Full Text Searchable PDF User Manual

Metal Detector

43149

Set up anD operating inStructionS

Distributed exclusively by Harbor Freight tools

®

.

3491 Mission Oaks Blvd., Camarillo, CA 93011

Visit our website at: http://www.harborfreight.com

read this material before using this product.

Failure to do so can result in serious injury.

SaVe tHiS Manual.

Copyright

©

2000 by Harbor Freight Tools

®

. All rights reserved. No portion of this manual

or any artwork contained herein may be reproduced in any shape or form without the

express written consent of Harbor Freight Tools. Diagrams within this manual may not be

drawn proportionally. Due to continuing improvements, actual product may differ slightly

from the product described herein. Tools required for assembly and service may not be

included.

For technical questions or replacement parts, please call 1-800-444-3353.

Manual revised 09c

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 2

SpeciFicationS

Stem Length 15” - 27-1/2”

Coil

8” Diameter

Power Supply Qty 3, 9 Volt Batteries

Built-in Battery Tester

Audio

3 distinct sounds for different

metals

Weight

3.25 lb.

Save this Manual

You will need the manual for the safe-

ty warnings and precautions, assembly

instructions, operating and maintenance

procedures, parts list and diagram. Keep

your invoice with this manual. Write the

invoice number on the inside of the front

cover. Keep the manual and invoice in a

safe and dry place for future reference.

SaFety WarningS anD

precautionS

Warning:

When using tool, basic safety

precautions should always be fol-

lowed to reduce the risk of personal

injury and damage to equipment.

read all instructions before using this

product!

Handle the tool carefully at all

1.

times

. Dropping the Tool can cause

damage to circuit boards and the

case, which can cause the product to

work improperly.

only use and store the tool in

2.

normal temperature environments.

Extremes in temperature can shorten

the effectiveness of electronic devic-

es and melt or damage plastic parts.

avoid electrical shock.

3.

Any metal

detector may discover underground

power lines, explosives or other items

which when struck could cause per-

sonal injury. Do not use this product

in areas where there might be under-

ground electric lines or pipes buried

at shallow depths. Never search in

military zones where bombs or other

explosives may be buried. Avoid

striking any line known or suspected

to be carrying electric power. Do not

search any pipeline, particularly if

it could contain a flammable gas or

liquid. In areas of uncertain condi-

tions, use reasonable caution before

using the Tool. If there is any ques-

tion about a condition being safe of

unsafe, do not operate the Tool.

Keep the tool clean.

4.

Wipe the

housing after each use. The search

coil is washable and can be fully sub-

merged. Never submerge the control

housing. Protect the control housing

from rain, blowing surf and heavy

mist. Disassemble the stem and

wipe it clean after use in sandy areas.

Dress properly

5.

. Do not wear loose

clothing or jewelry as they can be

caught in moving parts. Protective,

electrically nonconductive clothes

and nonskid footwear are recom-

mended when working. Wear restric-

tive hair covering to contain long hair.

use the right tool for the job

6.

. Do

not attempt to force a small tool or

attachment to do the work of a larger

industrial tool. There are certain

applications for which this tool was

designed. Do not modify this tool and

do not use this tool for a purpose for

which it was not intended.

Stay alert

7.

. Watch what you are do-

ing, use common sense. Do not oper-

ate any tool when you are tired.

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 3

check for damaged parts

8.

. Before

using any tool, any part that ap-

pears damaged should be carefully

checked to determine that it will oper-

ate properly and perform its intended

function. Check for alignment and

binding of moving parts; any broken

parts or mounting fixtures; and any

other condition that may affect proper

operation. Any part that is damaged

should be properly repaired or re-

placed by a qualified technician. Do

not use the tool if any switch does not

turn On and Off properly.

replacement parts and acces-

9.

sories

. When servicing, use only

identical replacement parts. Use of

any other parts will void the warranty.

Only use accessories intended for

use with this tool. Approved accesso-

ries are available from Harbor Freight

Tools.

Do not operate tool if under the in-

10.

fluence of alcohol or drugs

. Read

warning labels on prescriptions to

determine if your judgment or reflex

-

es are impaired while taking drugs. If

there is any doubt, do not operate the

tool.

Maintenance

11.

. For your safety, main-

tenance should be performed regu-

larly by a qualified technician.

People with pacemakers should con-

12.

sult their physician(s) before using

this product. Electromagnetic fields

in close proximity to a heart pace-

maker could cause interference to, or

failure of, the pacemaker.

WARNING: Handling the cord on

13.

this product will expose you to lead,

a chemical known to the State of

California to cause cancer, and birth

defects or other reproductive harm.

Wash hands after handling.

(California Health & Safety Code §

25249.5,

et seq.

)

Warning: the warnings, cautions,

14.

and instructions discussed in this

instruction manual cannot cover

all possible conditions and situ-

ations that may occur. it must be

understood by the operator that

common sense and caution are

factors which cannot be built into

this product, but must be supplied

by the operator.

unpacKing

When unpacking, check to make

sure all parts shown on the Parts Diagram

and Parts Lists are present. If any parts

are missing or broken, please call Harbor

Freight Tools at 1-800-444-3353.

preparing to operate

assembly

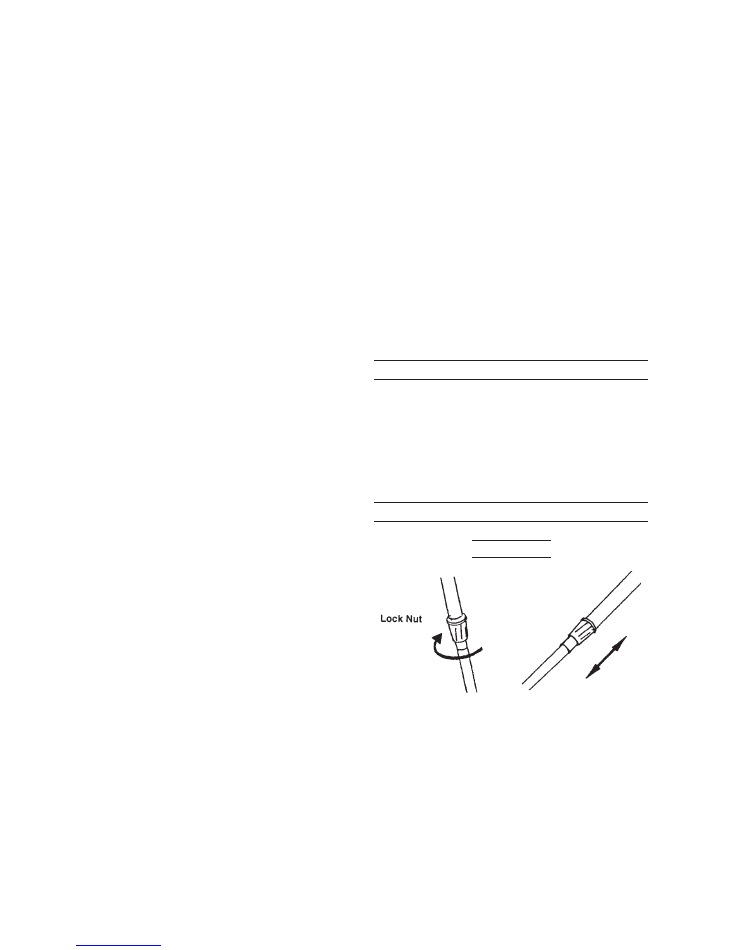

Figure 1

Figure 2

1. Turn the lock nut on the stem clock-

wise to loosen (see Figure 1).

Adjust the length of the stem so that

2.

when you stand upright with the tool

held in your hand, the search coil is

level with and about 1/2 to 2 inches

above the ground (see Figure 2).

reV 07f; 09c

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 4

Turn the stem’s lock nut counter-

3.

clockwise to lock it in place.

Unscrew the knob on the search coil

4.

and take off the knobs and connector.

Insert the stem and align the holes on

the search coil bracket and the stem.

Push the connector through the holes

and tighten the knob.

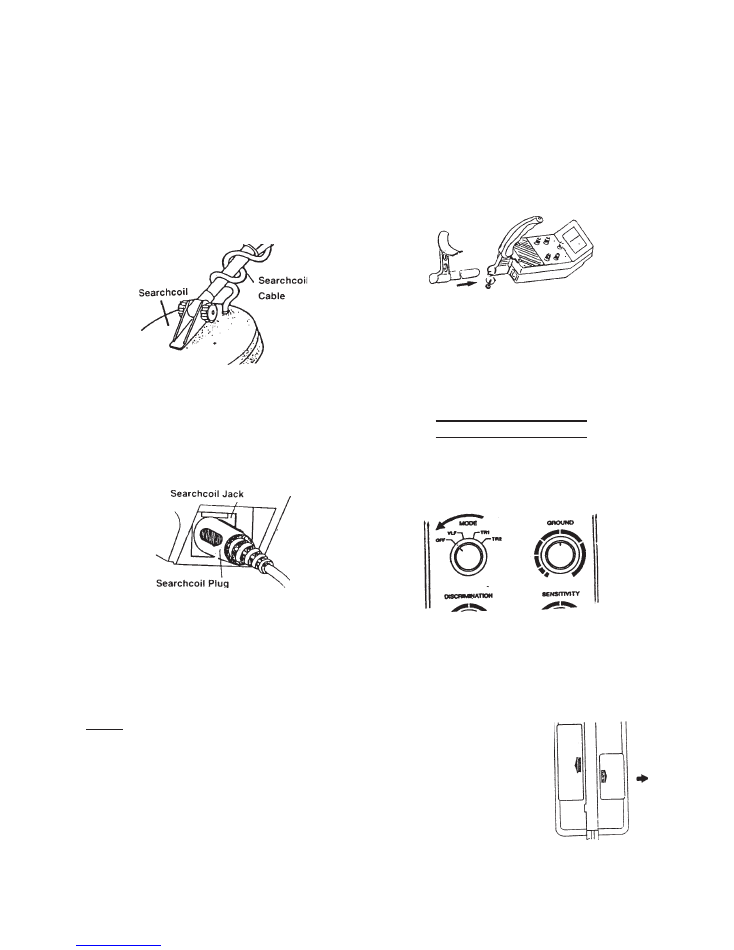

Figure 3

5. Wind the search coil cable around the

stem. Make sure you leave enough

slack in the cable to allow for adjust-

ment when you are using the Tool on

uneven ground (see Figure 3).

Figure 4

6. Plug in the search coil’s plug into the

search coil jack on the Tool’s control

panel. Make sure that the pins on the

plug align with the holes in the jack

(see Figure 4).

note:

The search coil’s plug fits into the

connector only one way. Never force

the plug; the plug could become dam-

aged. To disconnect the plug, never

pull on the cable; always take hold of

the plug and pull it out of the connec-

tor.

Loosen the knob at the search coil’s

7.

end, then adjust the search coil’s end,

then adjust the search coil to the de-

sired angle. The search coil should

be parallel with the ground. Tighten

the knob enough to keep the search

coil from rotating or wobbling.

Figure 5

8. To insert the arm support (see Figure

5), loosen the knob at the base of the

handle. Insert the arm support and

tighten the knob to hold the arm sup-

port in place.

Battery installation

The Tool is powered by three, 9 Volt

batteries. Battery installation is described

below:

Figure 6

1. If the Tool is on, turn MODE to OFF

(see Figure 6).

2. Press the right battery compartment

cover’s tab and slide

the cover in the direc-

tion of the arrow (see

Figure 7).

Place one 9 Volt bat-

3.

tery into the battery

compartment on top

of the ribbon. Place

Figure 7

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 5

the battery so that it matches the

polarity symbols (+ and -) that are

marked inside the compartment.

Replace the right battery compart-

4.

ment cover.

5. Press the left battery compartment

cover’s tab and slide

the cover off in the

direction of the arrow

(see Figure 8).

Place two 9 Volt bat-

6.

teries into the bat-

tery compartment on

top of the ribbons,

matching the polarity symbols (+ and

-) marked. Replace the left battery

compartment cover.

note:

The life of the batteries can be

extended by using headphones (not

included), which require less power

than the built-in speaker. See the

section on headphones below.

caution!

Always remove old or weak

batteries; old batteries can leak

chemicals that can damage electronic

parts. If you do not plan to use the

Tool for a week or more, remove the

batteries. Use only fresh batteries

of the required size. Do not mix old

and new batteries or different types of

batteries.

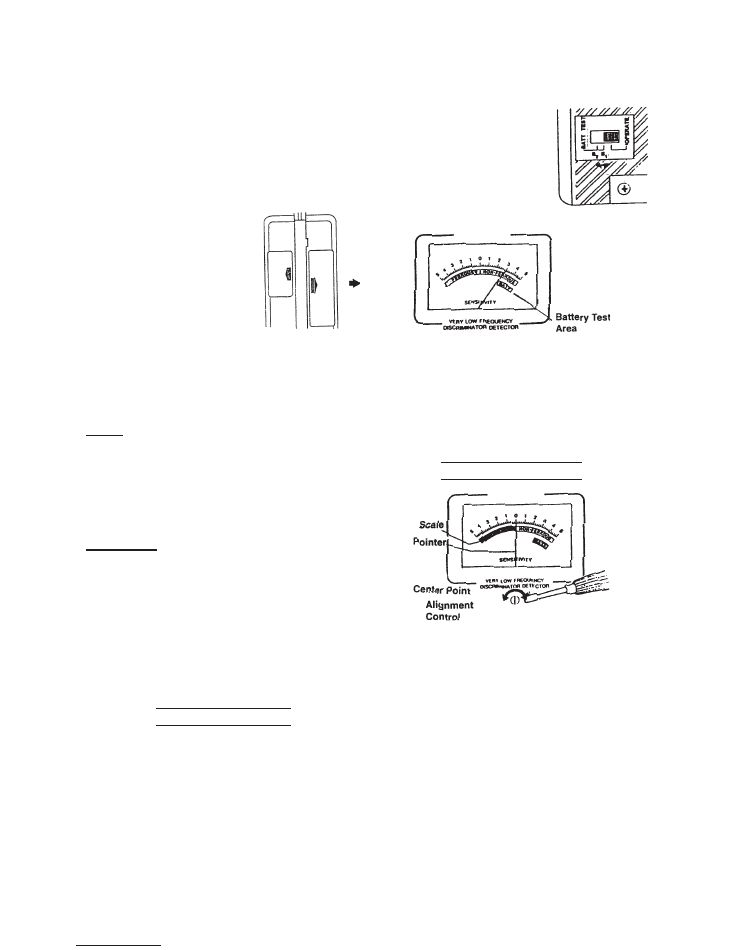

testing Batteries

Test the battery power when the Tool

does not turn on, or has weak volume, or

will not tune properly or operates errati-

cally.

Set the

MoDe

to

VlF

(very low

frequency). To test the

batteries in the left battery

compartment, set

Batt

teSt

to

B1

. To test the

battery in the right battery

compartment, set

Batt

teSt

to

B2

(see Figure 9).

Figure 10

If the pointer on the viewmeter is

within the

Batt

scale’s green area, the

batteries have enough power. If the point-

er is not within the green area, the batter-

ies need to be replaced (see Figure 10).

Meter adjustment

Figure 11

Set

MoDe

to

oFF

. Using a screw-

driver, adjust the alignment control until the

pointer lines up with

o

on the scale (see

Figure 11).

Figure 8

Figure 9

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 6

earphone use

Figure 12

Stereo earphones (not included) can

be connected to the Tool. Using ear-

phones saves battery power and makes

it easier to identify changes in the sound

patterns. Earphones are connected to the

ear jack on the side of the Control Housing

(see Figure 12).

When using earphones, protect your

hearing by:

Set the volume to the lowest setting

a.

before you begin listening. Adjust

the volume to a comfortable level.

Never listen at extremely high vol-

b.

ume levels; permanent hearing loss

can result.

Once the volume is set, do not

c.

increase it. Over time, your ears

adapt to the volume level, so a

volume level that does not cause

discomfort might still damage your

hearing.

operation

This tool distinguishes between fer-

rous and non-ferrous metals. Ferrous

metals contain iron. Non-ferrous metals

do not (examples: gold, silver, copper,

platinum, aluminum, lead, and zinc).

When the Tool senses a metallic object,

the meter reading changes and the de-

tector might sound a tone. The reaction

depends on what metal is detected.

Basic operation

Set the

1.

Batt teSt

to

operate.

2. Hold the detector comfortably, then

as shown in Figure 13,

rotate

MoDe

to the

desired position.

Set it to

•

VlF

to test

the battery power

and adjust

tune

and

grounD

(see direc-

tions below and on

page 8).

Set it to

•

tr1

to de-

tect extreme differences in metals,

such as between gold and iron. The

difference shows on the meter (iron

as a ferrous metal, gold as a non-

ferrous metal).

Set it to

•

tr2

to detect finer distinc

-

tions between metals. For example,

between aluminum and gold.

tuning

tune

fine tunes the balance be

-

tween the tool’s receiver and the transmit-

ter circuitry, to provide consistent pointer

and tone indications.

Figure 14

Figure 15

To Tune, do the following and see Figure

14 and 15, above:

Rotate

1.

VoluMe

to the 10 o’clock

position.

Set

2.

MoDe

to

VlF.

Figure 13

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 7

Set

3.

grounD

,

DiScriMination

,

and

SenSitiVity

to mid-range.

Figure 16

4. Hold the search coil at least 1 foot

away from the ground and any metal

object. Hold down the red button on

the handle and slowly rotate

tune

until the viewmeter pointer rests at or

near 0 (see Figure 16).

As you use the Tool to search for

5.

items, you can fine tune by using the

other control (see Fine Tuning the

Tool on page 8).

note:

To return the pointer to the center

of the viewmeter at any time, simply

press the red button on the handle.

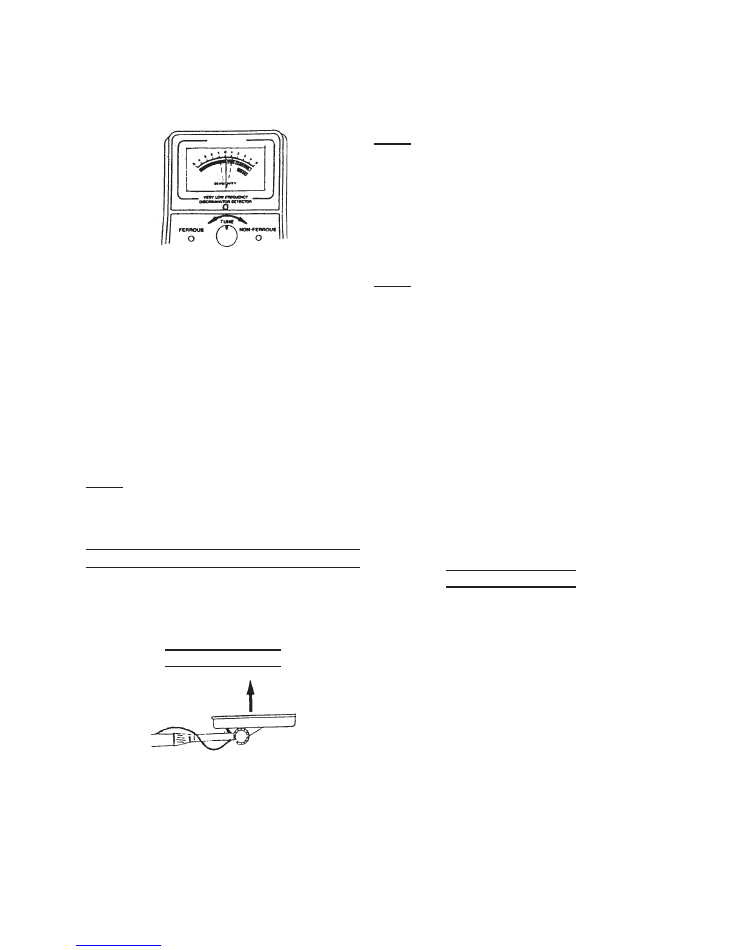

teSting tHe tool

You must first test the detector to find

out how it reacts to different metals. It can

be tested indoors or outdoors.

indoor testing

Figure 17

1. After removing watches, rings or any

other metal jewelry, place the de-

tector on a wooden or plastic table.

Adjust the search coil’s angle so that

the flat part faces upward (see Figure

17).

note:

Never test on a floor inside a build

-

ing, as it may have a type of metal

present.

Set

2.

MoDe

to

tr1

. Move a sample

of the material being tested (example:

coin or gold ring) about 2 inches

above the search coil.

note:

The Tool will not detect without mo-

tion. You must move the object since

you are not sweeping the Tool.

If the Tool detects the material, the

3.

NON-FERROUS and FERROUS indi-

cators flash and the pointer moves to

FERROUS or NON-FERROUS while

the detector determines the type of

metal it is detecting. If it detects non-

ferrous metal, it also sounds a tone.

If the Tool does not detect the materi-

4.

al, check the battery power and verify

that the search coil is properly con-

nected. Also, you might need to fine

tune the detector (see next page).

outdoor testing

Locate an area outdoors where there

1.

is no metal present. Place a sample

of the material to be tested (coin or

gold ring) on the ground.

Set

2.

MoDe

to

tr1.

With the search coil being held ap-

3.

proximately 1 to 2 inches above the

ground, slowly move the search coil

over the area where you placed the

sample. Sweep in a side to side mo-

tion as follows:

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 8

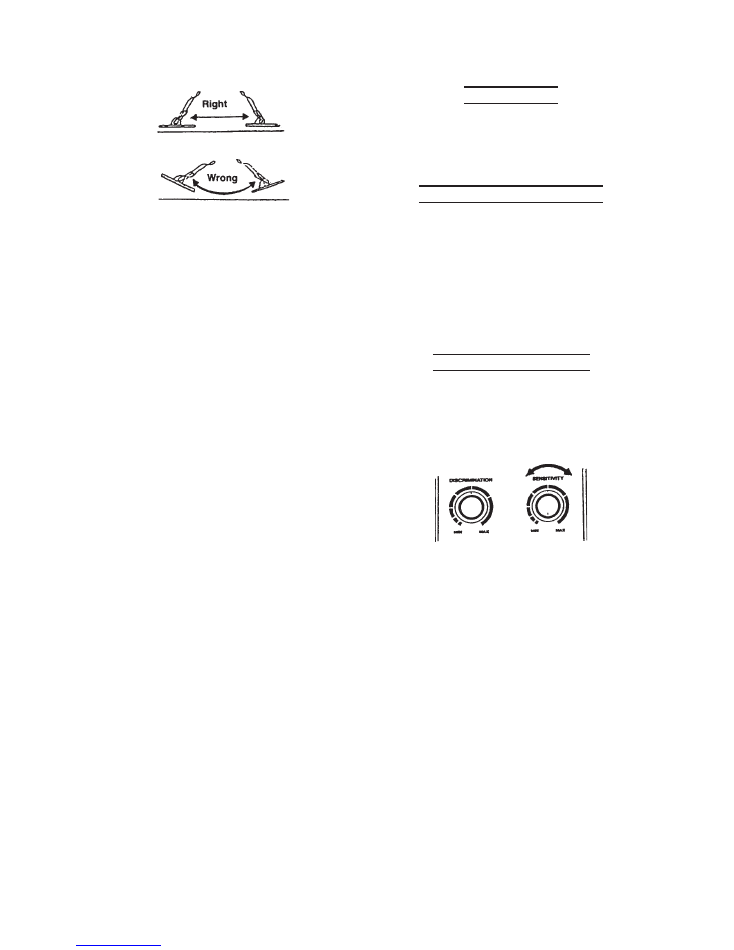

Figure 18

4. Sweep slowly to avoid missing tar-

gets. Never raise the sweep coil

while sweeping; sweep back and

forth as if it was a pendulum (see

Figure 18).

If the Tool detects the item, it sounds

5.

a tone and the pointer moves to the

type of metal it found. After detect-

ing metal, switch

MoDe tr1

to

tr2

to determine the quality of the metal.

If nothing was detected, try again

(make sure the search coil is being

moved properly).

The detector will respond strongly

6.

when it detects most valuable metal

objects. If the signal does not repeat

after being swept over the target a

few times, the target is probably junk

metal.

False signals can occur from elec-

7.

trical interference, large, irregular

pieces of junk metal, or finding trash

on the ground. False signals usually

occur broken or are non-repeatable.

After finding a metal item, wait a few

8.

seconds after the tone stops before

continuing; this allows the detector

time to reset. You can also press the

red button on the handle to return the

pointer to the center of the viewmeter.

Fine tuning

Once you practice with the unit, you

can fine tune it to make it more selective in

what is found.

adjusting SenSitiVity

To adjust the search coil’s ability to

detect objects at different depths in the

ground, rotate

SenSitiVity

between

Min

and

MaX

. For maximum detection depth,

leave

SenSitiVity

set as high as pos-

sible. If the Tool begins to “chatter”, de-

crease

SenSitiVity

until the noise stops.

adjusting grounD

For accurate operation, it is criti-

cal that you take the time to correctly set

grounD. grounD

tunes out false sig-

nals from mineralized soil.

Figure 19

To set

grounD

:

Set

1.

MoDe

to

VlF

and lower the

search coil to 1/2 to 2 inches above

the ground.

If the pointer swings to the right, turn

2.

grounD

to the left.

If the pointer swings to the left, turn

grounD

to the right.

Lift the search coil about 12 inches

3.

from the ground and press the red

button on the handle. The pointer will

return to the center. Repeat these

three steps until the pointer stays

close to the center each time you

lower the search coil to the ground.

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 9

After setting

4.

grounD

the Tool is

ready for the soil type at that particu-

lar site. It will not need to be reset

until you move to a new location.

adjusting DiScriMination

Discrimination is the Tool’s ability to

differentiate between types of metal. This

setting determines whether the detector

will distinguish between different types of

ferrous and non-ferrous metals. If

MoDe

is set to

tr2

, start with

DiScriMination

set to mid-range. While the Tool is being

used, adjust

DiScriMination

to the best

position. As you set it higher, the detector

becomes more sensitive to the differences

between large aluminum and gold pieces,

for example, but other valuable items such

as coins and small rings, might be over-

looked.

As you set

DiScriMination

to

higher levels, the detector first does not

detect small pieces of silver paper, then

thick foil, and finally metal objects like cola

pull tabs. Each time you change areas,

you must reset

DiScriMination.

False Signals and Detection Hints

As you sweep the search coil back

and forth over the ground surface, you will

recognize the difference between signals

that occur at random and signals that

are stable and repeatable. The key is to

dig only for those targets that produce a

strong, repeatable signal. This will prevent

you from wasting time focusing on trash

induced signals.

No metal detector is totally accurate.

Many conditions influence the success of

metal detection. Among the factors that

influence results are the angle at which the

object rests in the ground, the depth of ob-

ject, the amount of iron the object contains

and the size of the object.

To accurately pinpoint a target:

Once the detector detects a target

1.

that is buried, continue to sweep the

search coil over the target in a nar-

rowing side-to-side motion.

Stop the search coil directly over the

2.

spot on the ground. Then move the

search coil straight forward away

from you and straight back towards

you. Make a mental note of the exact

spot on the surface where the detec-

tor beeps. Repeat these steps in

an X pattern. The target should be

directly below the X at the area where

the loudest response is heard.

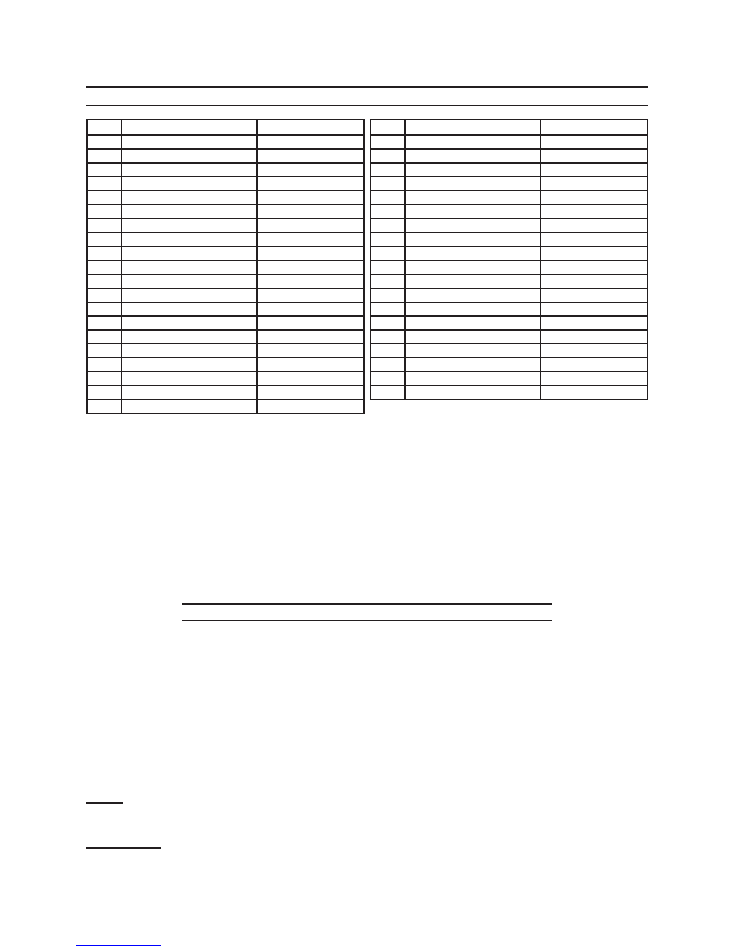

trouBleSHooting

problem

Suggestion for cure

False signals are being

displayed

Sweeping too fast or at the wrong angle.

1.

Heavily oxidized metals are detected. Pinpoint the target from several

2.

different angles. If the detector does not display and sound the same

signal each time, the target is probably heavily oxidized metal.

Once a target is found, the

display does not show the

correct metal type

May be more than one target in the area.

1.

If target is heavily oxidized, an incorrect reading may occur. This does

2.

not signify a problem with the detector.

It may be a type of metal which is not recognizable to the detector.

3.

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 10

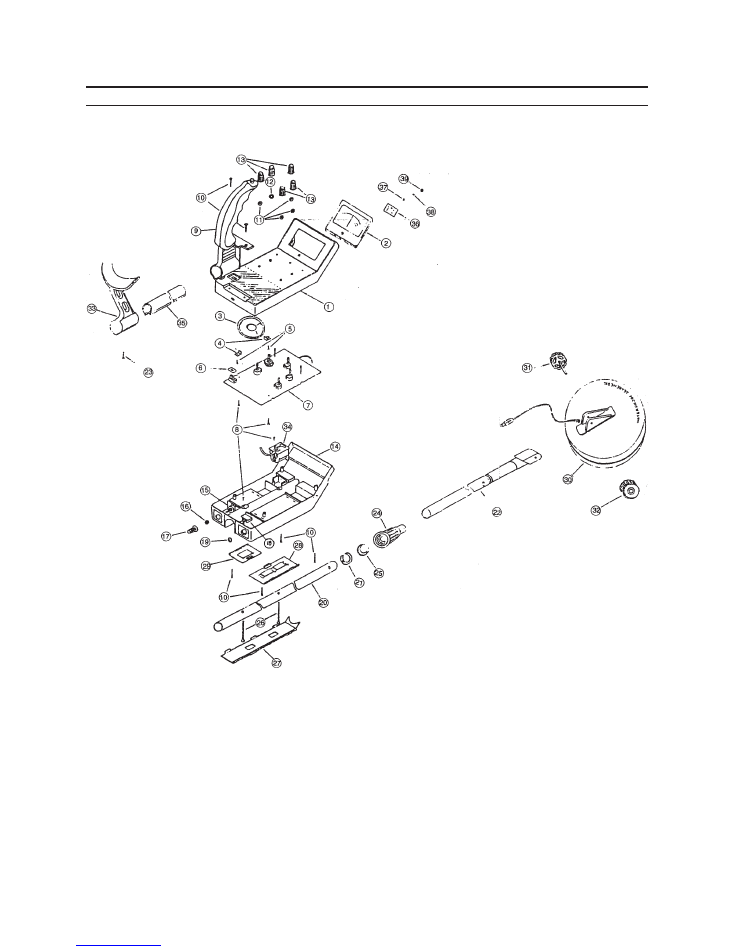

pleaSe reaD tHe FolloWing careFully

THE MANUFACTURER AND/OR DISTRIBUTOR HAS PROVIDED THE PARTS DIAGRAM IN THIS

MANUAL AS A REFERENCE TOOL ONLY. NEITHER THE MANUFACTURER NOR DISTRIBUTOR

MAKES ANY REPRESENTATION OR WARRANTY OF ANY KIND TO THE BUYER THAT HE OR SHE

IS QUALIFIED TO MAKE ANY REPAIRS TO THE PRODUCT OR THAT HE OR SHE IS QUALIFIED TO

REPLACE ANY PARTS OF THE PRODUCT. IN FACT, THE MANUFACTURER AND/OR DISTRIBUTOR

EXPRESSLY STATES THAT ALL REPAIRS AND PARTS REPLACEMENTS SHOULD BE UNDERTAKEN

BY CERTIFIED AND LICENSED TECHNICIANS AND NOT BY THE BUYER. THE BUYER ASSUMES

ALL RISK AND LIABILITY ARISING OUT OF HIS OR HER REPAIRS TO THE ORIGINAL PRODUCT OR

REPLACEMENT PARTS THERETO, OR ARISING OUT OF HIS OR HER INSTALLATION OF REPLACE-

MENT PARTS THERETO.

note:

Some parts are listed and shown for illustration purposes only and are not avail-

able individually as replacement parts.

Warning! Service

and maintenance should only be performed by a qualified

technician.

part

Description

Mfr’s part no.

1

Control Box Top

SQC6.116.042

2

Meter

M3006

3

Loud Speaker

YD-50

16 ohm 0.25 W

4

Fixing Board

SQC8.610.154

5

Screws ST2.9 x 6

GB845-85

6

Lining Board

SQC8.683.031

7

Main PCB

SQC2.908.526

8

Screws ST2.9 x 8

GB845-85

9

Handle

SQC6.465.033

10 Screws ST3.9 x 16

11 Nut M6 x 0.75

GB808-76

12 Nut M8 x 0.75

GB808-76

13 Control Knob

SQC8.337.334

14 Control Box Button

SQC6.116.044

15 Potentiometer B-10K

R1710N16K

16 Nut M6 x 0.75

GB808-76

17 Control Knob

SQC8.337.330

18 Stereo Earphone PCB

SQC5.566.003

19 Nut M6 x 0.5

20 Aluminum Stem (19mm)

SQC8.009.002

part

Description

Mfr’s part no.

21 Stem Lock Ring

SQC8.225.012

22 Stem

SQC6.336.001

23 Screw M3 x 10

GB819.85

24 Stem Lock Nut

SQC8.225.011

25 Stem Lock Ring

SQC8.220.081

26 Screws M4 x 28

27 Cover (Stem)

SQC7.852.078

28 Cover (Large)

SQC6.170.030

29 Cover (Small)

SQC6.170.031

30 Search Head

SQC5.939.000

31 Head Knob (Screw)

SQC6.354.021

32 Head Knob (Nut)

SQC6.354.022

33 Bracket

SQC6.154.001

34 Socket PCB

SQC5.566.004

35 Aluminum Stem

SQC8.009.001

36 Board

SQC8.610.157

37 Flat Washer

GB848-85-3

38 Spring Washer

GB859-87-3

39 Nut M3

GB6172-86

partS liSt

SKU 43149

For technical questions, please call 1-800-444-3353.

Page 11

partS DiagraM