Full Text Searchable PDF User Manual

KORG KP3

SERVICE MANUAL

TABLE OF CONTENTS

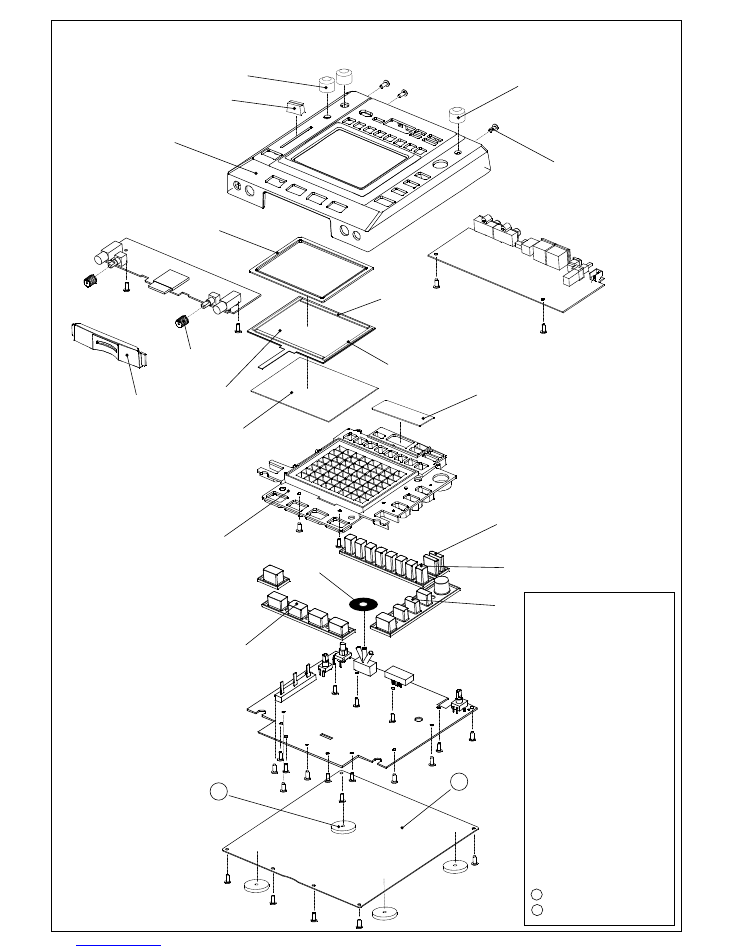

ASSEMBLY SKETCH (HOOKUP): 2

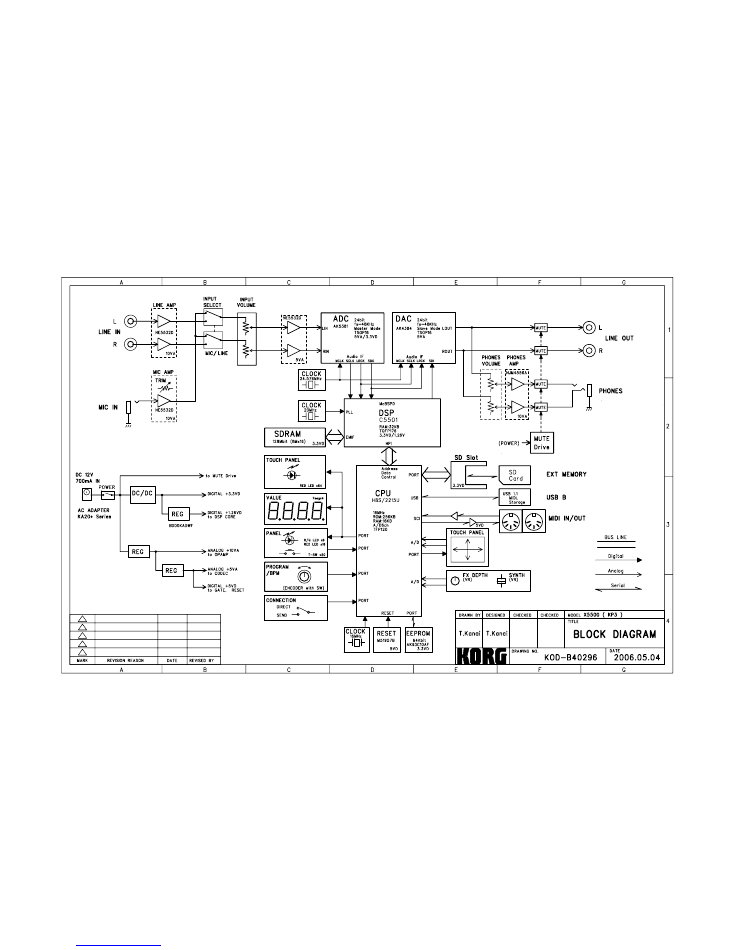

BLOCK DIAGRAM:

3

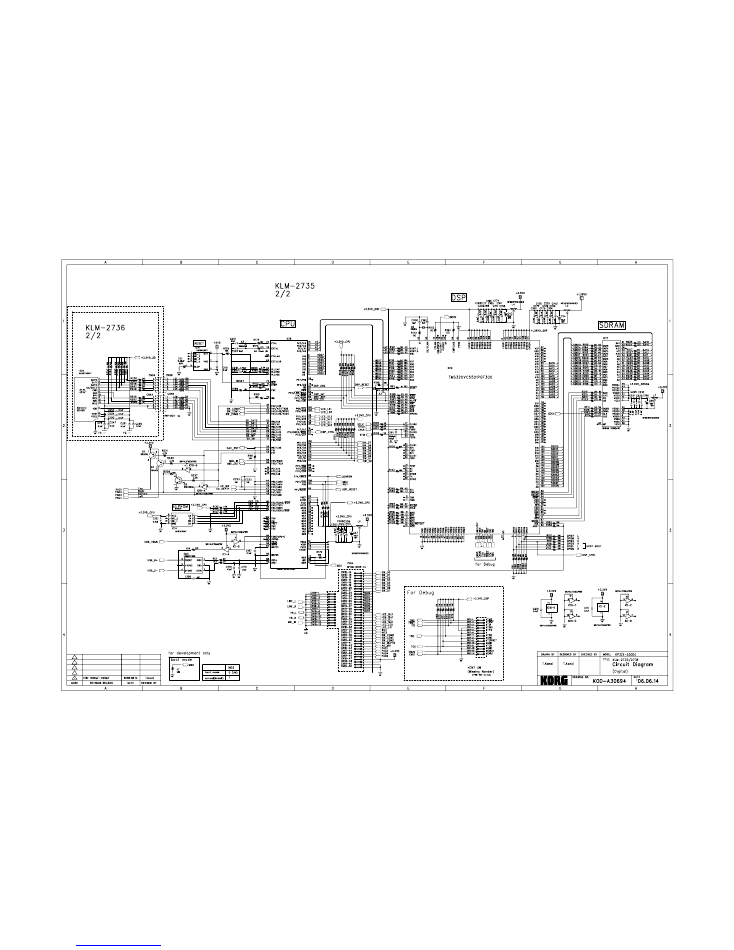

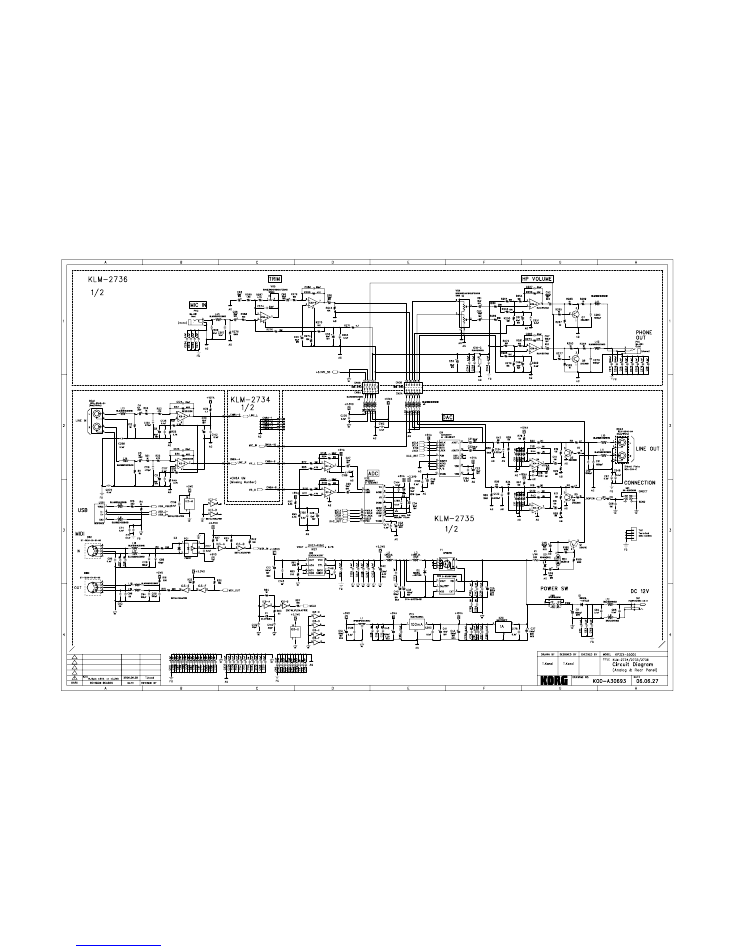

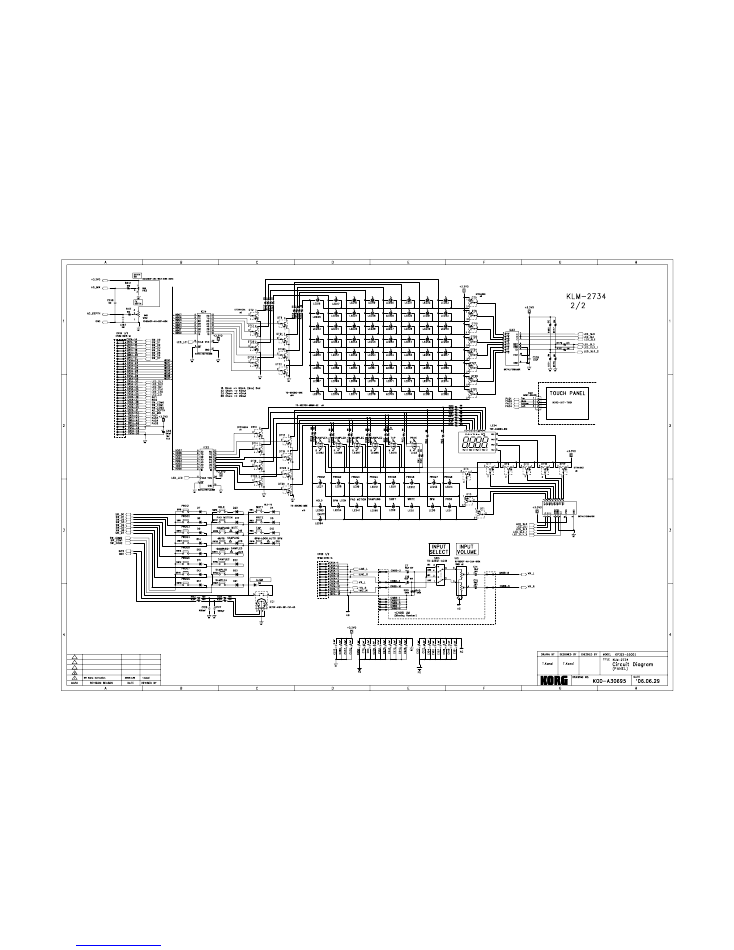

SCHEMATIC DIAGRAM: 4-6

TEST MODE: 7-10

PAD CALIBRATION: 11-12

PARTS LIST: 1

3

-1

4

Issued

Nov.6

, 2006

Ver.

2 Changed P11

Added Pad Cal 3/13/08 - GA

X-5500 Hookup

①

②

③

④

⑤

⑥

⑦

⑩

⑧

⑨

⑪

⑫&⑬

⑭

⑮

⑯

⑰

⑲

⑱

⑳

21

22

①:

UPPER CASE

②:

SLIDER KNOB

③:

VR KNOB

④:

ENCODER KNOB

⑤:

BTB 3BBC 3

×

8

⑥:

PAD FRAME

⑦:

SPONGE SEAL A

⑧:

SPONGE SEAL B

⑨:

TOUCH PANEL

⑩:

VR KNOB(2Color)

⑪:

SD FRAME

⑫:

SUPPORT PLATE

⑬:

SHEET

⑭:

WINDOW

⑮:

LED FRAME

⑯:

RUBBER KEY 1

⑰:

RUBBER KEY 2

⑱:

RUBBER KEY 3

⑲:

RUBBER KEY 4

⑳:

SWITCH MASK

:

URETHANE LEG

:

BOTTOM PLATE

21

22

R86 68Ω→33Ωに変更

2006.7.25

T.Kanai

KORG KP3 TEST MODE

2006.8.30 KORG PD3 T.Kanai

How to enter the simple TEST MODE

English by M.Y.

Pushing following switches, and turn

the

power ON.

CONNECTION[SEND] & [7] + [TAP/RANGE]

: Skipping the Audio Loop Back Inspection and the USB check

CONNECTION[SEND] & [5] + [TAP/RANGE]

: Skipping the MIDI Loop Back inspection and the USB check.

Other test modes for repairing

Pushing following switches, and turn

the

power ON.

CONNECTION[SEND] & [1] + [TAP/RANGE]

: Skipping the Audio Measurements and PAD surface inspection

CONNECTION[SEND] & [2] + [TAP/RANGE]

: Audio Measurement only

CONNECTION[SEND] & [3] + [TAP/RANGE]

: PAD all surface inspection only

CONNECTION[SEND] & [4] + [TAP/RANGE]

: Full inspection (Internal and External)

CONNECTION[SEND] & [6] + [TAP/RANGE]

: External inspection

[TAP/RANGE] + [SAMPLING]

: Display of System Version

[1] + [2] + [SAMPLING]

: Load the Preset

[SAMPLING] + [SAMPLE BANK C] + [SAMPLE BANK D]

: IPL Mode

Functions of switches

[TAP/RANGE]

: Step Up (When an error occurred in the internal inspection, retry the inspection.)

[SAMPLE BANK A]

: Step + (Move within the item)

[SAMPLE BANK B]

: Step - (Move within the item)

[SAMPLE BANK C]

: Item Number Up

[SAMPLE BANK D]

: Item Number Down

[SAMPLE BANK A] + [TAP/RANGE]

: When an error occurred in the internal inspection, skip the inspection

Error Code

KP3 displays the Error Code in the LED, when an error occurred in the internal inspection.

4 digits of the LED indicates the error code.

[Er.**]

* (Ten's digit) : Item number (item of the internal inspection)

* (One's digit): Test number( In the internal inspection)

Item

1. DSP IF Check

Notice: When the start-up condition or the forwarding between CPU <-> DSP is NG,

2. DSP - SDRAM Check

KP3 cannot start the test mode, because after the forwarding the Boot code,

3. CPU ROM Check

KP3 moves to the self check sequence (TEST MODE).

4. EEPROM Check

5. Loop Back Check (Audio)

6. MIDI Loop Check

7. Card Check

8. USB Check

*USB check needs a special computer, so skip by [SAMPLE BANK A] + [TAP/RANGE]

when an error occurred in the inspection.

*

Initial Settings

Set the volumes and the switches like followings.

CONNECTION

: SEND

INPUT Select

: LINE

INPUTVR

: MAX

→

Fx Depth

: MIN

→

Slider

: MIN (0)

→

PHONES VR

: MAX

MICTrim:MAX

: MAX

SD Card

(

Protect OFF)

(Caution:) Use the AC Adaptor of KA-20*series

Internal Inspection

1. DSP IF Check

When an error occurred, the inspection stops displaying [Er.11]-[Er.13] in the LED display.

2. DSP SDRAM Check

When "Data Error", the inspection stops displaying [Er.22] or [Er.23] in the LED display.

When "Address Error", the inspection stops displaying [Er.21] in the LED display.

3. CPU ROM Check

When "Checksum Error", the inspection stops displaying [Er.31] in the LED display.

Connection for the automatic inspections

Cable

MIDI OUT

MIDI IN

MIDI cable

LINE OUT L

LINE IN L

RCA cable

LINE OUT R

LINE IN R

RCA cable

4. EEPROM Check

When "Verify Error", the inspection stops displaying [Er.41] in the LED display.

5. OVER LOAD Line Check ( Audio LoopBack )

<<<In the simple TEST MODE, you can skip this.>>>

a: OUTPUT Lch(LINE IN (Rch: GND Level)

Connect the LINE OUT(L) to the LINE IN(L), when the level of the LINE IN(L) is out of the decided range,

the inspection stops displaying [Er.51] in the LED display.

Connect the LINE OUT(L) to the LINE IN(L), when the level of the LINE IN(R) is more than the decided level,

the inspection stops displaying [Er.52] in the LED display.

b: OUTPUT Rch(LINE IN (Lch: GND Level)

Connect the LINE OUT(R) to the LINE IN(R), when the level of the LINE IN(R) is out of the decided range,

the inspection stops displaying [Er.53] in the LED display.

Connect the LINE OUT(R) to the LINE IN(R), when the level of the LINE IN(L) is more than the decided level,

the inspection stops displaying [Er.54] in the LED display.

(Caution) *1 Before the internal inspection, connect LINE OUT(L) to LINE IN(L), LINE OUT( R )to LINE iN ( R ) by two cables.

*2 Set INPUT VOLUME at MAX, INPUT SELECT (toggle) is LINE side.

6. MIDI Loop Check

<<<In the simple TEST MODE, you can skip this.>>>

When KP3 cannot receive the Data, the inspection stops displaying [Er.61] in the LED display.

During receiving the data when KP3 could not receive some data, the inspection stops displaying [Er.62] in the LED display.

When the received data is different value, the inspection stops displaying [Er.63] in the LED display.

(Caution) *3. Connect MIDI IN and MIDI OUT by a MIDI cable, before the internal inspection.

7. Card Check

After [C.Ins] is appeared in the LED display, insert a SD card.

When a SD card is not inserted and KP3 could not detect that a card is not inserted, [Er.71] is displayed in the LED.

After inserted a SD card and remove your hand from the card, then confirm that the card is rocked.

When KP3 could not detect that a SD card is inserted, [Er.72] is displayed in the LED.

When KP3 could not write or read the data, [Er.73] is displayed in the LED.

When the inspection has completed as OK, [C.Pul] is displayed in the LED, then pull out the SD card.

(Caution) *4 Use the SD card as protect OFF.

*5 Do not insert the SD card before [C.Ins] is displayed in the LED.

8. USB Check

<< Skip this inspection>>

* The special computer is needed for this inspection, so skip by [SAMPLE BANK A] + [TAP/RANGE].

* Errors are displayed as [Er.8*], ignore these errors.

9. All LEDs light

a. Confirm that all LEDs light.

All LEDs except followings light. : LEDs(8x8) of PAD, 7segments LED[8888], [SMPL]SW

LED of two colors are followings

.:PEAK, [TAP/RANGE]

、

[SAMPLE BANK A], [SAMPLE BANK B], [SAMPLE BANK C], [SAMPLE BANK D]

Confirm that there is not the uneven brightness, and that there is not slanted LED.

After the confirmation, push [TAP/RANGE] , then the inspection proceeds to 10 External Inspection.

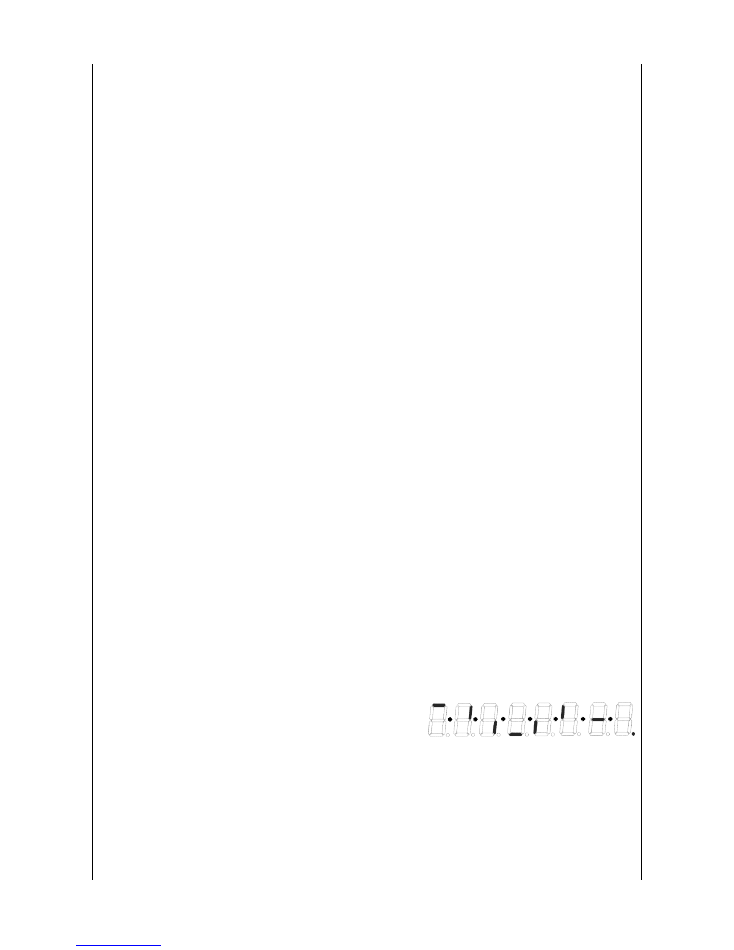

10. 7 Segments LED, segments light one by one.

For each digit, segments light one by one like the right figure.

After confirmation of the four digits, push [TAP/RANGE] SW and proceed

to next inspection.

(Caution) *6. You need all digit's inspection to proceed to the next inspection.

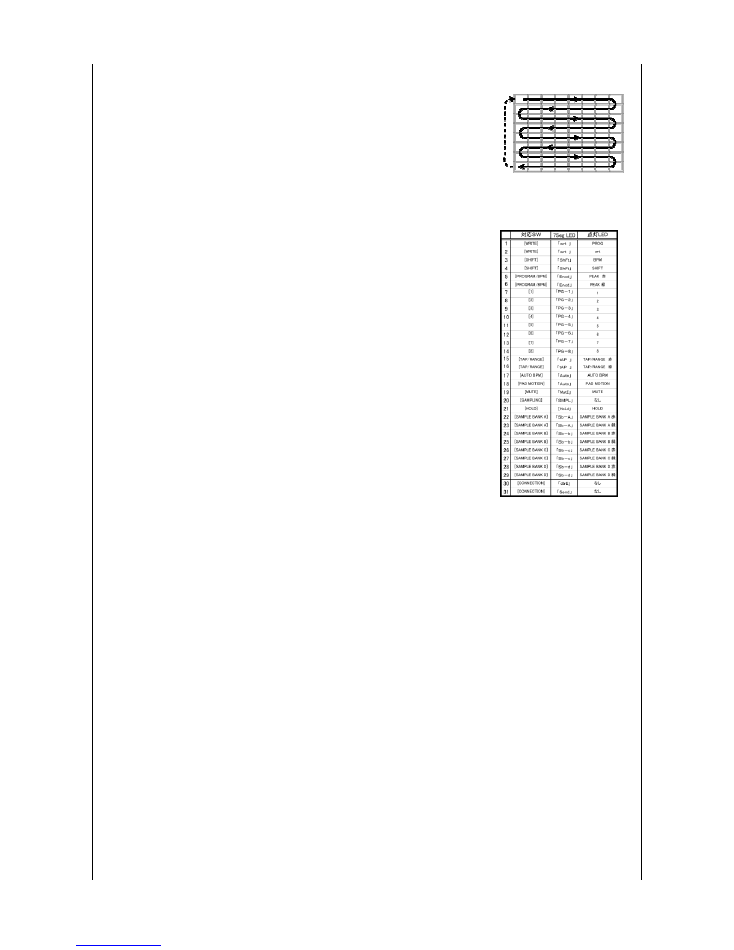

11. PAD LEDs, LEDs light one by one.

LEDs light one by one, from upper left-upper right-next right-next left-

like the right figure.

Push [TAP/RANGE] to proceed to next inspection.

(Caution) *7 You need one cycle of inspection to proceed to the next inspection.

12. Switch & LED Check

*In the 7segments LED, the switch you should push at first is displayed.

{wrt] is displayed in the LED.

*Proceed the inspection as following order.

*When the waiting for pushing the switch, the switch which should be push is displayed in the LED,

and LED lights which is corresponding the switch.

*After switch's inspection, next is inspection of the [CONNECTION]SW.

[dIrE] is displayed in the LED, set [CONNECTION]SW to "DIRECT".

[Send} is displayed in the LED, set {CONNECTION]SW to "SEND"

(Caution) *8 Confirm that the indicated LED lights in the indicated color. (No indication is red.)

*9 When other wrong) switch is pushed or plural switches are pushed, LED blinks.

*10 [SAMPLING]SW has no LED, so it does not light and {SMPL] is displayed in the LED.

*11 [CONNECTION]SW has no corresponding LED, so it is only in the 7 segments LED display.

13. Encoder Check

[Enc.0] is displayed in the LED.

Pull out the knob, adjust the shaft of the Encoder(PROGRAM/BPM) at the start position.

After adjusting, push {TAP/RANGE]SW then [ 0} is displayed in the LED display.

a. Encoder right

Rotate the encorder to the right one cycle.

After one rotation, confirm [ 30] is displayed. Then push [TAP/RANGE] to proceed to next step.

After one rotation, [ -30] is displayed or other display than[ 30] is displayed, it is NG.

During rotation,

[5]LED lights, at 1/4 position

[5],[6] LEDsi light at 2/4 position

[5],[6],[7] LEDs light 3/4 position

When passed even if one click, [5],[6],[7],[8] LEDs turn OFF

[5],[6],[7],[8] LEDs light after one rotation Rotate left and the display is less than 30, the corresponding LED lights.

b. Encoder left

Rotate the encorder to the left one cycle.

After one rotation, confirm [ 30] is displayed. Then push [TAP/RANGE] to proceed to next step.

After one rotation, [ -30] is displayed or other display than[ 30] is displayed, it is NG.

During rotation,

[4]LED lights, at 1/4 position

[4],[3] LEDs light at 2/4 position

[4],[3],[2]LEDs light 3/4 position

When passed even if one click, [4],[3],[2],[1 LEDs turn OFF

[4],[3],[2],[1] LEDs light after one rotation Rotate left and the display is less than 30, the corresponding LED lights.

Confirm that there is no rubbing or feeling of not smooth when rotation.

14. FX DEPTH Check

[FX.dP] is displayed in the LED display.

Rotate FX DEPTH to the left end, all LEDs of [1]-[8] are OFF.

Rotate FX DEPTH to the right, [1], [2], [3], [4], [5], [6], [7], [8] LEDs turn ON (increasing one by one),

and at the right end all LEDs of [1]-[8] turn ON. Rotate to the left, LEDs turn OFF one by one (decreasing).

After finished, inspection proceeds to next.

PROG [WRITE]

→

WRITE [WRITE]

→

BPM [SHIFT]

→

SHIFT [SHIFT]

→

PEAK

赤

[PROGRAM/BPM]

→

PEAK

緑

[PROGRAM/BPM]

→

1 [1]

→

2 [2]

→

3 [3]

→

4 [4]

→

5 [5]

→

6 [6]

→

7 [7]

→

8 [8]

→

TAP/RANGE

赤

[TAP/RANGE]

→

TAP/RANGE

緑

[TAP/RANGE]

→

AUTO BPM [AUTO BPM]

→

PAD MO

SWITCH | 7SEG-LED | LED lights

RED

GREEN

RED

GREEN

R

G

R

G

R

G

R

G

Confirm that there is no rubbing or feeling of not smooth when rotation.

After the confirmation, proceed to next inspection.

15. LEVEL (Slider) Check

[SLdr] is displayed in the LED display.

Push [TAP/RANGE] to start the inspection.

Move LEVEL slider from MIN(lowest)->MAX(highest)->MIN(lowest)

At MIN(lowest) position, all LEDs of [1]-[8] are OFF.

Move to MAX(highest), [1], [2], [3], [4], [5], [6], [7], [8] LEDs turn ON (increasing one by one),

At MAX(highest) position all LEDs of [1]-[8] turn ON.

Move to MIN(lowest), LEDs turn OFF one by one (decreasing).

Confirm that there is no rubbing or feeling of not smooth when moving.

After the confirmation, proceed to next inspection.

16. Touch PAD Check

[Pd.1 ] is displayed in the LED display.

One LED upper left turns ON, push this part by your finger then [P_1 ] is displayed in the LED then remove the finger from the PAD.

The next LED turns ON.

[P2. ] is displayed in the LED display.

4 LEDs of upper left turn ON, push the center of these then [P_2 ] is displayed in the LED. then remove the finger from the PAD.

[P3. ] is displayed in the LED display.

One LED lower right turns ON, push this part by your finger then [P_3 ] is displayed in the LED then remove the finger from the PAD.

After removing the finger from PAD, inspection proceeds to next.

17. Touch PAD Calibration

Complete steps 2 & 3 of "Calibrating the Touch Pad" on the next page; or p

ush [SAMPLE BANK D]

to

skip this item.

18. Inspection of the PAD surface.

After audio measurement, push [SAMPLE BANK D] then [Pd.2 ] is displayed in the LED and start the inspection of the PAD surface.

When you touch the PAD, KP3 sounds.

Stroke slowly all the surface of the PAD and confirm that the frequency of the sound does not change.

When the sound changed to high frequency sound, the inspection is NG

because other part than the part you touch is pushed.

When stroking the PAD, confirm that there is not strange feeling.

Confirm that sound stops when you remove the finger from the PAD.

The inspection is NG when the sound does not stop after removed from the PAD.

Confirm that there are no dusts and etc. on the surface and beneath the PAD.

19.Preload

Move the {CONNECTION]SW to "DIRECT" to the status of waiting for the preload.

[PrLd] is displayed in the LED display, pushing [SAMPLE BANK A] sw and push [TAP/RANGE] to execute the preload.

After finished preload, KP3 restarts in normal operation and [LOAd] in the LED display changes to [FLE.1].

[FLE.1] is not displayed in the LED display after few while the preload is failed.

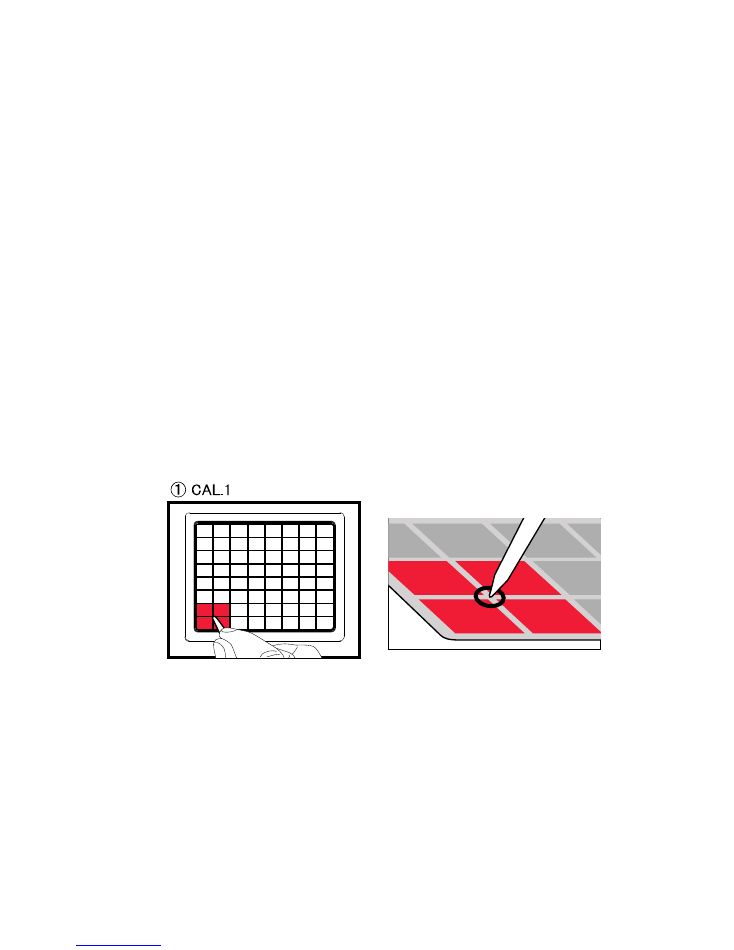

Calibrating the Touch Pad

Depending on the operating environment, the touch pad segments that light when the

pad is pressed might be out of position. When this happens, the following steps should

be taken to re-calibrate the touch pad.

Please use a plastic pointing device such as a PDA stylus or a gaming device touch pen.

using a sharp or metallic object will risk damaging the touch pad surface.

1.

Turn on the power while pressing the PROGRAM MEMORY 7, PROGRAM

MEMORY 8 and [SAMPLING] buttons.

"CAL.1" should appear on the display and the four bottom left touch pad segments

should light up.

2.

Using the pointing device, lightly touch the centre of the four lit segments where

the grid lines cross as shown in the diagram below.

!NOTE! do not move the pointing device from this position while the pad is touched.

After touching this point for a short while, the calibration will move onto the next

step: the next set of four segments will light and the display should read “CAL.2”.

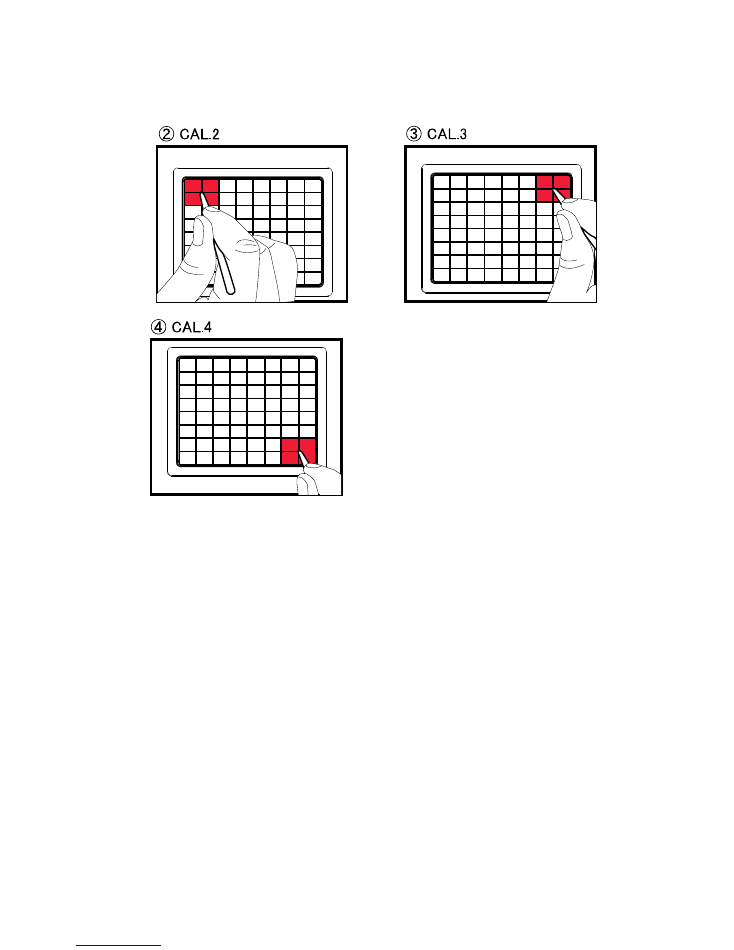

3.

Remove the pointing device from the touch pad and repeat for the next position

indicated by the segment lights.

Complete all four steps as shown in the following diagrams.

4.

After completing the four steps, the touch pad lights will go out and "P.oFF" will be

displayed.

!NOTE! do not turn the power off until "P.oFF" is displayed.

5.

The unit is now re-calibrated. Turn the power off and on as usual and confirm that

the KP3 operates correctly.

1 / 2

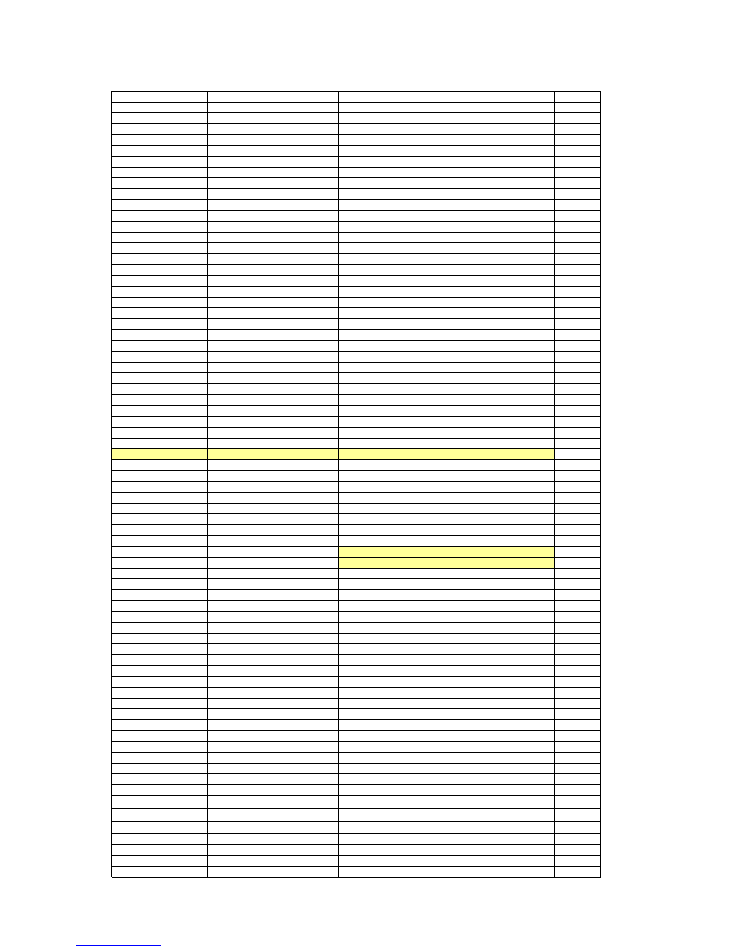

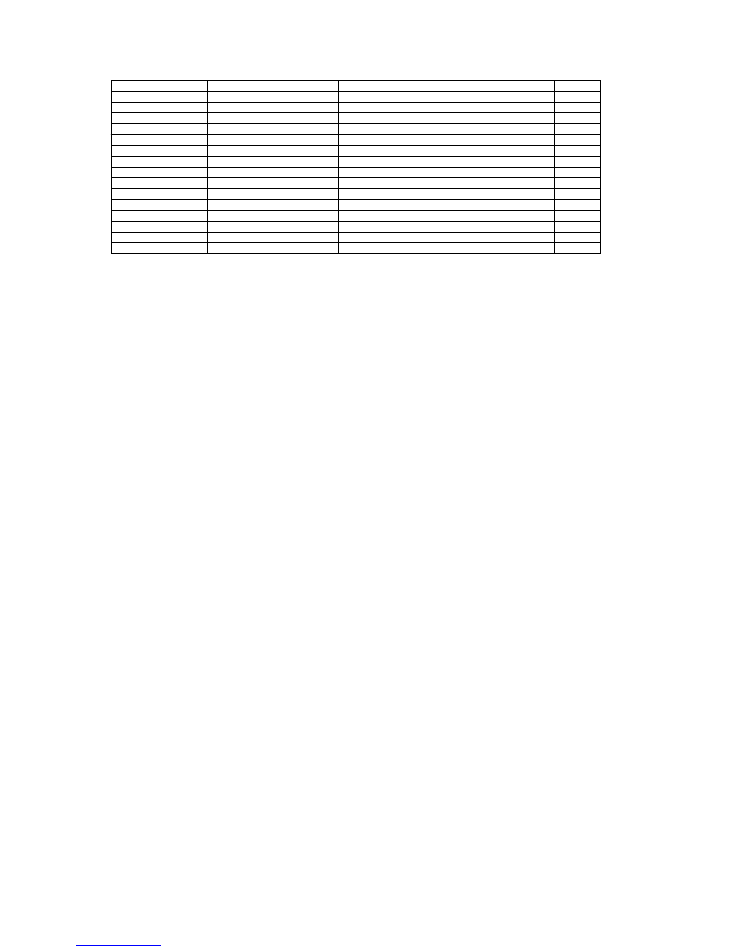

KORG KP3 PARTS LIST

Part Number

Category

Part Name

QTY

510306510001

POWER MOS FET

CPH6316-TL-E (S)

1

510310510502

DOUBLE DIODES

MC2840-T112-1 (S)

1

510310511507

DIODE

RLS-73 TE-11 (S)

22

510310511506

SCHOTTKY DIODE

RB051L-40TE25 (S)

2

510310511001

ZENER DIODE

RD10M-T1B-A (B3) (S)

1

510300510503

TRANSISTOR

2SA812-T1B-A M5-7 M6 RANK(S)

3

510300510502

TRANSISTOR

2SC1623A-T1B AT

1

510300511504

TRANSISTOR

2SC3661-TB-E (S)

4

510300511009

DIGITAL TR

DTC114EKA T146 (TS) (S)

16

510300511015

DIGITAL TR

DTB143EK T146 (S)

16

510312513001

Chip LED

TO-2013BC-MRE (S)

80

510312513009

Chip LED

TO-3227BC-MRMG EE (S)

6

510316521502

SEGMENT LED

TOF-3461BH-B9

1

510646502093

X-5500 LED SPACER E10236-2(D)

1

510324021160

OPAMP

NE5532DR (TS)

3

510320511008

OPAMP

NJM4556AM-TE1-#ZZZB (S)

1

510320515502

Logic IC

SN74LVU04APWR

1

510320516029

Logic IC

SN74LV125APWR (S)

1

510320516013

Logic IC

SN74LV126APWR (S)

1

510320516016

Logic IC

IC SN74LV138ANSR (TS) (S)

2

510320516056

Logic IC

SN74LV574ANSR (S)

2

510320516010

Logic IC

SN74LV05APWR (S)

1

500324023008

IC

S-8520F33MC-BNST2G

1

510320511009

REGULATOR IC

NJM78L05UA-TE2 (TS)(S)

1

510320514025

REGULATOR IC

BA17810FP

1

510320514026

LDO IC

BD00KA5WF

1

500330003700

PHOTO COUPLER

PS9117-F3-A

1

510320512002

RESET IC

M51953BFP#CF1J (S)

1

500324018018

EEPROM

AK93C10AF-E1

1

500320004718

CPU

HD64F2215UTE16V (X5500)

1

510320516070

DSP

TMS320VC5501PGF300

1

500324026004

SDRAM

MT48LC8M16A2P-75:G TR

1

510324019513

A/D Converter

AK5381VT

1

510324038010

D/A Converter

AK4384ET-E2

1

510335520001

CRYSTAL

HC-49US 16MHZ (D)

1

510335520007

CRYSTAL

HC-49US 20.000MHZ (D)

1

510335552008

CRYSTAL

HC-49US 24.576MHZ SS (D)

1

510374524026

SLIDE VR

RA4522F-20-15C1-B5K-0015

1

510370521001

ROTARY ENCODER

RE111F-41B1-15F-15P-05

1

510374524027

ROTARY VR

RV112BCF-40-20A-B10K

1

510374524017

ROTARY VR

RV09ACF-40-20F-B5K-0057

1

510360521510

VR

R0923NOAH1B104FE0061 (D)

1

510360521511

VR

R0925GOAH1B103FE0061 (D)

1

510450520019

DIN JACK

ST-1550-01-S1-60

2

510474520501

USB CONNECTOR

GE813A02 (USB B TYPE) (D)

1

510450520008

PHONE JACK

MJ-081 (PHONE-J MONO GOLD) (D)

1

510450520009

PHONE JACK

MJ-084 (PHONE-J ST GOLD) (D)

1

510450520010

RCA PIN JACK

RCA-204G-04 (D)

2

510450522504

DC JACK

PJCP042100-42-0 (D)

1

510374522002

SLIDE SW

SK-22D06G8 2P2T (D)

1

510374522018

TOGGLE SW

TS-22E01-AC18-NI

1

510374520004

PUSH SW

SPUN192600 (D)

1

510450520011

RCA PIN JACK

SHIELD PLATE RCA-204-E (D)

2

510470521003

HARNESS

HNS-3153 FLATCABLE 5P 2MM (D)

3

510470521005

HARNESS

HNS-3155 6P 2MM BD-IN/HSG (D)

1

510474523003

CONNECTOR

5597-04APB7F (39532044)

1

500474043700

FFC CONNECTOR

XF2M-5015-1A

2

510470521552

FFC

HNS-3647

1

510474510501

CARD CONNECTOR

AXA273021T

1

500415004302

TOUCH PANEL

N010-0517-T902

1

510C33682734

PCB ASS'Y

KLM-2734-KP3 (ASS'Y)

(1)

510C33682735

PCB ASS'Y

KLM-2735/6-KP3 (ASS'Y)

(1)

510640507004

Mechanical Part

X-5500 UPPER CASE KOC-C10259

1

510640506510

Mechanical Part

X-5500 BOTTOM PLATE KOC-C30714

1

510500502531

Mechanical Part

X-5500 RUBBER KEY 1 KOC-E30429

1

510500502532

Mechanical Part

X-5500 RUBBER KEY 2 KOC-E30430

1

510500502533

Mechanical Part

X-5500 RUBBER KEY 3 KOC-E30431

1

510500502534

Mechanical Part

X-5500 RUBBER KEY 4 KOC-E30432

1

510500502535

Mechanical Part

X-5500 ENCORDER KNOB

E30426

1

510646502094

Mechanical Part

X-5500 VR KNOB

KOC-E30427

2

510646502095

Mechanical Part

X-5500 SLIDER KNOB KOC-E30428

1

2 / 2

Part Number

Category

Part Name

QTY

500620040700

Mechanical Part

KNOB P423-90F(X-9100) E40519-1

2

500620018201

Mechanical Part

PSW KNOB (

ユシュツ

) E40224

1

510646502096

Mechanical Part

X-5500 SD FRAME

KOC-E20275

1

510646502099

Mechanical Part

X-5500 LCD FRAME

KOC-E20276

1

510646506504

Mechanical Part

X-5500 SUPORT PLATE KOC-F30119

1

510646506505

Mechanical Part

X-5500 WINDOW

KOC-F41269

1

510646502097

Mechanical Part

X-5500 LED FRAME KOC-E10236-1

1

510500501515

Mechanical Part

X-5500 SWITCH MASK KOC-F41307

1

510500500008

Mechanical Part

X-332CHINA URETHANE-LEG F40709

4

510500501510

Mechanical Part

SHIELD FORM 10X10X60

1

510500501511

Mechanical Part

SHIELD FORM 10X10X12

1

510405540009

AC ADAPTER

KA-201 12V 700mA EIAJ-Plug(100JP)

(1)

510405540010

AC ADAPTER

KA-203 12V 700mA EIAJ-Plug(120US/CN/EX)

(1)

510405540011

AC ADAPTER

KA-209 12V 700mA EIAJ-Plug(230GE/FR/WG)

(1)

510405540012

AC ADAPTER

KA-206 12V 700mA EIAJ-Plug(230UK)

(1)