Full Text Searchable PDF User Manual

ENGLISH

RAM T1 & T2

Marine Linear Actuator

User Manual

bandg.com

simrad-yachting.com

2

The information in this manual was, to the best of our knowledge,

correct when it went to press and Simrad or B&G cannot be liable for

any inaccuracies or omissions. There may also be differences

between the specifications in the manual and the product as a result

of ongoing development for which we accept no liability.

This precision engineered product was designed and manufactured in

the United Kingdom.

Please keep this manual in a safe place

3

CONTENTS

Important Safety Information

Compliance Statement

Emergency Quick Release

Emergency

Steering

Description

Performance

• Technical

Data

Dimensions

Actuator Selection

Location

Tiller bolt

Mounting Foot

Quadrant

Considerations

Coil Connections

Maintenance

Servicing

Fault finding

Hydraulic Fluid

Commissioning

Dismounting the unit from its base

Dimensions for Mounting Foot

General Information

Contact Details

End of Life Disposal

Page 4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

4

IMPORTANT SAFETY INFORMATION

Failure to install and maintain this equipment in accordance with the

instructions contained in this Manual could result in damage or injury.

This equipment must be installed and maintained by a person who is

qualified to do so. This equipment is only for use with marine autopilots

within the limitations stated in the following pages. Autopilot steering

systems are navigational aids and the user must still maintain a perma-

nent watch.

This equipment meets the latest EMC (Electromagnetic Compatibility)

standards required for use in the marine environment.

In order to ensure conformance and to prevent interference with

electronic systems the unit must be properly bonded to earth and the

supply cables screened.

Caution!

In operation this unit can rotate the vessels wheel rapidly.

Keep clear of the wheel when this unit is engaged to avoid entrapment.

Beware of hot motor and solenoid components and the risk of

entrapment from moving parts.

Do not flash test.

COMPLIANCE STATEMENT

The RAM T1 & T2 complies with CE under directive 2014/30/EU. The

relevant Declaration of Conformity is available in the following websites

under model documentation section:

www.simrad-yachting.com or www.bandg.com

Complies with the requirements of level 2 devices of the Radio

communications (Electromagnetic Compatibility) standard 2017.

Warning!

The user is cautioned that any changes or modifications not expressly

approved by the party responsible for compliance could void the user’s

authority to operate the equipment.

5

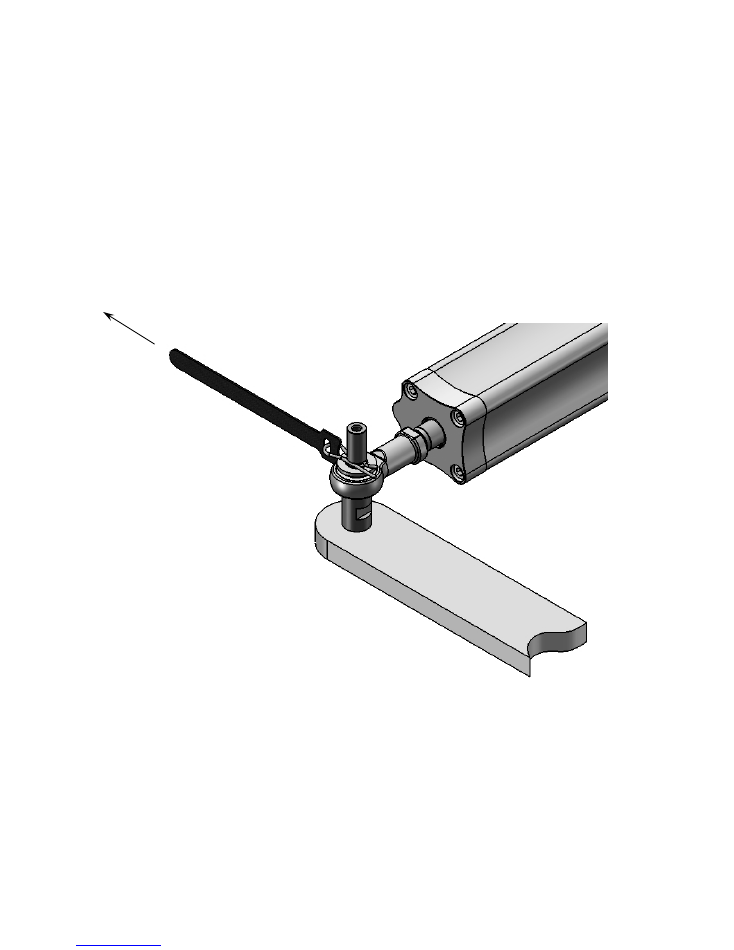

EMERGENCY QUICK RELEASE

In the unlikely event of failure of the actuator a quick release R-Clip is fitted

to the tiller bolt which secures the actuator to the steering quadrant.

Pull the red tab to release the R-Clip and then manually lift the actuator

clear of the steering quadrant.

EMERGENCY STEERING - PRIMARY STEERING FAILURE

If the primary steering fails it may be possible to steer the boat via the

autopilot controls.

6

DESCRIPTION

The RAM T1/T2 Hydraulic linear actuator combines a cylinder, pump,

motor, clutch and reservoir in a pre-filled, sealed unit. Designed to be

used on vessels fitted with mechanical primary steering that can be back

driven.

When the clutch is disengaged the cylinder is free and moves with the

primary steering. To operate the unit in autopilot mode the course com-

puter energises the clutch solenoid coil and runs the bi-directional motor

to extend and retract the ram.

Internal relief valves protect the unit and its mountings from rudder

strikes, grounding etc.

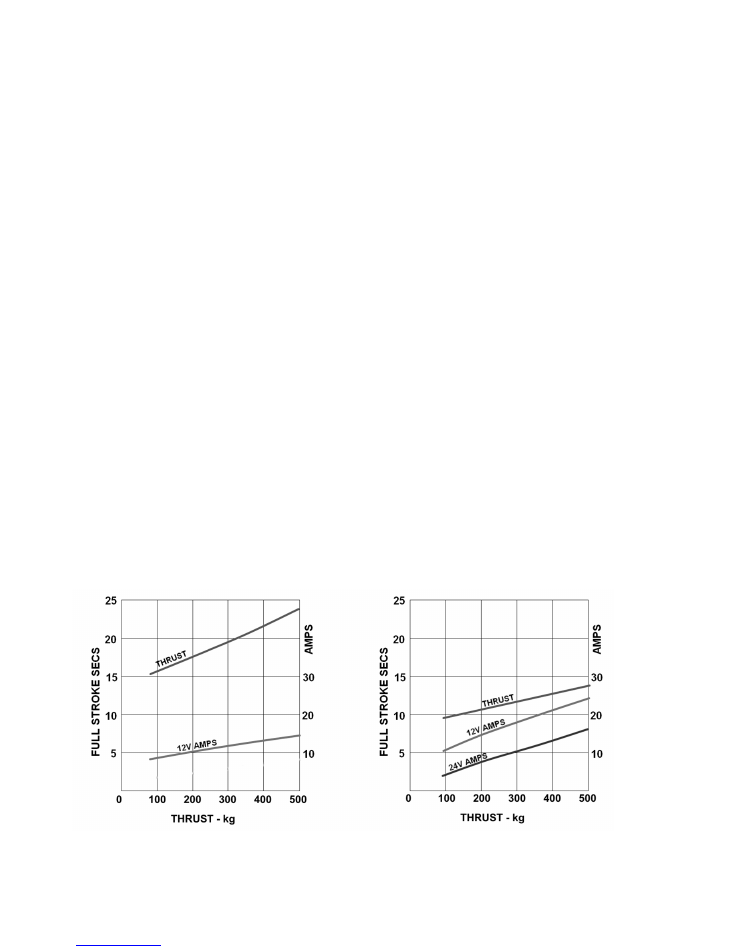

PERFORMANCE

Hard over time

Typical max thrust

seconds at 5 kg

kg

RAM

T1

13

700

RAM T2

9

700

7

TECHNICAL DATA

Voltage

T1 = 12 VDC, T2 = 12 / 24 VDC

Current

Typical

Amp-hour

Typical Current

60 kg at 25% duty

Intermittent 650 kg

12v

24v

12v

24v

RAM T1

2.0

-

19.0

-

RAM

T2

2.5

1.3

25.0

12.0

Ingress protection

IP67

EMC Protection

BS EN 60945:2002 (DC)

Ignition Protection

BS EN 28846:1993

Declaration of

Conformity EMC

Directive

2014/30/EU

Ambient operating

Temperature

-15 to + 55 deg C

Max Operating

Thrust

700

kg

(Intermittent)

Relief Valve setting

62 bar

(730 kg)

Orientation

Red lead to positive - Extends

Black lead to positive – Retracts

Clutch coil

12 watt

Clutch connection

DIN 43650 (6-8 mm cable)

Fluid

ISO VG10 to VG40 hydraulic mineral fluid

to

ISO

6743-4

HV

The following commercial fluids are suitable.

Fuchs Renolin B 15 HV1

Seastar

HA5430

Weight

8

kg

8

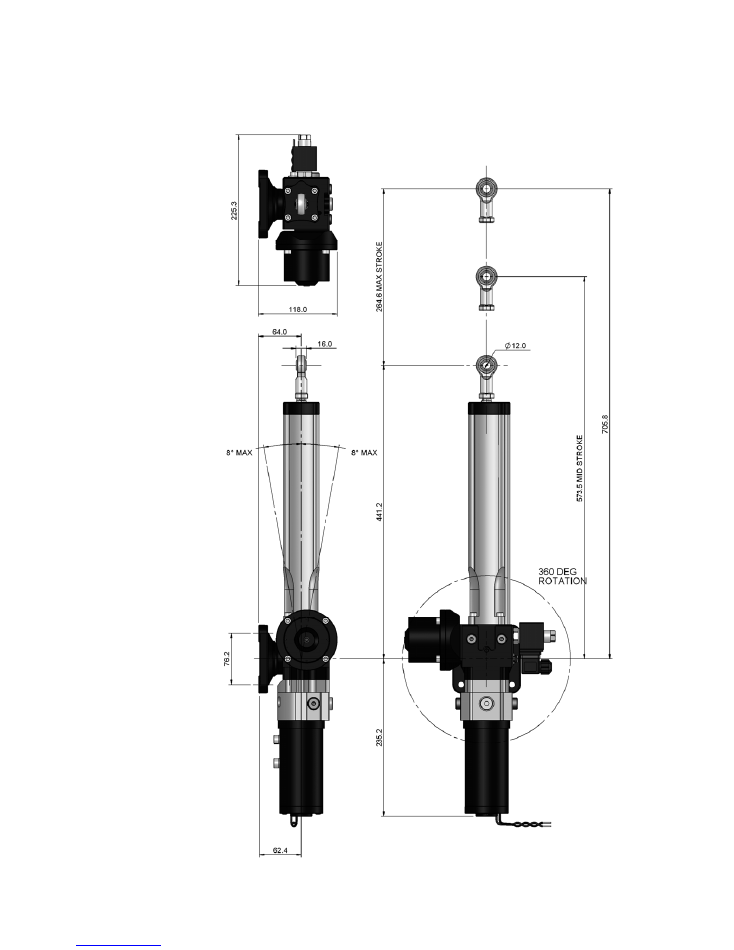

DIMENSIONS

9

ACTUATOR SELECTION

It is important to select the correct size of actuator as it directly influences the

steering performance and power consumption.

The type of vessel to be steered must be considered. The hard over time may

be faster on a light weight planning craft and modern yachts or slower on a

displacement power boat or long keel yacht.

Also consider the rudder, an unbalanced rudder will require more torque than

a semi-balanced or balanced design.

Hard over time

Tiller arm Rudder Deg. Typical Max Torque

RAM

T1

13

sec

190

mm

80

120

kg

13

sec

213

mm

70

140

kg

13

sec

245

mm

60

160

kg

RAM

T2

9

sec

190

mm

80

120

kg

9

sec

213

mm

70

140

kg

9

sec

245

mm

60

160

kg

Hard over time is the time to move the cylinder full stroke (255 mm at 5 kg)

Typical max torque intermittent is calculated at 650 kg thrust.

RAM

T1

25°C

RAM

T2

25°C

10

LOCATION

The RAM T1 & T2 Actuators are designed for under-deck installations only.

When considering where to mount the actuator the following points should

be taken into account.

: Keep cable runs short

: Mount away from sources of heat

: Install the actuator above areas liable to flooding.

: Use a solid surface, capable of supporting the large thrusts generated by

this unit.

: Ensure that piston movement is limited by the rudder hard stops and not

by the actuator end stops.

: Allow sufficient clearance for removal of the mounting pin. (See page 17)

: Check that no part of the actuator fouls the vessel or rudder quadrant

throughout its full range of movement.

: Keep the area in which it is mounted clear of equipment and obstructions.

: Maintain access to the quick release tab at all times and ensure that it is

not liable to entanglement.

11

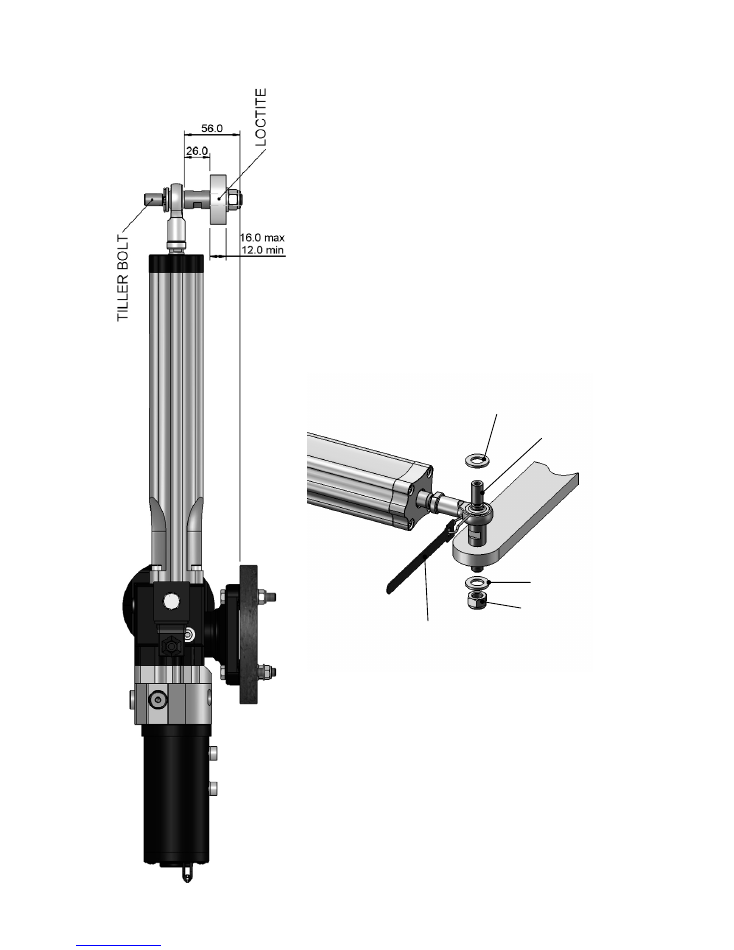

TILLER BOLT

The tiller bolt supplied is suitable for

a quadrant thickness of 12 to 16 mm.

The tiller bolt mounting hole should

be drilled Ø12.2 to 12.3 mm.

An application of Loctite 638 or

equivalent where shown is

recommended.

Tighten the M12 nut to 27 Nm Torque

MOUNTING FOOT

The four M8 nuts, bolts and washers

supplied are suitable for mounting the

actuator onto a surface of

between 12 mm and 24 mm thick.

Tighten the four M8 nuts to 17 Nm.

WASHER

TILLER BOLT

WASHER

M12 LOCK NUT

R-CLIP & QUICK

RELEASE TAB

12

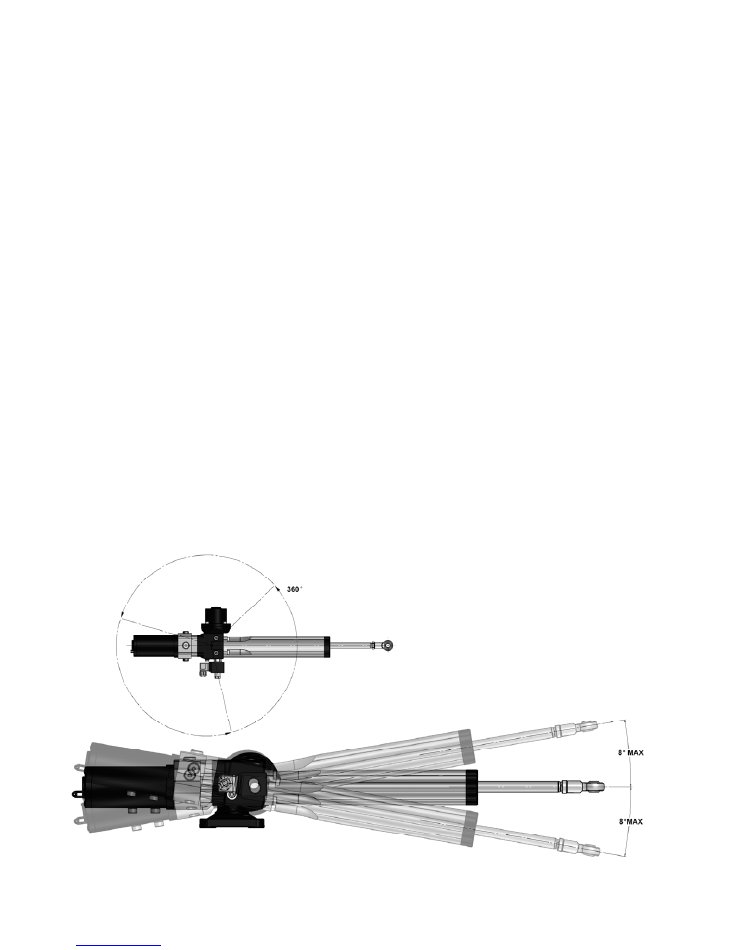

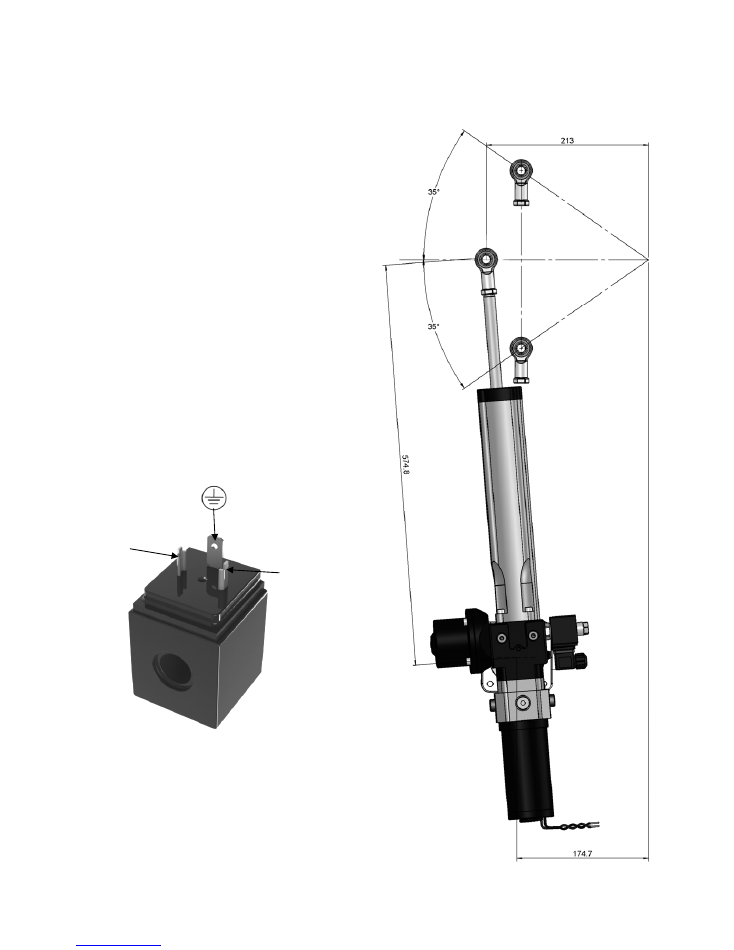

QUADRANT

Typical installation for an 8.4”

(213 mm) radius with total

rudder angle of 70 degrees.

CONSIDERATIONS

Allow sufficient clearance for removal

of the mounting pin (Ref. page 17)

and rod end from the tiller bolt.

COIL CONNECTIONS

PIN 1

POSITIVE

PIN 2

NEGATIVE

NOT USED

13

MAINTAINANCE

The RAM T1/T2 is a sealed unit, quality precision engineering will ensure

many years of trouble free service if the following points are adhered to.

: Keep the piston rod free from damage

: Avoid exposing the unit to salt water.

Perform the following checks regularly:

: Check the security of the mounting bolts and tiller pin.

: Examine electrical cables and connections for damage and corrosion.

: Lubricate the mounting pin and rod end with marine grade grease.

SERVICING

In the unlikely event that new seals are required a kit is available:

Hydraulic Projects Ltd Part No. ML+40sk.

Please quote your units serial number when ordering (Ref. page 19).

Caution

For filling and bleeding a special tool is required:

Hydraulic Projects Ltd Part no. R4051.

Failure to use this tool may result in damage to the actuator.

14

The motor is a non-serviceable item and should be replaced with a new

motor and drive coupling Kit.

Part Nos. 12V UNITS = R4510-sk 12 100 X

24V UNITS = R4510-sk 24 100 X

Quote your units serial number when ordering Ref. page 19)..

The motor can be replaced without affecting the integrity of the hydraulic

circuit.

To remove the motor:

Undo the two M6 socket head cap screws and remove the motor, coupling

and water seal O ring.

If the coupling is worn or damaged replace. Lubricate the slots with a small

quantity of good quality grease.

If any hydraulic fluid is found in the coupling area the shaft seal must be

replaced – see service kit ML+40sk for instructions.

Reassemble by replacing the O ring, engage the coupling between the

motor and pump shafts, ensure the motor locates correctly in the pump

spigot.

Using low strength thread locking compound, replace and tighten the two

M6 socket head cap screws. (13.5 Nm).

Caution

Keep all parts clean during dismantling and reassembly.

15

FAULT FINDING

Under no circumstances dismantle the unit unless it is certain that

the fault is internal. Doing so will allow air into the cylinder,

requiring the unit to be bled for which special tools are needed.

Ref. page 13.

Caution

Any damage to the piston rod will damage its seals and allow air into the

cylinder and oil leaks.

1) Motor does not run

: check electrical connections.

: check course computer output.

2) Motor runs, but erratic or no piston movement

: check for solenoid operation.

: check for air in the cylinder and external leaks.

: check drive coupling.

3) Excessive noise

: check the motor for damage.

: check for air in the cylinder and external leaks.

: check drive coupling.

4) Failure of clutch to engage or disengage

: check solenoid operation.

16

HYDRAULIC FLUID

Caution

Do not use Brake fluid

Use mineral based good quality hydraulic fluid compatible with nitrile hy-

draulic seals.

Ref Technical Data on page

7.

COMMISSIONING

Caution

Be aware of the danger of moving linkages and the risk of entrapment.

The unit is pre-filled and sealed from new. Do not disassemble the unit,

this will allow air to enter and necessitate refilling and bleeding the unit

Ref. page 13.

Use the primary steering to check the full range of movement before com-

missioning the autopilot

Caution

Check the unit for damage and leaks after installation.

17

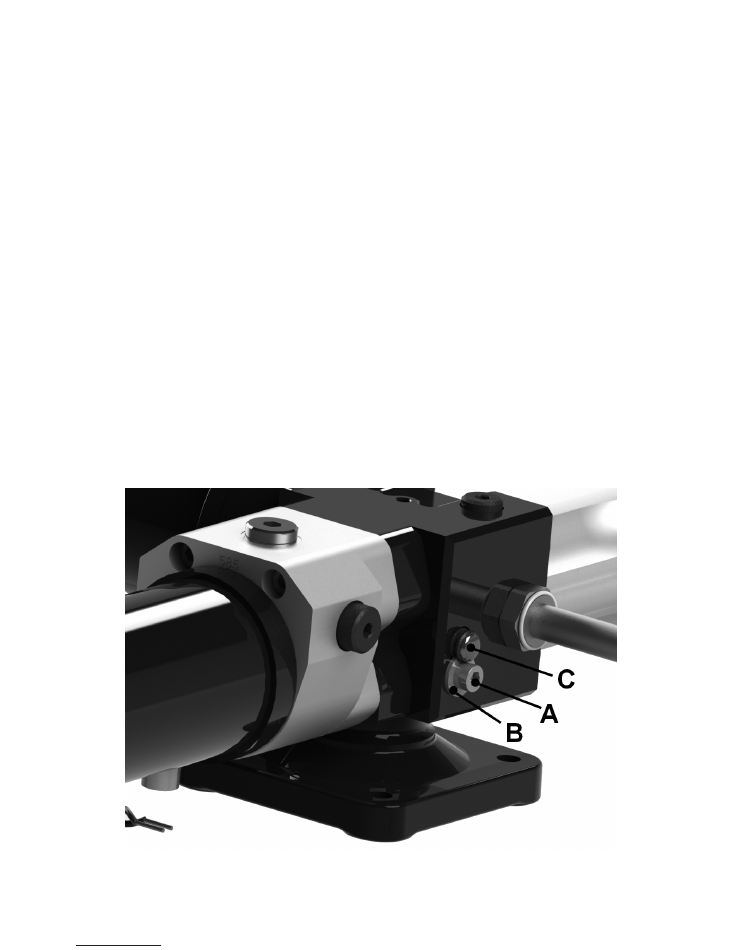

DISMOUNTING THE UNIT FROM ITS BASE

The RAM T1/T2

features a quick-dismount base.

To remove the base from the unit first take off the coil which is secured

by a 17 mm A/F nut. Next undo and remove the Allen screw ‘A’ and

the retaining plate ‘B’ . Withdraw the mounting pin ‘C’ which will release

the base.

NOTE!

The pin is a close engineered fit and if it proves difficult to remove take

off the plastic cap from the head of the pin and insert screw ‘A’ into it.

It will then be possible to withdraw the pin using a pair of pliers or

grips.

IMPORTANT!

Avoid damage to the pin

Assembly is a reversal of the removal process. Ensure the plastic cap

is re-fitted to the pin upon completion.

18

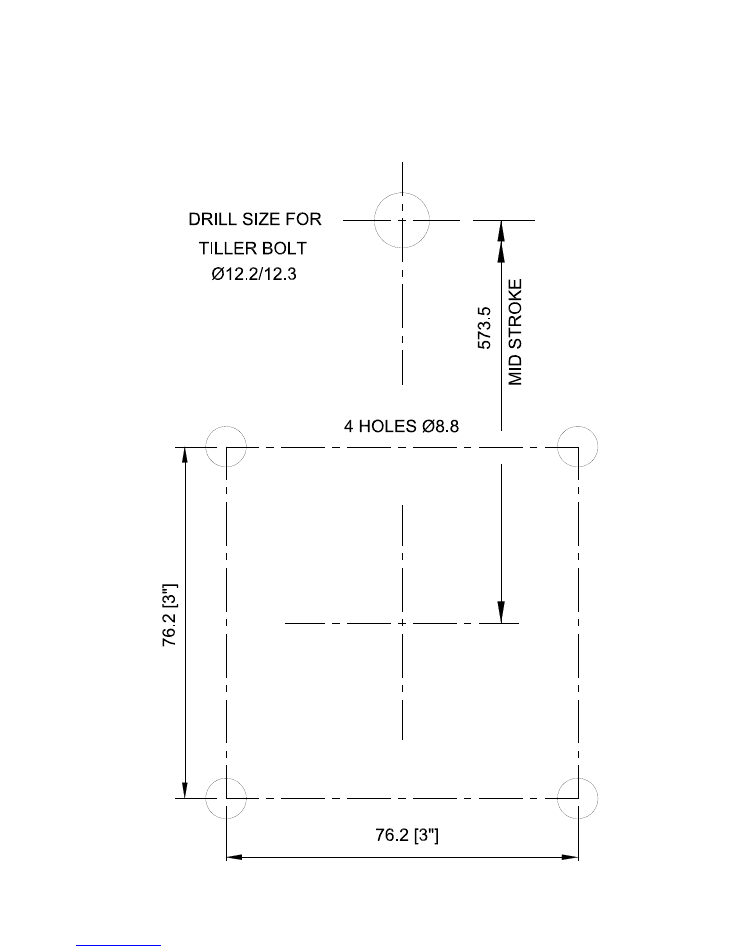

DIMENSIONS FOR MOUNTING FOOT

(NOT

TO

SCALE)

19

Keep this manual in a safe place. Quote the model and serial

numbers in all correspondence.

Model Number:

________________________________

Serial Number:

________________________________

Date of Purchase:

________________________________

Dealer:

________________________________

________________________________

________________________________

CONTACT DETAILS

For inquiries in general, contact Simrad or B&G:

www.simrad-yachting.com

or

www.bandg.com

For inquiries of spare parts, contact Hydraulic Projects Limited:

www.hypro.co.uk

GENERAL INFORMATION

END OF LIFE DISPOSAL

Please dispose of End of Life items responsibly.

In the event that you are unable to use your

nearest local authority civic amenity sites to

recycle, units can be returned to your dealer.

988-12093-001