Full Text Searchable PDF User Manual

INSTALLATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

2

3

CONTENTS

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

ACCESSORIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

HOW TO INSTALL BRC230Z4 / BRC230Z8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

HOW TO INSTALL BRC24Z4 / BRC24Z8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

INSTALLING REMOTE SENSOR 1 & 2 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

FIELD SETTING. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

DSI SWITCH SETTINGS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

HOW TO CONNECT BRCW902A15 EXTENSION CABLE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FAULT / INSPECTION / TEST MODE. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

FAULT CODE SHEET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

CONTROLLER MOUNTING BRACKET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

ELECTRIC WIRING WORK. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SUB CONTROLLER INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

4

SAFETY CONSIDERATIONS

Please read these “SAFETY CONSIDERATIONS” carefully before installing the zone controller and be sure to install it correctly.

After completing the installation, make sure that the zone controller operates properly. Please instruct the customer on how to

operate the zone controller.

Please inform the customer that they should store this installation manual along with the operation manual for future reference.

This controller comes under the term “appliances not accessible to the general public”.

Meaning of warning and caution symbols

WARNING

. . . . . . Failure to observe a warning may result in death, injury or damage to the equipment.

CAUTION

. . . . . . Failure to observe a caution may result in injury or damage to the equipment.

WARNING

Ask your Dealer or qualified personnel to carry out installation work. Do not try to install the zone controller yourself.

Perform installation work in accordance with this installation manual. Improper installation may result in electric shock or fire.

Be sure to use only the specified accessories and parts for installation work. Failure to use the specified parts may result in electric

shock, fire or the zone controller failing.

Make sure that all electrical work is carried out by qualified personnel according to local laws, regulations and this installation manual.

An insufficient power supply capacity or improper electrical construction may lead to electric shock or fire.

Make sure that all wiring is secured, the specified wires are used, and no external forces act on the terminal connections or wires.

Improper connections or installation may result in fire.

When wiring the power supply and connecting the wiring between the unit electrical box, zone controller box and zone motors,

position the wires so that the zone controller box cover can be securely fastened.

Improper positioning of the zone controller box cover may result in electric shock, fire or the terminals overheating.

Before obtaining access to the terminals and electrical parts, all supply circuits must be disconnected.

Do not install the remote controller where it may be exposed to rain or moisture. Water or other fluids on the electrical components

may result in fire or electric shock.

Earth the zone controller box. Do not connect the earth wire to gas or water pipes, a lightning conductor or a telephone ground wire.

Incomplete earthing may result in electric shock.

Be sure to install an earth leakage breaker. Failure to install an earth leakage breaker may result in electric shock.

Do not install the remote controller where flammable gases may leak, where there are carbon fibre or ignitable dust suspended in the air,

or where volatile flammables such as thinner or gasoline are handled.

Do not install the remote controller where the area is filled with steam or the ground is always wet. Insulation of the electric components

may be damaged in such conditions and may result in electric shock.

CAUTION

Install the zone controller, power cords and connecting wires at least 1 metre away from televisions or radios in order to

prevent image interference or noise.

(Depending on the radio waves, a distance of 1 metre may not be sufficient enough to eliminate noise.)

Do not install the zone controller in the following locations:

(a) Where a mineral oil mist, oil spray or vapour is produced, for example in a kitchen.

Plastic parts may deteriorate.

(b) Near machinery emitting electromagnetic waves.

Electromagnetic waves may disturb the operation of the control system and result in a malfunction of the equipment.

(d) Where salinity in the air is relatively high.

5

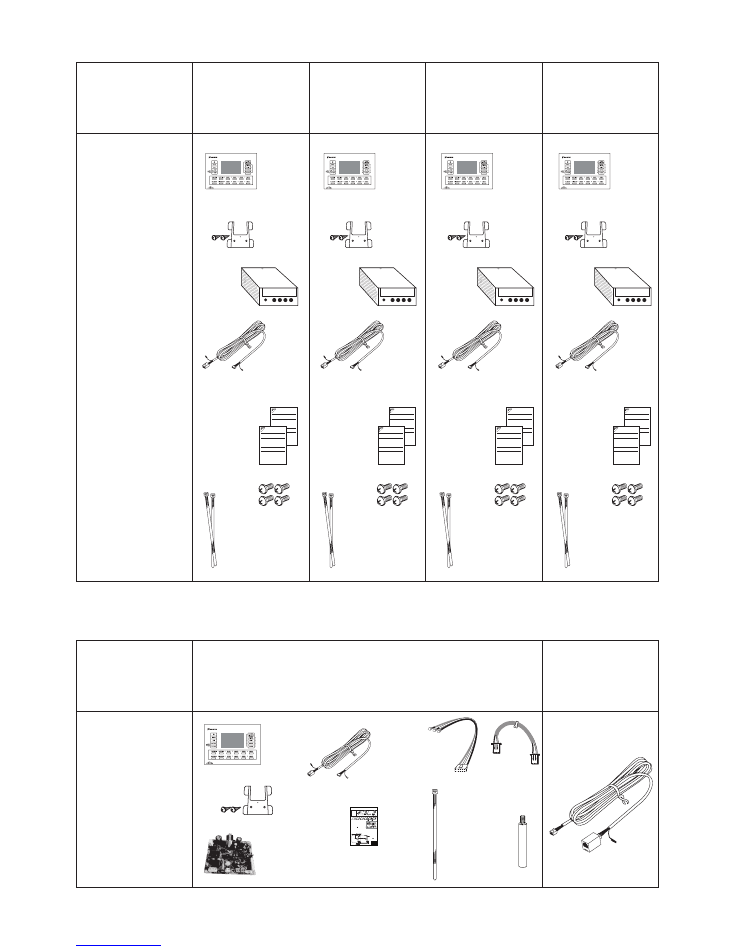

ACCESSORIES

MODEL

MODEL

(SUB CONTROLLER) BRCSZC

15M

EXTENSION

LEAD

BRCW902A15

SHAPE

&

QUANTITY

SHAPE

&

QUANTITY

(4 zone 230-240V)

BRC230Z4

(8 zone 230-240V)

BRC230Z8

(4 zone 24VAC)

BRC24Z4

(8 zone 24VAC)

BRC24Z8

CABLE

TIE

X 5

SUB ZONE

KEYPAD

X 1

P1/P2

HARNESS

X 1

POWER

HARNESS

X 1

PCB

POST

X 4

INTERFACE

PCB X 1

15M

CONTROLLER

CABLE

X 1

X 1

SCREW

X 2

MOUNTING

BRACKET

INSTALLATION

INSTRUCTION

X 1

230-240V

8 ZONE

CONTROL

BOX

X 1

M6 SCREW

X 4

SPARE

CABLE

TIE

X 2

ZONE

KEYPAD

X 1

15M

CONTROLLER

CABLE

X 1

24V

4 ZONE

CONTROL

BOX

X 1

M6 SCREW

X 4

SPARE

CABLE

TIE

X 2

ZONE

KEYPAD

X 1

15M

CONTROLLER

CABLE

X 1

SCREW

X 2

MOUNTING

BRACKET

X 1

INSTALLATION

INSTRUCTION X 1

OPERATION

MANUAL

X 1

INSTALLATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

OPERATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

24V

8 ZONE

CONTROL

BOX

X 1

M6 SCREW

X 4

SPARE

CABLE

TIE

X 2

ZONE

KEYPAD

X 1

15M

CONTROLLER

CABLE

X 1

SCREW

X 2

MOUNTING

BRACKET

X 1

INSTALLATION

INSTRUCTION X 1

OPERATION

MANUAL

X 1

INSTALLATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

OPERATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

SCREW

X 2

MOUNTING

BRACKET

X 1

INSTALLATION

INSTRUCTION X 1

OPERATION

MANUAL

X 1

INSTALLATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

OPERATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

230-240V

4 ZONE

CONTROL

BOX

X 1

M6 SCREW

X 4

SPARE

CABLE

TIE

X 2

ZONE

KEYPAD

X 1

15M

CONTROLLER

CABLE

X 1

SCREW

X 2

MOUNTING

BRACKET

X 1

INSTALLATION

INSTRUCTION X 1

OPERATION

MANUAL

X 1

INSTALLATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

OPERATION MANUAL

ZONE CONTROLLER

Air Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE READ THESE INSTRUCTIONS CAREFULLY BEFORE INSTALLATION.

KEEP THIS MANUAL IN A HANDY PLACE FOR FUTURE REFERENCE.

1. Insert one end of P1/P2 harness into socket S9 located on the lower interface

PCB (A1P). Diagram 1.

2. Loosen (4) plastic nuts. Diagram 2.

3. Screw in (4) PCB post and gently tighten. Diagram 3

4. Install upper Interface PCB (A2P) in the same direction as lower Interface

PCB (A1P). Diagram 4.

5. Add (4) plastic nuts and gently tighten. Diagram 4.

6. Plug the loose end of P1/P2 harness into socket S7 of upper Interface PCB

(A2P). Diagram 4.

7. Wire Power harness into LN terminal block X3M (Black- A)

(White –N) (Green – Earth). Diagram 5.

8. Plug the other end of the power harness into S1 socket of the upper Interface

PCB (A2P). Diagram 5.

9. Pass the Remote controller cable through the 2 open cable ties. If the cable

ties have already been tightened cut the cable ties and use the spare cable

ties supplied to secure the controller leads. Diagram 7.

10. Plug the remote controller cable connector into socket S8 of upper Interface

PCB (A2P). Diagram 6.

11. Wire the controller lead earth shield cable to the earth shield post. Diagram 7.

TO REMOTE CONTROLLER

TO RELAY PCB S19 (8 ZONE ONLY)

TO RELAY PCB S19 (4 ZONE)

A2P

A1P

L N E

S12

S7 S8

S2

S1

S1

S3

S13

S12

S13

S8

TN1

(NOTE 2)

TN2

S7 S8

S2

S3

S8

TO SUB CONTROLLER

TN1

TN2

TO P1 P2 TERMINAL

BLOCK (NOTE1)

B

W

G X3M

Sub Controller Instructions BRCSZC

S9

S9

S9

S9

S1

A N

S7

1

2

3

4

5

6

7

S9

S8

A N

ACCESSORIES

CABLE

TIE

X 5

SUB ZONE

KEYPAD

X 1

P1/P2

HARNESS

X 1

POWER

HARNESS

X 1

PCB

POST

X 4

INTERFACE

PCB X 1

15M

CONTROLLER

CABLE

X 1

MODE

FAN

TEMP

ADJUS

T

BUT

TO

N

TEMP

SHIF

T

7 DA

Y

TIME CLOC

K

ON/OFF

TIME

R

ENTE

R

CLEA

R

TEST/EXI

T DAY TIME ZONE1 ZONE2 ZONE3 ZONE

4

SEL

SENSO

R FIX SENSO

R

ZONE5 ZONE6 ZONE7 ZONE

8

MODE

FAN

TEMP

ADJUS

T

BUT

TON

TEMP

SHIF

T

7 DA

Y

TIME CLOC

K

ON/OFF

TIME

R

ENTE

R

CLEA

R

TEST/EXI

T DAY TIME ZONE1 ZONE2 ZONE3 ZONE

4

SEL

SENSO

R FIX SENSO

R ZONE5 ZONE6 ZONE7 ZONE

8

4PDA0687

NOTE:

1.

P1 P2 TERMINAL BLOCK

LOCATED IN THE ELECTRICAL

BOX OF INDOOR UNIT.

2.

TN1, TN2 ONLY USE DAIKIN

REMOTE TEMPERATURE

SENSOR KRCSO1-1

3. :TERMINAL

:CONNECTOR

4.

SYMBOLS SHOW AS FOLLOWS

B: BLACK

W: WHITE

G: GREEN

A1P INTERFACE PRINTED CIRCUIT BOARD

A2P INTERFACE PRINTED CIRCUIT BOARD

TN1 REMOTE SENSORS 1

TN2 REMOTE SENSORS 2

S1

S9-S7

S7

S8

CONNECTOR

230~240V

A1P 7 A2P COMMUNICATION

A1P INDOOR COMMUNICATION

REMOTE CONTROLLER

A1P

A2P

X3M

SCREW

X 2

MOUNTING

BRACKET

INSTALLATION

INSTRUCTIONS

INST

ALLA

TION

MANUAL

ZONE

CONTROLLER

Air

Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE

READ

THESE

INSTRUCTIONS

CAREFULL

YBEFORE

INST

ALLA

TION.

KEEP

THIS

MANUAL

IN A

HANDY

PLACE

FOR

FUTURE

REFERENCE.

OPTIONAL ACCESSORIES

6

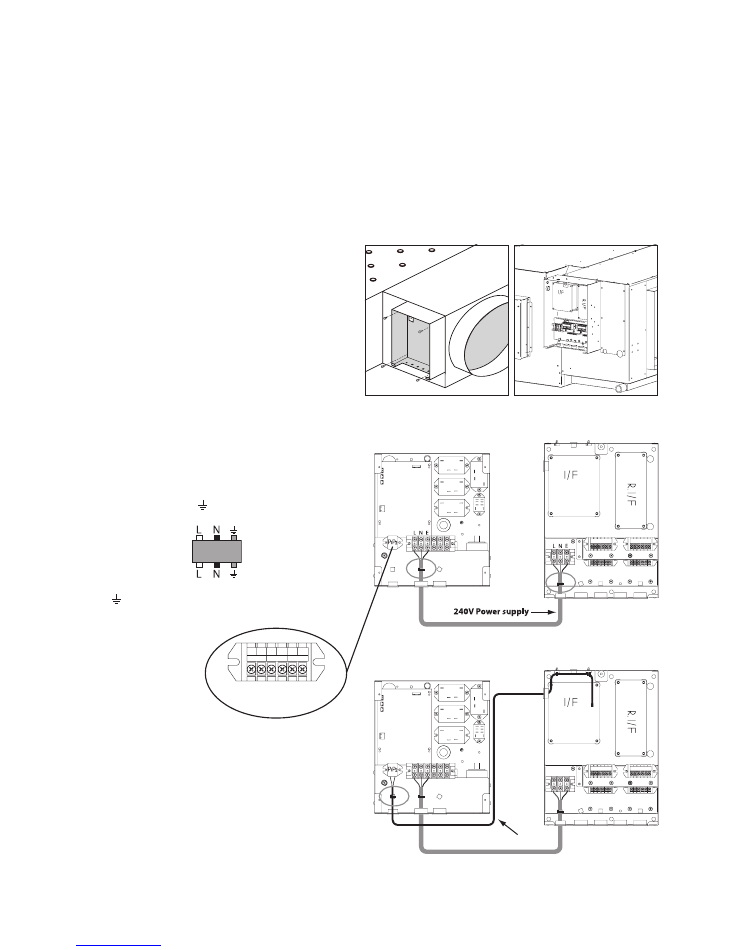

HOW TO WIRE & INSTALL BRC230Z4 / BRC230Z8

Step 1.

Attach the Zone control box to the body of the indoor

unit using the (4) M6 screws supplied. (Fig.1)

Be careful not to cause damage to the internal

components of the Zone control box when attaching the

box to the indoor unit.

Step 2.

Pass both ends of the field supplied cable through the

plastic bushes of the indoor unit electrical box and zone

controller box. Strip both ends of the cable. Connect the

stripped wires to the LN terminals of the unit electrical

box and the zone controller box.

By using a cable tie (field supplied), secure both ends of

the LN cable to the anchor as shown in (Fig.2)

ensuring the cable tie is secured to the outer insulation

of the cable.

Step 3.

Connect the loose end of P1 P2 communication cable to

the P1 P2 terminal block of the indoor unit electrical box.

(No polarity)

By using a cable tie (field supplied) secure P1 P2

communication cable to the anchor as shown in (Fig.3).

P1 P1 Communication wire

L N E

L N E

S7

Note 1:

You may find it easier to wire the control box before mounting the box to the indoor unit, for example when the

ceiling space is tight. If you choose to wire the control box before mounting it to the indoor unit ensure to allow

adequate cable length.

Note 2:

Please refer to Electric Wiring Work Pg. 14 of this manual to determine cable connection style and to ensure the

wiring connections are appropriate.

Note 3:

Ensure all field wiring passes through the black plastic wiring bushes located at the bottom of the controller box.

Fig.1

Fig.2

Fig.3

FDYQ(N)71-160

FDYQ(N)180-250

Indoor Unit Electrical Box Zone Controller Box

Indoor Unit Electrical Box Zone Controller Box

P1 P2 F1 F2 T1 T2

REMOTE

CNTRL

TRANSMISSION

WIRING

FORCED

OFF

Indicates 180 - 250

terminal block

7

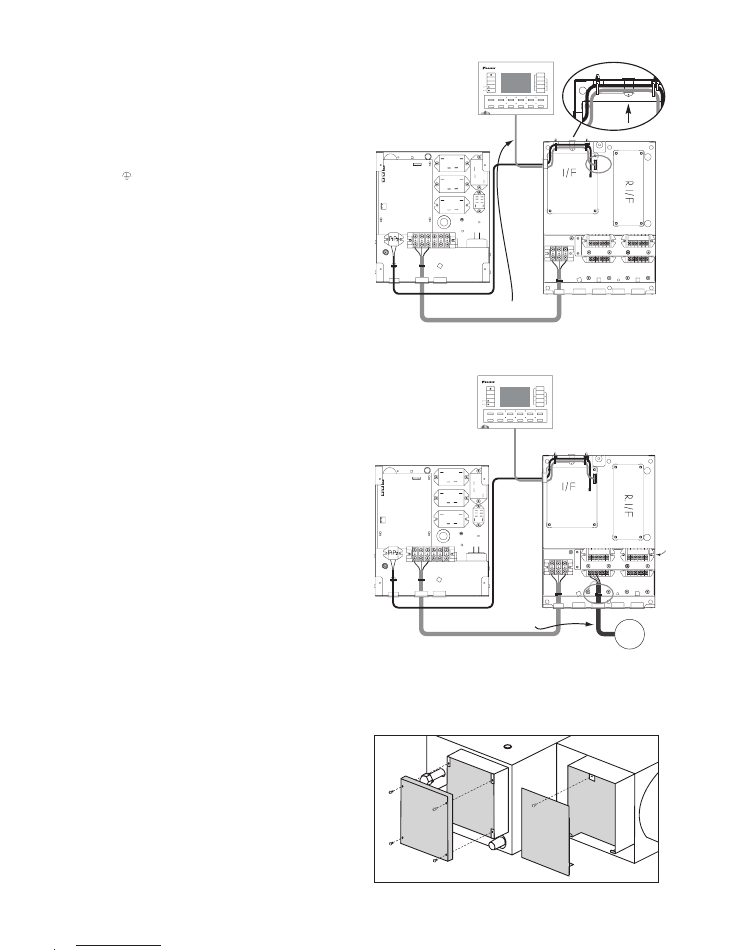

Step 4.

Pass the remote controller cable through the two open

cable ties (factory supplied).

Connect the remote controller cable to the Interface PCB

( A1P) by inserting the remote controller cable plug into

socket S8. (Fig.4)

Wire the shield wire of the remote controller cable to

the shield fastening point. (Fig.4a)

Note 4:

When installing KRCSO1-1 (option) or BRCSZC (option),

do not tighten the cable ties until you have passed all

cables through the 2 open cable ties.

Tighten the 2 cable ties to anchor. (Fig.4a)

Step 5.

Wire the zone motors to the zone motor terminal blocks

X4M (Fig.5) (zone motor field supplied)

Pay close attention to the terminal labelling.

When wiring “motor open motor closed” zone motors

ensure open, close & neutral wires are wired to

respective terminals.

Note 5:

For zone motors that require earthing.

(Ensure zone motors are earthed to the individual earth

connections provided.)

Open = Active

Closed = Active

Common = Neutral

When using a spring return zone motor only use the

Open & Common terminal connections.

By using a cable tie (field supplied), secure the zone

motor leads to the anchor as shown in (Fig.5) ensuring

the cable tie is secured to the outer insulation of the

cable.

Note 6:

Refer to DSI settings on page 12 before installing the

zone controller box cover.

Step 6.

Install the indoor unit electrical box cover and the zone

control box cover. (Fig.6)

Ensure the cover fits tightly and cables are not in contact

with the underside of cover or cover edges.

Remote controller wiring

L N E

L N E

S7

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

(AIP)

S8

Zone motor connection

L N E

L N E

S7

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

ZONE

MOTOR

X4M

Fig.4

Fig.4a

Fig.5

Fig.6

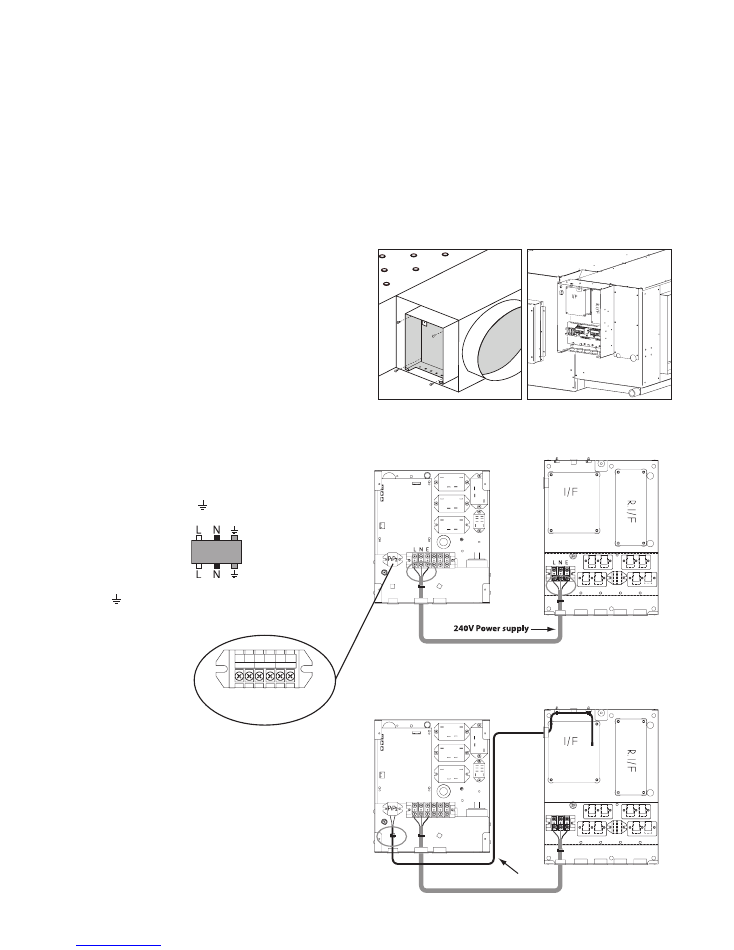

Step 1.

Attach the Zone control box to the body of the indoor

unit using the (4) M6 screws supplied. (Fig.1)

Be careful not to cause damage to the internal

components of the Zone control box when attaching the

box to the indoor unit.

Step 2.

Pass both ends of the field supplied cable through the

plastic bushes of the indoor unit electrical box and zone

controller box. Strip both ends of the cable. Connect the

stripped wires to the LN terminals of the unit electrical

box and the zone controller box.

By using a cable tie (field supplied), secure both ends of

the LN cable to the anchor as shown in (Fig.2)

ensuring the cable tie is secured to the outer insulation

of the cable.

Step 3.

Connect the loose end of P1 P2 communication cable to

the P1 P2 terminal block of the indoor unit electrical box.

(No polarity)

By using a cable tie (field supplied) secure P1 P2

communication cable to the anchor as shown in (Fig.3).

Note 1:

You may find it easier to wire the control box before mounting the box to the indoor unit, for example when the

ceiling space is tight. If you choose to wire the control box before mounting it to the indoor unit ensure to allow

adequate cable length.

Note 2:

Please refer to Electric Wiring Work Pg. 14 of this manual to determine cable connection style and to ensure the

wiring connections are appropriate.

Note 3:

Ensure all field wiring passes through the black plastic wiring bushes located at the bottom of the controller box.

8

24VAC

24VAC

P1 P1 Communication wire

L N E

L N E

S7

HOW TO WIRE & INSTALL BRC24Z4 / BRC24Z8

Fig.2

Fig.3

Indoor Unit Electrical Box Zone Controller Box

Fig.1

FDYQ(N)71-160

FDYQ(N)180-250

Indoor Unit Electrical Box Zone Controller Box

P1 P2 F1 F2 T1 T2

REMOTE

CNTRL

TRANSMISSION

WIRING

FORCED

OFF

Indicates 180 - 250

terminal block

9

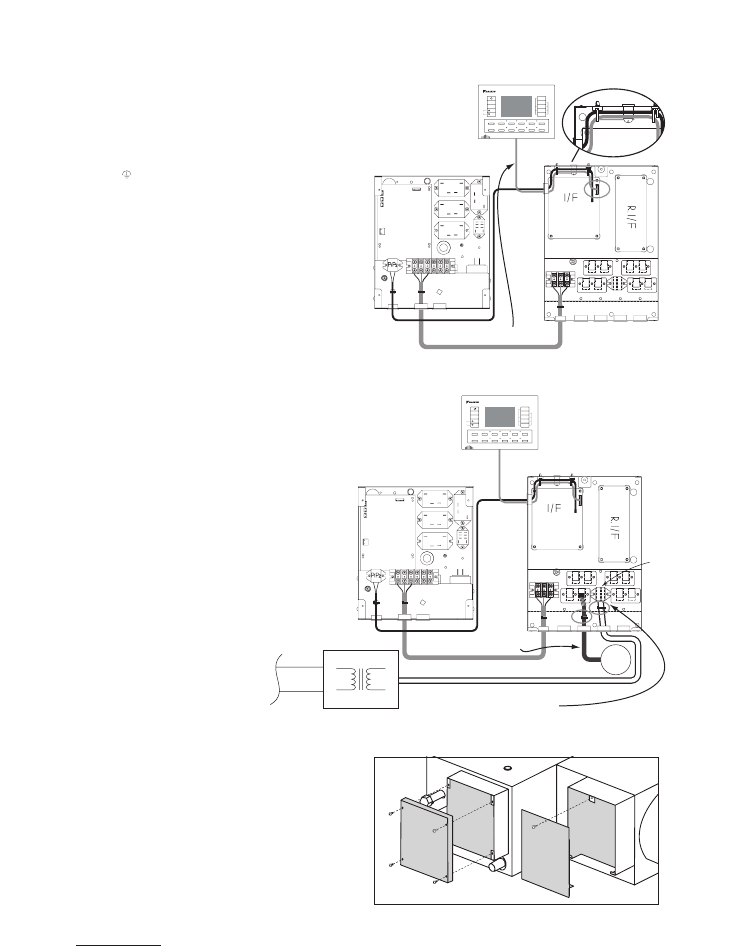

Step 4.

Pass the remote controller cable through the two open

cable ties (factory supplied).

Connect the remote controller cable to the Interface

PCB ( A1P) by inserting the remote controller cable plug

into socket S8. (Fig.4)

Wire the shield wire of the remote controller cable to

the shield fastening point. (Fig.4a)

Note 4:

When installing KRCSO1-1 (option) or BRCSZC

(option), do not tighten the cable ties until you have

passed all cables through the 2 open cable ties.

Tighten the 2 cable ties to anchor. (Fig.4a)

Step 5.

Connect the zone motor RJ12 plugs into the respective

zone sockets. (zone motors and leads field supplied)

By using a cable tie secure zone motor leads to the

anchor as shown in (Fig.5)

Step 6.

Wire 24V AC supply leads from the transformer (field

supplied) to the terminal block X5M located in the

zone controller box. (Fig.5)

By using a cable tie secure the 24V supply cable to

the anchor. (Fig.5)

Important: Ensure the transformer is adequately

sized for the zone motor electrical load and is

suitable for the installation conditions. (FIELD

SUPPLIED)

Note5:

Refer to DSI settings on page12 before installing the

zone controller box cover.

Step 7.

Install the indoor unit electrical box cover and the Zone

control box cover. (Fig.6)

Ensure the cover fits tightly and cables are not in

contact with the underside of cover or cover edges.

24VAC

Remote controller wiring

L N E

L N E

S7

(AIP)

S8

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

Fig.4

Fig.6

24VAC

Zone motor connection

L N E

L N E

S7

X5M

TRANSFORMER

CONNECTION

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

ZONE

MOTOR

220-240 V

24VAC

24 VAC

P

R

I

M

A

R

Y

S

E

C

O

N

D

A

R

Y

Fig.5

Fig.4a

INSTALLING REMOTE SENSOR 1 & 2

10

0

10

0

1

0

10

0

1

0

23

6

1

0

23

6

2

0 2

0 2

23

6

23

6

Step 1

Step 2

Step 3

Step 4

Step 5

Step 6

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

Blinking

KRCSO1-1

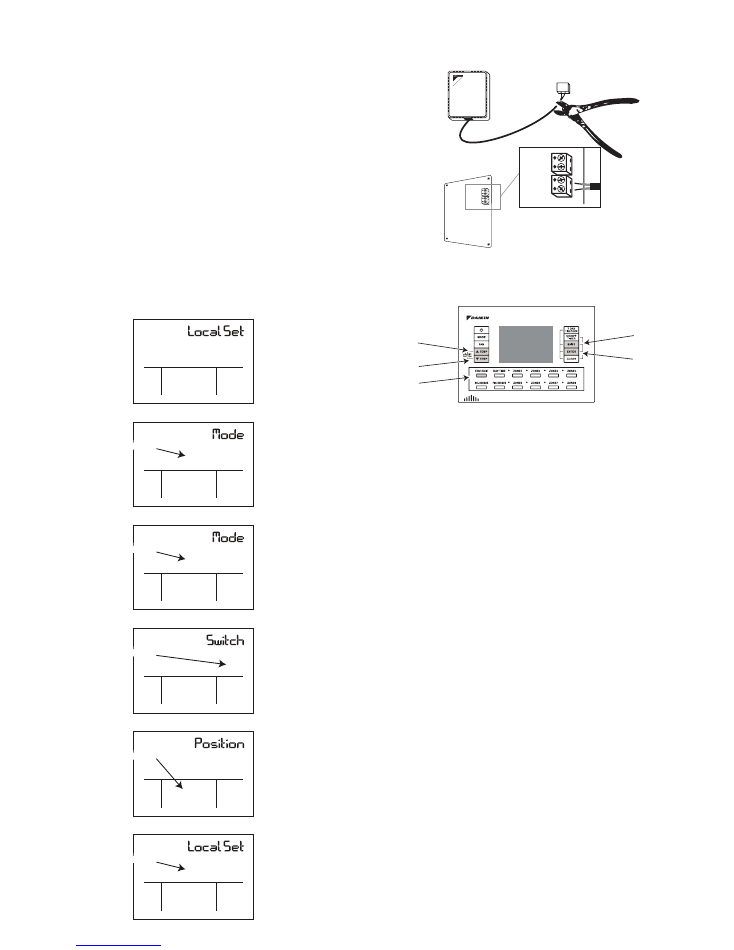

Step 1.

Using Daikin option KRCSO1-1 cut plug off lead. (Fig.7)

Step 2.

Carefully strip the insulation of the leads exposing the core wire. Insert

the 2 stripped wires into the two terminal holes of terminal block TN1.

Repeat the process using terminal block TN2 if a second sensor is

required.

Step 3.

Carefully tighten the terminal screws, be careful not to over tighten the

screws. (When connecting 1 sensor use terminal block TN1) Please

refer to note 4. (Page 7 or 9) Ensure cables are secured by the 2 cable

ties provided.

Do not allow KRCSO1-1 cables to come in contact

with live power or PCB’s.

FIELD SETTINGS

TEMP UP

TEMP DOWN

SHIFT

ENTER

TEST / ENTER

Example. How to set Field Setting 23-6-02 (High Static

Fan)

Step 1.

Press and hold the test button for approximately 4

seconds or until the “Local Set” screen is displayed.

(Note 1: If you do not continue to hold the test button

the inspection screen will be displayed, if the inspection

screen appears press the test button twice and the

screen will resume normal display.)

Step 2.

Press the “Shift” button once, “Mode” and the first digit

will be displayed. The first digit of the Field code

number will start to flash.

Step 3.

Choose the Field setting number you wish to set by

using the “Temperature up or down” buttons. Eg. 23

Step 4.

Press the “Shift” button once, “Switch” will be displayed

and the second digit will start to flash. By using the

“Temperature up” button change the second digit if

required. Eg. 6

(Note 2: Wait for the second digit to

appear before adjusting.)

Step 5.

Press the “Shift” button once, “Position” will be

displayed and the third digit will start to flash. By using

the “Temperature up” button change the third digit if

required. Eg. 02

Step 6.

Press the “Enter” button once, “Local Set” will be

displayed.

Step 7.

Press the “Test” button once. 88 may display for a few

seconds, normal display will resume once 88

disappears.

Fig.7

*Required for system set up. If field settings are not

entered the system will operate in the default

condition. (Pg.11)

TN1

PCB

(GREEN)

TN2

TN1

TN2

11

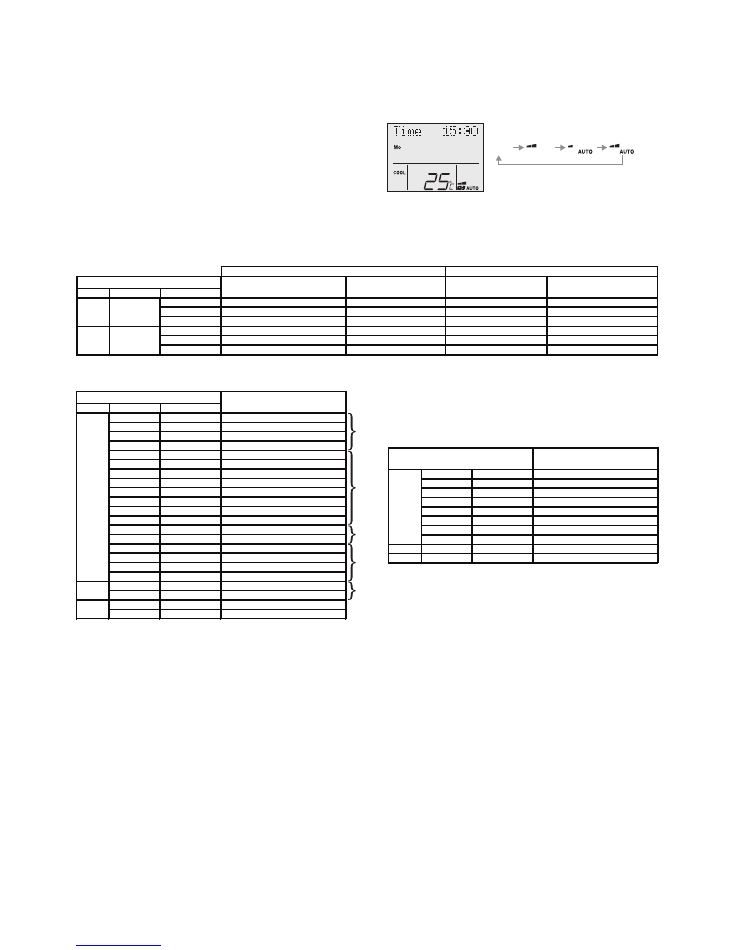

Note 3.

You have a choice of 5 temperature sensors.

1.) Indoor Sens – Temperature sensor located in the

indoor unit.

2.) Master RC - Master controller sensor

3.) Sub RC - When using option BRCSZC Sub controller.

4.) Sens 1 - When using option KRCSO1-1

5.) Sens 2 - When using option KRCSO1-1

Only the indoor sensor will be activated

(factory set) all other sensors must be activated by

the field set codes, once activated sensor selection

can be achieved by pressing the SEL SENSOR

button on the remote controller.

Temperature sensor activation

Zone restriction

Note 4.

Example: You may only require the use of 4 zones out

of the 8 available zones. By applying the Field setting

1b - 3 - 0_ you can restrict the number of zones you

want to operate, for example 4 zones. The remaining

unused zones will not function when the zone buttons

are pressed. ( 1b - 3 - 04 )

Before setting zone restriction make sure all zones are

switched off.

0

01

Sensor 1 OFF

1

01

Sensor 2 OFF

0

02

Sensor 1 ON

(Remote sensor KRCSO1-1 required)

1

02

Sensor 2 ON

(Remote sensor KRCSO1-1 required)

3

01

Zone 1 only

3

02

Zones 1-2

3

03

Zones 1-3

3

04

Zones 1-4

3

05

Zones 1-5

3

06

Zones 1-6

3

07

Zones 1-7

3

08

Zones 1-8

4

01

Keep 1 Zone ON

4

02

All Zones OFF

5

01

Master RC OFF

5

02

Master RC ON

6

01

Sub RC OFF

6

02

Sub RC ON

(Sub controller BRCZSC required)

6

01

Standard static pressure

(FDYQ(N)71-160 only)

6

02

High static pressure

(FDYQ(N)71-160 only)

3

01

Filter sign indication ON

3

02

Filter sign indication OFF

Set item

1b

Field Settings

Mode

Switch

Position

23

20

0

01

Sensor 1 OFF

1

01

Sensor 2 OFF

3

08

8 Zones available

4

02

All zones OFF

5

01

Master RC OFF

6

01

Sub RC OFF

2

01

Fan operation heating (Thermo off.)

7

01

Fan operation cooling (Thermo off.)

23

6

01

Standard static pressure

(FDYQ(N)71-160 only)

20

3

01

Filter sign indication ON

1b

Default Settings

Set item

Note 3.

Pg11

Note 4.

Pg11

Note 6.

Pg12

Note 3.

Pg11

Note 5.

Pg11

Fan static Pressure

Note 5.

When a higher airflow is required for example when the

pressure inside the ducting is high, use field setting

23-6-02 to increase the airflow.

For models with a capacity index of 180-250 please

refer to the installation instructions supplied with the air

conditioner.

Auto fan function with air sampling mode

Auto fan function will activate once the set point

temperature is achieved (thermo off) and will

deactivate when the room temperature is outside the

set point range (thermo on).

During Auto fan function the indoor fan will stop for a

period of 6 minutes and then start for a period of 30

seconds or more (depending on model) in order to

sample the room temperature.

Auto fan function will only activate when the “Indoor

Sens” (Indoor unit air temperature sensor) is selected.

Auto fan function will operate the same as Std. fan

function when other sensors are selected.

Fan operation during thermo. Off

Mode

Switch

Position

01

LL

OFF (Air sampling LL)

LL

OFF (Air sampling LL)

02

Set speed

OFF (Air sampling Set speed)

Set speed

OFF (Air sampling Set speed)

03

OFF

OFF (Air sampling OFF)

OFF

OFF (Air sampling OFF)

1

LL

OFF (Air sampling LL)

Set speed

2

Set speed

OFF (Air sampling Set speed)

Set speed

3

OFF

OFF (Air Sampling OFF)

Set speed

Set speed

Set speed

Set speed

Applies to models FDYQ(N)71FV1 & FDYQ(N)100-160KV1

Applies to models FDYQN200-250KV1 & FDYQ180-250MV1

1b

1b

2

Fan during heating

Std. Fan function

Auto fan function with

air sampling mode

7

Fan during Cooling

Std. fan function

Auto fan function with

air sampling mode

The table below indicates the possible Std. & Auto fan functions available during thermo off for heating & cooling,

please select the most appropriate fan function to suit the clients requirements.

Other field settings

Indoor fan settings

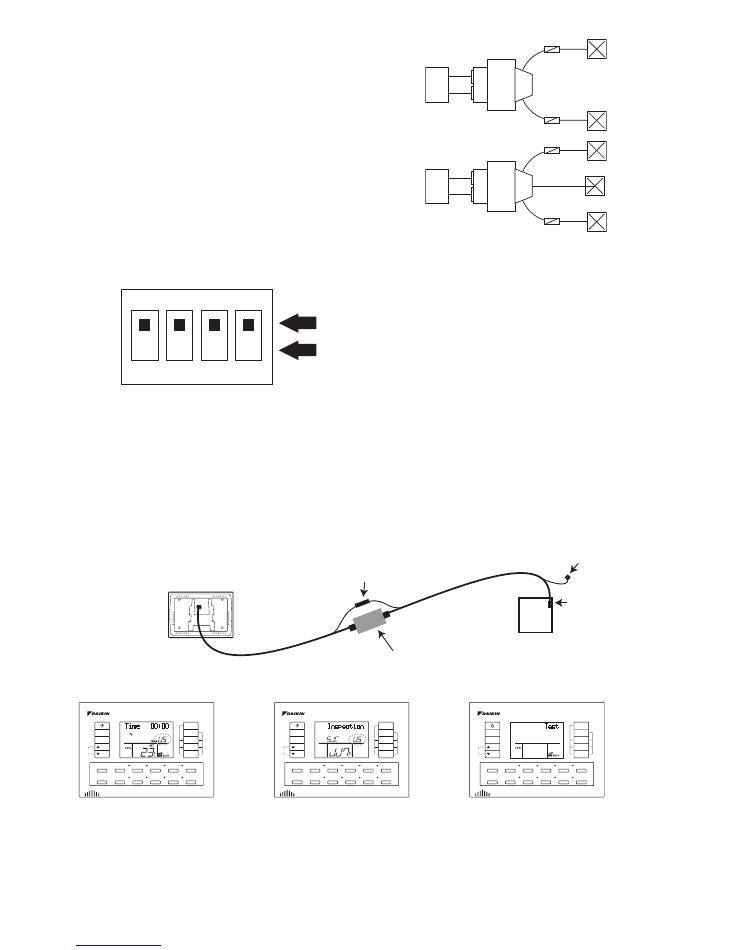

DS1 SWITCH

SW1 ON (Master controller) – When connecting one

remote controller only or when connecting two remote

controllers one controller must be selected to Master.

(Second controller is optional BRCSZC)

SW1 OFF (Sub controller) - When connecting two

remote controllers one controller must be selected to

Sub controller. (Second controller is optional BRCSZC)

SW2 Must remain in the ON position.

SW3 Must remain in the ON position.

SW4 ON (Start Up Delay Timer OFF)-The indoor fan

will start once the unit initialisation time is completed.

SW4 OFF (Start Up Delay Timer ON)-The indoor fan

will not start until at least 60 seconds has passed.

It is advisable when using spring return zone motors to

set SW4 OFF this will allow at least 60 second for the

zone motor to open before the indoor fan starts.

DS1 SWITCH

SW1 - ON = Master controller

SW1 - OFF = Sub controller

SW2 - No Function

SW3 - No Function

SW4 - ON = Start Up Delay Timer OFF

SW4 - OFF = Start Up Delay Timer ON

12

DS1

1

2

3

4

ON

OFF

Note 6.

Layout 1 (No Common Zone)

It is recommended to set the field set code to “Keep 1

Zone ON” One zone will remain on at all times when the

air conditioning unit is in operation to ensure damage to

the ducting system will not occur by over pressurising.

(1b - 4 - 01)

Layout 2 (Common Zone)

You can set “All Zones OFF” You will be able to

manually switch all the zones off if required.

(1b - 4 - 02)

ZONE 1

ZONE 2

ZONE 1

COMMON

ZONE 2

Duct Configuration

Back of controller

S8

Interface

PCB

Earth post

Earthed shield link

Adapter

How To Connect BRCW902A15 Extension Cable

(Optional Accessories)

DS1 Switch Settings

A two-digit code will flash on the

LCD screen when a fault occurs.

(Brief description of fault codes can

be found on Pg. 13.)

The inspection display will appear

once the TEST/EXIT button is

pressed. The inspection screen will

store the last fault code. To clear

the fault code press the clear

button for 4 seconds or until 00

appears. There are some fault

codes that will clear if the power is

switched OFF and then back ON again.

To enter the test mode press the

TEST/EXIT button twice. During the

test mode the system will be forced

to function according to the mode

set. The compressor will be forced to

operate for 30 minutes.

Fault Mode

Inspection Mode

Test Mode

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

Layout 1

Layout 2

13

0

1

2

3

EF

89

AH

Fa

n

in

te

rlo

ck

(ma

nua

l)

Ad

nor

ma

l

dra

in

wa

te

r

le

ve

l o

r p

lu

g

mi

ss

in

g

CJ

45

67

In

su

ffic

ient

wa

te

r s

upply

Dr

ain

le

ve

l

ab

ov

e

limi

t

AC

inpu

t ov

er-

cur

re

nt

Fa

ul

ty

el

ec

tron

ic

ex

pa

ns

io

n

va

lve

He

at

er

ov

er

hea

tin

g

Fau

lty

o

r di

rty

air

cl

ea

ne

r

E

H

No

load

up

Fa

ul

ty

ca

pa

ci

ty

se

ttin

g

Adn

or

ma

l h

ea

t

ex

ch

an

ger

(1)

tem

p.

Ad

no

rm

al

he

at

ex

cha

nge

r (

2)

te

mp

.

Fa

n

mo

to

r

ove

rloa

d ov

er-

cu

rre

nt

lo

ck

Ai

r d

ire

cti

on

adjus

t m

ot

or

lo

ck

Ac

tiv

ati

on of

saf

et

y de

vic

e

(g

en

er

al)

Fa

ul

ty

PC

B

In

do

or

INDOOR

OUTD

OOR

Fa

ul

ty

se

ns

or

sy

stem

(g

ener

al

)

U

F

J

L

P

A

C

Fa

ul

ty

dr

ain

wa

te

r le

ve

l

se

ns

or

sy

stem

Fa

ul

ty

heat

ex

ch

ange

r

te

mp

. se

ns

or

sy

stem

(R

2T

)

Fa

ul

ty ga

s

pipe

te

mp

.

sen

so

r sy

stem

(R

3T)

Fa

n

mo

to

r

ov

er

lo

ad

ov

er

-

cu

rre

nt, fa

ul

ty

lo

ck

se

ns

or

sy

stem

Ai

r d

irec

tion

m

oto

r lo

ck

,

fa

ul

ty se

nso

r

sys

te

m

Fa

ult

y AC

in

pu

t

cu

rren

t s

en

so

r

Fa

ul

ty a

ir

su

cti

on

te

mp

.

se

nso

r sy

stem

(R1

T)

Fa

ult

y ai

r

su

ct

io

n

te

mp

.

se

ns

or s

ys

te

m

Fault

y or

di

rty

se

ns

or

Fa

ul

ty

hum

idit

y

se

ns

or

sy

stem

Faul

ty te

mp

.

sens

or

(re

mo

te

co

nt

ro

lle

r)

Faul

ty

ra

diat

ion

sens

or

sy

stem

Faul

ty

high

pr

essu

re

swit

ch

Ac

tiva

tio

n o

f

sa

fe

ty dev

ic

e

(g

ener

al

)

Fa

ult

y PC

B

out

do

or

Ab

no

rma

l h

ig

h

pre

ssu

re

(HP

S)

Co

m

pre

ss

or

m

ot

or

ov

er

lo

ad

Co

mp

re

sso

r

mo

to

r ov

er-

cu

rre

nt

lo

ck

Ab

no

rm

al

lo

w

pr

es

su

re

(LP

S)

Ou

t d

oor

fa

n

mo

to

r ov

er

lo

ad

ov

er

-c

urr

en

t

lo

ck

AC

in

pu

t o

ver

-

cu

rre

nt

Fa

ul

ty

el

ec

tron

ic

ex

pa

nsi

on

va

lve

Pu

mp

ov

er

-

cur

re

nt

lo

ck

Ad

nor

ma

l

wa

te

r te

mp

.

Ac

tiva

tion

of

field add

ed

sa

fe

ty

de

vice

Faul

ty

dr

ain

wa

te

r le

ve

l

sy

stem

Fa

ul

ty h

eat

stor

age uni

t

Fa

ul

ty

se

nso

r

sy

stem

(g

ener

al

)

Fa

ul

ty

ai

r

te

mp

. se

ns

or

sy

stem

Fau

lty p

ow

er

suppl

y se

ns

or

sys

te

m

Fa

ult

y h

ig

h

pr

es

su

re

sw

itc

h

Fau

lty

lo

w

pre

ss

ure

sw

itch

Com

pr

esso

r

mo

to

r fa

ult

y

ov

erl

oa

d

se

ns

or

sy

stem

Co

m

pr

es

so

r

mo

to

r ov

er

-

cu

rre

nt

lo

ck

fa

ult

y s

ens

or

sy

stem

Abn

or

m

al

ou

td

oo

r fa

n

mo

to

r si

gn

al

Faul

ty

AC

in

pu

t

po

we

r se

ns

or

sy

stem

Fa

ult

y o

ut

door

air

te

mp

.

sen

so

r sy

stem

Fa

ult

y

dis

ch

arge ai

r

te

mp

. s

ens

or

sy

ste

m

Pu

m

p

ov

er

-

cu

rre

nt

lo

ck

fa

ult

y se

nso

r

sy

stem

Fa

ul

ty

ho

t

wa

te

r se

ns

or

sy

stem

Fa

ul

ty

dr

ain

wa

te

r le

ve

l

se

ns

or

sy

stem

Heat

st

or

age

un

it alar

m

Ac

tiv

ati

on o

f

co

mm

on

sa

fe

ty dev

ic

e

fo

r sy

ste

m

No

.

1

&

No.

2

Ac

tiva

tion

of

sa

fet

y d

evi

ce

fo

r sy

ste

m

No

.

1

Ac

tiva

tion

of

sa

fe

ty d

ev

ic

e

fo

r s

ys

te

m N

o.

2

Fa

ul

ty

dis

cha

rg

e pi

pe

te

mp

.

Re

frig

er

an

t

ov

erc

ha

rg

e

Adn

or

ma

l

dis

ch

ar

ge

pre

ss

ur

e

Ad

no

rm

al

hi

gh

oil

te

mp

.

Adno

rm

al

su

cti

on

pre

ss

ure

Ad

nor

ma

l oil

pr

es

su

re

Adno

rm

al

su

rfac

e

oil

le

ve

l

Fa

ult

y

ref

rige

ra

nt

te

mp

. se

ns

or

sy

ste

m

Fa

ult

y

pr

es

su

re

se

nso

r s

ys

te

m

(g

ene

ra

l)

Fa

ult

y cu

rren

t

se

ns

or

sy

ste

m

Fa

ul

ty

di

sc

ha

rg

e p

ip

e

te

m

p.

se

nso

r

sy

stem

Fa

ult

y lo

w

pre

ss

ur

e

eq

uiv

alen

t

sa

tu

ra

tio

n

tem

p.

se

nso

r

sy

ste

m

Fa

ul

ty su

cti

on

pi

pe

te

mp

.

se

nso

r sy

stem

Fa

ul

ty h

ea

t

ex

change

r

te

mp

. se

nso

r

sy

stem

(R

4T

)

Fa

ult

y r

ec

ei

ver

ou

tle

t liq

ui

d

pip

e s

en

sor

(R

7T

)

Fa

ult

y liq

uid

pip

e

te

m

p.

se

nso

r sy

stem

Fau

lty

su

bc

oo

ler

h

ea

t

exc

ha

nge

r ga

s

pipe

sen

so

r

(R

5T

)

Fa

ult

y

dis

cha

rg

e

pre

ss

ure

se

nso

r sy

stem

Fault

y o

il

te

mp

. se

nso

r

sys

te

m

Fa

ult

y su

ct

io

n

pre

ssu

re

se

ns

or

sy

stem

Fa

ul

ty o

il

pr

es

sur

e

se

ns

or

sys

te

m

Fa

ul

ty su

rfa

ce

oil le

vel

sen

sor

sy

ste

m

Fa

ul

ty IN

V

sy

stem

Fa

ul

ty

PC

B

Adn

orm

al

te

mp

. r

ise

in

side

c

on

tro

l

bo

x

Ad

no

rm

al

te

m

p.

ri

se

o

f

ra

dia

tion

fin

(po

we

r

transi

stor

)

DC

ou

tp

ut o

ver

-

cur

ren

t-

in

sta

nt

an

eo

us

AC

ou

tp

ut

ove

r-

cur

re

nt

-

in

sta

nta

ne

ou

s

Air

co

nd

itio

ner

(mu

lti)

ge

ne

ra

l

in

pu

t o

ve

r-

cur

ren

t

In

ve

rte

r c

urr

en

t

ab

no

rma

l

In

ve

rte

r st

ar

t-

up

er

ror

Fa

ult

y po

we

r

tran

sis

to

r

Fau

lty

tran

sm

iss

ion

be

tw

ee

n IN

V

and c

on

tro

l

PC

B

G

as

sh

or

ta

ge

(ice

th

erm

al

sto

ra

ge

eq

uipm

ent

)

High

vo

ltag

e

of

cap

ac

itor

in

in

ve

rte

r ci

rc

uit

or

po

we

r

im

ba

la

nc

e

Fau

lty

te

mp

.

ris

e

se

ns

or

in

side

co

nt

ro

l

bo

x

Fa

ult

y

ra

dia

tion

fin

(p

ow

er

tran

sist

or

)

te

mp

. ri

se

Fa

ul

ty

DC

cu

rre

nt

se

ns

or

sy

stem

Fau

lty

AC

o

r

DC

ou

tp

ut

cu

rren

t se

ns

or

sy

ste

m

Air

co

nd

itio

ner

(mu

lti)

ge

ner

al

inpu

t ov

er

-

cu

rre

nt

Fa

ilu

re

o

f

transm

issi

on

bet

we

en

ind

oo

r and

ou

td

oo

r unit

s

Fa

ul

ty

tran

sm

issi

on

be

tw

een

in

doo

r uni

t a

nd

re

mo

te

co

nt

ro

lle

r

Fa

ul

ty

tran

sm

iss

io

n

bet

ween

in

door

unit

s

(m

ai

n

&

su

b)

Sh

or

t o

f g

as

Re

ver

se

d

ph

as

e

co

nn

ec

tion

Fa

ul

ty p

ow

er

su

pply

vo

ltage

Fa

ult

y

tran

sm

issi

on

(gener

al

) or

ch

ec

k

oper

ati

on

is

no

t co

mp

le

te

Im

pr

op

er

co

mb

in

ati

on o

f

in

doo

r &

ou

td

oo

r,

in

do

or

&

re

mo

te

c

on

t.

Fa

ul

ty

ca

pa

ci

ty

set

ting

SYSTE

M

In

co

rre

ct

wir

ing

/p

ip

ing

(w

iri

ng

/p

iping

co

nnec

tion

erro

r)

In

do

or

/o

ut

do

or

un

it ad

dr

es

s

no

t en

te

re

d

Fa

ult

y c

ent

ra

l

con

tro

l

addr

ess

se

tting

(A

dd

re

ss

dupl

ica

tion

s)

Faul

ty

tran

sm

issi

on

to

/fr

om

pe

rip

her

al

equipm

en

t (a

ir

cont

ro

l

Faul

ty

tran

sm

issi

on

be

tw

een

indoor

uni

t and

ce

nt

ra

l

co

nt

ro

lle

r

Fa

ult

y

tra

ns

mi

ss

io

n

be

tw

ee

n

ou

td

oo

r unit

s

Fa

ult

y

tra

nsm

issi

on

to

/fr

om

re

m

ot

e

co

nt

ro

lle

rs

(m

ain

&

su

b)

Fa

ult

y

tra

ns

mi

ss

io

n

be

tw

een

indoor

&

ou

td

oo

r in

th

e

sa

me

sy

stem

Co

nte

nts

Co

de

Sec

tio

n

Co

de

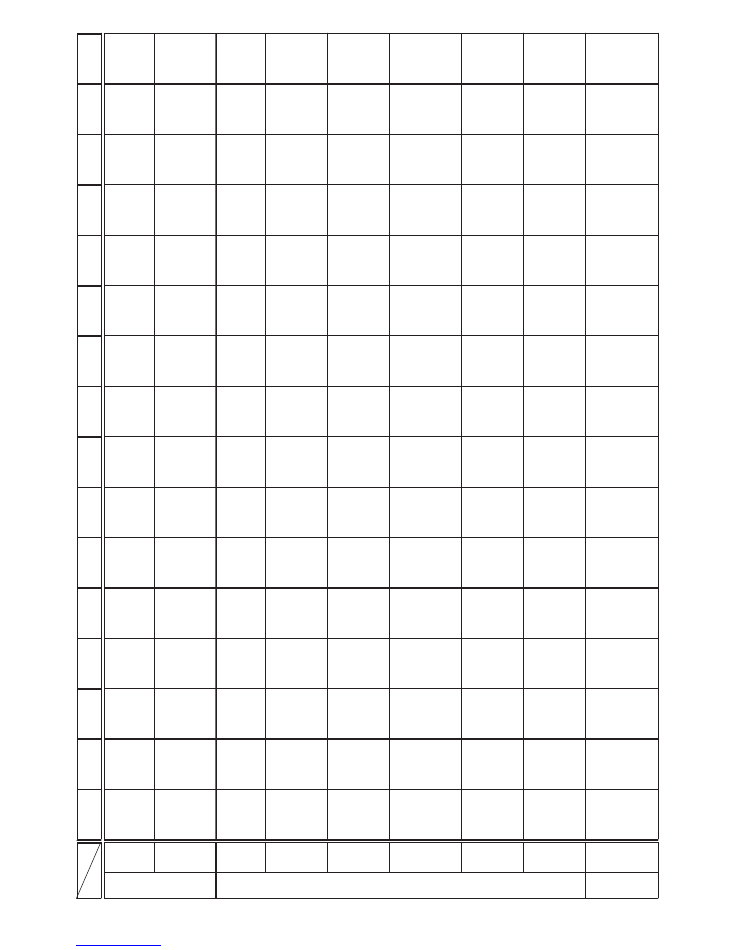

14

Round crimp-style

terminal

Electric wire

PRECAUTIONS

Precaution for wiring on site

Do not clamp remote controller cords together with wires connecting the units together. Doing so may cause malfunction.

Remote controller cords and wires connecting the units should be located at least 50 mm from other electric

wires. Failure to follow this guideline may result in malfunction due to electrical noise. Read the notes mentioned

below when wiring to the power supply terminal block. Precautions to be taken for power supply wiring. (Use a

round crimp-style terminal for connection to the power supply terminal block. In case it cannot be used due to

unavoidable reasons, be sure to observe the following instructions.)

Do not connect wires of different gauge to the same power supply terminal. (Looseness in the connection may

cause overheating.)

When connecting wires of the same gauge, connect them according to the figure.

Make certain that prescribed wires are used, carry out complete connections, and secure the wires so that

outside forces are not applied to the terminals.

CAUTION

After connecting the wires, be sure that no pressure is applied to the wire connections by using cable ties (field

supplied) and securing them to the anchor points. Also, when wiring, make sure the cover of the terminal box fits

snugly by arranging the wires neatly and attaching the terminal box cover firmly. When attaching the terminal box

cover, make sure no wires get caught under the edges.

Make sure the remote control cord, the wiring between the electrical boxes, and other electrical wiring do not pass

through the same locations outside the unit, separating them by at least 50 mm, otherwise electrical noise

(external static) could cause interference to the control system.

All field supplied parts and materials and electric works must conform to local codes. (ie. AS / NZS 3000)

Use copper wire only.

For electric wiring work, refer also to the "WIRING DIAGRAM" label attached to the electrical box cover.

For remote controller wiring details, refer to this installation manual.

All wiring must be performed by an authorised electrician in accordance with local codes. (ie. AS / NZS 3000)

A circuit breaker capable of shutting down power supply to the entire system must be installed.

Ensure that the air conditioner and zone controller box are effectively earthed.

CORRECT

WRONG

WRONG

Connect wires of

the same gauge to

both sides

Do not connect

wires of the same

gauge to one side

Do not connect

wires of different

gauges

ELECTRIC WIRING WORK

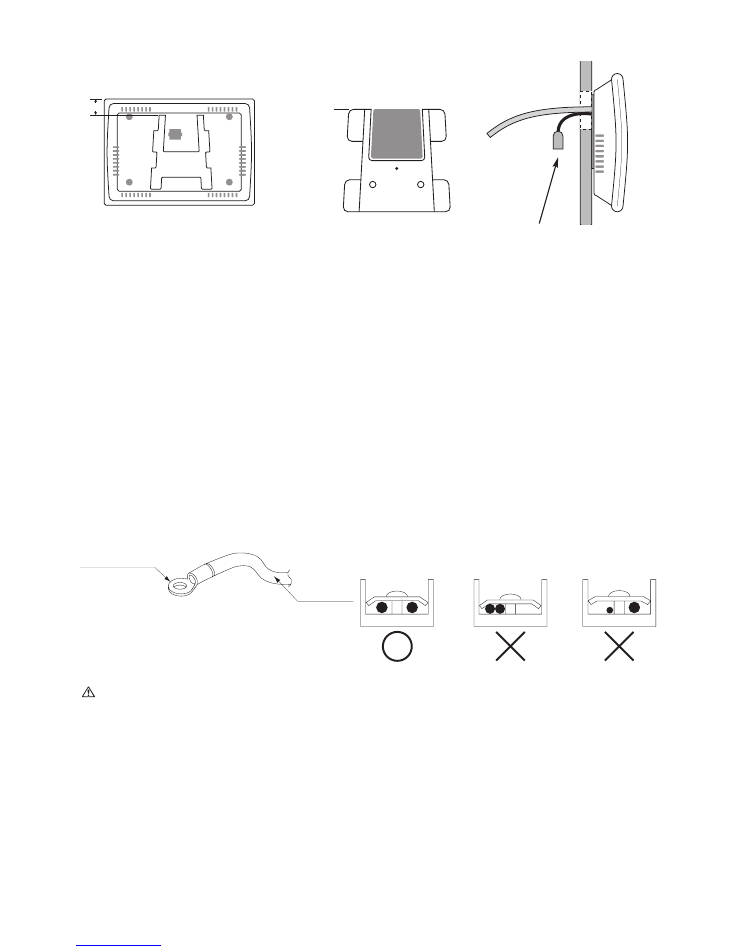

CONTROLLER MOUNTING BRACKET

18mm

Hole flush

with

top of

bracket

HOLE

IN

WALL

Installed controller height 18mm

above top of mounting bracket.

Do not cut hole above height of

bracket.

Earth shield spade receptacle is

used only when extension cable

(BRCW902A15) is installed. When

BRCW902A15 is not used tuck

insulated spade receptacle in wall

cavity

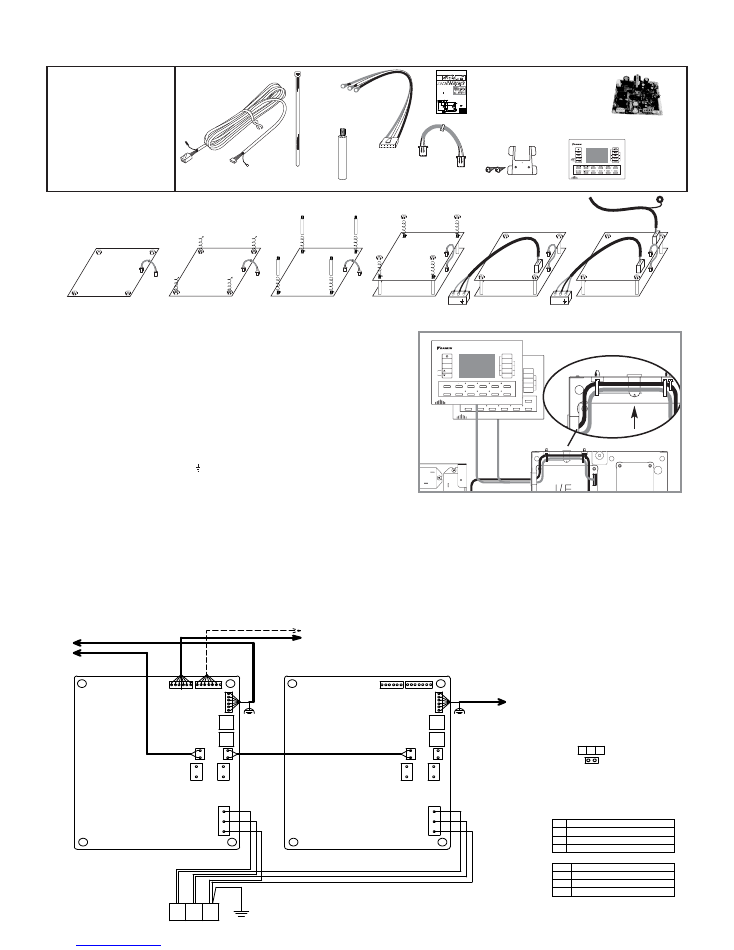

1. Insert one end of P1/P2 harness into socket S9 located on the lower interface

PCB (A1P). Diagram 1.

2. Loosen (4) plastic nuts. Diagram 2.

3. Screw in (4) PCB post and gently tighten. Diagram 3

4. Install upper Interface PCB (A2P) in the same direction as lower Interface

PCB (A1P). Diagram 4.

5. Add (4) plastic nuts and gently tighten. Diagram 4.

6. Plug the loose end of P1/P2 harness into socket S7 of upper Interface PCB

(A2P). Diagram 4.

7. Wire Power harness into LN terminal block X3M (Black- L)

(White –N) (Green – Earth). Diagram 5.

8. Plug the other end of the power harness into S1 socket of the upper Interface

PCB (A2P). Diagram 5.

9. Pass the Remote controller cable through the 2 open cable ties. If the cable

ties have already been tightened cut the cable ties and use the spare cable

ties supplied to secure the controller leads. Diagram 7.

10. Plug the remote controller cable connector into socket S8 of upper Interface

PCB (A2P). Diagram 6.

11. Secure the earth shield to the earth shield post. Diagram 7.

TO REMOTE CONTROLLER

TO RELAY PCB S19 (8 ZONE ONLY)

TO RELAY PCB S19 (4 ZONE)

A2P

A1P

L N E

S12

S7 S9

S2

S1

S1

S3

S13

S12

S13

S8

TN1

(NOTE 2)

TN2

S7 S9

S2

S3

S8

TO SUB CONTROLLER

TN1

TN2

TO P1 P2 TERMINAL

BLOCK (NOTE1)

B

W

G X3M

Sub Controller Instructions BRCSZC

S9

S9

S9

S9

S1

L N

S7

1

2

3

4

5

6

7

S9

S8

L N

ACCESSORIES

CABLE

TIE

X 5

SUB ZONE

KEYPAD

X 1

P1/P2

HARNESS

X 1

POWER

HARNESS

X 1

PCB

POST

X 4

INTERFACE

PCB X 1

15M

CONTROLLER

CABLE

X 1

Remote controller wiring

A N E

A N E

S7

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

MODE

FAN

TEMP

ADJUST

BUTTON

TEMP

SHIFT

7 DAY

TIME CLOCK

ON/OFF

TIMER

ENTER

CLEAR

TEST/EXIT

DAY TIME

ZONE1

ZONE2

ZONE3

ZONE4

SEL SENSOR

FIX SENSOR

ZONE5

ZONE6

ZONE7

ZONE8

4PDA0687

NOTE:

1.

P1 P2 TERMINAL BLOCK

LOCATED IN THE ELECTRICAL

BOX OF INDOOR UNIT.

2.

TN1, TN2 ONLY USE DAIKIN

REMOTE TEMPERATURE

SENSOR KRCSO1-1

3. :TERMINAL

:CONNECTOR

4.

SYMBOLS SHOW AS FOLLOWS

B: BLACK

W: WHITE

G: GREEN

A1P INTERFACE PRINTED CIRCUIT BOARD

A2P INTERFACE PRINTED CIRCUIT BOARD

TN1 REMOTE SENSORS 1

TN2 REMOTE SENSORS 2

S1

S9-S7

S7

S8

CONNECTOR

230~240V

A1P 7 A2P COMMUNICATION

A1P INDOOR COMMUNICATION

REMOTE CONTROLLER

A1P

A2P

X3M

SCREW

X 2

MOUNTING

BRACKET

X 1

INSTALLATION

INSTRUCTION

X 1

1. Insert one end of P1/P2 harness into socket S9 located on the lower interface

PCB (A1P). Diagram 1.

2. Loosen (4) plastic nuts. Diagram 2.

3. Screw in (4) PCB post and gently tighten. Diagram 3

4. Install upper Interface PCB (A2P) in the same direction as lower Interface

PCB (A1P). Diagram 4.

5. Add (4) plastic nuts and gently tighten. Diagram 4.

6. Plug the loose end of P1/P2 harness into socket S7 of upper Interface PCB

(A2P). Diagram 4.

7. Wire Power harness into LN terminal block X3M (Black- A)

(White –N) (Green – Earth). Diagram 5.

8. Plug the other end of the power harness into S1 socket of the upper Interface

PCB (A2P). Diagram 5.

9. Pass the Remote controller cable through the 2 open cable ties. If the cable

ties have already been tightened cut the cable ties and use the spare cable

ties supplied to secure the controller leads. Diagram 7.

10. Plug the remote controller cable connector into socket S8 of upper Interface

PCB (A2P). Diagram 6.

11. Wire the controller lead earth shield cable to the earth shield post. Diagram 7.

TO REMOTE CONTROLLER

TO RELAY PCB S19 (8 ZONE ONLY)

TO RELAY PCB S19 (4 ZONE)

A2P

A1P

L N E

S12

S7 S8

S2

S1

S1

S3

S13

S12

S13

S8

TN1

(NOTE 2)

TN2

S7 S8

S2

S3

S8

TO SUB CONTROLLER

TN1

TN2

TO P1 P2 TERMINAL

BLOCK (NOTE1)

B

W

G X3M

Sub Controller Instructions BRCSZC

S9

S9

S9

S9

S1

A N

S7

1

2

3

4

5

6

7

S9

S8

A N

ACCESSORIES

CABLE

TIE

X 5

SUB ZONE

KEYPAD

X 1

P1/P2

HARNESS

X 1

POWER

HARNESS

X 1

PCB

POST

X 4

INTERFACE

PCB X 1

15M

CONTROLLER

CABLE

X 1

Remote controller wiring

A N E

A N E

S7

MODE

FAN

TEMP

ADJUS

T

BUT

TON

TEMP

SHIFT

7 DA

Y

TIME CLOC

K

ON/OFF

TIMER

ENTE

R

CLEA

R

TEST/EXI

T DAY TIME ZONE1

ZONE2

ZONE3

ZONE

4

SEL

SENSO

R FIX SENSO

R

ZONE5

ZONE6

ZONE7

ZONE

8

MODE

FAN

TEMP

ADJUS

T

BUT

TON

TEMP

SHIFT

7 DA

Y

TIME CLOC

K

ON/OFF

TIME

R

ENTE

R

CLEA

R

TEST/EXI

T DAY TIME ZONE1

ZONE2

ZONE3

ZONE

4

SEL

SENSO

R FIX SENSO

R

ZONE5

ZONE6

ZONE7

ZONE

8

4PDA0687

NOTE:

1.

P1 P2 TERMINAL BLOCK

LOCATED IN THE ELECTRICAL

BOX OF INDOOR UNIT.

2.

TN1, TN2 ONLY USE DAIKIN

REMOTE TEMPERATURE

SENSOR KRCSO1-1

3. :TERMINAL

:CONNECTOR

4.

SYMBOLS SHOW AS FOLLOWS

B: BLACK

W: WHITE

G: GREEN

A1P INTERFACE PRINTED CIRCUIT BOARD

A2P INTERFACE PRINTED CIRCUIT BOARD

TN1 REMOTE SENSORS 1

TN2 REMOTE SENSORS 2

S1

S9-S7

S7

S8

CONNECTOR

230~240V

A1P 7 A2P COMMUNICATION

A1P INDOOR COMMUNICATION

REMOTE CONTROLLER

A1P

A2P

X3M

SCREW

X 2

MOUNTING

BRACKET

INSTALLATION

INSTRUCTIONS

INST

ALLA

TION MANUAL

ZONE

CONTROLLER

Air

Conditioners

MODELS

BRC230Z4

BRC230Z8

BRC24Z4

BRC24Z8

BRCSZC

PLEASE

READ

THESE

INSTRUCTIONS

CAREFULL

YBEFORE I

NST

ALLA

TION.

KEEP

THIS M

ANUAL

IN A

HANDY

PLACE

FOR

FUTURE RE

FERENCE.

DAIKIN AUSTRALIA PTY. LIMITED

77-83 Alfred Road, Chipping Norton, NSW 2170 Australia

Phone: 1300 78 72 66

www.daikin.com.au

DAIKIN INDUSTRIES LTD.

Head office:

Umeda Centre Building, 4-12 Nakazaki-Nishi 2 chome,

Kita-ku, Osaka, 530-8323 Japan

Tokyo office:

Shinjuku Sumitomo Building, 6-1 Nishi-Shinjuku

2 chome, Shinjuku, Tokyo, 163-0290 Japan

4PDA0685