Full Text Searchable PDF User Manual

OUTDOOR

TM

Keep the instructions

for future reference.

This IM applies to both SRPH67 & SRPH69.

GB

2

WARNING

1. For use outdoors or in amply ventilated

areas.

2. An amply ventilated area must have a mini-

mum of 25% of the surface area open.

3. The surface area is the sum of the walls

surface.

4. This appliance is not fitted with “Atmo-

sphere sensing device”.

WARNING:

Read the instructions before

installation and use.

Warning:

This appliance must be installed

and the gas cylinder stored in accordance

with the regulations in force.

Warning:

Use only the type of gas and the

type of cylinder specified by the manufac-

turer.

Warning:

Do not obstruct the ventilation

holes of the cylinder housing.

Warning:

In case of violent wind particular

attention must be taken against tilting of the

appliance.

Warning:

Do not move the appliance when in

operation.

Warning:

Shut off the valve at the gas cylin-

der or the regulator before moving the appli-

ance.

Warning:

The

Warning:

The heater can’t be used when the

tubing or the flexible hose

must be changed within the prescribed inter-

vals.

GB

heat exchange tube is retracted into cylinder

compartment.

WARNING:

The use of this appliance in

enclosed areas can be dangerous and is

PROHIBITED.

Warning:

Do NOT keep the heater fully

extended and the heat exchange tube must be

lowered down to position during transportation!

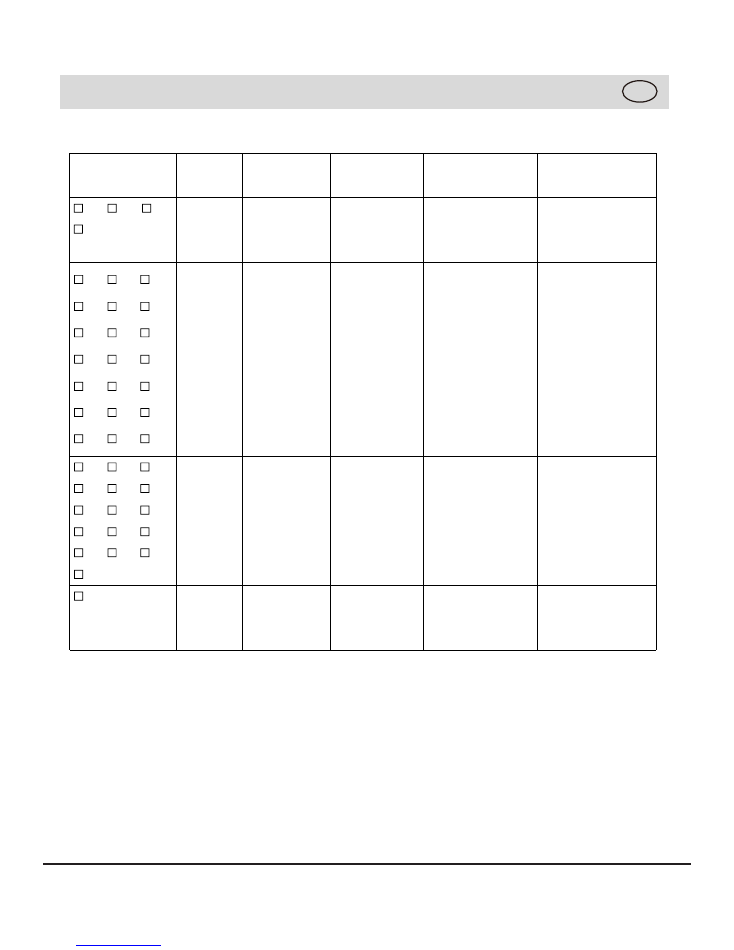

Country

Category Nominal heat

input(Hs)

Gas

consumption

Injector

diameter(Ø)

Gas & Pressure

AT CH

DE

SK

I

3B/P(50)

11kW

800 g/h(G30)

800 g/h(G30)

1.39mm

G30 Butane and

G31 Propane at

50mbar

BE CY

DK

EE

FI

FR

HU IT

LT

NL

NO SE

SI

SK

RO

HR TR

BG

IS

LU

MT

I

3B/P(30)

11kW

800 g/h(G30)

1.67mm

G30 Butane and

G31 Propane at

30mbar

BE CH CY

CZ ES FR

GB GR

I E

IT

L T

LU

LV PT SK

SI

PL

I

3+(28-30/37)

11kW

I

3B/P(37)

11kW

800 g/h (G30) 1.67mm

1.67mm

G30 Butane at

28-30mbar

and

G31 Propane at

37mbar

3

Technical data

GB

Manufacturer:

SHINERICH INDUSTRIAL LIMITED

Address: 8/F, Noble Center, 1006 Fuzhong

3rd Road, Futian District, Shenzhen,GD

518026, CHINA

Phone: +86 - 755 - 8826 7676

For questions, replacement parts, service

help, or other assistance, please call

Distributor name

Address:

Email:

G30 Butane and

G31 Propane at

37mbar

4

GB

Find a large, clean area to assemble your

appliance. Please refer to the parts list and

assembly diagram as necessary.

Please use protective gloves when assem-

bling this product.

To avoid losing any small component or

hardware, assemble your product on a hard

level surface that does not have cracks or

openings.

To avoid damage to soft floor or carpet, do

not assemble or move the appliance on soft

floor or carpet.

Follow all steps in order to properly

assemble your product.

Make sure all the plastic protection rip off

before assembling.

Do not force parts together as this can result

in personal injury or damage to the product.

When applicable, tighten all hardware con-

nections by hand first, once the step is com-

pleted, go back and full tighten all hardware.

Caution: Whilst every effort has made in

manufacture of your appliance to remove

any sharp edge, you should handle all com-

ponents with care to avoid accidental injury.

Time to assemble

Number of people required to assemble

One people

Assembly instructions

10 minutes

5

Further information

GB

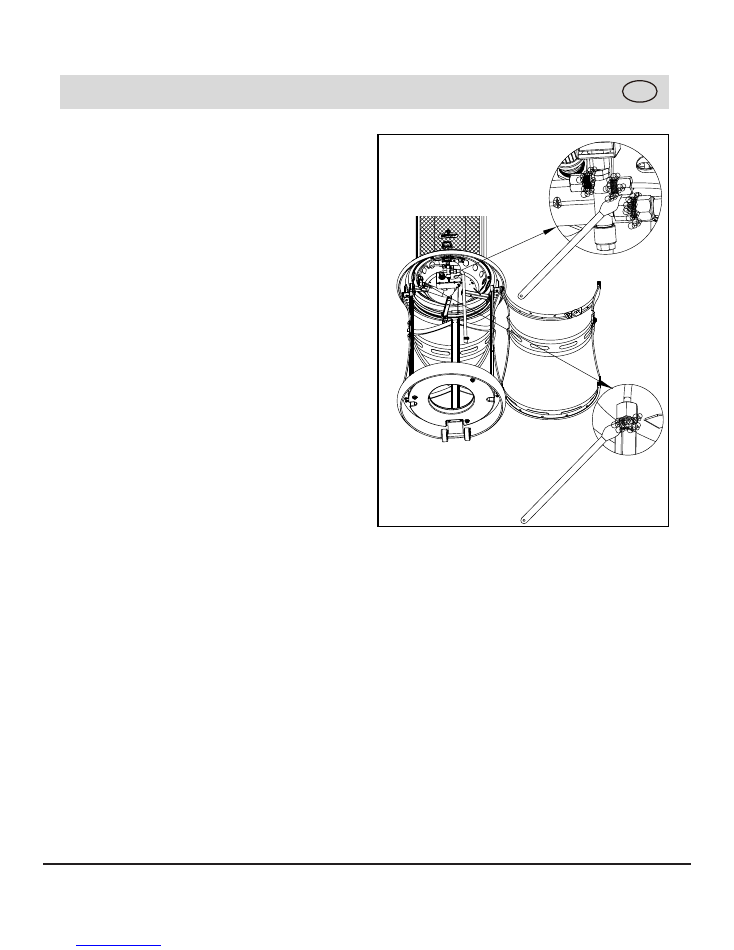

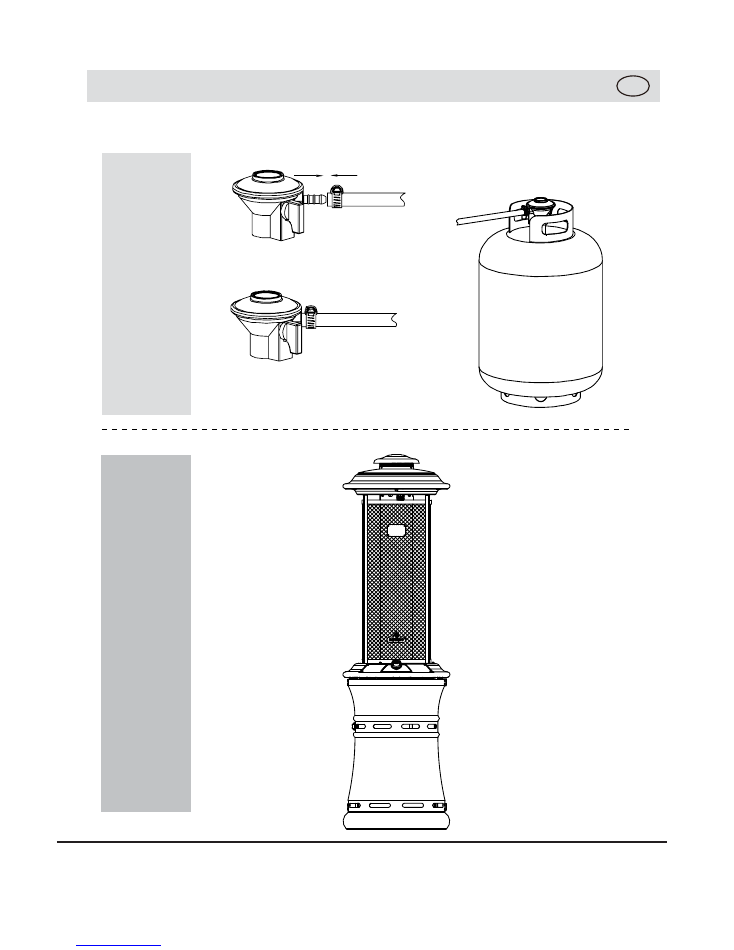

Disconnect LP Gas cylinder

Before disconnecting make sure the LP gas

tank valve in “CLOSED”. Disconnect gas line

from LP gas cylinder by turning knob

counterclockwise until it is loose.

For storage and cylinder exchange, discon-

nect hose at the cylinder only, DO NOT

disconnect hose from appliance.

To change the gas cylinder in an amply ven-

tilated area, away from any ignition source

(candle, cigarettes, other flame producing

appliances…).

LPG cylinder not provided. The appliance is

designed to operate with a cylinder of size Ø

31.8 x 58 cm.

This appliance requires a 15 kg butane LPG

cylinder or a 13 kg propane LPG cylinder.

Gas regulator should be the correct one and

be set according to specific gas category

(see Technical data on page 3).

Gas regulator should be approved according

to EN 12864 with proper capacity (g/h), pres-

sure, working temperature and inlet + outlet

connection for the country of destination.

The regulator illustrated on the manual is for

United Kingdom, the regulator in your country

maybe different with the one on the illustration.

Flexible gas rubber pipe should be approved

according to EN 1763-1 with proper inner Ø

to match pipe holders of gas circuit and gas

regulator, pressure and working tempera-

ture.

The length of the hose is 0.41 m and it

should not exceed 0.7 m. The hose shall be

readily visible across its entire length for

inspection after installation.

Danger:

You must have the proper regulator and

cylinder in order for the appliance to operate

safely and efficiently. Use of an incorrect or

faulty regulator is dangerous and will invali-

date any warranty.

Connect LP Gas cylinder

Before connecting, be sure that there is no

debris caught in the head of the LP tank,

head of the regulator valve or in the head

of the burner and burner ports.

Connect gas line to tank by turning knob

clockwise until it stops, make sure that the

tube is not subject to twisting.

After connecting to gas cylinder, a leak test-

ing is necessary.

Important Notes:

6

GB

Leak testing (to be performed in a well-

ventilated area)

Your Outdoor Patio Heater has been

checked for leaks at all the factory made

connections. To check the connection of the

gas hose/regulator/LPG cylinder.

1) Make leak test solution by mixing 1 part

washing up liquid and 3 parts water.

2) Spoon several drops (or use squirt bottle)

of the solution onto the gas hose/regulator

and regulator/LPG cylinder connection.

3) Inspect the connections and look for

bubbles.

4) If no bubbles appear, the connection is

safe.

If bubbles appear, there is leak, loosen and

re-tighten this connection. Repeat the test.

If bubbles form again, stop trying; contact

your local dealer for assistance.

Leak test annually, and whenever the gas

cylinder is removed or replaced.

Note:

In the event of gas leakage, the appli-

ance must not be used or if already alight,

the gas supply must be shut off and the

appliance investigated and rectified before it

is used again.

7

GB

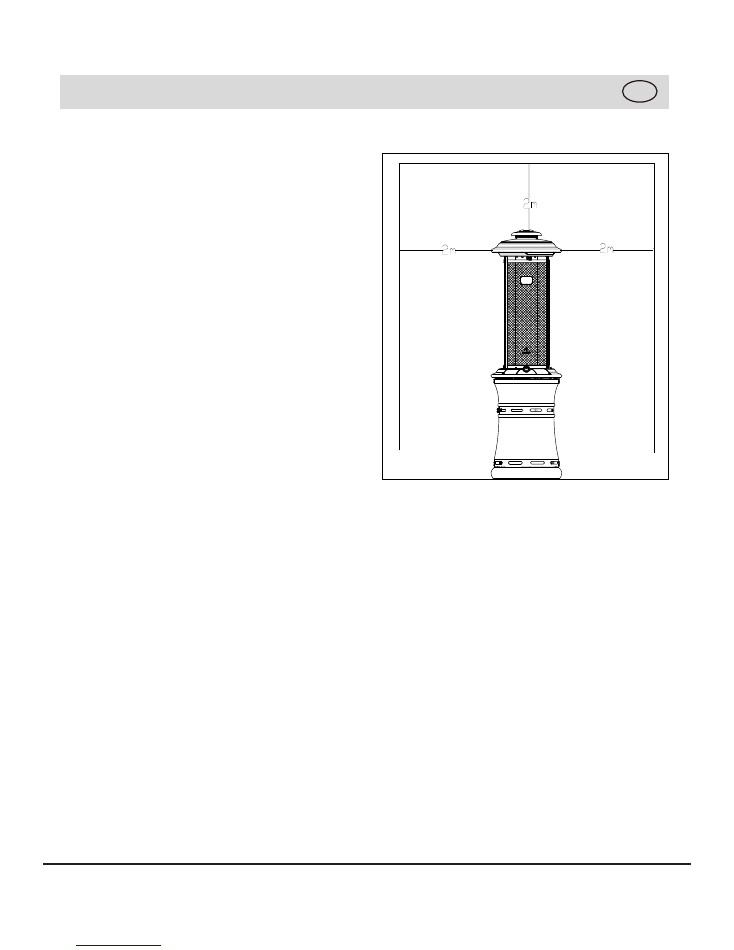

Minimum clearance from combustible

surfaces

This heater is primarily used for the heating

of outdoor patios, decks, spas, pools and

open working areas.

Combustible materials are considered to be

wood, compressed parter, plant fibres, plas-

tic or other materials that are capable of

being ignited and burned.

Always make sure that adequate fresh air

ventilation is provided. Follow the spacing

tolerances shown in the following figure right

at all times.

This heater must be placed on level, firm

ground.

Never operate in an explosive atmosphere.

Keep away from areas where gasoline or

other flammable liquids or vapors are stored

or used.

8

GB

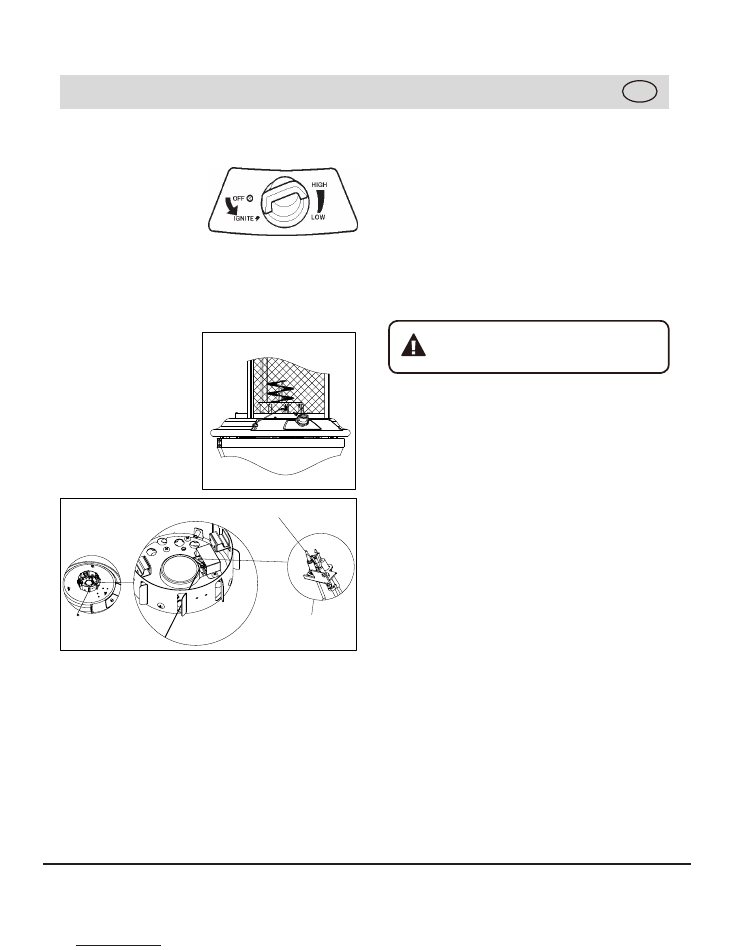

LIGHTING PROCEDURE

1. Turn the control knob OFF. Slowly open

the gas cylinder valve.

2. Push in and turn

control knob

anti-clockwise to

IGNITE.

3. Keep control knob depressed for up to 30

seconds until pilot is lit.

If pilot does not light, turn control knob to

OFF and wait 5

minutes between

ignition attempts for

gas to dissipate.

Note:

it is possible

to light the appliance

using a long match,

by lighting the burner

through the ignition

hole provided.

4. When the pilot is lit keep knob pressed

for up to 20 seconds to heat the thermo-

couple flame sensor, then release it (first

ignition generally takes more time, because

the gas circuit is full of air).

5. If the pilot does not stay lit, repeat steps

2 - 4.

6. Turn knob to LOW position.

7. Adjust the heat input by turning the knob

from the LOW position, to the HIGH posi-

tion, as required.

8. After lighting, turn knob from LOW to

HIGH, position and back, to check flame

stability.

9. In case of accidental break down of the

flame (due to wind or other reasons), a

Flame Safely Device (FSD) will automati-

cally shut-off gas supply within 90 seconds.

Flame Characteristic

The flame pattern at the emitter screen

should be visually checked whenever heater

is operated.

If black soot is accumulating on the emitter

grid or reflector, the heater should be

turned

off

immediately. The heater should not be

operated again until the unit is serviced and

or repaired.

These lighting instructions must be

followed. An unsafe condition can

occur if they are not followed correctly.

Thermocouple

Pilot Assembly

9

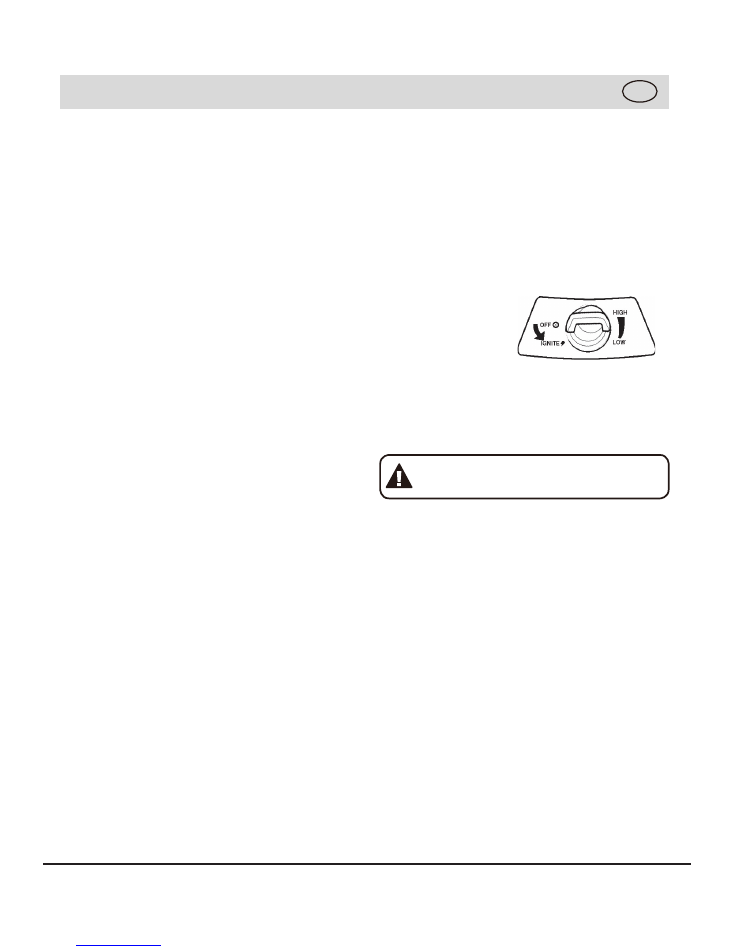

Shut down instructions:

1. Push in and turn control knob clockwise

to OFF position.

2. Turn LPG cylinder gas valve clockwise to

OFF position when heater is not in use.

Note:

After use, some discolouration of the

emitter screen is nomal.

The event of gas leakage:

1. Turn the

control knob

to OFF position.

2. Turn LPG

cylinder valve

to OFF position.

3. Wait 5 minutes to allow gas to dissipate.

4. If odor continues, immediately call

gas supplier.

Warning:

Heater will be hot after use.

Handle with extreme care.

GB

OPERATING PROCEDURE

Note: The burner may be noisy when initially

turned on, To eliminate excessive noise from

the burner, turn the control knob to the LOW

position. Then, turn the knob to the level of

heat desired.

When heater is ON:

Emitter grid will become bright red due to

intense heat. The colour is more visible at

night. Burner will display tongues of blue

flame. These flames should not produce

thick black smoke, indicating an obstruction

of airflow through the burners.

Operation pressure checked:

If the flame is very small, this is because the

supply pressure is not enough. Please refill

gas cylinder.

Re-light:

1. Turn the control knob to OFF position.

2. Wait five (5) minutes before attempting to

relight pilot.

3. Repeat steps beginning with step 2 of the

lighting instruction above.

10

Cleaning and maintenance

To enjoy years of outstanding performance

from your heater make sure you perform the

following maintenance activities on a regular

basis:

● Keep exterior surfaces clean.

●

Use warm soapy water for

cleaning.

Never

use flammable or corrosive cleaning agents.

●

While washing your unit, be sure to keep

the area around the burner and pilot assem-

bly dry at all

times.

If the gas control is

exposed

to water in any way, do NOT try to

use it. It must be replaced.

●

Air flow must not be

obstructed.

Keep

con-

trols, burner, and circulating air passage-

ways

clean.

Signs of possible blockage

include:

Gas odor with

extreme

yellow tipping of

flame.

Appliance does NOT reach the desired tem-

perature.

Appliance glow is excessively uneven.

Appliance makes popping noises.

●

Spiders and insects nest in burner or

orifices.

This dangerous condition can

damage heater and render it unsafe for

use.

Clean burner holes by using a heavy-duty

pipe

cleaner.

Compressed air may help clear

away small particles.

●

Carbon deposits may create a fire

hazard.

Clean heat reflector with warm

soapy

water

if any carbon deposits develop.

GB

Check the tubing or the

flexible

hose (at

least once per month and each time the

cylinder is

changed).

If it shows signs of

cracking, splitting or other deterioration, it

must be

exchanged

for a new hose of the

same length and of the equivalent quality.

STORAGE

Between uses:

● Turn the control knob to OFF position.

● Turn LPG cylinder to OFF position.

●

Store appliance upright in an area

sheltered from direct contact with inclement

weather (such as rain, sleet, hail, snow, dust

and debris).

●

If desired, cover appliance to protect

exterior surfaces and to help prevent debris

in air passages.

During periods of extended inactivity or

when NOTE transporting;

●

Turn the control knob to

OFF

position (full

disk). before covering.

●

Disconnect

LPG

Cylinder and move to a

secure, well-ventilated location

outdoors.

DO NOT store in a location that will

exceed

50 °C.

●

The

LPG

cylinder must be kept out of

reach of children, and not in a building,

garage or any other enclosed area.

●

Store

●

●

●

Remove safety screws. Remove knob from

Keep gas chamber door partially open. Turn

control panel and store in door.

appliance upright in an area shel-

tered from direct contact with inclement

weather (such as rain, sleet, hail, snow, dust

and debris).

●Always

remove the battery from the patio

flare if not being used for long periods of time

as battery leakage can cause corrosion in

the battery ignition housing.

●

If desired, cover appliance to protect

exte

-

rior surfaces and to help prevent debris in air

passages.

NOTE

Wait until appliance is cool before

covering.

Slowly descend heat exchange tube.

heat exchange tube clockwise.

11

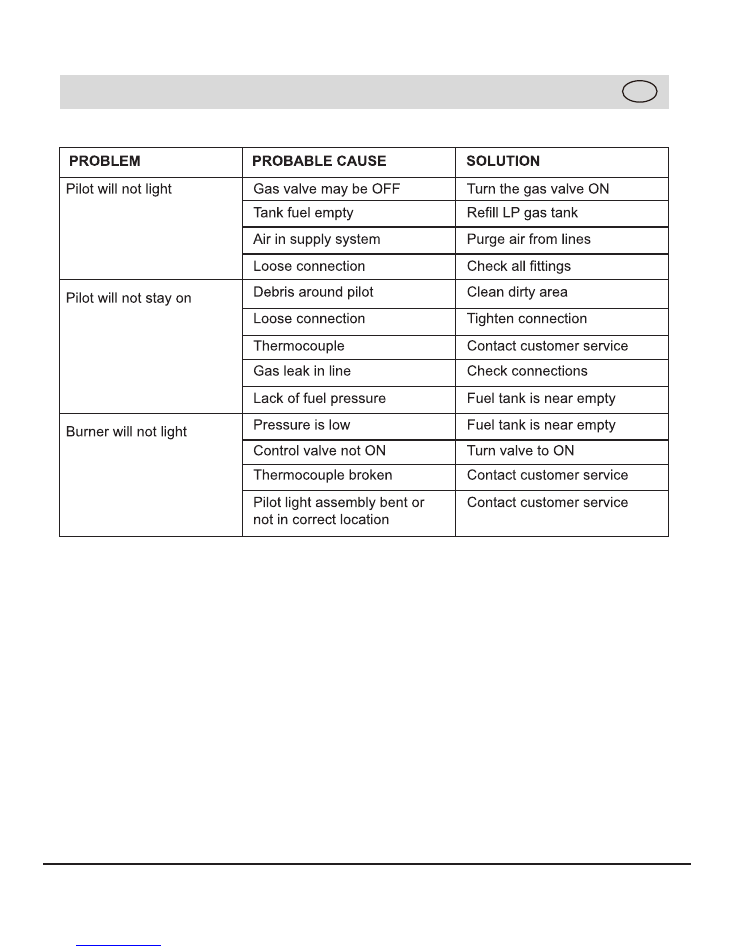

TROUBLESHOOTING

GB

12

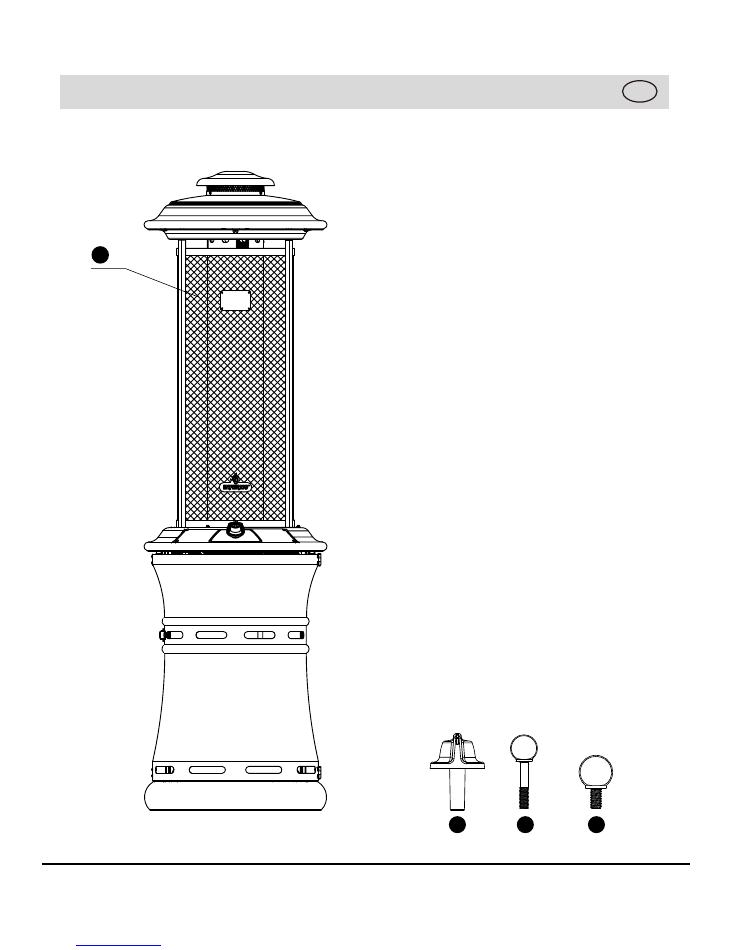

EXPLODED VIEW

GB

2

3

4

1

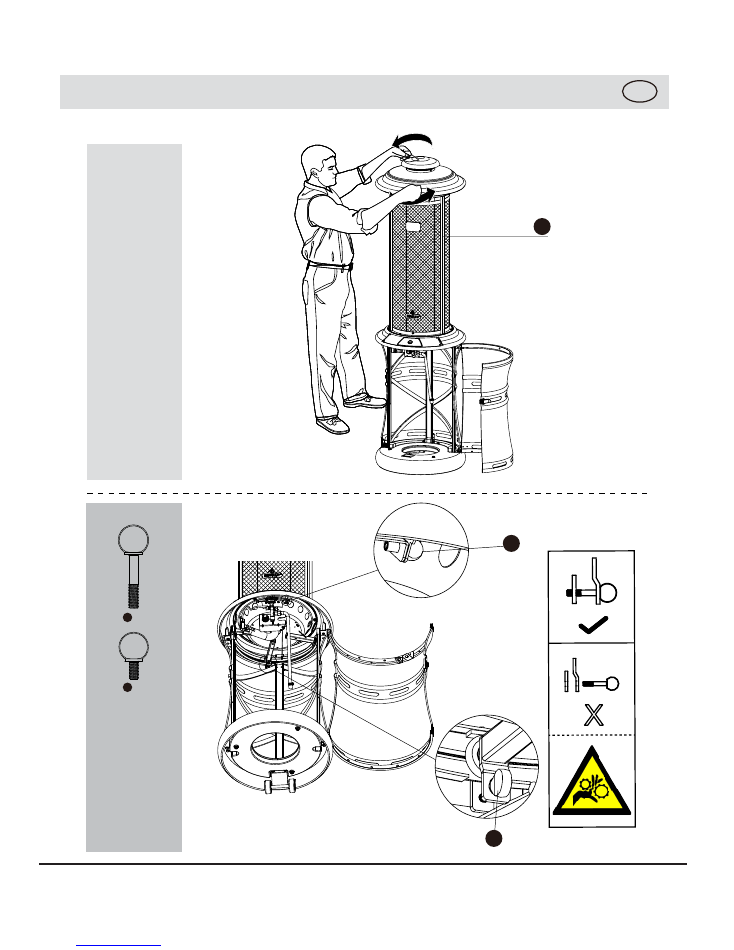

ASSEMBLY INSTRUCTIONS

13

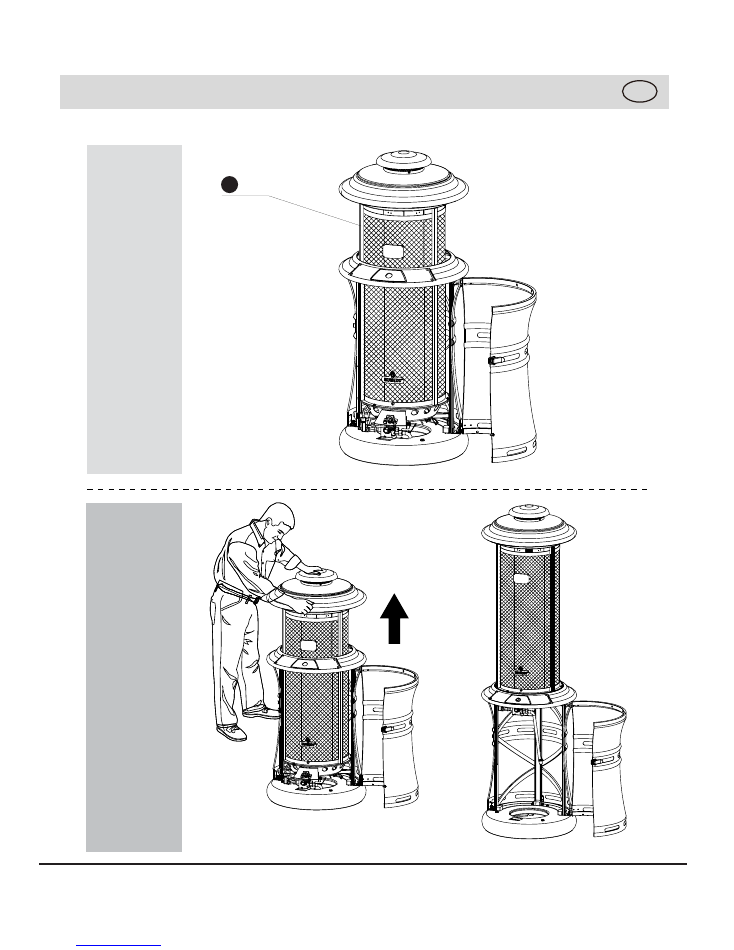

1

2

GB

1

14

3

4

ASSEMBLY INSTRUCTIONS

GB

1

4

3

3

4

X1

X1

X

15

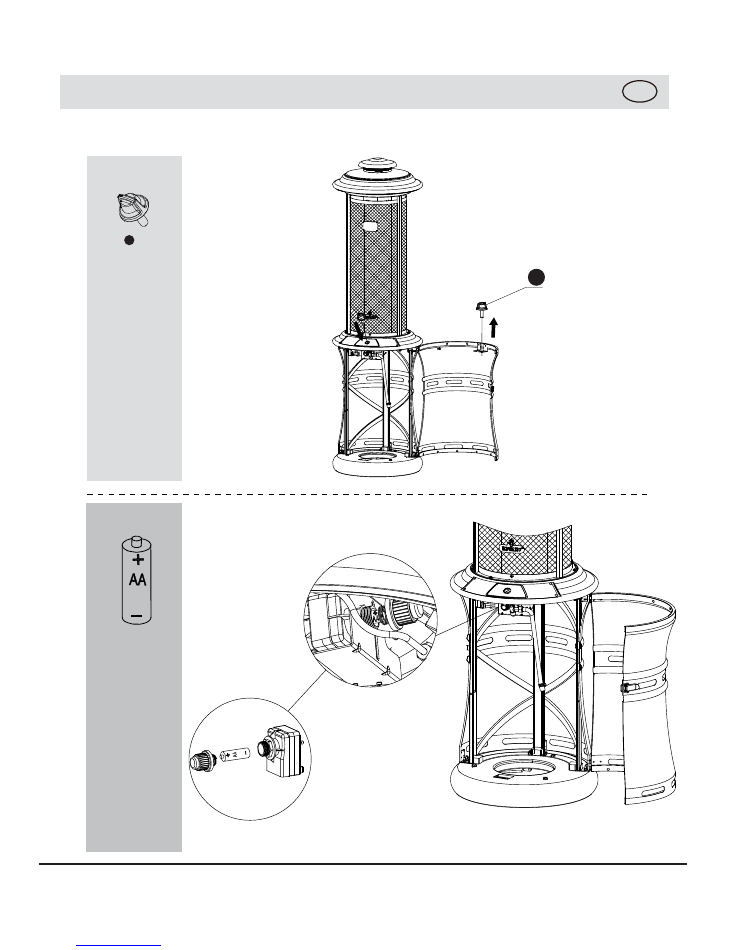

5

6

x1

(not included)

ASSEMBLY INSTRUCTIONS

GB

2

2

16

7

8

ASSEMBLY INSTRUCTIONS

GB