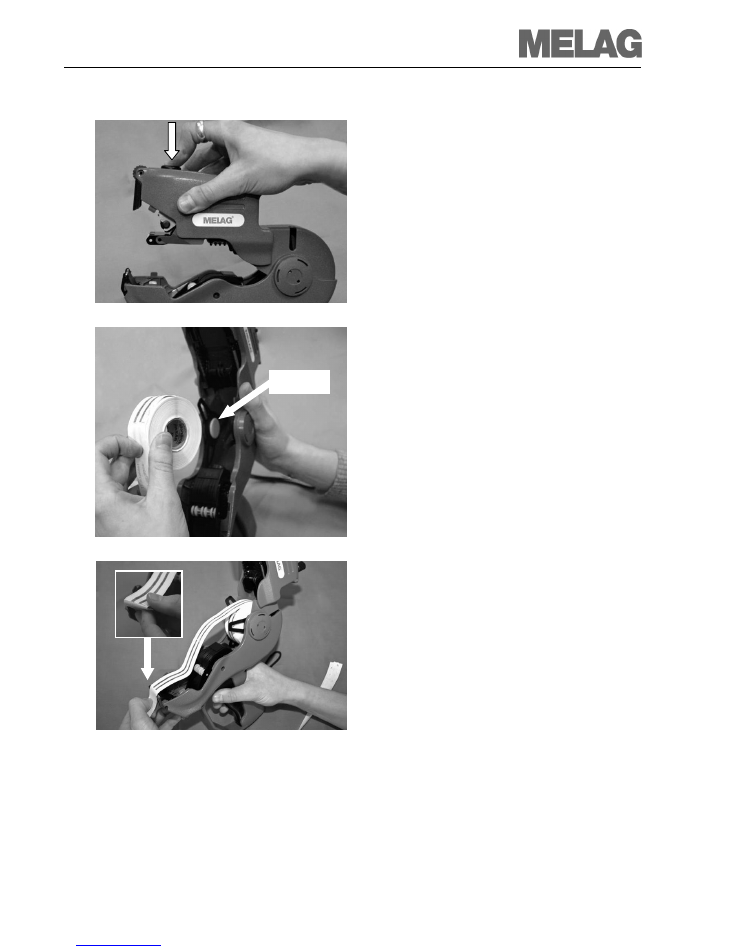

Inserting the label roll

Opening the label printer

Press the black release button (see page 8,

overview, B)) located on the housing and

open the upper section of the label printer

backwards.

Inserting the label roll:

1. Remove the new label roll from its

packaging; extend around 18 cm and

dispose of the first 12 labels.

2. Push the roll into the bracket until it clicks

into position.

3. Lay the free strip over the label guide and

extend it c. 15 cm. The first label on the

strip must finish directly on the guide. To

ensure an improved grip at this point, kink

the strip (see detail left) and hold it in

position whilst closing the top section.

bracket

Operating Manual MELAdoc label printer

10

4. Close the label printer. Ensure that the

strip is held in position so that it is not

pulled into the machine. This is important

to ensure faultless central pressure.

5. Kink the free end of the label strip

downwards.

This makes it easier to feed the free strip

into the label printer as will be described.

6. Guide the hanging strip below into the

opening of the lower shaft located

underneath the white guide roll (see

detailed diagram left) and push in as far

as is possible.

Operating Manual MELAdoc label printer

11

7. Press the trigger (page 8, overview, E)),

until the strip has been fully taken in and

has left the rear shaft (see diagram left).

The label strip may require feeding by

hand so that it is drawn in.

8. The first printed label issued from the

guide needs to be removed. It will have

been printed over several times.

The MELAdoc is now ready to print.

Removing jammed labels

1.

Open the MELAdoc (see page 9,

Opening the

label printer

) and pull out the label roll.

2. Remove all loose labels in the interior of

the label printer.

3. Open the label guide upwards and to the

left as shown in the diagram on the left. In

this way you can access and remove the

jammed labels.

4. Shut the label guide.

5. If necessary, use a standard label remover to remove adhesive residue.

6. The label roll can then be returned to the MELAdoc label printer.

Operating Manual MELAdoc label printer

12

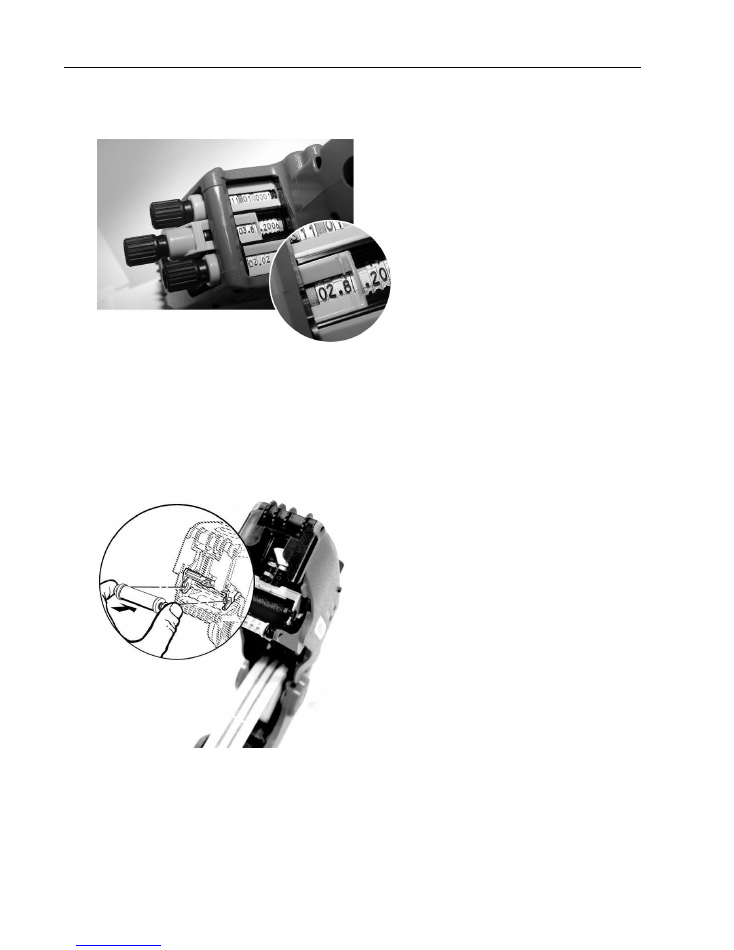

Setting the date

7. Pull out the setting wheel to change the personal number, date etc.

8. Move the marker (see detailed diagram) to the position to be changed. Turning the black

wheel sets the desired value.

9. After having set the value, return the wheel to its starting position.

Inserting the inking roller

Open the device to insert the inking roller

(see page 9,

Opening the label printer

)

1. Open the packaging of the inking roller and

remove it.

2. Hold the inking roller horizontal by its ends

as depicted.

3. Insert the inking roller in the bracket using

a little pressure until it clicks.

Note!

Do not touch the inking roller at any point

other than at its both ends. Otherwise, the

ink will colour.

Operating Manual MELAdoc label printer

13

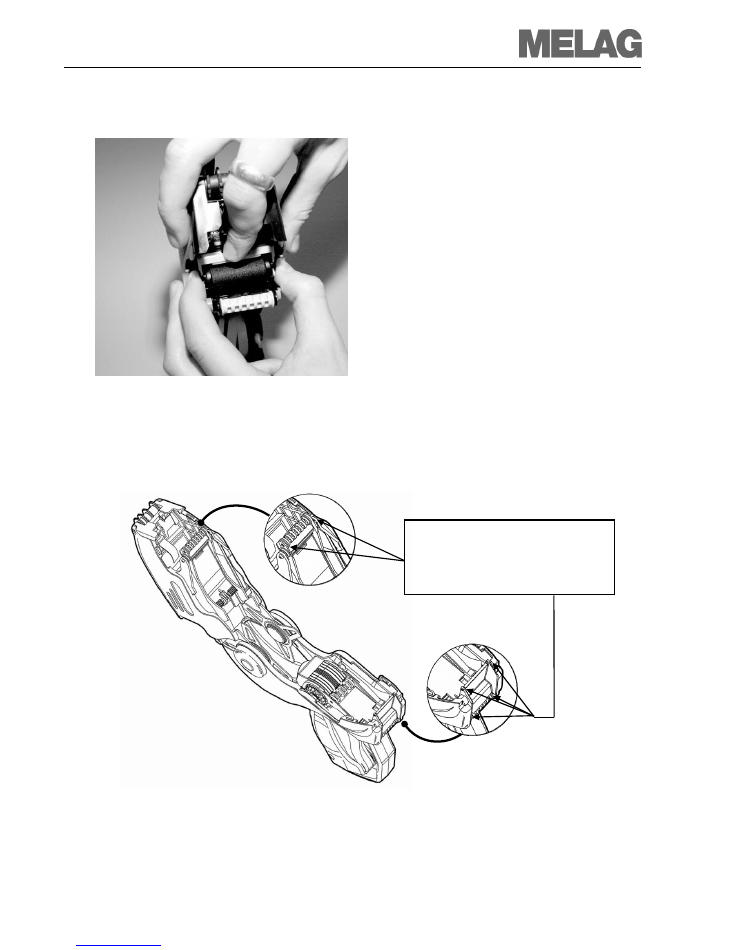

Removing the inking roller

Before removing the inking roller, it is

necessary to open the label printer.

1. Open the MELAdoc label printer as

described above.

2. Hold the inking roller by its ends as

depicted. Depress the lever-shaped

ejector button with the small arrow. This

releases the ends of the inking roller from

its anchoring and it can be removed.

3. The empty inking roller can be disposed

as domestic waste.

Maintenance:

To guarantee faultless functioning,

add a drop of standard silicone-based

lubricant at the locations indicated.

Operating Manual MELAdoc label printer

14

Measures for use - example

Operating Manual MELAdoc label printer

15

Operating Manual MELAdoc label printer

16

Glossary

Bowie&Dick test

Checks and simulates the steam penetration of a 7kg textile package. A load of this size is

usually not permitted for small steam sterilizers Moreover, experience shows that small

steam sterilizers are more often used to sterilize hollow articles than textiles. Of greater

practical relevance for hollow bodies is verification using a steam penetration test (Helix

test). The Helix test sets greater requirements for the autoclave than the Bowie&Dick test.

For the Helix-Test, MELAG recommends the

MELAcontrol

®

(Article No. 01080).

Vacuum test

In accordance with DIN 58946-6:2002, this test must be carried out for large steam

sterilizers on a monthly basis, as far as the manufacturer has not prescribed shorter test

intervals (e.g. daily). With small steam sterilizers, this test only serves the purpose of

trouble shooting when errors occur (e.g. upon a failed Helix test). As long as the

manufacturer has not issued any further specifications, the test should not be performed

on a daily basis.

Empty chamber sterilization

This procedure removes any condensate remaining in the steam conduits of a large

steam sterilizer from the previous day. This also serves to pre-warm the sterilizer.

Whether empty chamber sterilization is necessary is determined by the respective

manufacturer. MELAG autoclaves do not require empty chamber sterilization.

Indicators

The impossibility of making a certain prediction of the appearance (return discolouration)

of a coloured indicator (Helix test or Bowie&Dick test) after five or more years means that

it is necessary to make a written record of the successful colour change. It is not

necessary to store the indicators used.

Operating Manual MELAdoc label printer

17

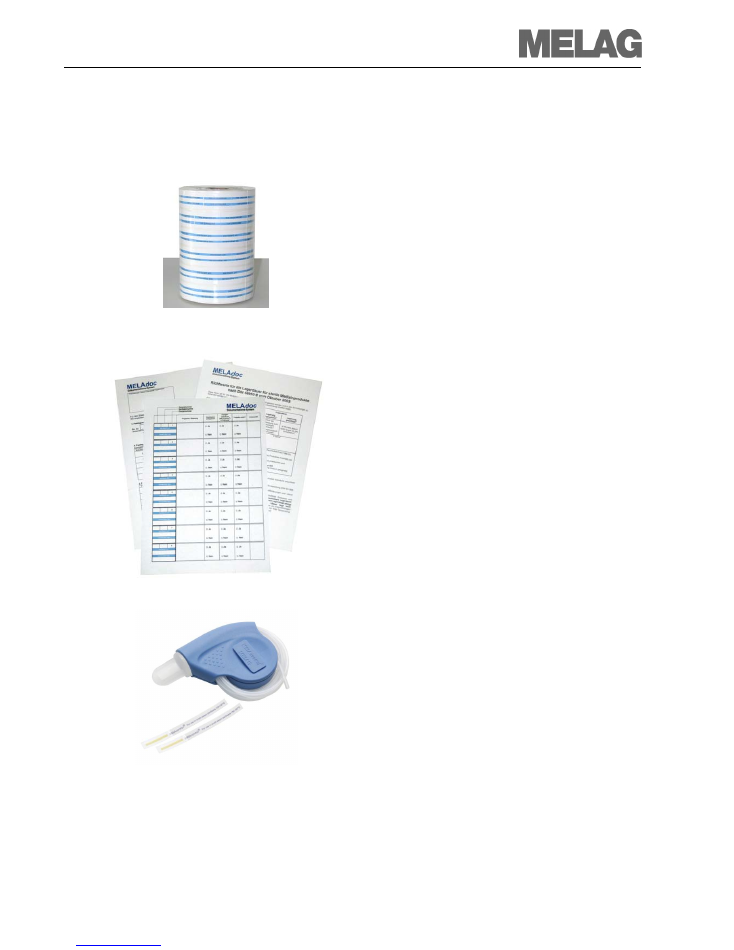

Appendix - Accessories

MELA

doc

labels

6 replacement rolls with 750 labels, including an

inking roller (Article No. 01096*).

MELA

doc

documentation sheets

1 block contains 100 sheets. We recommend

using a single sheet per day and per autoclave.

(Article No. 01091).

MELA

control

®

– Batch control system

MELAcontrol

®

is a test system for the purpose of

batch control and testing the functioning of the

fractionation of a pre-vacuum of a “class

B“ autoclave or a MELAG Cliniklav

®

25 in

accordance with EN 867-5.

The practice set consists of 1 test body (Helix)

and 250 indicator strips (Article No. 01080*).

* Exclusively available from a specialist stockist

www.melag.com