Full Text Searchable PDF User Manual

Page1

AIR CONDITIONING

PORTA TEMP 240/320DX

CAUTION

PLEASE READ THIS LEAFLET CAREFULLY

1. DO NOT APPLY MAINS WATER PRESSURE TO THIS UNIT. WHERE

APPROPRIATE, ACCESS TO THE FILLING POINT FOR THE WATER

CIRCULATING SYSTEM IS REACHED BY THE REMOVAL OF THE FILLER

ACCESS PLATE IN THE ROOM UNIT BACK PANEL.

2. WHEN REMOVING THE UNIT FROM AN INSTALLATION DISCONNECT WATER

QUICK COUPLINGS IN THE ROOM UNIT FIRST.

INTERNAL ACCESS SHOULD BE RESTRICTED TO CALOREX TRAINED STAFF

ONLY.

SD259755 ISS 4

Page 2

BLANK PAGE

Page3

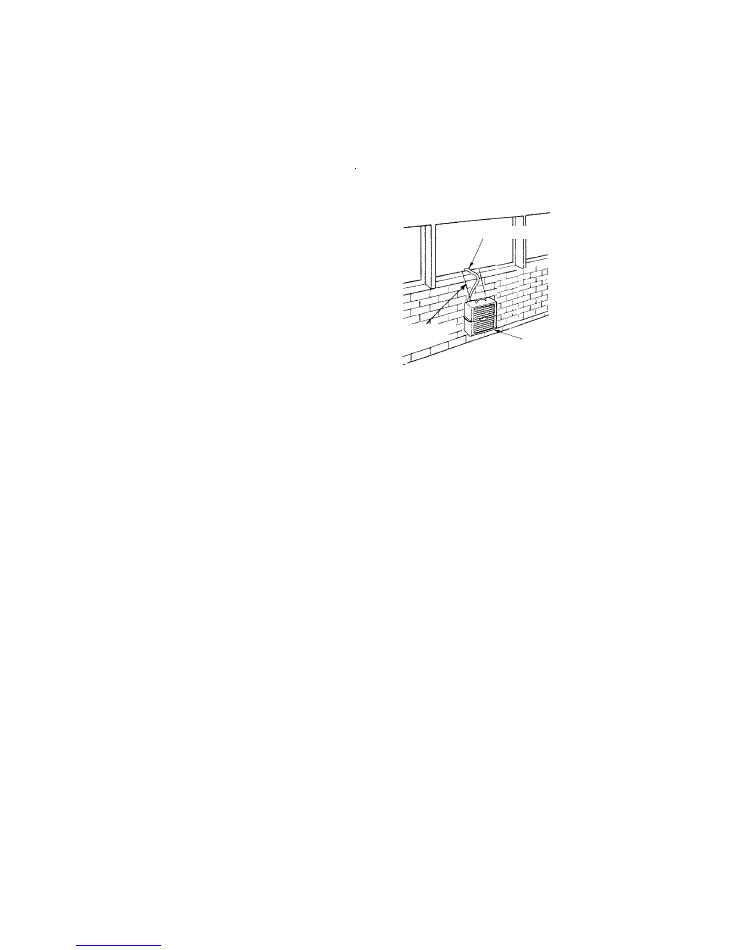

DO NOT LET HEAT EXCHANGER HANG

FROM ITS FLEXIBLE LINE

SUPPORT HEAT EXCHANGER

WEIGHT USING HOOKS

AND CHAINS PROVIDED

OR STAND ON FIRM

GROUND.

DROPS OF CONDENSATE

MAY APPEAR HERE

Fig 1

PAC240 SHOWN

EXTERNAL HEAT EXCHANGER (HEX).

The heat exchanger must stand external to the area

being cooled and, preferably, in the outside atmosphere.

It can stand freely on a flat surface or, in the case of the

PAC.240 may be hung in the upright position from a

sindow sill, balcony etc, see Fig 1. USE THE CHAINS

PROVIDED TO SUPPORT THE HEAT EXCHANGER.

IT WOULD BE HIGHLY DANGEROUS TO SUPPORT

THE HEAT EXCHANGER BY MEANS OF THE

FLEXIBLE LINES ALONE.

CONDENSATE.

In operation, the room unit is constantly condensing water

vapour out of the atmosphere (reducing relative

humidity). This water has to be drained away. An

automatic condensate pump is fitted inside all room

units. The flexible hose outlet from the condensate pump

runs to the outside, inside the flexible sheath , the

condensate is deposited in the base of the heat

exchanger, considerable re-evaporation of this water

takes place on the warm air stream passing through and

around the heat exchanger, but please remember that

there will also be a degree of dripping through the base

of the heat exchanger.

HAVE GREAT REGARD FOR THIS CHARACTERISTIC

WHEN POSITIONING THE EXTERNAL HEAT

EXCHANGER.

The flexible water pipes should be routed so as to avoid

any possibility of kinking or unnecessary restrictions to

the flow of water inside. Also, remember that plastic

and rubber becomes much more flexible when warm

and, as a result, much more susceptible to distortion.

5) MACHINE LINK-UP.

Ensure the mains supply lead to the room unit is

disconnected. A 5m (extendable to 30m) line set to

connect water between the room unit and the external

heat exchanger will have been supplied. The water pipe

connections are by means of “quick connect couplers”.

These are simple “push-on” connectors which, when

disconnected (after pulling back sprung loaded locking

ring), re-seal the water system on either side. The

complete system will have been filled with the necessary

amount of water/antifreeze prior to its arrival on site. A

condensate drain pipe coupler 6mm clear polythene

(push fit), should also be connected. Having made the

couplings, the system is operational immediately.

WARNING !

This unit MUST be transported and operated in the upright

position at all times.

1) COMMISSIONING INSTRUCTIONS

As standard, these units are supplied with a NEMA power

plug attached to the power supply cord. They require a 208/

230volt 1 phase 60Hz supply with the following appropriately

protected current rating:-

PAC.240 20 AMPS

PAC.320 30 AMPS

The size of any extension cable that may be used is as

follows and must be rated above the fuse size also allowing

for voltage drop and be suitable for the environment:

PAC.240

14AWG up to 30 feet

12AWG over 30 feet

PAC.320

10AWG up to 30 feet

8AWG over 30 feet

If the cable is on a "cable drum" then ensure that it is

completely unwound; serious complications will occur

otherwise.

2) SYSTEM DESCRIPTION.

The system comprises a room unit cooling section, an

external heat exchanger and the two are inter-connected

by means of flow and return water pipes and an electrical

supply to the heat exchanger fan.The room unit is fitted

with an automatic condensate disposal pump which

discharges the condensate via a small plastic pipe

into

the base of the external heat exchanger

and all

interconnecting pipes and electrics are enclosed in a flexible

plastic sheath. In addition, both ends of each pipe are fitted

with "quick connect" couplings that open on coupling but

reseal to become water tight on disconnect.

3) AIRFLOW

The angled outlets at the top of the room unit are fitted with

air grilles that allow the angle of air outlet to be adjusted

vertically and horizontally and, in conjunction with the fan

speed control switch, the air velocity and direction can be

carefully set up to obtain maximum coverage of the area

being cooled without causing drafts. Care should be taken

to avoid outlet air being obstructed as this will cause the air

to "eddy" around the unit resulting in recirculation and short/

inaccurate cycling of the machine. Ideally, cold air should

be directed to create a "blanket" all across the ceiling area

allowing natural convection to drop the air over the whole

area at very low velocity.

4) SITING

Ideally, the room unit should be positioned equidistant along

the shortest wall in the room

blowing down the length of

the room. If there is more than one unit in the same area,

then they would normally be positioned side by side, and

equidistant along the long wall, all pointing in the same

direction. Sometimes it may be necessary to position units

around the perimeter of an area but, in this case, great

care should be taken to avoid one unit blowing cold air

straight into another which will adversely affect the machine

operation. Good and correct air flow is, perhaps, the single

most important aspect of satisfactorily applying portable

air conditioners. If in doubt seek the advice of your supplier.

Page 4

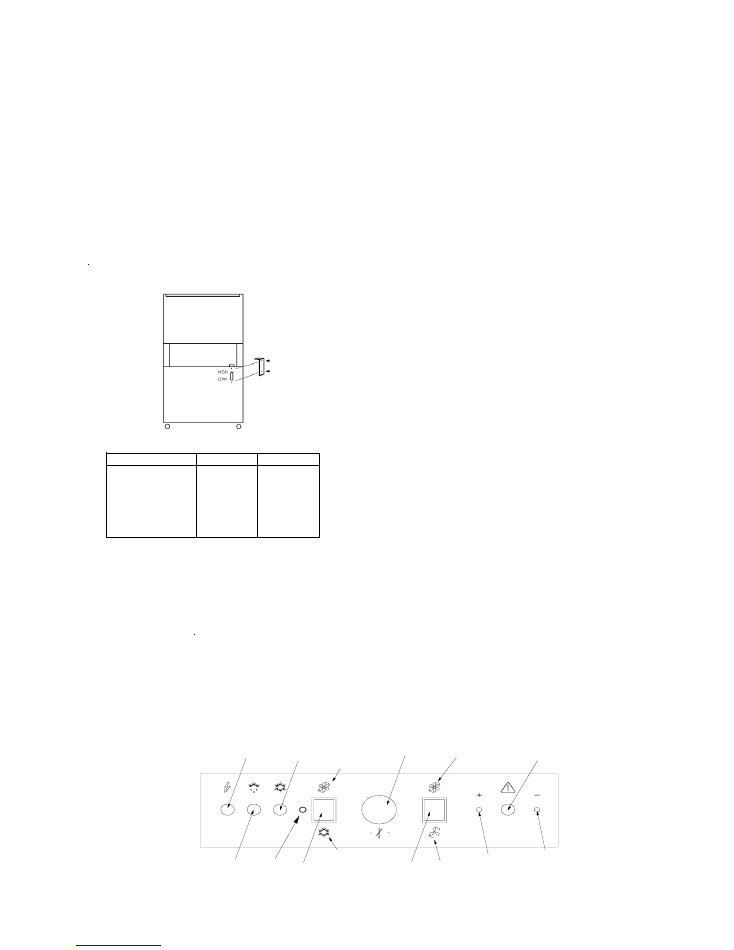

6) ROOM UNIT WATER LEVELS

.

The water system in the room unit will be to the correct

level when delivered. However if for some reason the level

has fallen, antifreeze (33%) and water will have to be added.

The header tank filler and level indication is located to the

rear of the room unit and can be accessed by removing the

two screws holding the security plate over the filler tank

cap, see Fig 2. Ensure the machine is running in cooling

mode before removing the header tank cap, and as with all

pressure caps, remove slowly. It is recommended that a

mixture, by volume, of one part antifreeze to two parts water

is utilised, this will prevent freezing down to an external

temperature of -30°C/-5ºF. The approximate total volume

the systems, room unit with external heat exchanger and

lines is as follows:-

DO NOT APPLY MAINS WATER PRESSURE TO THE

SYSTEM.

Fig 2

10

C

34

C

1

2

3

4

5

6

7

8

THERMOSTAT

KNOB

MAINS LIGHT

(RED)

MODE

SWITCH

FAN ONLY

POSITION

COOLING

POSITION

FAN SPEED

SWITCH

FAN SPEED

HIGH

FAN SPEED

LOW

COOLING LIGHT

(GREEN)

ATTENTION LIGHT

(AMBER)

HIGH

PRESSURE

RE-SET

LOW

PRESSURE

RE-SET

DEFROST

LIGHT (WHITE)

OFF

POSITION

7) OPERATING INSTRUCTIONS.

The Control Panel on the room unit is illustrated below,

see Fig 3.

a) Revolve thermostat knob fully CLOCKWISE to the

number "8" position.

b) Plug in the room unit mains cable, and switch on

electricity, red mains light will illuminate.

c) Select "Fan Only" with the mode switch. The fan will

start.

d) Select "Fan Speed", with the fan speed switch, high or

low depending on air velocity required.

e) Select "Cooling" with the mode switch, and revolve the

thermostat knob fully ANTI-CLOCKWISE to the number

"1" position. If fitted the external heat exchanger fan and

the water pump in the room unit will start. After a delay of

10mins the green "Cooling" light will illuminate and the

machine will proceed to cool the air.

f) Monitor the room temperature and when it has reduced

to the desired level, very slowly revolve the thermostat knob

back, clockwise, until the green "Cooling" light goes out.

The room unit will now control the room temperature cooling

automatically at this setting.

Fig 3

LINESET LENGTH Total Volume

Units

16FT

2.65

U.S Gallons

21FT

3.07

U.S Gallons

32FT

3.25

U.S Gallons

48FT

3.85

U.S Gallons

64FT

4.45

U.S Gallons

80FT

5.05

U.S Gallons

Page5

8) ROUTINE MAINTENANCE

The air filter must be kept clean, never allow to become

choked with dust or dirt. If allowed to do so, the performance

of the unit will become impaired, resulting in loss of air flow,

freezing up of the evaporator coil and possible component

damage.

ACCESSING THE FILTER

Lift open the return air grille on the front face of the unit,

Fig 4. On refitting the filter ensure that it is correctly

positioned covering the whole rear face of the grille. The

filter (see Fig. 4) can be washed in warm, soapy water,

rinsed and shaken dry before replacement. Frequency of

cleaning depends upon application and can only be

determined by the user. However, you should never allow

more than two months to elapse between cleaning. The

probable life of the filter will be about one year and spares

are available from the supplier of the unit itself. Failure to

have filter fitted during operation will cause serious damage.

FIG 4.

The refrigeration circuit inside the room unit is fitted with a

HIGH and a LOW pressure sensing switch. They are both

manually re-settable. A pencil or screwdriver with gentle

pressure on the knob behind is all that is required to re-set.

Necessary access is provided through the control console.

HOWEVER, DO NOT ATTEMPT TO RE-SET WITHOUT

FIRST DISCOVERING WHY THE TRIP

OCCURRED IN THE FIRST PLACE

LIFT AND REMOVE AIR FILTER

UNSCREW RETAINERS AND OPEN PANEL TO REMOVE FILTERS

9) MACHINE NOT WORKING?

ONLY A COMPETENT ELECTRICIAN SHOULD

ATTEMPT TO RECTIFY ELECTRICAL SUPPLY

PROBLEMS. DO NOT REMOVE ANY PANELS FROM

THE MACHINE.

Problem

- No air flow from room unit.

Diagnosis

-Red "MAINS" light off.

Cure

- Turn on electricity and/or check mains supply

fuse.

Problem

- No air flow from room unit.

Diagnosis

- Red "MAINS" light on, White "DEFROST"

light on.

Cure

- Machine in defrost mode, do not adjust anything,

machine will revert to normal run after 10 mins.

Problem

- Insufficient air flow from room unit.

Diagnosis

- Blocked air filter.

Cure

- Clean filter

Problem

- No cooling.

Diagnosis

- Green "COOLING" light off.

Cure

- Revolve thermostat knob fully anti-clockwise to

"1". Wait 10 minutes for time delay on start-up

Problem

- No cooling.

Diagnosis

- Amber "ATTENTION" light illuminated.

High pressure trip.

Cure

- Press "+" button to re-set and check for :-

Lack of water flow ... kinked hoses? Shortage of

water ... top up.

External heat exchanger unit mounted in very high

temperature? Water frozen? Add glycol (33%).

External heat exchanger coil blocked with dirt ... clean.

Problem

- No Cooling.

Diagnosis

- Amber "ATTENTION" light illuminated.

Low pressure trip.

Cure

- Press, "-" button to re-set and check for :-

No air flow, blocked filter?

Evaporator blocked with ice. Very low external

temperature?

Problem

- No Cooling.

Diagnosis

- Amber "ATTENTION" light illuminated.

Low pressure trip.

Cure

- Condensate pump not reducing water level.

Kink in Condensate tube between room unit and heat

exchanger? Leak inside room unit. Sump filter inside

room unit blocked. Condensate tube frozen.

Page 6

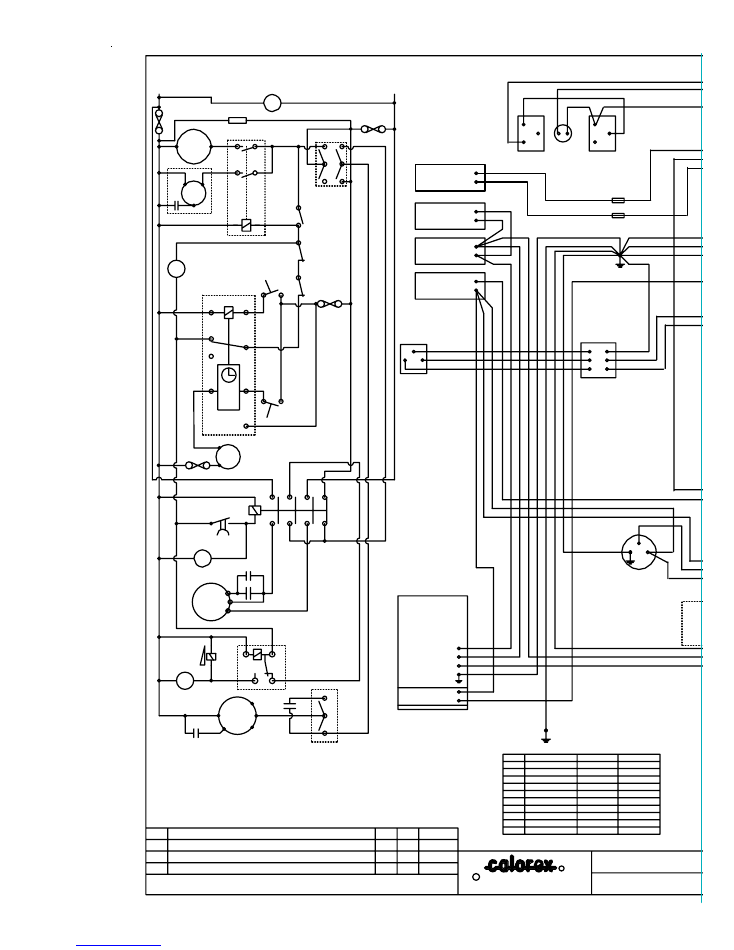

21

22

HE

X

WA

T

E

R

PU

M

P

7

4

9

6

B

A

6

3

5

2

1

4

HEX UNIT

MV

AI

R

ST

AT

1 4

HP

L

P

FS

1

FS

2

A2

A1

5

3

1

6

4

2

FL

MC

C1

C3

S

R

C

AU

X

N/

C

D

6

min

s

1

2

4

3

DL

6

5

4

C2

MV

CL

S2

FT

B

Y

RL

S1

SUMP HEATER

F1

F2

COOL

FAN ONLY

LOW

HIGH

IN

N

CO

M

NC

IN

L

OU

T

NO

PUMP

CONTROLLER

TIME

MP

DELAY

L1

L2

K 1

DO NOT SCALE PRINT

10 FLOAT SWITCH COAXIAL LEADS REMOVED

3 SUPPRESSORS ADDED TO RELAYS No2 & 3

4 W/R & W WIRES TO FLOAT SWITCHES WERE BLACK

5 CONTACTOR CHANGED

SUPPRESSORS DELETED

FLOAT SWICHES

COAX LEAD ADDED

6 2 off RELAYS DELETED & PUMP CONTROLLER ADDED

7 PUMP CONTROLLER CLARIFIED ON CIRCUIT DIAGRAM

8 FLOAT SWITCH FS1 TURNED AROUND 180 deg

9

PLUG LEAD COLOURS ADDED.

11 GREY FLOAT SWITCH LEADS WERE BLACK.

ISS

DRAWING CHANGE

12 TERMINAL BLOCK ADDED FOR WATER PUMP

97

R

c

U.C.C.

CALOREX HEAT PUMPS LTD

MATERIAL

FINISH

1024 CJW 08:02:01

GSM 3:6:97

GSM 23:6:97

952 GSM 23:1:98

961 GSM 4:6:98

961 GSM 3:12:98

JAC

1004

1050 CJW 29:06:04

C/N

APPD

DATE

1084 CJW 15:04:05

C

L

H

C

L

H

LP SWITCH

HP SWITCH

TERM BLOCK

EARTH STUD

FAN CAP

COMP RUN CAP

HARD START CAP

COMPRESSOR

SUMP HEATER

BASE EARTH

B 1,5

BR 1,5

B 0

,5

B

0,

5

B 0

,5

BR 0,5

B 0,5

GR/B 0,5

O

/B

K

0,

5

GR

/B

0

,5

R

/B

L 0,

5

R 1,5

BL

1

,5

BL 1,5

P 1,5

P 1,5

G

/Y

1,

5

PLUG

MAINS LEAD

FAULT

G/Y 1,5

BLACK FLYING LEADS

V

0,

5

V

0,

5

G/Y 1,0

BL

U

E

BRO

W

N

BL

AC

K

YE

LL

O

W

G

R

EEN

G

/Y

0,

5

B

0,

5

W

0,

5

B

L 0,

5

W 0,5

FAN MOTOR

CA

P

TB

SOCKET

G/Y 1,5

G/Y 1,5

G/Y 1,0

G/Y 1,0

G/Y 1,0

G/Y 1,0

BR 0,5

S

R

C

E

L

N

LAMP

C3

C1

C2

FL

MC

TERMINAL BOX

G/Y (G USA)

BR (BL USA)

B (W USA)

GSM 3:8:98

08:02:01

SOCKET TO HEX UNIT

B 0,5

BR 0,5

B 0,5

E

L

N

G/R GREEN/RED

GRUN/ROT

VERT/ROUGE

BL

B

BR

GR

O

P

R

W

G/Y GREEN/YELLOW

WHITE

RED

PINK

ORANGE

GREY

BROWN

BLUE

BLACK SCHWARZ

BLAU

BRAUN

GRAU

ORANGE

ROSA

ROT

WEIB

GRUN/GELB

NOIR

BLEU

MARRON

GRIS

ORANGE

ROSE

ROUGE

BLANC

VERT/JAUNE

V VIOLET

VIOLETT VIOLETTE

G GREEN

GRUN

VERT

HEX

UNI

T

O/BK 0,5

P 0,5

GR/B 0,5

R

/B

L 0,

5

Page7

1

---

GSM 9:4:97

NTS

B

FT

S1

HP

LP

D

K

MC

MV

C1

C2

Y

AT

CONTACTOR

DEFROST THERMOSTAT

FAN MODE SWITCH

LOW PRESSURE SWITCH

DELAY TIMER

RELAY

COMPRESSOR MOTOR

FAN MOTOR

COMPRESSOR CAPACITOR

FAN CAPACITOR

SOLENOID VALVE

AIR THERMOSTAT

HIGH PRESSURE SWITCH

SCHALTSCHUTZ

VEREISUNGSSCHUTZTHERMOSTAT

GEBLASESCHALTER

HOCHDRUCKSCHALTER

NIEDERDRUCKSCHALTER

VERZOGERUNGSRELAIS

RELAIS

KOMPRESSORMOTOR

VENTILATORMOTOR

KONDENSATOR KOMPRESSOR

KONDENSATOR VENTILATOR

MAGNETVENTIL

LUFTTHERMOSTAT

CONTACTEUR

THERMOSTAT DE DEGIVRAGE

SELECTEUR DE MODE DU VENTILATEUR

REINITIALISATION DEFAUT HAUTE PRESSION

REINITIALISATION DEFAUT BASSE PRESSION

TEMPORISATEUR

RELAIS

COMPRESSEUR

MOTEUR DU VENTILATEUR

CONDENSATEUR DU COMPRESSEUR

CONDENSATEUR DU VENTILATEUR

VANNE ELECTROMAGNETIQUE

THERMOSTAT AIR

MP

CONDENSATE PUMP

KONDENSATPUMPE

POMPE A CONDENSAT

FL

FAULT LAMP

LAMPE 'FEHLER'

VOYANT PANNE

DL

DEFROST LAMP

LAMPE 'ENTEISEN'

VOYANT DEGIVRAGE

CL

CHILL LAMP

LAMPE 'KUHLEN'

VOYANT REFROIDISSEMENT

RL

MAINS (OR RUN) LAMP

LAMPE 'STROM EIN' ODER 'LAUF'

VOYANT SECTEUR (FONCTIONNEMENT)

S2

FAN SPEED SWITCH

SCHALTER VENTILATORGESCHWINDIGKEIT

COMMUTATEUR VITESSE VENTILATEUR

F1 CONTROL

FUSE

KONTROLLSICHERUNG

FUSIBLE

PRINCIPAL

F2

CONDENSATE FUSE

KONDENSATSICHERUNG

FUSIBLE CONDENSAT

C3

HARD START CAPACITOR

HARTSTARTKONDENSATOR

CONDENSATEUR DEMARRAGE DIRECT

FS1

FLOAT SWITCH HIGH LEVEL

SCHWIMMERSCHALTER HOHER STAND

INTERRUPTEUR A FLOTTEUR NIVEAU HAUT

FS2

FLOAT SWITCH LOW LEVEL

SCHWIMMERSCHALTER NIEDRIGER STAND

INTERRUPTEUR A FLOTTEUR NIVEAU BAS

C4 SUPPRESSOR

SUPPRESSEUR

ENTSTORUNGSELEMENT

D355550

WIRING DIAGRAM

PAC240/HEX240

TOLERANCE UNLESS SPECIFIED

HOLES TO BS 4500 E12

INSPECTION LEVEL

DIMS

SHT No.

CONT'

DRAWN

DRG No.

APPROVED

DATE

SCALE

TITLE

AIR STAT

4

5

6

1

2

3

3 POSN SWITCH

A B

7

4

9

6

5

3

1

6

4

2

21

DELAY TIMER

1 4

2 3

DEFROST STAT

FAN MOTOR

SOLENOID VALVE

CONDENSATE

FLOAT SWITCH

HIGH LEVEL

FLOAT SWITCH

LOW LEVEL

MAINS

DEFROST

CHILL

BR 1

,5

B

1.

5

B 0,5

B 0,5

CONTACTOR B

AUX

A1

22

BR

B 0,5

R/

B

R

0

,5

W

0,

5

BL/W 0,5

RELAY No 1

W/

B

L 0

,5

P 0,5

P 0

,5

P 0,5

O

/B

L 0,

5

O 0,5

O 0,5

GR/B 0,5

W

/R

0,

5

W/

R

0

,5

B 0

,5

G

/R

0,

5

R 0,5

R

W

0,

5

GR 0,5

GR

0

,5

BR 0,5

B

R

0,

5

B

R

1,

0

R

/B

0,

5

R/B 0,5

R/BL 0,5

BLUE FLYING LEAD

BLACK FLYING LEAD

WHITE

BROWN

BR 0,5

RED NOT USED

R 1

,5

BL

1

,5

FLYING LEAD

FLYING LEAD

SUMP

GREY

GREY

GREY

GREY

R/B

R

0

,5

BR 0

,5

W/

B

L 0

,5

B

0,

5

BR 1

,5

B

1,

5

W/R 0,5

B 0,5

W/R 0,5

G/Y 1,0

G/Y 1,0

B 0,5

B

0,

5

W

/R

0,

5

W

0,

5

O 0,5

BR

0

,5

B 0,5

BR

G/Y 1,0

PUMP

W/R 0,5

W 0,5

G/

R

0

,5

G

/R

0,

5

B

0,

5

B

R

0,

5

BR 0

,5

FAN ONLY

COOL

1

4

W/BL LINK

GR 0,5

B 0,5

N/C

AT

S1

CL DL RL

D

FT

MV

MP

Y

FS1

FS2

NOTE ORIENTATION OF SWITCHES

B 0

,5

A2

W

0,

5

1,5

0,5

0,5

B 0

,5

8 COM

7 N/C

6 N/O

5 FAULT SIGNAL

4 OUT

3 SIGNAL IN

2 L

1 N

B 0

,5

B 0

,5

PUMP CONTROLLER

4

5

6

1

2

3

2 POSN SWITCH

FAN SPEED

S2

CONTROL FUSE 7A

CONDENSATE FUSE 1A

BR 1,5

BR 0,5

BR 0,5

BR 0,5

BR 0,5

G/R 0,5

F1

F2

LAB

E

L D

355

551

D355550

IS

SU

E 1

2

FLYING LEADS

IF IN DOUBT ASK

DRG No.

B 0

,5

R 1.0

BL 1.0

WATER PUMP

TERM BLOCK

IN TERM BOX

B 0,5

BR

1

.0

O/BK 0,5

GR/B 0,5

R/B 0,5

G/Y 1,0

G/Y 1,0

G/Y 1,0

BR 1,5

B 1,5

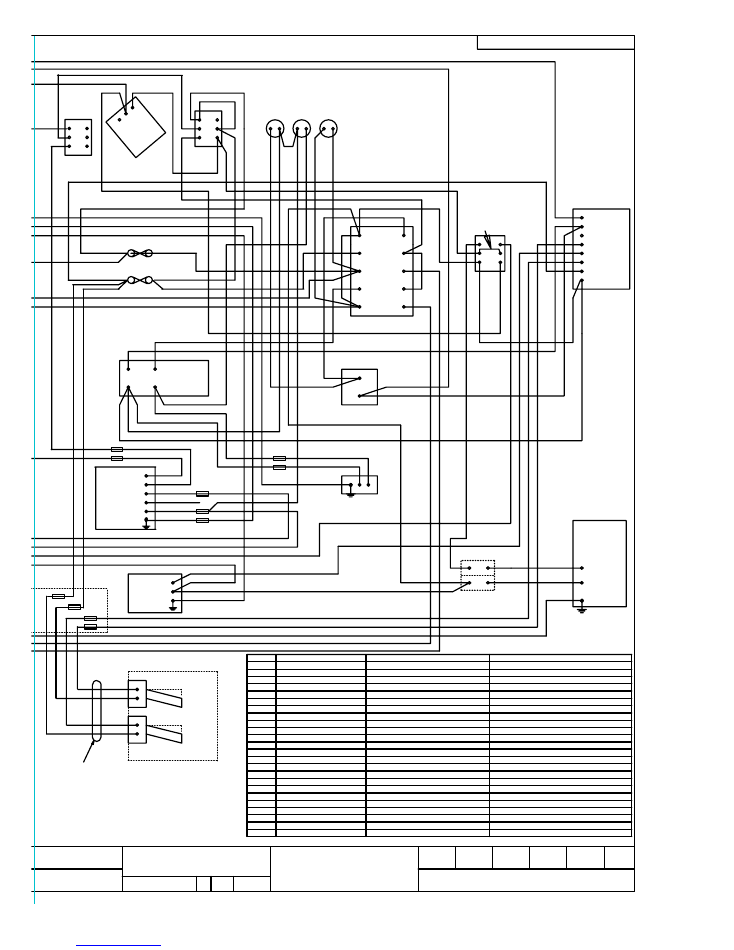

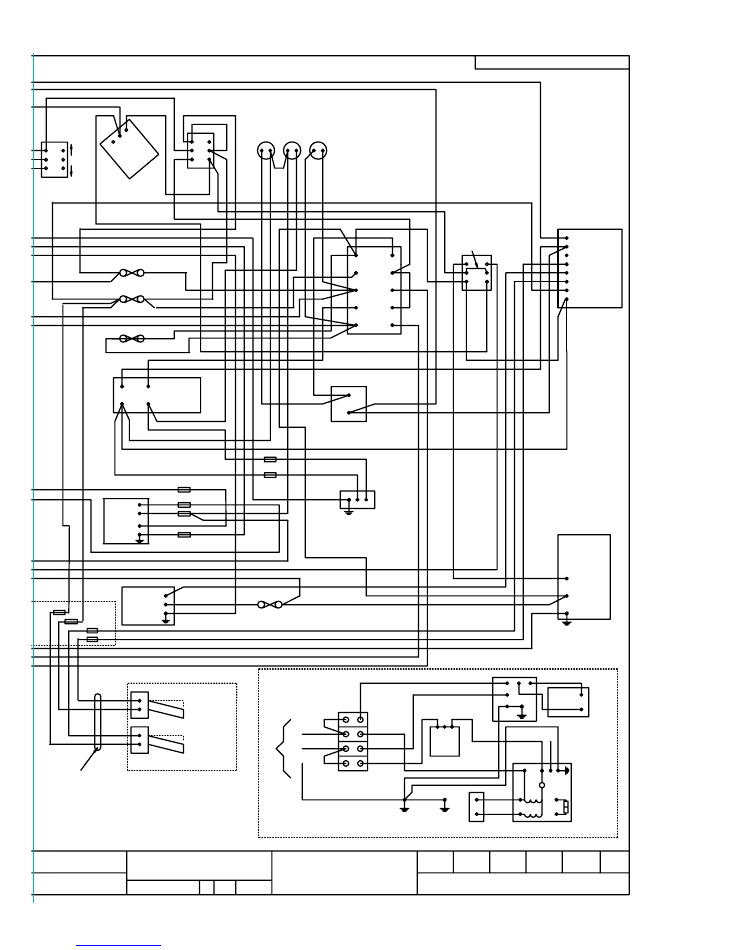

Page 8

RED FLYING LEAD

RED FLYING LEAD

R/

B

L 0,

5

BL 0,5

R/B 0,5

2 CHANGES TO SUIT EXISTING PAC22 LOOM

05:11:03

1A

1A

F4

F2

10A

INSIDE

VIEW

R/BL 0,5

97

L1

L2

1 AS DRAWN

19:01:02

BL

B

BR

GR

O

P

R

W

G/Y GREEN/YELLOW

WHITE

RED

PINK

ORANGE

GREY

BROWN

BLUE

BLACK SCHWARZ

BLAU

BRAUN

GRAU

ORANGE

ROSA

ROT

WEIB

GRUN/GELB

NOIR

BLEU

MARRON

GRIS

ORANGE

ROSE

ROUGE

BLANC

VERT/JAUNE

V VIOLET

VIOLETT VIOLETTE

G GREEN

GRUN

VERT

TERM BLOCK

30A

EARTH/GROUND STUD

FAN CAP

COMP RUN CAP

HARD START CAP

SOCKET TO HEX UNIT

COMPRESSOR

SUMP HEATER

BASE EARTH

B 2,5

BR 2,5

B 0,

5

B 0,

5

B

0,

5

B 0,5

BR 0,5

B 0,5

BR 0,5

BL 0,5

R/

B

0

,5

R 2,5

BL

2

,5

BL 2,5

P 2,5

P 2,5

G/Y 2,5

PLUG

MAINS LEAD

G/Y 2,5

BLK FLYING

LEADS

B 0,5

G/Y 1,0

TERMINAL BLOCK

G/Y 2,5

G/Y 2,5

G/Y 1,0

G/Y 1,0

G/Y 1,0

G/Y 1,0

BR 0,5

S

R

C

GND

L1

L2

C3

C1

C2

GR/

B

0

,5

C

L

H

C

L

H

LP SWITCH

HP SWITCH

GR/B 0,5

O/

B

L 0

,5

FAULT

V 0

,5

V 0

,5

LAMP

FL

MC

G/Y (G USA)

BR (BL USA)

B (W USA)

HEX

WA

T

E

R

PU

M

P

7

4

9

6

B

A

6

3

5

2

1

4

HEX UNIT

MV

AI

R

ST

AT

1 4

HP L

P

FS

1

FS2

A2

A1

5

3

1

6

4

2

FL

MC

C1

C3

S R

C

AUX

N/

C

D

6

mi

ns

1

2

4

3

DL

6

5

C2

MV

CL

S2

FT

B

Y

RL

S1

SUMP HEATER

F1

10A

F3

COOL

FAN ONLY

LOW

HIGH

IN

N

COM

NC

IN

L

OU

T

NO

PUMP

CONTROLLER

TIME

MP

DELAY

K 1

FAN SPEED CAP

C4

ISS

C/N

APPD

DATE

R

c

U.C.C.

CALOREX HEAT PUMPS LTD

MATERIAL

FINISH

DO NOT SCALE PRINT

DRAWING CHANGE

Page9

F4

CONTROL FUSE 10A

B 0,5

1A

B 2,5

B 2,5

B 2,5

R/BL 0,5

B 0,5

B 0,5

GR

N(

G

R

N/

Y

E

L

)

BLK

D355552

LABEL D64355553

D355552

WIRING DIAGRAM

PAC320DX/HEX320D

ISSU

E 2

HEX UNIT

1

---

CJW 19:01:02

NTS

AIR STAT

4

5

6

1

2

3

3 POSN SWITCH

A B

7

4

9

6

5

3

1

6

4

2

21

DELAY TIMER

1 4

2 3

DEFROST STAT

FAN MOTOR

SOLENOID VALVE

CONDENSATE

FLOAT SWITCH

HIGH LEVEL

FLOAT SWITCH

LOW LEVEL

MAINS

DEFROST

CHILL

BR 2,

5

B

2.

5

BR 2,5

B 0,5

B 0,5

CONTACTOR B

AUX

A1

22

BR 0,5

BR

B 0,5

B 0,5

BR 0,5

R/BR 0,5

W

0,

5

BL/W 0,5

RELAY No 1

W

/BL

0,

5

P 0,5

P

0,

5

P 0,5

O/

B

L

0

,5

O 0,5

O 0,5

GR/B 0,5

W/

R

0

,5

W/

R

0

,5

B 0

,5

G/

R 0

,5

R 0,5

R

W 0

,5

GR 0,5

GR 0

,5

BR 0,5

BR

0

,5

B

R

1,

0

BLACK

BROWN

BR 0,5

BLUE

R 2

,5

BL

2,

5

FLYING LEAD

FLYING LEAD

SUMP

GREY

GREY

GREY

GREY

R/

B

R

0

,5

BR

0,

5

W

/BL

0,

5

B 0

,5

BR

2

,5

B 2

,5

W/R 0,5

B 0,5

W/R 0,5

G/Y 1,0

G/Y 1,0

B 0,5

B 0

,5

W/

R

0

,5

W

0,

5

O 0,5

BR

0,

5

B 0,5

BR

G/Y 1,0

PUMP

W/R 0,5

W 0,5

G/

R 0

,5

G

/R

0,

5

B 0

,5

BR

0

,5

B

R

0,

5

FAN ONLY

COOL

1

4

W/BL LINK

GR 0,5

B 0,5

WATER PUMP

BR 1,0

N/C

AT

S1

CL DL RL

D

FT

MV

MP

Y

FS1

FS2

NOTE ORIENTATION OF SWITCHES

B 0,

5

A2

W 0

,5

2,5

0,5

0,5

B 0,

5

8 COM

7 N/C

6 N/O

5 FAULT SIGNAL

4 OUT

3 SIGNAL IN

2 L

1 N

B 0

,5

B 0,

5

PUMP CONTROLLER

PUMP

FAN MOTOR

CA

PA

C

IT

O

R

CA

P

A

C

IT

O

R

BASE PLATE

EARTH

M

A

IN

S

SUPPL

Y

L1

L2

GND

WHT

BLK

GRN

GRN/YEL 1,50

BRN

BRN

WHT 1,00

PR

OT

EC

TO

R

MAINS

START

NO

NC

C

WATER STAT

BLK

R

E

D(

NO

T

U

S

E

D

)

WH

T

BL

K

WIRED TO RUN COUNTER CLOCKWISE

R

EVE

R

S

IN

G PLU

G

YEL(WHT)

BL

K

GR

N(

GR

N

/Y

E

L)

/WHT

BLK

A

T Z

S

E

F2

CONTROL FUSE 10A

CONDENSATE FUSE 1A

BR 0,5

BR 0,5

G/R 0,5

F1

F3

FLYING LEADS

BLK 1,00

WHT

YEL(WHT)

BLK

BLK

GRN

GRN (GRN/YEL)

GRN

G/Y

4

5

6

1

2

3

2 POSN SWITCH

FAN SPEED

S2

HIGH

LOW

TOLERANCE UNLESS SPECIFIED

HOLES TO BS 4500

E12

INSPECTION LEVEL

DIMS

SHT No.

CONT'

DRAWN

DRG No.

APPROVED

DATE

SCALE

IF IN DOUBT ASK

TITLE

DRG No.

Page 10

BLANK PAGE

Page11

BLANK PAGE

Page 12

BLANK PAGE