Full Text Searchable PDF User Manual

INSTRUCTION

آ

آ

آ

آ

Industrial

Sewing

Machines

First published : July 1997

Second edition : October 2000

No. 000079

PX302-4W

PX302-5W

INTRODUCTION

INTRODUCTION

INTRODUCTION

INTRODUCTION

Thank you for your purchasing Kansai Special's PX Series.

Read and study this instruction manual carefully before beginning any of the

procedures and save it for later use.

1. This instruction manual describes adjustments and maintenance procedures on this

machine.

2. Before starting the machine, check to make sure the pulley cover, safety cover, etc.

are secured.

3. Before adjusting, cleaning, threading the machine or replacing the needle, be sure

to turn off the power.

4. Never start the machine with no oil in the reservoir.

5. Refer to the parts list as well as this instruction manual before performing

preventive maintenance.

6. The contents described in this instruction manual are subject to change without

notice.

CONTENTS

CONTENTS

CONTENTS

CONTENTS

1. NEEDLES & THREADING THE MACHINE

1-1 Needles

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

1-2 Replacing the needle

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

1-3 To thread the machine

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

1

2. MACHINE SPEED

2-1 Machine speed & direction in which the machine pulley runs

・・・・・・・

2

2-2 Motor & belt

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

2

3. LUBRICATION

3-1 Oil

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

3-2 To fill the machine with oil

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

3-3 Replacing the oil and the filter element

・・・・・・・・・・・・・・・・・・・・・・・・・・・

3

4. SEWING MACHINE INSTALLATION

4-1 Cutting the machine table

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

4

4-2 To install the machine

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5

5. TIMING OF THE LOOPER TO THE NEEDLE

5-1 Needle height

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

5

5-2 Needle drop and needle side stroke

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

5-3 To install the looper

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

6

5-4 Eccentric for adjusting the looper left to right

・・・・・・・・・・・・・・・・・・・・・

7

5-5 Position of the looper rocker

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

7

5-6 Looper left-to-right movement

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8

5-7 Looper/needle front-to-back relationship

・・・・・・・・・・・・・・・・・・・・・・・・・・

8

5-8 Looper setting distance

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

8

5-9 Adjusting the looper back spring

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9

6. ADJUSTING THE NEEDLE GUARD

・・・・・・・・・・・・・・・・・・・・・・・・・

9

7. ADJUSTING THE FEED DOG & STITCH LENGTH

7-1 Feed dog height

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

9

7-2 Stitch length

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

7-3 Differential feed ratio

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

8. ADJUSTING THE PRESSER FOOT

8-1 Presser foot pressure

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

10

8-2 Position of the presser foot and foot lift

・・・・・・・・・・・・・・・・・・・・・・・・・・

11

9. ADJUSTING THE STITCH FORMATION

9-1 Adjusting the looper thread eyelets

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

11

9-2 Position of the looper thread take-up

・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

9-3 Adjusting the needle thread guard

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

10. CLEANING THE MACHINE

・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・・

12

1

م€گ

1

م€‘

NEEDLES & THREADING THE MACHINE

1111----1 Needles

1 Needles

1 Needles

1 Needles

UO163 of Schmetz or Organ

Select the proper needle for the fabric and thread.

< Comparison table of needle sizes >

Schmetz

UY163GAS Nm65 Nm70 Nm75 Nm80 Nm90

Organ UO163

#9

#10

#11

#12

#14

1111----2 Replacing the needle

2 Replacing the needle

2 Replacing the needle

2 Replacing the needle

When replacing the needle, check the needle carefully

to see that the scarf is turned to the rear of the

machine (see the illustration).

1111----3 To thread the machine

3 To thread the machine

3 To thread the machine

3 To thread the machine

Thread the machine correctly by referring to the illustration below. Incorrect

threading may cause skip stitching, thread breakage and/or uneven stitch formation.

< Note >

When replacing the needle, be sure to turn off the

machine. A clutch motor continues running for a while

after the machine is turned off. Therefore keep on

pressing the pedal until the machine stops.

A

,

B ... Needle threads

C

,

D ... Looper threads

2

م€گ

2

م€‘

MACHINE SPEED

2222----1 Machine speed & direction in which the machine pulley runs

1 Machine speed & direction in which the machine pulley runs

1 Machine speed & direction in which the machine pulley runs

1 Machine speed & direction in which the machine pulley runs

Maximum speed : 3,500 rpm

Standard speed : 3,000 rpm

To extend machine life, run the machine

approximately 15~20% below the maximum speed

for the first 200 hours of operation (approx. 1

month). Then run the machine at the standard

speed.

The machine pulley turns counterclockwise as

seen from the end of the machine pulley (see the

illustration).

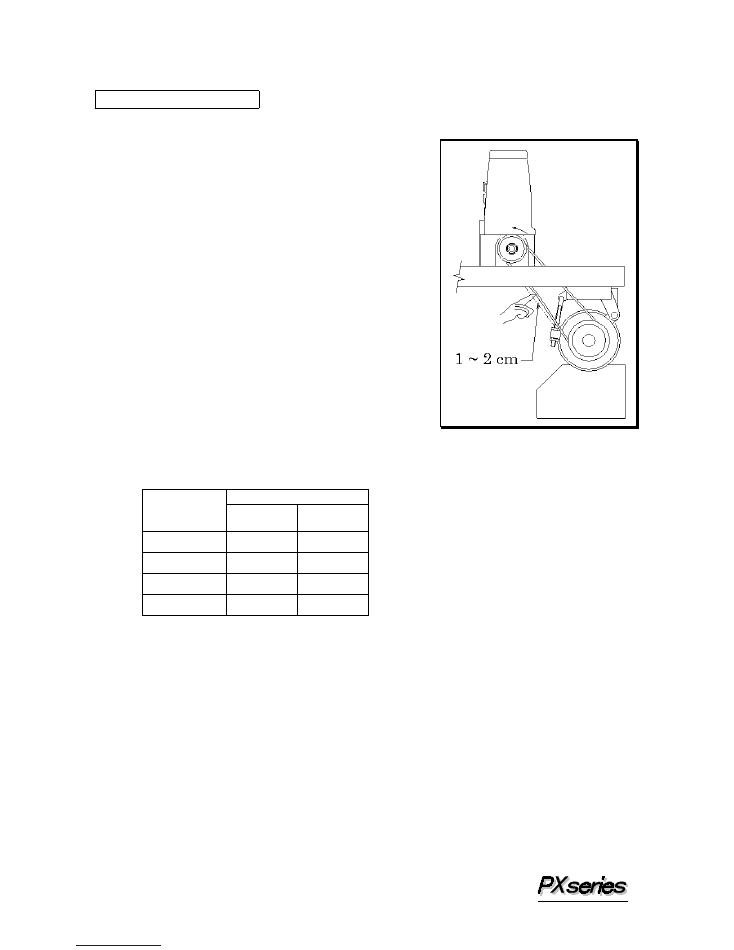

2222----2 Motor & belt

2 Motor & belt

2 Motor & belt

2 Motor & belt

Motor : 3-phase, 2-pole, 400W clutch motor

Belt

: M type V belt

Select the proper motor pulley according to the

machine speed (refer to the motor pulley outer

diameter on the table below). Adjust the position

of the motor by pressing the finger onto the middle

of the belt so that 1~2cm deflection can be

achieved (see the illustration).

< Motor pulley selection table >

Machine speed (SPM)

Motor pulley

outer diameter

(mm)

50Hz 60Hz

60 2500

2950

70 2900

3450

80 3300

(3900)

90 (3700)

(4400)

3

م€گ

3

م€‘

LUBRICATION

3333----1 Oil

1 Oil

1 Oil

1 Oil

Use Kansai Special’s genuine oil

(Part No. 28-611)

3333----2 To fill the machine with oil

2 To fill the machine with oil

2 To fill the machine with oil

2 To fill the machine with oil

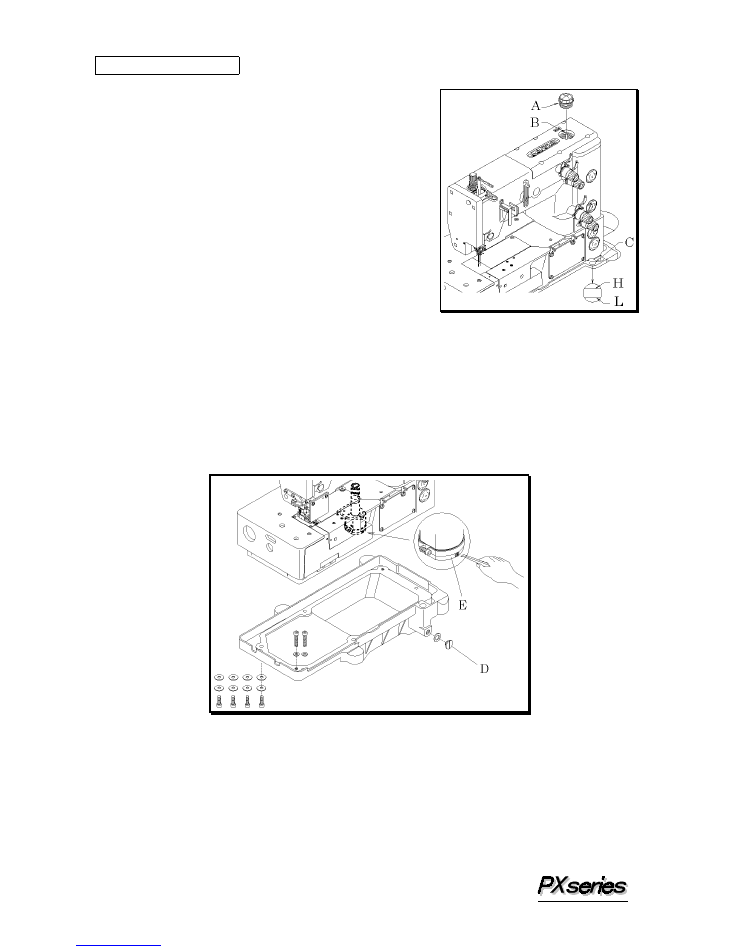

Remove oil plug A. Fill the machine with oil until

the oil level is at the top line (see H in the

illustration) on oil gauge C.

After the first lubrication, add oil so that the oil

level will be between H and L.

After filling the machine with oil, tighten plug A

and run the machine to check the oil is splashing

from oil pipe outlet B.

3333----3 Replacing the oil and the filter element

3 Replacing the oil and the filter element

3 Replacing the oil and the filter element

3 Replacing the oil and the filter element

To extend machine life, be sure to replace the oil after the first 250 hours of operation.

To replace the oil, follow the procedures below.

1. Remove the V belt from the motor pulley and then remove the machine from the

table.

2. Remove screw D and then drain the oil.

Be careful not to stain V belt with the oil.

3. After draining the oil, be sure to tighten screw D.

4. Fill the machine with oil by referring to 3-2 shown above.

If filter element E is contaminated, proper oiling may not be performed.

Clean the filter element every six months. If just a little or no oil flows out from the

nozzle with the proper amount of oil in the machine, check the filter element.

To clean the filter element, remove oil reservoir.

4

م€گ

4

م€‘

SEWING MACHINE INSTALLATION

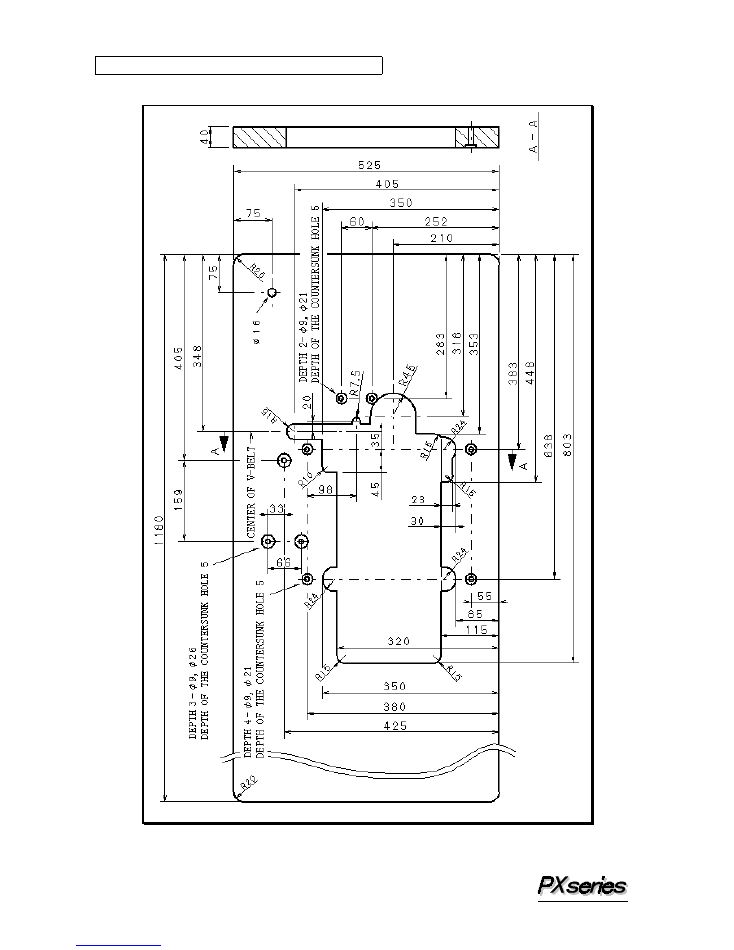

4444----1 Cutting the machine table

1 Cutting the machine table

1 Cutting the machine table

1 Cutting the machine table

5

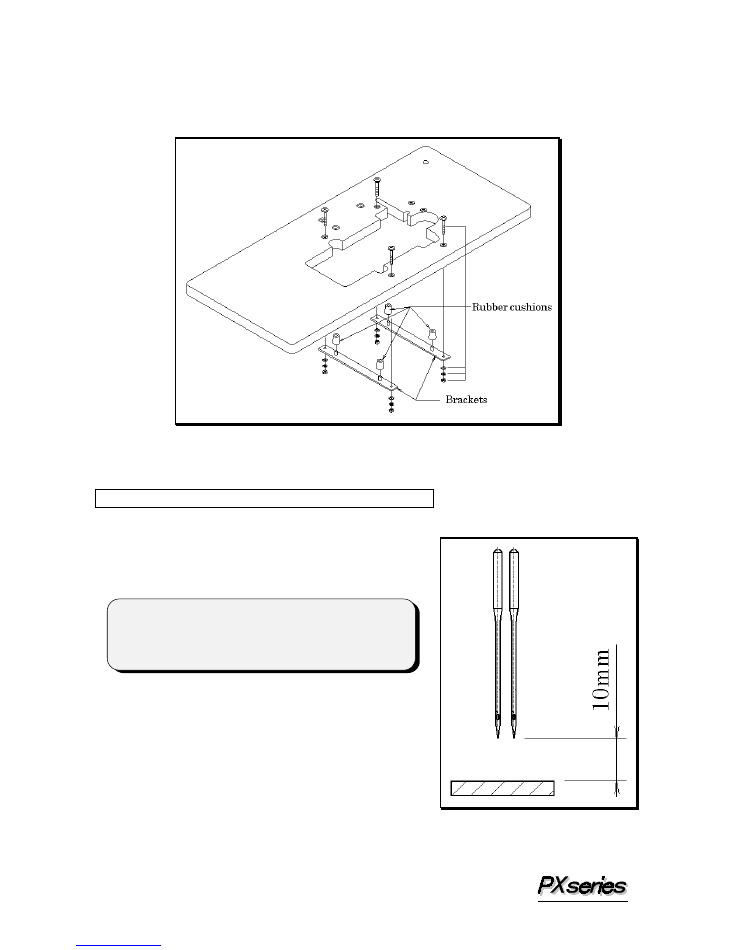

4444----2

2

2

2 To install the machine

To install the machine

To install the machine

To install the machine

Install the brackets on the underside of the table board (see the illustration below).

Fit the rubber cushions onto the brackets.

Mount the machine head on the rubber cushions correctly.

م€گ

5

م€‘

TIMING OF THE LOOPER TO THE NEEDLE

5555----1

1

1

1 Needle height

Needle height

Needle height

Needle height

When the needle bar is at the top of its stroke, there

should be a distance of approximately 10mm from

the top surface of the needle plate to the point of

the needle. Adjustment is made by loosening

screws A.

< Note >

After the above adjustment is made, check to make

sure each needle drops correctly into the center of

each needle drop hole.

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----4W, 302

4W, 302

4W, 302

4W, 302 ----5W

5W

5W

5W

ï¼

ï¼

ï¼

ï¼

6

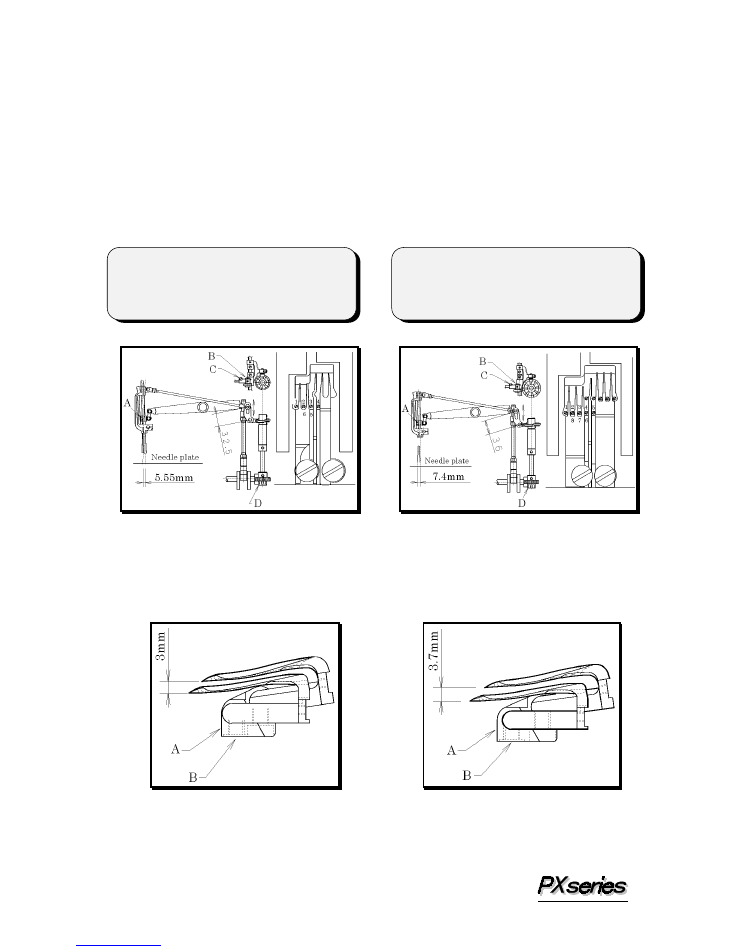

5555----2

2

2

2 Needle drop and needle side stroke

Needle drop and needle side stroke

Needle drop and needle side stroke

Needle drop and needle side stroke

The needle side stroke on this machine is 5.55mm (302-4W) and 7.4mm (302-5W).

To increase the stroke, loosen screw B and move it up in the slot. To decrease the stroke,

loosen screw B and move it down in the slot. The point of the needle should be centered

left to right between fingers of the needle plate when the needle drops to the needle plate.

Adjustment is made by loosening screw C. The needle side stroke movement should

start when the point of the needle moves up from the top surface of the needle plate.

The needle side stroke movement should stop when the point of the needle reaches the top

surface of the needle plate. This timing adjustment is made by worm gear D. To adjust

the position of the needle drop, loosen screws A and turn the needle bar as required.

5555----3333 To install the looper

To install the looper

To install the looper

To install the looper

To set the angle and height of the looper, insert the looper fully into looper holder A and

tighten screw B.

< Note >

Position of the needle drop 1, 2, 3, 4, 5 from

the left side, 5 is the extreme right end. 5,

6, 7, 8, 1 from the right side

< Note >

Position of the needle drop 1, 2, 3, 4 from

the left side, 4 is the extreme right end.

4, 5, 6, 1 from the right side

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----4W

4W

4W

4W

ï¼

ï¼

ï¼

ï¼

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

333302

02

02

02 ----5W

5W

5W

5W

ï¼

ï¼

ï¼

ï¼

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----4W

4W

4W

4W

ï¼

ï¼

ï¼

ï¼

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----5W

5W

5W

5W

ï¼

ï¼

ï¼

ï¼

7

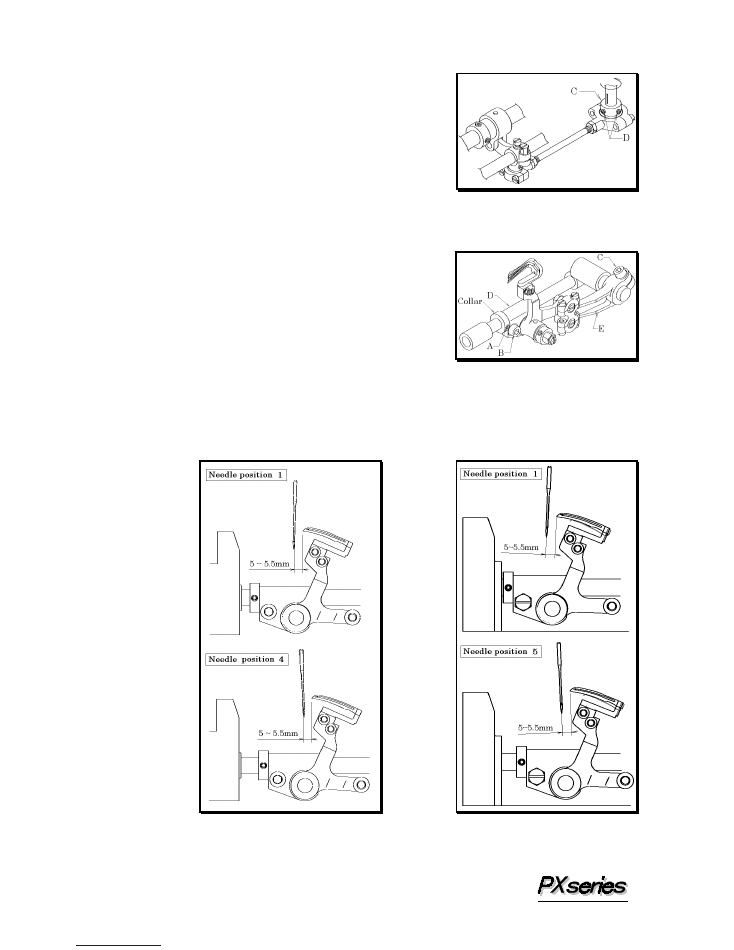

5555----4 Eccentric for adjusting the looper left to right

4 Eccentric for adjusting the looper left to right

4 Eccentric for adjusting the looper left to right

4 Eccentric for adjusting the looper left to right

To adjust the position of the eccentric, loosen screws D.

Align the screw which comes second in the turning

direction of the eccentric with the mark on the shaft.

Then tighten screws D temporarily. Then make a

fine adjustment so that the looper shaft can reach the

extreme right end of its travel while the needle is at

the bottom of its stroke with position 4. After this

adjustment, tighten the screws securely. For

PX302-5W, adjust each looper shaft to come the same

position while the needle is at the bottom of its stroke with position 3 and position 7.

5555----5 Position of the looper rocker

5 Position of the looper rocker

5 Position of the looper rocker

5 Position of the looper rocker

The setting distances of the looper with the needle at

position 4 and position 1 should be equal (5.5mm) (For

PX302-5W, the needle at position 1 and position 5) (see

5-2). To achieve this adjustment, loosen screw A to

loosen the collar. Loosen screws B and C.

Then adjust looper rocker D and lever E.

â– آ

Example

If the setting distance with the needle at position 1 is 5mm and the setting distance with

the needle at position 4 is 6mm, move looper rocker D approximately 1mm to right.

After the adjustment is made, tighten screws B and C securely. Then tighten screw A

with the collar fitted onto looper rocker D.

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----4W

4W

4W

4W

ï¼

ï¼

ï¼

ï¼

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----5W

5W

5W

5W

ï¼

ï¼

ï¼

ï¼

8

5555----6 Looper left

6 Looper left

6 Looper left

6 Looper left----to

to

to

to----right movement

right movement

right movement

right movement

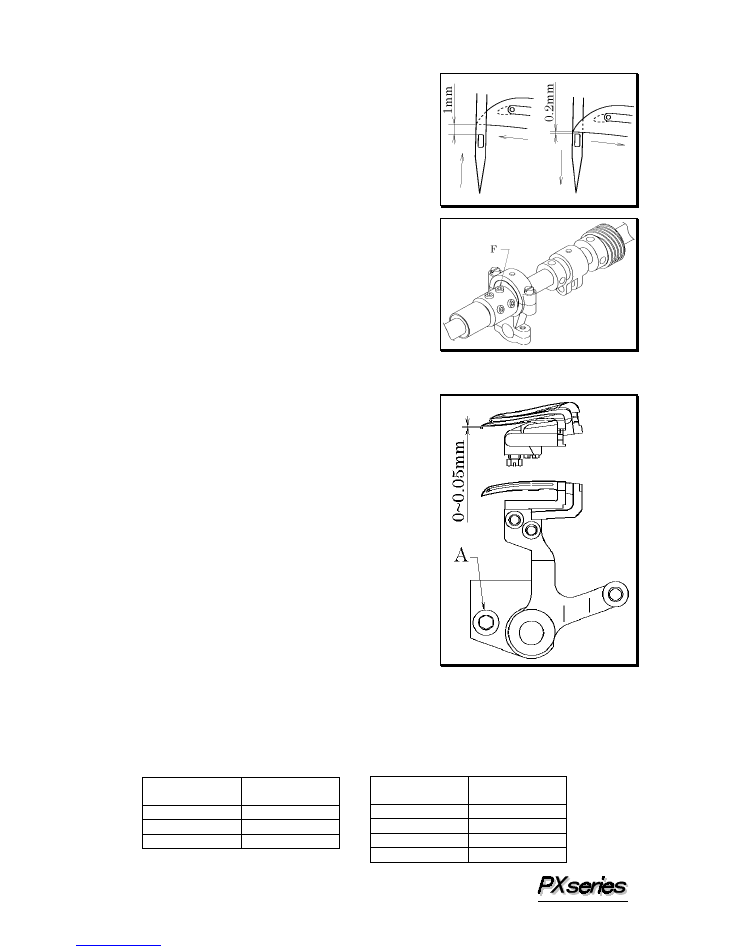

This adjustment should be made when the needle is

at position 1 (see 5-2). When the point of the

looper, moving to the left, has reached the left side

of the needle, it should be 1mm above the top of the

needle's eye. When the point of the looper, moving

to the right, has reached the left side of the needle,

it should be 0.2mm above the top of the needle's

eye.

The looper moves 0.8mm faster than the needle (see

the illustration on the right).

For PX302-5W when the needle is at position 2.

â–

Adjustment is made by loosening three screws F.

After the adjustment, tighten these three screws

equally.

5555----7 Looper/needle front

7 Looper/needle front

7 Looper/needle front

7 Looper/needle front----to

to

to

to----back relationship

back relationship

back relationship

back relationship

Adjust when the needle is at position 3 or 5 (see

5-2).

When the point of the looper is at the center of the

needle, there should be a clearance of 0mm between

the needle and the looper.

Adjustment is made by loosening screw A.

5555----8 Looper setting distance

8 Looper setting distance

8 Looper setting distance

8 Looper setting distance

Check the looper setting distance by referring to the table below.

If the looper setting distance is not correct, perform 5-4, 5-5 procedure again.

Needle position

Setting distance

(mm)

1, 4

5.5

2, 6

4.7

3, 5

5.8

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----4W

4W

4W

4W

ï¼

ï¼

ï¼

ï¼

<

<

<

<

M

M

M

M odel

odel

odel

odel

ï¼ڑ

ï¼ڑ

ï¼ڑ

ï¼ڑ

302

302

302

302 ----5W

5W

5W

5W

ï¼

ï¼

ï¼

ï¼

Needle position

Setting distance

(mm)

1, 5

5.5

2, 8

4.2

3, 7

4.8

4, 6

6

9

5555----9 Adjusting the looper back spring

9 Adjusting the looper back spring

9 Adjusting the looper back spring

9 Adjusting the looper back spring

It is the best that the surface of the spring touches the

looper closely within the range of B.

Check to see if the surface of the spring touches the

looper closely at least on points C within the range of

B.

Spun thread #60 should be removed from the spring at

approximately 80~100g of tension.

م€گ

6

م€‘

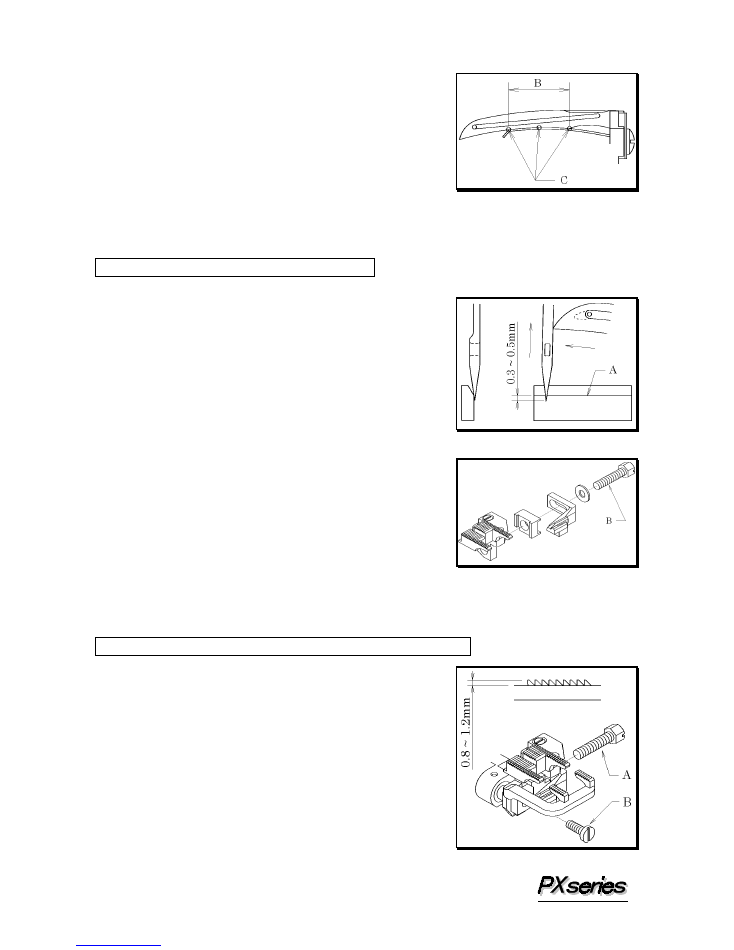

ADJUSTING THE NEEDLE GUARD

This adjustment should be made when the needle is at

position 4 (see 5-2). When the point of the looper,

moving to the left, has reached the right side of the

needle, line A on the needle guard should be

0.3~0.5mm above the point of the needle (see the

illustration on the right). Then the needle must

slightly touch the needle guard. Adjustment is made

by loosening screw B.

م€گ

7

م€‘

ADJUSTING THE FEED DOG & STITCH LENGTH

7777----1 Feed dog height

1 Feed dog height

1 Feed dog height

1 Feed dog height

When the feed dog is at the top of its stroke, the feed

dog teeth should be 0.8~1.2mm above the top surface

of the needle plate. Adjustment is made by loosening

screws A and B.

10

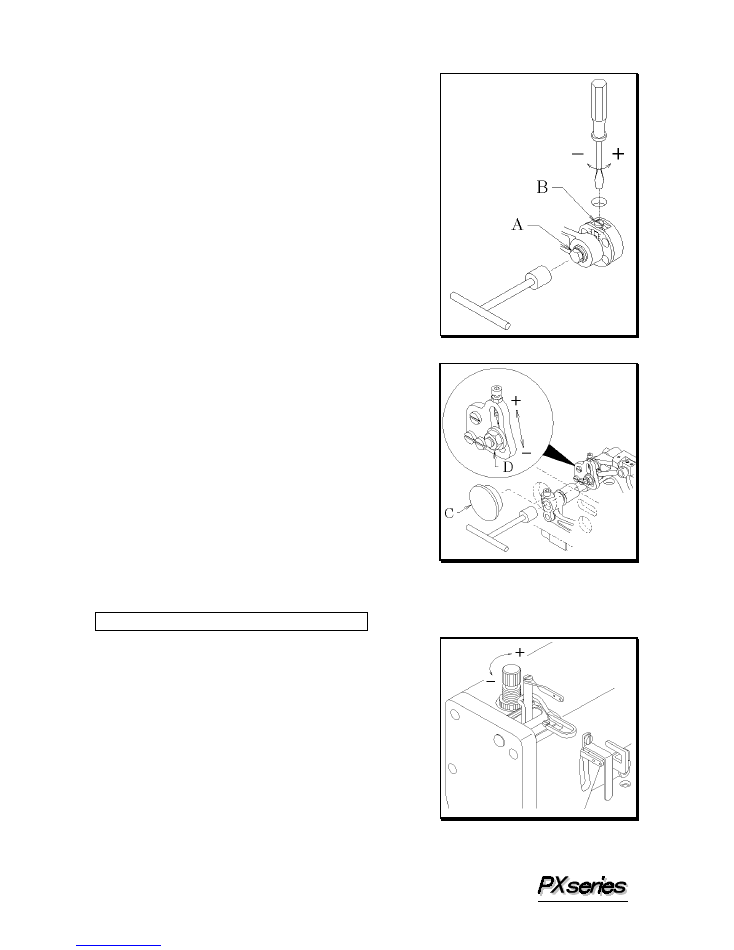

7777----2 Stitch length

2 Stitch length

2 Stitch length

2 Stitch length

Loosen bolt A with a 9.5mm T-wrench.

Then turn screw B as required.

To decrease the stitch length, turn it clockwise.

To increase the stitch length, turn it

counterclockwise (see the illustration on the right).

7777----3 Differential feed ratio

3 Differential feed ratio

3 Differential feed ratio

3 Differential feed ratio

Remove rubber plug C. Loosen nut D.

To increase the differential feed ratio, move up the

nut. To decrease the differential feed ratio, move

down the nut.

م€گ

8

م€‘

ADJUSTING THE PRESSER FOOT

8888----1 Presser foot pressure

1 Presser foot pressure

1 Presser foot pressure

1 Presser foot pressure

The presser foot pressure should be as light as

possible, yet be sufficient to feed the fabric and

produce uniform stitches. To increase the presser

foot pressure, turn the adjusting knob clockwise

(see the illustration on the right).

11

8888----2 Position of the presser foot and foot lift

2 Position of the presser foot and foot lift

2 Position of the presser foot and foot lift

2 Position of the presser foot and foot lift

The presser foot should not touch the needle.

Adjustment is made by loosening screw A and then

moving the presser foot to the right or left.

â– آ

Foot lift

Fit the collar onto the bushing with the presser foot

9mm above the top surface of the needle plate.

Then tighten screw B.

م€گ

9

م€‘

ADJUSTING THE STITCH FORMATION

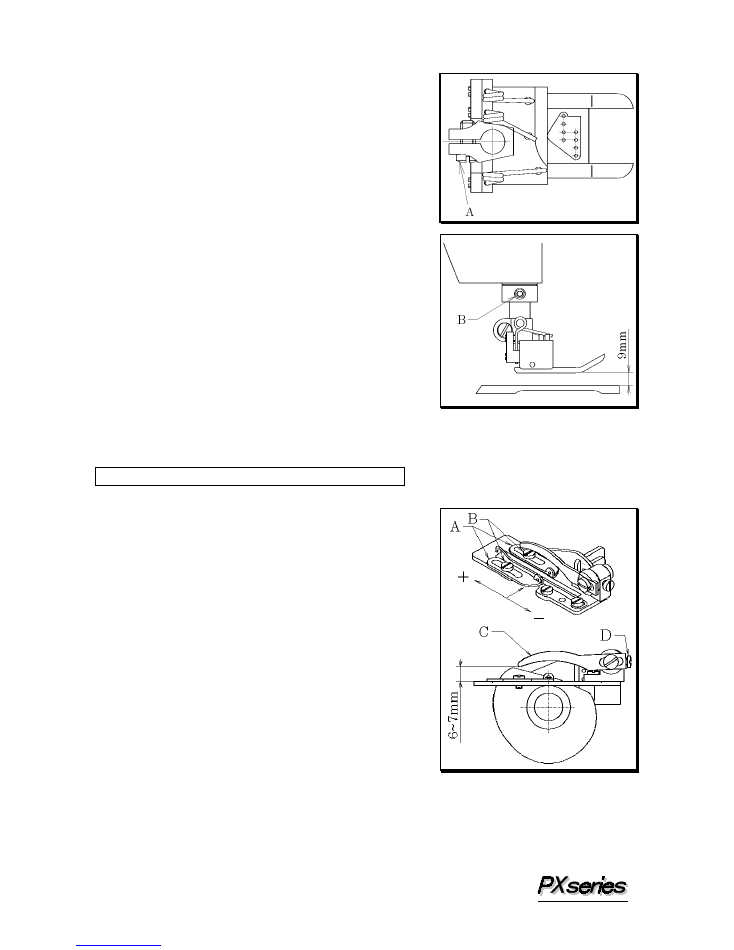

9999----1 Adjusting the looper thread eyelets

1 Adjusting the looper thread eyelets

1 Adjusting the looper thread eyelets

1 Adjusting the looper thread eyelets

Align the eyes on the looper thread eyelets A with

the center line of the shaft. Adjust looper thread

eyelets A according to sewing conditions such as the

fabric or thread to be used by loosening screws B.

To increase the amount of the thread to be supplied,

move the eyelets backward. To decrease the

amount of the thread to be supplied, move the

eyelets frontward. Thread guide C should be

6~7mm above the guide plate. Adjustment is

made by loosening screw D.

12

9999----2 Position of the looper thread take

2 Position of the looper thread take

2 Position of the looper thread take

2 Position of the looper thread take----up

up

up

up

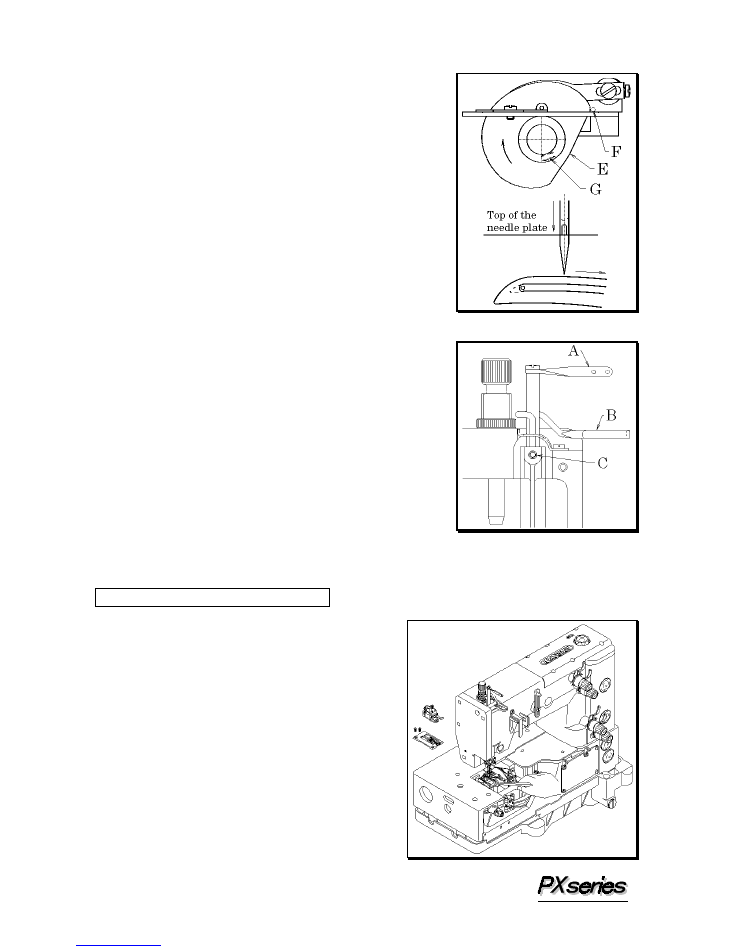

When the bottom of the needle's eye has reached the

top surface of the needle plate while the needle is

descending, the looper thread taken up by looper

thread take-up E should be removed from the looper

thread take-up at point F. Adjustment is made by

screw G.

9999----3 Adjusting the needle thread guard

3 Adjusting the needle thread guard

3 Adjusting the needle thread guard

3 Adjusting the needle thread guard

With the needle bar at the bottom of its stroke, the

centers of eyes on needle bar thread eyelet A should be

level with the top surface of needle thread guard B.

Adjustment is made by screw C.

To tighten the needle thread, move up needle bar

thread eyelet A. To loosen the needle thread, move

down needle bar thread eyelet A.

م€گ

10

م€‘

CLEANING THE MACHINE

At the end of each day, remove the presser

foot and the needle plate and then clean the

slots of the needle plate and the area around

the feed dogs.