Full Text Searchable PDF User Manual

VIBMB402

086U8255 Rev 4

UK-specific appendix to

Installation instructions

DHP-A

DHP-A Opti

DHP-AQ Maxi

DHP-H

DHP-H Opti

DHP-H Opti Pro

DHP-L

DHP-L Opti

DHP-L Opti Pro

2 – Appendix UK

To be read together with Installation instructions

Contents

1

Important information/Safety regulations . . . . . . . . . . . . . . . . . . . 3

1 .1

Test results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2

About documents and labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

2 .1

Manufacturer labels . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

3

Piping installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 .1

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3 .2

System solution . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3 .3

Discharge pipe arrangement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4

Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

4 .1

How to flush the tap water system . . . . . . . . . . . . . . . . . . . . . . . . . .14

4 .2

How to drain the tap water system . . . . . . . . . . . . . . . . . . . . . . . . . .14

4 .3

Inspection access . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Appendix UK – 3

1

Important information/Safety regulations

DD

D D

These instructions are a UK-specific appendix to those instructions found in the Installation instructions .

DD

D D

Read the Installation instructions prior to installation .

DD

D D

For

DHP Opti Pro SP

(Single Phase) heat pumps it is imperative that the maximum hot water temperature

is altered from the default factory setting from 95°C to 60°C . Refer to Chapter 9 .8 menu Service – HGW

Parameter MAX TEMP in Installation instructions .

DD

D D

Hard Water Areas; Normally it is not a problem to install a heat pump in hard water areas since the normal

domestic hot water working temperature will be not greater than 60°C . In areas where exceptional water

conditions prevail, consideration may need to be given to the fitting of a device capable of inhibiting scale .

In such circumstances the advice of the local water authority should be sought .

DD

D D

The immersion heater, thermostat, and thermal cut-out are supplied by Danfoss and are factory fitted . If a

replacement part is necessary, it must be replaced with a Danfoss spare part .

DD

D D

The water heater is protected with a sacrificial aluminium anode . Under normal circumstances no mainte-

nance is needed .

DD

E D

Note! Leave the following documents with the end-user;

-

This manual

-

Installation instructions

-

User manual

The above documents are an integral and essential part of the product . They should be kept with the appli-

ance so that they can be consulted by the user and our authorised personnel .

Please read carefully the instructions and notices about the appliance contained in this manual, as they pro-

vide important information regarding the safe installation, use and maintenance of the heat pump .

1.1

Test results

1.1.1

Heat up time

The heat up time is measured when heating the water from 14°C to 60°C .

DWH 300: Heat up time 1 hour 53 minutes

DHP-H, DHP-A, DHP-AQ Maxi and DWH 200: Heat up time 1 hour 3 minutes

1.1.2

Re-heat time

The re-heat time is measured when 70% of the hot water has been drained and replaced by equal amount

14°C water and re-heated to 60°C .

DWH 300: Re-heat times 70% 1 hour 25 minutes

DHP-H, DHP-A and DWH 200: Re-heat time 70% 41 minutes

DHP-AQ Maxi: 1 hour 6 minutes according to EN12897 .

1.1.3

Pressure drop

The measured pressure drop throgh the primary heater is 15 kPa .

1.1.4

Hot water capacity

DHP-AQ Maxi: 160 liter according to EN12897 .

4 – Appendix UK

2

About documents and labels

2.1

Manufacturer labels

The heat pump and the indoor unit are marked with durable, permanently fixed labels .

2.1.1

Manufacturer label:

P. O. Box 950 SE-67129 Arvika

Sweden

DHP-H 6

Heat Pump

Source of heat Max

Mpa

0,3

System of heat Max

Mpa

0,3

Source of heat Min/Max

˚C

-10 / +20

Refrigerant Type

*R407C

Operation Pressure Min/Max

MPa

0,08/3,1

Refrigerant

Kg

1.2

Connection

Electric connection

V

400 3N~50Hz

Power input Total

kW

5,0/8,0/11,0

Power input Heat pump

kW

2.0

Power input Auxiliary Heater kW

3/6/9

Pressure Vessel

Volume Sec/Prim

l

180/7.5

Design Pressure Sec/Prim

MPa

1.0 / 0.3

Test Pressure Sec/Prim

MPa

1.43 / 0.43

Design Temp

˚C

100

Rating condition EN 14511

B0W35 A2/W35 A7/W35

(see technical documentation)

Heating capacity

kW

5.33

--

--

Coefficient of Performance

4.04

--

--

* This product contains fluorinated greenhouse

gases covered by the Kyoto Protocol

--

Serial No

086U5000*testBRE

086U5000*testBRE

Model --

YY-WW

09-33

IP

21

Appendix UK – 5

2.1.2

Manufacturer label: DHP-AQ

P. O. Box 950 SE-671 29 Arvika

Sweden

DHP-AQ CONTROL MAXI 6-13 SP

Heat Pump

Source of heat Max

Mpa

0

System of heat Max

Mpa

0

Source of heat Min/Max

˚C

Refrigerant Type

*

Operation Pressure Min/Max

MPa

--

Refrigerant

Kg

Connection

Electric connection

V

230 1N~50Hz

Power input Total

kW

3.1/6.1/9.1

Power input Heat pump

kW

Power input Auxiliary Heater kW

3/6/9

Pressure Vessel

Volume Sec/Prim

l

180/7.5

Design Pressure Sec/Prim

MPa

1.0 / 0.3

Test Pressure Sec/Prim

MPa

1.43 / 0.43

Design Temp

˚C

100

Rating condition EN 14511

B0W35 A2/W35 A7/W35

(see technical documentation)

Heating capacity

kW

--

Coefficient of Performance

--

* This product contains fluorinated greenhouse

gases covered by the Kyoto Protocol

--

Serial No

086U0283xxxxxxxx

086L0283xxxxx

Model CU-*104-303

YY-WW

11-27

IP

x 2

6 – Appendix UK

2.1.3

Additional label:

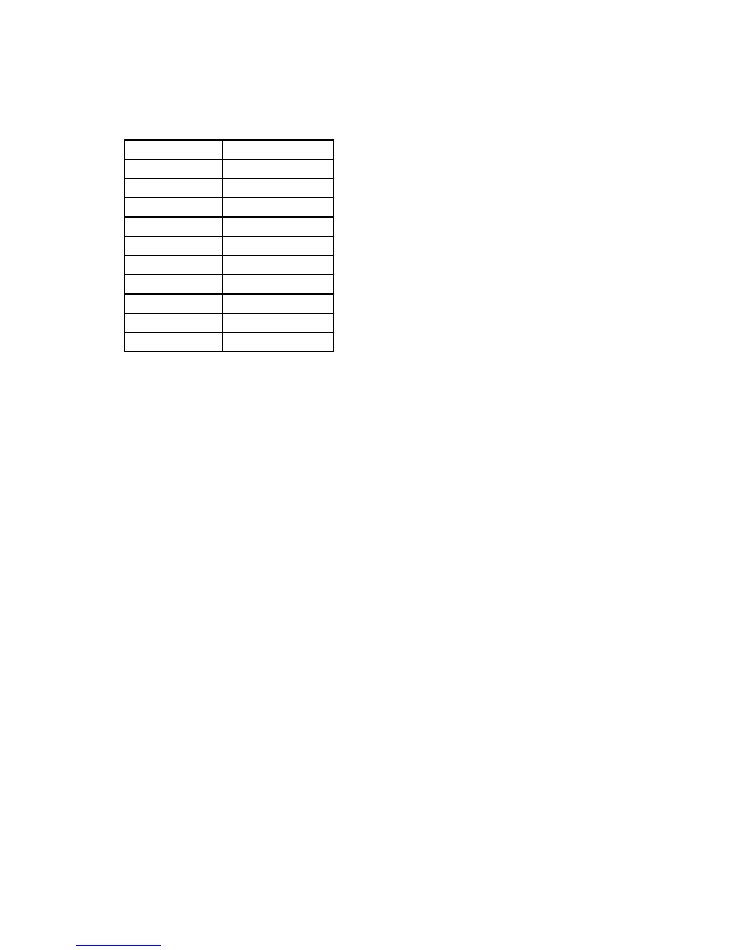

Weight when full (kg)

DHP-H 4

405

DHP-H 6

409

DHP-H 8

409

DHP-H 10

409

DHP-H 12

418

DHP-H 16

422

DHP-A 6

440

DHP-A 8

440

DHP-A 10

440

DHP-A 12

448

Heat Pump *)

*) Incl. DHP Opti and Opti Pro

This label will ensure that this product conforms to the

requirements of United Kingdom Building Regulations.

The information is entirely valid in a UK specific installations.

Maximum water supply pressure

10 bar

Pressure reducing valve

3 bar

Expansion valve

6 bar

Expansion vessel charge pressure

3 bar

Operating pressure

5,5 bar

Temp and pressure release valve

10 bar; 90−95˚C

Maximum primary working pressure

1,5 bar

Immersion heater

D76 / 9 kW / 230 V

WARNING TO THE USER

(a) Do not remove or adjust any component part of this

unvented water heater. Contact the installer.

(b) If this unvented water heater develops a fault, such

as a flow of hot water from the discharge pipe,

switch the heater off and contact the installer.

WARNING TO THE INSTALLER

(a) This installation is subject to building regulation approval,

notify the Local Authority of intention to install.

(b) Use only manufacturer's recommended replacement parts.

(c) INSTALLED BY:

Name._________________________________________

Address._______________________________________

Tel No._________________________________________

Completion date.________________________________

Appendix UK – 7

2.1.4

Additional label: DHP-AQ Control Maxi 6–13 SP

This label will ensure that this product conforms to the requirements

of United Kingdom Building Regulations and EN12897:2006.

The information is entirely valid in a UK specific installation.

Weight when full

286 kg

PT valve replacement no.

086U8267

Oper. temp non self-reset. thermostat

88˚C

Maximum flow temperature

65˚C

Operating pressure heat source

1 bar

Primary heating power input

9 kW

Primary flow rate

0,16−0,31 l/s

Actual capacity

180 liter

Standing heat loss

1,8 kWh / 24 h

Maximum water supply pressure

10 bar

Pressure reducing valve

3 bar

Expansion valve

6 bar

Expansion vessel charge pressure

3 bar

Operating pressure

5,5 bar

Temp and pressure release valve

10 bar; 90−95˚C

Maximum primary working pressure

1,5 bar

Immersion heater

D76 / 9 kW / 230 V

WARNING TO THE USER

a) Do not remove or adjust any component part of this

unvented water heater. Contact the installer.

b) If this unvented water heater develops a fault, such as a flow

of hot water from the discharge pipe,

switch the heater off and contact the installer.

WARNING TO THE INSTALLER

a) This installation is subject to Building Regulations notification.

b) Use only appropriate components for installation and maintenance.

c) INSTALLED BY:

Name.______________________________________

Address.____________________________________

Tel No._____________________________________

Completion date._____________________________

8 – Appendix UK

3

Piping installation

3.1

General

In section 5 .2 you will find connection diagrams .

3.1.1

Unvented package DHP and DWH200

Danfoss code reference UNV0180 .

Package contents:

Position Danfoss code

Number

Description

110

FITT0050

1

Expansion vessel 19 liter

-

FITT0052

1

Expansion vessel bracket

132

FITT0053

1

Flexible hose

-

FITT0001

1

Tundish 15x22 mm

129

FITT0054

1

Unvented manifold assembly

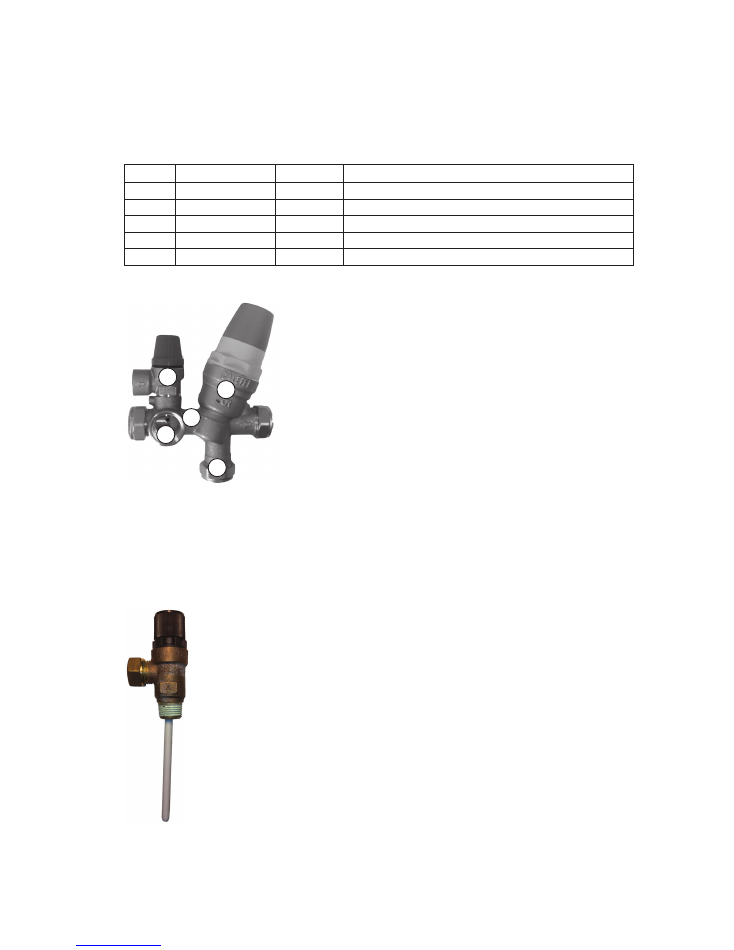

3.1.2

Unvented manifold assembly

E

A

B

C

D

Figure 1.

Unvented manifold assembly.

Position Name

A

Pressure reducing valve

B

Non-return valve

C

Cold water to house

D

To expansion vessel

E

Safety relief valve

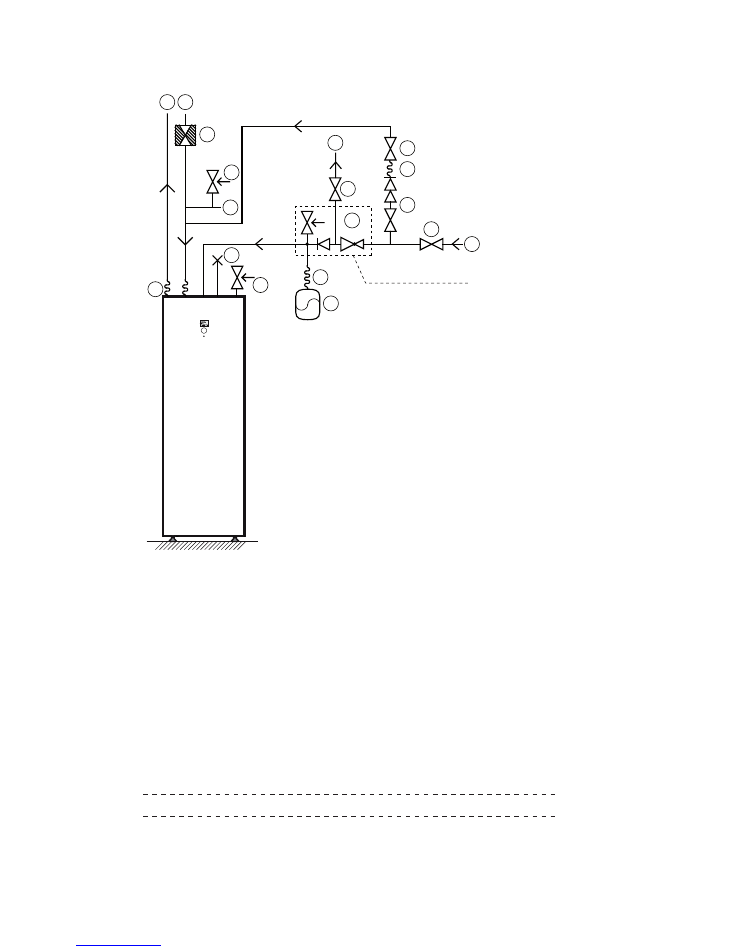

3.1.3

Temperature and pressure relief valve

Figure 2.

Factory fitted Temperature and pressure relief valve

Appendix UK – 9

3.2

System solution

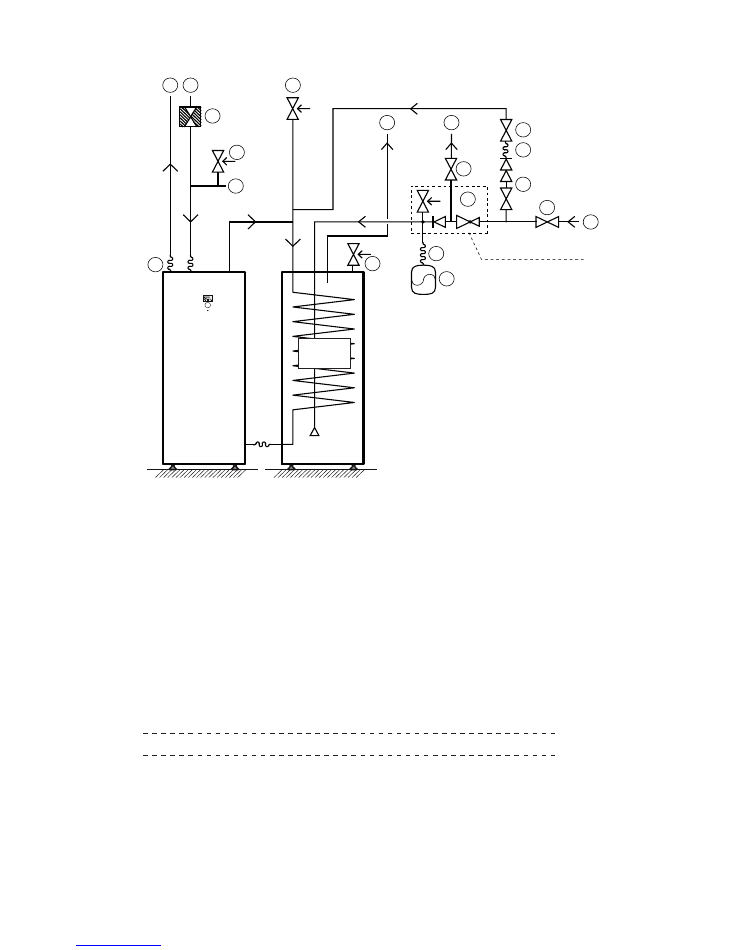

3.2.1

Unvented package installation, DHP-H and DHP-A models

126

110

80

128

96

80

86

80

129

132

91

96

10 11

113

12

12

85

Unvented manifold assembly

(see figure 1)

DHP-H

DHP-A

Figure 3.

The principal installation solution of the unvented package on DHP-H and DHP-A models.

Position Name

10

Supply line heating system

11

Return line heating system

12

Cold water

80

Shut-off valve

85

Venting valve

86

Safety relief valve heating system

91

Strainer

96

Flexible hose

110

Expansion vessel

113

Expansion heating system

126

Factory fitted combined Temperature and pressure relief valve*

128

Double check valve with Shut-off valve

129

Unvented manifold assembly: Pressure reducing valve, Safety relief valve, Non-return valve

132

Flexible hose Unvented package

*

) The water heater tank in DHP-H and DHP-A models is factory fitted with a Temperature and pressure relief

valve . The connection from this valve must not be used for other purposes other than discharge pipe con-

nection . Please see chapter 5 .3 Discharge pipe arrangement .

DD

E D

Note! No valve should be fitted between the safety relief valve and the storage cylinder .

10 – Appendix UK

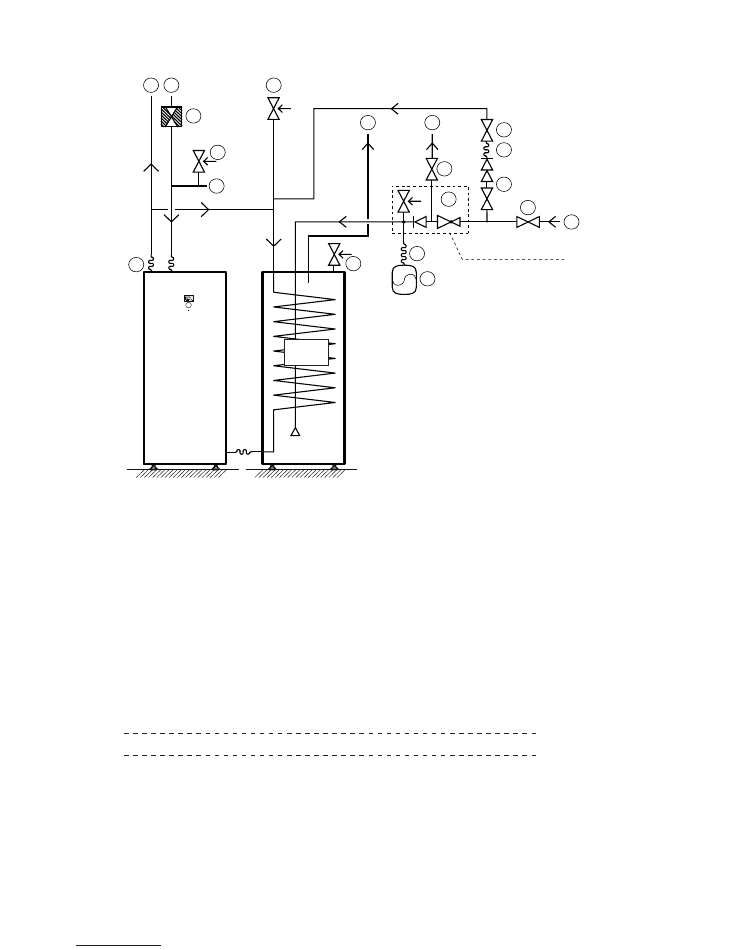

3.2.2

Unvented package installation, DHP-L models, DWH 200, DWH 300

DHP-L

126

110

80

128

96

80

104

80

129

132

Unvented manifold assembly

(see figure 1)

DWH 200

DWH 300

96

10 11

13

12

12

86

91

113

Figure 4.

The principal installation solution of the unvented package on DHP-L models together with DWH.

Position Name

10

Supply line heating system

11

Return line heating system

12

Cold water

13

Hot water

80

Shut-off valve

86

Safety relief valve heating system

91

Strainer

96

Flexible hose

104

Safety relief valve 2,5 bar

110

Expansion vessel

113

Expansion heating system

126

Factory fitted combined Temperature and pressure relief valve*

128

Double check valve with Shut-off valve

129

Unvented manifold assembly: Pressure reducing valve, Safety relief valve, Non-return valve

132

Flexible hose unvented package

*

) The water heater tank in DWH is factory fitted with a Temperature and pressure relief valve . The connec-

tion from this valve must not be used for other purposes other than discharge pipe connection . Please see

chapter 5 .3 Discharge pipe arrangement .

DD

E D

Note! No valve should be fitted between the safety relief valve and the storage cylinder .

Appendix UK – 11

3.2.3

Unvented package installation, DHP-L Opti Pro models, DWH 200, DWH 300

DHP-L Opti Pro

126

110

80

128

96

80

80

129

132

Unvented manifold assembly

(see figure 1)

DWH 200

DWH 300

96

10

13

12

12

104

11

86

91

113

Figure 5.

The principal installation solution of the unvented package on DHP-L Opti Pro models with DWH

Position Name

10

Supply line heating system

11

Return line heating system

12

Cold water

13

Hot water

80

Shut-off valve

86

Safety relief valve heating system

91

Strainer

96

Flexible hose

104

Safety relief valve 2,5 bar

110

Expansion vessel

113

Expansion heating system

126

Factory fitted combined Temperature and pressure relief valve*

128

Double check valve with Shut-off valve

129

Unvented manifold assembly: Pressure reducing valve, Safety relief valve, Non-return valve

132

Flexible hose Unvented package

*

) The water heater tank in DWH is factory fitted with a Temperature and pressure relief valve . The connec-

tion from this valve must not be used for other purposes other than discharge pipe connection . Please see

chapter 5 .3 Discharge pipe arrangement .

DD

E D

Note! No valve should be fitted between the safety relief valve and the storage cylinder .

12 – Appendix UK

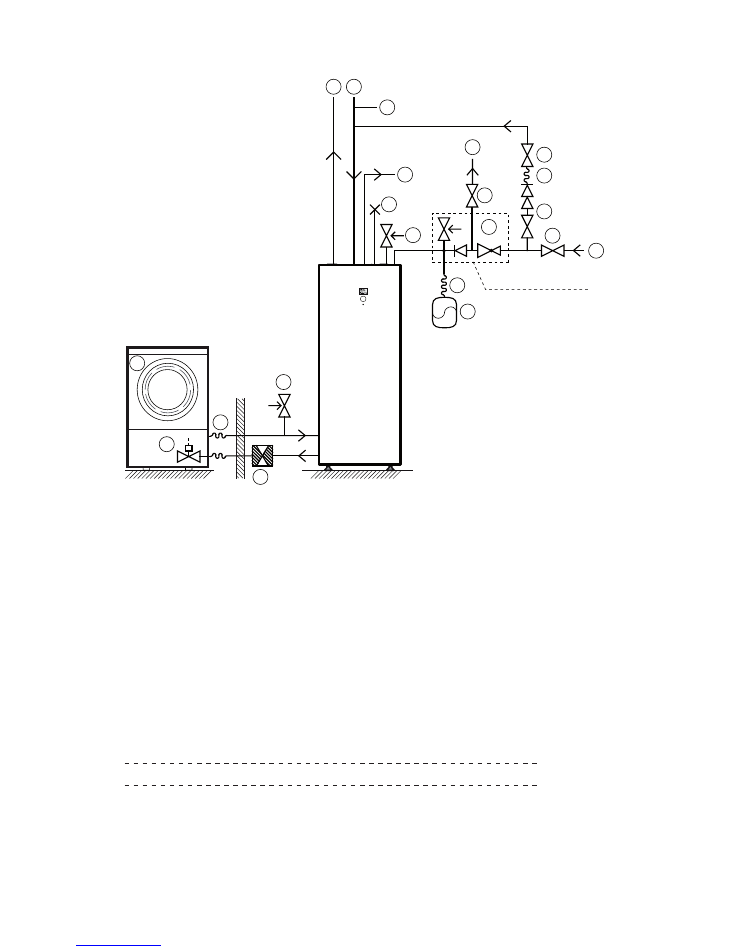

3.2.4

Unvented package installation, DHP-AQ Maxi

DHP-AQ Maxi

126

80

128

96

80

91

80

129

Unvented manifold assembly

(see figure 1)

96

10 11

13

12

12

100

113

5

71

110

132

85

Figure 6.

The principal installation solution of the unvented package on DHP-AQ Maxi

Position Name

5

Heat pump unit

10

Supply line heating system

11

Return line heating system

12

Cold water

13

Hot water

71

Flow guard

80

Shut-off valve

85

Venting valve

91

Strainer

96

Flexible hose

100

Safety relief valve

110

Expansion vessel

113

Expansion heating system

126

Factory fitted combined Temperature and pressure relief valve*

128

Double check valve with Shut-off valve

129

Unvented manifold assembly: Pressure reducing valve, Safety relief valve, Non-return valve

132

Flexible hose Unvented package

*

) The water heater tank in DHP-Q Maxi models is factory fitted with a Temperature and pressure relief valve .

The connection from this valve must not be used for other purposes other than discharge pipe connection .

Please see chapter 5 .3 Discharge pipe arrangement .

DD

E D

Note! No valve should be fitted between the safety relief valve and the storage cylinder .

Appendix UK – 13

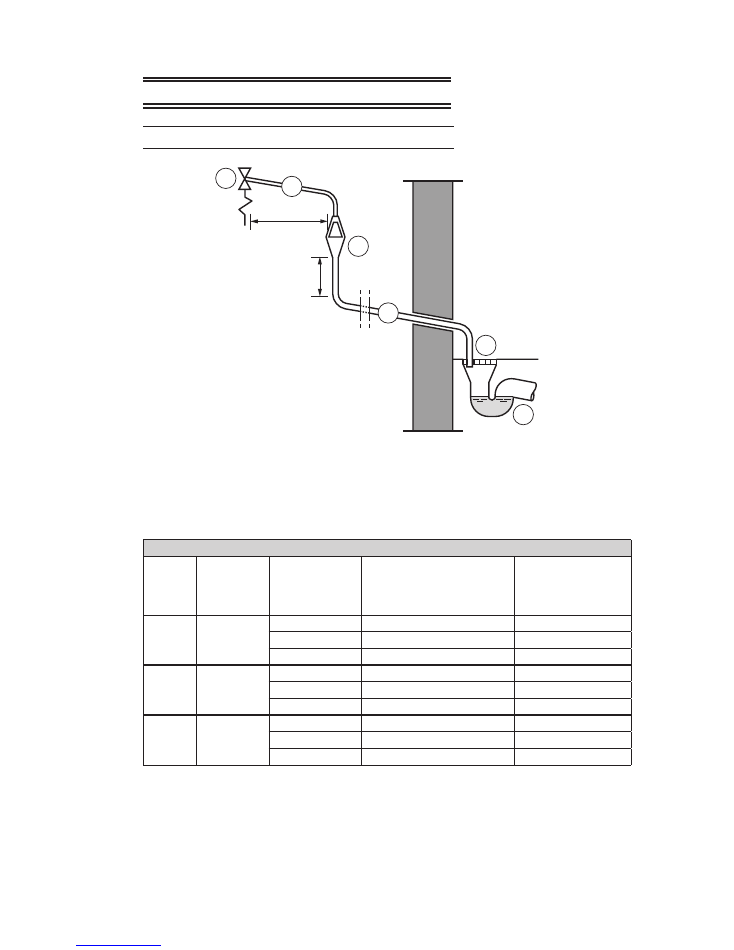

3.3

Discharge pipe arrangement

DD

B D

The tundish must be positioned away from any electrical devices .

DD

D D

The tundish must be installed so that it is visible to the occupants .

Figure 7.

3

4

5

6

1

2

600 mm maximum

300 mm minimum

The principal installation solution of the discharge pipe assembly.

Position Name

1

Safety device (for example, temperature relief valve)

2

Metal discharge pipe from safety device to tundish

3

Tundish

4

Discharge pipe from tundish, with continuous fall (1 in 200)

5

Discharge below fixed grating

6

Trapped gully

Sizing of copper discharge pipe (4) for common temperature relief valve outlet sizes

Valve

outlet

size

Minimum

size of dis-

charge pipe

(2)

Minimum size of

discharge pipe (4

from tundish)

Maximum resistance allowed,

expressed as a length of

straight pipe (that is, no

elbows or bends)

Resistance created by

each elbow or bend

G1/2

15 mm

22 mm

Up to 9 m

0 .8 m

28 mm

Up to 18 m

1 .0 m

35 mm

Up to 27 m

1 .4 m

G3/4

22 mm

28 mm

Up to 9 m

1 .0 m

35 mm

Up to 18 m

1 .4 m

42 mm

Up to 27 m

1 .7 m

G1

28 mm

35 mm

Up to 9 m

1 .4 m

42 mm

Up to 18 m

1 .7 m

54 mm

Up to 27 m

2 .3 m

14 – Appendix UK

4

Commissioning

4.1

How to flush the tap water system

When the tap water and the heating system have been filled up, the unit shall be running at maximal, nor-

mal operating temperature for a minimum of one hour . After that the tap water system shall be flushed out

and re-filled .

4.2

How to drain the tap water system

After the tap water system has been flushed out, the cold and hot water pipes and the water heater tank

need to be drained . To drain the system follow the instructions below:

1 .

Close the shut-off valve on the incoming water supply .

2 .

Open both cold and hot water taps which are situated as low as possible in the building to depressu-

rise the system .

DD

E D

Please note that there can be some water remaining in the cold water pipe which must be taken care of

when loosening the pipe .

3 .

Loosen and remove the cold water pipe at the top of the heat pump .

4 .

Insert a plastic hose to use as a siphon into the cold water connection and bring it to the bottom of

the water heater tank .

5 .

Place the other end of the hose near a gully .

6 .

Use the siphon effect to empty the water heater tank .

DD

E DD

For location and dimension of connections, please see chapter 4 .1 in the

Installation Instructions

.

4.3

Inspection access

The hot water tapping connection can be used as an inspection access .

Appendix UK – 15