Full Text Searchable PDF User Manual

3000 PSI GASOLINE

HIGH PRESSURE WASHER

INSTRUCTION MANUAL

COPYRIGHT © 2009 ALL RIGHTS RESERVED BY KING CANADA TOOLS INC.

MODEL: KPW-3000FM

Read this manual. Do not attempt to operate this pressure washer until you have

read and understood the safety, operation, and maintenance instructions

WARRANTY & SERVICE

INFORMATION

1-YEAR

LIMITED WARRANTY

FOR THIS 3000PSI GASOLINE PRESSURE WASHER

KING CANADA TOOLS

OFFERS A 1-YEAR LIMITED WARRANTY

FOR NON-COMMERCIAL USE.

BEFORE CALLING THE ABOVE TOLL-FREE NUMBER, PLEASE READ THIS MANUAL, SPECIFICALLY THE

SAFETY PRECAUTIONS, THE INSPECTION BEFORE OPERATION AND THE TROUBLESHOOTING GUIDE.

• DO NOT RETURN THE DEFECTIVE PRODUCT TO THE RETAILER.

WARRANTY INFORMATION

PROOF OF PURCHASE

Please keep your dated proof of purchase for warranty and servicing purposes.

REPLACEMENT PARTS

Replacement parts are available at our authorized KING CANADA service centers across canada. For servicing, call the above toll free

number to get servicing instructions and be sure to have your proof of purchase if you are claiming warranty work.

LIMITED TOOL WARRANTY

KING CANADA makes every effort to ensure that this product meets high quality and durability standards. KING CANADA warrants to

the original retail consumer a 1-year limited warranty as of the date the product was purchased at retail and that each product is free

from defects in materials.

THIS WARRANTY IS NOT TRANSFERABLE AND DOES NOT COVER

• Damage or liability caused by shipping, improper handling, improper installation, improper maintenance, improper modification, or the

use of accessories and/or attachments not specifically recommended.

• Repairs necessary because of operator abuse or negligence, or the failure to install, operate, maintain, and store

the product according to the instructions in the owner’s manual.

• Damage caused by cold, heat, rain, excessive humidity, corrosive environments and materials, or other contaminants.

• Expendable items that become worn during normal use such as fuel filters, air cleaners, spark plugs, and engine oil.

• Cosmetic defects that do not interfere with product functionality.

• Freight costs from customer to an authorized warranty service location.

• Repair and transportation costs of products or parts determined not to be defective.

• ANY INCIDENTAL, INDIRECT OR CONSEQUENTIAL LOSS, DAMAGE, OR EXPENSE THAT MAY RESULT FROM ANY DEFECT,

FAILURE OR MALFUNCTION OF THE PRODUCT.

• RETAIN THE ORIGINAL CASH REGISTER SALES RECEIPT AS PROOF OF PURCHASE FOR WARRANTY WORK.

KING CANADA shall in no event be liable for death, injuries to persons or property or for incidental, special or consequential damages

arising from the use of our products. Shipping and handling charges may apply. If a defect is found, KING CANADA will either repair or

replace the product.

KING CANADA TOOLS INC. MONTREAL, QUEBEC, CANADA H9P 2Y4

BASIC SAFETY INFORMATION

EXHAUST FUMES ARE DANGEROUS

Never operate the engine in a closed area or it may cause

unconsciousness and death within a short time. Operate in a well

ventilated area.

Operate pressure washer in clean, dry, well ventilated area. Never

operate unit in enclosed areas such as garages, basements, storage,

sheds, or in any location occupied by humans or animals.

Keep children, pets and others away from area of operating unit.

Breathing exhaust fumes will cause serious injury or death.

Gasoline

engines produce toxic carbon monoxide exhaust fumes.

FUEL IS HIGHLY FLAMMABLE AND POISONOUS

•Always turn off the engine when refueling.

•Never refuel while smoking or in the vicinity of an open flame.

•When operating or transporting this pressure washer, be sure to keep

it upright. If it tilts, fuel may leak from the carburetor or fuel tank.

ENGINE AND MUFFLER MAY BE HOT

•Place the pressure washer in an appropriate location, away from

children and pedestrians.

•Avoid placing any flammable materials near the exhaust outlet during

operation.

•Keep a 4ft. clearance from buildings or other equipment around the

pressure washer to prevent overheating.

WARNING!

The engine muffler will be very hot after use, avoid

touching the engine or muffler while they are still hot.

ATTEMPTING TO FILL THE FUEL TANK WHILE THE ENGINE IS

RUNNING.

Gasoline and gasoline vapors can become ignited by coming in

contact with hot components such as the muffler, engine exhaust

gases, or from an electrical spark.

Turn engine off and allow it to cool before adding fuel to the tank. Equip

area of operation with a fire extinguisher certified to handle gasoline or

fuel fires.

SPARKS, FIRE, HOT OBJECTS

Cigarettes, sparks, fires, or other hot objects can cause gasoline or

gasoline vapors to ignite.

INADEQUATE VENTILATION

Materials placed against or near the pressure washer or operating it in

areas where the temperature exceeds 40° C ambient (such as storage

rooms or garages) can interfere with its proper ventilation features

causing overheating and possible ignition of the materials or buildings.

Operate pressure washer in a clean, dry, well ventilated area a

minimum of four feet from any building, object or wall. DO NOT

OPERATE UNIT INDOORS OR IN ANY CONFINED AREA.

APPLICATION

This equipment is designed for specific applications. Do not modify or

use for any application other than which it is designed.

STORAGE

Store the pressure washer in a well ventilated area with the fuel tank

empty. Fuel should never be stored or placed near the pressure

washer.

SAFETY GLASSES

Always wear safety glasses while operating.

BASIC & SPECIFIC

SAFETY PRECAUTIONS

SPECIFIC SAFETY INFORMATION

NEVER OPERATE UNDER THE FOLLOWING CONDITIONS

• When a noticeable change in engine speed occurs.

• Engine misfires.

• Loss of water pressure.

• Smoke or flammes in the area.

• Excessive vibration.

WATER SPRAY

Never direct the water spray towards

ANY

person, animal, electrical

wiring or the pressure washer itself. Care must be taken not to spray

too close to the surface or damage could occur. King Canada is not

responsible for damage caused during use.

HOT MUFFLER & HIGH PRESSURE HOSE

Do not touch the muffler, it becomes very hot during operation. Keep

hose away from the hot muffler or it may damage the hose. Do not use

a damaged high pressure hose. Do not kink the high pressure hose.

KEEP HANDS AWAY

Do not touch the nozzle of the water spray during operation.

COLD WEATHER STARTS

Do not operate this pressure washer in temperatures below 5

0

C. Before

starting engine in cold weather, make sure ice has not formed in any

part of the equipment.

DETERGENTS

Only use recommended detergents for pressure washers.

PREVENT ACCIDENTAL WATER SPRAY

To prevent accidental water spray, the locking latch on the wand trigger

should be placed in the locked position when not in use.

PREVENT PUMP DAMAGE

Do not run the pressure washer engine for more than 5 minutes

without pressing the wand trigger or damage to the pump may result.

Never let the machine run unless connected to the water supply and it

is on. Never run caustic fluids or acid through this machine.

SAFETY FEATURES

Thermal relief valve

- Thermal relief valve protects the pump from

overheating in case a nozzle becomes clogged. This system should not

be abused, make every effort to prevent the pump from overheating.

Low-oil auto shut-off

- This pressure washer is equipped with a low oil

shut-off system. If the engine oil level goes below the recommended oil

level, the pressure washer will automatically shut-off. This protects your

engine and prevents operating without proper lubrication.

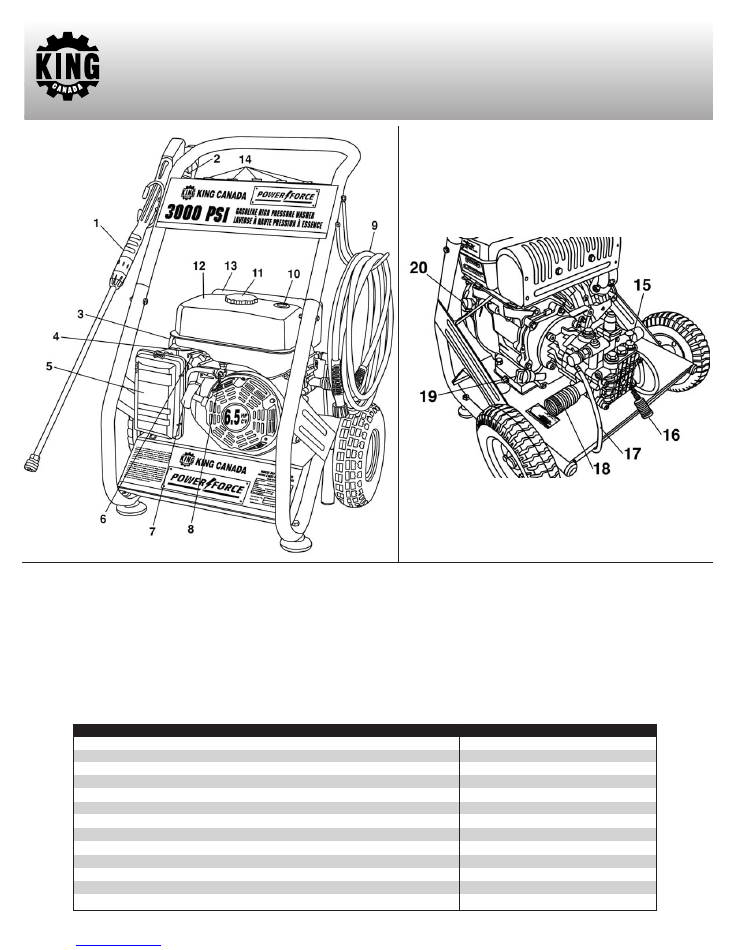

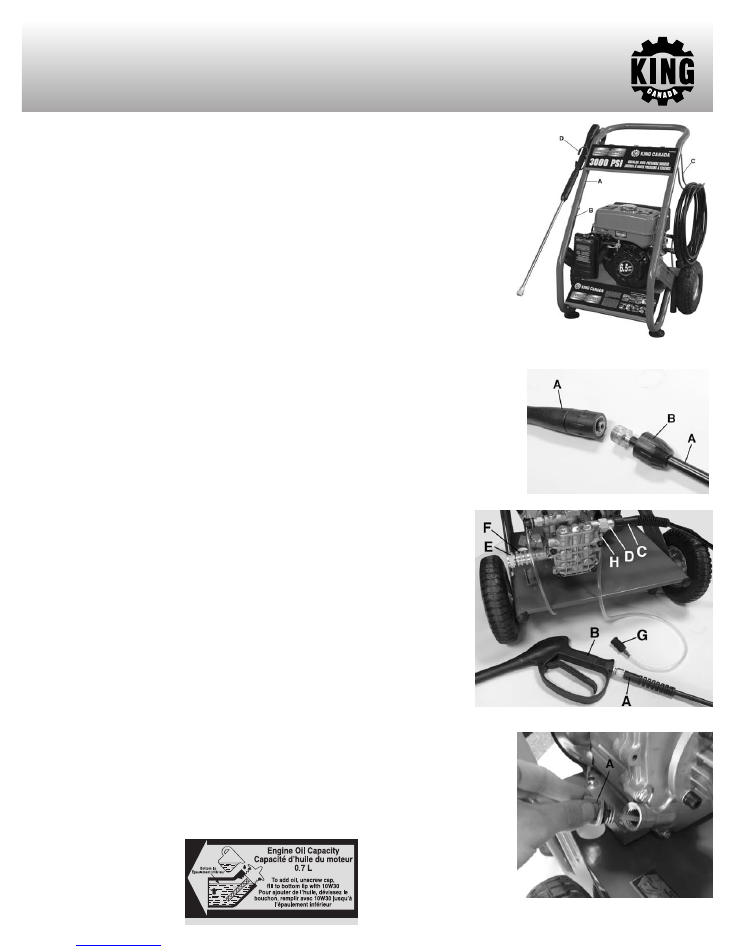

GETTING TO KNOW

YOUR PRESSURE WASHER

1. Stainless steel wand.

2. Trigger locking latch.

3. Spark plug wire.

4. Choke lever.

5. Air cleaner element/cover.

6. Throttle lever. Adjusts engine speed.

7. Recoil starter. Starts the engine.

8. Fuel valve. Regulates the flow of fuel to the engine. The fuel

shut-off valve must be fully opened before starting the engine.

9. 30 ft. high pressure hose.

10. Fuel level indicator window with float gauge.

11. Fuel cap. Make sure the fuel cap is always screwed on tightly.

12. Fuel tank. Unleaded gasoline only! 4 Liter capacity.

13. Muffler. Warning! Muffler gets hot.

14. Nozzles (0

0

, 15

0

, 25

0

, 40

0

and detergent)

15. Pump.

16. Detergent injector filter and inlet hose.

17. Thermal relief cap and drain pipe.

18. Garden hose inlet with quick connect coupling.

19. Oil gauge dipstick. 0.7 Litre engine oil capacity.

20. Engine On/Off switch.

MODEL

KPW-3000FM

Maximum water pressure

3000 PSI

Maximum water volume

2.7 GPM

Maximum inlet pressure

90 PSI

Maximum temperature of pumped fluid

25

0

C

Inlet and discharge ports

1/2” BSP (British Standard Pipe)

Engine (OHV)

6.5 HP

No load speed

3,600 RPM

Displacement (cc)

196

Fuel

Unleaded Gasoline

Fuel tank (L)

4.0

Oil capacity (L)

0.7

Dimensions (LxWxH)

25” x 21” x 35”

Weight

99 lbs

ASSEMBLY & PRE-START CHECK

WARNING! Before turning on your pressure washer engine, you MUST check oil level, fuel

level and air cleaner filter.

ASSEMBLY

Remove all the contents from the carton and proceed to the following assembly instructions;

Top handle

Install the top handle (A) to the frame (B) by sliding the top handle posts into the frame posts and

secure them together using 2 pan head screws, 4 washers and 2 nylon hex. nuts.

Wheels

Install the wheels to the frame by first pressing its spring loaded pin, then insert wheel shaft into frame

and align spring loaded pin with hole in frame until the pin snaps. Repeat for the other wheel.

Hose and wand supports

Assemble the hose support (C) Fig.1 to the right side of the frame using 2 pan head screws,

4 washers and 2 nylon hex. nuts. Then assemble the wand support (D) to the left side of the frame

again using 2 pan head screws, 4 washers and 2 nylon hex. nuts.

Wand and hose

Assemble the 2 piece stainless steel wand (A) Fig.2. Lower the rubber piece (B) to expose the

threaded fitting and screw the 2 pieces together, reposition the rubber piece. It is recommended to

install Teflon tape on the threads to prevent water leakage.

Next install the hose (A) Fig.3 to the wand (B) and install the other end of the hose (C) Fig.3 to the

pump outlet (D) as shown in Fig.3. It is recommended to install Teflon tape on the threads to prevent

water leakage.

Quick connect coupling and detergent injector

Install the quick connect coupling (E) Fig.3 to the water hose inlet (F). It is recommended to

install Teflon tape on the threads to prevent water leakage. Then install the detergent

injector tube (G) over the detergent siphon fitting (H).

PRE-START CHECK

OIL LEVEL

WARNING! This pressure washer has been shipped from the factory without oil or

very little oil in the crankcase. Operating the unit without the correct amount of oil can

damage the engine. Oil crankcase capacity: 0.7 litres.

Always check the oil level before starting the engine, make sure the pressure

washer is on a level surface. To check oil level;

1) Turn the oil gauge dipstick (A) Fig.4 counterclockwise, remove it and clean it with a clean cloth.

2) Fully reinsert the oil gauge dipstick and pull it out to check the oil level.

3) If the oil level is halfway up the dipstick or below, refill with SAE 10W30 oil through the dipstick hole

until the oil level reaches 3/4 up the dipstick or until it reaches the bottom lip of the dipstick hole as

shown in illustration below.

4) Reposition the oil gauge dipstick and tighten it by turning clockwise.

Figure 1

Figure 2

Figure 3

Figure 4

PRE-START CHECK

FUEL LEVEL

WARNING! Make sure there is enough fuel in the fuel tank before operating.

Check the fuel level indicator window (A) Fig.5, if the red float gauge is all the way up, it is not

necessary to add fuel. If you do not see or hardly see the red float gauge, it is necessary to add

fuel.

1) If it is necessary to add fuel, first make sure the engine is OFF, then remove the fuel cap (B)

by turning it counterclockwise.

2) When refueling, make sure the fuel filter (C) Fig.5 is in place and keep in mind all safety

precautions and make sure to add enough fuel based on usage. Use clean unleaded

gasoline with a minimum of 87 octane. Do not mix oil with gasoline.

Fuel tank capacity: 2.2 Litres.

AIR CLEANER FILTER

The air cleaner filter should be checked after prolonged storage, the following steps should be

done when checking air cleaner filter;

1) Snap the top and bottom clips (A) Fig.6 backwards and remove the air cleaner cover (B).

2) Remove the air cleaner filter (C) Fig.6, wash filter in kerosene, squeeze kerosene out, soak

filter in engine oil and squeeze engine oil out.

3) Replace filter and replace the air cleaner filter cover.

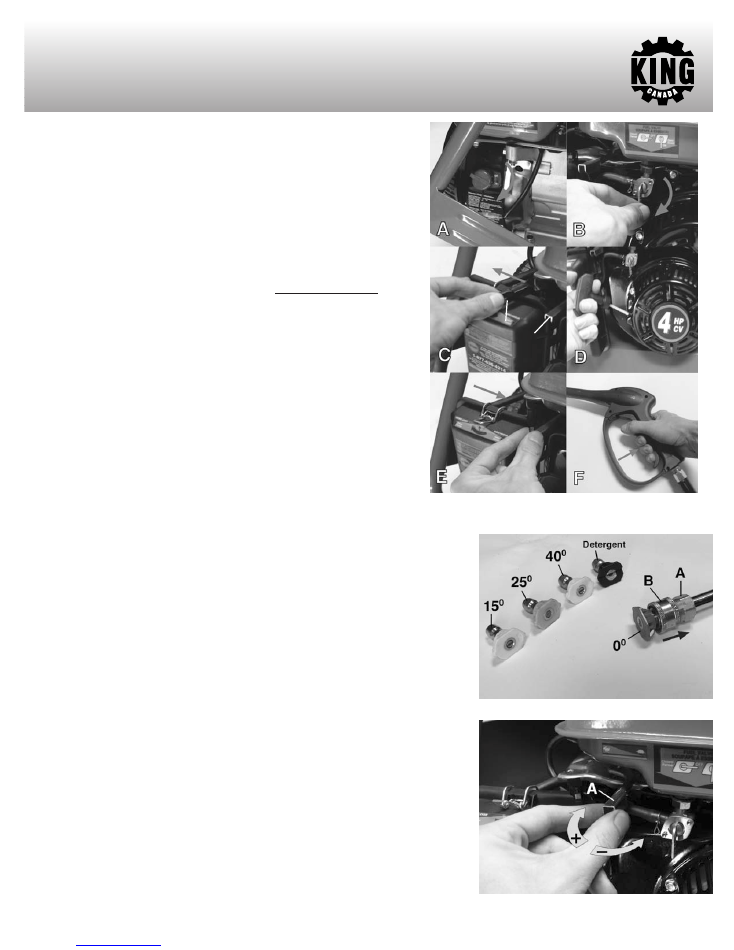

START-UP PROCEDURES

Follow these instructions to safely start your high pressure washer.

1) Check engine oil level, fill to recommended level if necessary. Fig.7A.

2) Check gasoline level, fill if necessary. Fig.7B.

3) This pressure washer comes with a pump quick connect coupling. It allows you

to quickly connect or disconnect the inlet garden hose from the pump. Pulling

the mid ring will disconnect the quick connect coupling. Connect inlet garden

hose (not supplied) to the pump quick connect coupling

AND TURN WATER

ON

. Fig.7C. The water supply must provide a minimum of 4 GPM at 20 PSI or

the pump may be damaged.

4) Squeeze stainless steel wand trigger. Fig.7D. This will allow air to escape

from the hose in order to prime the pump. Squeeze trigger until there is a

steady flow of water.

PRE-START CHECK &

START-UP PROCEDURES

Figure 5

Figure 6

Figure 7

START-UP PROCEDURES

& OPERATION

START-UP PROCEDURES

continued

....

Follow these instructions to safely start your high pressure washer.

5) Turn engine switch to the “On” position. Fig.8A.

6) Open fuel valve (“On” position). Fig.8B.

7) Close the Choke lever (A) by moving the lever towards the left. Also move the

throttle lever (B) to its maximum setting (towards the left) Fig.8C.

8) Pull recoil starter to start engine. Fig.8D. Pull recoil starter slowly until

resistance is felt, then pull rapidly to start engine.

Repeat if necessary.

9) Once engine starts, open choke lever by moving the lever towards the right.

Fig.8E.

10) If motor fails to start, repeat steps 3-10.

11) Press trigger. Fig.8F

OPERATION

SPRAYING WATER & NOZZLE USAGE

This pressure washer comes with a stainless steel wand, its tip has a quick connect coupler

(A) Fig.9 to fit different nozzles. The spray pattern is adjusted by installing the appropriate spray

pattern nozzle to the quick connect coupler. Five nozzles are included, 0

0

, 15

0

, 25

0

, 40

0

and a

detergent nozzle. To install a nozzle to the quick connect coupler, pull the coupler ring (B)

backwards and insert the desired nozzle (C), release the coupler ring to lock it in place.

Nozzle usage;

0

0

(red)

- Thin and powerful stream of water for difficult stains and debris removal.

15

0

(yellow)

- Thin angled spray for focused cleaning.

25

0

(green)

- Medium angled spray for focused cleaning.

40

0

(white)

- Large fan pattern for wider cleaning applications.

Detergent (black)

- This nozzle must be used in conjunction with a cleaning detergent at low

pressure. Only use this nozzle when using a detergent or cleaning solution.

ADJUSTING WATER PRESSURE

The water pressure is regulated by the throttle lever (A) Fig.10. Moving the throttle lever

towards the left will increase the engine speed and thus increasing the water pressure. Moving

the throttle lever towards the right will decrease the engine speed and thus decreasing the

water pressure.

Figure 8

Figure 9

Figure 10

A

B

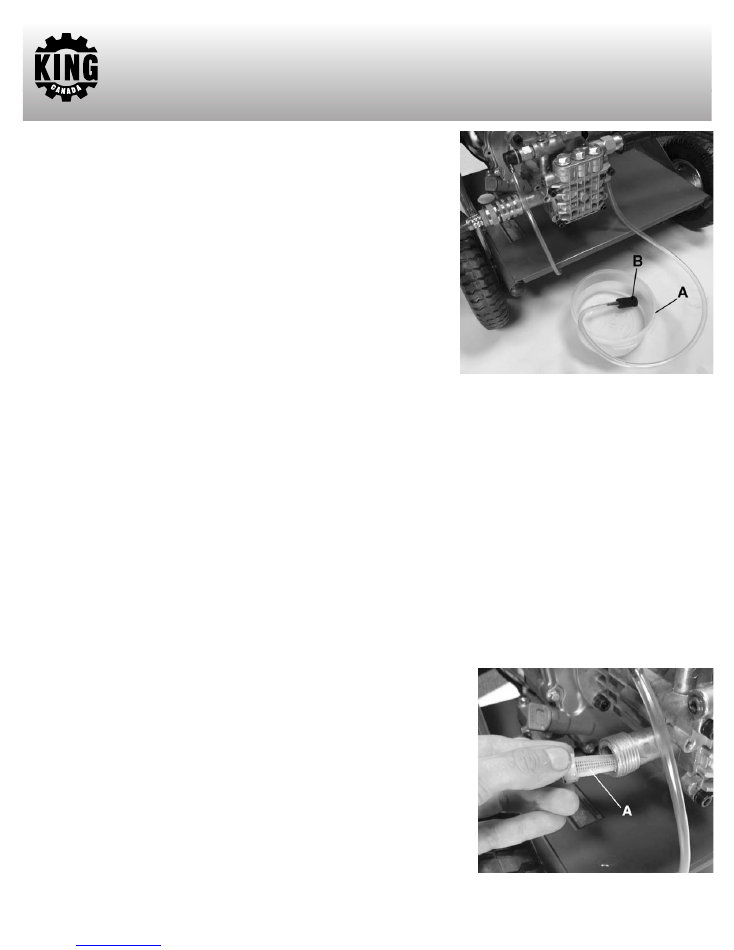

DETERGENT INJECTOR (LOW PRESSURE)

This high pressure washer is intended for use only with car wash or pressure washer

detergents with mild soaps. Only use detergents that are compatible with the aluminum

and brass parts of the pressure washer pump. Do not use powdered soaps, they may clog

the injection system. Follow the detergent manufacturer directions. The use of detergent

is advantageous, it ensures a quick way to soak the dirt before spraying.

To set-up the detergent injector, install it to the siphon injector fitting on the pump as

described in assembly instructions Fig.3. Then follows these instructions;

1) Pour the contents of your detergent into a container (A) Fig.11 and place it next to the

pressure washer pump.

2) When using a detergent, the stainless steel wand must be fitted with the detergent

nozzle (black). This can be done by pulling the coupler ring (B) Fig.9 backwards and

inserting the detergent nozzle, release the coupler ring to lock it in place.

3) Inspect the detergent injector filter (B) Fig.11, make sure it is not clogged. Then place

it all the way to the bottom of the container. The detergent will automatically mix with

the water.

4) If the throttle lever (A) Fig.10 is not in the fast position, the injection of the detergent

may be decreased or stop completely, in this case, move the throttle lever towards the left to increase engine speed and pressure.

Important Note

: When you have finished using the detergent injector system, remove the injector filter from the detergent container and place

it in a different larger container containing only clean water and let the pressure washer run until you no longer notice detergent coming out of

the wand.

USING THE PRESSURE WASHER TO CLEAN

Most cleaning jobs can be made by using only water, but it is also advantageous to use detergent to penetrate and remove the dirt more

effectively. When using soap or a detergent, make sure the surface to clean is dry. Wetting the surface first is not recommended, it will dilute the

detergent and will reduce the cleaning effectiveness. Avoid hot surfaces or use in direct sunlight, this will minimize the chances of the detergent

damaging the painted surface. Do not let the detergent dry or it may damage the painted surface.

Allow the detergent to remain on the surface for a short time before rinsing with clean water under high pressure. Position the tip of the wand 6”

to 8” away from the surface to clean at a 45

0

angle.

APPLYING WAX

Right after the cleaning operation is done, you can use this pressure washer to apply wax. Place the injector filter into the wax container and

apply the wax sparingly in an even pattern over the wet surface. Once done, remove the injector filter from the container and rinse off the excess

wax. Wipe dry to reduce water spotting.

MAINTENANCE

WATER SCREEN

This pressure washer is equipped with a water inlet screen (A) Fig.12. This water screen must

be kept clean at all times or else it will restrict the water flow to the pressure washer and may

damage the pump. Remove the quick connect coupling from the water inlet, remove and clean

screen. Never operate this pressure washer without the water inlet screen in place.

OPERATION & MAINTENANCE

Figure 11

Figure 12

MAINTENANCE & STORAGE

MAINTENANCE

ENGINE MAINTENANCE

Engine Oil Replacement

Engine oil should be replaced after the first 20 hours of operation or after the first month of use, it

should be replaced every 100 hours or 6 months after. To replace engine oil; Loosen the oil gauge

dipstick (A) Fig.13. Place an oil pan underneath drain hex. bolt (B), remove hex. bolt (B) and drain

oil. Once all the oil has completely drained, retighten the hex. bolt (B).

Recommended Engine Oil

It is recommended to use SAE10W30 4-stroke gasoline engine oil. Fill with clean engine oil through

the oil gauge dipstick hole to recommended level.

Inspecting, Replacing or Cleaning Spark Plug

The spark plug should be checked every 100 hours of operation or every 6 months. To replace or

clean spark plug;

1) Dismantle the spark plug wire (A) Fig.14 by pulling it off the spark plug (B). Using the supplied

spark plug wrench, undo the spark plug by turning counterclockwise.

2) Check to see if there is carbon sediment build-up, if so just remove it. If the carbon sediment is

excessive, replace the spark plug.

3) Measure the electrodes clearance using a feeler gauge. The spark plug electrode clearance

should be between 0.7-0.8mm. If the clearance exceeds 0.8mm, replace the spark plug. The

original spark plug supplied is an LD F6TC, you can replace it with an NGK BP6ES spark plug or

equivalent.

4) Reinstall spark plug in the reverse order.

PUMP MAINTENANCE

Pump Oil Replacement

Pump oil should be annually replaced with approx. 4.7 fl. oz. (138ml) of SAE 300 non detergent oil.

To replace pump oil, undo oil bolt (A) Fig.15, and drain pump oil. Once oil has completely drained,

fill with recommended oil. Retighten oil bolt.

Pressure Washer Storage

If you plan on storing your pressure washer for an extended period of time, the following steps

should be followed;

1) Add fuel stabilizer to fuel tank to minimize the formation of fuel gum deposits during storage.

2) Run engine at least 5 minutes after adding stabilizer to allow it to enter the fuel system.

NOTE:

If a fuel stabilizer is not used, all gasoline must be drained from the tank and carburetor to

prevent gum deposits from forming on these parts and causing possible malfunction of the engine.

3) Turn fuel shut-off valve to the “OFF” position, remove drain hex. bolt (A) Fig.16 from the

carburetor (B).

4) Now turn fuel shut-off valve to the “ON” position and drain the fuel from the tank, carburetor and

hose.

5) Reposition the carburetor drain hex. bolt once the fuel is completely drained.

6) Drain engine oil from engine as described in “Engine Oil Replacement”.

7) Pour approximately one teaspoon of engine oil through the spark plug hole and pull the recoil

starter slowly until you feel increased pressure which indicates the piston is on its compression

stroke and leave it in this position. This closes both the intake and exhaust valves to prevent the

inside of the cylinder from rusting.

8) Cover the pressure washer and store it in a clean, well ventilated and dry place.

Preventing Freezing Damage

If your pressure washer is subjected to freezing temperatures, damage could occur.This type of

damage

is not covered under warranty

. To avoid possible damage, a small amount of antifreeze

can be used. Place the unit on its side with the water inlet facing upwards, pour 1/4 cup of antifreeze

into the water inlet. Disconnect spark plug wire, then pull recoil starter several times to circulate the

antifreeze in the pump system. Reconnect spark plug wire. It is also important to make sure the wand

and all hoses are disconnected and drained of all water or they may burst. When taking pressure

washer out of storage, run water through the system until it runs clear.

Figure 13

Figure 14

Figure 15

Figure 16

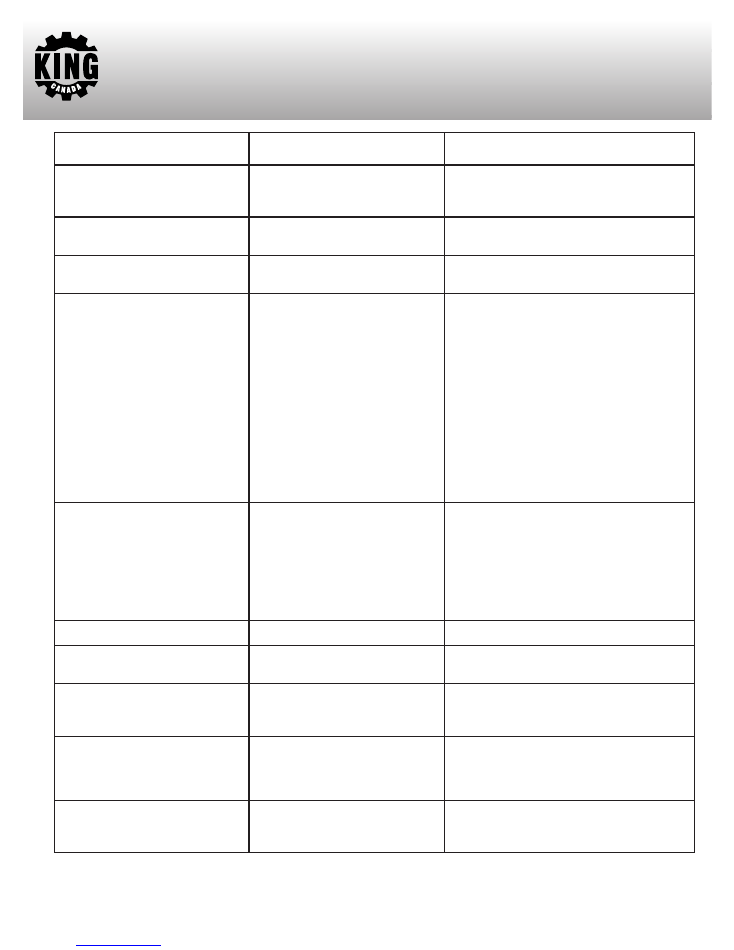

TROUBLESHOOTING

PROBLEM

Engine will not start or stops while

operating

Engine is overloaded

Pressure increases when gun is

closed

Engine is running but pump won’t

build maximum pressure or has

irregular pressure

No intake of chemicals

Trigger will not move

Water in crankcase

Noisy operation

Rough/pulsating operating with

pressure drop

High crankcase temperatures

CAUSE

1. Low-oil shutdown

2. Engine switch not in “ON” position

3. Pressure built up in the hose

1. Nozzle partially blocked

2. Excessive pressure

1. Bypass valve is blocked

1. Faucet closed

2. Unit has been stored in freezing

temperatures

3. Inadequate water supply

4. Water inlet screen clogged

5. Kink in garden hose

6. Wand tip worn or damaged

7. Air in pump

8. Engine speed not set to maximum

position

9. Suction or discharge valves

clogged or worn out

10. Bypass valve not operating

effectively

1. Injection tube not securely inserted

into unit

2. Tube cracked or split

3. Wrong nozzle

4. Injector turned off

5. Injection tube strainer clogged

6. Nozzle blocked

7. Dried chemicals injector

1. Gun safety lock engaged

1. High humidity

2. Worn seals

1. Worn bearings

2. Air mixed with water

1. Inlet restriction

2. Air mixed with water

1. Wrong grade of oil

2. Improper amount of oil in

crankcase

CORRECTION

1. Fill engine with oil

2. Turn switch “ON”

3. Squeeze trigger while starting

1. Clean nozzle

2. Shorten the spring coil of the reflux valve

1. Clean the bypass valve

1. Open faucet

2. Thaw out unit completely including hose, gun

and wand

3. Provide a minimum of 4 GPM at 20 PSI

4. Clean screen

5. Straighten garden hose

6. Replace wand

7. Let it run with gun open and wand removed

until steady stream of water is released

8. Set throttle to maximum position

9. Clean the suction or discharge valves

10. Clean the bypass valve

1. Push firmly into injector fitting

2. Replace tube

3. Switch to low pressure nozzle

4. Turn collar counter-clockwise

5. Clean strainer

6. Clean nozzle

7. Dissolve by running warm water

1. Release safety lock

1. Change oil more frequently

2. Change the oil seals

1. Change the bearing

2. Check inlet lines for restrictions and/or proper

sizing

1. Check system for stoppages, air leaks,

correctly sized inlet, plumbing to pump

2. Check inlet lines for restrictions and/or proper

sizing

1. Use SAE 10W30 oil

2. Adjust oil level to proper amount

PARTS DIAGRAM & PARTS LISTS

Refer to the Parts section of the King Canada web site for the most updated parts diagram and parts list.