Full Text Searchable PDF User Manual

STUDIO 3000

OPERATING INSTRUCTIONS

MANUFACTURED

IN THE UK

The Studio 3000 is a combined Programmer and Temperature Controller which

has been specifically designed for use with pottery kilns. Control of the entire

firing cycle is fully automatic, to provide simply set, accurate and repeatable

firings. The creation and progress of a firing program can be easily followed using

the Mimic Display.

2

ID-299 Iss 3 08/07/98

1

ID-299 Iss 3 08/07/98

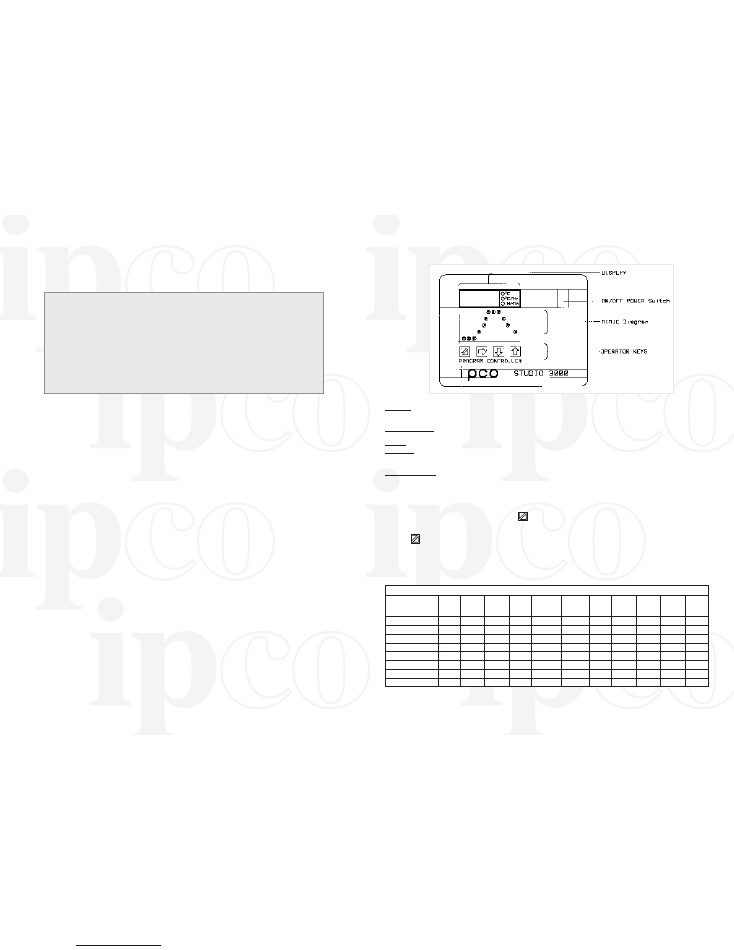

The Quick Guide (Part 1)

The controls and ‘Running’ a program.

This will normally show the kiln temperature in ºC.

Display

When entering or amending a program other information will bedisplayed.

The three LED’s to the right of the display show the units ofthe information being displayed.

On/Off Switch

This switches power to the controller.

Mimic

When a program is running the progress through the firing cycle is indicated by the green LED’s in the centre of

Diagram

each segment.

When entering or viewing the stored program the red LED’s indicate which part of the cycle is being displayed.

Operator Keys

These are used to Stop or Start a firing cycle and to change the stored values.

TO RUN A PROGRAM

Switch On (Or plug in) the kiln.

Switch On the controller. (The Display should light up and after a while show the current temperature.)

Check the mimic has no lights lit. (If there are Press the key to clear them.)

Press the

→

key to display the program number.

Press either the

↑

or

↓

key to change the program number if required.

Press the key to run the program.

On all but the single program version of the Studio 3000, ten firing programs can be stored in the controllers memory. For ease of use

the Controller pre-set programs can be used or modified to suit your requirements.

PLEASE READ THIS

This manual describes all aspects of the use of your STUDIO 3000 controller. It is split into three sections. Page one should be read by

all users as it covers important SAFETY information If you are a non technical user you are advised to fully read pages two and three

which give a pictorial view of the basic use of the controller. If you are an experienced user you should find all the information you

need under the headings shown below in the contents list. If after all this you have problems then the fault finding section should be

referred to.

CONTENTS

TOPIC

Page

TOPIC

Page

Installation ......................................1

Event Relay ....................................5

Quick Guide....................................2 + 3

3 Zone Control................................6

At Switch ON .................................4

Electrical Connections....................7

During the firing .............................4

Option Wiring .................................8

Security Lock..................................5

Configuration..................................9

Gas Relay........................................5

Fault Finding ..................................10

Alarm Relay....................................5

Specifications..................................11

Installation

Mounting

The controller should be mounted on a flat vertical surface away from the kiln, so that it cannot be affected by the

heat that will radiate during the firing of the kiln.

A removable bracket at the rear of the controller is used for fixing. Slide the mounting bracket from the rear of

the controller and fix using two No 8 countersunk screws.

Connection

It is vital that all electrical installation is carried out in a professional manner.

We do not recommend DIY installation of this product.

Before using the controller ensure the ‘Sensor Type’ (Shown on the rear of the controller), and the

thermocouple in the kiln are the same.

In most instances the controller will either have a plug which matches your kiln, or will be connected by your

supplier. If a plug is fitted check that the pin layout of the plug and socket are an exact match before plugging in.

If in doubt contact your kiln supplier

Safety

It is strongly recommended that where a kiln is to be fired unattended that an additional totally

independent over temperature safety system is fitted.

Ensure there is no risk of water entering the controller or its connecting leads.

If you have not bought the kiln & controller as a package be sure you have read and followed EVERY part of this

manual.

Declaration

This Equipment conforms to European Standards for Electrical Interference EN50081-1 and EN50082-2 when

installed as described in this manual. (See “Electrical Connections”)

Compliance Dated 1st December 1995

Problems

In the unlikely event that your controller does not perform correctly ;-

Please first refer to the “Fault Finding” Section.

Check, or get someone else to check, that your firing sequence has been correctly entered.

Contact your supplier in the first instance, since they should have knowledge of your installation which we may

not be aware of.

When contacting us please check the initial display of the instrument (See “At switch on”)

Settings for Studio 3000 MP & MPL Controllers

Program Type

Slow

Normal

High

Stoneware Porcelain

Low

Med

High

Lustre

Enamel

Biscuit

Biscuit

Biscuit

Temp Temp

Temp

Glaze Glaze Glaze

Program

Number

- Pn.01 Pn.02 Pn.03 Pn.04 Pn.05 Pn.06

Pn.07 Pn.08 Pn.09 Pn.10

Delay

Hr-Min

0 0 0 0 0 0 0 0 0 0

Ramp 1 Rate

ºC/Hr

50

100

100

100

100

150

150

150

Pass

Pass

Ramp

1

Temperature

ºC 200 600 600 200 200 500 500 500

-

-

Ramp

2

Rate

ºC/Hr

250 250 250 250 150 250 250 250 125

120

Soak

Temperature ºC 1,020 1,020 1,160 1,260 1,290 960

1,070 1,120 750 800

Soak

Time

Hr-Min

0 0-10 0 0-10 0 0-10 0 0 0 0

Ramp

3

Rate

ºC/Hr

Pass Pass Pass Pass Pass Pass Pass

Pass Pass Pass

4

ID-299 Iss 3 08/07/98

3

ID-299 Iss 3 08/07/98

At Switch ON

The initial display when you switch ON gives useful information about your controller.

The display is in the form X N

1

.N

2

.N

3

where X is a letter and N are numbers.

X is the thermocouple type r, S, n, or k

N

1

.N

2

is the software version (It should be quoted if you contact us with a technical query)

N

3

is the model type of your controller;-

1 = Single Program. (ST3SP)

2 = Multi Program. (ST3MP)

3 = Multi Program with linking. (ST3MPL)

4 = MPL with optional event relay (ST3E)

5 = 3 Zone control. (ST3Z)

Program Entry

The ‘Quick Guide’ should be used as a first approach to entering programs. The following gives specific detail not covered

by the guide and assumes you are familiar with the general operation of the controller.

RAMPS

All ramps may be Up or Down.. The controller decides automatically which way to ramp depending upon the values you

enter into the program. When you start a program the start temperature for a ramp is the current kiln temperature.

To omit a ramp segment from a firing cycle, decrement the ramp rate below zero until ‘PASS’ is displayed. (You cannot

‘PASS’ Ramp 2 since this would also remove the subsequent Soak)

To jump immediately to the next segment, increment the ramp rate above 1000ºC/Hr until ‘FULL’ is displayed. During a

firing this will immediately load the ramp end setpoint and then wait until the kiln catches up before proceeding with the

next segment.

SOAK

You may Soak for up to 99 Hr 59 Min. Selecting zero for a soak time will give what is called a “Cut-Off” firing, where the

kiln rises to the desired soak temperature but does not hold at this temperature.

LINKING (Not applicable to SP and MP models)

At the point of the program entry where ‘End’ is displayed, you may link to another program if a more complex firing cycle

is required. Whilst ‘End’ is displayed in program entry press and hold the secret key under the ‘P’ of IPCO. The

↑

/

↓

keys

allow a Ln number to be displayed. When the program is run this link number will direct the controller to continue firing

with the values in the ‘linked’ program. You may make as many links as you wish, however, each link uses up one of your

ten programs which are thus not available to be run independently. Also be very careful that you do not link back to a

program which is earlier in your current firing cycle, or a continuous loop will result.

During The Firing

The display will normally show the temperature in the kiln.

The kiln LED is lit when power is being applied to the kiln.

The Slow LED (Flashing) is lit if the kiln is too slow to follow the program. Whilst a

program is running

(i.e.. One of the green LED’s will be lit) a number of other features are available;-

MONITORING FIRING PROGRESS

The

↓

key may be used to examine additional values held within the controller. What is displayed will depend upon the

position in the program and the model version. For the SP, MP and MPL versions the values shown are ;-

(Flashing ºC LED indicates ‘Monitoring’ operation)

RAMP;- Prog No, Current setpoint.

SOAK;-

Prog No, Current setpoint, Remaining soak time.

For the Three Zone unit the above value are followed by Zone 2, & Zone 3 current temperatures.

REVIEW PROGRAM

The

→

key will allow you to step through all the current program values and amend them as required. These amendments

will normally have immediate effect upon the firing.

JUMP TO NEXT SEGMENT

Pressing the È key will advance the program one segment.

If the next segment is a ramp the start temperature will be the actual temperature at which the button was pressed. The rate of

rise (or fall) and the end temperature are as defined in the program. If the next segment is a soak the controller will

immediately apply the soak temperature as the setpoint and wait for the kiln to catch up.

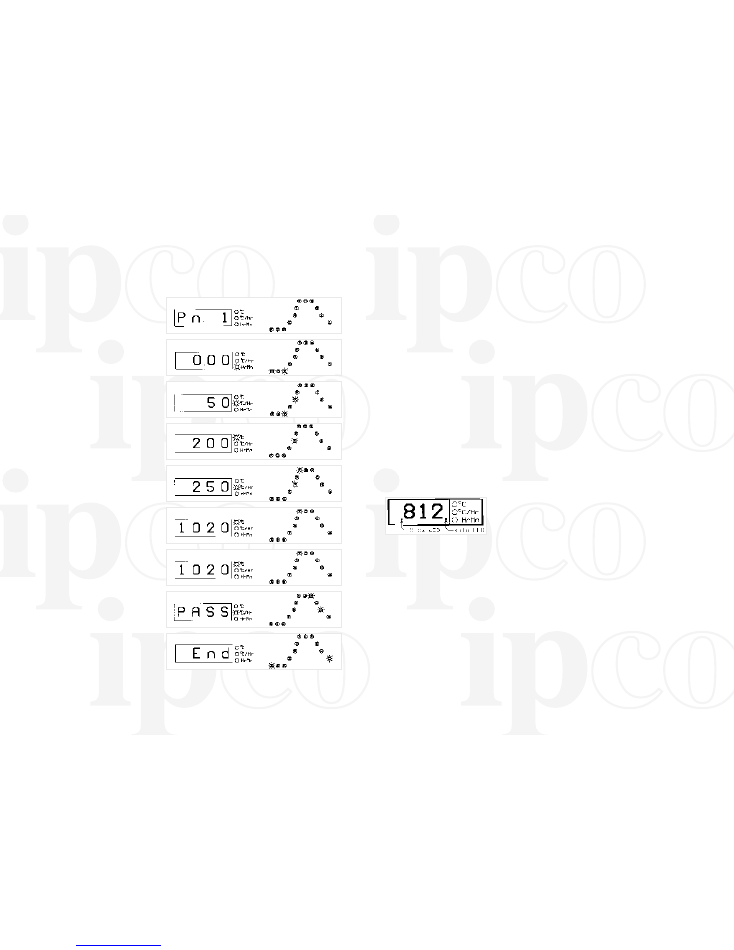

The Quick Guide (Part 2)

Viewing or Modifying a firing Cycle

N.B. These instructions assume that you are using the controller for the first time. If the controller has been used then values other

than those illustrated may be displayed.

Switch ON the controller - Ensure no LED’s are lit on the Mimic - Follow the sequence shown below.

- - - - - - - - - - - - - - - - - - Press

→

to access the stored firing values.

PROGRAM NUMBER

↑

To Increase Prog Number.

↓

To Decrease Prog Number.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

DELAY TIME

↑

To Increase Delay Time.

↓

To Decrease Delay Time.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

RAMP RATE

↑

To Increase Ramp Rate

↓

To Decrease Ramp Rate

- - - - - - - - - - - - - - - - - - Press

→

to proceed

RAMP END TEMPERATURE

↑

To Increase Temperature

↓

To Decrease Temperature.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

RAMP RATE

↑

To Increase Ramp Rate.

↓

To Decrease Ramp Rate.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

‘SOAK’ TEMPERATURE

↑

To Increase Temperature.

↓

To Decrease Temperature.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

‘SOAK’ TIME

↑

To Increase Time.

↓

To Decrease Time.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

RAMP RATE

↑

To Increase Ramp Rate

↓

To Decrease Ramp Rate.

- - - - - - - - - - - - - - - - - - Press

→

to proceed

END / LINKING / RELAY

See “Program Entry” for a detailed

description of the linking feature

See “Auxiliary Relay 2 for a detailed

description of the auxiliary relay.

Otherwise;-

- - - - - - - - - - - - - - - - - - Press

→

to End program entry.

6

ID-299 Iss 3 08/07/98

5

ID-299 Iss 3 08/07/98

EVENT MODE - (Having selected

r L -E

EVENT (Segment) RELAY )

You may program the relay to operate for any combination of the segments.

i.e. Delay, Ramp 1, Ramp 2, Soak, Ramp 3, End.

Use

↑

/

↓

to select whether you want the relay ON (Green LED lit) , or OFF (Green LED off) in this segment.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Step through each segment and repeat above for each segment.

TEMPERATURE MODE - (Having selected

r L - t

TEMPERATURE RELAY )

You may program one ON operation at a your specified temperature and one OFF operation at a further specified temperature.

These two operations must be in different segments. If a duplicate action is attempted, the previously set action will be

cancelled. Operations can only be entered in Ramp segments. These must be ramps that will cause the kiln to pass through the

programmed temperature. When the controller first starts the relay will be OFF. This means that the first operation should be

an ON (Even if in terms of your process something is turned Off! )

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

The Red LED’s on the mimic will show the segment selected

A Green LED shows an operation is programmed into this segment.

The display indicates whether an operation is an ON or an OFF.

Use

↑

/

↓

to select or remove an operation.

↓

Selects (or removes) an ON operation

↑

Selects (or removes) an OFF operation

NB.

If the segment has ‘PASS’ as a parameter then the above actions are inhibited.

Having Selected an operation (i.e. Green LED lit.)

Press and hold the secret key to display the temperature at

which the operation occurs.

Use

↑

/

↓

to adjust the switching temperature.

Release the secret key to accept the value.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Repeat the above step for each segment.

Two / Three Zone Control

(Please also refer to “Option wiring”.)

For a full three zone control the kiln requires three thermocouples and three contactors driving the heating elements of three

separate zones. The thermocouples are situated in each of the heating zones so as to monitor the temperature in that zone.

We recommend the use of type N mineral insulated thermocouples in three zone kilns. These ensure leakage currents

from the elements will not effect the operation of the thermocouples and / or the controller.

Full three term (PID) control is available on all three zones. As shipped the Integral and Derivative terms are turned off for

the slave zones. This reduces the risk of the slaves influencing the main zone. (See also “Configuration”)

Refining the control

Where a consistent difference exists between zones during a firing then use the offset (See “Configuration”) to enter a value

numerically opposite that being achieved. e.g.. If zone 2 is always 3OC above the main zone, then enter ‘-3’ in the offset for

zone 2.

Where the difference varies over the temperature range or between various loads then reduce the value of ‘Proportional Band

(See “Configuration”) for each of the offending zones.

Security Lock

(Not fitted on single program version)

Access codes can be entered, amended, or if security is not required can be omitted.

SET LOCK NUMBER

Ensure no LED’s are lit on the mimic display.

Press and hold down the switch hidden under the “P” of IPco for 10 seconds.

The display will initially show ‘Lock’.

After 10 seconds the display will show the current lock number.

Use

↑

/

↓

keys to set a code. (range = 00 to 99. note;- 00 is No Lock)

Once the hidden switch is released, the code number will be stored.

‘LOCKED’ OPERATION

With a Lock number set, any attempt to Stop / Start / Modify the program will display the message ‘Lock’.

To continue at this point with the selected operation ;-

Press and hold down the switch hidden under the “P” of IPco

Ln 00 is displayed.

Use

↑

/

↓

keys to select the code that you have already set.

Release the secret key and the desired function will occur.

Gas Relay

(Option)

No parameters are required for this option. The relay turns ON at the first instance of heat demand by the controller. It turns

OFF at the ‘End’ of a firing cycle or if an Error is detected.

See also Electrical Connections. See also “Option wiring”

Alarm Relay

(Option)

No parameters are required for this option The relay turns ON when the controller is switched ON. It turns OFF if the kiln

temperature exceeds the highest programmed setpoint by 20OC, or if an error is detected (See ‘Problems’). Where linked

programs are used the alarm will initially be determined by the first program. As each additional program is linked to, then

the alarm value will be determined by the highest setpoint encountered during the complete firing sequence. In a three zone

controller, an over temperature in any zone will cause the alarm. See also “Option wiring”

Auxiliary Relay

(Option)

After the last ramp, entry of parameters for the auxiliary relay is prompted by

r L y

Use

↑

/

↓

to select.

r L - t

TEMPERATURE RELAY

r L -E

EVENT (Segment) RELAY

r L y

NO OPERATION

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

The first segment to be programmed will be indicated by a Red LED. Each press of the

→

key will advance you to the next

segment. Green LED’s show you where operation of the relay will occur.

N.B. You MUST ensure that the temperatures and segments that you program for the auxiliary relay

will occur during your program. No Validation is performed.

8

ID-299 Iss 3 08/07/98

7

ID-299 Iss 3 08/07/98

Option Wiring

ALARM only

Output Relay 2 is fitted.

The alarm is normally closed, going open circuit in the event of a fault.

This output may be fitted to provide additional protection of the kiln. It principally guards against failure of the main

contactor. It should not be seen as a direct replacement for an over temperature policeman.

EVENT only

Output Relay 2 is fitted.

May be configured as a user programmable Event (e.g.. To operate a damper)

(See also notes on programming under ‘Auxiliary Relay’)

This will normally be used to either drive a motorised valve for damper control, or an external signalling device to initiate

other parts of a control system. To drive a motorised valve an additional external (Customer Supplied) relay must be used.

This should have N.O. and N.C. contacts to drive the ‘Open’ and ‘Close’ feeds on the valve.

ALARM + EVENT

Output Relays 2 & 3 are fitted.

O/P 2 is the Event and O/P 3 is the Alarm.

GAS

O/P 4 is fitted (This may be in addition to any of the above.)

This output may be fitted to provide ignition and shutdown of a gas fired kiln. The Burner should have an ignition control input

(which is fed from the ‘Gas’ relay), and a High/Low fire control input (which is fed from the main control output.)

ZONE

All O/P Relays are fitted.

Selection of functions is via link blocks. (See previous page)

For a three zone control only one output is available for alarm or event. The provision of both is thus not possible. It is

recommended that an entirely separate over temperature alarm be fitted in this instance. This should be considered standard

practice for an installation of the likely value of a three zone kiln.

2 Zone control may be implemented simply by not using the third zone. The unwanted zone must have its thermocouple input linked

between +VE to -VE to prevent the controller causing an open circuit thermocouple. error message.

It is vital that the correct relationship between thermocouple and contactor is maintained, such that the thermocouple is

measuring the temperature of the heater it is controlling. Failure to observe this may cause damage to the kiln.

The connections to a three zone kiln will be influenced by the design of the kiln, and no definitive connection information can be

given. The following points may be of assistance.

1/ Where uniformity of temperature is the principal objective, then the main control output (Terminal 1) should drive the

slowest zone in the kiln. Since the controller can only slow down the natural rate of rise of the kiln it is thus in the best

position to keep the “slaves” in step with the “master”.

2/ Whilst the slaves are identical in function the display implies that zone 2 is above zone 3. Providing this orientation in

practice will be less confusing to the user.

3/ Ensure that the thermocouples are positioned as far away from direct element heat as possible, and in the centre, or

slightly below the centre of each heating zone.

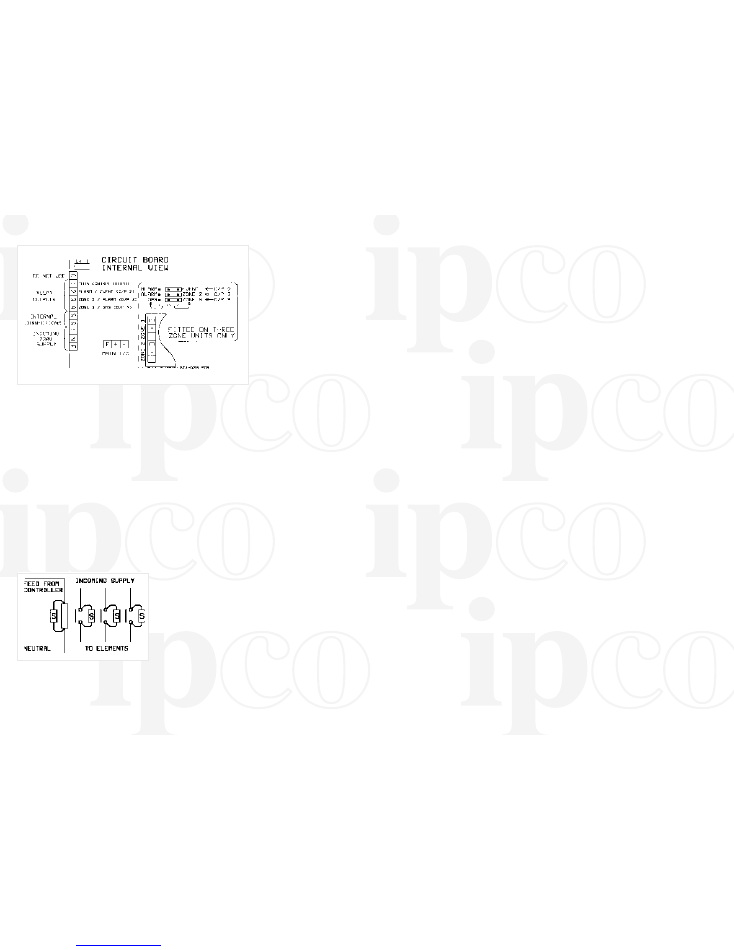

Electrical Connections

Please Note

The Industrial Pyrometer Co do

not supply specific wiring

diagrams for individual kilns since

the accuracy of such information

cannot be confirmed.

Incoming Supply

This should be connected to a 230V supply via a fuse of 1A rating. An Earth connection is essential.

Thermocouple Inputs

Ensure that the Studio 3000 Controller and the Thermocouple are of the same type, otherwise accurate control of temperature

in the Kiln will not be possible. The letter prefix on the Serial Number Label (N, K, R or S) will indicate the thermocouple

type that has been programmed into your Controller.

All input wiring should use screened cable of the appropriate compensating type, with correct polarity maintained

throughout.

See also

‘At switch On’ for explanation of the initial identification message.

‘Parameter Setting’ to change the instrument thermocouple type.

Control Outputs

NB

ALL outputs are low current and MUST drive remote relays or contactors which in turn drive the load.

The ‘C’ (Common) terminal is internally connected to 230V via the ON/OFF switch.

To isolate the relays from this 230V feed remove link LK1 The maximum switching voltage is still 230V.

MAIN OUTPUT (Relay 1)

This output feeds the kiln contactor coil

OPTIONS (Relays 2 to 4)

See following page for Option output information.

EMC

To comply with current EMC regulations, the system, of which this controller is a part, must conform to the relevant standards for

electrical emissions. It is the responsibility of the end supplier to ensure this is achieved.

The following is our recommendation only.

The control contactor(s) should be fitted with suppressers at all terminals

which are switching the load.

(This means that they cannot be relied upon for safety isolation)

The coil should be fitted with a suppressers.

S = Suppression Device

e.g. Farnell

218-913

R.S.

210-364,210-370

Where slave relays are used these should also be suppressed.

Do not fit suppressers to over temperature controllers, or safety isolation contactors.

10

ID-299 Iss 3 08/07/98

9

ID-299 Iss 3 08/07/98

Problems

The following list covers the most commonly encountered questions asked by users and some possible causes.

There is no display on the controller

1

The ON/OFF switch on the controller (see fig 1) is in the OFF position.

2

The kiln is switched off at an Isolator .

3

A fuse has blown in the kiln or the supply which feeds the kiln.

The controller displays OPEN

1

The Thermocouple, or the wires between it and the controller, are damaged.

For a quick check;-

Switch OFF, Short + and - on the instrument T/C input, Switch ON. Display should show aprox 20ºC.

The controller displays FAIL

1

The wiring to the thermocouple is reversed.

When I turn on the controller it starts to run a program immediately.

1

You have switched OFF the controller while a program was running. It is advisable to clear any lights on the mimic using

the STOP / START button before you switch off .

When I attempt to run a program I cannot change the program number.

1

If any lights show on the mimic you have a program either running or being viewed , you must clear these lights before

you can change program.

2

Pressing the STOP / START key will only run the current program. To change a program you must run the sequence

shown in the “quick guide” .

The Kiln Under fires

1

If the controller ‘kiln’ light is on but kiln is not heating the fault is in the kiln or it’s wiring. Or;

You have an energy regulator on the kiln which is not at 100%. Or;-

The kiln has a faulty element. (See also ‘During the Firing’)

2

The thermocouple type does not match the instrument. (See “Electrical connections”)

3

Loose wires to the thermocouple (The display may be erratic.)

The Kiln Over fires

1

The thermocouple type does not match the instrument.

2

You have a sticking contactor in the kiln - Refer to an electrician

3

Loose wires to the thermocouple (The display may be erratic.)

When I attempt to enter a temperature in a program it will not go above a certain point.

1

A safety limit is available to prevent excessive temperatures being programmed. Check that this is correct for your

application. (See “Configuration” to change this value)

The Damper does not operate at the end of a firing.

1

You must ensure that the values entered in a program cause the firing cycle to pass through the switching points entered

into the relay temperature. If you do not the controller may have ended its program, and hence stopped any further actions,

before the desired switching of the damper.

When I press a key the controller displays ‘Lock’

1

The security lock has been activated. You should refer to the ‘Security Lock’ instructions. Use the Set Lock Number’

instructions to determine , or change, the current lock number The ‘Locked Operation’ instructions define the way to

operate the controller with this security active.

Configuration

The controller operation may be modified to satisfy a variety of situations by amending the parameters.

This information is given for completeness and should only be modified by experienced personnel.

To access these parameters first switch the controller OFF. Press and hold the secret key while switching the controller ON. Continue

to hold the secret key until the first parameter below is shown. Release the secret key and continue as shown below.

Thermocouple type

tc.?

Use

↑

/

↓

Keys to select. r,S,n,k

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Setpoint Limit

SP-L

Press secret key to display

Default 1350ºC

Use

↑

/

↓

to modify

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Control Strategy (3 Zone Control ONLY)

Con.?

Use

↑

/

↓

to modify

0 = Differential (Default)

1 = Absolute

NB In differential mode the slaves follow the measured value from the main zone.

In absolute mode the main and slaves all follow the controller setpoint.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Offset (zone 1 - see NB 1)

1. ??

Use

↑

/

↓

to modify

Range = +99 to -99(ºC).

Default = 0

This value is added to the controller setpoint and thus allows trimming of the achieved temperature in

the kiln. e.g. I-05 is entered when the controller is at 500ºC Then this zone will be attempting to control

at 495ºC

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Proportional Band (zone 1- see NB 1) These values are qualitative and do not relate to engineering units

P1.??

Use

↑

/

↓

to modify

Range = 0 to 99 Default = 13

This defines the band over which the controller gives proportional control

A setting of zero gives ON/OFF control

A setting of one gives the narrowest control band (tightest control)

A setting of 99 gives the widest control band

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Integral Time (zone 1- see NB 1) These values are qualitative and do not relate to engineering units

l I ??

Use

↑

/

↓

to modify

Range = 0 to 99 Default = 20

The integral time sets the rate of which the controller reduces any offset between desired (Setpoint) and

measured temperature.

A setting of zero turns Integral action OFF

A setting of 99 gives the slowest response.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

Derivative Time (zone 1- see NB 1) These values are qualitative and do not relate to engineering units

d1.??

Use

↑

/

↓

to modify

Range = 0 to 99 Default = 90

The Derivative time sets the rate of reaction to a rapid change in measured value.

A value of 99 gives the slowest response

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - Press

→

to proceed

NB. 1

These parameters are then repeated for zones 2 + 3 (the slaves)

The Default values for Zones 2 + 3 Integral and Derivative are zero.

TO EXIT THIS FUNCTION PRESS

NB, 2 Parameters are only stored when the

→

Key is pressed after making a change

If you change a parameter and then press then this last item is not updated.

DISPLAY

MEANING

OPEN

Thermocouple open circuit.

FAIL

Thermocouple connection reversed.

Err3

Not in use.

Err4

Process temperature has exceeded higher program by 20

∫

C

Err5

Error reading internal memory. Refer to supplier.

Err6

Error reading internal memory. Refer to supplier.

Specifications

Size

W - 220mm x H - 168mm x D - 80mm

Ambient

0 to 50ºC maximum.

Supply

230V +/-15%

Thermocouple

Type R, S, K, or N.

(See ‘Configuration’ for change information)

Outputs

Single pole 3 Amp contacts. All outputs give 230V output via internal link.

(See ‘Electrical Connections’ if isolated switching is required)

Display

R or S -20ºC to +1600ºC, K or N 0 to 1300ºC

Accuracy +/-3ºC over stated operational ambient.

Delay & Soak times 0 to 99 Hours 59 Minutes in one minute increments.

Ramp Rates

1 to 1000 ºC per Hour., “PASS”, or “FULL”

Setpoints

0 to maximum of display

(This depends upon thermocouple type selected.)

(will be limited by Setpoint limit - See below.)

Setpoint Limit

Adjustable over full display range.

Programs

10 (Except for single program version)

Pre loaded for convenience but all user modifiable.

Linking

On models MP/L,MP/E & MP/Z.

Supplied By;-

Designed and manufactured by ;-

The Industrial Pyrometer Co Ltd

66/76 Gooch Street North, Birmingham, B5 6QY, England.

Tel: +44 (0) 121 622 3511 Fax: +44 (0) 121 666 6386