Full Text Searchable PDF User Manual

PW-H10 Hot Line-H

Mod. I 1207 AA M - I 1408 AA M - I 1408 AO M

IDROPULITRICE ACQUA CALDA/

HOT WATER CLEANER/NETTOYEUR EAU

CHAUDE/HEISSWASSERHOCHDRUCKREINIGER/HIDROLIMPIADORA POR

AGUA CALIENTE/MÁQUINA DE LAVAR COM ÁGUA QUENTE/

MANUALE ISTRUZIONI

/INSTRUCTIONS MANUAL/MANUEL D’ INSTRUC-

TIONS/BEDIENUNGSANLEITUNG/MANUAL DE INSTRUCCIONES/MANUAL DE

INSTRUÇÕES/

F - INDEX

Page

Préparation 27

Description des symboles

28

Préface

29

Instructions générales pour l’ installation

et l’ utilisation

29

Emplois de l’ appareil

32

GB - CONTENTS

Pag.

Preparation 15

Description of symbols

16

Introduction 17

General warnings for installation and use

17

Intended

use 20

Preliminary

operations

20

I - INDICE

Pag.

Preparazione

3

Descrizione

simboli

4

Prefazione

5

Avvertenze generali di installazione ed uso

5

Destinazione d’ uso

8

D - INHALT

Seite

Vorbereitung 39

Beschreibung der Symbole

40

Vorwort

41

Allgemeine Installierungs- und

Benutzungsbedingungen 41

Benutzungsweck

44

Vorbereitende

Schritte

44

E - INDICE

Pág.

Preparación 51

Descripción de los símbolos

52

Prefacion

53

Advertencias generales de instalación y

de

uso

53

Aplicaciones 56

P - ÍNDICE

Pág.

Preparação 63

Descrição dos símbolos

64

Prefácio

65

Advertências gerais de instalação e

utilização

65

Destino de emprego

68

Operazioni

preliminari

8

Uso

10

Consigli per l’ uso dei detergenti

11

Manutenzione

11

Accantonamento

13

Rottamazione

13

Inconvenienti e rimedi

14

Use

22

Advise on using detergents

23

Maintenance 23

Periods of inactivity

25

Scrapping

25

Trouble-shooting

26

Opérations préliminaires

32

Utilisation

34

Conseil pour l’ emploi des détergents

35

Entretien

35

Rangement 37

Mise au rebut

37

Pannes et remèdes

38

Benutzung

46

Ratschläge zur Verwendung von

Waschmitteln

47

Instandhaltung

47

Abstellen

49

Verschrottung

49

Störungen und entsprechende Lösungen

50

Operaciones preliminares

56

Uso

58

Consejos para el uso de detergentes

59

Manutención 59

Almacenamiento

61

Desguace

61

Inconvenientes y remedios

62

Operações preliminares

68

Utilização

70

Conselhos para a utilização de detergentes 71

Manutenção 71

Inactividade 73

Demolição

73

Problemas e soluções

74

RS - ОГЛАВЛЕНИЕ

Стр.

Подготовка

75

Символьные обозначения

76

Введение

77

Общие правила установки и эксплуатации 77

Предназначение

80

Предварительные операции

80

Эксплуатация

82

Рекомендации по использованию моющих

средств

83

Хранение

83

Утилизация

85

Неисправности и их устранение

86

English

- 15 -

Water circuit connection.

Electrical connection.

TRANSLATION OF ORIGINAL INSTRUCTIONS

The text has been carefully checked, however any misprints should be notified to the manufacturer.

The manufacturer also reserves the right to alter and update this publication without prior notice for the sake of

product improvement.

All reproductions of this manual, in whole or in part, are forbidden without the manufacturer's authorization.

Continue reading this manual without connecting the cleaner to the power mains and the water supply.

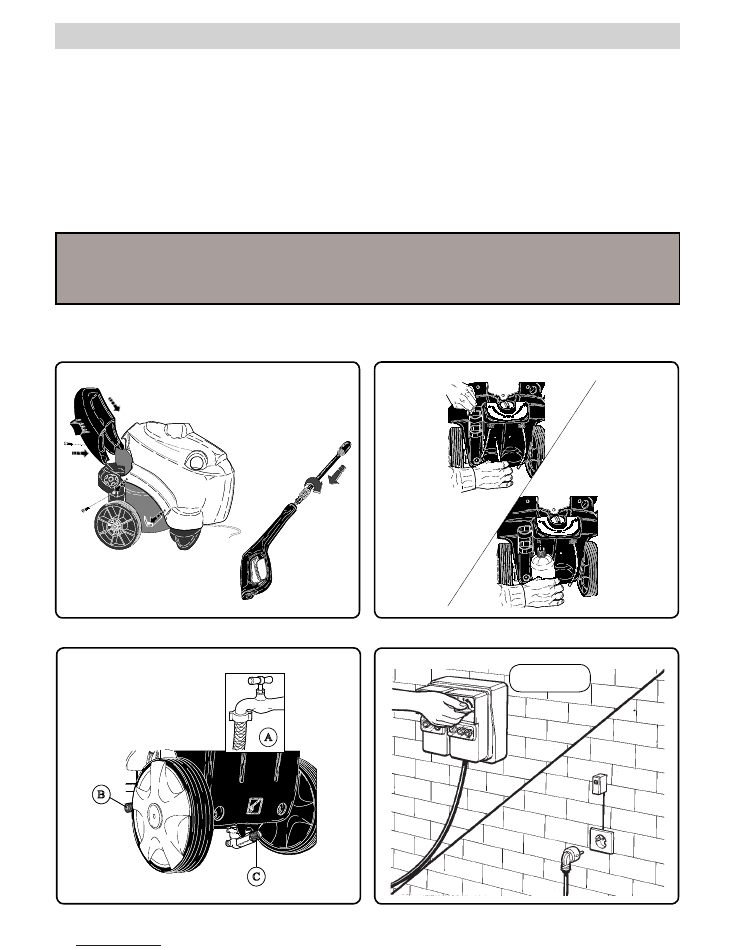

PREPARING THE CLEANER

for buying this cleaner. You have shown that you do not accept compromises:

you want the best

.

We have prepared this manual to enable to fully appreciate the qualities and high performance that this cleaner can offer you.

Please read it completely before using the machine.

The

CE

mark on your cleaner shows that it has been constructed in compliance with the European Standards on safety.

We can also offer you a wide range of cleaning machines such as:

VACUUM CLEANERS, FLOOR CLEANERS, FLOOR SWEEPERS

and a complete range of

ACCESSORIES, CHEMICALS

and

DETERGENTS

suitable for cleaning all kinds of surfaces.

Ask your Dealer for the complete catalogue of our products.

Congratulations! We wish to thank you

Fitting

the rear tank.

B

B

B

C

C

C

A

A

A

B

C

A

B

B

B

C

C

C

A

A

A

B

C

A

Fitting the lance.

Fitting the handlebar

30 mA

English

- 16 -

SWITCHING OF THE PUMP

MOTOR.

LIGHTING THE BURNER.

FUEL (DIESEL).

CHEMICHALS

(DETERGENT).

DO NOT FEED WITH

DRINKING WATER.

USE AN EN 12729 TYPE BA

SYSTEM SEPARATOR.

DO NOT DIRECT THE JET

AGAINST PEOPLE, ANI-

MALS, POWER SOCKETS

OR THE MACHINE IT SELF.

ATTENTION: RISK OF BUR-

NS.

ATTENTION: RISK OF

ELECTRIC SHOCK.

EARTH.

WATER INPUT.

WATER OUTPUT.

DESCRIPTION OF SYMBOLS ON THE CLEANER

English

- 17 -

GENERAL SAFETY RULES FOR

THE USE OF HIGH PRESSURE

CLEANERS

Warning

- The electric connection must be performed

by qualified technicians who are able to

work in observance of the governing rules

(in compliance with the provisions of the IEC

60364-1 standard) and of the manufacturer’s

instructions.

A wrong electric connection may cause

damage to persons, animals or things, and

the manufacturer cannot be considered

responsible for these.

- The H.P. cleaners with power lower than 3

kW are equipped with a plug for connection

to the electric supply.

In this case please check if the electric

power system and the electric sockets are

compatible with the max. power of the ap-

pliance indicated on the plate. (kW). In case

of doubt, please apply to qualified personnel.

If the socket and the plug of the machine are

not compatible, have the plug replaced with

a suitable type by qualified personnel.

- Before connecting the machine make sure

that the data indicated on the plate corre-

spond to those of the electric supply.

- Do not use extensions to power the high

pressure washer.

If you use an extension, the plug and socket

must be watertight. Unsuitable extensions

may be dangerous.

- The electric safety of this machine may be

assured only when it is properly connected to

an efficient grounding system in accordance

with the governing laws for electric safety. (In

compliance with the provisions of the IEC

60364-1 standard)

CLASSIFICATION

The user must observe the conditions of use of the applian-

ce prescribed by the Rules, and particularly he must respect

the following classification:

As for the protection against electric shock, the H.P.cleaner

belongs to

CLASS I.

The H.P. cleaner is factory set and all its safety devices are

sealed.

It is forbidden to alter their adjustment values.

In the Hot water cleaner the water is heated by a burner feed

with

Diesel

fuel.

The H.P. cleaner must be always used on a firm and flat

ground, furthermore it must not be moved while it is working or

connected to the electric supply.

Failure to observe this prescription may cause danger for the

user.

The H.P. cleaner must not be used in the presence of corrosive

or potentially explosive atmospheres. (vapours or gas)

!

!

CLASSIFICATION OF RISKS:

Danger

Identifies an imminent risk which could lead to serious or fatal

injury.

Warning

Identifies a risk situation which could lead to serious injury.

Information

Identifies a risk situation which could lead to minor injury or

damage to things.

PREFACE

Warning

You must read this manual before installing, starting up and

using the high pressure washer.

This manual is an integral part of the product.

Read the warnings and instructions contained in the manual

carefully as they provide important information on

USER SA-

FETY and MAINTENANCE

, paying particular attention to the

general safety regulations.

KEEP THIS MANUAL IN A SAFE PLACE FOR FUTURE

REFERENCE.

Warning

Those operating and servicing the high pressure washer must

be aware of the contents of this manual.

!

!

!

English

- 18 -

person responsible for their safety.

Children must be supervised to ensure they

do not play with the high pressure washer.

- Use only original accessories that can allow

safe working of the appliance.

- The flexible hose connecting the lance to

the H.P. cleaner must not be damaged.

In case of damage, replace it immediately.

- Hoses, connections and fittings for high

pressure systems are very important to

guarantee the safety of the H.P. cleaner.

Use only original spare parts which have the

manufacturer’s approval.

- Do not use the H.P. cleaner when persons

or animals are in its of action field.

- High pressure jets may be dangerous if not

properly used.

The jet must never be directed at persons

or animals, electric appliances or at the

appliance itself.

- The high pressure water jet causes a re-

action power on the lance. Hold the lance

grip vigorously.

- The use of the H.P. cleaner must be con-

sidered according to the kind of washing

which must be performed.

Protect yourself against the ejection of solid

materials or corrosive substances by means

of adequate protective clothing.

- The use of the H.P. cleaner must be con-

- It is necessary to check this essential safety

requisite. In case of doubt, ask for accurate

control of the power system by qualified

personnel.

The manufacturer may not be considered

responsible for damages occurred because

of the lack of the grounding system.

- The H.P. cleaner must be connected to the

electric supply by means of an omnipolar

switch with opening contacts of at least 3

mm. This switch must have electric features

which are consistent with the appliance.

(This requisite does not apply to H.P. cle-

aners with plug and electric power lower

than 3 kW).

It is recommended that the electric supply

to this machine should include a residual

current device that will interrupt the supply

if the leakage current to earth exceeds 30

mA for 30 ms or a device that will prove the

earth circuit.

- The appliance is disconnected from the

electric supply only by pulling out the plug or

switching off the omnipolar switch.

- Failure to respect the above absolves the

manufacturer of all liability and represents

negligent use of the product.

The water cleaner is considered as a fixed

device.

- Water cleaners with the “Total Stop” device

should be considered as off when the omni-

polar switch is in the “O” position or the plug

is unplugged from the socket.

- The high pressure washer is not intended

for use by children, adolescents or persons

with reduced physical, sensory or mental

capabilities, under the influence of alcohol

or lacking experience and knowledge.

Operators must be made aware of the

instructions for using the appliance by a

English

- 19 -

sidered according to the place where the

washing is performed (for example: food

plants, pharmaceutical plants, etc.)

Pertinent rules and safety conditions must

be followed.

- Do not direct water jets at your own or other

people’s body in order to clean clothes or

shoes.

- While working it is forbidden, to stop the trig-

ger (lever) of the lance in delivery position.

- In the hot water H.P. cleaners a Diesel fuel

burner is used for water heating. The use

of other fuels is dangerous.

- Before starting any cleaning or maintenan-

ce operation, disconnect the machine from

the electric and water supply networks.

- Periodically, at least once a year, have the

safety devices checked by one of our service

centres.

-

The machine is for outdoor use.

If the ap-

pliance is to be used in an enclosed space

(not advisable)

, install a flue gas extraction

system and guarantee adequate ventilation.

- The hot water cleaner must be supervised

while it is working.

- Do not clog the openings or the ventilation

grilles and the heat and smoke extraction

systems in the hot water cleaners.

- Do not use the machine if the supply cable

is damaged.

For the replacement of the damaged cable

apply exclusively to one of our technical

service centres.

The supply cable of this appliance must not

be replaced by the user.

- The electric power cable must never be

under mechanical tension and must be pro-

tected against accidental crushing.

- The use of any electric appliance requires

the respect of some basic rules:

• Do not touch the appliance with wet or

damp hands or feet.

• Do not use the appliance bare-footed or

with unsuitable clothing.

• Do not pull the supply cable or the applian

-

ce itself in order to disconnect the plug from

the electric supply.

(For water cleaners rated at less than 3 kW

fitted with plug).

- In case of damage or malfunction, switch

off the appliance (disconnecting it from the

water main and from the electricity main via

the omnipolar switch or by unplugging the

plug in the case of water cleaners rated at

less than 3 kW) without tampering with it.

As for the protection against electric shock,

the H.P.cleaner belongs to

CLASS I.

Apply to one of our technical service

centres.

Failure to observe the above warning

frees the manufacturer from all respon

-

sibility and constitutes negligent use of

the product.

English

- 20 -

PRELIMINARY OPERATIONS

UNPACKING

After unpacking, ensure that the cleaner is undamaged.

If in doubt, do not use the machine.

Contact your dealer.

Packaging (bags, boxes, nails, etc) is potentially dangerous and

should be kept out of reach of children. It should be disposed of

or retained in respect of national environmental legislation.

FITTING THE SEPARATE PARTS OF THE MACHINE

All the fundamental parts and safety devices of the machine are

assembled by the manufacturer.

For reasons of packing and transport, some secondary cleaner

parts are supplied separately.

The user must fit these parts as explained in the instructions

supplied in each assembly kit.

DATA PLATE:

The data plate bearing the main technical characteristics of your

cleaner is located on the trolley and is always visible.

When buying your cleaner, ensure that it has an

identification plate. If there is no plate, inform the manu

-

facturer and/or the dealer immediately. Machines without

a plate must not be used and the manufacturer declines all

responsibility for them. Products without a plate must be

considered anonymous and potentially dangerous.

INTENDED USE

This appliance is intended exclusively for cleaning machines,

vehicles, buildings and general surfaces suitable for treatment

with a high pressure jet of detergent solution between 25 and

250 bar (360 - 3600 PSI).

This appliance has been designed for use with the detergents

supplied or recommended by the manufacturer. The use of

other detergents or chemicals may influence the safety of the

appliance.

This appliance must be used only for the purpose for which it

was specifically designed.

All other uses are to be considered incorrect and therefore

unreasonable.

Examples of unreasonable use:

- Washing surfaces not suitable for cleaning with a high

pressure jet.

-

Washing people, animals, electric equipment or the machi-

ne itself.

-

Using unsuitable detergents or chemicals.

- Blocking the trigger (lever) of the lance in delivery posi-

tion.

The manufacturer cannot be held responsible for any damage

due to improper, incorrect or unreasonable use. As far as safety

rules are concerned, the cleaners are manufactured according

to the European Standard.

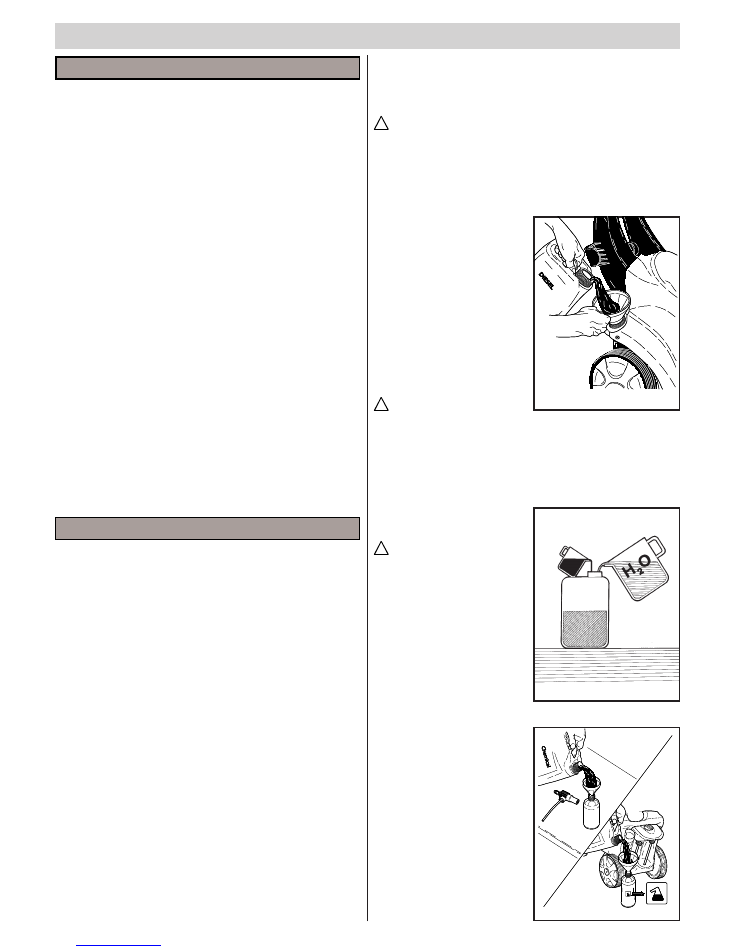

FIG. 1

Warning

Do not use different fuel from that indicated on the iden

-

tification plate.

Check the fuel level from time to time while the cleaner

is operating.

Attempting to use the cleaner without fuel may cause

damage to the fuel pump.

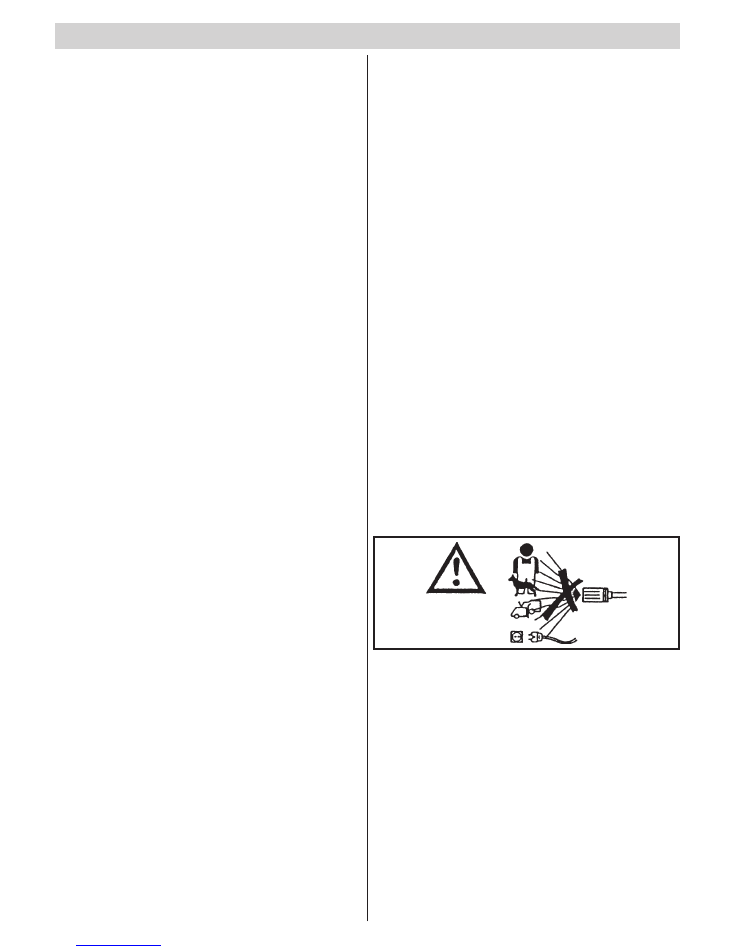

FILLING THE FUEL TANK

Fill the tank with fuel for Diesel

motors (fig. 1).

!

!

FIG. 3

FIG. 2

FILLING THE DETERGENT

TANK

Warning

From the range of recommen-

ded products, choose the one

most suited to the washing job

to be done (fig. 2) and dilute

it with water according to the

instructions on the pack.

Fill the detergent tank with the

diluted product (fig. 3).

Ask your dealer for the cata-

logue of the detergents that

can be used depending on

the type of washing job to be

done and the type of surface

to be treated.

After using a detergent, the

detergent intake circuit must

be flushed out with clean

water.

!

English

- 21 -

Danger

The cleaner must operate with clean water. Dirty or sandy

water, corrosive chemicals and solvents can cause severe

damage to the cleaner.

Danger

Never suck up liquids containing solvents or acids in the pure

state, for example petrol, paint solvents or diesel. The spray mist

from the lance is highly inflammable, explosive and poisonous.

Failure to respect the above absolves the manufacturer

of all liability and represents negligent use of the product.

Information

Respect the instructions provided by the water utility

company.

Current regulations specify that the appliance may not be con-

nected to the drinking water supply unless a suitable system

separator is fitted.

Use a suitable EN 12729 type BA system separator.

Water passing through a system separator is no longer classi-

fied as drinking water.

Warning

Do not connect the machine to a drinking water container.

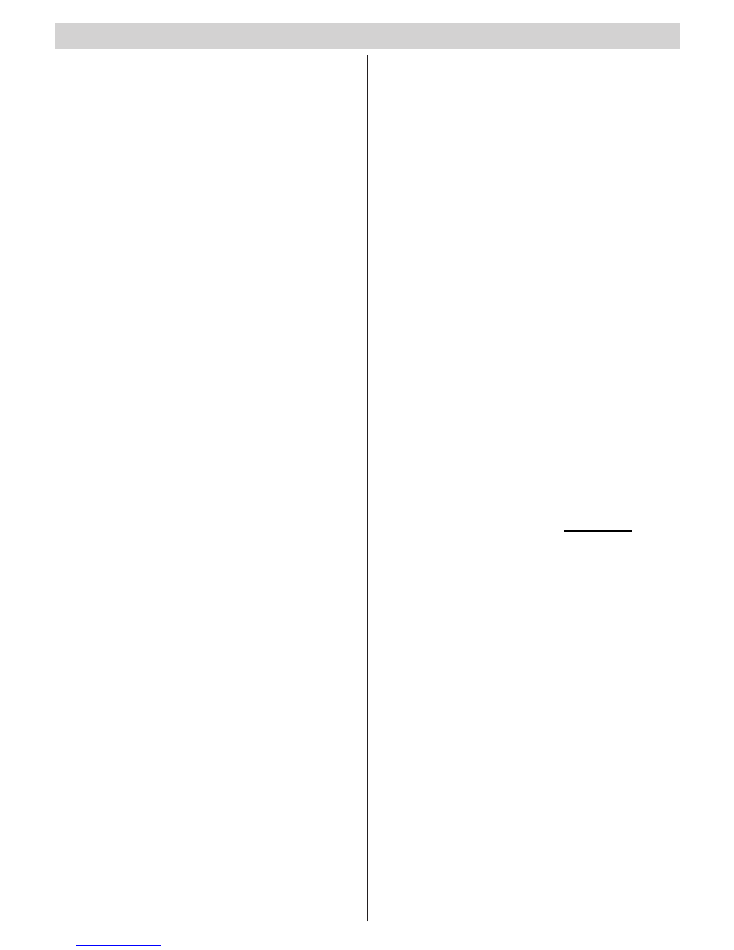

ELECTRICAL CONNECTION

The water cleaner must be connected to a mains electricity

supply conforming to current legislation and standards.

Ensure that the mains voltage available is the same as the vol-

tage at which the cleaner is supposed to work; this is indicated

on the identification plate.

Danger

- The electric cable must be protected from accidental crushing.

- Do not use the machine if the supply cable is damaged.

- The use of any electric appliance requires the respect of

some basic rules:

• Do not touch the appliance with wet or damp hands or feet.

• Do not use the appliance bare-footed or with unsuitable

clothing.

• Do not pull the supply cable or the appliance itself in order

to disconnect the plug from the electric supply.

(For water cleaners rated at less than 3 kW fitted with plug).

As for the protection against electric shock, the H.P.cleaner

belongs to

CLASS I

.

Failure to observe the above warning frees the manufac

-

turer from all responsibility and constitutes negligent use

of the product.

COMMAND AND CONTROL DEVICES

Warning

Before connecting the machine to the water supply and to the

power mains, it is essential to know the function of the cleaner's

command and control devices.

SAFETY DEVICES

The safety devices protect the user and the appliance. They

must not be tampered with or used for other than their desi-

gnated purpose.

Safety valve:

protects the high pressure hydraulic circuit in

the event of a by-pass valve malfunction or if the hydraulic

circuit is blocked.

The safety valve is calibrated by the Manufacturer and sealed.

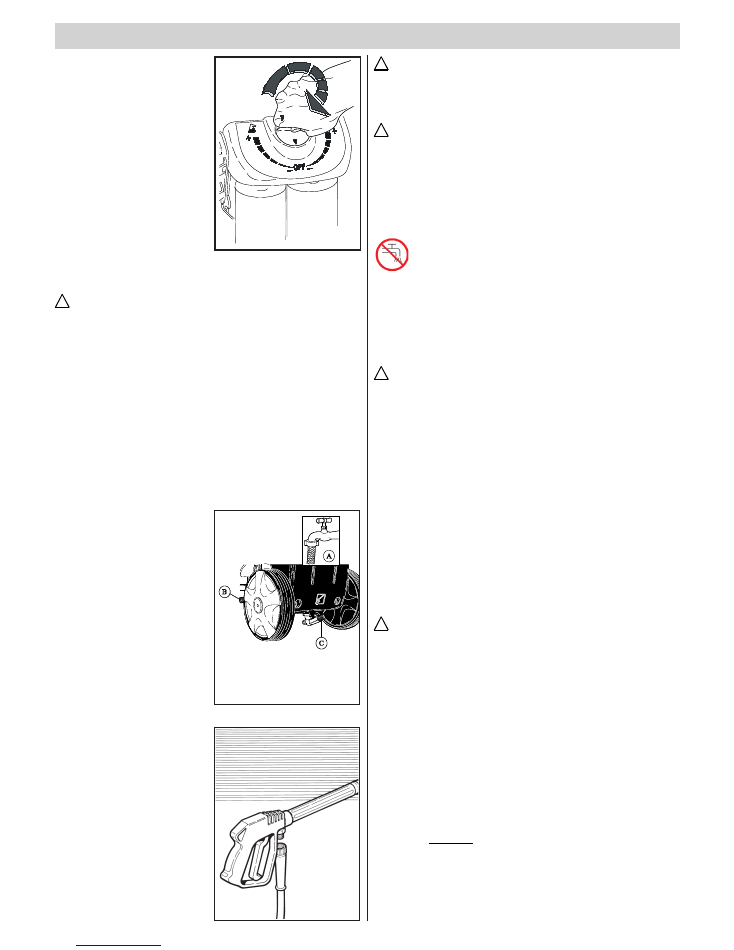

FIG. 6

FIG. 5

Operations involving the safe-

ty valve must be performed by

a technical service centre only.

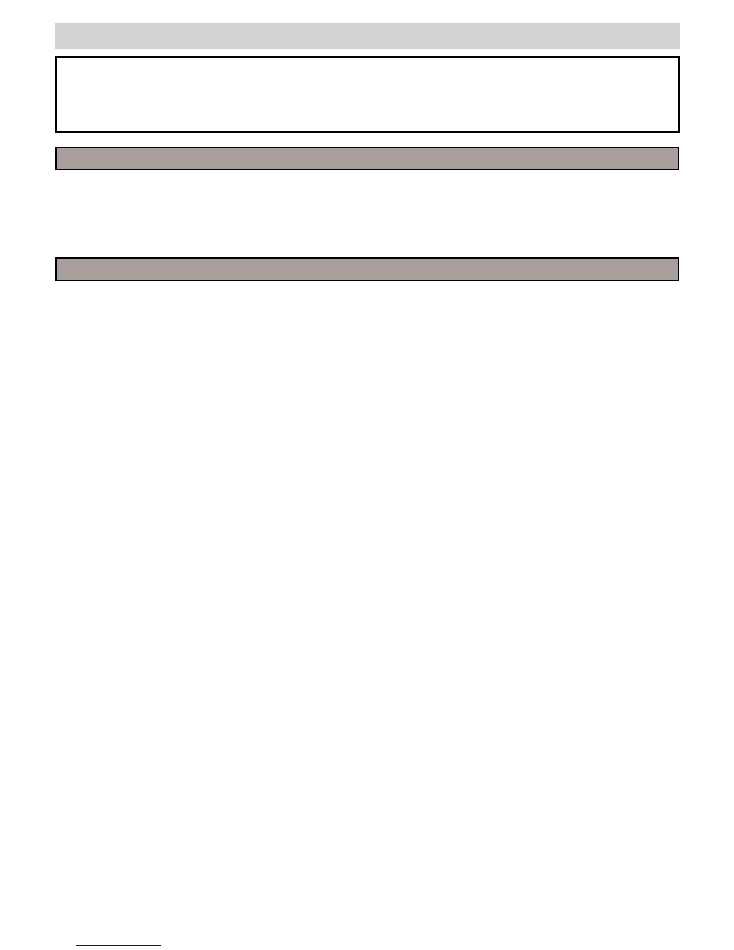

Safety device on lance

handgrip:

Prevents the trig-

ger on the handgrip from being

operated accidentally.

Thermal cutout:

stops the

high pressure washer if the

electric motor overheats.

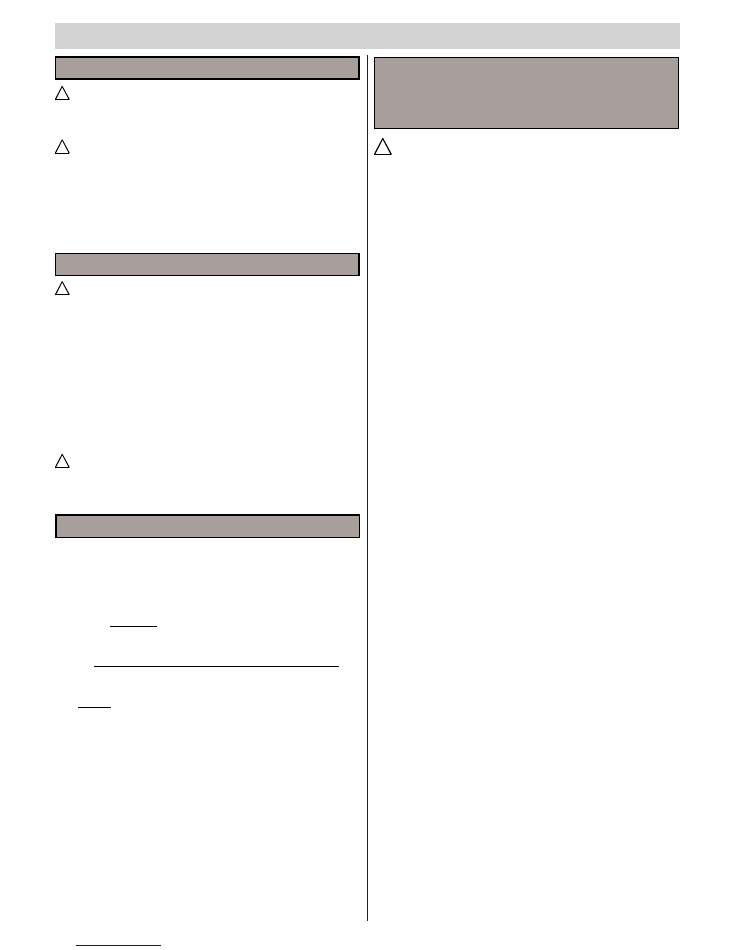

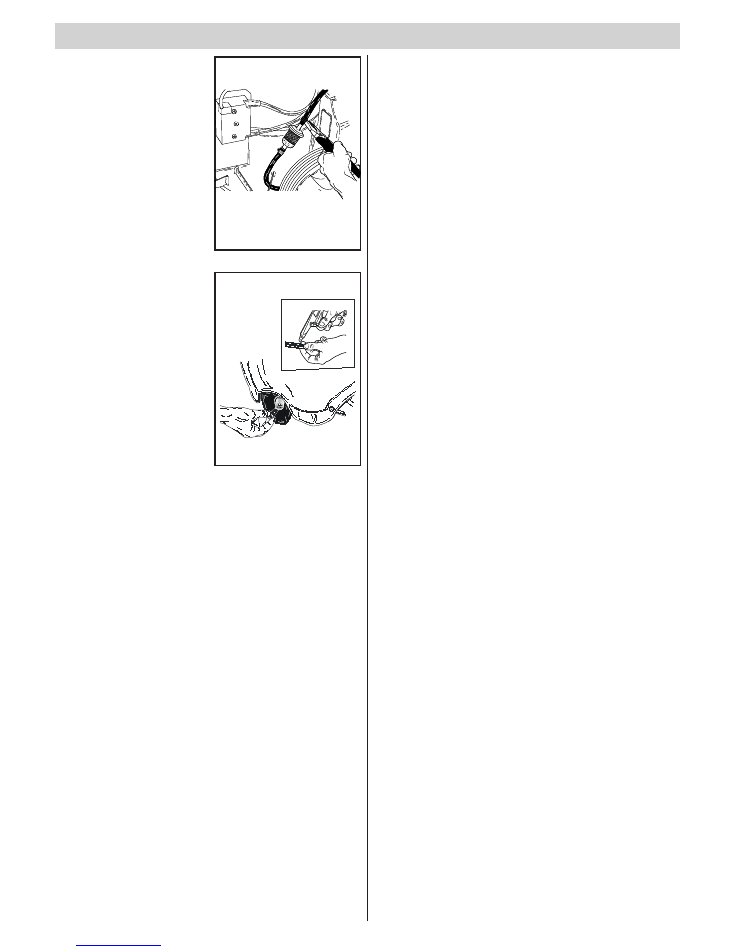

WATER CIRCUIT CONNEC-

TION

Connect the feed hose to the

mains (fig. 5A) and to the ho

-

setail on the cleaner (fig. 5B).

Check that the pressure and

quantity of the water supplied

by the mains are sufficient for

the cleaner to work properly:

2 to 8 BAR (29 to 116 PSI).

Maximum temperature of

feeding water 50°C (122°F).

Connect the high pressure

hose to the cleaner (fig. 5C)

and to the lance (fig. 6).

FIG. 4

WAX-SOAP KIT

(

If available

)

Select the desired tank by

turning the selector appropri-

ately. Detergent can only be

delivered in the low-pressure

position. (Fig. 4).

!

!

!

!

B

B

B

C

C

C

A

A

A

B

C

A

B

B

B

C

C

C

A

A

A

B

C

A

!

English

- 22 -

or the plug is unplugged from

the socket.

- When the water cleaner is not

used, close the safety device

on the handle.(fig.10).

- Dry use of the water cleaner

causes serious damage to

pump gaskets.

can be fitted with a head with rotary nozzle to clean the most

stubborn dirt.

Danger:

Aim the jet from a certain distance to avoid damage caused by

the high pressure.

Do not aim the jet at people, animals or electrical sockets.

STOPPING THE CLEANER

1

)

Turn the burner off by rotating the ON/OFF switch to the “I”

position (fig. 7A).

2

) Let the cleaner run with cold water only for at least 30 seconds

to cool down the boiler.

3

) Stop the cleaner by turning the selector switch to pos. "0"

(fig. 7A).

4

) Discharge the pressure from the H.P. hose by pressing the

trigger on the gun.

5

)

Disconnect the water cleaner from the mains electricity

supply via the Solenoid switch or by unplugging the plug from

the socket.

6

) Turn off the water supply tap (fig. 5A).

Warning

- If the water cleaner is left, even temporarily, turn it off by using

the Solenoid switch or by unplugging the plug from the socket.

- Water cleaners with the "Total Stop” device should be con-

sidered as off when the Solenoid switch is in the “O” position

FIG.10

Washing at high pressure

with a concentrated jet of

water

Turn the nozzle in an anti-

clockwise direction.

Washing at high pressure

with a fan-shaped jet of

water

Turn the nozzle in a clockwise

direction.

ROTARY HEAD (optional

accessory)

The high pressure washer

FIG. 7

FIG. 8

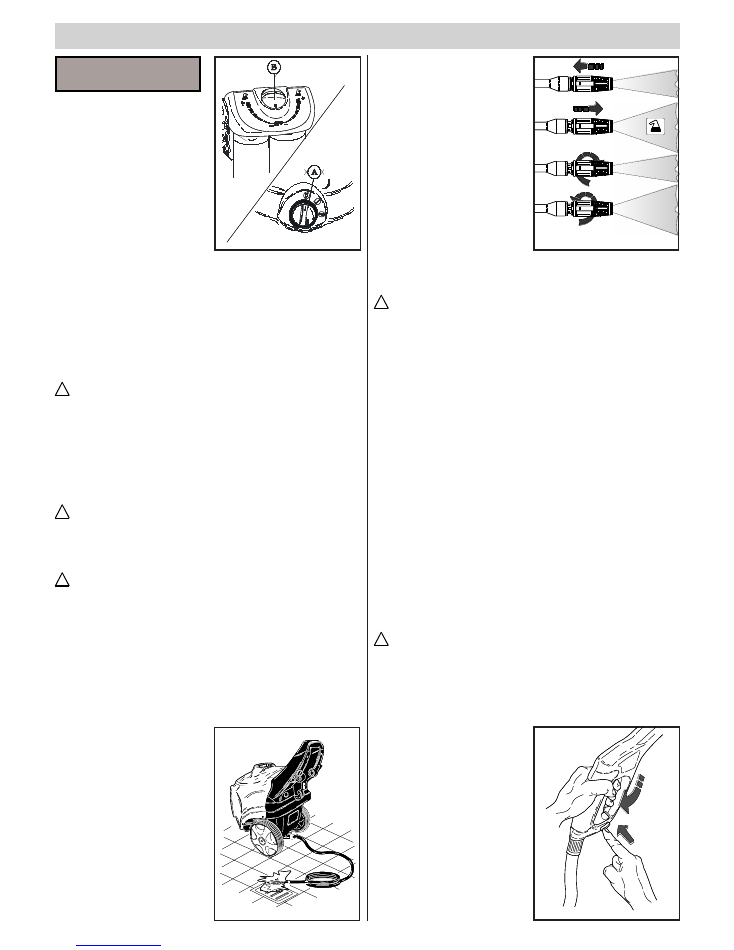

USING

THE CLEANER

CONTROL PANEL

A

- On/off switch

B

- Detergent control tap (if

available).

STARTING THE CLEANER

1

) Turn on the water supply tap (fig. 5A).

2

) Connect the water cleaner to the mains electricity supply by

plugging the plug into the socket.

3

) Start the cleaner by turning the selector switch to pos. I

(fig. 7A).

Warning

The high pressure water jet generates a reaction force in the

lance. Keep a firm grip on the lance handle.

4

) Press the trigger on the gun and begin washing.

5

)

To operate the water cleaner with hot water, turn the ON/OFF

switch to the Hot Water position. (fig. 7A).

Warning

In water cleaners with the “Total Stop” system, the motor starts

and stops when the lever on the lance handle is actioned or

released.

Danger

Do not block the handle lever in the delivery position.

IMPORTANT!

To eliminate any impurities or air bubbles from the water

circuit we advise starting the cleaner for the first time

without the lance and letting the water run out for a few

seconds.

Impurities could block the nozzle and cause malfunction

(Fig. 8).

USING THE ACCESSORIES.

USING THE MULTIREG

ADJUSTABLE NOZZLE (fig.

9)

Pressure must be selected

with the gun switched off.

Low pressure washing and

detergent suction.

(Version with detergent

suction).

Shift the nozzle forward.

!

!

!

!

!

FIG. 9

English

- 23 -

MAINTENANCE

ONLY THE OPERATIONS AUTHORIZED IN THIS IN-

STRUCTIONS MANUAL MAY BE CARRIED OUT BY

THE

USER.

ALL OTHER OPERATIONS ARE FORBIDDEN.

Danger

For maintenance of the boiler, high pressure pump, the electrical

parts and all parts with a safety function, you must apply to our

Technical service centre.

The manufacturer is not liable in case of tampering, changes, in-

correct repairs or maintenance carried out on the machine by a

third person not provided with the manufacturer’s authorization.

All documents pertaining to the repair and planned service

interventions, as well as any certificates concerning the device

installation according to the laws in force (in compliance with the

FIG. 11

ADVICE ON USING DETERGENTS

Warning

This cleaner has been designed for use with the detergents

supplied or recommended by the manufacturer.

The use of other detergents or chemicals may influence the

safety of the cleaner.

1

)

For environmental compatibility

, we recommend a reaso-

nable use of detergents, according to the instructions on the

pack.

2

) From the range of recommended products, choose the

one most suited to the washing job to be done and dilute it

with water according to the instructions on the pack or in the

catalogue of the detergents most suited for the type of hot or

cold water cleaner.

3

) Ask your dealer for the detergents catalogue.

OPERATING PHASES FOR CORRECT CLEANING WITH

DETERGENTS.

provisions of the IEC 60364-1 standard) must be kept carefully

by the user, together with the Instructions Manual.

Periodically, at least once a year, have the safety devices and

the rated values checked at one of our technical service centres.

Particularly, as for the hot water high pressure cleaner, which is

factory set, the exhaust system must be checked.

The rating done by the manufacturer determines a production of

exhaust gases with a CO content lower than 0,04% and a smoke

content corresponding to a smoke point nr.2 Shell-Bacharach

according to the laws in force.

Danger

Disconnect the water cleaner from the mains electricity supply

via the Solenoid switch or by unplugging the plug from the socket

and close the water supply tap (see chapters on connecting to

the electricity and water mains

)

before carrying out any main-

tenance jobs. Once maintenance has been completed, ensure

that the closing panels have been correctly reassembled and

anchored with the screws provided before reconnecting the

cleaner to the mains.

Failure to do so may cause a risk of electric shock.

!

!

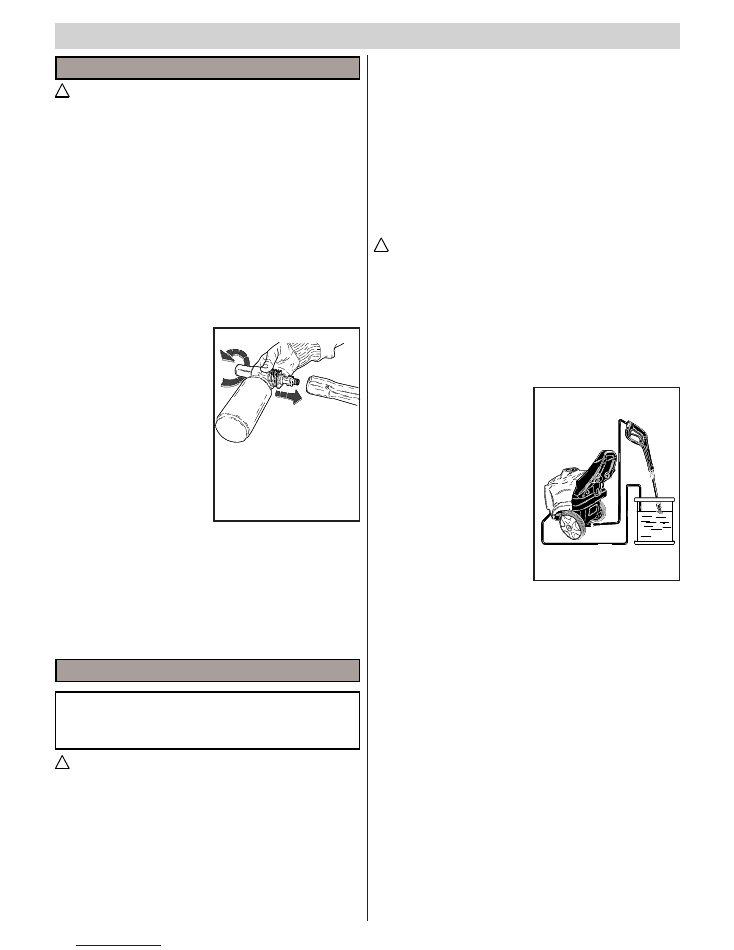

FIG.12

PRECAUTIONS AGAINST

FROST

The cleaner must not be

exposed to frost.

If the cleaner is left in premises

where it is exposed to frost,

when work is over or for sto-

rage, antifreeze must be used

to prevent serious damage to

the hydraulic circuit.

OPERATIONS FOR USING

ANTIFREEZE (fig. 12).

1

) Turn off the water supply (tap), disconnect the hose and run

the cleaner until it is completely empty.

2

) Stop the water cleaner with the ON/OFF switch in the “O”

position.

3

) Prepare a container with the solution of antifreeze.

4

) Immerse the tube in the container with the anti-freeze solu-

tion.

5

) Start the water cleaner with the ON/OFF switch in the “I”

position.

6

) Start the cleaner and let it run until antifreeze comes out

through the lance.

7

) Suck up antifreeze with the detergent intake system too.

8

)

Disconnect the water cleaner from the mains electricity

supply via the Solenoid switch or by unplugging the plug from

the socket.

Anti-freeze may cause environmental pollution. Always follow

the instructions given on the pack. (Dispose of carefully.)

PUMP OIL CHANGE.

Contact our technical service centre for replacement.

1)

Prepare the solution of

detergent at the concentration

most suitable for the type of

dirt and the surface that is to

be washed.

2)

Remove the extension tube

from the handgrip and attach

the detergent spray kit (fig.

11), operate the water clea-

ner and spray the surface to

be washed, starting from the

bottom and working upwards.

In the version with detergent

suction, open the detergent tap (fig. 7B) and move the nozzle

forwards. Leave to work for a few minutes.

3)

Rinse the whole surface well from top to bottom with hot or

cold water at high pressure.

4)

After use with detergent, rinse the high pressure water circuit

by operating the pump for one minute with the detergent tap

completely closed.

!

English

- 24 -

FIG.13

CLEANING THE FUEL

FILTER.

Remove and replace the in-

line fuel filter (fig. 13).

Change it from time to time.

FIG.14

CLEANING THE WATER

FILTER

Clean the water intake filter

regularly and free it from any

impurities (fig. 14).

CHANGING THE NOZZLE

The high pressure nozzle fitted on the lance must be chan

-

ged from time to time, as this component is subject to

normal wear during use. Wear may generally be detected

by a drop in the working pressure of the cleaner. To replace

it, consult your supplier and/or dealer for instructions.

DESCALING

Descaling must be carried out from time to time because the

scale present in the water partially deposits inside the hydraulic

circuit and the coil which with time becomes clogged.

Apply to our technical service centre to have the machine

descaled from time to time; this will save you money and

increase the efficiency of the cleaner.

TABLE OF ROUTINE MAINTENANCE TO BE PER-

FORMED BY THE USER.

Description of operations:

Check power cable - pipes - high pressure

connectors.

Each use

Change and clean fuel filters.

Every 100 hours

Clean fuel tank.

Every 100 hours

Clean water filter.

Every 50 hours

TABLE OF

EXTRAORDINARY MAINTENANCE

TO

BE PERFORMED BY THE TECHNICAL SERVICE

CENTRE.

Description of operations:

Boiler:

Clean Coil.

Every 200 hours

Descale coil.

Every 300 hours

Oil change in H.P. pump.

Every 500 hours

Clean fuel pump.

Every 200 hours

Change fuel nozzle.

Every 200 hours

Regulade electrodes.

Every 200 hours

Change electrodes.

Every 500 hours

Change seals on H.P. pump.

Every 500 hours

Change lanze nozzle.

Every 200 hours

Calibrate and check the safety

devices.

Once a year

English

- 25 -

IMPORTANT:

These intervals refer to normal working conditions. For heavy duty use decrease the interval for each job.

For maintenance and/or repairs, use only original spare parts which offer the greatest characteristics of quality and

reliability. Failure to use original spare parts absolves the manufacturer from all liability and transfers it to the

person carrying out the operation.

PERIODS OF INACTIVITY

If the machine is to remain inactive for a long period, disconnect the supply sources, drain the tank(s) of all the operating fluids

and protect any parts that could be damaged by the accumulation of dust.

Grease the parts that could be damaged by drying out, such as the supply hoses. When bringing back into use, ensure that

there are no cracks or cuts in the water supply hoses.

Oil and chemical products must be disposed of according to current legislation.

SCRAPPING

If you no longer wish to use the water cleaner, you should render it unusable by removing the power cable.

You should also make sure that all potentially hazardous parts of the appliance are made safe, particularly for children who could

play with the unused water cleaner.

This product is classified as WEEE type special waste and is covered by the requisites of the new environmental protection

regulations. It must be disposed of separately from ordinary waste in compliance with current legislation and standards.

Do not use parts dismantled for scrap as spare parts.

English

- 26 -

FAULTS

When the switch is turned the cleaner

does not start.

No jet or leakage from high pressure

water circuit.

The pump functions but does not reach

rated pressure.

When the lance is open, the pressure

drops and rises.

When the ON/OFF switch to the Hot

Water position, the boiler does not

come on.

Water not enough.

Excessive smoke from exhaust.

Inadequate detergent suction.

Water leakage from head.

Water in the oil.

TROUBLE-SHOOTING

Before carrying out any operations, disconnect the water cleaner from the mains electricity supply via the omni

-

polar switch or by unplugging the plug from the socket.

CAUSES

Faulty electric connection.

Thermal protection has tripped.

Water supply filter clogged.

Faulty connection to the mains water

supply.

Mains water supply tap closed.

Leakage from high pressure circuit.

Water supply filter clogged.

Faulty connection to the mains water

supply.

Lance nozzle worn.

Valves dirty or worn.

Detergent tap open.

Pressure adjustment devices on lance

open (if present).

Nozzle clogged or deformed.

Inadequate water supply.

No diesel.

Filters clogged.

Boiler element coated with scale.

Incorrect combustion.

Fuel contaminated with impurities or

water.

Tap closed.

No detergent.

Element or tube clogged.

Gaskets worn.

Excessive humidity in atmosphere.

REMEDIES

Check the mains voltage.

Reset (if it trips again, apply to the tech-

nical service centre).

Clean.

Check.

Open.

Contact Service Centre.

Clean.

Check.

Contact Service Centre.

Contact Service Centre.

Close.

Close.

Clean or contact Service Centre.

Check.

Check the level of diesel in the tank and

make sure the fuel supply circuit is free

of water.

Clean or replace.

Contact Service Centre.

Clean or replace diesel filters.

Contact Service Centre.

Empty the tank and clean thoroughly.

Clean diesel filters.

Open.

Fill the detergent tank.

Contact Service Centre.

Contact Service Centre.

Contact Service Centre.

IMPORTANT:

For maintenance and/or repairs, use only original spare parts which offer the greatest characteristics of quality and

reliability. Failure to use original spare parts frees the manufacturer from all responsibility.

Cod. PLDC40177 - 09/2014

IP Cleaning SpA

Sede Legale/Amministrativa - Registered Office/Administration

V.le Treviso, 63

30026 Summaga di Portogruaro (Venice) Italy

Tel. +39 0421 205511 Fax +39 0421 204227

www.ipcleaning.com info@ipcleaning.com