Full Text Searchable PDF User Manual

Konvekta AG

Konvekta AG

Konvekta AG

Konvekta AG

Am Nordbahnhof 5

34613 Schwalmstadt

Germany

+49 ( 0 ) 66 91 / 76 – 0

+49 ( 0 ) 66 91 / 76 – 200

Info@konvekta.com

www.konvekta.com

Operating Instru

Operating Instru

Operating Instru

Operating Instrucccction

tion

tion

tion

for

for

for

for KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA Air Conditioning

Air Conditioning

Air Conditioning

Air Conditioning

unit

unit

unit

unit

KL40T / KL45T

KL40T / KL45T

KL40T / KL45T

KL40T / KL45T

with control K5

with control K5

with control K5

with control K5

Versions:

Versions:

Versions:

Versions:

12 / 24 Volt DC

12 / 24 Volt DC

12 / 24 Volt DC

12 / 24 Volt DC

Recirculated Air

Recirculated Air

Recirculated Air

Recirculated Air

Fresh Air

Fresh Air

Fresh Air

Fresh Air

Heating

Heating

Heating

Heating

ID#: BBA

ID#: BBA

ID#: BBA

ID#: BBA----KL40T12AB

KL40T12AB

KL40T12AB

KL40T12AB

Version: A03

Version: A03

Version: A03

Version: A03

BAKL40T12AB

Edition: 18.03.2009

Page: 2/15

Contents

Contents

Contents

Contents

Page:

Page:

Page:

Page:

•

Introduction

Introduction

Introduction

Introduction................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

.........................................................

.........................

.........................

......................... 3

33

3

•

Information on the operating instructions

Information on the operating instructions

Information on the operating instructions

Information on the operating instructions ................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

.....................................

.....

.....

..... 4

44

4

1.

1.

1.

1.

Technical

Technical

Technical

Technical data

data

data

data................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

.....................................................

.....................

.....................

..................... 5

55

5

1.1.

Pressure Switches...................................................................................................................................................5

1.2.

Compressors ...........................................................................................................................................................6

2.

2.

2.

2.

Determined use

Determined use

Determined use

Determined use ................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

.................................................

.................

.................

................. 6

66

6

3.

3.

3.

3.

Generally information for a/c unit

Generally information for a/c unit

Generally information for a/c unit

Generally information for a/c unit................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

...................................................

...................

...................

................... 6

66

6

3.1.

Operating Conditions............................................................................................................................................7

4.

4.

4.

4.

Introduction control K5

Introduction control K5

Introduction control K5

Introduction control K5 ................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

...................................

...

...

... 7

77

7

5.

5.

5.

5.

Operation

Operation

Operation

Operation................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

............................................................

............................

............................

............................ 7

77

7

5.1.

Operation panel / function of the keys .............................................................................................................8

5.2.

A/C operation ON / OFF.....................................................................................................................................9

5.2.1.

Manual adjustment of the blower speed..................................................................................................... 10

5.3.

Heating operation fully automatic => only in case of a/c units with heating option........................... 10

5.3.1.

Manual heating operation

=> only in case of a/c units with heating option

..................................... 11

5.4.

REHEAT activate / stop => only for in case of a/c units with heating option ...................................... 11

5.5.

Switch Recirc. Air operation => only in case of a/c units with Rec. air flaps option.......................... 12

5.6.

Change over of the temperture indication to ° Fahrenheit ...................................................................... 12

6.

6.

6.

6.

Maintenance / Servicing

Maintenance / Servicing

Maintenance / Servicing

Maintenance / Servicing................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

...................................

...

...

... 13

13

13

13

6.1.

Trouble indication in the display...................................................................................................................... 13

6.1.1.

Trouble at the temperature sensor F0 (room sensor, blue):................................................................ 13

6.1.2.

Trouble at the temperature sensor F1 (air outlet, yellow): .................................................................. 13

6.2.

Oil change Compressor type KVX ................................................................................................................. 13

6.3.

Return air grid ...................................................................................................................................................... 14

6.4.

Condenser coil..................................................................................................................................................... 14

6.5.

Trouble shooting ................................................................................................................................................. 14

7.

7.

7.

7.

Warranty Conditions

Warranty Conditions

Warranty Conditions

Warranty Conditions ................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

......................................

......

......

...... 15

15

15

15

8.

8.

8.

8.

Waste disposal in accordance with legal provisions

Waste disposal in accordance with legal provisions

Waste disposal in accordance with legal provisions

Waste disposal in accordance with legal provisions ................................

................................

................................

................................................................

................................

................................

..................................................

..................

..................

.................. 15

15

15

15

9.

9.

9.

9.

History of modification

History of modification

History of modification

History of modification ................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

................................................................

................................

................................

...................................

...

...

... 15

15

15

15

Appendix:

Appendix:

Appendix:

Appendix:

•

Maintenance Schedule Bus

WP07050618

•

KONVEKT

KONVEKT

KONVEKT

KONVEKTA

A

A

A Service Stations

BAKL40T12AB

Edition: 18.03.2009

Page: 3/15

Introduction

Introduction

Introduction

Introduction

These operating instructions have been written for drivers, operators and the maintenance staff of your

air conditioning unit.

In this context, we refer implicitly to the compliance with our general installation guideline

In this context, we refer implicitly to the compliance with our general installation guideline

In this context, we refer implicitly to the compliance with our general installation guideline

In this context, we refer implicitly to the compliance with our general installation guidelines. These can

s. These can

s. These can

s. These can

be obtained from the KONVEKTA techn

be obtained from the KONVEKTA techn

be obtained from the KONVEKTA techn

be obtained from the KONVEKTA techniiiical after sales service:

cal after sales service:

cal after sales service:

cal after sales service:

TKD@konvekta.com

TKD@konvekta.com

TKD@konvekta.com

TKD@konvekta.com

....

It contains:

It contains:

It contains:

It contains:

•

Operating instructions

•

Safety information

•

Service information

These operating instructions have to be read carefully and made use of before the first start-up and

after that regularly by each person who is involved in handling the machine:

•

Operation including troubleshooting and waste disposal of fuels and auxiliary agents.

•

Servicing, inspection, repair

•

Transport

This facilitates the handling and avoids trouble caused by improper operation. Working in compliance

with these operating instructions increases operation reliability and service life of the air conditioning

unit and reduces life cycle costs.

Please complete these instructions by adding the

Please complete these instructions by adding the

Please complete these instructions by adding the

Please complete these instructions by adding the national provisions for pr

national provisions for pr

national provisions for pr

national provisions for pre-

e-

e-

e-

vention of accidents and environmental pr

vention of accidents and environmental pr

vention of accidents and environmental pr

vention of accidents and environmental pro

o

o

otection.

tection.

tection.

tection.

These instructions are part of the air conditioning unit. Always have a copy

These instructions are part of the air conditioning unit. Always have a copy

These instructions are part of the air conditioning unit. Always have a copy

These instructions are part of the air conditioning unit. Always have a copy

at

at

at

at hand in the driver’s cabin.

hand in the driver’s cabin.

hand in the driver’s cabin.

hand in the driver’s cabin.

You will certainly understand that we will not recognize any wa

You will certainly understand that we will not recognize any wa

You will certainly understand that we will not recognize any wa

You will certainly understand that we will not recognize any warrrrran

ran

ran

ranty claims due to unproper

ty claims due to unproper

ty claims due to unproper

ty claims due to unproper

handling, inadequate maintenance, a

handling, inadequate maintenance, a

handling, inadequate maintenance, a

handling, inadequate maintenance, ap

pp

pplications that do not correspond with the determined

plications that do not correspond with the determined

plications that do not correspond with the determined

plications that do not correspond with the determined

use, utilization of unadmitted fuels or the non

use, utilization of unadmitted fuels or the non

use, utilization of unadmitted fuels or the non

use, utilization of unadmitted fuels or the non----observance of safety prov

observance of safety prov

observance of safety prov

observance of safety proviiiisions.

sions.

sions.

sions.

KONVEKTA will annul without prenotice all obligations conce

KONVEKTA will annul without prenotice all obligations conce

KONVEKTA will annul without prenotice all obligations conce

KONVEKTA will annul without prenotice all obligations concerning guarantee, service co

rning guarantee, service co

rning guarantee, service co

rning guarantee, service con-

n-

n-

n-

tracts etc. regardless if granted by KONVEKTA or its distributors in case other than original

tracts etc. regardless if granted by KONVEKTA or its distributors in case other than original

tracts etc. regardless if granted by KONVEKTA or its distributors in case other than original

tracts etc. regardless if granted by KONVEKTA or its distributors in case other than original

KONVEKTA spare parts or parts bought from KONVEKTA AG have been used for maint

KONVEKTA spare parts or parts bought from KONVEKTA AG have been used for maint

KONVEKTA spare parts or parts bought from KONVEKTA AG have been used for maint

KONVEKTA spare parts or parts bought from KONVEKTA AG have been used for mainte-

e-

e-

e-

nance and r

nance and r

nance and r

nance and re

ee

epair.

pair.

pair.

pair.

These operating instructions contain

These operating instructions contain

These operating instructions contain

These operating instructions contain all necessary information to operate your air conditio

all necessary information to operate your air conditio

all necessary information to operate your air conditio

all necessary information to operate your air condition

nn

ning

ing

ing

ing

unit. In case you need more explanations please contact the next KONVEKTA service st

unit. In case you need more explanations please contact the next KONVEKTA service st

unit. In case you need more explanations please contact the next KONVEKTA service st

unit. In case you need more explanations please contact the next KONVEKTA service sta-

a-

a-

a-

tion

tion

tion

tion

.

See hand book„KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA Service Stations

BAKL40T12AB

Edition: 18.03.2009

Page: 4/15

Information on the operating instructions

Information on the operating instructions

Information on the operating instructions

Information on the operating instructions

These operating instructions are valid for the

a/c-units

type:

•

KL40T/12V

•

KL45T/12V

•

KL40T/24V

•

KL45T/24V

When taking the unit into operation we recommend adding the following data. This will also be important

for your orders of spare parts, and in case of warranty.

Serial number of the unit

:

................................................................

Order No.:

................................................................

Year of construction:

................................................................

(MM/JJ)

Date of first operation:

................................................................

(

TT/

MM/JJ)

The machine corresponds to the security prescriptions of the EC # 89/392/EWG i.d.F.

The machine corresponds to the security prescriptions of the EC # 89/392/EWG i.d.F.

The machine corresponds to the security prescriptions of the EC # 89/392/EWG i.d.F.

The machine corresponds to the security prescriptions of the EC # 89/392/EWG i.d.F.

91/368/EWG and 93/44/EWG.

91/368/EWG and 93/44/EWG.

91/368/EWG and 93/44/EWG.

91/368/EWG and 93/44/EWG.

Due to the fact that sc

Due to the fact that sc

Due to the fact that sc

Due to the fact that scope of supply depends on the order, equipment of your product may differ

ope of supply depends on the order, equipment of your product may differ

ope of supply depends on the order, equipment of your product may differ

ope of supply depends on the order, equipment of your product may differ

in some parts of description.

in some parts of description.

in some parts of description.

in some parts of description.

In case your product is equipped with details not shown or described in the operating i

In case your product is equipped with details not shown or described in the operating i

In case your product is equipped with details not shown or described in the operating i

In case your product is equipped with details not shown or described in the operating in

nn

nstruction,

struction,

struction,

struction,

your KONVEKTA

your KONVEKTA

your KONVEKTA

your KONVEKTA ----Service

Service

Service

Service----Station will always be at dispo

Station will always be at dispo

Station will always be at dispo

Station will always be at disposal for informing you about correct o

sal for informing you about correct o

sal for informing you about correct o

sal for informing you about correct op-

p-

p-

p-

eration.

eration.

eration.

eration.

In the course of further developments we reserve the right to technical modifications without

prenotice. Guarantee and liability conditions of KONVEKTA AG

KONVEKTA AG

KONVEKTA AG

KONVEKTA AG’s general business conditions are

not enlarged by the above notes.

Indications and photos should neither be copied and circulated nor used for competitor’s purposes.

All rights according to the copyright remain expressly reserved.

Manufacturer: KONVEKTA AG, P.O. Box 2280, D

KONVEKTA AG, P.O. Box 2280, D

KONVEKTA AG, P.O. Box 2280, D

KONVEKTA AG, P.O. Box 2280, D----34607 Schwalmstadt

34607 Schwalmstadt

34607 Schwalmstadt

34607 Schwalmstadt

BAKL40T12AB

Edition: 18.03.2009

Page: 5/15

1.

1.

1.

1.

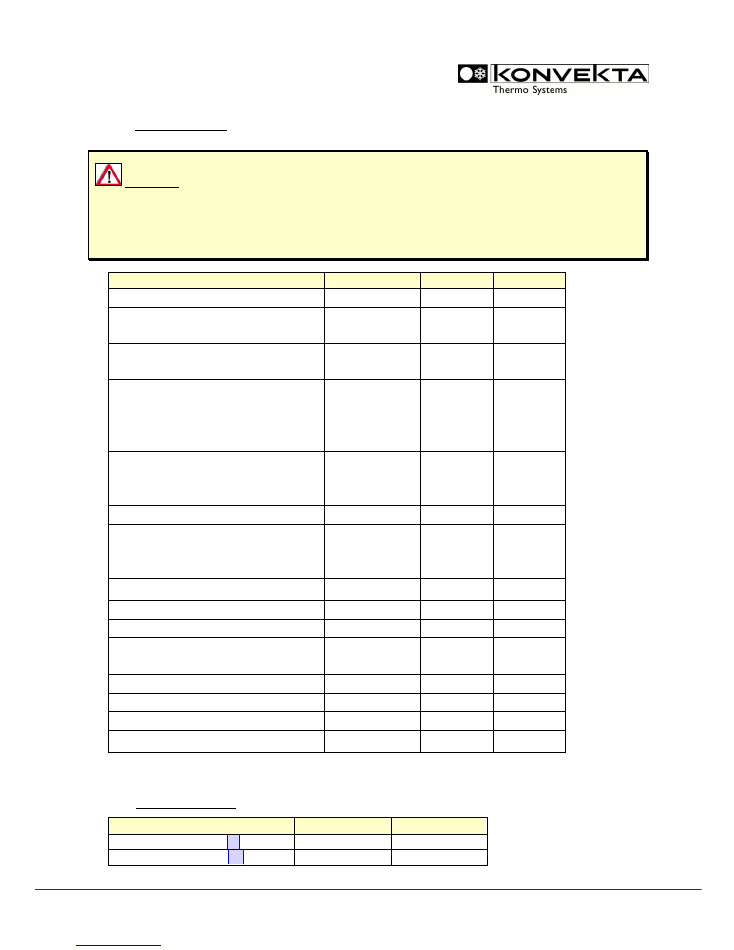

Technical data

Technical data

Technical data

Technical data

Important!

Important!

Important!

Important!

In vehicles that are equipped with an a/c unit with heating function the heating medium has to consist of wa-

ter/glycol – antifreeze protection (conform the mixing ratio to manufacturers` instructions). This is abso-

lutely necessary to prevent the heaters from frost damage!

(The prevalent antifreeze filling of the vehicle manufacturers goes down to -40°C)

Type

Type

Type

Type

::::

KL40T

KL40T

KL40T

KL40T

KL45T

KL45T

KL45T

KL45T

Refrigerant

Refrigerant

Refrigerant

Refrigerant

R134a

R134a

····---- quantity

quantity

quantity

quantity

with front box

[kgs]

approx.

2,5

3,3

2,5

3,3

Operating voltage

Operating voltage

Operating voltage

Operating voltage

resp.

[Volt DC]

12

24

12

24

Current consumption

Current consumption

Current consumption

Current consumption

(three-stage) at 13V:

(three-stage) at 26V:

(stageless) at 26V

[Ampere]

88

44

53

88

44

53

Cooling capacity

Cooling capacity

Cooling capacity

Cooling capacity with KVX40

KVX30 or TM31

TM21

[Watt]

18.000

15.000.

12.000

18.000

15.000.

12.000

Heating capacity Q= 80

Heating capacity Q= 80

Heating capacity Q= 80

Heating capacity Q= 80

[Watt]

15.000

15.000

Evaporator

Evaporator

Evaporator

Evaporator –

––

– Air volume

Air volume

Air volume

Air volume*,

, ,

,

free-blowing

[m

3

/h]

three-stage

stageless

4.000

4400

4.000

4400

Measurements:

Measurements:

Measurements:

Measurements:

---- length

length

length

length

[mm]

1.966

1.966

---- width

width

width

width

[mm]

1.368

1.836

-

hight,

hight,

hight,

hight,

-

depending on roof radius

depending on roof radius

depending on roof radius

depending on roof radius

[mm]

221

183 – 221

229

183 – 229

Weight

Weight

Weight

Weight of unit, Version:

-

Recirculated Air

Recirculated Air

Recirculated Air

Recirculated Air

[kgs ]

approx.

65,5

78,5

-

Fresh Air

Fresh Air

Fresh Air

Fresh Air

[kgs ]

approx.

66,5

79,5

-

Heating

Heating

Heating

Heating

[kgs ]

approx.

69

82

* With standard fans and/or blowers

1.1.

1.1.

1.1.

1.1.

Pressure Switches

Pressure Switches

Pressure Switches

Pressure Switches

Bar OFF

Bar OFF

Bar OFF

Bar OFF

Bar ON

Bar ON

Bar ON

Bar ON

L

LL

Low p

pp

pressure switch (LP)

0,3 ± 0,1

2,1 ± 0,2

H

H

H

High p

pp

pressure switch (HP)

25 +0,0/ −0,5

18 ± 0,5

BAKL40T12AB

Edition: 18.03.2009

Page: 6/15

1.2.

1.2.

1.2.

1.2.

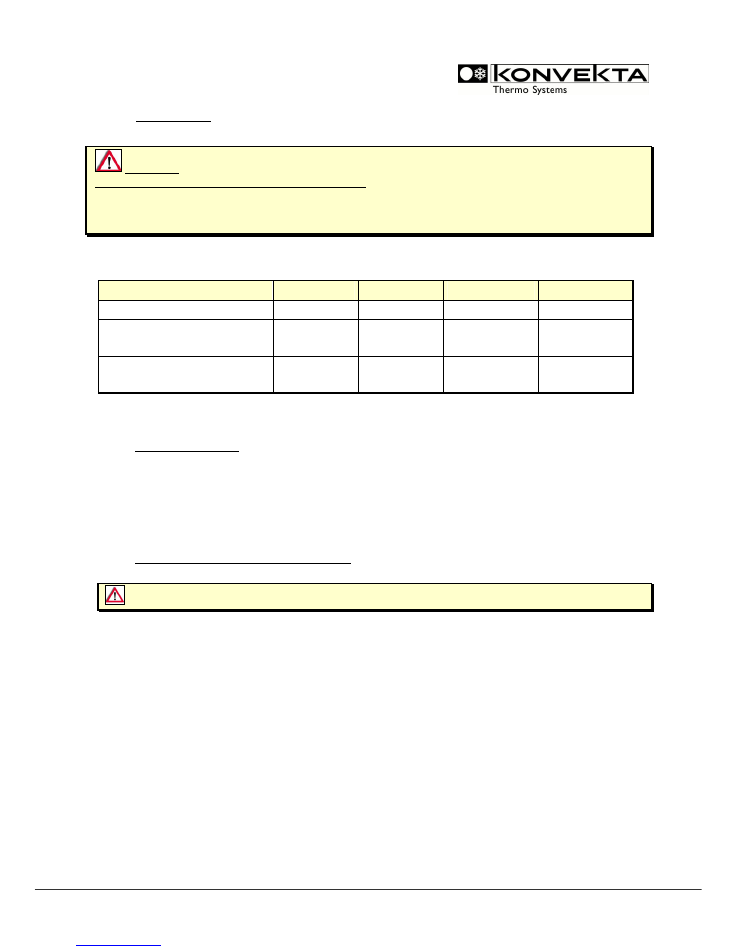

Compressors

Compressors

Compressors

Compressors

Important:

Important:

Important:

Important:

To avoid leakages at the shaft seal of the compressor:

To avoid leakages at the shaft seal of the compressor:

To avoid leakages at the shaft seal of the compressor:

To avoid leakages at the shaft seal of the compressor:

The compressor should be started every 4 weeks for approx. 15 minutes!

This also applies when the vehicle is not into operation for a longer period or when the air conditioning unit

is not used!

Compressor type depending on scope of delivery, see identific

Compressor type depending on scope of delivery, see identific

Compressor type depending on scope of delivery, see identific

Compressor type depending on scope of delivery, see identificaaaation plate at compressor.

tion plate at compressor.

tion plate at compressor.

tion plate at compressor.

Kompressor Typ

Kompressor Typ

Kompressor Typ

Kompressor Typ

KVX40/390

KVX40/390

KVX40/390

KVX40/390

KVX30/325

KVX30/325

KVX30/325

KVX30/325

HDC 33

HDC 33

HDC 33

HDC 33

TM21

TM21

TM21

TM21

Weight (kgs) approx.

33

24,5

15,5

9,7

Oil brand

- quantity (kgs)

Esteröl SE55

2

Esteröl SE55

2

ZXL 100PG

0,5

ZXL 100PG

0,18

Magnetic clutch

1)

- Weight (kgs)

12 / 24V DC

12

12 / 24V DC

7,6

12 / 24V DC

12 / 24V DC

1)

ø depending on vehicle type

2.

2.

2.

2.

Determined use

Determined use

Determined use

Determined use

The

KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA

air conditioner represents an air conditioning system that works with the ozone friendly

refrigerant R 134a and which creates a pleasant and individually adjustable room temperature by means of

forced convection. The determined use includes also the observance of the Operating instruction and the

proof of regular inspections as well.

3.

3.

3.

3.

Generally information for a/c unit

Generally information for a/c unit

Generally information for a/c unit

Generally information for a/c unit

Attention in case of roof top a/c units: Never switch on the a/c unit during car

Attention in case of roof top a/c units: Never switch on the a/c unit during car

Attention in case of roof top a/c units: Never switch on the a/c unit during car

Attention in case of roof top a/c units: Never switch on the a/c unit during car----wash!

wash!

wash!

wash!

The a/c unit is operational with running engine only.

At cooling operation the humidity inside the vehicle is decreased, which avoids steamed up windows.

The a/c unit works most effectively with windows and doors shut. If, however, the interior of the stand-

ing vehicle has been heated up severely by exposure to sunlight, short-time opening of windows and

doors may accelerate the cooling down process.

At high outside temperature and humidity condensate might drip off the evaporator and make a puddle

under the vehicle. This is quite normal and no sign for a leakage.

The filter in the return air grid (optional) retains pollution. If the external air is contaminated with gas

switch over to return air operation. The filter should be cleaned or replaced respectively on a regular

basis so that the capacity of the a/c unit is not affected.

If you think that the a/c unit is damaged, switch it off immediately.

If you think that the a/c unit is damaged, switch it off immediately.

If you think that the a/c unit is damaged, switch it off immediately.

If you think that the a/c unit is damaged, switch it off immediately. To avoid further damage have it check

at a KONVEKTA Service Station

. Only after that you can take unit into operation.

See hand book„KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA Service Stations“

BAKL40T12AB

Edition: 18.03.2009

Page: 7/15

3.1.

3.1.

3.1.

3.1.

Operating Cond

Operating Cond

Operating Cond

Operating Conditions

itions

itions

itions

NOTE:

NOTE:

NOTE:

NOTE:

KONVEKTA uses components made of copper and aluminium, which last a whole unit lifetime under normal

environmental conditions. Should the units be operated under aggressive environmental conditions, i.e. air

containing salt-, phosphate- or ammoniac extremely, a corrosion of the cupper- and aluminium components

can not be ruled out. The cupper- and aluminium components of the KONVEKTA systems are not suitable

for such extreme application conditions. We indicate emphatically, that corrosion is not subject to warran-

ties for defects. KONVEKTA does not take over any warranties for defect, neither for corrosion nor for

consequential damage resulting there from, nor for damages caused by cleaning the systems with highly

compressed or corrosion advancing substances.

4.

4.

4.

4.

Introduction control K5

Introduction control K5

Introduction control K5

Introduction control K5

The air conditioning control K5

K5

K5

K5 is a control and regulation device for air conditioners in modern buses. The

bus driver is relieved from all questions of an optimum air conditioning in the passengers’ compartment by a

simple and clear handling.

All functions of the a/c unit are adjustable by different key-buttons. Every button has an indicating lamp,

called

LED

LED

LED

LED

used as a control function of the buttons or in case of operating. Control board K5

K5

K5

K5 is connected

onto the original dash board lightning of the vehicle. This means that in case of running vehicle lamp, night

lightning of control board is also activated.

Auto

Auto

Auto

Auto----test

test

test

test

After activation the control unit performs an auto-test which lasts 20 seconds. Only after finishing this test

the control outputs of the unit are unblocked.

Afterwards the adjusted temperature is indicated.

5.

5.

5.

5.

Operation

Operation

Operation

Operation

Risk of accident!

Risk of accident!

Risk of accident!

Risk of accident!

Priority must be given to the traffic.

Do only operate your air conditioner if the traffic situation does allow it.

Please make sure that all operation and indicating elements can be recognized and read properly.

Protect the displays and all indicating instruments against sun rays and other optical faults.

Take into consideration that the keys at the control are not designed for extreme demands.

An excessive or quick pressing of the keys for temperature adjustment does not accelerate the cooling

process but leads possibly to damage on the operation panel and spoils the total functioning of your air

conditioner.

BAKL40T12AB

Edition: 18.03.2009

Page: 8/15

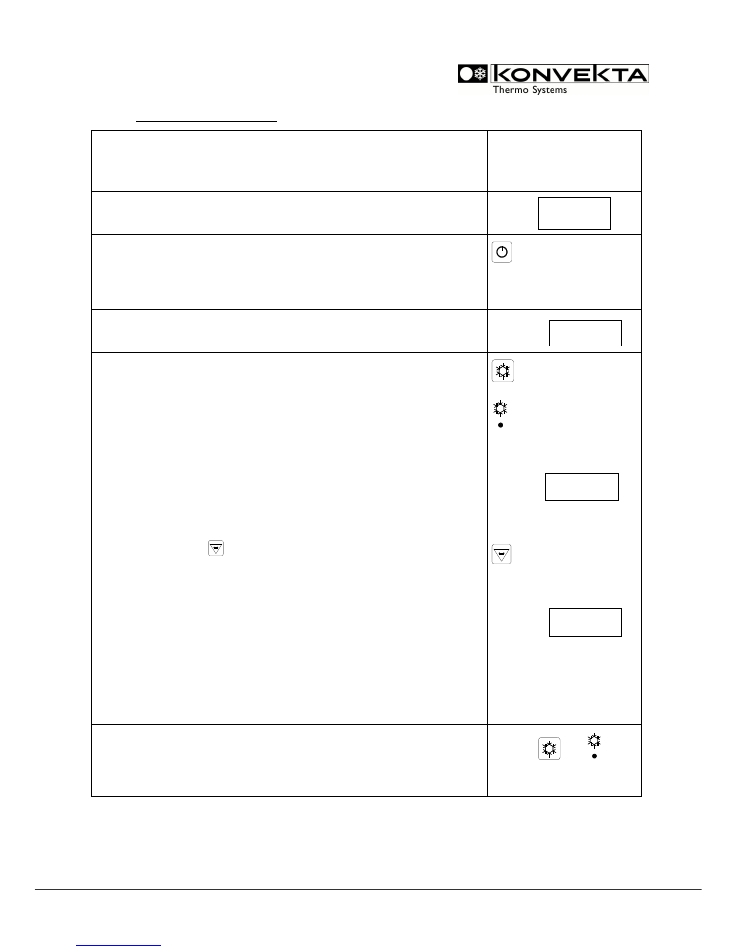

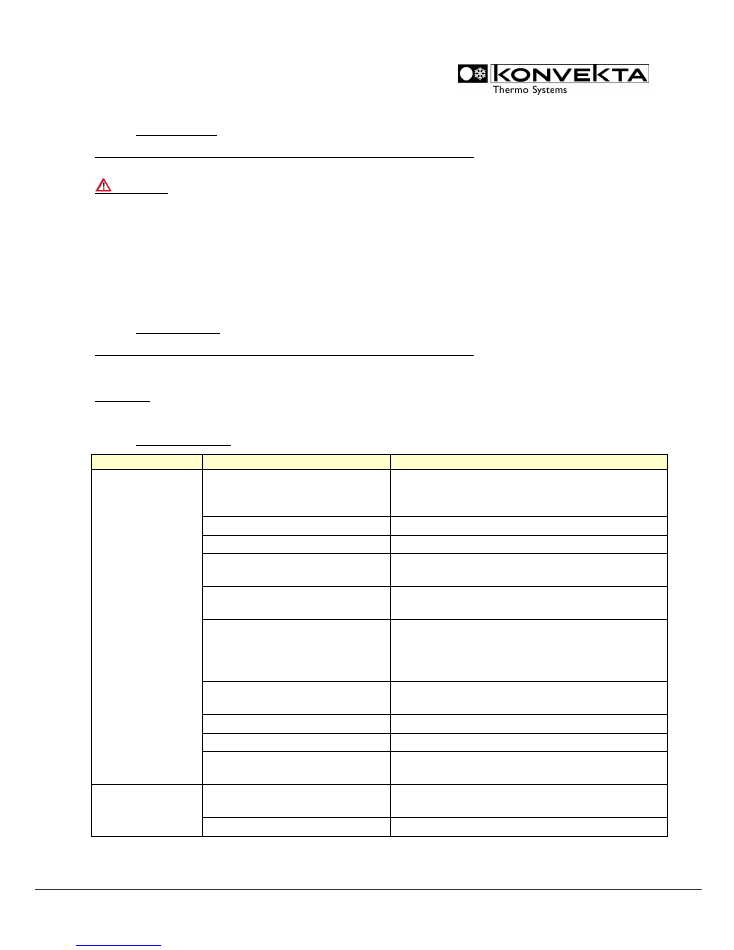

5.1.

5.1.

5.1.

5.1.

Operati

Operati

Operati

Operation panel / function of the keys

on panel / function of the keys

on panel / function of the keys

on panel / function of the keys

Note:

Note:

Note:

Note:

After the switching on the control is adjusted to the set value stored before it was switched off.

1.

Key for switching the control ON/OFF

2.

Key for reduction of the selected temperature setting,

Alternatively: Manual adjustment „slow speed“

3.

Key for switching ON/OFF the a/c operation

4.

Key for increasing the desired room temperature setting,

Alternatively: Manual adjustment "high speed“

5.

LED lamp indicates that a/c operation is activated.

6.

LED lamp indicates that circulated air function is activated.

7.

LED lamp indiactes that a manual set-up was effected.

8.

4-digit seven-segmental display for indication of the selected room temperature (°Celsius or

°Fahrenheit)

Alternatively: Error code indication in case of trouble.

9.

Key for switch-over fresh air- / circulated air operation.

10. Shift-key fan speed manual / automatic

11. Key for switching the REHEAT-operation ON/OFF

12. Shift-key heating operation manual / automatic

13. Illuminated display indicates the fan speed (in 10%- steps), Alternatively: Indication of the heat-

ing valve position

3

33

3 4

44

4

5

55

5 6

66

6

7

77

7

11

11

11

11 12

12

12

12

1

11

1

2

22

2 8

88

8

13

13

13

13

10

10

10

10

9

99

9

(BBZW0038)

BAKL40T12AB

Edition: 18.03.2009

Page: 9/15

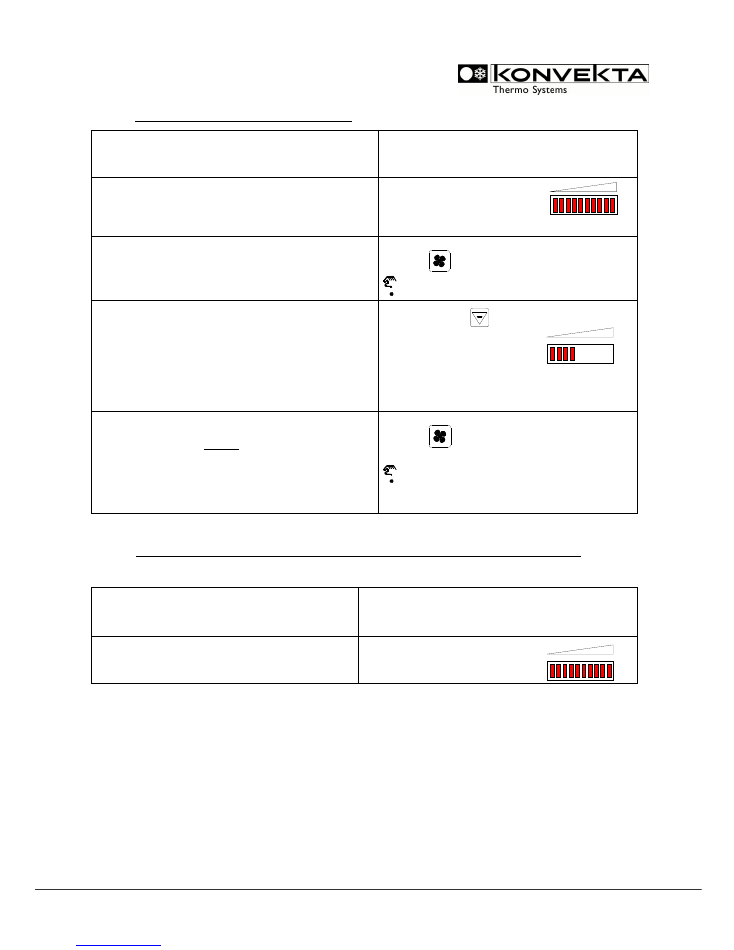

5.2.

5.2.

5.2.

5.2.

A/C operation ON / OFF

A/C operation ON / OFF

A/C operation ON / OFF

A/C operation ON / OFF

Start vehicle engine

(refer to orig. operating instruction of the vehicle).

Note:

Note:

Note:

Note: If only the vehicle ignition was switched on without starting the vehicle

engine, the blower speed will be reduced to the lowest level after 10 min. in

order to prevent a considerable discharge of the vehicle battery.

Software- and control unit number is indicated for 5sec.

switch ON

ON

ON

ON control:

N

N

N

NOTE:

OTE:

OTE:

OTE:

After activation the control unit performs an auto-test which lasts 20 seconds.

Only after finishing this test the control outputs of the unit are unblocked.

press key

The last selected desired temperature, e.g. B. 28°C is indicated:

Switch ON a/c operation:

By pressing key

you can select the desired temperature down-

wards (e.g. from 28°C up to 21°C = press 7 times)

The new set-value will be shown in the display:

The a/c operation is activated since the room temperature exceeds the set-value by

7K. The blower speed is 100%, since the difference between room temperature and

set value exceeds 3K.

In case the room temperature and set value are roughly equal the blower speed will

be reduced and after the room temperature and set value have reached the same

level the evaporator blowers will operate at the lowest possible speed.

press key,

LED lights up , a/c opera-

tion activated

adjusted temperature e.g.:

is indicated.

press key 7xtimes

new set-value:

will be indicated and stored

after 5sec.

Switch Off a/c operation:

press

key

, LED

goes

out, a/c operation is switched

OFF

0 − 2

F

28

C

28

C

21

C

BAKL40T12AB

Edition: 18.03.2009

Page: 10/15

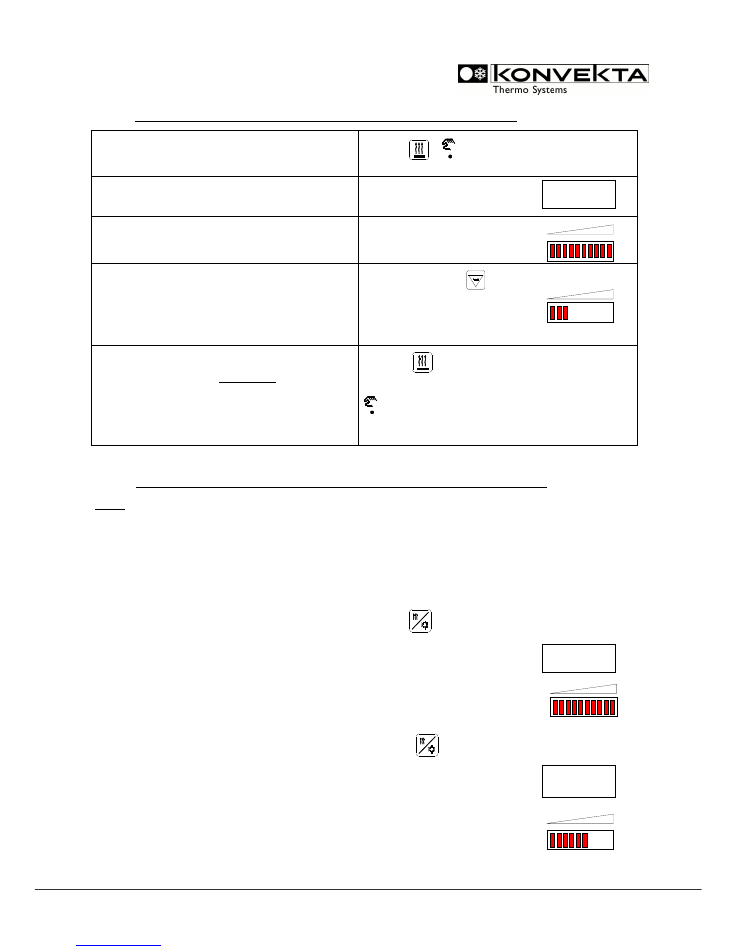

5.2.1. Manual adjustment of the blower speed

The set value will be indicated in the display.

e.g. 21°C:

The blower speed will be indicated by an illumi-

nated display.

e.g. speed 100%:

Push shift-key „fan speed manual/automatic“:

Press key

:

LED „

manual adjustment“ is lighting up

Reduction of the blower speed:

e.g. press 6 times :

new fan speed will be indicated:

−

After 5 sec. the new fan speed will be stored.

−

The new fan speed will be indicated.

The automatic blower speed is deactivated.

The automatic blower speed is deactivated.

The automatic blower speed is deactivated.

The automatic blower speed is deactivated.

Note:

Note:

Note:

Note:

By pressing again the fan key the automatic operation

will be reactivated. The fan speed is regulated depend-

ing on the difference between the existing and set

value.

press key

:

LED „manual adjustment

LED „manual adjustment

LED „manual adjustment

LED „manual adjustment

““““ goes out.

goes out.

goes out.

goes out.

Automatic blower speed is activated

Automatic blower speed is activated

Automatic blower speed is activated

Automatic blower speed is activated.

5.3.

5.3.

5.3.

5.3.

Heating operation fully automatic => only in case of a/c units with heating option

Heating operation fully automatic => only in case of a/c units with heating option

Heating operation fully automatic => only in case of a/c units with heating option

Heating operation fully automatic => only in case of a/c units with heating option

−

Basis: Actual existing room temperature of 10 °C

desired temperature is indicated:

e.g. 21°C:

Blower speed actually 100%, will be indicated

with an illuminated display.

e.g. speed 100%:

Heating operation is activated since the room temperature is 11K below the set value. The evaporator

blower operates with the lowest possible speed. The blower speed will be increased since the room

temperature is more than 3 K below the set value. A requirement therefore is that the air outlet tem-

perature is higher than the set value. When room temperature and set value reach roughly the same level

the fan speed will be reduced. After room temperature and set value have reached exactly the same level

the evaporator blower will operate at the lowest possible speed. The heating valve is 100% opened.

When room temperature and set value reach roughly the same level the heating valve will be cycle timed

- see

PID- performance

. The air outlet temperature will be constantly kept at the level necessary to

achieve the preselected set value.

BAKL40T12AB

Edition: 18.03.2009

Page: 11/15

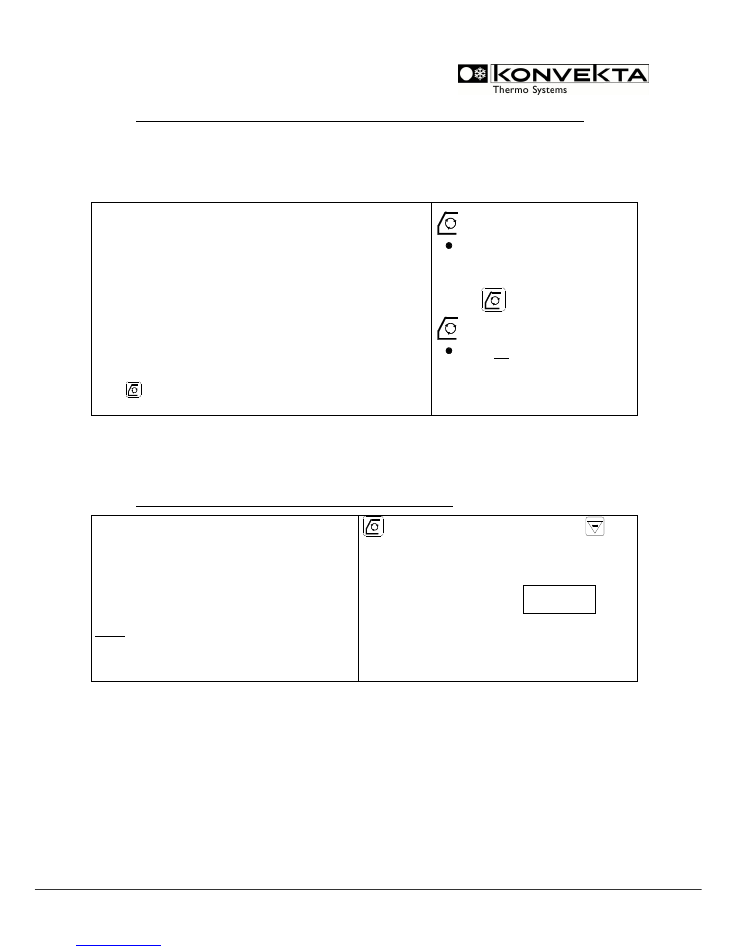

5.3.1. Manual heating operation => only in case of a/c units with heating option

Press shift

Press shift

Press shift

Press shift----key heating operation:

key heating operation:

key heating operation:

key heating operation:

press key

,

LED

LED

LED

LED „

manual Adjustment“ is ligh

is ligh

is ligh

is lightttting

ing

ing

ing

up

up

up

up

„H“

„H“

„H“

„H“

for manual adjustment of the heating valve

will be indicated in the display.

The valve control will be indicated by an illumi-

nated display.

display 100%:

Reduction of the heating valve adjustment:

−

heating valve adjustment 30% will be indi-

cated and after 5 sec. the new value will be

stored.

−

Automatic heating is deactivated.

e.g.

press key 7 times:

:

New heating valve adjustment 30%

will be indicated.:

Note:

Note:

Note:

Note:

By pressing again the heating key the automatic

operation will be reactivated. The heating valve

will be switched on/off automatically depending

on the difference between existing value and set

value.

press key

:

LED

LED

LED

LED „

manual Adjustment“ goes out

goes out

goes out

goes out

Automatic heating is activated

Automatic heating is activated

Automatic heating is activated

Automatic heating is activated.

5.4.

5.4.

5.4.

5.4.

REHEAT activate / stop => only for in case of a/c units with heating option

REHEAT activate / stop => only for in case of a/c units with heating option

REHEAT activate / stop => only for in case of a/c units with heating option

REHEAT activate / stop => only for in case of a/c units with heating option

Note:

Note:

Note:

Note:

In the REHEAT- operation the compressor is constantly operating in order to dehumidify the air. If required

the heating is switched on by the control panel in order to prevent that the selected room temperature

changes.

REHEAT- operation is restricted to max. 10 min. After 10 min. the REHEAT operation is stopped by the

control panel.. REHEAT

REHEAT

REHEAT

REHEAT will be activated for a period of 10 minutes.

Activate REHEAT operation

Activate REHEAT operation

Activate REHEAT operation

Activate REHEAT operation

press key

, REHEAT -operation is activated

„rH“

„rH“

„rH“

„rH“ will be indicated in the display:

Blower speed 100% will be indicated with an il-

luminated display.

blowerspeed 100%:

REHEAT Betrieb deaktivieren

REHEAT Betrieb deaktivieren

REHEAT Betrieb deaktivieren

REHEAT Betrieb deaktivieren

press again

, REHEAT - operation is deactivated

Set temperature value will be indicated

e.g.21°C:

Blower speed of actually 60% will be indicated

with an illuminated display.

e.g. blower speed 60%:

H

rH

21

21

21

21

C

C

C

C

BAKL40T12AB

Edition: 18.03.2009

Page: 12/15

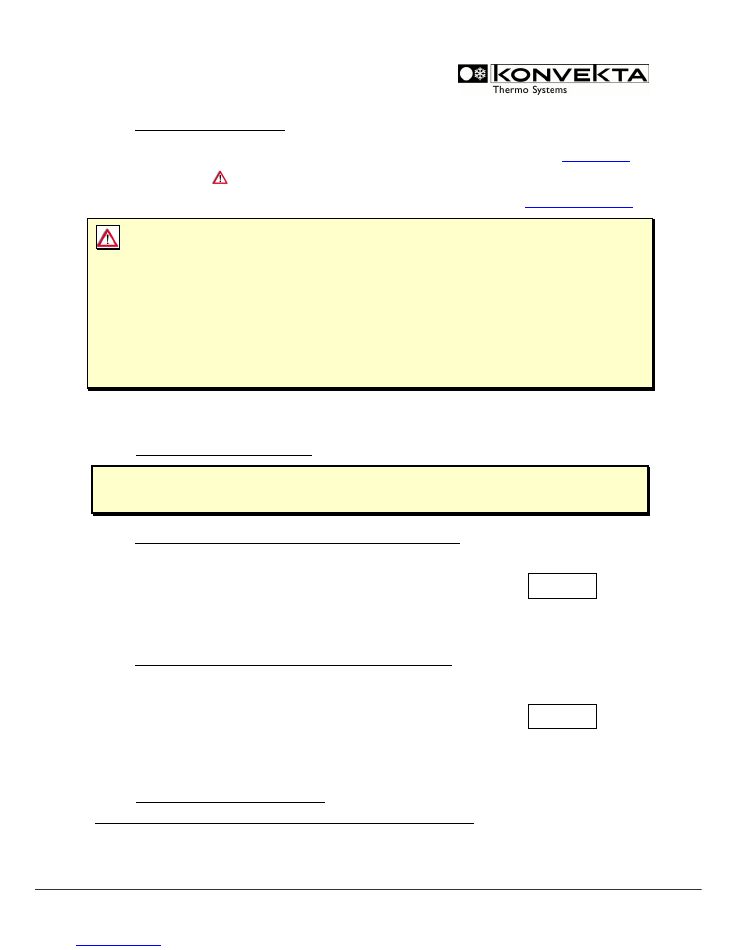

5.5.

5.5.

5.5.

5.5.

Switch Recirc. Air operation => only in case of a/c units with Rec. air flaps option

Switch Recirc. Air operation => only in case of a/c units with Rec. air flaps option

Switch Recirc. Air operation => only in case of a/c units with Rec. air flaps option

Switch Recirc. Air operation => only in case of a/c units with Rec. air flaps option

In case of recirculated air operation, the income of fresh air is interrupted and the air inside the vehicle is

going to be circulated which avoids that outside air, possibly dirty because of exhaust fumes (tunnel driving)

has a chance to penetrate into interior room of the vehicle.

If windows are misting up, return air operation should be switched off:

switch over from circulated air operation to fresh air operation

NOTE:

NOTE:

NOTE:

NOTE:

If key

is pressed again the fresh air flap will be react

react

react

reactiiiivated

vated

vated

vated and

circulated air operation restarted (LED-display will light up).

LED light up, recirculated air opera-

tion is active

Press key

,

LED is not lighting, fresh air opera-

tion restarted

Note:

Note:

Note:

Note:

After the switching on the control is adjusted to the set value stored before it was switched off.

5.6.

5.6.

5.6.

5.6.

Change over of the temperture indication to ° Fahrenheit

Change over of the temperture indication to ° Fahrenheit

Change over of the temperture indication to ° Fahrenheit

Change over of the temperture indication to ° Fahrenheit

Switch over:

Note:

Note:

Note:

Note:

By pressing the „-“ and „circulated air“-key the

temperature indication switches over to

Celsius

again.

press constantly, afterwards press the key

preselected set temperature value will be indicated in °

Fahrenheit.

5 0

F

BAKL40T12AB

Edition: 18.03.2009

Page: 13/15

6.

6.

6.

6.

Maintenance / Servicing

Maintenance / Servicing

Maintenance / Servicing

Maintenance / Servicing

Service and maintenance works have to be executed on basis of

“Maintenance Schedule, no:

WP05070618

.

---- Only skilled personnel are allowed to execute these works

Only skilled personnel are allowed to execute these works

Only skilled personnel are allowed to execute these works

Only skilled personnel are allowed to execute these works!

!

!

! ----

For general instructions on repair – and maintenance works please contact via email:

TKD@konvekta.com

TKD@konvekta.com

TKD@konvekta.com

TKD@konvekta.com

Danger of accident!

Danger of accident!

Danger of accident!

Danger of accident!

The experts in charge of installation and maintenance works should at least be trained in acco

The experts in charge of installation and maintenance works should at least be trained in acco

The experts in charge of installation and maintenance works should at least be trained in acco

The experts in charge of installation and maintenance works should at least be trained in accorrrrdance with

dance with

dance with

dance with

the EN 378

the EN 378

the EN 378

the EN 378 ---- part 4 and

part 4 and

part 4 and

part 4 and strictly obey the legal regulations.

strictly obey the legal regulations.

strictly obey the legal regulations.

strictly obey the legal regulations.

All works or modifications at the air conditioner which are improperly executed can lead to function tro

All works or modifications at the air conditioner which are improperly executed can lead to function tro

All works or modifications at the air conditioner which are improperly executed can lead to function tro

All works or modifications at the air conditioner which are improperly executed can lead to function trou-

u-

u-

u-

bles and can jeopardize the operation safety. We recommend having works and modifications only ex

bles and can jeopardize the operation safety. We recommend having works and modifications only ex

bles and can jeopardize the operation safety. We recommend having works and modifications only ex

bles and can jeopardize the operation safety. We recommend having works and modifications only exe

ee

ecuted

cuted

cuted

cuted

in a KONVE

in a KONVE

in a KONVE

in a KONVEKTA service station

KTA service station

KTA service station

KTA service station

Also the prescribed regular maintenance works should be ex

Also the prescribed regular maintenance works should be ex

Also the prescribed regular maintenance works should be ex

Also the prescribed regular maintenance works should be exe

ee

ecuted in an

cuted in an

cuted in an

cuted in an

authorized KONVEKTA service st

authorized KONVEKTA service st

authorized KONVEKTA service st

authorized KONVEKTA service staaaation

tion

tion

tion

....

Before having the maintenance executed please read carefully the KONVKETA safety prescri

Before having the maintenance executed please read carefully the KONVKETA safety prescri

Before having the maintenance executed please read carefully the KONVKETA safety prescri

Before having the maintenance executed please read carefully the KONVKETA safety prescrip

pp

ptions

tions

tions

tions

(TD00052A

(TD00052A

(TD00052A

(TD00052A

), in order to avoid

), in order to avoid

), in order to avoid

), in order to avoid dangers and accidents!

dangers and accidents!

dangers and accidents!

dangers and accidents!

See hand book„KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA Service Stations

Source of supply: KONVEKTA AG

KONVEKTA AG

KONVEKTA AG

KONVEKTA AG, P.O. Box 2280, D-34607 Schwalmstadt

6.1.

6.1.

6.1.

6.1.

Trouble indication in the display

Trouble indication in the display

Trouble indication in the display

Trouble indication in the display

ATTENTION:

ATTENTION:

ATTENTION:

ATTENTION:

In case of trouble indication in the display (

In case of trouble indication in the display (

In case of trouble indication in the display (

In case of trouble indication in the display (

F0

F0

F0

F0

resp.

resp.

resp.

resp.

F1

F1

F1

F1

) the control pane

) the control pane

) the control pane

) the control panel is not ready for operation.

l is not ready for operation.

l is not ready for operation.

l is not ready for operation.

Operation of the a/c system only after verification by qualified a

KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA

-Service- Station

1)

1)

1)

1)

....

6.1.1. Trouble at the temperature sensor F0 (room sensor, blue):

A trouble at the room temperature sensor will be indicated by

a flashing display.

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault----finding and removal (for ex. cable ru

finding and removal (for ex. cable ru

finding and removal (for ex. cable ru

finding and removal (for ex. cable rup

pp

pture,

ture,

ture,

ture,

short

short

short

short----circuit, sensor not connected)

circuit, sensor not connected)

circuit, sensor not connected)

circuit, sensor not connected) the control panel can be operated again.

the control panel can be operated again.

the control panel can be operated again.

the control panel can be operated again.

6.1.2. Trouble at the temperature sensor F1 (air outlet, yellow):

A trouble at the air outlet temperature sensor will be indicated

by a flashing display.

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault

The control panel is not ready for operation. Only after the fault----finding and removal (for ex. cable ru

finding and removal (for ex. cable ru

finding and removal (for ex. cable ru

finding and removal (for ex. cable rup

pp

pture,

ture,

ture,

ture,

short

short

short

short----circuit, sensor not connected) the c

circuit, sensor not connected) the c

circuit, sensor not connected) the c

circuit, sensor not connected) the control panel can be operated again.

ontrol panel can be operated again.

ontrol panel can be operated again.

ontrol panel can be operated again.

6.2.

6.2.

6.2.

6.2.

Oil change Compressor type KVX

Oil change Compressor type KVX

Oil change Compressor type KVX

Oil change Compressor type KVX

Reference to maintenance Schedule Bus No.: WP 07 05 06 18 Item WK15:

Reference to maintenance Schedule Bus No.: WP 07 05 06 18 Item WK15:

Reference to maintenance Schedule Bus No.: WP 07 05 06 18 Item WK15:

Reference to maintenance Schedule Bus No.: WP 07 05 06 18 Item WK15:

First oil change at the first maintenance of the vehicle, then approx. every 3 years. At every oil change the oil

suction strainer has to be cleaned. Observe the oil quantity according to the compressor type (s. item 1.2).

F 0

F 1

BAKL40T12AB

Edition: 18.03.2009

Page: 14/15

6.3.

6.3.

6.3.

6.3.

Return air grid

Return air grid

Return air grid

Return air grid

Reference to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK13:

Reference to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK13:

Reference to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK13:

Reference to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK13:

Clean the return air grid in the passenger area monthly. In case of enormous dirt weekly.

Important:

Important:

Important:

Important:

-

If the filter is soiled, the cooling performance of the air conditioner will decrease.

-

It is not a

It is not a

It is not a

It is not alllllowed to operate the air conditioner without filter.

lowed to operate the air conditioner without filter.

lowed to operate the air conditioner without filter.

lowed to operate the air conditioner without filter.

-

If filter is defective, filter must r

If filter is defective, filter must r

If filter is defective, filter must r

If filter is defective, filter must replace!

eplace!

eplace!

eplace!

-

In case the a/c unit will be operated continuously with dirty filter, the evaporator blowers will be dam-

aged

-

Due to a reduction of the evaporator air flow, the a/c function „defrosting“ will be activated more often

resulting in a decrease of the cooling capacity and damage of the cooling compressor!

6.4.

6.4.

6.4.

6.4.

Condenser coil

Condenser coil

Condenser coil

Condenser coil

Reference

Reference

Reference

Reference to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK03:

to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK03:

to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK03:

to Maintenance Schedule Bus No.: WP 07 05 06 18 Item WK03:

Always keep condenser coil fins clean. Severe soiling cause’s excess pressure within the a/c-unit system and

it automatically stops working.

Attention:

Attention:

Attention:

Attention: The condenser coil fins have to be cleaned with compressed air at least once a year, in case of

severe soiling more often.

6.5.

6.5.

6.5.

6.5.

Trouble shooting

Trouble shooting

Trouble shooting

Trouble shooting

Trouble

Trouble

Trouble

Trouble

Cause

Cause

Cause

Cause

Repair

Repair

Repair

Repair ----

only by refrigeration expert

only by refrigeration expert

only by refrigeration expert

only by refrigeration expert

a/c is not running

thermostat is open

-

check thermostat- adjust new if necessary

-

check evaporator blower and replace, if neces-

sary

electric wiring disconnected

-

check wiring at switch plate

relay defective

-

check relay and replace, if necessary

defrosting thermostat cuts off

-

check evaporator blower and replace, if neces-

sary

too low outside temp. (possible

icing of evaporator)

-

switch on "ventilation" only

excess pressure

-

check if condenser fans are running

-

check fuses

-

clean condenser coil with compressed air

-

let unit run until pressure is stabilized

deficiency or refrigerant, leakage in

unit

-

check unit for leaks

-

refill refrigerant

low pressure, drier clogged

-

replace drier

magnetic clutch

-

check connections at magnetic clutch

compressor does not compress

-

check pressure at suction and discharge side

replace compressor, if necessary

strong noise at

compressor

Defect bearing on compressor.

-

replace bearing or complete compressor only

slack V-belt

-

check V-belt at compressor drive

See hand book„KONVEKTA

KONVEKTA

KONVEKTA

KONVEKTA Service Stations

By user

BAKL40T12AB

Edition: 18.03.2009

Page: 15/15

7.

7.

7.

7.

Warranty Conditions

Warranty Conditions

Warranty Conditions

Warranty Conditions

The current „General Warranty Conditions KONVEKTA AG“ will apply. A copy will be furnished by the

warranty department. Please contact

gwl@konvekta.com

8.

8.

8.

8.

Waste disposal in accordance w

Waste disposal in accordance w

Waste disposal in accordance w

Waste disposal in accordance with legal provisions

ith legal provisions

ith legal provisions

ith legal provisions

After the phase of use the last proprietor is responsible for the adequate waste management. The enviro

After the phase of use the last proprietor is responsible for the adequate waste management. The enviro

After the phase of use the last proprietor is responsible for the adequate waste management. The enviro

After the phase of use the last proprietor is responsible for the adequate waste management. The environ-

n-

n-

n-

mental regulations in the exporting country must be observed.

mental regulations in the exporting country must be observed.

mental regulations in the exporting country must be observed.

mental regulations in the exporting country must be observed.

The following list contains the most important regulating literature, valid for the

Federal Rep. of Germany

:

Resolution for dangerous substances

Resolution for used oil

Law for waste circulation (KRW/AfgG))

Law of water balance

Resolution for the proofs of utilization and re-

moval

Resolution for the waste management of old cars and

the adaptation of road prescriptions

Criminal Code (StGB) 28th section „criminal

acts against the environment” §326 - Environ-

ment jeopardizing waste management

Resolution (EWC) No.3093/94 for materials that af-

fect the ozone layer

Law of chemicals § 27 - penal prescriptions

Resolution to prohibit certain ozone destroying halo-

gen hydrocarbons.

The used refrigerant endangers the environment. When dealing with refrigerants the existing prescriptions

and regulations are to be followed. Only skilled

Only skilled

Only skilled

Only skilled personnel are allowed to carry out these works!

personnel are allowed to carry out these works!

personnel are allowed to carry out these works!

personnel are allowed to carry out these works!

Water endangering substances - acc. to §§19g-19l - are solid, liquid, and gaseous substances. e.g.: mineral and

tar oils (cooling oils), halogen containing organic combinations (refrigerants).

Source of supply:

-

Bundesanzeiger

-

Beuth Verlag

-

dtv (Deutscher Taschenbuch Verlag

9.

9.

9.

9.

History of modification

History of modification

History of modification

History of modification

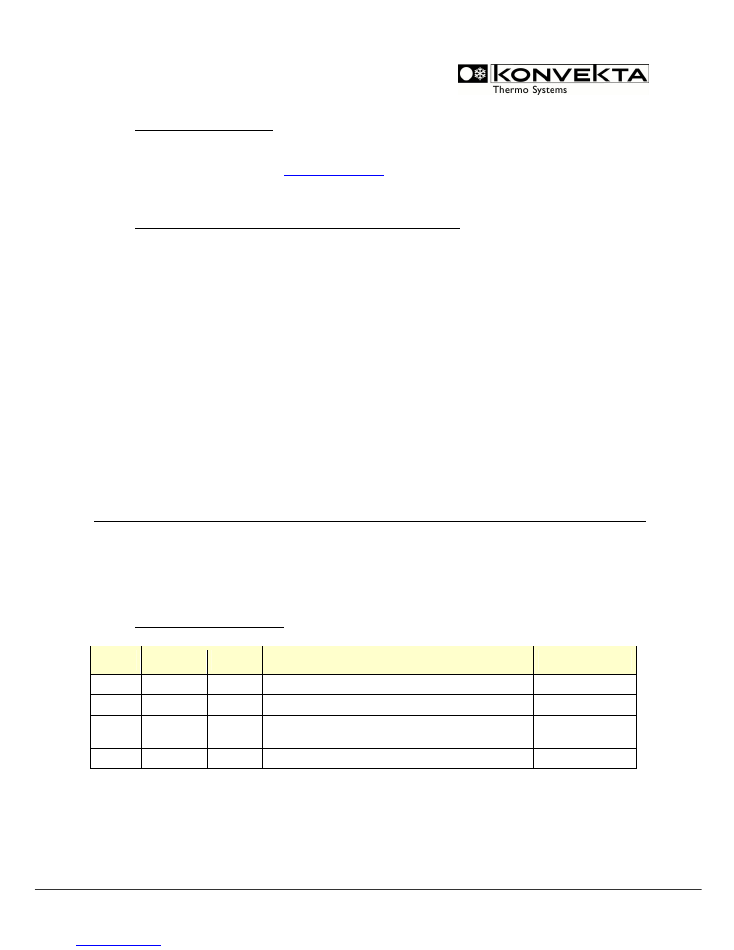

vers

vers

vers

versiiiion

on

on

on date

date

date

date

name

name

name

name

remark

remark

remark

remark

file

file

file

file

A00

07.03.2007

S. Pfluger source file

BAKL40T12AB

A01

09.07.2007

B.Keßler

Added KL45T and technical data

BAKL40T12AB

A02

20.11.2007

B.Keßler

Fact 1.2 has now been replaced and added Fakt 1 “Im-

portant”

BAKL40T12AB

A03

18.03.2009

B. Keßler Pkt.1.2 updated; TM31 replaced by HDC 33

BAKL40T12AB