Full Text Searchable PDF User Manual

STANDARD HEATER APPLICATIONS

INSTALLATION & OPERATION INSTRUCTIONS

BKI

Æ

1418

The Cata-Dyne™ heater can be used in all

industrial indoor locations where a source of

infrared radiant heat is required, providing

adequate ventilation is available.

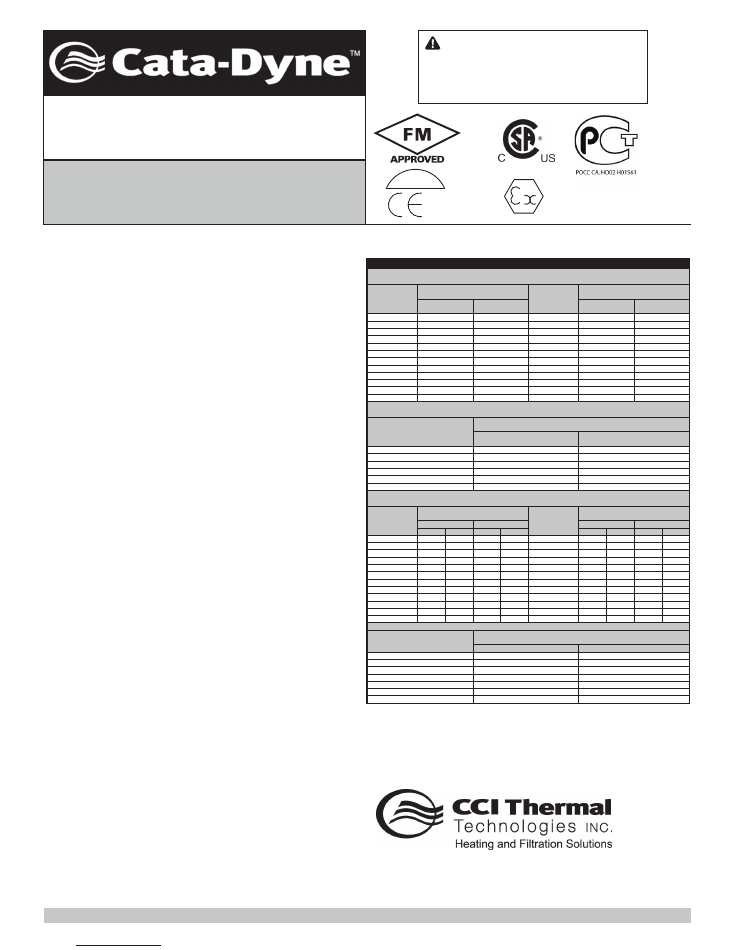

CERTIFICATION

Model WX (Series X) & MKII Cata-Dyne™

Explosion-proof, flameless infrared catalytic gas

heaters are certified by the Canadian Standards

Association (CSA) for use in Class I, Divisions 1

and 2, Group D hazardous (classified) locations

and FM Approvals, for use in Class I, Division

1, Group D hazardous (classified) locations,

temperature code T2C at an ambient temperature

of 40ºC (104ºF). WXS models are suitable for

Class I, Division I, Group D, temperature code

T2B at an ambient temperature of 40°C (104°F).

Models WX & MKII are certified ATEX/CE for use

in gas environments, Category 2, Zone 1 & 2,

Group IIA.

The Model BX (Series G) Cata-Dyne™ heater

is certified by CSA and FM for use in general

industrial non-hazardous locations. Models listed

are certified for industrial use only, for either

natural gas or propane gas. CSA approved models

are equipped for high altitudes: 0 - 4,500 ft. (0-

1,370 m) above sea level.

INSTALLATION

To ensure maximum efficiency of your Cata-

Dyne™ heater, it should be installed with the

heating surface positioned plus or minus 45° from

the vertical plane at a height of no more than

8 ft. (2.44 m). All heaters must be installed in

accordance with the latest revisions of the codes

described in table 4 and in accordance with any

local codes and regulations. Before installing the

heater, all information on the heater nameplate

must be carefully reviewed. The nameplate lists all

the fuel and electrical requirements for the heater.

E-mail: info@ccithermal.com

www.ccithermal.com

M20724-009 Date of Issue: July 2010

alteration, excessive vibration, service or maintenance

can cause property damage, injury or death. Read the

installation, operating and maintenance instructions

thoroughly before installation or servicing this equipment.

WARNING:

Improper installation, adjustment,

Head Office & Factory:

5918 Roper Road, Edmonton, Alberta, Canada T6B 3E1

Telephone: (780) 466-3178 Fax: (780) 468-5904

Toll Free: 1-800-661-8529

Table 1

The WX Series Cata-Dyne™ features an improved efficiency catalyst pad that required nearly 33%

less fuel to generate the same value as our BX Series Cata-Dyne™ heater.

10.543

50,000

60,000

BX 12 x 72

30,000

36,000

8.786

25,000

30,000

7.322

8.786

48,000

11.715

14.058

14.644

17.572

1.464

1.757

8.786

10.543

5.857

7.029

7.322

7.322

25,000

25,000

4.393

5.272

30,000

36,000

10,000

12,000

2.929

3.514

20,000

24,000

13.179

4,167

5,000

1.220

1.464

45,000

54,000

13.179

2,222

2,667

0.651

0.781

15.815

36,000

8.786

10.543

45,000

5.491

0.879

18,750

22,500

BX 18 x 30

10.983

15,000

3.661

4.393

30,000

37,500

6.590

5,000

6,000

1.464

1.757

22,500

27,000

6.590

7.908

0.732

18,000

4.393

5.272

NAT

WX 12 x 36

WX 12 x 48

Approved for use in Class I, Division 1 and 2, Group D hazardous (classified) locations by both FM and CSA T-Code T2C @ 40°C Am

bient

NAT

Max. Btu/hr

Model Number

LPG

NAT

LPG

NAT

LPG

BX 6 x 6

LPG

1,250

1,500

0.366

0.439

15,000

Cata-Dyne™ Heater - Models Available - CSA Only

WX 24 x 30

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

WX 6 x 6

WX 12 x 24

5,000

MKII 12x12

MKII 12x24

MKII 18x24

MKII 18x48

Approved for use in general industrial non-hazardous locations by both FM and CSA

MKII 24x24

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

Max. kW

BX 6 x 12

BX 6 x 24

2,500

3,000

BX 12 x 48

BX 12 x 60

WXS 6 x 12

Approved for use in Class I, Division 1, Group D hazardous (classified) locations by FM, T-code T2B at 40°C ambient

WXS 6 x 6

20,000

24,000

5.857

7.029

40,000

WXS 12 x 12

0.513

1.025

2.050

0.911

1.708

WXS 10 x 12

WX 6 x 12

WX 6 x 24

WX 18 x 24

WX 18 x 30

WX 18 x 36

For Both Natural and Propane Gas

Max. Btu/hr

Max. kW

WX 6 x 60

WX 8 x 8

WX 10 x 12

WX 12 x 12

BX Model (Series G)

MKII 24x48

Model Number

6,000

15,000

18,000

BX 6 x 60

BX 8 x 8

BX 10 x 12

BX 12 x 12

12,500

BX 12 x 24

BX 12 x 36

BX 18 x 24

WX Model (Series X)

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

Approved for use in Class I, Division 1 and 2, Group D hazardous (classified) locations by both FM and CSA T-Code T2C @ 40°C Am

bient

Model Number

Model Number

WX 12 x 72

WX 12 x 60

Specifications (Btu/hr Input Ratings)

Model Number

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

Max. Btu/hr

Max. kW

BX 24 x 36

BX 24 x 48

BX 24 x 60

BX 18 x 36

BX 18 x 48

BX 18 x 60

BX 18 x 72

BX 24 x 24

BX 24 x 30

WX 24 x 24

WX 24 x 36

WX 24 x 48

WX 24 x 60

11.715

14.644

4.393

1.220

1.464

2.929

4.393

WX 18 x 48

WX 18 x 60

WX 18 x 72

20,000

40,000

Model Number

For Both Natural and Propane Gas

Specifications (Btu/hr Input Ratings)

WXS 12 x 24

1,750

3,500

7,000

3,111

5,833

7,000

14,000

WXS 6 x 24

WXS 8 x 8

2.050

4.100

Max. kW

Max. Btu/hr

Max. kW

8.786

5.857

11.715

7.322

8.786

20,000

25,000

30,000

1,250

2,500

5,000

12,500

2,222

4,167

Max. kW

5,000

10,000

15,000

Max. Btu/hr

0.732

1.464

3.661

0.651

5.857

7.322

8.786

15,000

18,750

22,500

30,000

37,500

45,000

0.366

30,000

40,000

50,000

60,000

13.179

5.857

20,000

25,000

5.491

6.590

8.786

10.983

30,000

1.464

2.929

4.393

17.572

5,000

10,000

15,000

Max. Btu/hr

WX 24 x 72

MK II Model (Series X)

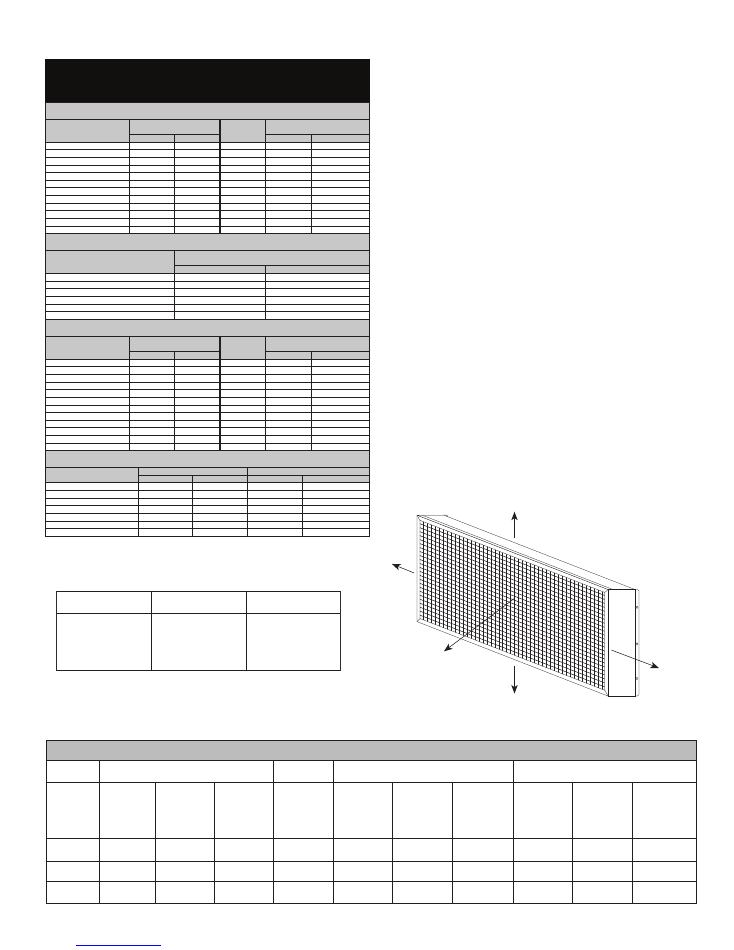

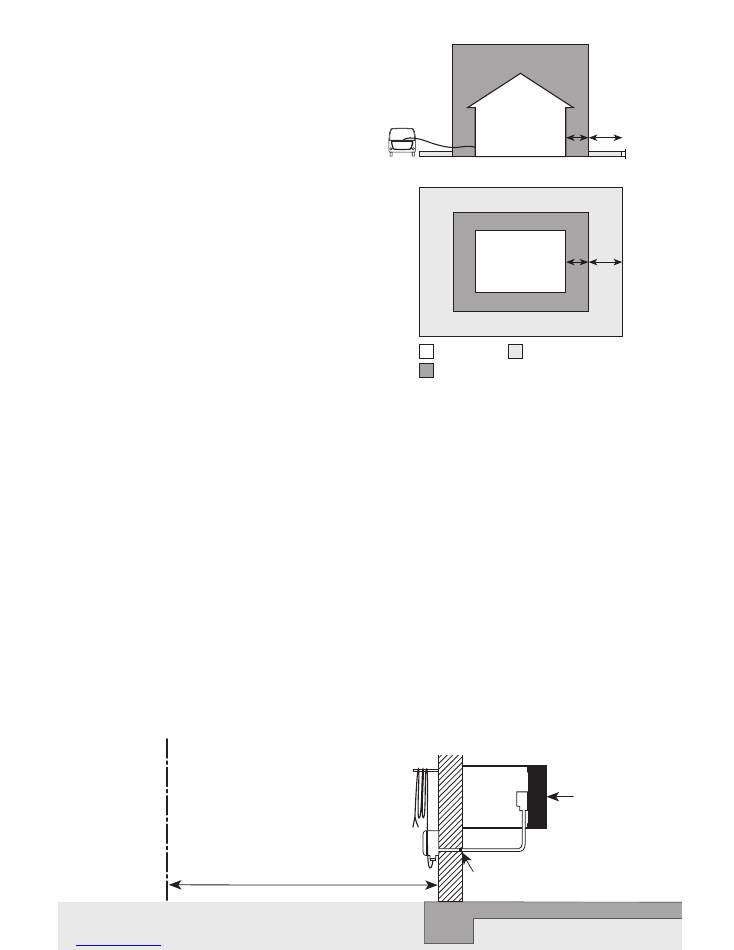

HEATER CLEARANCE

Vertical (0°)

0-45° up

0-45° down

28 in. (711 mm) 42 in. (1067 mm) 60 in. (1524 mm)

12 in. (305 mm)

18 in. (457 mm)

18 in. (457 mm)

42 in. (1067 mm)

7 in. (178 mm)

0 in. (0 mm)

12 in. (305 mm)

18 in. (457 mm)

18 in. (457 mm)

18 in. (457 mm)

18 in. (457 mm)

18 in. (457 mm)

18 in. (457 mm)

12 in. (305 mm)

12 in. (305 mm)

12 in. (305 mm)

28 in. (711 mm)

28 in. (711 mm)

42 in. (1067 mm)

42 in. (1067 mm)

60 in. (1524 mm)

60 in. (1524 mm)

42 in. (1067 mm)

24 in. (610 mm)

22 in. (559 mm)

32 in. (813 mm)

54 in. (1372 mm)

C - Sides

D - Radiant Surface

A - Top

B - Bottom

Radiant

Surface

Position

Heaters

Up To

12,000 Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000 Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000 Btu/hr

(17.572 kW)

All Heaters

Up To

60,000 Btu/hr

(17.572 kW)

Heaters

Up To

12,000 Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000 Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000 Btu/hr

(17.572 kW)

Heaters

Up To

12,000 Btu/hr

(3.514 kW)

Over 12,000

Up To

48,000 Btu/hr

(14.058 kW)

Over 48,000

Up To

60,000 Btu/hr

(17.572 kW)

SPECIFICATIONS

Clearances

Appropriate clearances from the heating surface must be

observed during the installation of the Cata-Dyne™ heaters

(See Figure 1 & Table 4). Maintain nameplate clearances

from combustible materials such as wood, cloth, paper, etc.

If the heater is to be installed overhead maintain clearances

as stated in figure 1 & table 4 from vehicles parked below.

Fuels

The Cata-Dyne™ flameless gas heater is designed to

operate on clean, dry natural gas or propane as specified

on the heater nameplate.

Natural Gas - these heaters are designed to use natural

gas (1,000 Btu/ft

3

, 37 MJ/m

3

) at 7 in. w.c. (1.73 kPa), 4.5

in. w.c. (1.12 kPa), or 3.5 in. w.c. (0.86 kPa).

Propane - these heaters are designed to use propane

gas (2,500 Btu/ft

3

, 92 MJ/m

3

) at 11 in. w.c.

(2.72 kPa).

A

C

D

B

C

FIGURE 1

Note: Maintain nameplate clearances

from combustible materials such as

wood, cloth, paper as well as any

vehicles parked in the area of the

heater.

NOTE: Ensure that the heater is not operational in an ex-

cessive vibration environment or premature failure of the

heater may occur.

All Cata-Dyne™ Heaters

Installed In Canada

CSA/CAN – C22.1-02, Canadian

Electrical Code

CSA/CAN – B149.1-00, Natural

Gas and Propane Installation

Code

NFPA 70, National Electrical Code

NFPA 54, National Fuel Gas Code

All Cata-Dyne™ Heaters

Installed Internationally

All Cata-Dyne™ Heaters

Installed In the USA

Install according to local and

national/international fuel and

electrical codes.

Table 2

Table 3

Table 4

The WX Series Cata-Dyne™ features an improved efficiency catalyst pad that required nearly 20%

less fuel to generate the same value as our BX Series Cata-Dyne™ heater.

0.366

1.220

0.651

3.661

1.464

2.929

1.464

MK II Model (Series X)

Approved for use in Class I, Division 1 and 2, Group D hazardous (classified) locations by both FM and CSA T-Code T2C @ 40°C Ambient

25,000

30,000

WX 12 x 60

WX 12 x 72

4.393

5.857

WXS 6 x 6

MKII24x48

Model Number

Nat. Gas Btu/hr

BX6x12

3,000

0.879

Max. Btu/hr

Model Number

WXS Model (Series X)

15,000

20,000

MKII12x12

MKII12x24

MKII18x24

MKII18x48

30,000

36,000

MKII24x24

Model Number

Approved for use in general industrial non-hazardous locations by both FM and CSA

Cata-Dyne™ Heater - Models Available

2,222

WX 24 x 30

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

BX6x24

BX8x8

6,000

3,500

18,000

24,000

For Both Natural and Propane Gas

Model Number

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

Propane Btu/hr

Nat. Gas kW

Max. Gas Input

Propane kW

Approved for use in Class I, Division 1, Group D hazardous (classified) locations by FM, T-code T2B at 40°C ambient

Max. Gas Input

1,250

2,500

5,000

12,500

5.272

BX18x24

4,167

5,000

10,000

Specifications (Btu/hr Input Ratings)

0.911

1.708

2.050

1,750

3,500

7,000

3,111

5,833

7,000

7,000

14,000

4.100

0.513

1.025

2.050

0.911

0.513

1.025

2.050

WXS 6 x 12

WXS 6 x 24

WXS 8 x 8

WXS 10 x 12

14,000

1,750

3,500

7,000

3,111

5,833

22,500

18,000

WXS 12 x 12

WXS 12 x 24

BX6x6

1,500

0.439

BX12x72

5,000

4.393

5.491

6.590

WX 6 x 6

WX 6 x 12

WX 6 x 24

WX 18 x 24

WX 18 x 30

WX 18 x 36

0.732

Max. Btu/hr

Max. kW

Max. kW

WX 6 x 60

WX 8 x 8

WX 10 x 12

WX 12 x 12

WX 12 x 24

WX 12 x 36

WX 12 x 48

7.322

8.786

BX Model (Series G)

1.708

15,000

30,000

For Both Natural and Propane Gas

Specifications (Btu/hr Input Ratings)

Max. kW

Max. Btu/hr

2.050

4.100

BX10x12

BX12x12

BX12X24

BX12x36

BX12x48

BX12x60

6,000

12,000

WX Model (Series X)

Model Number

Specifications (Btu/hr Input Ratings)

For Both Natural and Propane Gas

Max. Btu/hr

Max. kW

Approved for use in Class I, Division 1 and 2, Group D hazardous (classified) locations by both FM and CSA T-Code T2C @ 40°C Ambient

Max. Btu/hr

Max. kW

Model Number

20,000

40,000

1.464

2.929

8.786

4.393

5.857

11.715

5,000

10,000

1.757

1.025

1.464

1.757

3.514

5.272

7.029

8.786

10.543

BX18x30

BX18x36

BX18x48

BX18x60

BX18x72

BX24x24

BX24x30

BX24x36

BX24x48

BX24x60

BX24x72

27,000

36,000

45,000

54,000

24,000

30,000

36,000

48,000

60,000

72,000

6.590

7.908

10.543

13.179

15.815

7.029

8.786

10.543

20,000

25,000

14.058

17.572

21.087

8.786

10.983

13.179

5.857

7.322

15,000

18,750

22,500

30,000

37,500

45,000

30,000

40,000

50,000

60,000

14.644

17.572

8.786

11.715

WX 24 x 36

WX 24 x 48

WX 24 x 60

WX 24 x 72

WX 18 x 48

WX 18 x 60

WX 18 x 72

WX 24 x 24

CATA-DYNE

TM

HEATER- MODELS AVAILABLE FOR FM ONLY

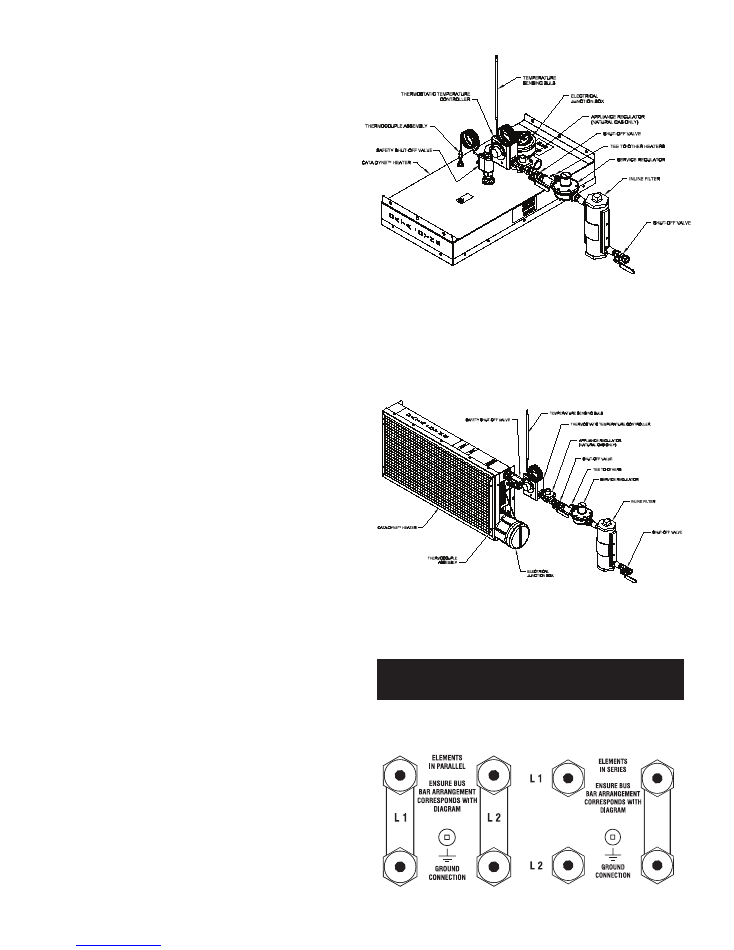

Piping

A main shut-off valve must be installed upstream of

all auxiliary heater controls.

The 100% safety shut-off valve and appliance

regulator (natural gas heaters only) must be installed

in the upright position (horizontally).

The thermostatic temperature controller should be

installed with the dial shaft in the horizontal position.

The maximum inlet pressure to the 100% safety

shut-off valve, thermostatic temperature control

and appliance regulator is 1/2 psi (3.4 kPa). If the

inlet pressure is higher than this, a low-pressure

service regulator must be installed upstream of these

components.

The maximum inlet pressure to the low-pressure

service regulator (available from CCI Thermal) is

250 psi (1.7 MPa). If the inlet pressure is higher than

this, a high-pressure regulator must be installed

upstream.

All components should be installed as indicated in

Figure 2 (WX and BX models only) or Figure 3 (MKII

model only).

1.

2.

3.

4.

5.

6.

FIGURE 2

Diagram illustrates typical Natural Gas installation.

Gas appliance regulators and manual shut off valves are

required standard components for all CSA approved heaters;

they are available as optional accessories for FM approved

heaters.

Electrical

All wiring is to be installed in accordance with the latest

revisions of the Canadian Electrical Code (CEC)/

National Electrical Code (NEC) and/or any applicable

local codes.

It is desirable to install an indicating light on all starting

systems. This will reduce the possibility of the power

being left on once the heater is started, which can

severely reduce the lifespan of the heater.

Ground connections for 120 V and higher voltage

heaters are required as indicated in Figures 4 and 5.

The number of terminals in the junction box can be two

of four depending on the number of elements used in

the fabrication of the heater. All MKII models incorporate

a single element and therefore have only two terminals.

The connection procedure for the different combinations

is as described in Figures 4 and 5:

1.

2.

3.

4

.

FIGURE 4

FIGURE 5

FIGURE 3

Diagram illustrates typical Natural Gas installation.

Gas appliance regulators and manual shut off valves are required

standard components for all CSA approved heaters; they are

available as optional accessories for FM approved heaters.

CAUTION:

Install MKII series heaters with controls on sides or bottom of heater

only.

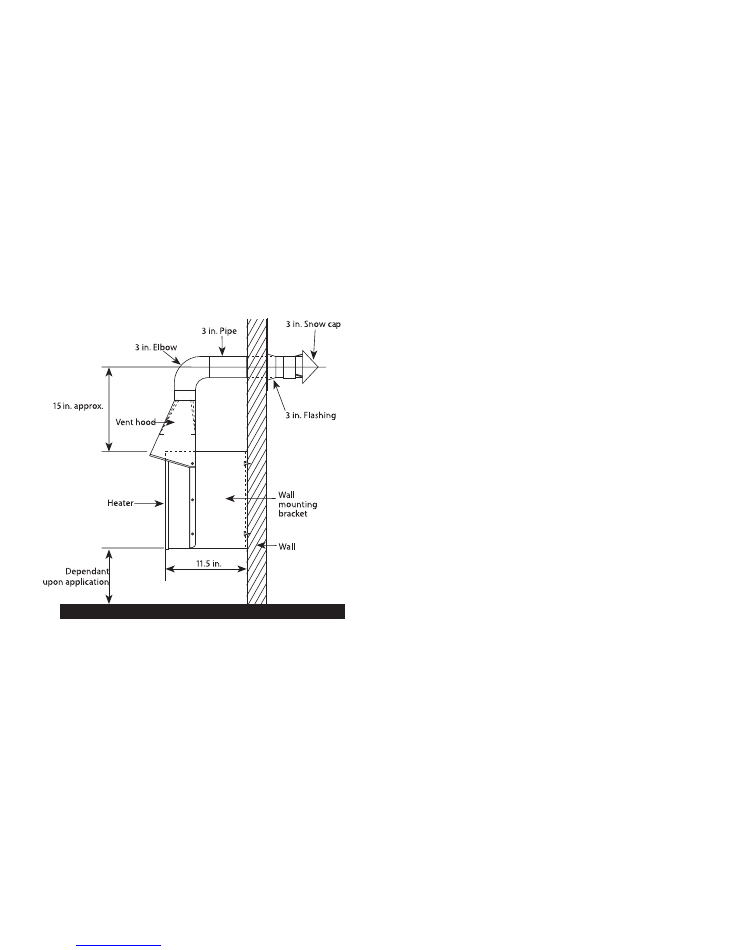

Ventilation

The catalytic reaction in Cata-Dyne™ heaters occurs

when natural gas or propane reacts with oxygen to

produce water vapor, carbon dioxide and infrared energy.

Ventilation must be provided to allow adequate supply of

oxygen for the reaction.

For every 1.0 ft

2

(0.093 m

2

) of heater surface, 50 ft

3

/hr

(1.42 m

3

/hr) of air supply is required. For example, a WX

24 x 24 heater (20,000 Btu/hr / 5.857 kW) would require

200 ft

3

/hr (5.66m

3

/hr) of air to ensure proper operation of

the Cata-Dyne™ heater.

To reduce the carbon dioxide and water vapor

concentrations in the building, a vent hood assembly can

be installed to provide positive ventilation from the heater

(See Figure 6).

FIGURE 6

OPERATION

All Cata-Dyne™ heaters are supplied with a Safety Shut-Off

Valve (SSOV)/Thermocouple assembly to ensure the safe

operation of the heater. Under no circumstances should the

reset button be held or locked into the depressed position

by use of a mechanical restraint. A tamper resistant model

SSOV is available if desired.

4. Turn on the power to the electrical elements.

5. After 15 minutes, depress the reset button on the top

of the 100% safety shut-off valve. The button should

return to the original position and internally open the

valve and allow gas to flow to the heater. If the valve

does not stay open when the reset button is released,

it may be necessary to wait an additional few minutes

and then depress the reset button again. This will allow

the electrical elements additional time to warm up.

6. When the catalytic reaction is well established, turn off

the electrical power to the elements.

7 If the heater is equipped with a thermostatic

temperature controller, it can be set to the desired

setting after the catalytic reaction has been established

for at least one hour.

Shut Down

Turn off the gas supply to the heater.

Multi-Heater Start-up

Cata-Dyne™ heaters can also be purchased/installed in multi-

heater assemblies. If these assemblies are 12 V, each heater

must be started individually. This ensures the correct voltage

and current will be reaching the heater from the power supply.

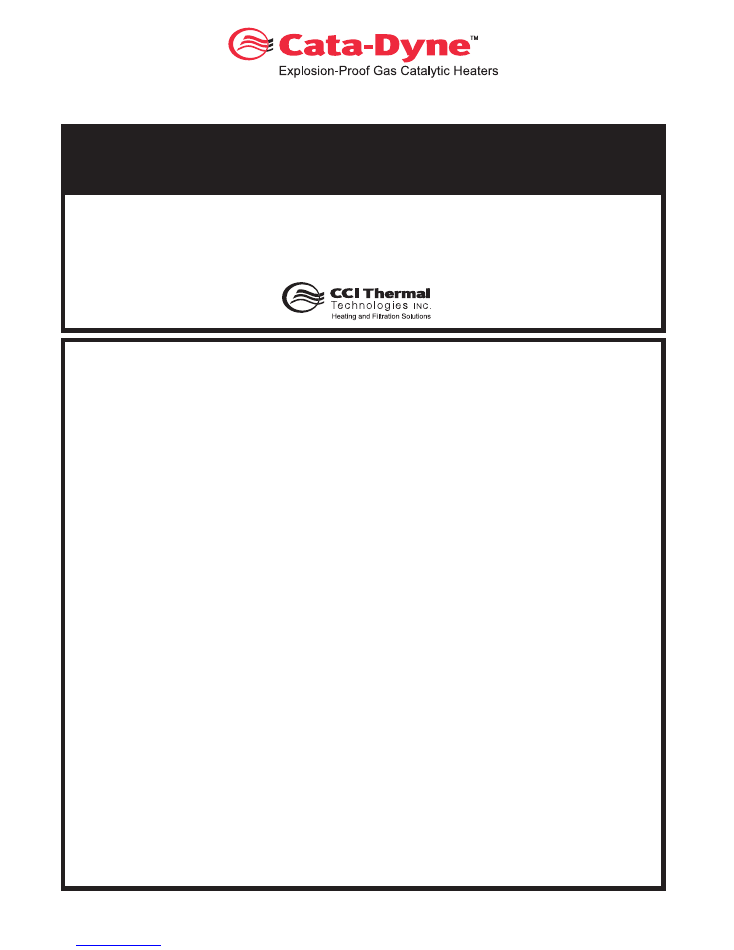

12 V HAZARDOUS

ELECTRICAL INSTALLATIONS

Most oil and gas production buildings have an area

classification as follows:

1. Class I, Division 1, within the building.

Refer to figures 7 and 8.

2. Class I, Division 2, up to 10 ft. (3 m.) from the building

in any direction. Refer to figures 7 and 8.

3. Class I, Division 2, between 10 ft. (3 m.) and

25 ft. (7.6 m.) from the building in all directions at an

elevation of 18 in. (0.45 m.) above the ground.

Refer to figures 7 and 8.

Connection to the power supply must be outside of the

Class I, Division 2 location. (refer to Figure 9). All electrical

apparatus and wiring within this area must conform to the

appropriate codes.

Start-up

1. Ensure the heater has been installed according to all

instructions and relevant codes.

2. Turn on the main gas supply to the system.

3. If the heater is equipped with a thermostatic

temperature controller, rotate the dial completely

clockwise to the fully open position.

10 ft.

3.0 m

15 ft.

4.6 m

Vehicle located outside

hazardous area

18 in.

0.46 m

10 ft.

3.0 m

15 ft

4.6 m

Class I

Division 1 (Zone 1)

Class I

Division 2 (Zone 2)

Class I Division 2 (Zone 2)

18 in. (0.46 m) above ground

Subject to possible

transient vapour

FIGURE 7

FIGURE 8

SPOT HEATING

There are several factors to consider when Cata-Dyne™

heaters are utilized for spot heating.

Infrared energy travels in straight lines from the face of the

Cata-Dyne™ heater covering approximately 160° of an arc

and is inversely proportional to the square of the distance.

The heater should therefore be mounted as close as

practical (min of 28 in. (71 cm)) to the object requiring heat

for maximum temperature rise.

Match the shape of the object requiring heat with the

appropriate Cata-Dyne™ heater, e.g. WX/BX 6 x 24 for long

narrow objects or WX/BX 12 x 12 for a square object.

Objects requiring heat should be painted dull, dark colors for

maximum infrared absorption and objects not requiring heat

should be painted light or reflective colors.

Insulate and protect plastic, rubber and similar materials from

direct intense infrared heat.

SPACE HEATING

A separate heat load calculation should be done for each

building in which a Cata-Dyne™ heater will be installed for

space heating purposes.

The heatload calculation determines the building heat losses

through the structure and allows for air infiltration (refer to

the Cata-Dyne™ catalog or visit www.ccithermal.com for the

sample Heat Load Calculation).

Cata-Dyne™ heaters produce low intensity infrared heat that

is absorbed by objects within the range of the heat source.

The closer the object is to the source of heat the more

heat the object will absorb. Cata-Dyne™ heaters should

be placed close to the floor level within the building to heat

objects close to the floor.

Ideally, Cata-Dyne™ heaters should be mounted 1-3 ft.

(0.3-1 m) from the floor and equally spaced around the

building perimeter for space heating applications.

If low mounting is not practical, then overhead mounting may

be utilized. Overhead mounted heaters should be sloped

face down to a maximum 45° angle to direct the infrared

energy towards the floor. Overhead mounting should be

restricted to heaters of 30,000 Btu.hr (8.8 kW) capacity and

larger.

If the building requires only one heater, place the

Cata-Dyne™ heater as close as possible to the center of the

longest wall.

For multiple heater installations, space the Cata-Dyne™

heaters as evenly as possible around the perimeter of the

building.

Make sure the piping is large enough to handle the gas load

(refer to the sample Piping Calculation in the Cata-Dyne™

catalog for sizing information).

Make sure the electrical starting system has sufficient

current carrying capacity and conforms to all applicable

electrical codes.

It is advisable to install an indicator light in the electrical

circuit to reduce the possibility of the power being left on

once the heater is started.

25 ft.

7.6 m

+ _

Seal

CAUTION:

Connect battery

outside 25 ft. (7.6 m)

in non-hazardous area

OUTSIDE BUILDING - Class I Division 2

area use appropriate electrical fittings

CATA-DYNE Heater

c/w explosion proof

junction box

Standard

battery cable

Building wall

INSIDE BUILDING -

Class I Division 1 area use

appropriate electrical fittings

FIGURE 9

PERSONAL SAFETY

The Cata-Dyne™ flameless infrared catalytic gas heater

does not produce harmful carbon monoxide gas when used

with natural gas or propane. Adequate ventilation must

be incorporated in any building design to ensure oxygen

replenishment and removal of any carbon dioxide. Protective

grills should be used on any installation where personnel may

come in contact with the face of the heater.

ORDERING INFORMATION

You can order any of CCI Thermal’s products by telephone,

fax, mail, e-mail or directly on-line at www.ccithermal.com.

To assist us in processing your order as quickly and efficiently

as possible, please provide us with the following information:

□

Cata-Dyne™ product name

□

Cata-Dyne™ model number

□

Fuel gas - natural gas or propane

□

Starting voltage - 12, 24, 120, 208, 240, 480, or 600V

□

Accessories required:

- Protection Grill

- Wall Mount Brackets

- Thermostat

- Regulator

- Start Up Leads (12 V system only)

- Vent Hood

- Other

□

Company name and contact

□

Billing address and phone number

□

Shipping instructions

□

Special tagging instructions

□

Date required

□

Method of payment:

- on account - P.O. number required

- credit card - VISA or Mastercard number

- cash or cheque

GUARANTEE

Under normal use the Company warrants to the purchaser

that defects in material or workmanship will be repaired

or replaced without charge for a period of 18 months from

date of shipment, or 12 months from the start date of

operation, whichever expires first. Any claim for warranty

must be reported to the sales office where the product was

purchased for authorized repair or replacement within the

terms of this warranty.

Warranty is void if Cata-Dyne™ heaters are used with sour,

dirty or wet gas, or where sulphur content is greater than

allowable for utility gas specifications. Warranty is void if,

upon our inspection, if the SSOV or thermocouple have been

tampered with. Neither CCI Thermal nor the selling dealer

shall be held responsible for loss of time, inconvenience,

commercial loss or consequential damages relating to the

use of Cata-Dyne™ heaters.

RETURN GOODS POLICY

Prior written approval must be obtained from CCI Thermal

for the return of any Cata-Dyne™ product(s). A restocking

charge of 15% will apply. All returns must be shipped to

our factory in Edmonton, freight prepaid. Final acceptance

will be contingent on inspection at our factory.

REPAIRS

Cata-Dyne™ heaters may require periodic maintenance

or repair. Our factory is staffed with technicians who are

qualified to perform any required repairs. The procedure

to follow to have a heater repaired is as follows.

Send the heater to our factory in Edmonton. Include the

following information with the heater:

□

Company name and address

□

Contact name

□

Telephone number/fax number/e-mail

□

P.O. Number

□

Advise if an estimate is required prior to starting the

repair

□

Details on the repair or conversion required

□

Return shipping instructions

NOTE: Under the terms of our certification, all repairs

must be performed at our factory in Edmonton.

CLEANING

The Cata-Dyne™ heater box may be cleaned but only

once it has been allowed to cool. If your Cata-DyneTM

catalytic pad (white pad) is dirty it should never be

contacted in order to avoid damaging it. This means that

it should not be wiped down, sprayed with water or blown

with compressed air. Any contact with the catalytic pad

may damage the surface requiring the owner to return the

unit to the factory for repair.

TROUBLE SHOOTING

Ensure that the fuel matches that listed on the nameplate.

Ensure that the voltage matches that listed on the nameplate.

Check for any physical damage. All signs of physical

damage to the catalyst pad such as holes, tears or a general

deterioration of the catalyst bed signal that it is time to have

the heater repaired. Excessive vibration may cause damage

to the inner catalysts structure which may cause premature

failure.

Check the gas supply pressure at the heater – 7 in. w.c. (1.73

kPa), 4.5 in. w.c. (1.12 kPa), or 3.5 in. w.c. (0.86 kPa) for

natural gas and 11 in. w.c. (2.72 kPa) for propane.

Check the gas orifice for obstructions or dirt and ensure

the size matches that listed on the nameplate. It may be

necessary to install a filter upstream of the heater or regulator

if the gas supply is dirty. If the fuel supply is constantly dirty

and/or wet it would be advisable to use bottled propane fuel.

Check the mounting position of the heater. The face of the

heater should be preferably in the vertical position and should

not vary more than 45° from the vertical position for maximum

efficiency.

Check for saturation of the catalyst face caused by

condensation or rain running down the face of the heater. If

the heater has been exposed to water, it is advisable to place

the unit in a warm area for a period of a few hours or longer

if required. Once the moisture is removed, the heater can be

re-installed and re-started.

Check the jumper cable size to ensure that the resistance of

the cable is not reducing the current to the heater. This would

not allow sufficient power to the electrical element to preheat

the catalyst to the activity temperature. It is recommended to

run the service vehicle at fast idle while starting the heater.

Cata-Dyne™ heaters are designed to use clean fuel and

to be used in non-contaminated atmospheres. Sulphur

compounds in the fuel or atmosphere will poison the catalyst

bed over a period of time and render the heater inoperative.

If the heater has been exposed to sulphur compounds, it

should be sent to the factory for service.

Avoid spraying the face of the heater with high-pressure air,

steam or water because this can damage the catalyst bed, if

physical damage is visible, return the heater to the factory for

servicing.

Ensure that the temperature controller is correct for the model

size, fuel, and pressure specifications for the heater it is fitted

to. If the temperature controller is too low, the heater

will not

have sufficient fuel rating to operate and will stop.

1.

2.

3.

4.

5.

6.

7.

8.

9.

10.

11.

S

eparate Installation and Operation Instructions are available for oven and industrial heating applications.

Printed In Canada

PLEASE ADHERE TO INSTRUCTIONS PUBLISHED IN THIS MANUAL.

Failure to do so may be dangerous and may void certain provisions of your warranty.

For further assistance, please call:

24 Hr. Hotline: 1-800-661-8529

(U.S.A. and Canada)

Please have model and serial numbers available before calling.

5918 Roper Road, Edmonton, Alberta, Canada T6B 3E1

Phone: (780) 466-3178 Fax: (780) 468-5904

www.ccithermal.com

WARRANTY:

Under normal use the Company

warrants to the purchaser that defects in material or

workmanship will be repaired or replaced

without charge for a period of 18 months from

date of shipment, or 12 months from the start date of

operation, whichever expires first. Any claim for

warranty must be reported to the sales office where the

product was purchased for authorized repair or

replacement within the terms of this warranty.

Subject to State or Provincial law to the contrary, the

Company will not be responsible for any expense for

installation, removal from service, transportation, or

damages of any type whatsoever, including damages

arising from lack of use, business interruptions, or

incidental or consequential damages.

The Company cannot anticipate or control the

conditions of product usage and therefore

accepts no responsibility for the safe application and

suitability of its products when used alone or in

combination with other products. Tests for the safe

application and suitability of the products are the sole

responsibility of the user.

This warranty will be void if, in the judgment of the

Company, the damage, failure or defect is the result of:

• vibration, radiation, erosion, corrosion, process

contamination, abnormal process conditions,

temperature and pressures, unusual surges or

pulsation, fouling, ordinary wear and tear, lack of

maintenance, incorrectly applied utilities such as

voltage, air, gas, water, and others or any

combination of the aforementioned causes not

specifically allowed for in the design conditions or

• any act or omission by the Purchaser, its agents,

servants or independent contractors which for

greater certainty, but not so as to limit the generality

of the foregoing, includes physical, chemical or

mechanical abuse, accident, improper

installation of the product, improper storage and

handling of the product, improper application or the

misalignment of parts.

No warranty applies to paint finishes except for

manufacturing defects apparent within 30 days from

the date of installation.

The Company neither assumes nor

authorizes any person to assume for it any other

obligation or liability in connection with the product(s).

The Purchaser agrees that all warranty work required

after the initial commissioning of the product will be

provided only if the Company has been paid by the

Purchaser in full accordance with the terms and

conditions of the contract.

The Purchaser agrees that the Company makes

no warranty or guarantee, express, implied or

statutory,

(INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR WARRANTY OF FITNESS

FOR A PARTICULAR PURPOSE)

written or oral, of

the Article or incidental labour, except as is expressed

or contained in the agreement herein.

LIABILITY:

Technical data contained in the catalog or

on the website is subject to change without notice. The

Company reserves the right to make dimensional and

other design changes as required. The Purchaser

acknowledges the Company shall not be obligated

to modify those articles manufactured before the

formulation of the changes in design or improvements

of the products by the Company.

The Company shall not be liable to compensate or

indemnify the Purchaser, end user or any other party

against any actions, claims, liabilities, injury, loss, loss of

use, loss of business, damages, indirect or consequential

damages, demands, penalties, fines, expenses

(including legal expenses), losts, obligations and

causes of action of any kind arising wholly or partly from

negligence or omission of the user or the misuse, incorrect

application, unsafe application, incorrect storage and

handling, incorrect installation, lack of maintenance,

improper maintenance or improper operation of

products furnished by the Company.