Full Text Searchable PDF User Manual

DUR

AFL

O® SEC

TION 077200 R

OOF

VENT

S

www.duraflo.com

W E K N O W V E N T I L A T I O N

by

Effective Date: Nov 1, 2015

- 2 -

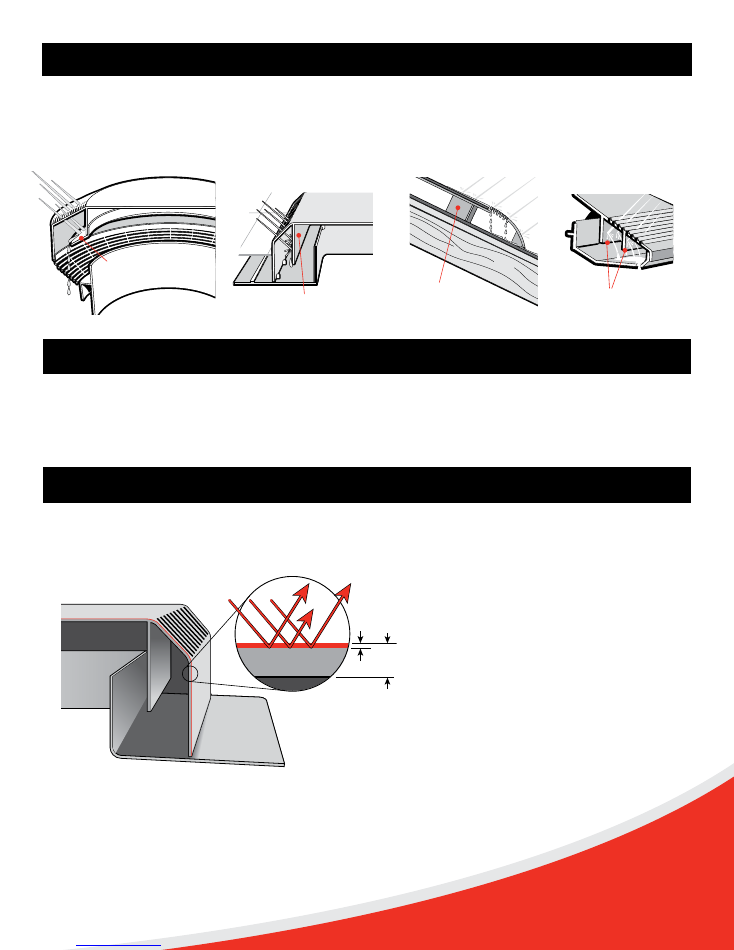

Extreme weather conditions across the

country has increased the demand for a

weather resistant vent. Duraflo has developed

the WeatherPRO® Series line of roof vents,

which are available now through your local

distributor or retail store.

With the WeatherPRO® Series, you no longer

need to worry about extreme weather. Designed

to allow for high volumes of airflow, while

providing excellent defence against weather

infiltration, the patented WeatherPRO® internal

baffles deflect water and snow allowing for

harmless draining out the drainage openings. The

WeatherPRO® series also incorporates a patent

pending moisture control system which directs

precipitation away from the vent openings.

Combining manufacturing quality, with

Duraflo WeatherPRO® technology, and a patent

pending moisture control system, will ensure

the WeatherPRO® Series is the first choice when

weather infiltration is an issue.

- 3 -

Injection molded from pure, high grade polypropylene with premium UV inhibitor additives

that blocks harmful UV Rays.

•

Over 15 years of accelerated

weathering testing

•

Customized UV inhibitor package in all

molded products

•

All colours contain UV inhibitors

•

CSA evaluated

Evaluated and passed based on

the following criteria:

•

ASTM G 155 Accelerated Weathering

•

ASTM D 638 Tensile Strength Difference

•

ASTM D 2843 Smoke Density Rating

•

ASTM D 635 Rate of Burning

Material & UV Protection

Material - Cold Impact Tested

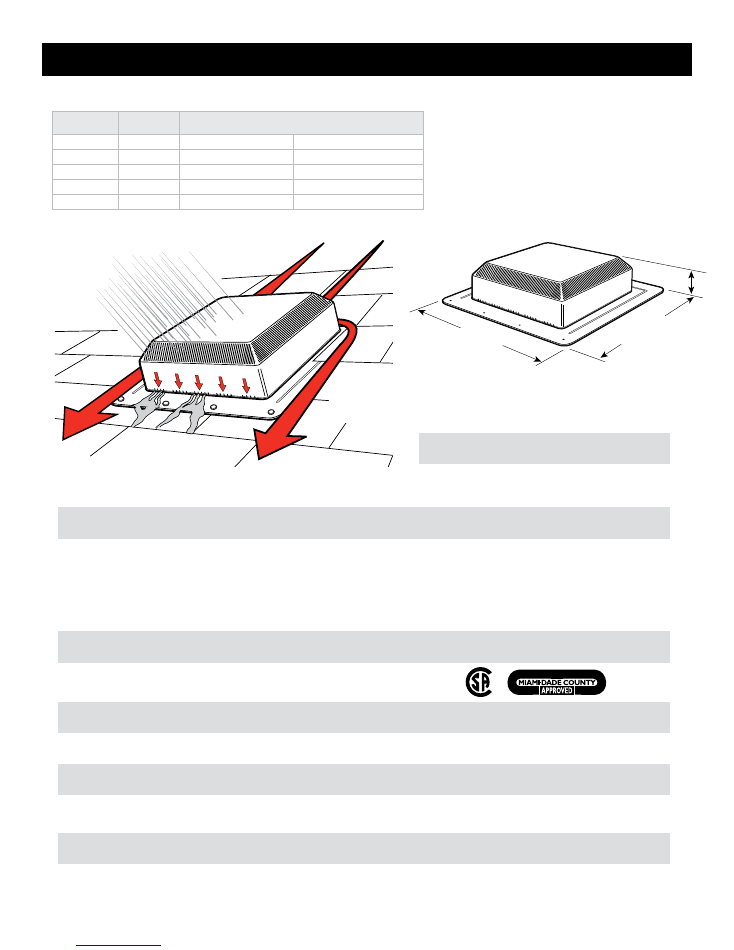

WeatherPRO® Upward Venting

The solid sidewalls and upward venting design behind the WeatherPRO® vents have been engineered to increase

weather protection while improving ventilation in high wind areas. The solid sidewalls work in part with the interior

baffles, providing the first line of defense against driving rain and snow. The solid sidewalls also act to push wind up

and over the cap of the vent, as opposed to under, like a traditional roof vent. This airflow over the cap of the vent

creates negative pressure to draw air from the attic.

The WeatherPRO® line of vents are manufactured from all virgin polypropylene allowing them to withstand the most

extreme climates. The material used in manufacturing the WeatherPRO® Series is cold impact tested at -40 degrees.

The material remains functional, flexible and resilient to damage even when installed with a nail gun.

UV Protected

Polypropylene

0.06”

(1.52 mm)

0.009”

(0.229 mm)

UV Rays are

blocked

after only

.009”

(0.229 mm)

Interior

baffle

shield

Interior baffle shield

Interior baffle shield

Interior baffle shields

- 4 -

DESCRIPTION

PART #

SIZE -

IMPERIAL

SIZE -

METRIC

Black

60PRO150BL

21-1/8”

x 21-1/8”

x 22”

536 mm

x 536 mm

x 559 mm

Brown

60PRO150BR

Grey

60PRO150G

Weatherwood 60PRO150WW

DESCRIPTION

PART #

SIZE -

IMPERIAL

SIZE -

METRIC

Black

60PRO140BL

21-1/8”

x 21-1/8”

x 19-1/2”

536 mm

x 536 mm

x 495 mm

Brown

60PRO140BR

Grey

60PRO140G

Weatherwood 60PRO140WW

DESCRIPTION

PART #

SIZE -

IMPERIAL

SIZE -

METRIC

Black

60PRO130BL

21-1/8”

x 21-1/8”

x 17”

536 mm

x 536 mm

x 432 mm

Brown

60PRO130BR

Grey

60PRO130G

Weatherwood 60PRO130WW

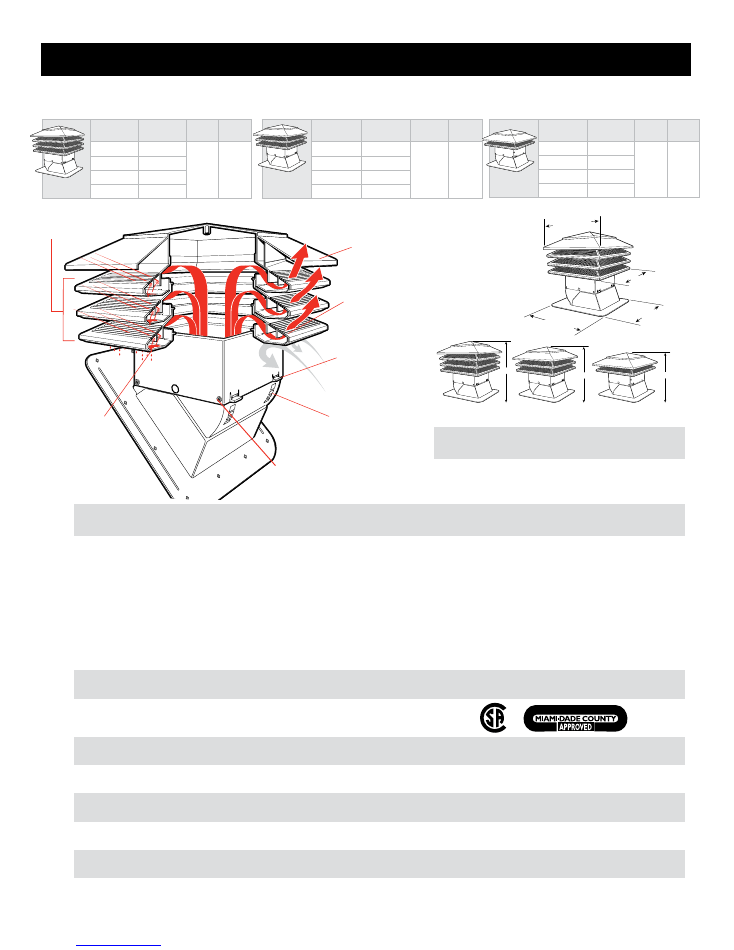

STATIC VENTS - PROVentilator, 1, 2 & 3 Tier Models

3 Tier

60PRO150 Model: 130 sq-in / 839 sq-cm

2 Tier

60PRO140 Model: 95 sq-in / 613 sq-cm

1 Tier

60PRO130 Model: 48 sq-in / 310 sq-cm

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood, Grey

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Description:

Net Free Venting Area

Approved Certifications

Durability

Colors Available

Weather Protection

Models:

WeatherPRO®

PROVentilators:

3 Tier

#60PRO150

2 Tier

#60PRO140

1 Tier

#60PRO130

Multiple pivot stop

points for quick

leveling

Molded in

screw guides

External Drip tray

allows moisture to

drain harmlessly away

from vent openings

Easily adjust to roof

pitch with front

and back locking

tabs

Large top

cap improves

appearance of the

roof line

Unique baffle

system wards off

wind driven snow

and rain

• CSA certified - Plastic Type B roof vents, for installation on sloping surfaces

• Miami Dade High Velocity Hurricane Zone certified

Model

Heights:

21-1/8”

20”

19-7/8”

21-1/8”

22”

19-1/2”

17”

3 Tier

2 Tier

1 Tier

3 Tier, 2 Tier & 1 Tier

3, 2 or 1 Tier

models

• One 3 Tier Model will ventilate 1000 - 1200 sq. ft. of attic space (approx)

• One 2 Tier Model will ventilate 400 - 500 sq. ft. of attic space (approx)

• One 1 Tier Model will ventilate 200 - 300 sq. ft. of attic space (approx)

• Patented internal weather baffles

• The chimney style design allows the PRO Ventilator to harness wind energy and create pressure variances

that powerfully draw air out from within the attic space.

• Roof pitch range 3/12 – 12/12

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Lightweight , no-assembly design makes for easy handling. Setting the pitch is quick and simple with centralized pivot

points, built-in adjustment tabs and pitch stops.

Common

Dimensions:

- 5 -

Net Free Venting Area

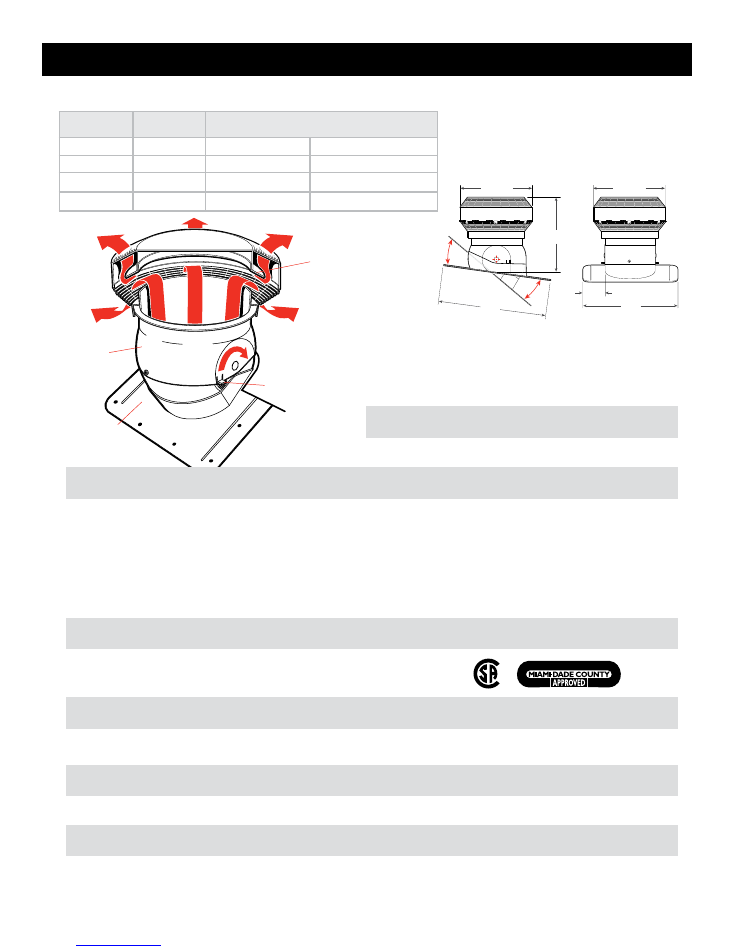

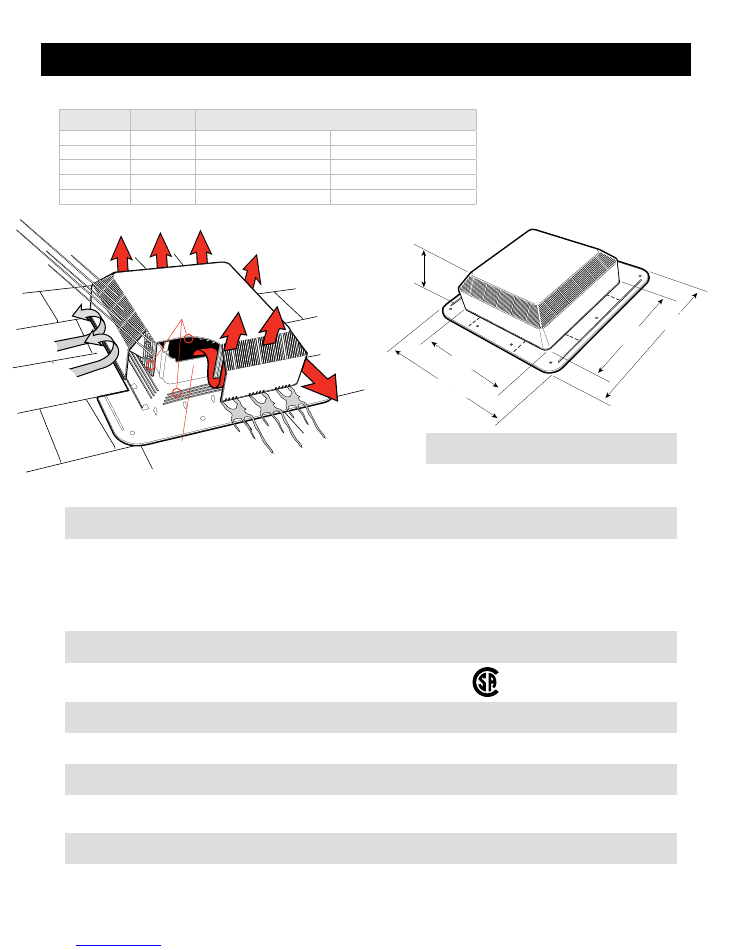

TURBINE VENTS - PROTURBO

DESCRIPTION

PART #

SIZE

IMPERIAL METRIC

Black

60PRO117BL

17-1/2” x 20” x 16-1/4” 445mm x 508mm x 413mm

Brown

60PRO117BR

17-1/2” x 20” x 16-1/4” 445mm x 508mm x 413mm

Weatherwood

60PRO117WW

17-1/2” x 20” x 16-1/4” 445mm x 508mm x 413mm

Grey

60PRO117G

17-1/2” x 20” x 16-1/4” 445mm x 508mm x 413mm

• No internal or external moving parts – requires no maintenance

• One Turbo will ventilate 1000 sq ft (93 sq. meters) of attic space (approx) – regardless of wind speed

• Roof pitch range from 3/12 to 12/12

• Large flashing allows for easy installation

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Available as a full unit (including base) or as replacement top only

• Lightweight , no-assembly design makes for easy handling. Setting the pitch is quick and simple with centralized pivot

points, built-in adjustment tabs and pitch stops.

117 sq-in / 755 sq-cm

• CSA certified - Plastic Type B roof vents, for installation on sloping surfaces

• Miami Dade High Velocity Hurricane Zone certified

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood, Grey

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Net Free Venting Area

Approved Certifications

Durability

Colors Available

Weather Protection

Model:

WeatherPRO® PROTurbo # 60PRO117

Pivoting top with

locking pitch guide

tabs – 3/12 to 12/12

Unique baffle

system wards

off wind driven

snow and rain

Cold impact

resistant to -40

Crush, Dent &

UV resistant

polypropylene

117 Sq. In.

Net Free

Venting Area

17-1/2”

17-1/2”

16-1/4”

3-3/4”

20”

21”

21”

A

C

D

A

B

3/12 - 12/12

3/12 - 12/12

(580mm)

(95mm)

(445mm)

(445mm)

(413mm)

(533mm)

Description:

Dimensions:

- 6 -

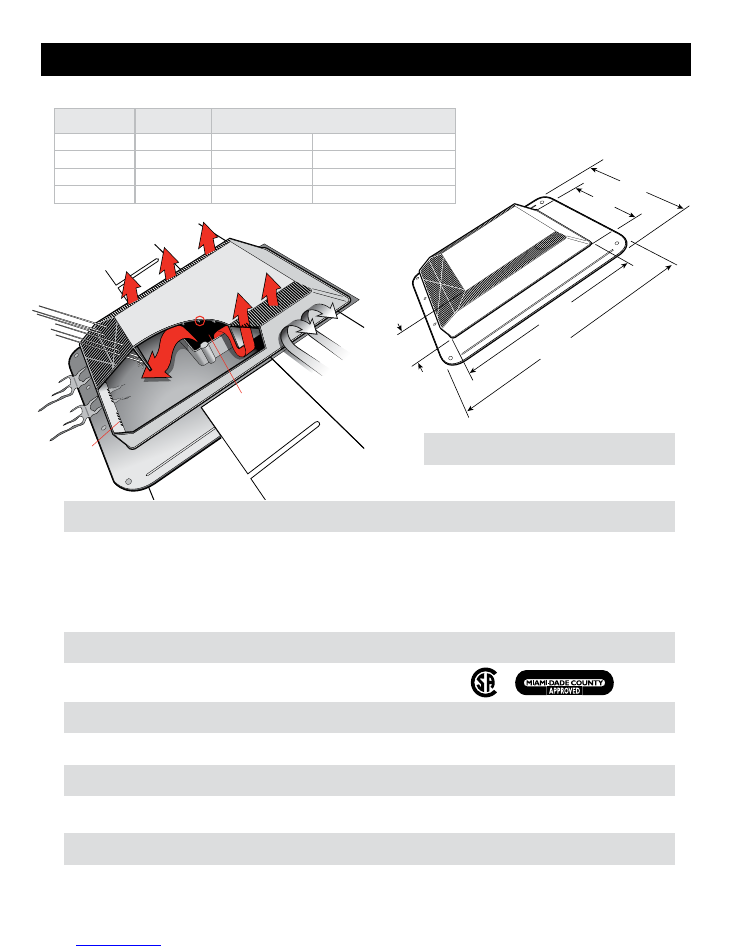

24”

(610 mm)

19”

(483 mm)

18”

(457 mm)

12”

(309 mm)

3-1/2”

(89 mm)

DESCRIPTION

PART #

SIZE

IMPERIAL METRIC

Black

60PRO50SLBL

18” x 24” x 3-1/2”

457 mm x 610 mm x 89 mm

Brown

60PRO50SLBR

18” x 24” x 3-1/2”

457 mm x 610 mm x 89 mm

Grey

60PRO50SLG

18” x 24” x 3-1/2”

457 mm x 610 mm x 89 mm

Weatherwood

60PRO50SLWW

18” x 24” x 3-1/2”

457 mm x 610 mm x 89 mm

2.

Drainage

openings

4.

Outer vertical

walls

5.

Protected vent

opening

Moisture drip

channels

1.

Air exits

over the

vent not under

3.

Diverts run-off

around cap

STATIC VENTS - PROSlantBack

• Patented internal weather baffles

• Five PRO SlantBack’s will ventilate 1000 sq. ft. (93 sq. meters) of attic space (approx)

• Roof pitch range 3/12 – 14/12

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Top venting design uses chimney effect to channel moist air away from roof eliminating shingle staining

• Vent cap design with built in weeping holes eliminates bird nesting and water pooling

• Unique design allows it to be used as an intake where soffit ventilation is limited or not available

50 sq-in / 322 sq-cm

• CSA certified – Plastic Type B roof vents, for installation on sloping surfaces

• Miami Dade High Velocity Hurricane Zone certified NOA# 11-0930.08

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood, Grey

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Description:

Net Free Venting Area

Approved Certifications

Durability

Colors Available

Weather Protection

Dimensions:

Model:

WeatherPRO®

SlantBack, # 60PRO50SL

- 7 -

Net Free Venting Area

2.

Drainage openings

1.

Air exits over the

vent not under

18-1/2”

(470 mm)

18-1/2”

(470 mm)

4-1/2”

(114 mm)

DESCRIPTION

PART #

SIZE

IMPERIAL METRIC

Black

60PRO50BL

18-1/2” x 18-1/2” x 4-1/2”

470 mm x 470 mm x 114 mm

Brown

60PRO50BR

18-1/2” x 18-1/2” x 4-1/2”

470 mm x 470 mm x 114 mm

Grey

60PRO50G

18-1/2” x 18-1/2” x 4-1/2”

470 mm x 470 mm x 114 mm

White

60PRO50W

18-1/2” x 18-1/2” x 4-1/2”

470 mm x 470 mm x 114 mm

Weatherwood 60PRO50WW

18-1/2” x 18-1/2” x 4-1/2”

470 mm x 470 mm x 114 mm

STATIC VENTS - PRO50

• Patented internal weather baffles

• Five WeatherPRO PRO50’s will ventilate 1000 sq. ft. (93 sq. meters) of attic space (approx)

• Roof pitch range 3/12 – 14/12

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Top venting design uses chimney effect to channel moist air away from roof eliminating shingle staining

• Vent cap design with built in weeping holes eliminates bird nesting and water pooling

50 sq-in / 322 sq-cm

• CSA certified – Plastic Type B roof vents, for installation on sloping surfaces

• Miami Dade High Velocity Hurricane Zone certified: NOA 04.0401.01

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood, Gray, White

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Description:

Net Free Venting Area

Approved Certifications

Durability

Colors Available

Weather Protection

Dimensions:

Model:

WeatherPRO®

PRO50, model # 60PRO50

3.

Diverts run-off

around cap

- 8 -

STATIC VENTS - PRO75

5-1/2”

(140mm)

217/8”

(555.63mm)

15.-7/8”

(403.23mm)

21-7/8”

(556mm)

21-7/8”

(555.63mm)

21-7/8”

(556mm)

15-7/8”

(403mm)

15-7/8”

(403.23mm)

15-7/8”

(403mm)

DESCRIPTION

PART #

SIZE

IMPERIAL METRIC

Black

60PRO75BL

21-7/8” x 21-7/8” x 5-1/2”

556 mm x 556 mm x 140 mm

Brown

60PRO75BR

21-7/8” x 21-7/8” x 5-1/2”

556 mm x 556 mm x 140 mm

Grey

60PRO75G

21-7/8” x 21-7/8” x 5-1/2”

556 mm x 556 mm x 140 mm

White

60PRO75W

21-7/8” x 21-7/8” x 5-1/2”

556 mm x 556 mm x 140 mm

Weatherwood 60PRO75WW

21-7/8” x 21-7/8” x 5-1/2”

556 mm x 556 mm x 140 mm

• Patented internal weather baffles

• Four PRO75’s will ventilate 1000 sq ft (93 sq. meters) of attic space (approx)

• Roof pitch range 3/12 – 12/12

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Top venting design uses chimney effect to channel moist air away from roof eliminating shingle staining

• Vent cap design with built in weeping holes eliminates bird nesting and water pooling

75 sq-in / 483 sq-cm

• CSA certified - Plastic Type B roof vents, for installation on sloping surfaces

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood, Grey, White

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Description:

Net Free Venting Area

Approved Certifications

Durability

Colors Available

Weather Protection

Dimensions:

2.

Drainage

openings

5.

Protected vent

opening

Moisture drip

channels

1.

Air exits

over the

vent not under

3.

Diverts run-off

around cap

4.

Outer vertical

walls

Model:

WeatherPRO® PRO75, model # 60PRO75

- 9 -

AirFoil

Designed Edge

(1219mm)

4 Ft.

4 Ft.

DESCRIPTION

PART #

A

IMPERIAL METRIC

Metric - Black

6072METBL

12-7/8”

327mm

Metric - Brown

6072METBR

12-7/8”

327mm

Metric - Weatherwood

6072METWW

12-7/8”

327mm

Imperial - Black

6073BL

11-5/8”

295mm

Imperial - Brown

6073BR

11-5/8”

295mm

Imperial - Weatherwood

6073WW

11-5/8”

295mm

CONTINUOUS RIDGE VENTS - WeatherPRO® Ridge

• Engineered with AirFoil Technology – based on the Bernoulli principle to maximize air lift

• Four pieces of WeatherPRO® PRORidge vent will ventilate 1000 sq. ft. (93 sq. meters) of attic space (approx)

• Patented internal weather baffle system

• Roof pitch range 3/12 – 12/12

• 4 foot sections, 12 pieces per carton

• Latch connectors on each end, built-in end caps every 3 in/7.6 cm

• Injection molded from pure, high grade polypropylene with premium UV inhibitors

• Available for use with either Metric or Imperial size shingles

18.3 sq-in per linear foot (387 sq-cm per linear meter)

• CSA certified - Plastic Type C ridge vent, for installation on roof ridge

• Engineered to resist denting, peeling, extreme heat and cold impact to -40

Black, Brown, Weatherwood

WeatherPRO’s patented internal baffles deflect water and snow, allowing for harmless draining out the drainage

openings. Designed to allow high airflow while providing excellent defense against weather infiltration.

Description:

Approved Certifications

Durability

Colors Available

Weather Protection

Dimensions:

Models:

WeatherPRO PRORidge, • Metric - 6072MET • Imperial - 6073

Net Free Venting Area

Net Free Venting Area

- 10 -

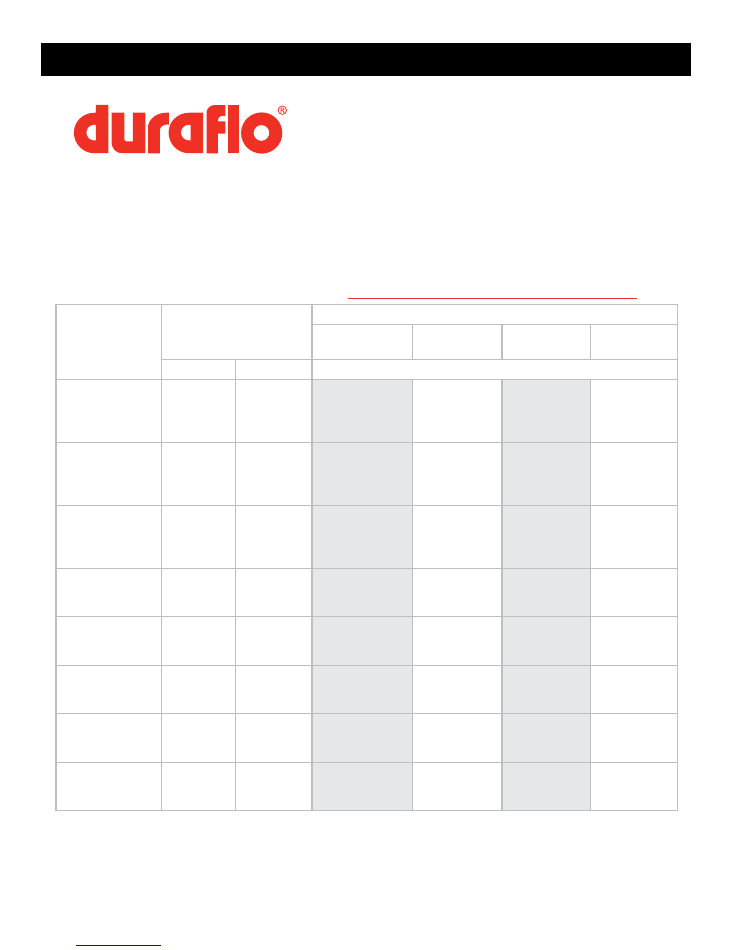

Ventilation Calculator

Ventilation requirements for your home

The included ventilation calculator is only a guide, please consult your local building code for specific ventilation requirements.

A home requires an equal amount of intake

(soffit) & exhaust (roof) ventilation.

Note: Roof pitches under 4/12 require double the amount of ventilation.

Use this chart to determine how many vents your attic requires.

Ventilation

Calculator

DESCRIPTION

NET FREE AREA

OF VENT

NUMBER OF VENTS NEEDED FOR

1000 sq. ft.

(93 sq. meters)

1500 sq. ft.

(139 sq. meters)

2000 sq. ft.

(186 sq. meters)

2500 sq. ft.

(232 sq. meters)

IMPERIAL

METRIC

OF ATTIC SPACE

3 TIER

WEATHERPRO

PROVENTILATOR

130

Sq. In.

839

Sq. cm

1

2

3

4

2 TIER

WEATHERPRO

PROVENTILATOR

95

Sq. In.

613

Sq. cm

2

3

4

5

1 TIER

WEATHERPRO

PROVENTILATOR

48

Sq. In.

310

Sq. cm

4

6

8

10

WEATHERPRO

TURBO

117

Sq. In.

755

Sq. cm

1

2

3

4

WEATHERPRO

SLANT BACK

50

Sq. In.

322

Sq. cm

5

8

10

12

WEATHERPRO

60PRO50

50

Sq. In.

322

Sq. cm

5

8

10

12

WEATHERPRO

60PRO75

75

Sq. In.

484

Sq. cm

4

5

7

8

WEATHERPRO

RIDGE VENTS

72

Sq. In.

465

Sq. cm

4

5

7

10

- 11 -

The included ventilation calculator is only a guide, please consult your local building code for specific ventilation requirements.

DESCRIPTION

NET FREE AREA

OF VENT

NUMBER OF VENTS NEEDED FOR

1000 sq. ft.

(93 sq. meters)

1500 sq. ft.

(139 sq. meters)

2000 sq. ft.

(186 sq. meters)

2500 sq. ft.

(232 sq. meters)

IMPERIAL

METRIC

OF ATTIC SPACE

3 TIER

WEATHERPRO

PROVENTILATOR

130

Sq. In.

839

Sq. cm

1

2

3

4

2 TIER

WEATHERPRO

PROVENTILATOR

95

Sq. In.

613

Sq. cm

2

3

4

5

1 TIER

WEATHERPRO

PROVENTILATOR

48

Sq. In.

310

Sq. cm

4

6

8

10

WEATHERPRO

TURBO

117

Sq. In.

755

Sq. cm

1

2

3

4

WEATHERPRO

SLANT BACK

50

Sq. In.

322

Sq. cm

5

8

10

12

WEATHERPRO

60PRO50

50

Sq. In.

322

Sq. cm

5

8

10

12

WEATHERPRO

60PRO75

75

Sq. In.

484

Sq. cm

4

5

7

8

WEATHERPRO

RIDGE VENTS

72

Sq. In.

465

Sq. cm

4

5

7

10

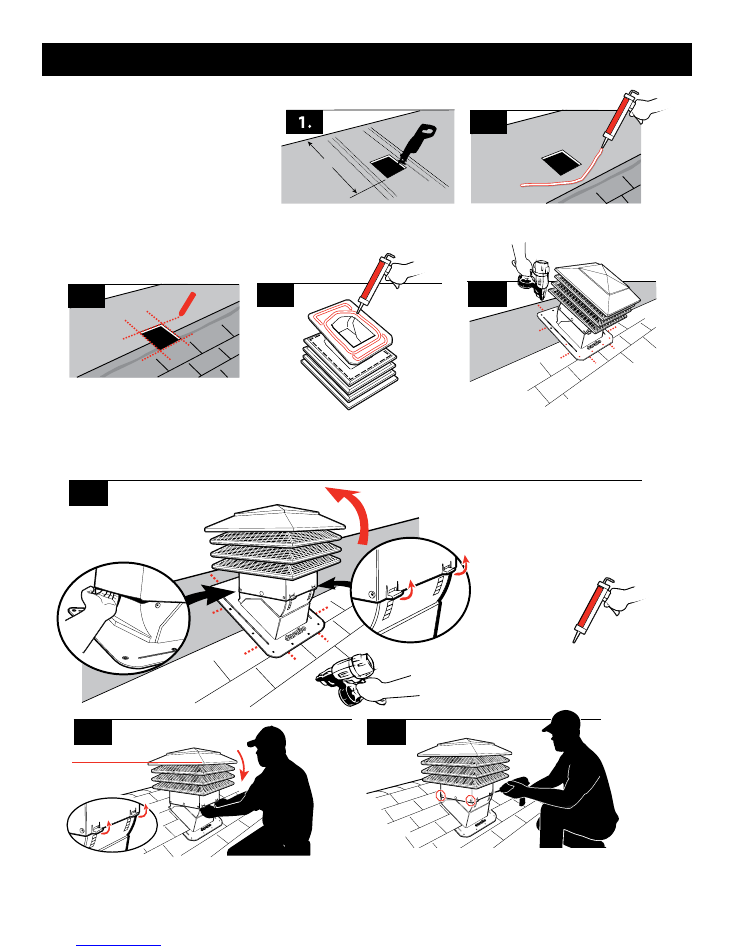

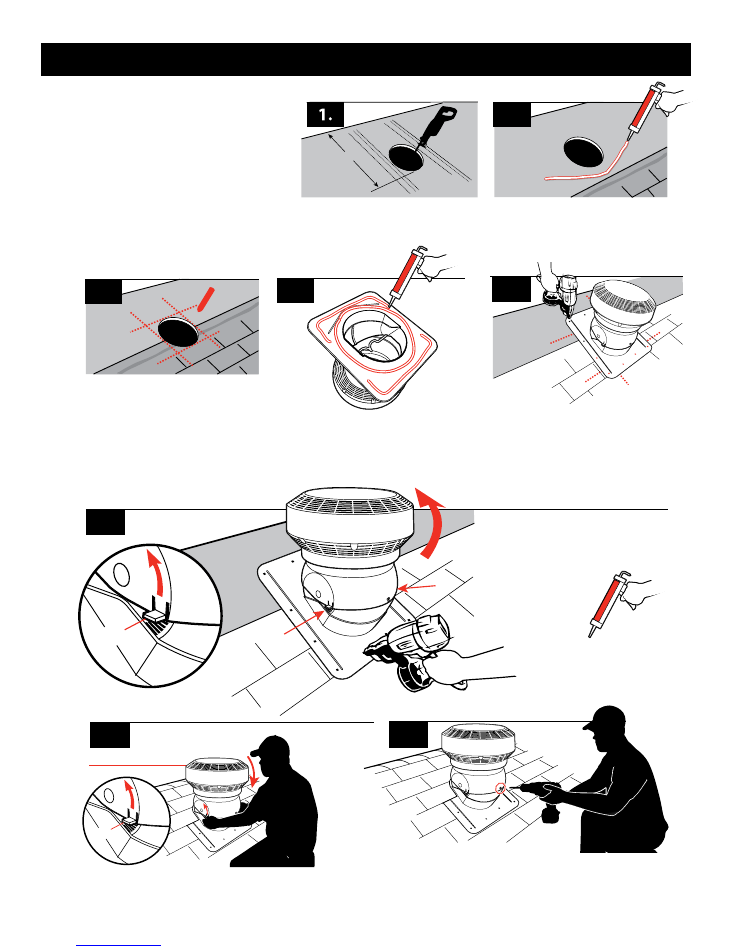

INSTALLATION - PROVentilator, 1, 2 & 3 Tier Models

4. Using a 1/2“ (1.3 cm) bead, apply a generous amount of

construction sealant to the base of the vent.

4.

Note: Use non-petroleum based sealants only. The use

of petroleum based sealants may void any

manufactures product warranty.

5.

5. Position the roof vent over the cut opening in the

roof. Center the vent by aligning edges of the vent

throat with the chalk lines previously marked. Using

the molded nail indicators, nail the top half of the vent

securely into place.

8.

8. Using the 4 screws supplied, secure vent into position as shown.

7.

7. Using the pitch tabs lower the top of the unit back to desired

pitch.

Ensure the top of the unit is level.

Level Top

Pitch Tabs

24”

(61 cm)

12” x 12”

(30.5 cm x 30.5 cm)

1. Apply underlayment on the sheathing and in the

center of the rafters cut a 12” (30.5 cm) square hole.

The edge of the hole should be at least 12” (30.5 cm)

and no more than 24” (61 cm) from the roof peak.

2. Using a 1/2” (1.3 cm) bead, apply a generous amount

of construction sealant to the underlayment infront of

hole before applying next shingle course.

2.

Underlayment

Shingles

3. Install next shingle course over sealant bead

and mark extended chaulk lines to help position

vent over opening in next step.

3.

6.

6. Gently lift the pitch calculating tabs (Fig A.),

rotating the top of the unit up to make room

for nailing the bottom half of the flange (Note:

Ensure the vent throat overlaps (Fig B.). Using

the molded nail indicators, nail the remainder

of the vent securely into place.

Fig. B.

Fig. A.

Note: For added

protection against

weather infiltration

seal any exposed

nail heads.

For New Construction

Note:

PROVentilator

placement

and the balancing of intake and

exhaust venting are extremely

important in achieving ideal

ventilator performance. For more

information on ventilation systems

see Duraflo.com or consult the local

building code.

- 12 -

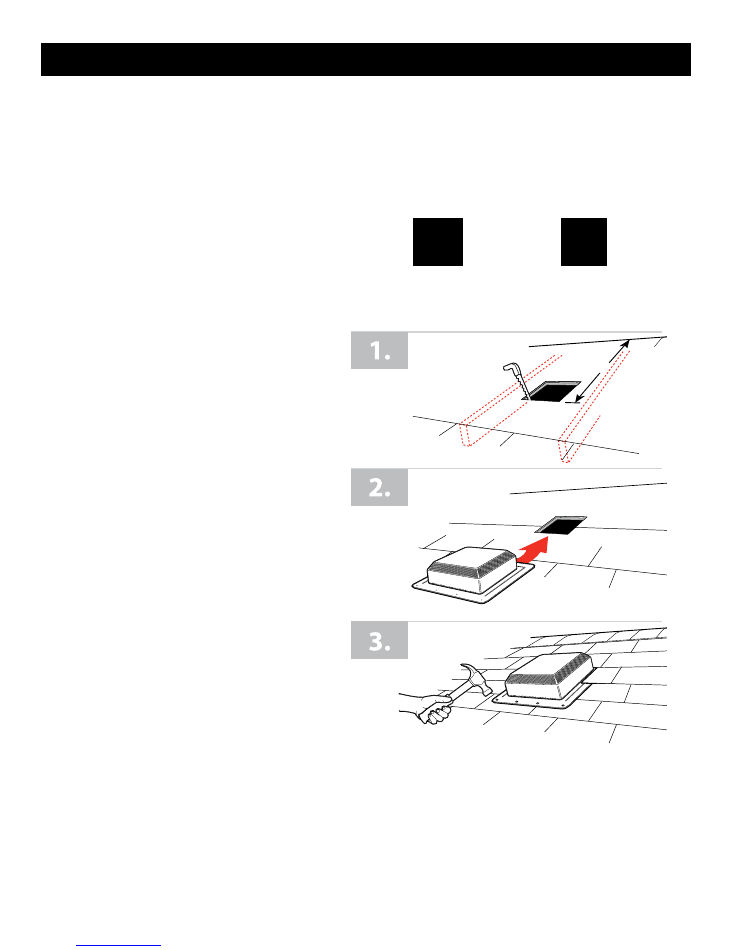

4.

4. Using a 1/2 inch bead, apply a generous amount of

construction sealant to the base of the vent.

Note: Use non-petroleum based sealants only. The use

of petroleum based sealants may void any

manufactures product warranty.

5.

5. Position the roof vent over the cut opening in the

roof. Center the vent by aligning edges of the vent

throat with the chalk lines previously marked. Using

the molded nail indicators, nail the top half of the vent

securely into place.

8.

8. Using the molded in screw guide in front of vent, secure vent into

position as shown with 1 screw supplied.

7.

7. Using the pitch tabs pivot the top of the unit to desired pitch.

Ensure the top of the unit is level.

Level Top

24”

12” x 12”

1. Apply underlayment on the sheathing and In the

center of the rafters cut a 12” round hole. The edge

of the hole should be at least 12” and no more than

24” from the roof peak.

2.

Underlayment

Shingles

3. Install next shingle course over sealant bead

and mark extended chaulk lines to help position

vent over opening in next step.

3.

6.

6. Gently lift the pitch calculating tabs (Fig A.),

pivoting the top of the unit up to and nail the

bottom half of the flange.

Note: For added

protection against

weather infiltration

seal any exposed

nail heads.

Fig. A.

Pitch Tabs

Pitch Tabs

2. Using a 1/2 inch bead, apply a generous amount

of construction sealant to the underlayment infront

of hole before applying next shingle course.

INSTALLATION - PROTurbo

For New Construction

Installation of Duraflo

WeatherPRO®

PROTurbo

should comply with all

local standards and regulations.

Before beginning a job, determine

how much ventilation is required in

both soffit and roof vents and what

sizes of vent would best suit the job.

If required, refer to Duraflo Ventilation

Calculator for guidance.

- 13 -

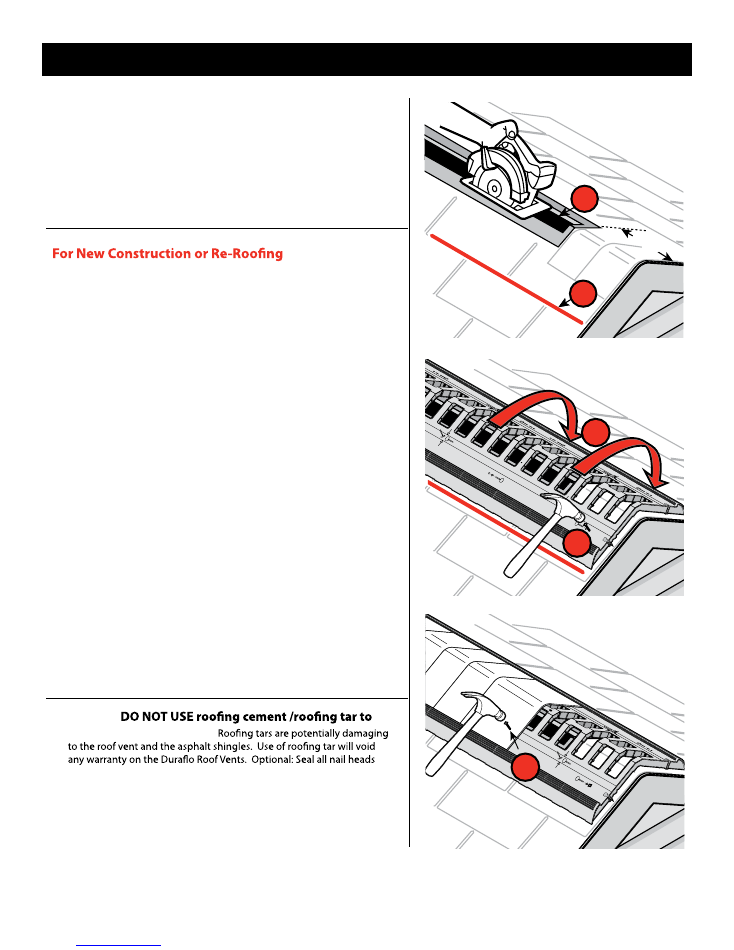

INSTALLATION - PRO SlantBack

For New Construction or Re-Roofing

1. Determine the location of vents:

Evenly space the roof vents along the width of

the roof, marking the location of all roof vents

before cutting holes. Centre the holes between

the rafters within two feet (24”)

(61 cm)

from

the peak of the roof.

Cut and prepare the opening:

Cut the holes in the sheathing before applying

shingles, cut a 6-1/2” x 8-1/2”

(16.5 cm x 21.6 cm)

opening. Shingle up until the first full course of

shingles covers the bottom of the hole. Cut the

excess shingles away from the hole.

2. Position the vent and nail the vent

in place:

Duraflo Roof Vents have a top arrow indicator.

Make sure the throat of the vent is in the proper

position centered over the opening. Using the

pre-marked nail holes, nail the vent securely

into place.

3. Complete the shingle installation:

Continue installing shingles, overlapping

the flange of the vent. Cut the shingles around

the top of the vent to match its shape.

Installation of Duraflo

WeatherPRO® SlantBack Vent

should comply with all local standards and regulations.

Before beginning a job, determine how much ventilation is required in both soffit and roof vents and what sizes

of vent would best suit the job. If required, refer to Duraflo Ventilation Calculator for guidance.

Caution:

DO NOT USE roofing cement /

roofing tar to seal the vent to the roof. The

wide flange and molded-in water guards

will force the water down the roof over

the shingles. The polypropylene flange

is large enough and flexible enough to

effectively self seal against the roof without

the aid of roofing tars. Roofing tars are

potentially damaging to the roof vent and

the asphalt shingles. Use of roofing tar

will void any warranty on the Duraflo Roof

Vents. Optional: Seal all nail heads with an

approved sealant, such as silicone. Make

sure the sealant is a non-petroleum product

(usually available in a plastic tube).

6-1/2”

(16.5 cm)

8-1/2”

(21.6 cm)

24”

(61 cm)

Rough Cut Opening

- 14 -

INSTALLATION - PRO50 & PRO75

For New Construction or Re-Roofing

1. Determine the location of vents:

Evenly space the roof vents along the width of

the roof, marking the location of all roof vents

before cutting holes. Centre the holes between

the rafters within two feet (24”)

(61 cm)

from

the peak of the roof.

Cut and prepare the opening:

Cut the holes in the sheathing before applying

shingles, for PRO50 cut a 7-1/4” x 7-1/4”

(18.4 cm x 18.4 cm) opening, for the PRO75 cut a

9-1/2” x 9-1/2” (24 cm x 24 cm) opening. Shingle

up until the first full course of shingles covers the

bottom of the hole. Cut the excess shingles away

from the hole.

2. Position the vent and nail the vent

in place:

Duraflo Roof Vents have a top arrow indicator.

Make sure the throat of the vent is in the proper

position centered over the opening. Using the

pre-marked nail holes, nail the vent securely

into place.

3. Complete the shingle installation:

Continue installing shingles, overlapping

the flange of the vent. Cut the shingles around

the top of the vent to match its shape.

Installation of Duraflo

WeatherPRO® PRO50 or PRO75 Roof Vent

should comply with all local standards and

regulations. Before beginning a job, determine how much ventilation is required in both soffit and roof vents

and what sizes of vent would best suit the job. If required, refer to Duraflo Ventilation Calculator for guidance.

Caution:

DO NOT USE roofing cement /

roofing tar to seal the vent to the roof. The

wide flange and molded-in water guards

will force the water down the roof over

the shingles. The polypropylene flange

is large enough and flexible enough to

effectively self seal against the roof without

the aid of roofing tars. Roofing tars are

potentially damaging to the roof vent and

the asphalt shingles. Use of roofing tar

will void any warranty on the Duraflo Roof

Vents. Optional: Seal all nail heads with an

approved sealant, such as silicone. Make

sure the sealant is a non-petroleum product

(usually available in a plastic tube).

PRO75

Rough Cut Opening

7-1/4”

(18.4 cm)

7-1/4”

(18.4 cm)

9-1/2”

(24 cm)

9-1/2”

(24 cm)

24”

(61 cm)

PRO50

Rough Cut Opening

- 15 -

INSTALLATION GUIDE

Step 1.

Cut a slot in sheathing along the ridge 2” (5 cm) wide 1” (2.5 cm)

on each side of peak).

If ridge beam is present, cut a slot 1” (2.5 cm) wide on each side of the

beam. A closed area of sheathing 12” (30.5 cm) in length should be at

both ends of ridge. The 12” (30.5cm) area should be coverd to prevent

infiltration.

Step 2.

For step 2 it is recommended a chalk line be used to ensure the ridge

vent is installed straight along the roof peak.

Place the first piece of vent with female end 1/2” (1.3 cm) from the

gable end. On one side of the peak fasten the first piece using nails at

each end and in middle sections. Fold the vent over the peak and

fasten the second side using the same nail pattern. (2” (5 cm) nails are

minimum length). Continue installing additional pieces along

ridge connecting the female end over the male end.

Step 3.

When reaching the ridge end, the last vent section may need to

be cut to length. There are molded-in end caps every 3” (7.6 cm) on the

underside of the ridge vent. Measure and cut amount needed to

install to within 1/2” (1.3 cm) of ridge end.

After fastening the ridge vent to the roof peak install ridge caps

using a min 2” (5 cm) nail. The ridge caps should be centered on the

vent and sit between the outer raised baffle walls.

Canplas Industries Ltd.

P.O Box 1800, 500 Veterans Drive

Barrie, Ontario, Canada L4M 4V3

Tel. (705) 726-3361

Toll Free 1-800-461-5300

Fax: (705) 726-2186

Canplas LLC

11402 East 53rd Ave.

Suite 200, Denver, CO, U.S.A. 80239

Tel: (303) 373-1923

Toll Free: 1-800-461-5307

Fax: (303) 373-1928

1

2B

2C

3

2A

Caution:

seal the vent to the roof.

with a non-petroleum based sealant product.

12” (30.5 cm)

INSTALLATION - WeatherPRO® RIDGE VENT

Installation of Duraflo

WeatherPRO® PRORidge Vent

should

comply with all local standards and regulations. Before

beginning a job, determine how much ventilation is required

in both soffit and roof vents and what sizes of vent would best

suit the job. If required, refer to Duraflo Ventilation Calculator

for guidance.

- 16 -

Specifications

SECTION 077200

- ROOF VENTS

PART 1 GENERAL

1.1

SECTION INCLUDES

A. Roof vents of the following types:

1. Continuous ridge vents. (WeatherPRO Ridge)

2. Turbine vents. (WeatherPRO Turbo Vent).

3. Static vents. (WeatherPRO 75)(WeatherPro 50)

(WeatherPRO Slant Back) (WeatherPRO

PROVentilator)

1.2

RELATED SECTIONS

A. Section 07310 - Asphalt Shingles: Rough-in and

installation requirements.

1.3

SUBMITTALS

A. Submit under provisions of Section 01300.

B. Product Data: Manufacturer’s data sheets on each

product to be used, including:

1. Preparation instructions and recommendations.

2. Storage and handling requirements and

recommendations.

3. Installation methods.

1.4

QUALITY ASSURANCE

A. Manufacturer Qualifications: Minimum 5 years

experience manufacturing similar products.

B. Installer Qualifications: Minimum 2 years experience

installing similar products.

1.5

PRE-INSTALLATION MEETINGS

A. Convene minimum two weeks prior to starting

Work of this section.

1.6

DELIVERY, STORAGE, AND HANDLING

A. Deliver and store products in manufacturer’s

unopened packaging bearing the brand name

and manufacturer’s identification until ready

for installation.

B. Handling: Handle materials to avoid damage.

1.7

PROJECT CONDITIONS

A. Maintain environmental conditions (temperature,

humidity, and ventilation) within limits

recommended by manufacturer for optimum

results. Do not install products under

environmental conditions outside manufacturer’s

recommended limits.

1.8

SEQUENCING

A. Ensure that products of this section are supplied to

affected trades in time to prevent interruption of

construction progress.

1.9

WARRANTY

A. Warranty: Provide manufacturer’s standard limited

warranty, and as follows:

1. WeatherPRO Ridge: 35 year limited warranty

2. WeatherPRO Turbo Vent: 35 year limited

warranty

3. WeatherPRO 75: 35 year limited warranty

4. WeatherPRO 50: 35 year limited warranty

5. WeatherPRO Slantback: 35 year limited warranty

6. WeatherPRO PROventilator: 35 year limited

warranty

PART 2 PRODUCTS

2.1

MANUFACTURERS

A. Acceptable Manufacturer:

Canplas Industries Ltd.; 500 Veterans Dr.

P.O. Box 1800, Barrie, ON, Canada

L4M 4V3. ASD. Toll Free Tel: (800) 461-1771.

Tel: (705) 726-3361. Fax: (705) 726-2186.

Email: duraflo@canplas.com

Web: http://www.canplas.com

B. Substitutions: Not permitted.

C. Requests for substitutions will be considered in

accordance with provisions of Section 01600.

2.2

ROOF VENTS

A. Roof ventilation shall be from a single source

of Duraflo Roofing Ventilation products

manufactured by Canplas Industries Ltd.

2.3

CONTINUOUS ROOF VENTS

A. Product: WeatherPRO Ridge as manufactured by

Canplas Industries Ltd.

1. Design: Internal baffles and drainage openings

easily deflect and direct away extreme weather.

Airfoil designed edge allows smooth airflow over

the ridge line maximizing effective ventilation

from the attic space. TriFold flexibility for use on

full range of pitches. Code regulated insect grill.

Net Free Area: 18.3 sq.in./lin.ft.(387 sq.cm/lin. m).

2. Miami Dade High Velocity Hurricane Zone

certified: NOA 05-0516.06.

SPEC NOTE: See www.arcat.com website for

Microsoft Word (editable) document.

SPEC NOTE: Canplas LLC and Canplas Industries Ltd. are

members of the Aliaxis Group of companies, a global leader

of plastic solutions for fluid transport in the field of building

materials. The Aliaxis Group provides products for both

residential and commercial building markets, in new build and

renovation segments, as well as a wide range of solutions for

industrial and public utility applications.

- 17 -

Specifications

3. CSA certified - Plastic Type C ridge vent, for installation

on roof ridge.

4. Construction: Injection molded from pure, high

grade polypropylene with premium UV inhibitor

additives. Engineered to resist denting, peeling,

extreme heat and cold impact to -40 degree F

(-40 degree C).

5. Model: Metric – Black (6072METBL).

6. Model: Metric – Brown (6072METBR).

7. Model: Metric – Weatherwood (6072METWW).

8. Model: Imperial – Black (6073BL).

9. Model: Imperial – Brown (6073BR).

10. Model: Imperial – Weatherwood (6073WW).

2.4

TURBINE VENTS

A. Product: WeatherPRO® Turbo Vent as manufactured

by Canplas Industries Ltd.

1. Design: No internal or external moving parts – requires

no maintenance. Internal baffles deflect water and

snow, allowing for harmless drainage out the drainage

openings.

Allows high airflow while providing excellent defense

against weather infiltration. Two-piece base fits roof

pitches from 3/12 to 12/12. 117 sq. in. (755 sq. cm) net

free area.

2. Construction: Injection molded from pure, high

grade polypropylene with premium UV inhibitor

additives. Engineered to resist denting, peeling,

extreme heat and cold impact to -40 degree F

(-40 degree C).

3. CSA certified - Plastic Type B roof vents, for installation

on sloping surfaces.

4. Miami Dade High Velocity Hurricane Zone certified

5. Model: Black (60PRO117BL) 17-1/2 inches x 20 inches

x 16-1/4 inches (445 mm x 508 mm x 413 mm).

6. Model: Brown (60PRO117BR) 17-1/2 inches x 20 inches

x 16-1/4 inches (445 mm x 508 mm x 413 mm).

7. Model: Weatherwood (60PRO117WW) 17-1/2 inches x

20 inches x 16-1/4 inches (445 mm x 508 mm x

413 mm).

8. Model: Grey (60PRO117G) 17-1/2 inches x

20 inches x 16-1/4 inches (445 mm x 508 mm x

413 mm).

2.4

STATIC VENTS

A. Product: WeatherPRO® 75 as manufactured by

Canplas Industries Ltd.

1. Design: Top venting design uses chimney effect to

channel moist air away from roof eliminating shingle

staining. Vent cap design with built in weeping holes

eliminates bird nesting and water pooling. Roof pitch

range 3/12 to 12/12. Net free venting area of

75 sq. in. (483 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

and cold impact to -40 degree F (-40 degree C).

3. CSA certified - Plastic Type B roof vents, for installation

on sloping surfaces.

4. Model: Black (60PRO75BL) 21.875 inches x 21.875

inches x 5.5 inches (556 mm x 556 mm x 140 mm).

5. Model: Brown (60PRO75BR) 21.875 inches x 21.875

inches x 5.5 inches (556 mm x 556 mm x 140 mm).

6. Model: White (60PRO75W) 21.875 inches x 21.875

inches x 5.5 inches (556 mm x 556 mm x 140 mm).

7. Model: Grey (60PRO75G) 21.875 inches x 21.875 inches

x 5.5 inches (556 mm x 556 mm x 140 mm).

8. Model: Weatherwood (60PRO75WW) 21.875 inches x

21.875 inches x 5.5 inches (556 mm x 556 mm x

140 mm).

B. Product: WeatherPRO® 50 as manufactured by

Canplas Industries Ltd.

1. Design: Top venting design uses chimney effect to

channel moist air away from roof eliminating shingle

staining. Vent cap design with built in weeping holes

eliminates bird nesting and water pooling. Roof pitch

range 3/12 to 14/12. Net free venting area of 50 sq. in.

(322 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

and cold impact to -40 degree F (-40 degree C).

3. CSA certified – Plastic Type B roof vents, for installation

on sloping surfaces.

4. Miami Dade High Velocity Hurricane Zone certified:

NOA 04.0401.01.

5. Model: Black (60PRO50BL) 18-1/2 inches x 18-1/2

inches x 4-1/2 inches (470 mm x 470 mm x 114 mm).

6. Model: Brown (60PRO50BR) 18-1/2 inches x 18-1/2

inches x 4-1/2 inches (470 mm x 470 mm x 114 mm).

7. Model: White (60PRO50W) 18-1/2 inches x 18-1/2

inches x 4-1/2 inches (470 mm x 470 mm x 114 mm).

8. Model: Grey (60PRO50G) 18-1/2 inches x 18-1/2 inches

x 4-1/2 inches (470 mm x 470 mm x 114 mm).

9. Model: Weatherwood (60PRO50WW) 18-1/2 inches x

18-1/2 inches x 4-1/2 inches (470 mm x 470 mm x

114 mm).

C. Product: WeatherPRO® Slant Back as manufactured

by Canplas Industries Ltd.

1. Design: Top venting design uses chimney effect to

channel moist air away from roof eliminating shingle

staining. Vent cap design with built in weeping holes

eliminates bird nesting and water pooling. Roof pitch

range 3/12 to 14/12. Net free venting area of 50 sq. in.

(322 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

- 18 -

and cold impact to -40 degree F (-40 degree C).

3. CSA certified – Plastic Type B roof vents, for installation

on sloping surfaces.

4. Miami Dade High Velocity Hurricane Zone certified.

5. Model: Black (60PRO50SLBL) 18 inches x 24 inches

x 3-1/2 inches (457 mm x 610 mm x 89 mm).

6. Model: Brown (60PRO50SLBR) 18 inches x 24 inches

x 3-1/2 inches (457 mm x 610 mm x 89 mm).

7. Model: White (60PRO50SLW) 18 inches x 24 inches

x 3-1/2 inches (457 mm x 610 mm x 89 mm).

8. Model: Grey (60PRO50SLG) 18 inches x 24 inches

x 3-1/2 inches (457 mm x 610 mm x 89 mm).

9. Model: Weatherwood (60PRO50SLWW) 18 inches x

24 inches x 3-1/2 inches (457 mm x 610 mm x 89 mm).

D.

Product: 3 TIER WeatherPRO PROVentilator as

manufactured by Canplas Industries Ltd.

1. Design: Chimney style design allows ventilator to

harness wind energy and create pressure variances

that draw air out from within the attic space. Roof

pitch range 3/12 to 12/12. Net free venting area of

130 sq. in. (838 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

and cold impact to -40 degree F (-40 degree C).

3. Tested and passed the Miami Dade County TAS No.

100(A)-95 110mph (177kmh) wind driven rain test.

4. Model: Black (60PRO150BL) 21-1/8 inches x 21-1/8

inches x 22 inches (536 mm x 536 mm x 559 mm).

5. Model: Brown (60PRO150BR) 21-1/8 inches x 21-1/8

inches x 22 inches (536 mm x 536 mm x 559 mm).

6. Model: Gray (60PRO150G) 21-1/8 inches x 21-1/8

inches x 22 inches (536 mm x 536 mm x 559 mm).

7. Model: Weatherwood (60PRO150WW) 21-1/8 inches

x 21-1/8 inches x 22 inches (536 mm x 536 mm

x 559 mm).

E.

Product: 2 TIER WeatherPRO PROVentilator as

manufactured by Canplas Industries Ltd.

1. Design: Chimney style design allows ventilator to

harness wind energy and create pressure variances

that draw air out from within the attic space. Roof

pitch range 3/12 to 12/12. Net free venting area of

95 sq. in. (613 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

and cold impact to -40 degree F (-40 degree C).

3. Tested and passed the Miami Dade County TAS No.

100(A)-95 110mph (177kmh) wind driven rain test.

4. Model: Black (60PRO140BL) 21-1/8 inches x 21-1/8

inches x 19-1/2 inches (536 mm x 536 mm x 495 mm).

5. Model: Brown (60PRO140BR) 21-1/8 inches x 21-1/8

inches x 19-1/2 inches (536 mm x 536 mm x 495 mm).

6. Model: Grey (60PRO140G) 21-1/8 inches x 21-1/8

inches x 19-1/2 inches (536 mm x 536 mm x 495 mm).

7. Model: Weatherwood (60PRO140WW) 21-1/8 inches

x 21-1/8 inches x 19-1/2 inches (536 mm x 536 mm

x 495 mm).

F.

Product: 1 TIER WeatherPRO PROVentilator as

manufactured by Canplas Industries Ltd.

1. Design: Chimney style design allows ventilator to

harness wind energy and create pressure variances

that draw air out from within the attic space. Roof

pitch range 3/12 to 12/12. Net free venting area of

48 sq. in. (310 sq. cm).

2. Construction: Injection molded from pure, high grade

polypropylene with premium UV inhibitor additives.

Engineered to resist denting, peeling, extreme heat

and cold impact to -40 degree F (-40 degree C).

3. Tested and passed the Miami Dade County TAS No.

100(A)-95 110mph (177kmh) wind driven rain test.

4. Model: Black (60PRO130BL) 21-1/8 inches x 21-1/8

inches x 17 inches (536 mm x 536 mm x 432 mm).

5. Model: Brown (60PRO130BR) 21-1/8 inches x 21-1/8

inches x 17 inches (536 mm x 536 mm x 432 mm).

6. Model: Grey (60PRO130G) 21-1/8 inches x 21-1/8

inches x 17 inches (536 mm x 536 mm x 432 mm).

7. Model: Weatherwood (60PRO130WW) 21-1/8 inches

x 21-1/8 inches x 17 inches (536 mm x 536 mm

x 432 mm).

PART 3 EXECUTION

3.1

EXAMINATION

A. Do not begin installation until substrates have been

properly prepared.

B. If substrate preparation is the responsibility of another

installer, notify Architect of unsatisfactory preparation

before proceeding.

3.2

PREPARATION

A. Clean surfaces thoroughly prior to installation.

B. Prepare surfaces using the methods recommended by

the manufacturer for achieving the best result for the

substrate under the project conditions.

3.3

INSTALLATION

A. Install in accordance with manufacturer’s instructions

and in proper relationship with adjacent construction.

3.4

FIELD QUALITY CONTROL

A. Provide inspection certificates of Authority Having

Jurisdiction (AHJ).

3.5

PROTECTION

A. Protect installed products until completion of project.

B. Touch-up, repair or replace damaged products before

substantial completion.

END OF SECTION

Specifications

- 19 -

Notes

- 20 -

Canplas, manufacturer of Duraflo ventilation

products, has over 45 years of plastics manufacturing

experience. This expertise allows Duraflo to

continue as the innovation leader in roof ventilation.

Throughout our history Duraflo has listened to you,

the customer, to create solutions to meet your

building needs. In developing and maintaining an

open dialogue with both our internal and external

partners, we have created a wide variety of unique

products second to none in the marketplace.

CANADA

Canplas Industries Ltd.

P.O. Box 1800, 500 Veterans Drive

Barrie, Ontario

Canada L4M 4V3

1-800-461-5300

Tel: (705) 726-3361

Fax: (705) 726-2186

www.duraflo.com

USA

Canplas LLC

11402 East 53rd Ave., Suite 200

Denver, Colorado

U.S.A. 80239

1-888-461-5307

Tel: (303) 373-1918

Fax: 1-888-461-5309

Molding a better future

®

www.arcat.com

www.csc-dcc.ca

www.csinet.org

PRINTED IN CANADA

GD-02057-10-15