Full Text Searchable PDF User Manual

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

1

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

2

Quick Guide to Keycreator’s Sheet Metal Design Tools- Part 1

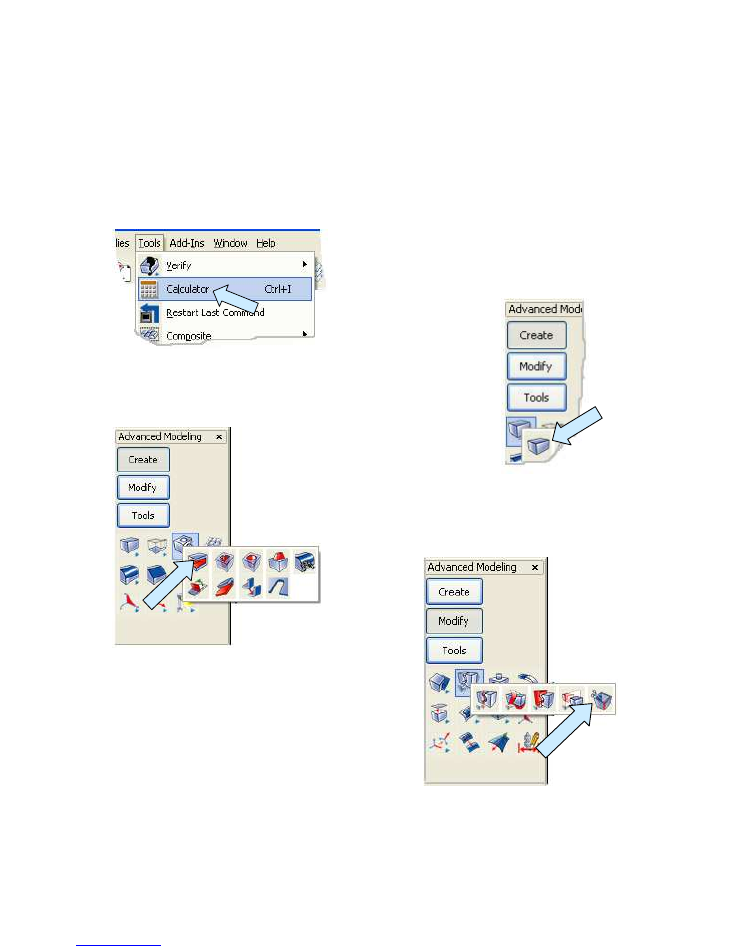

Many users are not aware of the sheet metal design capabilities in Keycreator. The

various tools are located in several different menu locations instead of in one common

palette, so I recommend that you create a special sheet metal toolbar to simplify your

work. If you are not familiar with creating a custom toolbar, I recommend that you use

my Tips and Tricks exercise on creating hot keys and toolbars or one of my books like

Doctor Walt’s Keycreator Workbook.

The first tool on the toolbar should be the

ONLINE CALCULATOR. You can find this in

the TOOLS Pulldown Menu.

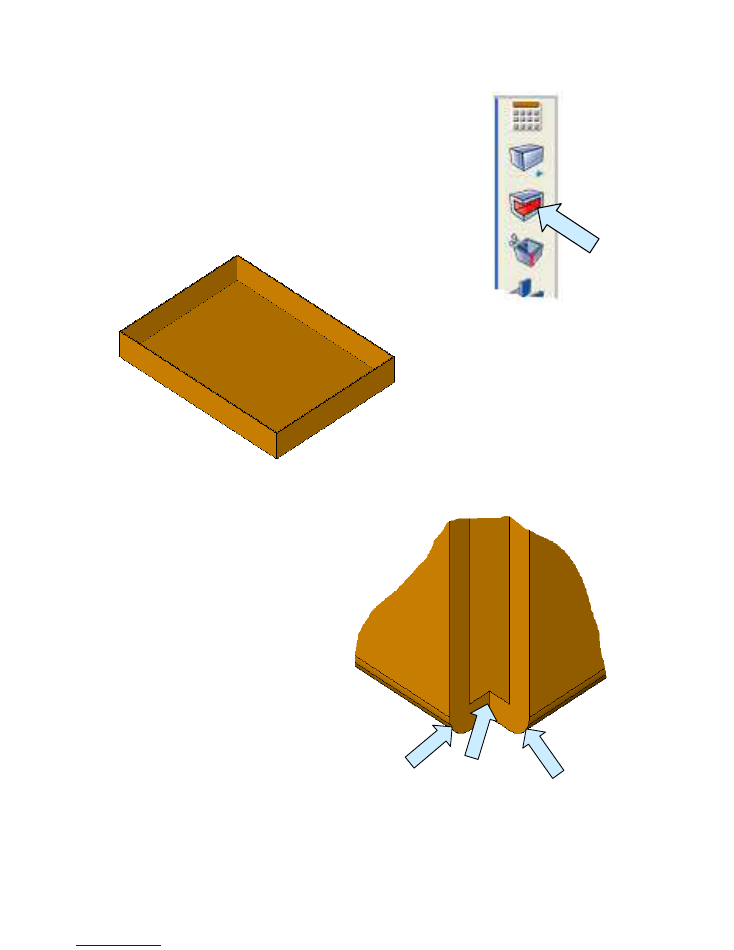

Next, I like to place the PRIMITIVE BLOCK Icon, since you

can start many sheet metal parts by making a basic plate or

volume that can be later shelled out.

The next useful tool is the SHELL Icon. You’ll

see in a moment how this comes in useful for

making sheet metal parts.

Now, drag the CUT SHEETMETAL CORNER

Icon onto your toolbar.

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

3

I place the four Icons labeled to the

right next on my toolbar, starting

with the AUTO BEND CORNER

Tool.

Next I place the CREATE

FLANGE Icon, then the ADD

SHEETMETAL BEND and then

the CREATE BEND RELIEF Icon.

Next, drag the EDIT SHEETMETAL

BEND and UNBEND ALL Icons onto the

toolbar.

Let’s also drag the SCRIBE FACE Icon onto the

toolbar.

ADD

SHEETMETAL

BEND

CREATE

FLANGE

AUTO

BEND

CORNER

CREATE

BEND

RELIEF

UNBEND ALL

EDIT

SHEETMETAL

BEND

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

4

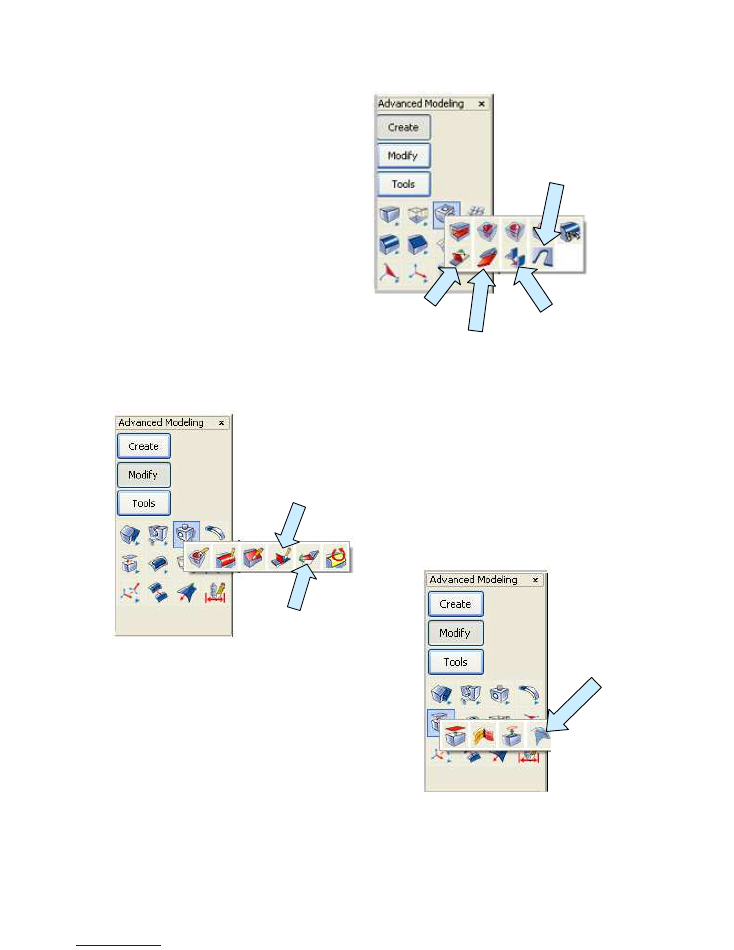

Finally, add the EXTRUDE FACE Icon to

complete the set of tools.

Your final toolbar should look like the one

illustrated below. You might want to reorient

it as a vertical toolbar and dock it at the right

side of your screen.

Now you can certainly create your own toolbar with a different collection of Icons. You

might argue that functions like the EXTRUDE FACE and ONLINE CALCULATOR

don’t belong on this toolbar since they are not purely specifically sheet metal tools. My

purpose is to give you all the tools you need to do teetotal design work all in one easy to

find place. This toolbar is available for download as part of this exercise.

Let’s see how this works

with a few simple examples.

We’ll start with the simple

teetotal case shown to the

right. The finished part is

available as design file

“metalcase01.”

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

5

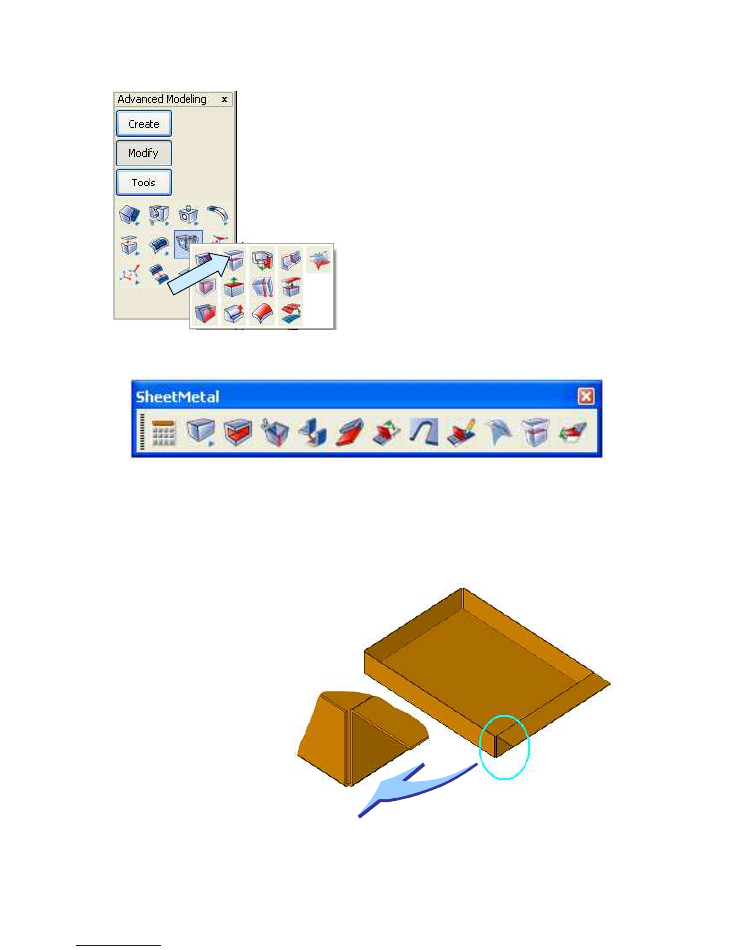

Start with a new file in view 1. Click on the ONLINE

CALCULATOR Icon and type “t = 0.032” to assign a value of

0.032 as the sheet metal thickness in this file.

Next, click on the BLOCK Icon.

A Dialog Box appears.

Use the Key In Option and type 8 for the width, 6

for the length, and 1 for the height.

Use the cursor option to place the file anywhere on

the screen.

Now, switch to the Isometric View and

Autoscale the display.

Your part should look like this.

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

6

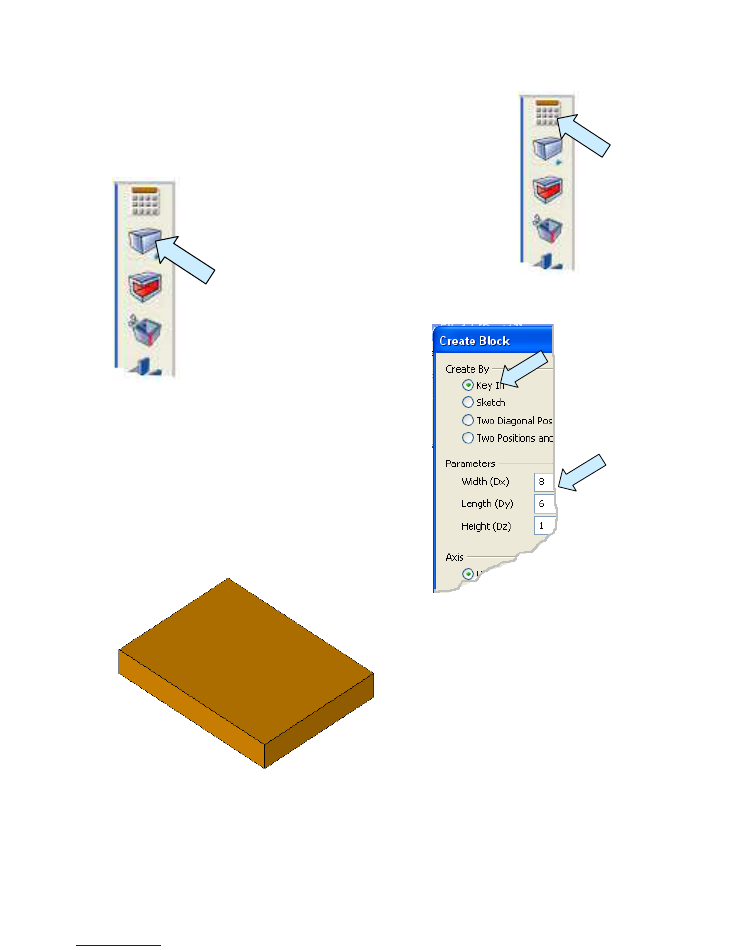

Next, click on the SHELL Icon.

When the Dialog Box appears, type “t” for the shell thickness.

Use the Select Faces to be Opened Option and click on the

OK Button.

Then, select the top surface of the block.

When the shelling operation is

completed, your part should look

like this:

Now what we have is fine as a

conceptual model of the part.

However, it does not represent a sheet

metal fabricated part for two reasons.

First, the bends at the bottom edges are

not sheet metal bends and second, the

corners are closed as though it were

molded from a piece of plastic.

I’ve illustrated what we want to

achieve in the enlarged view to the

right. (Note: In actual practice we use

a much smaller corner rip. I’ve made

this one large so you can see what is

going on.)

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

7

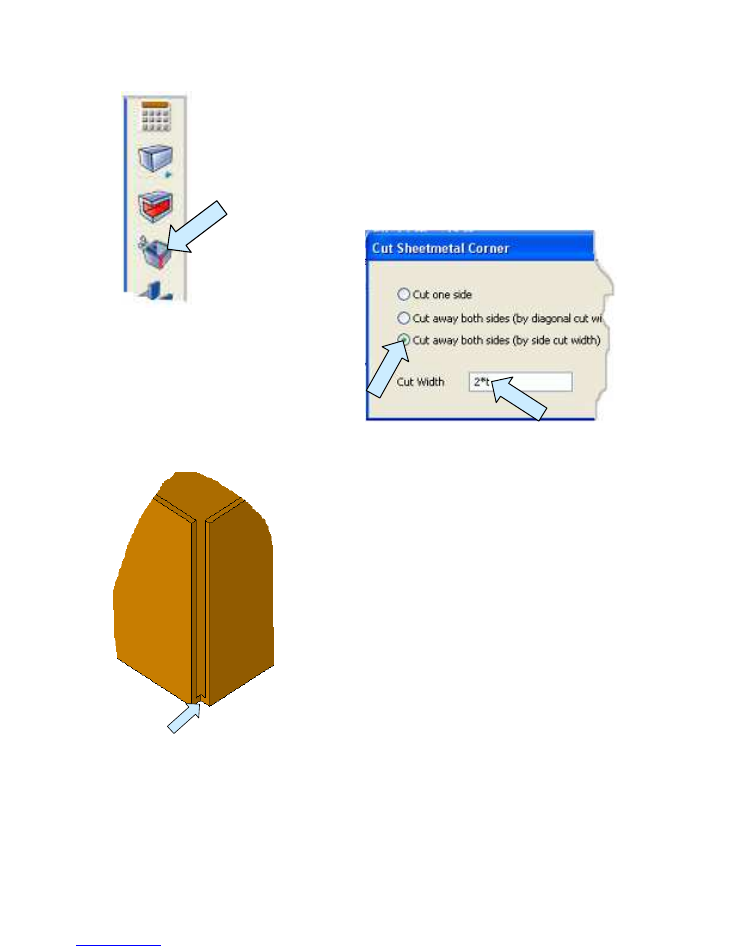

Let’s rip the four vertical corners first. To do this, click on the

CUT SHEETMETAL CORNER Icon.

A Dialog Box appears. Click on the

Cut Away Both Sides Option.

Then, type “2 * t” in the Cut Width

Field. Keycreator will automatically

calculate 2 times the sheet metal

thickness that you enter in step one of

this exercise.

Now, click on each of the vertical corners. (Don’t worry

about whether you are picking the inner or outer corner.

It doesn’t matter!)

Your part will now have ripped corners that look like

this:

Our next step is to fix the four bottom bends on the part.

You’ll notice that the inside and outside corners are both

sharp. For Keycreator to handle unbending this part,

these four corners must be replaced with true sheet metal

corners.

Although many sheet metal designers work with nominal zero radius bends on the inside

corners of parts, Keycreator requires just a small radius here to make everything work.

We’ll use 0.0001 for our exercise.

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

8

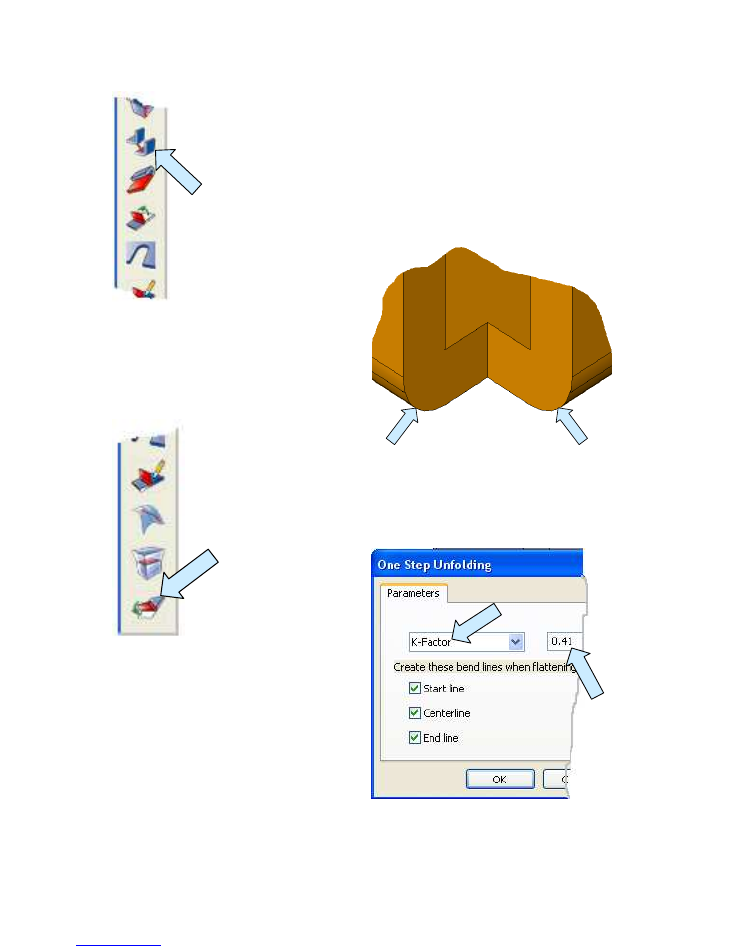

Click on the AUTO BEND CORNER Icon.

You are prompted for a radius value. Type 0.0001 and hit the

ENTER Key.

Now, click on each of the bottom corners on the part. (Again, don’t

worry about inner versus outer edge. Keycreator is smart enough to

know what you want!)

The bottom of your part will now have

true sheet metal bends.

Now, to create the flat development for the part, click on the

UNBEND ALL Icon.

A Dialog Box appears. Select the K-

Factor Option and type 0.41 for the value.

Then, click on the OK Button.

Dr Walt’s Quick Guide to Keycreator Sheet Metal Tools- Part 1

9

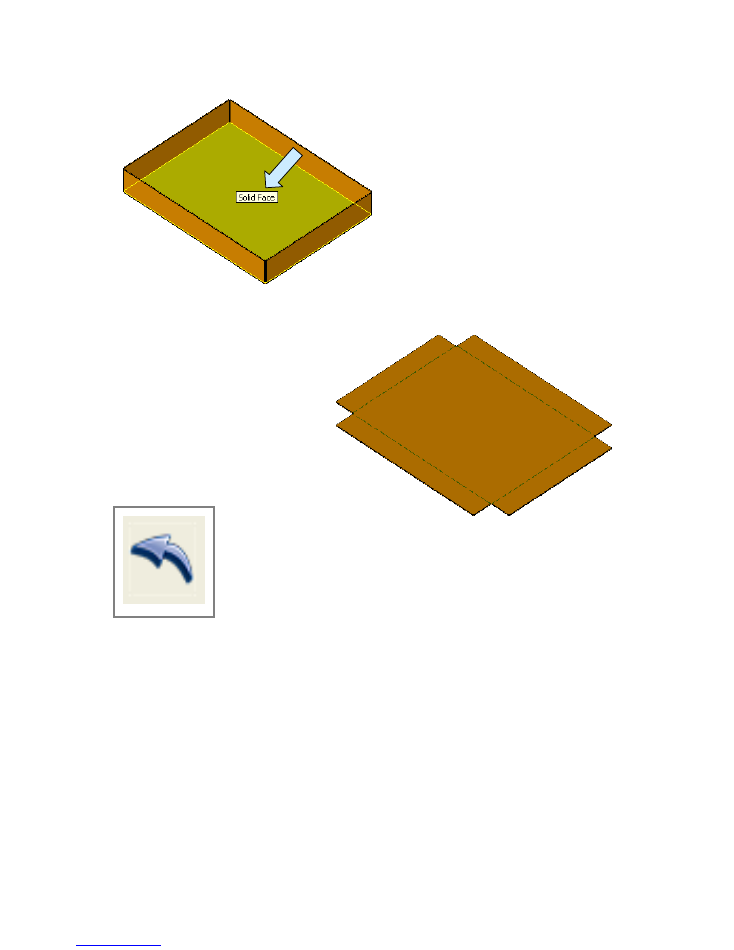

You are prompted to select a surface to

unfold from.

Click on the broad, inside surface of

the part.

The flat development is created on

the screen.

You can click on the UNDO Icon to revert to the folded part.

This ends Part 1 of our exercise. In an upcoming Tips and Tricks we’ll explore more neat

sheet metal operations, so save your sheet metal toolbar for future use!