Full Text Searchable PDF User Manual

November 2015 Revision 1

Installation and Operating Instructions for

Greymetal Wood Burning Stoves

Arctic 5

Lumo 5

Lumo 5 Rotary

Orbit

Greymetal Ltd

FTS

Drome Road

Zone 1

Deeside Industrial park

CH5 2LR

- 2 -

Important – please read section 7.2 before lighting!

Contents

1

INTRODUCTION ............................................................................................................................. 3

2

COMBUSTION AND HEATING FUNCTION ...................................................................................... 3

3

DESIGN .......................................................................................................................................... 3

4

SAFETY REQUIREMENTS ................................................................................................................ 4

4.1

General provisions ........................................................................................................................ 4

4.2

Safe distance of the stove in the room from flammable substances ............................................ 4

4.3

Danger Warnings .......................................................................................................................... 4

4.4

Fire in the chimney ....................................................................................................................... 5

5

ASSEMBLY ..................................................................................................................................... 5

5.1

Instructions for stove assembly .................................................................................................... 5

5.2

Central Air Feed (CAF) ................................................................................................................... 6

6

FUEL .............................................................................................................................................. 6

7

OPERATION ................................................................................................................................... 6

7.1

Combustion process ..................................................................................................................... 6

7.2

First kindling .................................................................................................................................. 7

7.3

Kindling ......................................................................................................................................... 7

7.4

Heating .......................................................................................................................................... 7

7.5

Glass cleaning / ‘Air-Wash’ function ............................................................................................. 8

7.6

Removal of ash.............................................................................................................................. 8

7.7

Operation with the door open ...................................................................................................... 8

7.8

Dampers left open ........................................................................................................................ 8

8

CLEANING AND MAINTENANCE .................................................................................................... 8

9

MOST FREQUENT FAILURES .......................................................................................................... 9

10

UNCOMMON FAILURES ................................................................................................................ 9

11

SERVICE ......................................................................................................................................... 9

11.1 Guarantee and after-guarantee service ........................................................................................ 9

11.2 Ordering of spare parts ................................................................................................................. 9

12

STOVE PACKAGE AND DISPOSAL ................................................................................................... 9

12.1 Package ......................................................................................................................................... 9

12.2 Stove disposal ............................................................................................................................... 9

13

ANNEXES ..................................................................................................................................... 10

13.2 Distances to combustible materials and size of hearth .............................................................. 10

13.3 Changin flue exit / uptake ........................................................................................................... 10

13.4 Instructions for cleaning cast-iron and tile stoves ...................................................................... 11

- 3 -

1

Introduction

The appliance is designed to heat domestic residential and social spaces. The stove is intended for use only by

adults with occasional attendance and supervision. The room in which the stove is installed must be provided with

a sufficient fresh air supply, possibly by gaps through windows and doors. In well-sealed buildings, sufficient fresh

air supply to the room must be ensured by a vent of 550mm

2

for each Kilowatt of rated nominal output.

The local Building Control department must be consulted prior to any DIY installation.

Please follow all of the instructions when installing and operating the stove.

The Clean Air Act 1993, Smoke Control Areas and DEFRA

Under the Clean Air Act, local authorities may declare the whole or part of the district of the authority to be a

smoke control area. It is an offence to emit smoke from a chimney of a building, from a furnace or from any fixed

boiler if located in a designated smoke control area. It is also an offence to acquire an "unauthorised fuel" for use

within a smoke control area unless it is used in an "exempt" appliance ("exempted" from the regulations which

generally apply in the smoke control area).

The Secretary of State for Environment, Food and Rural Affairs has powers under the Act to authorise smokeless

fuels or exempt appliances for use in smoke control areas in England. In Scotland and Wales this power rests with

Ministers in the devolved administrations for those countries. Separate legislation, the Clean Air (Northern Ireland)

Order 1981, applies in Northern Ireland. Therefore, it is a requirement that fuels burnt or obtained for use in

smoke control areas have been "authorised" in Regulations, and that appliances used to burn solid fuel in those

areas (other than "authorised" fuels) have been exempted by an Order made and signed by the Secretary of State

or Minister in the devolved administrations.

Further

information

on

the

requirements

of

the

Clean

Air

Act

can

be

found

here:

http://smokecontrol.defra.gov.uk/

Your local authority is responsible for implementing the Clean Air Act 1993 including designation and supervision

of smoke control areas and you can contact them for details of Clean Air Act requirements.

The Arctic 5, Lumo 5, Lumo 5 rotary, and Orbit 5kW stoves are exempt appliances that have been recommended as

suitable for use in smoke control areas when burning wood logs; and have been factory fitted with a secondary air

control which cannot be fully closed.

2

COMBUSTION AND HEATING FUNCTION

The stove is designed for combustion of wood and wood ‘eco’ briquettes by a burn-through system that ensures

excellent combustion conditions. If not in a smoke control area, lignite briquettes may also be used.

The heating function is achieved mainly by convection, and partially by radiant heat. The convection system is able

to heat up particularly cold rooms relatively quickly.

Convection heating works by sucking in the air from the room through the vents at the bottom of the stove into

the space between the firebox and the outer casing. It is heated in-between the double walls of the stove causing

it to rise. It flows back into the room through the vents in the upper part of the stove.

Heat is also radiated by the surface of the stove body, but the main source of radiant heat is the glass door surface.

- 4 -

3

DESIGN

The appliance is fabricated from pressed and welded sheet steel, and may include as an optional extra a stone or

ceramic outer casing. The stove combustion chamber is lined with refractory (heat resistant) vermiculite firebricks.

The refuelling door of the stove has a

ceramic

window, resistant to very high temperatures and thermal shocks.

The ceramic is almost clear, allowing heat radiation from the combustion chamber (‘firebox’) to pass through; and

allows a view of the flames when burning. There is a sold cast iron grate at the bottom of the firebox and an ash pit

below. The stove is spray painted with silicone polymer paint, resistant to high temperatures.

Primary air, secondary air and tertiary air is supplied to the firebox. Primary air is used for lighting and is

channelled under the grate; secondary air is channelled onto the glass from above and provides the self-cleaning

(‘air-wash’) of the glass. Tertiary air is fed to the upper part of the firebox through the vents at the back of the

firebox, and provides further combustion of un-burnt gases (burnout).

The Arctic, Lumo (non-rotary) and Orbit stoves have the option of feeding combustion air through the Central Air

Feed (CAF) from the outdoors. If the CAF is used, the stove does not take air from the room. These options are

specified in the

Product Technical Sheet (TS)

.

4

SAFETY REQUIREMENTS

4.1

General provisions

The principles of fire protection in the Building Regulations publication

“

Approved Document J

-

Combustion appliances and Fuel Storage systems (2010 edition incorporating 2010 and 2013 amendments)

http://www.planningportal.gov.uk/uploads/br/BR_PDF_ADJ_2010.pdf

must be observed when operating and

installing the stove.

The appliance may be used in a normally experienced environment according to

Approved Document J

.

In any change of environment, when a temporary danger of fire or explosion could emerge (e.g. when using glues,

solvents, paints etc.), the stove must not under any circumstances be in operation. The stove may be used further

only after thorough ventilation of the room, at best by draught.

The stove must be connected to a chimney with a draught of at least 12 Pascals. The installer should

test and certify the adequacy of the draught. The stove may be connected only to its own independent chimney.

4.2

Safe distance of the appliance from combustible surfaces:

Hearth:

The appliances

do not

cause the

hearth temperature

to exceed 100°C and can be placed on a non-combustible,

non-constructional hearth of 12mm thickness. The hearth must exceed the dimensions of the stove by at least 15

cm on each side, 10 cm at the back and 30 cm to the front. It must have a minimum thickness of 12mm.

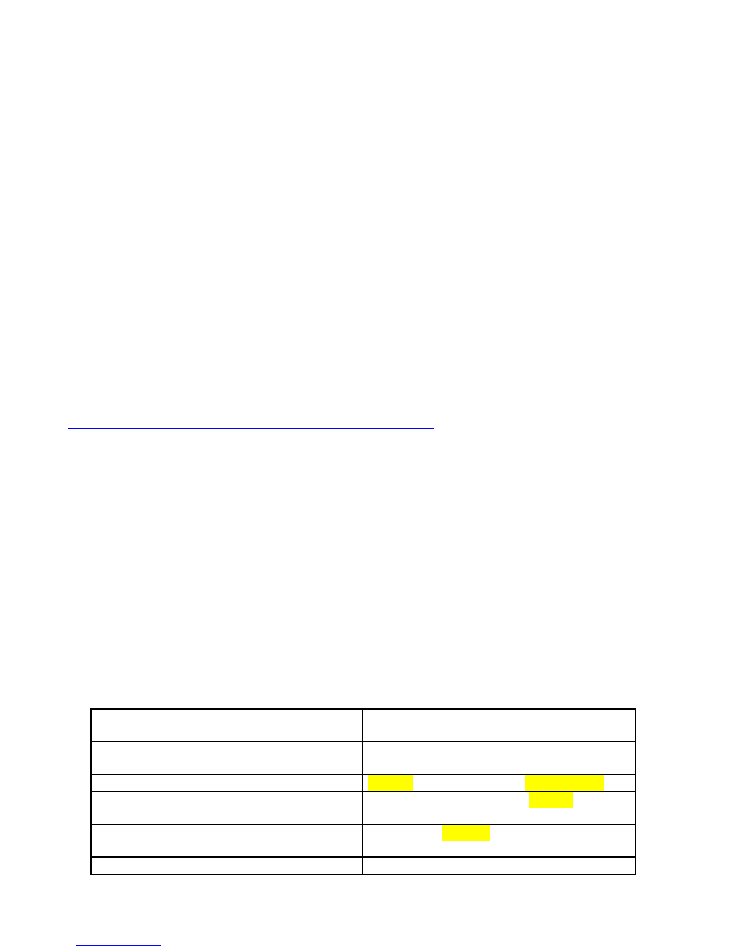

Table No. 1 – Information on flammability degree of some building materials according to BS EN 13501-1+A1

Status of flammability of building materials and

products

Building materials classified in the relevant

flammability degree

A non-flammable

granite, sandstone, heavy porous concretes,

bricks, ceramic tiles, special plasters

B uneasily flammable

acumine, wood-cement board, lihnos, itavere

C1 hardly flammable

broad-leaved wood, plywood, sirkoklit, laminated

paper, formica

C2 medium flammable

chipboards, solodure, cork boards, rubber,

flooring materials

C3 easily flammable

wood-fibre boards, polystyrene, polyurethane

- 5 -

When installing the stove in a room with combustible substances of flammability classes B, C1 and C2, safe

distances from the front of

800 mm

and in other directions

200 mm

must be observed, unless the Technical Sheet

or the CE plate on the rear of the stove specifies otherwise.

If the stove is installed in a room with combustible substances of class C3, the above stated distances must be

doubled.

Please consult

Table No. 1

for clarity.

There is no requirement for minimum clearance to non-combustible surfaces around the sides and back of the

stove. However, 100 mm is recommended to allow for heat and air circulation to the room. The further the stove is

placed in the room, the better the heat distribution.

Refer to Diagram 30, Page 42 of Document J for further installation dimensions and requirements for non-

combustible wall thickness etc.

4.3

Danger Warnings

Flammable liquids MUST NOT be used for lighting or heating! It is further forbidden to burn any plastics, wooden

materials with chemical binders (chipboards etc.) as well as unsorted household waste with remnants of plastics or

chemically treated wood etc.

The stove must be operated by adults only! It is inadmissible to let children near the stove

without supervision of adults. The stove surface is super-heated, particularly the glass; you can

suffer serious burns by touching it.

Where there are children under 8, a fire-guard must be used.

In operation, the stove requires occasional attendance and supervision. A protective mitten is included in each

stove for the safe operation of the air controllers and door handle. DO NOT put any combustible items on the

stove during operation or when it is still warm as they can ignite. DO NOT put any containers of cold liquids onto a

hot stove with stone or ceramic casing as it will cause the stone to break.

Please be extremely cautious when handling the ash pit and when removing hot ashes because there is a danger of

being burnt. Hot ashes must not come into contact with flammable items - e.g. when being emptied into dustbins.

The stove may be operated only according to these Instructions. It is inadmissible to perform any

unauthorized modifications to the stove.

4.4

Chimney Fires

If a fire occurs in the chimney, the fire in the stove must be put out immediately by removing the burning fuel with

the help of a small shovel to a suitable non-flammable container and the fire brigade must be called immediately

by dialling either 112 or 999.

5

ASSEMBLY

Warning:

When assembling the stove, all regulations in particular those related to national and European

standards for this type of appliance must be observed, refer to Approved Document J.

5.1

Instructions for stove assembly

Place the combustion air vents, if needed, so that they cannot become blocked.

- 6 -

When installing the appliance, adequate access for cleaning of the stove, firebox, connecting pipes and

chimney must be provided.

The appliance must be installed on a floor with adequate load bearing capacity.

If the stove hasn’t been used for some time, check the flue-ways to see whether or not they have

become blocked.

If installing a glass hearth, adhesive cork discs are placed underneath in order to eliminate unevenness.

Seal the glass with transparent silicon to the floor around the edges, so that dirt can’t go under it.

The flue pipes can be connected to most models to the top or rear exit (see Technical Sheet). The choice

of which exit depends on the user or on the flue draught. When changing the flue exit, see the instructions in

Annex No. 12.3

.

The cover for the hole in the stove’s outer shell can be found in the ash pan. When assembling and

disassembling the firebox plug and the cast-iron spigot, make sure they are air-tight using fire rope.

In stoves having a metal sheet top plate fitted with a break-off cover, the plug can be broken off with

the help of a screwdriver.

When using the rear outlet on stoves with a stone top plate, a lid made of the corresponding stone type

is included to plug the hole in the upper stone.

5.1.2. Chimneys and Flue Pipes:

Approved Document J deals with the installation of chimneys and flue pipes and should be referred to at all

times.

1.

There is a minimum gap required between an un-insulated flue pipe and combustible material. To a

combustible material it must be at least 3 x the outside diameter of the flue pipe (450 mm for 6” single wall

flue pipe). To a proprietary non-combustible shield it must be at least 1.5 x the flue diameter (e.g. 225 mm

for 6” single wall flue pipe).

2.

The rear flue exit is normally used when the chimney is tall and provides too powerful an up-draught.

Where the chimney is short, and the draught weak, the top flue exit will give better performance.

3.

Flue connections should be sealed with a suitable proprietary sealant such as fire cement or high

temperature rope seal. Cartridge sealing compounds are superior to fire cement.

4.

If a suitable approved factory made chimney system is to be used, it should be installed according to the

manufacturer’s instructions and the regulations found in Approved Document J. (“Stainless Steel Twin Wall

Insulated Chimney System”.)

5.

The flue draught should be at least 12 Pa for optimal performance, but in most cases a flue height of

4.5m should be adequate, measured from the stove’s top air inlet to the top of the flue.

6.

No horizontal sections are allowable.

7.

Flues should have a maximum of 4 bends with angles of 45 degrees. And a maximum of two bends in-

between each sweeping access point. [A D J Page 27 Diagram 15].

8.

The flue exit from the building should be positioned to comply with the requirements of the Building

Regulations. These can be seen on A D J page 31 Diagram 17.

9.

If the chimney is too high (draught exceeds 35 Pa) or so that the chimney draught can be regulated on

days with strong winds, it is necessary to fit the flue with a damper or flue balancer.

10. No other heating appliances should be connected to the same Flue or Chimney system.

5.2

Central Air Feed (CAF)

Sufficient fresh combustion air must be ensured by a hole with a minimum 10 cm diameter or equivalent area.

The hole for fresh air can be substituted by leaky windows and doors but we always advise an independent fresh

air supply.

If the option of a direct fresh air supply through the Central Air Feed from the outdoors to the stove is used, it

must be fed through a pipe with a diameter of 100 mm or equivalent ducting. The length of the pipe must not

exceed 5 metres; the length is reduced by 1 m for each 90 degree bend. The connector of the Central Air Feed is

bought as an optional extra. The Central Air Feed must never be blocked.

- 7 -

WARNING:

Kitchen and other Extractor fans: If they are placed in the same space (or house) as the

stove, then they must have their own independent air vent. It must be able to supply the same volume

of air to the space that the fan is capable of extracting. The Central Air Feed must also be used.

6

FUEL

The wood stove is designed for heating with firewood, wood briquettes also referred to as ‘heat logs’, and for

some products when not in smoke control areas, lignite briquettes (see TECHNICAL SHEET). The humidity of the

wood should be under 18%. Wood stored for at least 3 years in a well aired shed achieves such humidity. Kiln-dried

wood is the preferred fuel. When heating with briquettes, they must be stored in a completely dry environment;

otherwise they will become damp and fall apart. When heating with “wet” wood, the stove loses at least 20% of its

efficiency and output. The fuel consumption rises and the stove will “tar”. The tar will stain the glass heavily,

making cleaning difficult.

IMORTANT:

Only the above stated fuels may be used for heating in the stove. Liquid fuels and coal must not be used

undefined household waste including plastics etc. must not be burnt.

Refuelling on to a low fire-bed:

If there is insufficient burning material in the fire-bed to light a fresh fuel loading, excessive smoke

emission will occur. Refuelling must be carried out onto a sufficient quantity of glowing embers and ash

so that the new fuel load will ignite in a reasonably short period. If there are too few embers in the fire

bed, add suitable kindling to prevent excessive smoke.

Fuel overloading:

The maximum amount of fuel specified in this manual should not be exceeded, overloading can cause

excess smoke.

The optimal amount of wood to achieve the nominal output is found in the Technical Sheet of the

stove.)

7

OPERATION

The fireplace stove may be operated only in compliance with these Instructions. The stove must not be operated

by children. Only the defined fuels may be used for heating. The stove requires occasional supervision. The

manufacturer supplies a protective mitten together with the stove for safe operation.

7.1

Combustion process

The combustion of wood, eco briquettes and in some stoves lignite briquettes is carried out by the burn-through

system, which means that the combustion takes place in the whole fuel load at the same time.

To ensure the optimum conditions for easy kindling and successful ignition, a sufficient quantity of air must be fed

under the burning fuel, through the grate. That air is called the

primary air

and is always controllable. The feed of

secondary air

is also independently controllable. It improves the combustion and improves the cleaning of the

door glass. The tertiary air is a smaller supply and is intended to improve the general combustion process and is

permanently open.

When the right quantity and proportion of the types of air fed to the right places of the combustion chamber are

achieved, the combustion efficiency is increased, reducing the emissions of harmful gases to the atmosphere. The

arrangement of the air controllers is represented on the diagram in the Technical Sheet supplied with each stove.

In practice, the exact setting of the air control levers varies with a number of factors – the fuel humidity, the fuel

type, the chimney draught, the outside air pressure conditions etc. Therefore the user must fine tune the burning

process for optimal flame intensity and quality.

Generally speaking, however, when lighting, both vents are set fully open and during the main operation of the

stove, the primary is closed and the secondary left open in order to maximise the glass cleaning.

- 8 -

7.2

IMPORTANT! - First firing

The paint can become soft for a short time during first lighting. Do not touch the outer surface and do not put

anything on the stove. The rope seal of the door can also stick to the body of the stove at this time - leave the door

slightly open initially.

The first ever burn in the stove must be carried out so that the temperature rises slowly. It has been shown that in

this way, the paint is hardened more durably.

The manufacturer supplies the stove in a crate made of spruce timber; the wood is very dry and it has been chosen

especially for the first burn.

It is important that during the first burn, the full output is gradually achieved and maintained for an hour.

During

that time, the paint is burnt out, stabilized and achieves full hardness and abrasion resistance.

There will be some smoke and a chemical smell from the paint. The room must be extremely well ventilated and

pets removed.

7.3

Kindling

The grate should be clear before kindling. Place a large amount of crumpled newspaper or solid firelighters and

several pieces of kindling in the firebox. Set the primary air controller (choke) fully open. Set fire to the paper and

close or almost close the door. Leave to burn for several minutes until a high flame is reached and the chimney

fully warmed for maximum draught.

7.4

Heating

7.4.1

Burning wood and wood briquettes

Following the initial kindling, we recommend closing the primary air supply fully or almost fully. The burning rate is

regulated by the secondary air controller.

7.4.2

Burning lignite briquettes

The burning rate is regulated by the primary air control. Following the initial lighting phase, the manufacturer

recommends closing the secondary air supply fully or almost fully.

In practise, the optimal position of the controls will be a matter of trial and error and will vary depending on the

chimney draught.

Feed with fresh fuel when there are only glowing embers in the firebox

.

When the wood has burned down to embers, open the stove door 10 to 15 mm and wait 15 to 20 seconds before

opening the door fully and quickly put the fuel into the firebox. This procedure will significantly decrease the

volume of smoke entering the living room. To further reduce smoke spill-out, open the starting flap (on some

models only, labelled [firing valve]) immediately prior to loading.

7.5

Glass cleaning / ‘Air-Wash’ Function

This is dependent on the use of the correct dry fuel, plenty of combustion air (particularly secondary air) and

sufficient chimney draught. The method of operating the stove also influences the cleanness of the glass. We

advise you to stoke up only one layer of fuel, distributing the fuel as uniformly as possible in the firebox and as far

as possible from the glass. The same applies to briquettes. The distance between logs should be 5 to 10 mm. If the

glass darkens during burning, increasing the burning intensity will usually clean the glass automatically.

- 9 -

7.6

Removal of ash

Depending on the length and intensity of the heating phase, the ash should be shaken through the grate to the ash

pan with the help of a poker.

Please ensure that the ash pan is not overfilled, thereby obstructing the air feed

through the grate and leading to subsequent problems with lighting or burning.

The ash pan must be emptied when the ash is cold, ideally when preparing the lighting/kindling stage.

Ash from

burnt wood can be used in compost or as a fertilizer.

Warning:

Before emptying the ash pit, make sure it doesn’t contain hot embers that could start a fire.

7.7

The appliance must not be operated with the appliance door open

except briefly

when fuelling

.

Operation with the door open can cause excess smoke to enter the room.

7.8

Air Controls left open

Running for any length of time with the air controls fully open can cause excessive smoke. The appliance must not

be operated with air controls, appliance dampers or door left open except as directed in the instructions.

8

CLEANING AND MAINTENANCE

The appliance must be cleaned at least once a year; it must always be cold before cleaning.

During cleaning, any accumulations of tar in the flues, in the firebox and on the baffle plates above the

firebox should be removed as much as possible.

The grate must be kept unobstructed.

Repair any parts of firebrick lining that have fallen out, ideally with a new firebrick. The integrity of the

lining should be monitored during the heating season. The gaps between the individual boards serve for

thermal expansion, preventing cracking; the gaps

must not

be filled in any way (e.g. with accumulated ash).

Some cracks in vermiculite firebricks are normal and are to be expected. They

remain functional and should remain in use unless they have appreciable holes, have

disintegrated or fallen out.

Stove glass cleaners of varying strength are available, but damp newspaper can also work. The glass

must be cleaned only when cold. Never use water to clean painted parts of the stove surface; soft foam

sponge or soft flannel cloth will be suitable.

By regular cleaning of the chimney you will prevent soot deposits on the chimney walls from igniting.

We advise to use only dry, no more than slightly moistened cloth to clean the ceramic tiles. Clean the

stove only when cold.

The textured stucco surfaces should be cleaned only with the help of a broom or vacuum cleaner.

9

COMMON FAULTS

Disintegrated or broken vermiculite brick

A vermiculite board or complete lining can be ordered as spare part from the distributor.

Door sealing

A new rope seal can be ordered as a spare part from the distributor.

Damaged door, damaged glass.

- 10 -

Changing the door glass is fiddly and requires a modicum of practical ability but is not complicated. Make

sure the screws are cleaned with a fine wire brush and soaked overnight with a solvent such as white

spirit to soften the tar before attempting to remove them. Do not get solvent on the paint. Do not over-

tighten screws when replacing.

Doors virtually never need replacing, but changing the door is not difficult for anyone with a small degree

of practical skill. Contact the distributor for specific advice before attempting to remove the door.

10

UNCOMMON FAULTS

Some microscopic cracks may occur, sometimes referred to as “hair cracks”, during the traditional method of

manufacturing the ceramic tiles for the stoves’ outer casing. Such hair cracks are natural and are

not

considered

defects.

11

SERVICE

11.1

Guarantee and after-guarantee service

The guarantee and after-guarantee service is provided by the principal manufacturer, ABX, through its distributor

in the UK, Greymetal Ltd:

Greymetal Ltd

/

FTS

Drome Road

Zone 1, Deeside Industrial Park

CH5 2LR

Tel 01244 913320

e-mail:

info@greymetal.co.uk

Technical information related to installation and operation and spare parts may be obtained from

technical@greymetal.co.uk

11.2

Ordering spare parts

When ordering spare parts, please state the:

stove type

year of production/purchase

serial number

Identify the spare part with the help of the Technical Sheet, stating the name of the part and possibly its number

or position according to the diagram. Send the order by e-mail. Spare parts and accessories can be ordered from

the seller or directly from the manufacturer.

12

STOVE PACKAGE AND DISPOSAL

12.1

Package

The fireplace stove is, unless stated otherwise (see TECHNICAL SHEET), delivered in assembled condition on a

wooden transport pallet in protective wooden casing. The stove is wrapped in shrink wrap and fixed to the pallet.

The following package disposal is possible from the perspective of wastes:

Disassemble and burn the wooden base (see First kindling).

Throw the bag to municipal waste or deliver it to a collection point.

Cardboard: recyclable.

12.2

Stove disposal

For disposal of the entire stove, throw the vermiculite lining, glass and seals to land fill waste. Also ceramic, stone

and tile can be put into the rubble skip at the recycling centre. The steel sheet body and the together with cast iron

parts can be taken to a scrap yard.

- 11 -

13

ANNEXES

1.

Technical Sheet of the relevant stove type (separate sheet)

2.

Distances and size of hearth

3.

Swapping the flue spigot

4.

Instructions for cleaning of cast-iron and tile ovens

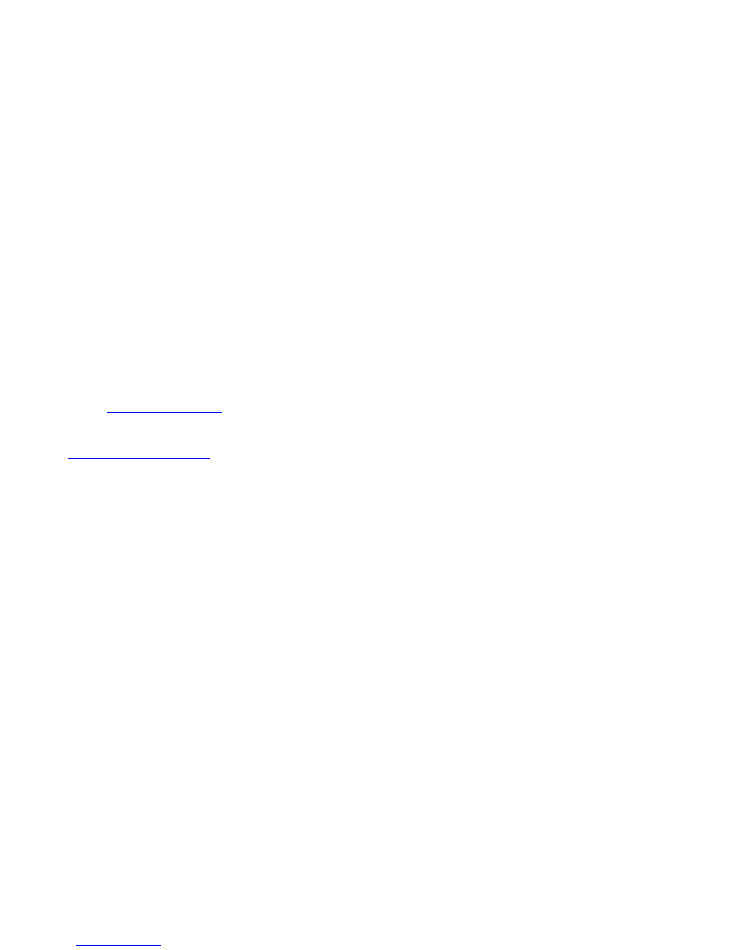

13.2

Distances and size of hearth

13.3

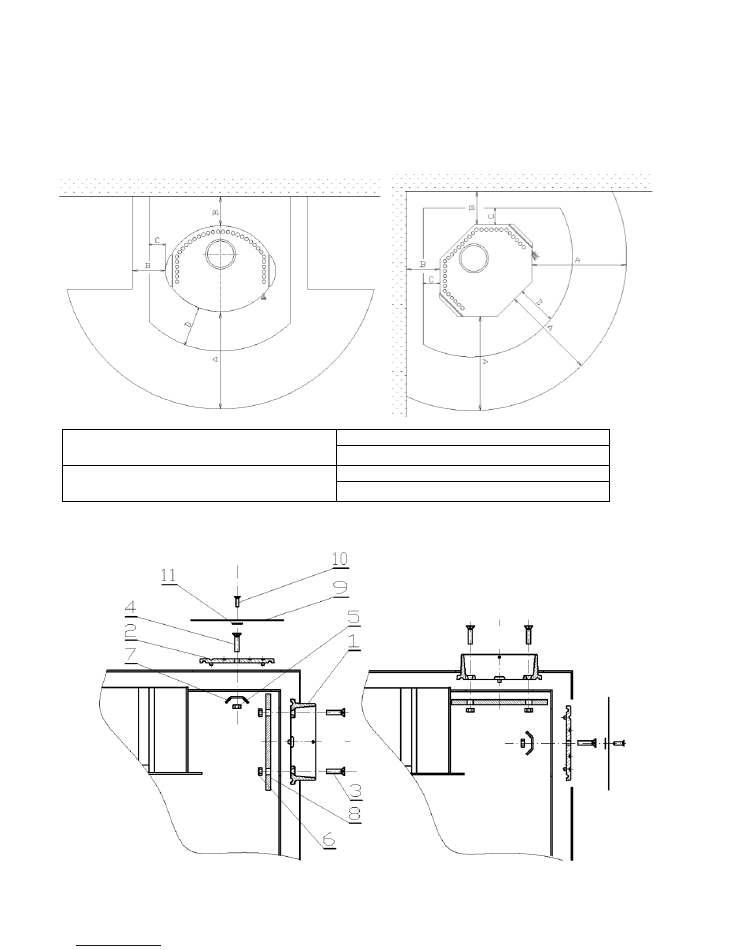

Swapping the flue spigot

Minimum distances from flammable

materials

A ≥ 800 mm

B ≥ 200 mm

Minimum size of protective foundation

board

C ≥ 100 mm

D ≥ 300 mm

REAR OUTLET

TOP OUTLET

- 12 -

1. UPTAKE NECK

∅

150

7. COVER PARTITION

2. UPTAKE PLUG

8. UPTAKE PARTITION

3. SCREW OF UPTAKE NECK M6 2 PCS

9. STEEL SHEET OF UPTAKE COVER

4. SCREW OF PLUG M8

10. SCREW OF UPTAKE COVER

5. NUT M8

11. HANDLE OF UPTAKE COVER

6. NUT M6 2 PCS

NOTE: FOR STOVES WITH A WELDED STEEL UPTAKE, THE UPTAKE PLUG (2) IS TO BE MOVED FROM ONE UPTAKE TO

THE OTHER USING ITEMS 4, 5, 7.

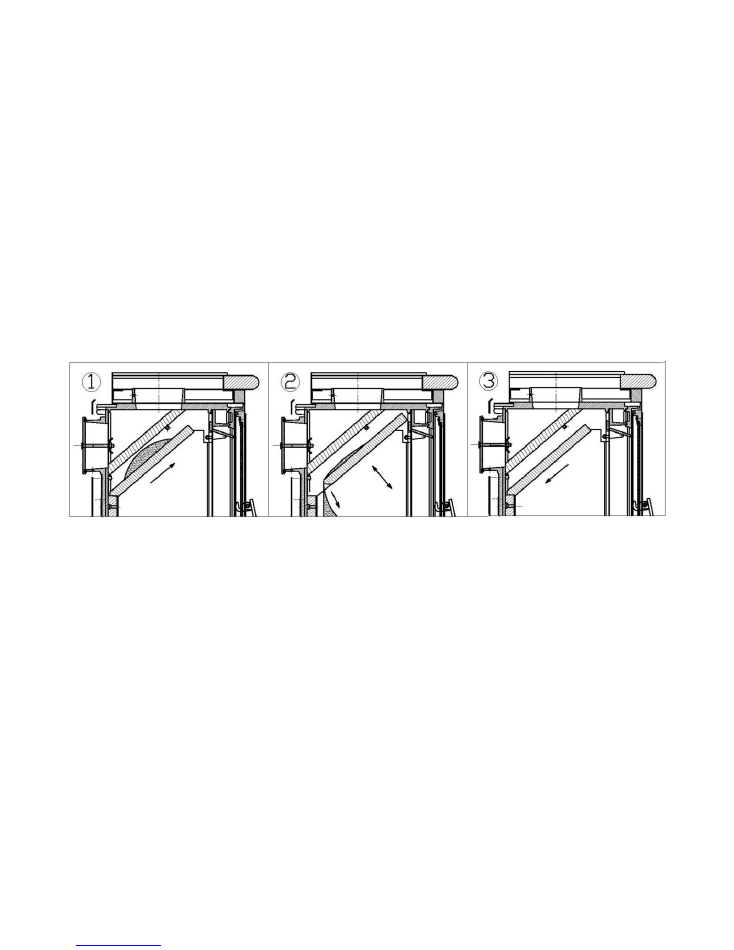

13.4

Instructions for cleaning of cast-iron and tile stoves

After long-term use of cast-iron and tile stoves and/or if some unsuitable fuel is used, the space between

vermiculite baffle plates and the fire box may become clogged with soot. The stove suffers insufficient draught and

does not heat properly. Therefore this space should be cleaned on a regular basis, i. e. at least once every 6

months. For the cleaning procedure, see the scheme.

(1)

The lower vermiculite guiding plate is pushed upwards.

(2)

The soot is released by careful knocking so that it falls down into the firebox.

(3)

The lower vermiculite plate is put back to its original position.

- 13 -