Full Text Searchable PDF User Manual

EHC Neptune Series

Unvented Hot Water Cylinders

Installation and

technical manual

THESE INSTRUCTIONS SHOULD BE READ CAREFULLY AND

RETAINED FOR FUTURE REFERENCE.

Unvented cylinders are a controlled service as defined in the latest edition of

the building regulations and should only be fitted by a competent person. The

relevant regulations are:

England and Wales – Building Regulation G3

Scotland – Technical Standard P3

N Ireland – Building Regulation P5

After installation the Benchmark log book must be completed and left, with

these instructions, with the householder for future reference.

The Electric Heating Company Ltd

Unit 40, Block 5, Third Road, Blantyre Industrial Estate, Blantyre, Glasgow, G72 0UP

Tel. 01698 820533

Fax. 01698 825697

info@electric-heatingcompany.co.uk

www.electric-heatingcompany.co.uk

CONTENTS

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 2

1.

Introduction .................................................................

2

2.

Unpacking the unit ......................................................

3

3.

Choosing a site ...........................................................

4

4.

Schematic diagram .....................................................

5

5.

General installation .....................................................

6

6.

Discharge arrangement ...............................................

8

7.

Electrical connections and wiring ................................

10

8.

Commissioning ...........................................................

11

9.

Servicing .....................................................................

12

10. Fault finding ................................................................

13

11. Technical data .............................................................

14

12. Technical specifications ..............................................

15

13. User instructions .........................................................

16

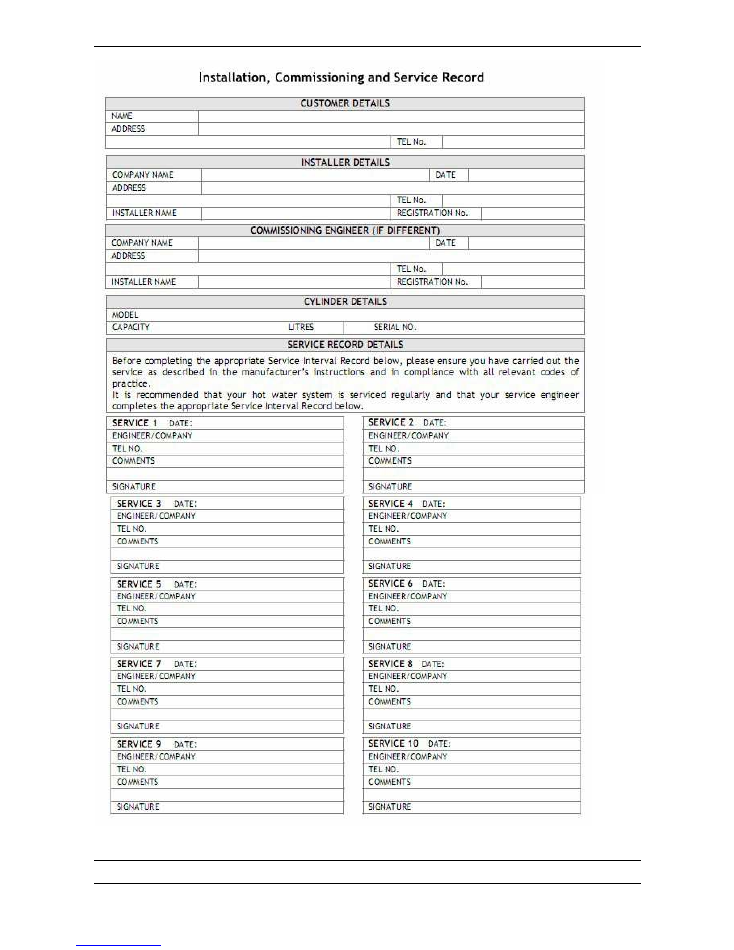

14. Benchmark Service Record ........................................

17

15. Guarantee ...................................................................

18

1.

Introduction

The Neptune unvented cylinder is made from Duplex Stainless Steel for excellent corrosion

resistance. The Neptune has a strong rust-proofed steel case and is highly insulated with

environmentally friendly foam.

It is available in 3 standard capacities: 120, 150 and 250 litres, in Direct and Indirect

versions.

This manual is provided to assist the installation and maintenance of the following models

NDIR120L

NDIR150L

NDIR210L

NIND120L

NIND150L

NIND210L

The Neptune is supplied complete with all the necessary safety and control devices needed

to connect to the cold water mains. All are pre-adjusted. High quality controls have been

selected to combine high flowrate performance with minimum pressure drop to make the

Neptune perform well in all areas, even those with poor water pressure. The Neptune is

WRAS approved to show compliance with Building Regulations G3+L.

STORAGE PRIOR TO INSTALLATION

Neptune should be stored in its original packaging in an upright position in an area free from

excessive damp.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 3

2.

Unpacking the unit

The Neptune comes complete with all the fittings you need to complete the installation:

Direct Models

(Electric)

Inlet control set

Temp & Pressure relief valve

15mm / 22mm Tundish

Expansion vessel

Wall mounting bracket

Expansion vessel hose

2 x 3 kW Immersion heaters

Installation & Maintenance Instructions

Benchmark Logbook

Indirect Models

(Gas, Oil or Electric boilers)

Inlet control set

Temp & Pressure relief valve

15mm / 22mm Tundish

Expansion vessel

Wall mounting bracket

Expansion vessel hose

1 x 3kW Immersion Heater

Two port zone valve

Dual Thermostat

Installation & Maintenance Instructions

Benchmark Logbook

Expansion vessel

15/22mm Tundish

Expansion vessel hose

Wall mount kit for expansion

vessel

Temperature and pressure

relief valve

Dual thermostat

High flow rate inlet control

set

Immersion Heater

Two port valve

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 4

3.

Choosing a site

Water supply

The Neptune operates at 3 bar (controlled by the inlet control set) and is capable of

delivering over 50 litres per minute. The high quality inlet control set has been designed to

make the most of the flow rates available however the performance of any Unvented system

is only as good as the mains water supply. The maximum possible water demand should be

assessed taking into consideration that both hot and cold services are supplied

simultaneously from the mains. The water supply should be checked to ensure it can meet

these requirements. If necessary consult the local water company regarding the likely

pressure and flow rate availability.

If measuring the water pressure note that a high static (no flow) mains pressure is no

guarantee of good flow availability. In a domestic installation 1.5 bar and 25 l/m should be

regarded as the minimum. The maximum mains pressure the inlet control set can cope with

is 16 bar. Consideration should be given to upgrading existing ½” (15mm) cold mains

pipework to a larger size if the recommended minimum pressure/flowrate is not being

achieved.

Siting the unit

The Neptune can supply outlets above it or at some distance from it. Site the unit to minimise

“dead leg” distances especially to the point of most frequent use. Outlets above the Neptune

will reduce the outlet pressure available by 0.1 bar for every 1m of height difference. The unit

should be protected from frost. Particular care is needed if siting in a garage or outbuilding.

All exposed pipework should be insulated.

The Neptune must be installed

vertically

on a flat base capable of supporting the weight of

the cylinder when full (see technical specification section – page 15 – for weights). The

minimum recommended cupboard size is 650mm square.

Access for maintenance of the valves should be considered. The immersion heaters are

375mm long and care should be taken that they can be withdrawn for servicing if required.

The discharge pipework from the safety valves should fall continuously and terminate safely.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 5

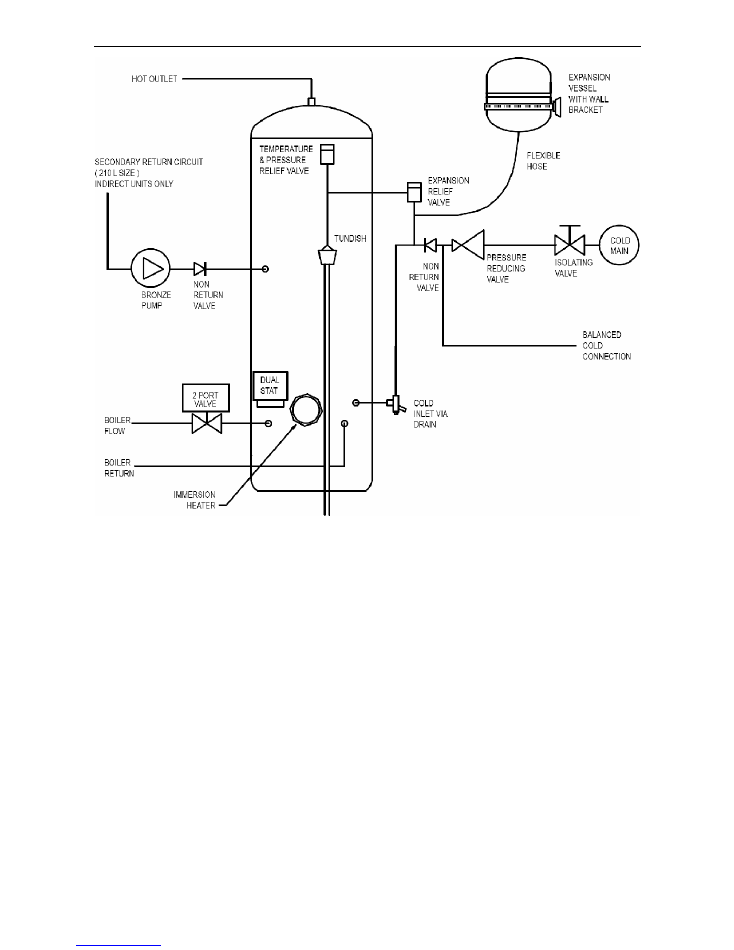

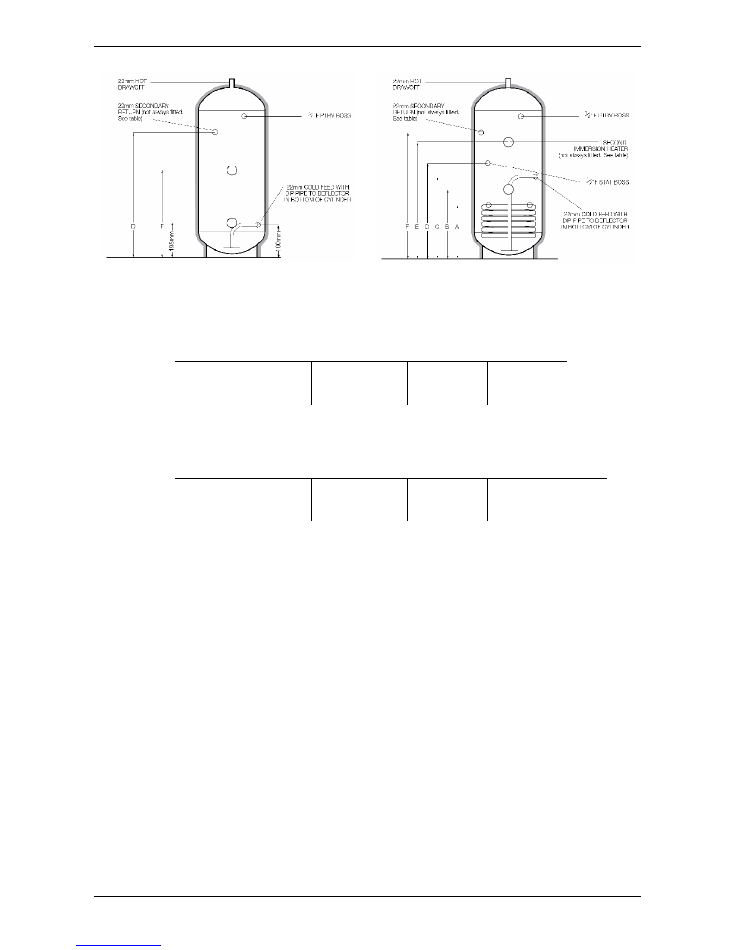

4.

Schematic diagram

Notes:

The Pressure reducing valve, Non return valve and

Expansion relief valve are combined together in the

inlet control set. On 120 – 150 litre sizes there is no

dedicated secondary return boss and the secondary

return circuit should be tee’d into the cold feed pipe

just above the drain elbow.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 6

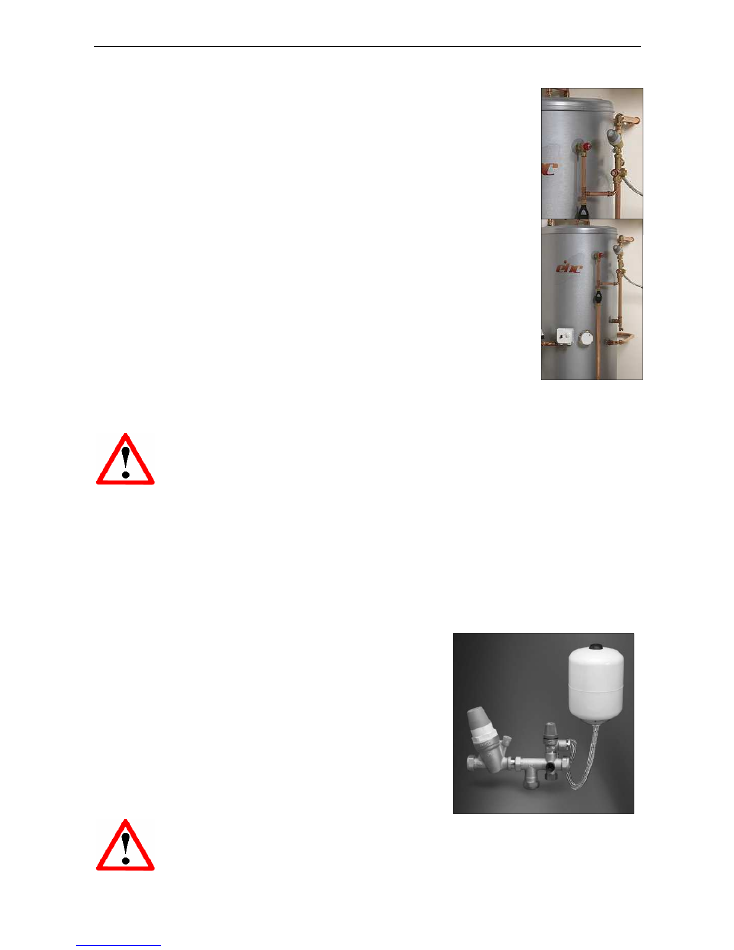

5.

General installation

Cold mains pipework

1.

Run the cold main through the building to the place where the Neptune

is to be installed. Take care not to run the cold pipe near hot water or

heating pipe work so that the heat pick up is minimized.

2.

Identify the cold water supply pipe and fit an isolating valve (not

supplied) A 22mm BS1010 stopcock can typically be used but a 22mm

quarter turn full bore valve would be better as it does not restrict the

flow as much. Do not use “screwdriver slot” or similar valves.

3.

Make the connection to the cold feed of the cylinder and incorporate a

drain valve. Position the inlet control just ABOVE the Temperature &

Pressure Relief Valve (TPRV) mounted on the side of the cylinder. This

ensures that the cylinder does not have to be drained down in order to

service the inlet control set. Ensure that the arrow points in the

direction of the water flow.

All of the pipe-work connections on the cylinder are 22mm

compression and supplied complete with gland nuts and olives, packed

in the Accessory Kit box. Only connect 22mm Table X copper tube to

these connections. Cut the tube with a pipe cutter and ensure no sharp

edges or burrs protrude. Slide both gland nut and olive onto the tube

and push tube fully home into the connection, ensuring the tube fully

bottoms on the connection recess. Smear the outer wall of the olive with

plumbing paste and tighten gland nut in the prescribed manner. Upon

filling/commissioning ensure all connections are completely watertight.

No control or isolation valve should be fitted between the expansion relief valve and

the storage cylinder. The relief valve connections must not be used for any other

purpose."

4.

Select a suitable position for the expansion vessel. Mount it to the wall using the bracket

provided. Use the hose to connect to the inlet control group. Ensure that the top of the vessel

is accessible for servicing.

Balanced cold connection

5.

If there are to be showers, bidets or monobloc taps in

the installation then a balanced cold supply is

necessary. There is a 22mm balanced connection on

the inlet control set.

Hot water pipework

6.

Run the first part of the hot water distribution

pipework in 22mm. This can be reduced to 15mm

and 10mm as appropriate for the type of tap etc. Your

aim should be to reduce the volume of the hot draw

off pipework to a practical minimum so that the time

taken for the hot water is as quick as possible.

Do not use monobloc mixer tap or showers if the balanced cold connection is not

provided. Outlets of this type can back-pressurize the unit and result in discharge.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 7

5.

General installation (continued)

Primary coil connections

7.

Connect the primary connections (Indirect only) using the compression connections

provided. The primary circuit must be positively pumped. Gravity circulation is not suitable.

Either primary connection may be used as the primary flow – reheat times are identical either

way. The primary circuit can be open vented or sealed with up to a maximum pressure of 3.5

bar.

8.

If you seal the primary circuit an additional expansion vessel and safety valve is required.

The boiler may be Gas, Electric, or Oil but must be under effective thermostatic control.

Uncontrolled heat sources such as some AGA’s, back boilers, solid fuel stoves, etc are NOT

SUITABLE. Please contact our technical department for guidance.

9.

Connect the two port zone valve ( indirect only ) into the primary flow pipework. The

direction of flow arrow should be towards the primary flow connection. Again a two port zone

valve should be fitted (supplied).

Secondary circulation

The Neptune can be used with secondary circulation. An appropriate WRAS approved

bronze circulator should be used in conjunction with a non return valve to prevent backflow.

On large secondary circulation systems it may be necessary to incorporate an extra

expansion vessel into the circuit to accommodate the increased system water volume.

Secondary circulation should be avoided on Direct electrically heated units being

used on off peak electricity tariffs.

A secondary return boss is fitted as standard on 210L

cylinders. On smaller sizes tee into the cold feed pipe above the drain.

Immersion heaters

Only immersion heaters with a thermal cutout may be used. To help ensure this the

immersion heaters have a special 1¾“ thread. They are rated at 3 kW at 240 V and are of a

low noise Incoloy construction. They have both a thermostat and a high limit cutout. Please

order the correct replacement via us, as fitting non-approved immersions may affect your

guarantee. When fitting, ensure the ‘O’ ring is positioned correctly on the head of the

immersion heater and lubricate before fitting. Fit it by hand until almost home then tighten

gently as the ‘O’ rings will seal easily.

The electrical supply to each immersion heaters must be fused at 13A via a double pole

isolating switch to BS 3456. The cable must be 2.5mm

2

heat resistant (85°C HOFR)

sheathed flex complying to BS 6141:1981 Table 8. Do not operate the immersion heater/s

until the unit is full of water. Do not operate the immersion heater/s if any sterilisation liquid is

in the cylinder as this will cause premature failure. Fit the immersion thermostat (indirect

only) into the thermostat pocket. Complete the wiring – use the appropriate wiring diagrams

on page 10.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 8

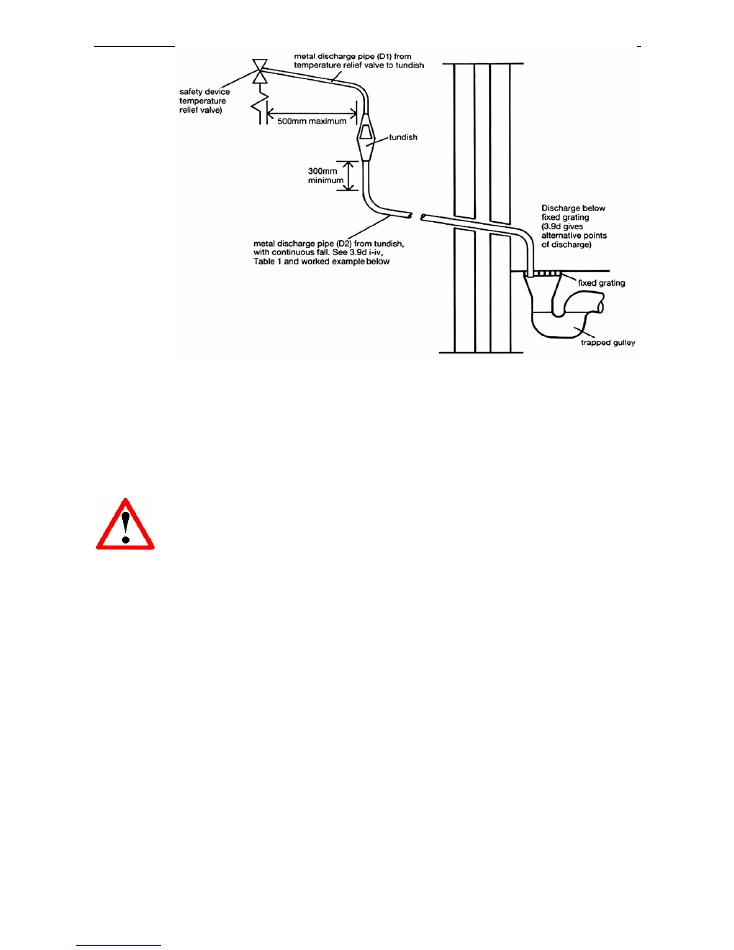

6.

Discharge arrangement

The above diagram is of a typical discharge pipe arrangement.

(extract from Building Regulation G3)

Note:

The discharge will consist of scalding water and steam. Asphalt, roofing felt and non-

metallic rainwater goods may be damaged by such discharges.

Note:

It is not acceptable to discharge straight into a soil pipe. Position the inlet control

group so that the discharge from both the two safety valves can be joined together via a

15mm end feed Tee. Connect the Tundish and route the discharge pipe.

The discharge pipework must be routed in accordance with Part G3 of schedule 1 of the

Building Regulations.

The information that follows is not exhaustive and if you are in doubt you should seek

advice.

The two safety valves will only discharge water under fault conditions. When operating

normally water will not be discharged. The tundish should be vertical, located in the same

space as the unvented hot water storage system and be fitted as close as possible and

within 500mm of the safety device e.g. the temperature relief valve. The discharge pipe (D2)

from the tundish should terminate in a safe place where there is no risk to persons in the

vicinity of the discharge, be of metal and:

A)

Be at least one pipe size larger than the nominal outlet size of the safety device

unless its total equivalent hydraulic resistance exceeds that of a straight pipe 9m

long i.e. discharge pipes between 9m and 18m equivalent resistance length should

be at least two sizes larger than the the nominal outlet size of the safety device,

between 18 and 27m at least 3 sizes larger, and so on. Bends must be taken into

account in calculating the flow resistance. Refer to diagram 1, Table 1 and the

worked example. An alternative approach for sizing discharge pipes would be to

follow BS6700 Specification for design installation, testing and maintenance of

services supplying water for domestic use within buildings and their curtilages.

B)

Have a vertical section of pipe at least 300mm long, below the tundish before any

elbows or bends in the pipework.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 9

6.

Discharge arrangement (continued)

C)

Be installed with a continuous fall.

D)

It is preferable for the discharge to be visible at both the tundish and the final point of

discharge but where this is not possible or practically difficult there should be clear

visibility at one or other of these locations. Examples of acceptable discharge

arrangements are:

1. Ideally below the fixed grating and above the water seal in a trapped gulley.

2. Downward discharges at a low level; i.e. up to 100mm above external

surfaces such as car parks, hard standings, grassed areas etc. are

acceptable providing that where children play or otherwise come into contact

with discharges, a wire cage or similar guard is positioned to prevent contact

whilst maintaining visibility.

3. Discharges at a high level; e.g. in to metal hopper and metal down pipe with

the end of the discharge pipe clearly visible (tundish visible or not) or onto a

roof capable of withstanding high temperature discharges of water and 3m

from any plastic guttering systems that would collect such discharges

(tundish available).

4. Where a single pipe serves a number of discharges, such as in blocks of

flats, the number served should be limited to not more than 6 systems so

that any installation can be traced reasonably easily. The single common

discharge pipe should be at least one pipe size larger than the largest

individual discharge pipe to be connected. If unvented hot water storage

systems are installed where discharges from safety devices may not be

apparent i.e. in dwellings occupied by blind, infirm or disabled people,

consideration should be given to the installation of an electronically operated

device to warn when discharge takes place.

Worked example

The example below is for G1/2 temperature relief valve with a discharge pipe (D2) having 4

No. elbows and length of 7m from the tundish to the point of discharge.

From Table 1:

Maximum resistance allowed for a straight length of 22mm copper discharge pipe (D2) from

a G1/2 temperature relief valve is: 9.0m

Subtract the resistance for 4 No. 22mm elbows at 0.8m each = 3.2m

Therefore the maximum permitted length equates to: 5.8m

5.8m is less than the actual length of 7m therefore calculate the next largest size. Maximum

resistance allowed for a straight length of 28mm

pipe (D2) from a G1/2 temperature relief valve equates to: 14m

As the actual length is 7m, a 28mm (D2) copper pipe will be satisfactory.

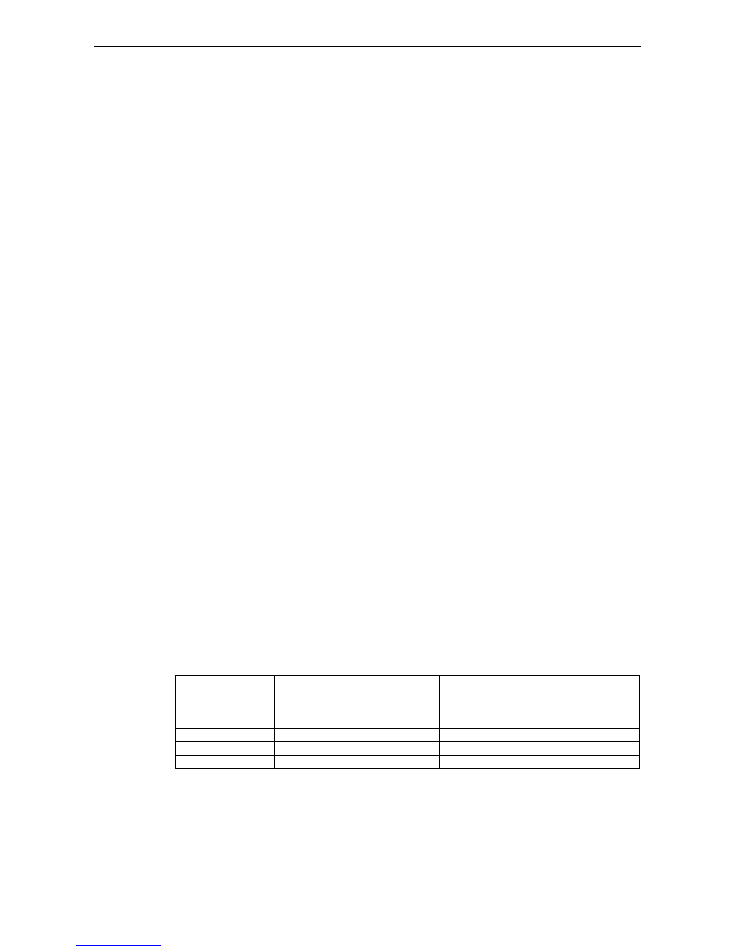

Table 1

Sizing of copper discharge pipe ‘D2’ for a temperature

relief valve with a G1/2 outlet size (as supplied).

Size of

discharge

pipework

Maximum length of straight

pipe (no bends or elbows)

Deduct the figure below from the

maximum length for each bend or

elbow in the discharge pipe

22mm

Up to 9m

0.8m

28mm

Up to 18m

1m

35mm

Up to 27m

1.4m

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 10

7.

Electrical connections and wiring

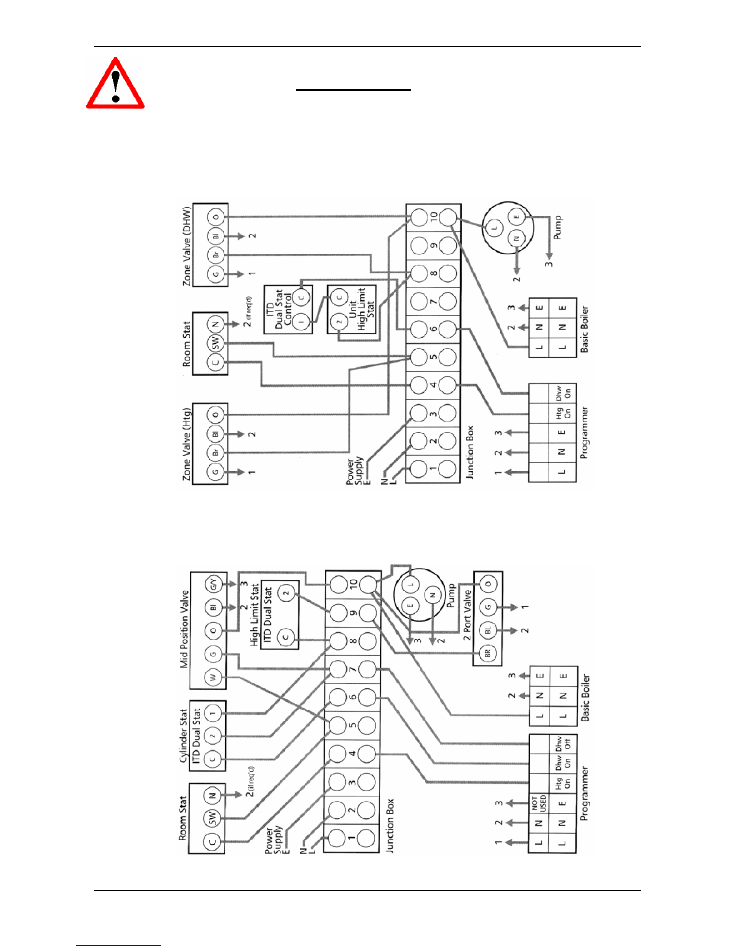

If the Neptune cylinder is used with the EHC Fusion Boiler. An S-Plan

configuration with Volt-connections on the Acuators gray and orange

wire must be used. If in doubt refer to the Fusion wiring diagram or

conatct the EHC Technical team.

TWO 2 PORT ZONE VALVE (S-PLAN)

VARIANT DUAL THERMOSTAT WIRING

3 PORT MID POSITION VALVE (Y-PLAN) + 2 PORT VALVE

VARIANT DUAL THERMOSTAT WIRING

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 11

8.

Commissioning

Filling

Check the pressure in the expansion vessel is 3 bar (45 PSI), i.e. the same as the setting of

the pressure reducing valve. The valve is of the car tyre (Schrader) type. Check all the

connections for tightness including any factory made connections such as the immersion

heater and the temperature and pressure relief valve. Before filling, open the hot tap furthest

away from the Neptune to let air out. Open the cold main isolation valve and allow the unit to

fill. When water flows from the tap allow it to run for a short while to flush through any dirt,

swarf or flux residue. Close the tap and open every other hot tap in turn to purge all

remaining air.

Direct units

After filling with water and after sterilisation liquid has been purged, switch on the power to

the immersion heaters and allow the unit to start to heat. The immersion heater is supplied

preset at 55°C. Turning fully to + sets to approx 65°C.

Indirect units

Consult the boiler manufacturers commissioning instructions and fill the primary circuit.

Ensure the lever on the two port valve is set to the

filling

position. When full move the lever

back. Switch the programmer to Domestic Hot water (DHW) and allow the unit

to start to heat. Adjust the dial of the dual thermostat to between 55°C and 65°C as required.

Storage temperature

The recommended storage temperature for both direct and indirect cylinders is 60-65°C. In

hard water areas consideration should be given to reducing this to 55°C. In many healthcare

applications the guidance on Legionella control and safe water delivery

temperatures will require storing the water at 60-65°C, distributing at 55°C and using

thermostatic mixing valves to control the final temperature.

For details consult the NHS Estates Guidance on safe hot water temperatures.

Safety valve checks

During heat-up there should have been no sign of water coming from either the expansion

relief valve or the temperature / pressure relief valve. Now hold both of these safety valves

fully open allowing as much water as possible to flow through the

tundish. Check that your discharge pipework is free from debris and is carrying the water

away to waste efficiently. Release the valves and check that they reseat properly.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 12

9.

Servicing

Servicing should only be carried out by competent installers and any spare parts used must

be purchased from The Electric Heating Company. NEVER bypass any safety devices or

operate the unit without them being fully operational.

Draining

Isolate from the electrical supply to prevent the immersion heaters burning out. Isolate the

unit from the cold mains. Attach a hose to the draining tap ensuring it reaches to a level

below the unit (This will ensure an efficient syphon is set up and the maximum amount of

water is drained from the unit). Open the hot tap closest to the unit and open the draining

tap.

WARNING: WATER DRAINED OFF MAY BE VERY HOT!

Annual maintenance

The Neptune requires an annual service in order to ensure safe working and optimum

performance. It is essential that the following checks are performed by a competent installer

on an annual basis. Should your boiler be of the type that requires annual servicing then the

annual servicing of the Neptune Cylinder is normally done at the same time.

1)

Twist the cap of the expansion relief valve on the inlet control set and allow water to flow for 5

seconds. Release and make sure it resets correctly. Repeat with the pressure / temperature

relief valve. In both cases check that the discharge pipework is

carrying the water away adequately. If not check for blockages etc. and clear.

WARNING: THE WATER DISCHARGED MAY BE VERY HOT!

2)

Check that any immersion heaters fitted are working correctly and that they are controlling

the water at a temperature between 55°C and 65°C.

3)

Check the pressure in the expansion vessel is charged to 3 bar. Turn off the water supply to

the unit and open a hot tap first. The air valve on expansion vessel is a Schrader (car tyre)

type. Air or CO

2

may be used to charge the expansion vessel.

4)

Unscrew the head on the inlet control set and clean the mesh filter within.

5)

The benchmark log book supplied with this unit should be updated at each service.

YOUR GUARANTEE MAY BE VOID WITHOUT PROOF OF ANNUAL SERVICING.

Spare parts

We carry the full range of spares listed below in stock. If you order before noon we will

dispatch the same day for delivery the next to most locations. Tel: 01698 820533.

TS201

Inlet control set (pressure reducing valve, strainer and expansion relief valve)

TS202

Temperature & pressure relief valve

TS3

Tundish

TS4

Expansion relief valve (cartridge only)

TS105

2 port valve

TS207

Dual thermostat

TS9

Immersion heater (same on all models)

TS212

12 litre Expansion Vessel (120 & 150 ltr sizes)

TS219

19 Litre Expansion vessel (210 ltr size)

TS216

Wall mounting bracket

TS214

Expansion vessel hose ( ¾” M x ¾” F )

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 13

10.

Fault finding

FAULT

POSSIBLE CAUSE

SOLUTION

Water escaping from the case

Compression fitting on hot draw off not sealing

Check / remake joint with sealing paste

Cold water at hot taps

Direct – Immersion heater not switched on or

cutout has triggered

Check / reset

Indirect – Boiler not working

Check boiler – consult boiler manufacturer’s

instructions

Indirect – Motorised valve fault

Check plumbing / wiring to motorised valve

Indirect – cut-out in dual stat has operated

Reset and investigate cause

Water discharges from

expansion relief valve

If continual – pressure reducing valve (part of

inlet control set) may not be operating properly

Check outlet pressure from inlet control set

is 3 bar

If continual – expansion relief valve seat may be

damaged

Remove cartridge – check seat and renew if

necessary

If intermittent – expansion vessel charge may

have reduced / bladder perished

With cylinder cold, check pressure in cyliner.

If this is the same as the incoming mains

pressure then you are getting backfeed.

Install a balanced cold supply – see page 6

Water discharges from

temperature and pressure relief

valve

Unit has overheated – thermal controls have

failed

Switch off power to boiler and immersion

heaters. Leave water supply on. Wait until

discharge stops. Isolate water suppy and

replace if faulty

Milky / cloudy water

Oxygenated water

Water from any pressurised system will

release oxygen bubbles when flowing. The

bubbles will settle out.

No hot water flow

Cold main off

Check and open stop cock

Strainer blocked in pressure reducing valve

Isolate water supply and clean

Inlet control set may be fitted incorrectly

Check and refit as required

Noise during hot water draw off

– typically worse in the morning

Loose airing cupboard pipework

Install extra clips

Hot or warm water from cold

tap

If tap runs cold after a minute or so the pipe is

picking up hear from the heating pipework

Insulate / re-route

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 14

11.

Technical Data

Materials

Inner shell – Duplex Stainless Steel

Coil – 22mm Diameter Stainless Steel

Bosses – Stainless Steel

Every Neptune cylinder is water tested to a pressure

of 15 bar.

Insulation

Fire retardant polyurethane foam, nominal thickness

50mm.

The foam is CFC-Free and HCFC-Free.

The foam has an Ozone Depletion Potential of

ZERO

and a Global Warming Potential of One.

Casework

Zintec corrosion proofed steels throughout

Durable metallic finish outer casing

Anode

None fitted / none required

Expansion Vessel

12 Litre size with 120 and 150 Litre models

18 Litre size with 210 Litre model

Control Settings

Pressure Reducing Valve – 3 Bar

Expansion Relief Valve – 6 Bar

Pressure and Temperature Relief Valve – 7 Bar/90°C

High Limit Thermostat in Dual Thermostat – 85°C

High Limit Thermostat in Immersion Heater – 85°C

Immersion Heater

1¾” BSP Parallel Threaded Head

Long Life Incoloy Sheathed Low Noise Element 14” Long

Long Life Incoloy Sheathed Thermostat Pocket 11” Long

Brazed Construction

Combined Thermostat and Safety Cut-Out

Element Rating 3kW at 240V AC

Approvals

WRAS Approved to the Water Regulations

WRC-NSF Approved to Building Regulations G3 & L

CE Compliant and fitted with a BEAB Approved

Immersion Heater

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 15

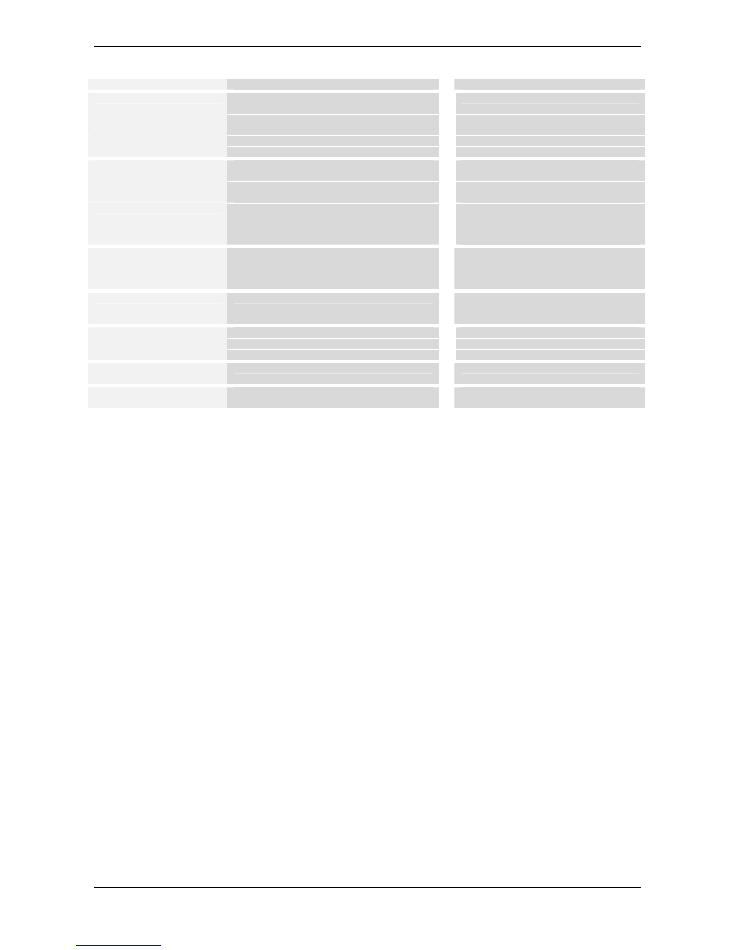

12.

Technical Specifications

Direct cylinder

Indirect cylinder

Direct cylinder

Model No.

Capacity

Litres

Rating

kW

Diameter

mm

Height

mm

Weight

Empty

kg

Weight

Full

kg

D

mm

F

mm

NDIR120L

120

3kW x2

550

906

30

150

–

510

NDIR150L

150

3kW x2

550

1093

35

185

–

610

NDIR210L

210

3kW x2

550

1469

45

255

1000

810

Indirect cylinder

Model No.

Capacity

Litres

Rating

kW

Diameter

mm

Height

mm

Weight

Empty

kg

Weight

Full

kg

A

mm

B

mm

C

mm

D

mm

F

mm

NIND120L

120

3kW

550

906

35

155

290 330

390

345

–

NIND150L

150

3kW

550

1093

40

190

330

370

465

385

–

NIND210L

210

3kW

550

1469

50

260

365

405

465

465 1150

Recovery times

INDIRECT

120L

150L

210L

Litres

*

14.04

15.55

22.00

Minutes

**

20.06

22.21

31.43

Minutes

DIRECT

120L

150L

210L

Litres

*

97.12

124.24

178.44

Minutes

**

138.75

177.48

254.92

Minutes

The Direct times are based upon 1 x 3 Kw element in the lower position

*Time in minutes to raise 70% of the contents of the cylinder back to 65C

** Time in minutes to raise whole contents from 15C to 65C

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 16

13.

User Instructions

The Neptune cylinder is automatic in normal use and requires only annual servicing. You

should employ a competent installer to perform the annual servicing. If your boiler is of the

type that requires annual servicing the annual service of the cylinder is usually done at this

time.

IF WATER IS FLOWING FROM THE SAFETY VALVES THROUGH THE TUNDISH THIS

INDICATES A FAULT CONDITION AND ACTION IS NEEDED.

If this water is hot turn the boiler and / or the immersion heater off. Do not turn off the water

until the discharge runs cool. The discharge may also stop.

CALL A COMPETENT PLUMBER OUT TO SERVICE THE UNIT.

Tell them you have a fault on an unvented cylinder. We stock all the spare parts they may

need.

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 17

14.

Service Record

EHC Neptune Unvented Cylinders –

Installation and technical manual

Page 18

15.

Guarantee

The Neptune’s stainless steel vessel carries a 25 year guarantee against faulty materials or

manufacture provided that:

It has been correctly installed as per this

document and all the relevant standards,

regulations and codes of practice in force

at the time.

It has not been modified in any way, other

than by the manufacturer.

It has not been misused, tampered with or

subjected to neglect.

It has only been used for the storage of

potable water.

It has not been subjected to frost damage.

The unit has been serviced annually.

The benchmark log book has been filled in

after each annual service.

The guarantee period starts from the date of

purchase and no registration is required.

The extended guarantee is not transferable,

and rests with the original householder.

The system is fed from a public water supply.

Please note that invoices for servicing may be requested to prove that the unit has been

serviced annually. All the components fitted to / or supplied with the Neptune carry a 2 year

guarantee.

EXCLUSIONS

– THE GUARANTEE DOES NOT COVER the effects of scale build up, any

labour charges associated with replacing the unit or its parts, nor any consequential losses caused

by the failure or malfunction of the unit.

GUIDANCE IN THE EVENT OF A PROBLEM

If you have a problem in the first year contact the plumber who fitted the unit. Thereafter contact

the plumber who carries out the annual servicing for you. If your Neptune develops a leak we will

supply you with a new one. We ask for an nominal upfront payment to prevent fraud. We will

require the original unit to be returned to us for inspection along with a copy of your benchmark log

book. If it is confirmed that it has failed within the terms of the warranty your upfront payment will

be refunded.

If a component part fails within the two year guarantee period we will send you a new one without

any upfront charge. Credit card details may be taken to prevent fraud. We ask you to post the faulty

part back to us within one month by recorded delivery.

If you do not return the part we will charge you for it and for the postage and packing. If your part

fails after two years service, we will ask for upfront payment.

For advice, support, or further

information on The Electric Heating

Company’s full range of electric

heating products, or one of our free

Product guide and installation DVDs,

call now on

01698 820 533.

The Electric Heating Company Ltd, Unit 40, Block 5, Third Road, Blantyre Industrial Estate, Blantyre,

Glasgow, G72 0UP

Tel. 01698 820533

Fax. 01698 825697

info@electric-heatingcompany.co.uk

www.electric-heatingcompany.co.uk