Full Text Searchable PDF User Manual

1

BELOŠEVAC BB , 14000 VALJEVO, SRBIJA

USAGE AND MAINTENANCE MANUAL FOR A SOLID FUEL STOVE

DEAR CUSTOMER,

Congratulations on your purchase of “BLIST” solid fuel stove. Please make installation

and use the stove in accordance with this manual, this will ensure safe operation and

long life of your stove.

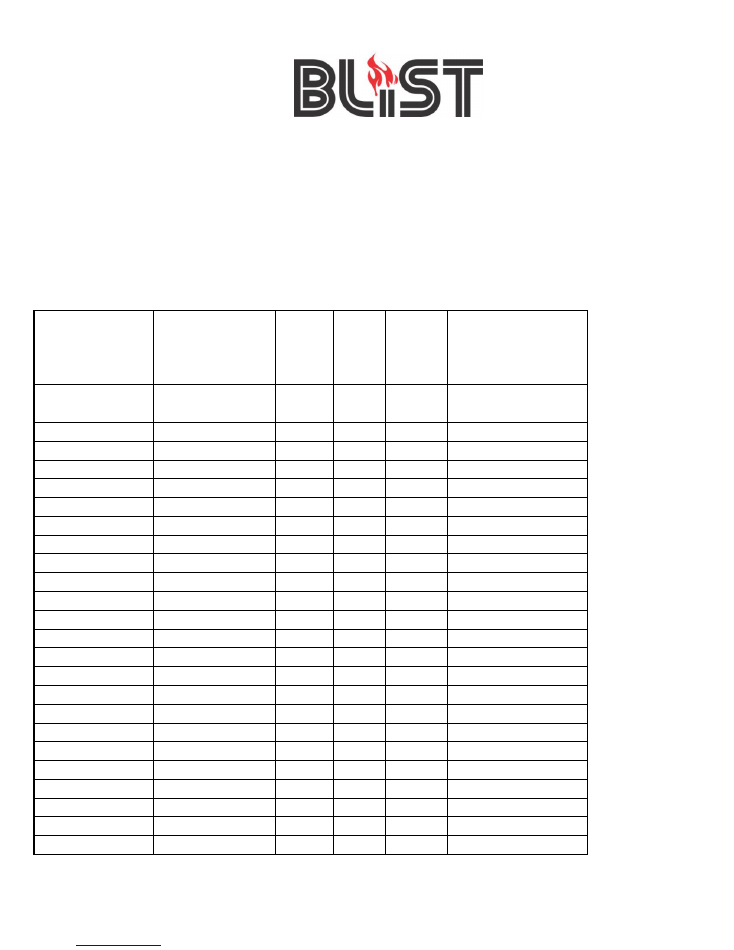

Table 1. Technical specification:

Model name

Dimension

Nominal

Power

Weight

Flue

coupling

diameter

Minimum distance

from surrounding

combustible materials

width/length/height

[mm]

[KW]

[kg]

[mm]

sides/rear/front [cm]

EKONOMIK lm

330x360x930

6,5

36

118

40/50/80

EKONOMIK

330x460x900

6,5

39

118

40/50/80

EKONOMIK LUX lm

330x360x930

6,5

37

118

75/55/80

EKONOMIK LUX

400x460x900

6,5

48

118

75/55/80

ZAR

480x460x930

7,5

61

118

70/55/80

OGANJ LM

490x460x930

8,5

58

118

70/75/80

OGANJ

490x460x930

8,5

66

118

70/75/80

BLIST B1

465x390x800

8

54

118

65/50/80

BLIST B10

465x390x970

8

57

118

65/50/80

BLIST B2

465x460x910

9

62

118

60/70/90

BLIST B22

510x500x910

11

73

118

60/70/100

BLIST BR

510x480x1060

11,5

94

118

60/70/100

BLIST BRM

580x560x1060

12

122

118

60/70/100

KONZUL LM

490x460x930

8

64

118

50/75/80

KONZUL

490x460x930

8

75

118

50/75/80

AMBASADOR LM

490x460x1040

9,5

82

118

65/75/80

AMBASADOR

490x460x1040

9,5

95

118

65/75/80

AMBASADOR LM R

490x460x1160

9,5

102

118

65/75/80

AMBASADOR R

490x460x1160

9,5

122

118

65/75/80

DIPLOMAT

480x450x1000

10

62

118

60/70/80

DIPLOMAT LUX

480x450x1000

10

68

118

60/70/80

B MAX 1

520x440x810

11

90

150

60/70/100

B MAX 2

665x440x810

14

116

150

60/70/110

2

1.

Description and purpose of the stove:

BLIST solid fuel stoves are designed in a way to enable efficient combustion of solid fuels with the

possibility of adjusting and regulating the amount of input air required for the combustion process.

The stove consists of parts from steel, with doors and top plate made of cast iron or steel (depending

on the model of the stove), and the grate in the combustion chamber made of cast iron. All stoves are

plated inside with schamotte bricks, which provides long-term heat accumulation. The stoves are

painted with special heat resistant paint. The glass on the door is the first class heat resistant ceramic

glass.

The stoves are designed for space heating of a wide spectrum such as living rooms, offices, restaurants,

schools, garages, warehouses, etc. ..

- Models: KONZUL, KONZUL LM, AMBASADOR, AMBASADOR LM , DIPLOMAT LUX,

AMBASADOR R and AMBASADOR LM R have sides coated with ceramic tiles which gives unique

atmosphere to your room.

- Models: BLIST BR, BLIST BRM, AMBASADOR R and AMBASADOR LM R have oven with

built-in thermometer. Thus, alongside with heating of space, these stove models can be used for

baking also (of different kind of bread, pies, meat, etc..)

2. Installation:

- all local regulations including those refering to national and European standards needs to be complied

with when installing the appliance.

- Place of installation must be horizontal and must have adequate carrying capacity, otherwise must

be taken appropriate actions to fulfill these conditions.

- the stove must not be placed near combustible materials (such as wooden, textile or plastic furniture

parts, etc..) nor near cooling devices. Minimum distance between the stove and such materials must be

provided according to data from Table 1.

- if the stove is placed on the floor made from combustible materials (wood, itison, floor plastic, etc.)

it is necessary to protect the floor with metal sheet of min.30cm width from the sides of the stove, and

min. 50cm from the front side of the stove. Flue pipes must be away from combustible objects min.

40cm.

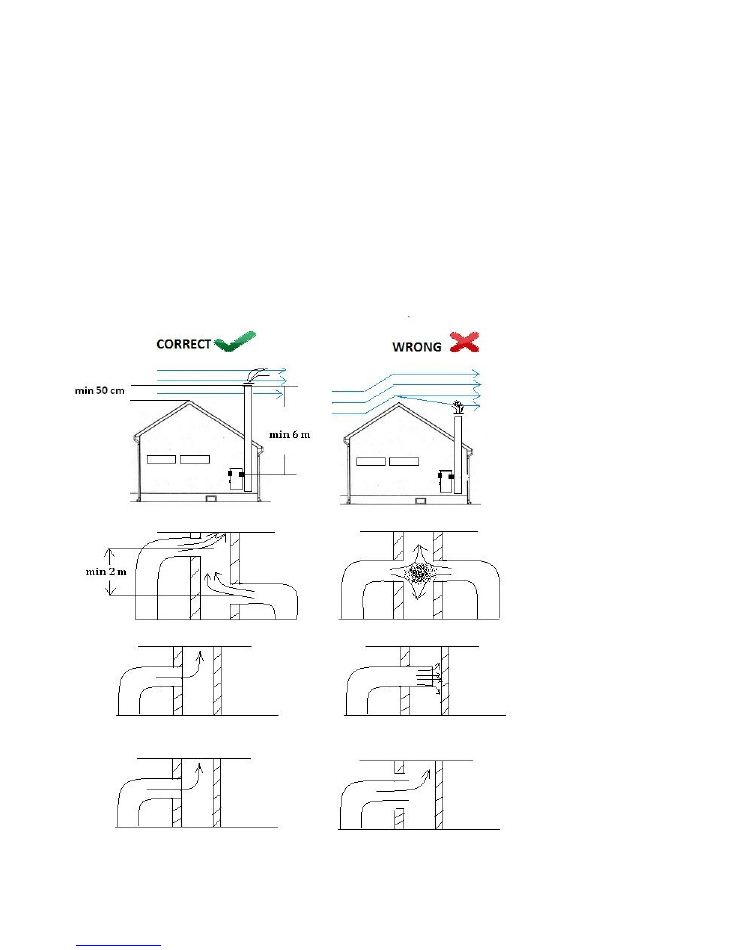

- When connecting the stove to the chimney you should consult a local competent institution. The

stove should be attached to a chimney with inner radius of at least 120mm and height of 6m. If multiple

stoves are attached to a single chimney, the attachment distance should be at least 2m. The chimney

should extend beyond the top of the roof min. 50cm. You should also pay attention that connection pipe

to the chimney does not stand out in the cross-section of the chimney, as well as the connection point of

flue pipe to the chimney must be tightly sealed. (see the Figure No.1) If two chimneys are going

parallel one to each other, they must have separate openings for cleaning, and cavities between the

chimneys also may not exist. Opening for cleaning the chimney must be tightly closed and sealed when

using the stove (while the fire runs in the stove). ). If the chimney is a newly built the fireplace must

not be constantly fired at full capacity until the chimney is completely dry.

- on the place of installation of the stove there must be provided free access for cleaning of the stove,

the flue connectors and the chimney itself.

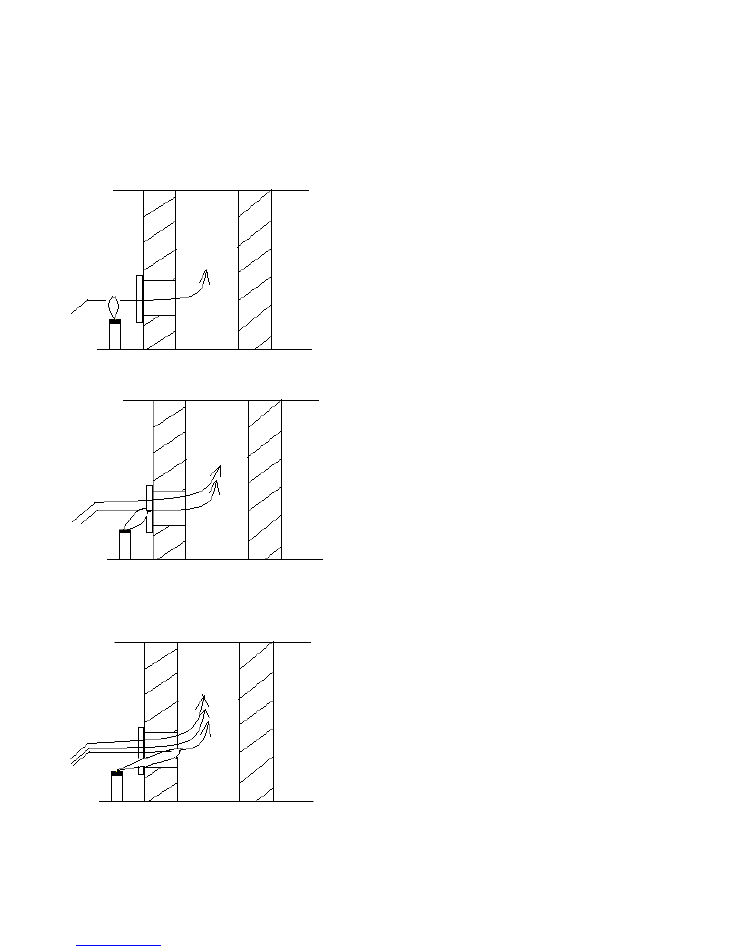

- In order that stove work properly the necessary flue draught must be 12

÷

14 Pa. Check of the airflow

can be carried out by using a candle also, as shown in Figure no. 2

3

- Fresh air is necessary for combustion of the fuel and proper functioning of the stove, and you must

provide that in the room where the stove is installed always be enough (fresh) air. Extractor fans,

cooker hoods and similar devices which extracts air from the room should not be placed in the same

room where the stove is installed. If this is the case or if the doors and windows are sealed, then if

necessary you must find a way to lead fresh air from outside for proper combustion. In this case, before

installing the stove, it is necessary to consult with a competent engineer/organization. If you do not

provide a sufficient amount of air for combustion, the fuel in the stove will not burn completely and the

room where the stove is placed can become contaminated with unhealthy and dangerous gases!

Figure No. 1 INSTALLATION OF THE STOVE

4

Figure No. 2 CHECKING OF THE FLUE DRAUGHT

weak air-flow

good air-flow

too strong air-flow

5

3. Usage:

- all local regulations including those refering to national and European standards needs to be complied

with when installing the appliance.

- recommended fuel: wood logs (beech wood, poplar wood, etc..), coal with less calories (brown coal)

The heating strength depends on the type and quality of fuel used.

- the initial heating of the stove should be gradual to avoid sudden stresses on the material. Do not use

the stove with full capacity during the first 8-10 hours of firing (1-2 days). Thermo-resistant paint on

the stove will be fully formed (harden) after first 2-3 hours of the firing the stove. During this time,

please do not touch the paint and do not put anything on the stove, in order to avoid damage of the

paint. During first 15-30 min. of firing the stove can emit unpleasant smell and smoke. During this

period small children and pregnant women should not be in the same room with the stove, and

windows of the room should be opened widely.

Starting and maintaining the fire:

- the combustion intensity is regulated with the primary air regulator located at the front of the stove

by turning it left-right, and with stack valve regulator (on models which possess it) located at the

chimney spout by rotating it.

When handle of input air regulator is in most right position it is in closed position (no air flow into the

burning chamber), and when in most left position it is fully opened (maximum flow of air into the

burning chamber). Between these two, gradually can be set medium positions.

When handle of stack valve regulator is in most left or most right position, it is in closed position

(mimimum output flow of combustion gases.. When handle of stack valve regulator is in upper

position, it is in fully opened position (maximum output flow of combustion gases). Between closed

and fully opened positions are medium positions.

- do not use gasoline, lighter fluid, Kerosene or other flammable liquids to start or rekindle the fire, for

the safety reasons. When starting the fire, make sure that air regulator and stack valve regulator (on

models which possess it) are in fully opened positions. Build a fire directly on the grate with crumpled

newspaper, kindling wood and commercialy available “firelighters”. Do not allow single pieces of

paper to float up the chimney especially alight. This is a common cause of chimney fire and can cause

structural damages to the property. When the kindling is burning well you can add larger pieces of

wood to gradually increase the size of fire

- when you want to refuel the stove, first put the input air regulator in closed position and after that

open the door slowly and carefully refuel the stove. Do not open the door abruptly as this may cause

the appearance of smoke in the room. Maximum filling height in the burning chamber should not be

more than 2/3 of the height of the chamber. Optimal filling height in the burning chamber is 1/2 of the

height of the chamber. It is advisable to wait for the fire to be reduced to hot embers before re-loading.

Do not let the congestion of grate in the combustion chamber with ash and non-burned fuel. Clean the

grate regularly.

- The stove is constructed and designed for continuous operation with the closed door of the

combustion chamber, except during refueling the stove. Do not open the door when the stove is in use

without the need.

- de-ash the ash pan regularly - do not allow a bed of ash to build up above the level of the sides of the

ash pan. Wood will burn better with the slight build up of ash in the ash pan.

- it is forbidden to use the stove for burning of organic and inorganic waste (animals, plastic, textiles,

oiled wood, etc..). During combustion of such materials can be released many harmful and toxic

supstances.

6

4. Maintenance:

- ash pan must be emptied regularly

- burning chamber and all surfaces which are in contact with smoke gases should be cleaned and

emptied periodically from the ash and other types of fuel waste. Clean interior surfaces inside the stove

guarantee economical operation of the stove. It is recommended to clean the stove once a month or

more frequently in the case of larger soiling and fuel waste.

- after each heating season the stove, pipes and the chimney must be thoroughly cleaned from the

soot. During the period of non-use the stove, leave the input air regulator and stack valve regulator in

maximum opened position to allow natural air flow through the stove, in order to avoid aggregation of

condensate inside the stove.

- clean the glass regularly with soft cloth. Clean the outside of the stove with soft cloth, but do not use

abrasive and other aggressive chemical cleaners as they could remove the paint from the stove. Do

cleaning only when the stove is cold.

- if there is a need for changing some part or repairing the stove you must call competent enginner to

do this maintenance

5.

SAFETY – CAUTION !

- the glass must not be cleaned with wet cloth nor sprinkled with water when is hot. Otherwise, the

glass may crack.

- very cold objects should not be placed on the top plate when is hot. Otherwise the top plate may

crack.

- do not use alcohol, petrol or any other liquid fuel!

- some parts of the stove can reach very high temperatures during operation the stove, thus it is required

adequate precaution while using the stove. Do not allow children to handle and play near the stove.

- It is not allowed to make any structural changes on the stove without the approval of the

manufacturer.